Patents

Literature

331 results about "Alpha-Methylstyrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

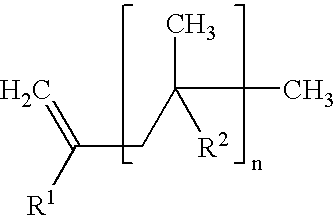

Α-Methylstyrene (AMS) is a chemical intermediate used in the manufacture of plasticizers, resins and polymers. It is a co-product formed in a variation of the cumene process. The homopolymer obtained from this monomer, poly(α-methylstyrene), is unstable, being characterized by a low ceiling temperature.

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

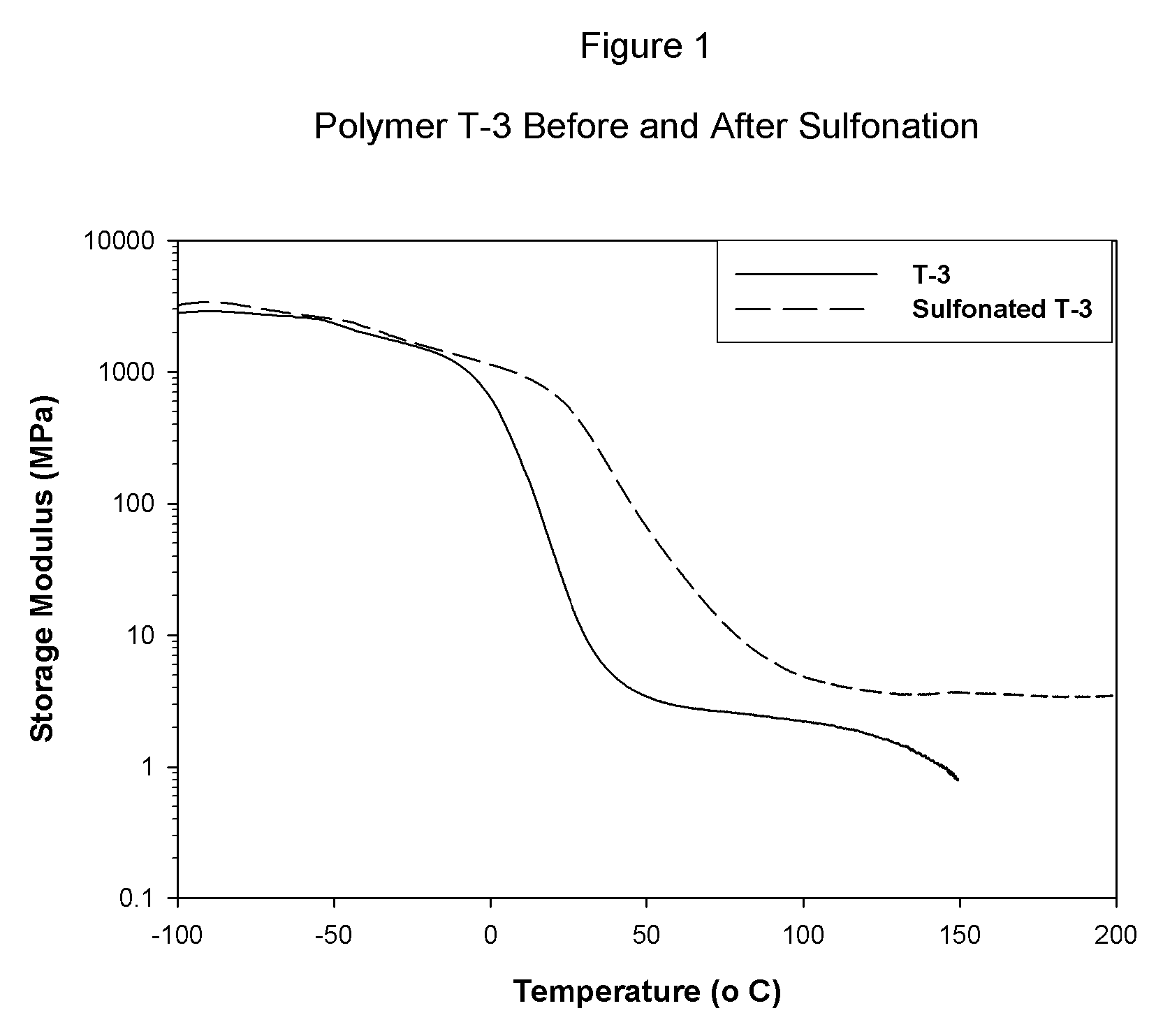

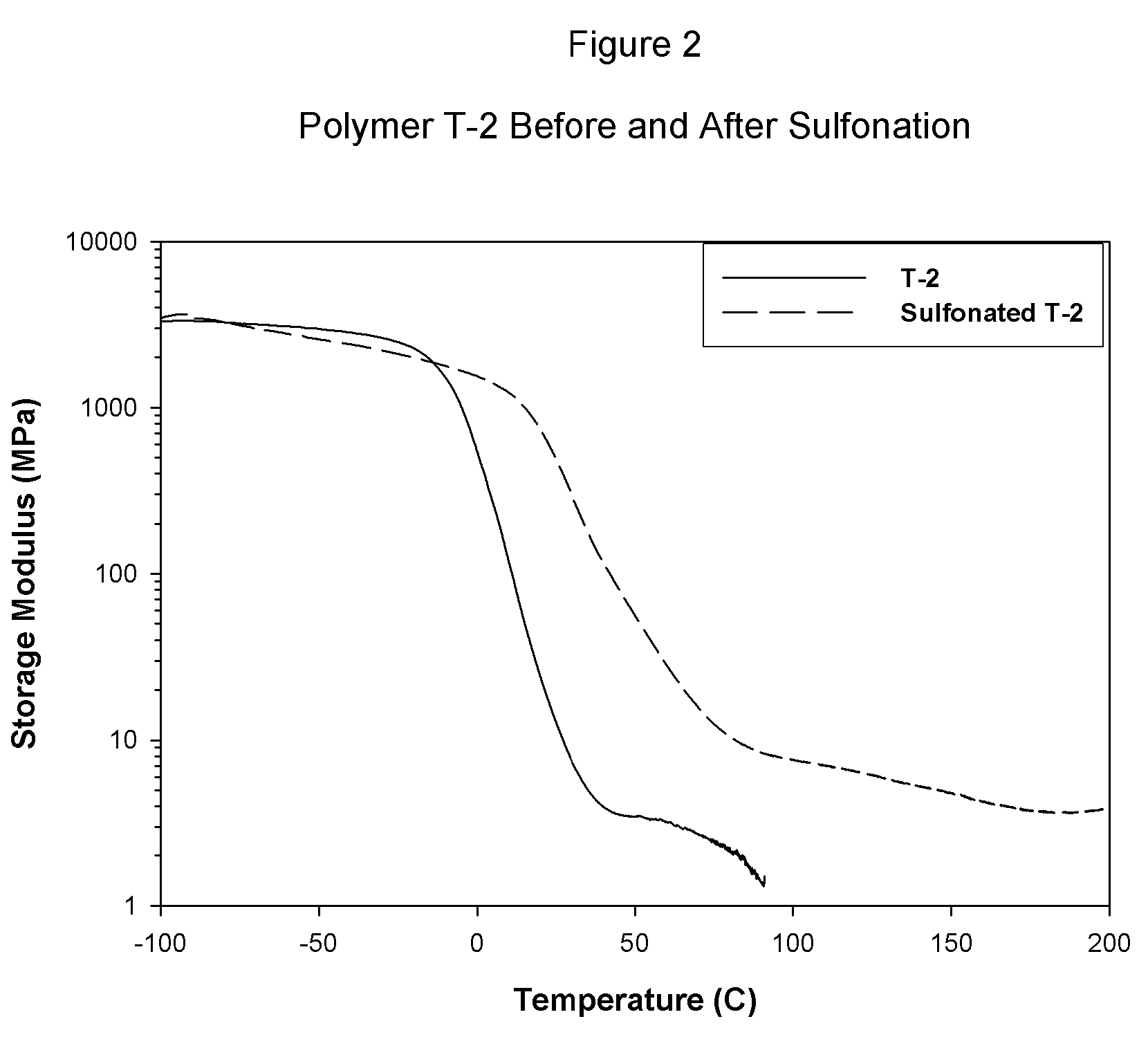

