Preparation method of Ge-based Metal Oxide Semiconductor (MOS) device with sub-nanometer equivalent to oxide thickness

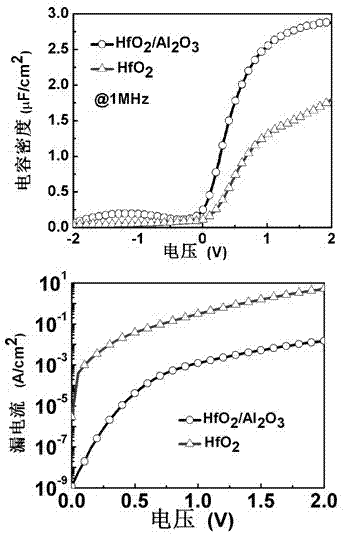

A technology of oxide thickness and MOS devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as hindering the preparation of Ge-based transistors, Fermi pinning effect, poor interface quality, etc., to reduce defect charges and interface state density, improved electrical properties, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

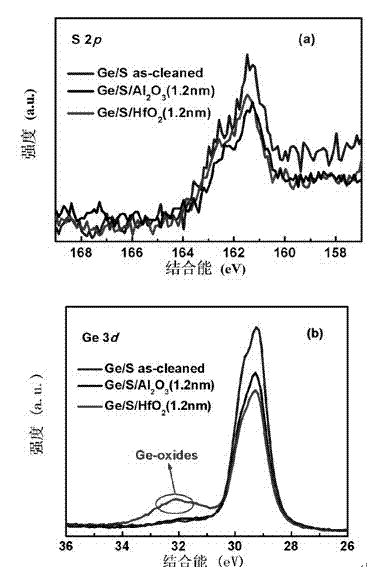

[0026] 1. Ge substrate cleaning and S passivation: The substrate material is a commercial single crystal germanium wafer, N type, orientation (100), resistivity 0.2-0.3 W cm. Sonicate with acetone and methanol for 5 minutes in turn to remove the oil on the Ge surface. HBr (HBr / H 2 O=1:3 weight ratio) Soak in aqueous solution for 5 minutes to remove the natural oxide layer on the surface. Then use 20% weight ratio (NH 4 ) 2 The S aqueous solution is soaked for 20 minutes to form a Ge-S bond on the Ge surface and further remove excess Ge oxides. Finally, rinse the treated germanium surface with deionized water, dry it with high-purity nitrogen, and put it into the ALD reaction chamber.

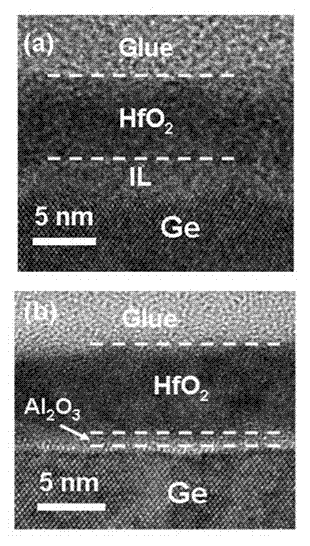

[0027] 2. Preparation of HfO by atomic layer deposition 2 / Al 2 o 3 Stacking structure film:

[0028] Growth temperature: 220 ℃; reaction source: trimethylaluminum (Al(CH 3 ) 3 TMA), four two (methyl ammonia) hafnium (Hf [N (CH 3 ) 2 ] 4, TDMAH), the oxygen source is water H 2 O;...

Embodiment 2

[0039] 1. Ge substrate cleaning and S passivation: The substrate material is a commercial single crystal germanium wafer, N type, orientation (100), resistivity 0.2-0.3 W cm. Use acetone and methanol to sonicate for 3 minutes in sequence to remove the oil on the Ge surface. HBr (HBr / H 2 O=1:3 weight ratio) Soak in aqueous solution for 3 minutes to remove the natural oxide layer on the surface. Then use 20% weight ratio (NH 4 ) 2 The S aqueous solution is soaked for 10 minutes to form a Ge-S bond on the Ge surface and further remove excess Ge oxides. Finally, rinse the treated germanium surface with deionized water, dry it with high-purity nitrogen, and put it into the ALD reaction chamber.

[0040] 2. Preparation of HfO by atomic layer deposition 2 / Al 2 o 3 Stacking structure film:

[0041] Growth temperature: 250 ℃; reaction source: trimethylaluminum (Al(CH 3 ) 3 TMA), tetrakis(methylethylammonia) hafnium (Hf[N(CH 3 )(C 2 h 5 )] 4, TEMAH), the oxygen source i...

Embodiment 3

[0046] 1. Ge substrate cleaning and S passivation: The substrate material is a commercial single crystal germanium wafer, N type, orientation (100), resistivity 0.2-0.3 W cm. Use acetone and methanol to sonicate for 10 minutes in sequence to remove the oil on the Ge surface. HBr (HBr / H 2 O=1:3 weight ratio) Soak in aqueous solution for 7 minutes to remove the natural oxide layer on the surface. Then use 20% weight ratio (NH 4 ) 2 Soak in aqueous solution of S for 40 minutes to form Ge-S bonds on the surface of Ge and further remove excess Ge oxides. Finally, rinse the treated germanium surface with deionized water, dry it with high-purity nitrogen, and put it into the ALD reaction chamber.

[0047] 2. Preparation of HfO by atomic layer deposition 2 / Al 2 o 3 Stacking structure film:

[0048] Growth temperature: 300 ℃; reaction source: trimethylaluminum (Al(CH 3 ) 3 TMA), tetrakis(methylethylammonia) hafnium (Hf[N(CH 3 )(C 2 h 5 )] 4, TEMAH), the oxygen source i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com