Three-proofing fabric finishing agent and preparation method thereof

A technology of three-proof finishing agent and fabric, which is applied in the fields of fiber treatment, textiles and papermaking, and can solve the problems of no mature fabric three-proof finishing agent products, and achieve the effects of improving initiation efficiency, low price, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

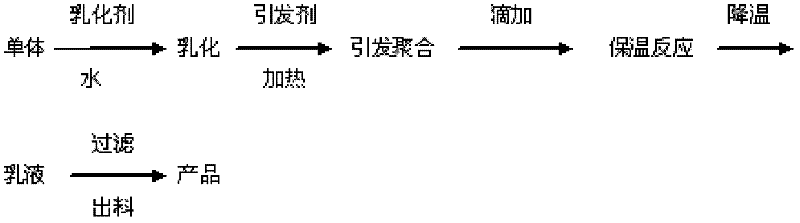

[0026] Referring to the accompanying drawings, it can be seen that the preparation method of the fabric three-proof finishing agent of the present invention comprises the following reaction steps:

[0027] ① Mix the raw material monomers uniformly for later use, then weigh the compound emulsifier, and a mixed solvent composed of acetone and water, and mix the raw material monomers, compound emulsifier and mixed solvent evenly to form a mixed solution;

[0028] ② Stir the mixture and pour it into a homogenizer to homogenize to obtain a milky white pre-emulsion;

[0029] ③Then dripping an initiator solution with a concentration of 10% by weight in the pre-emulsion at 50-90°C;

[0030] ④ After the dropwise addition, the reaction time of heat preservation is 5-10 hours, then cooled to room temperature and filtered to obtain the product;

[0031] The raw material monomers are 50-80 parts by weight of perfluorononenyloxyethyl methacrylate, 15-40 parts by weight of stearyl methacryl...

Embodiment 1

[0041] Perfluorononenyloxyethyl methacrylate 65g, stearyl methacrylate 28g, hydroxyethyl methacrylate 3g and glycidyl methacrylate 4g are mixed for subsequent use, then take 1g of composite emulsifier ( The molar ratio of lauryltrimethylammonium bromide and alkylphenol polyoxyethylene ether is 1: 2), the mixed solvent that 5g acetone and 200g deionized water are formed, stirs and mixes evenly, after two kinds of mixtures are stirred and mixed Pour into a homogenizer and homogenize twice to obtain a milky white pre-emulsion, then pour the pre-emulsion into a four-necked flask equipped with an electric stirrer, a thermometer, and a condenser tube, heat up to 60°C, and add dropwise 5g of 10% Aqueous solution of dimethyl azobisisobutyrate. After the dropwise addition, keep the temperature at 60°C for 8 hours, cool and filter to obtain the product.

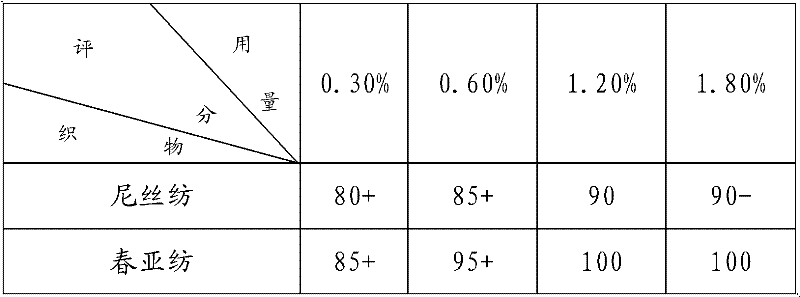

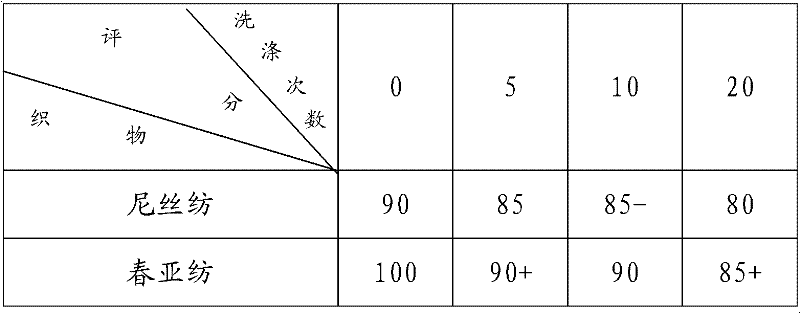

[0042] Characterize product properties

[0043] ①Water repellency of fabrics shall be carried out according to the provisions of GB...

Embodiment 2

[0060] Perfluorononenyloxyethyl methacrylate 50g, stearyl methacrylate 40g, hydroxyethyl methacrylate 5g and glycidyl methacrylate 5g are mixed for subsequent use, then take 5g of composite emulsifier ( The molar ratio of cetyltrimethylammonium bromide and fatty alcohol polyoxyethylene ether is 1: 1), the mixed solvent that 20g acetone and 300g deionized water are formed, stirs and mixes evenly, after two kinds of mixtures are stirred and mixed, pour Homogenize twice in a homogenizer to obtain a milky white pre-emulsion, then pour the pre-emulsion into a four-necked flask equipped with an electric stirrer, a thermometer, and a condenser tube, heat up to 50°C, and add dropwise 8 g of 10% dilute Aqueous solution of azodiisobutamidine hydrochloride. After the dropwise addition, keep the temperature at 50°C for 10 hours, cool and filter to obtain the product.

[0061] Characterize product properties

[0062] ①Water repellency of fabrics shall be carried out according to the prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com