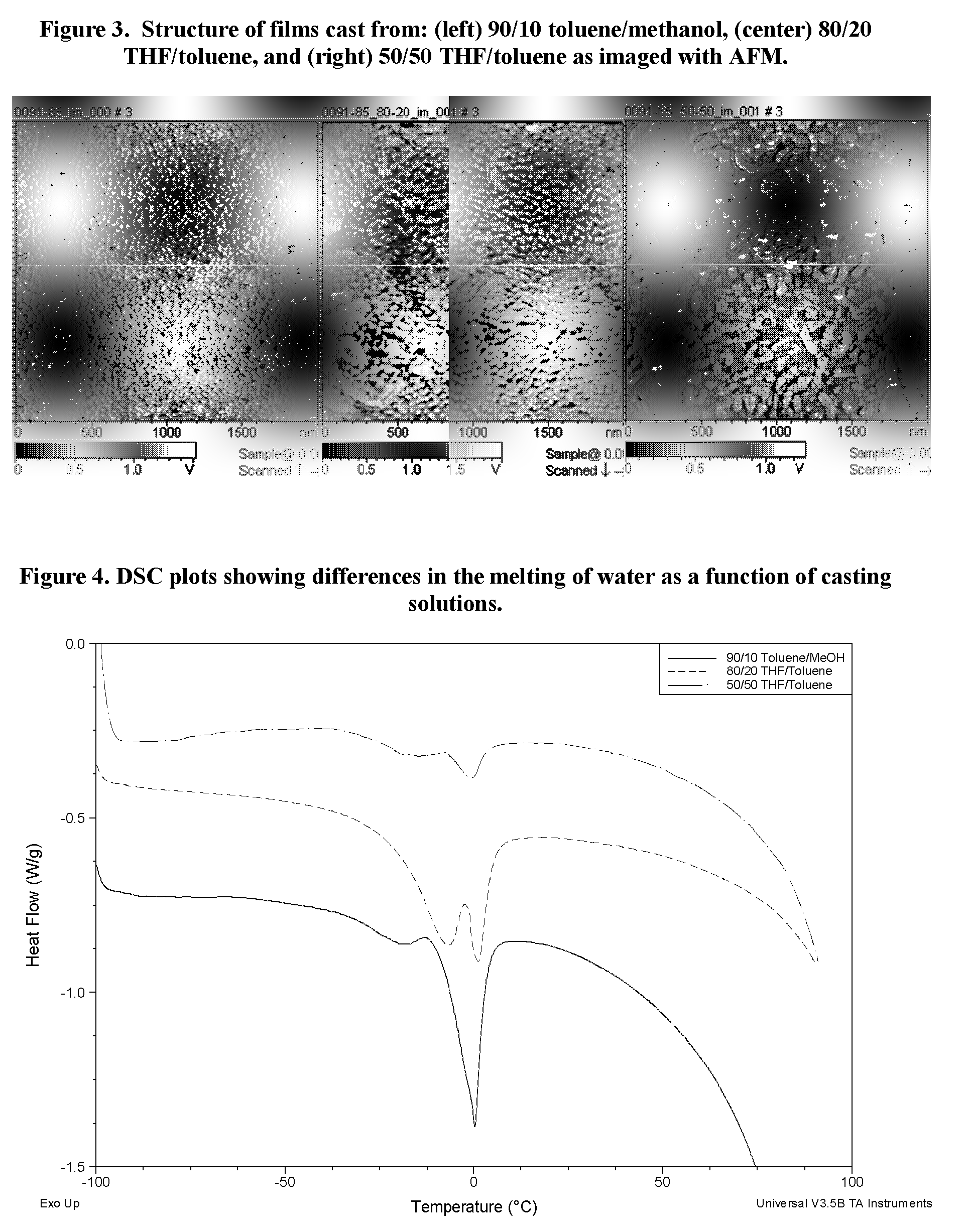

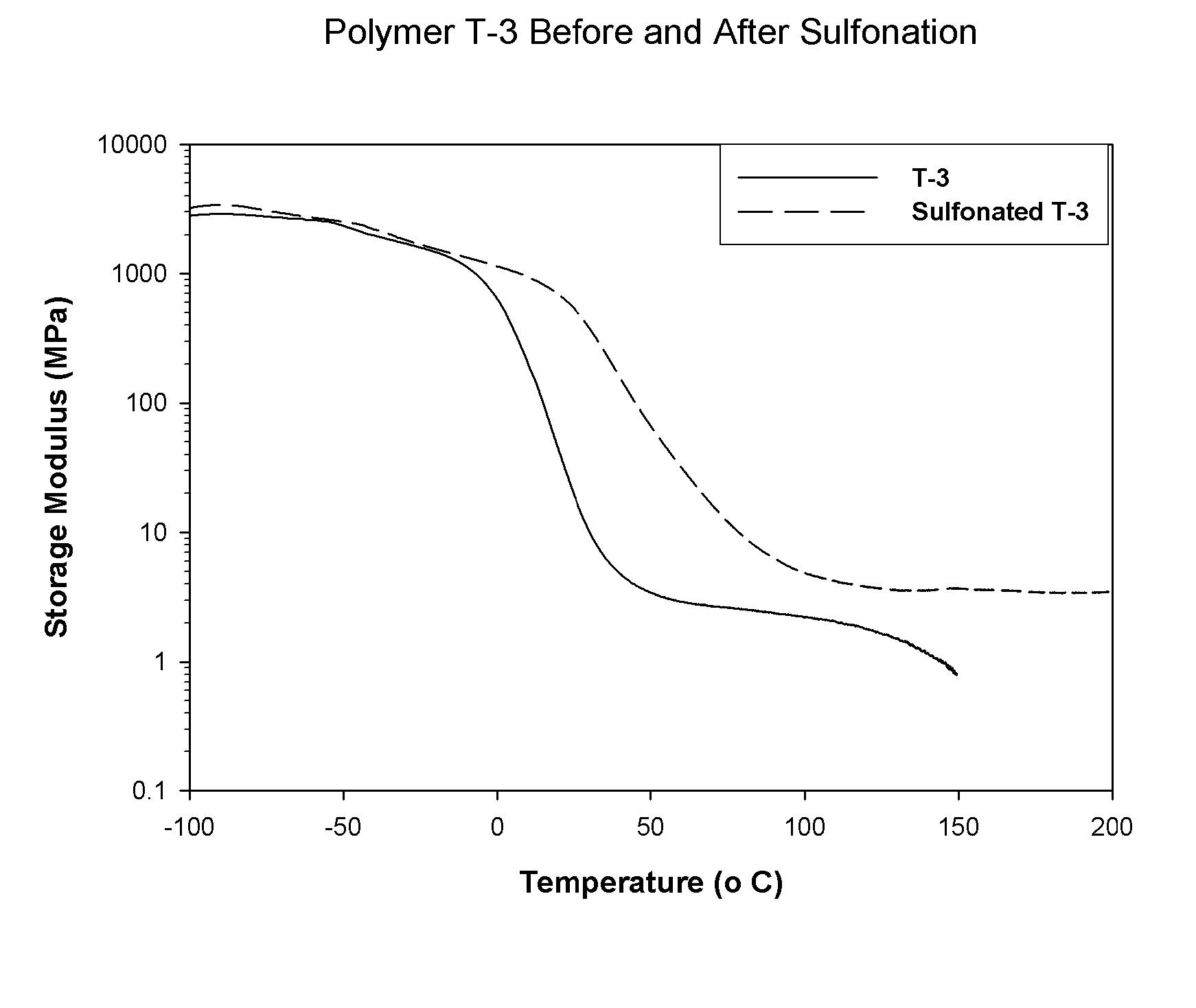

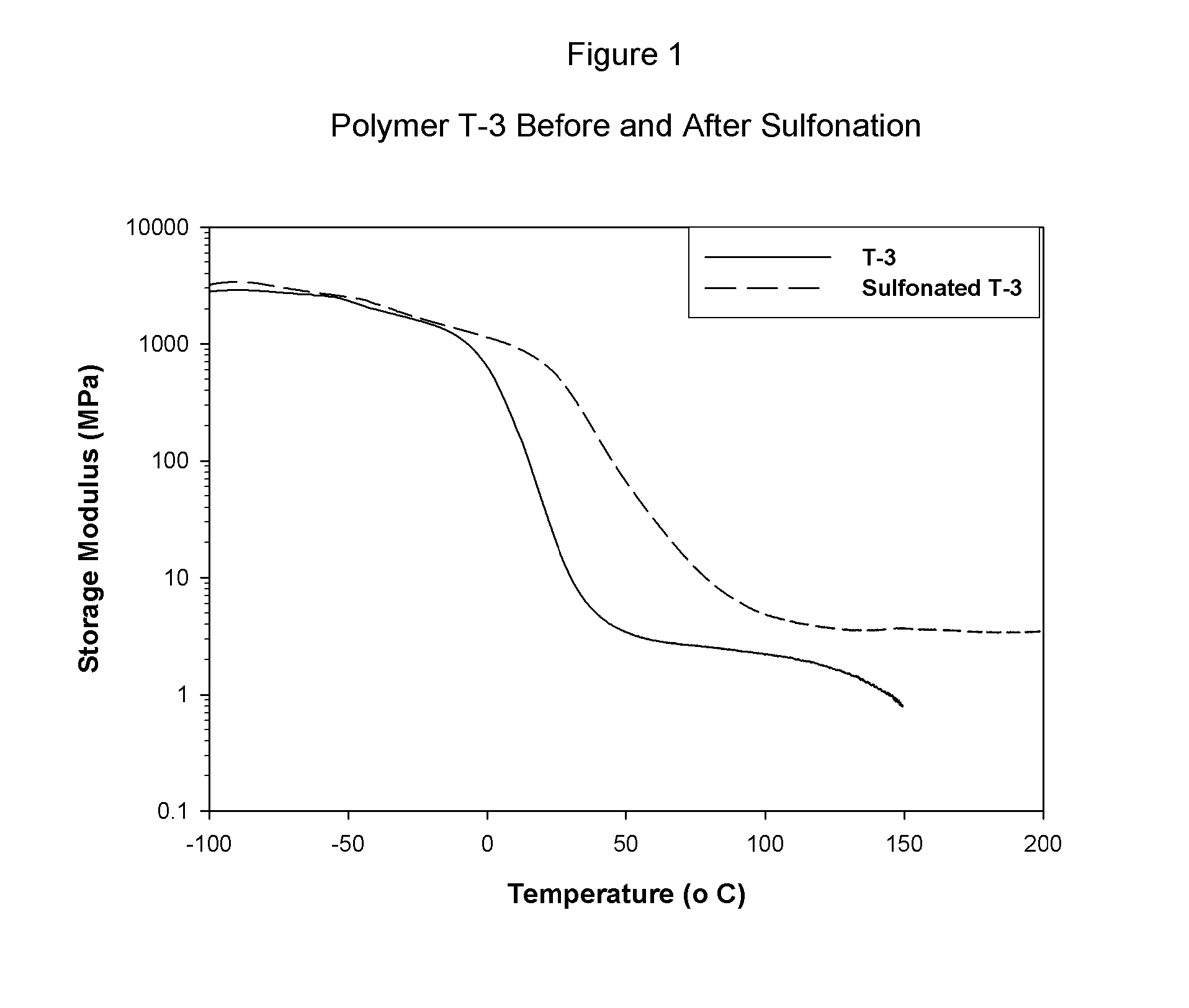

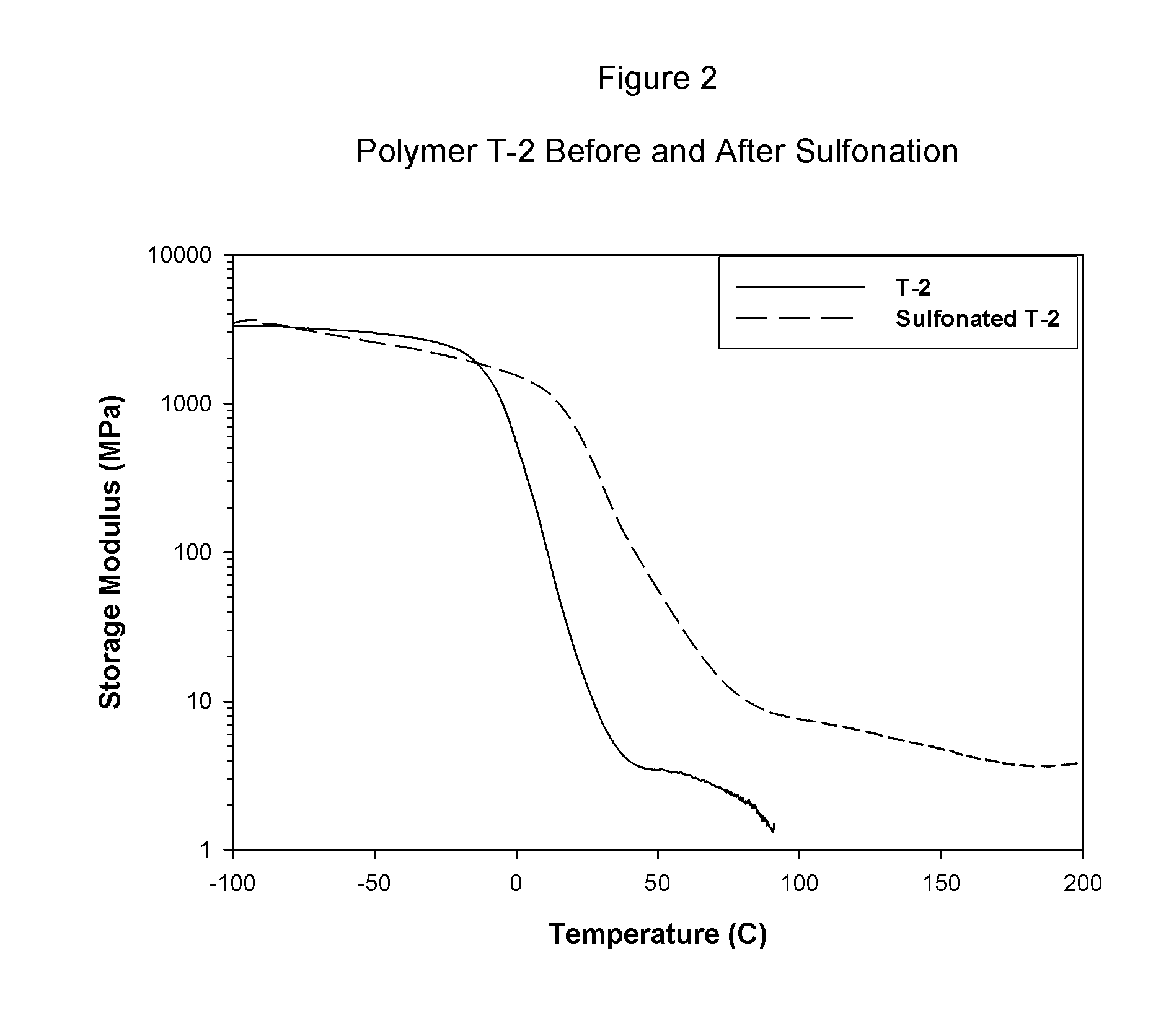

ActiveUS7737224B2Reduced responseHigh propertySemi-permeable membranesNegative electrodesMethacrylatePolymer science

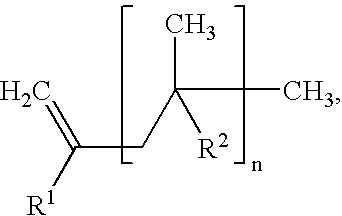

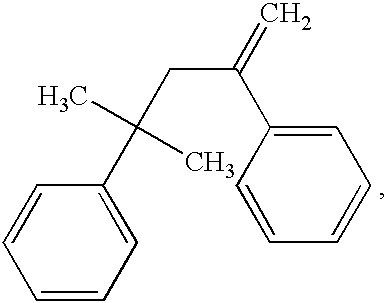

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Cross-linkable polymer composition

The invention pertains to a polymer obtainable from the steps:polymerizing a mixture, that is substantially free or organic solvents, of ethylenically unsaturated monomers which consist for at least 70% of methacrylates, and which comprises specific chain transfer agents, α-methylstyrene dimer being preferred, to form a first polymer,aqueous emulsion polymerizing a mixture comprising ethylenically unsaturated monomers in the presence of the first polymer to form a dispersion of a water-insoluble second polymer, wherein these steps are preferably performed in the absence or the substantial absence of a surfactant.

Owner:NUPLEX RESINS BV

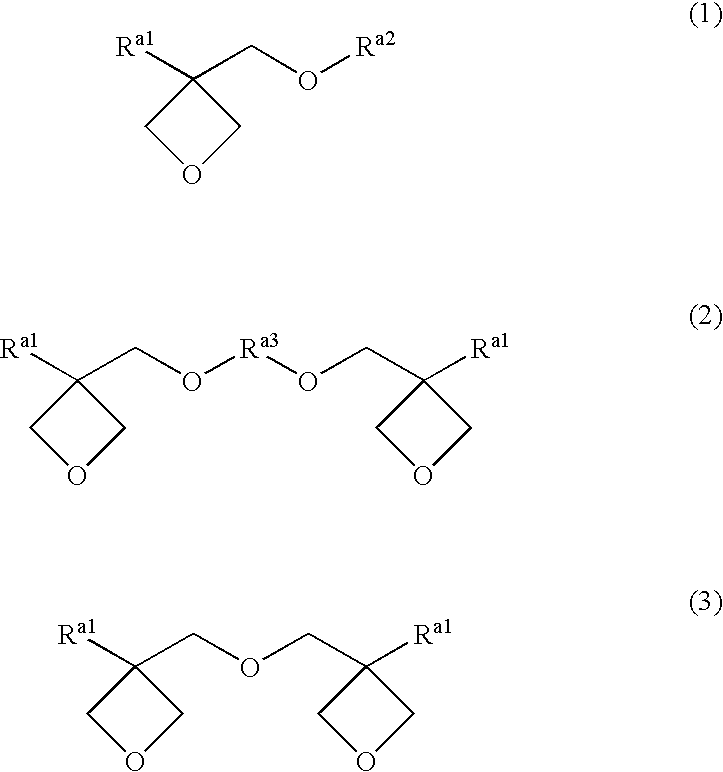

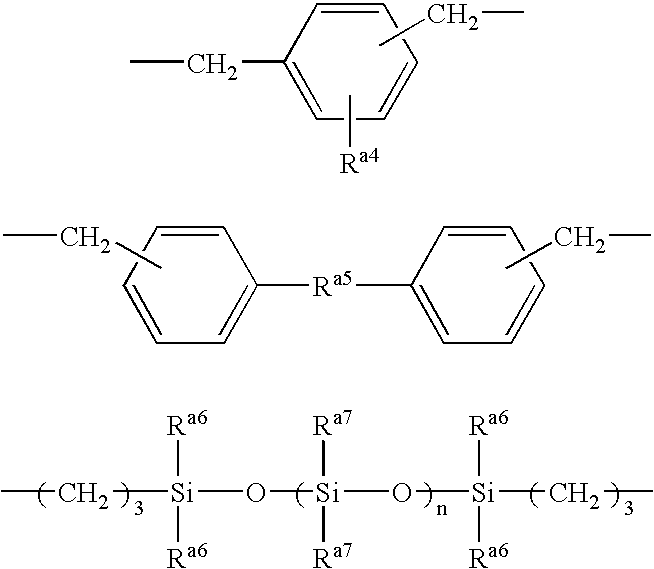

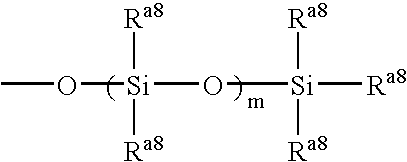

Ink composition, inkjet-recording method and printed material

InactiveUS20060222832A1Measurement apparatus componentsDecorative surface effectsOxepanePolymerization

An ink composition including a cationically polymerizable compound having a styryl or α-methylstyryl group such as 4-methylstyrene and a photocationic polymerization initiator. the ink composition preferably further includes another cationically polymerizable compound having at least one group selected from oxirane and oxetane groups.

Owner:FUJIFILM HLDG CORP +1

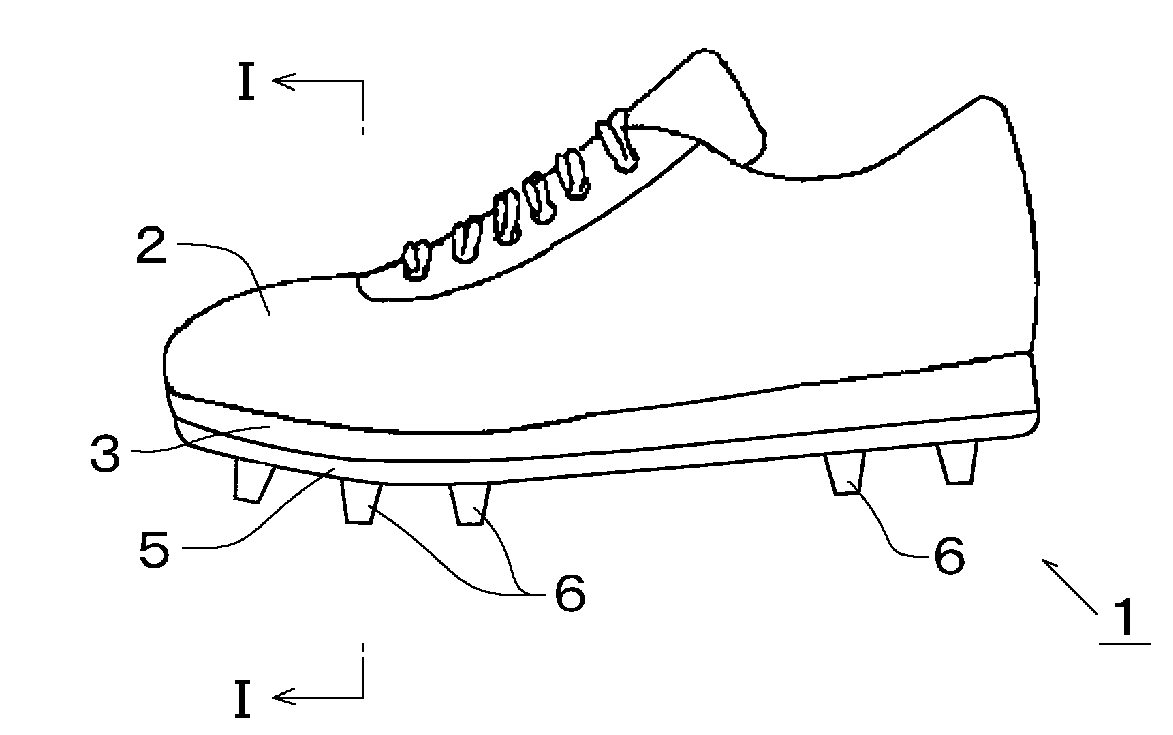

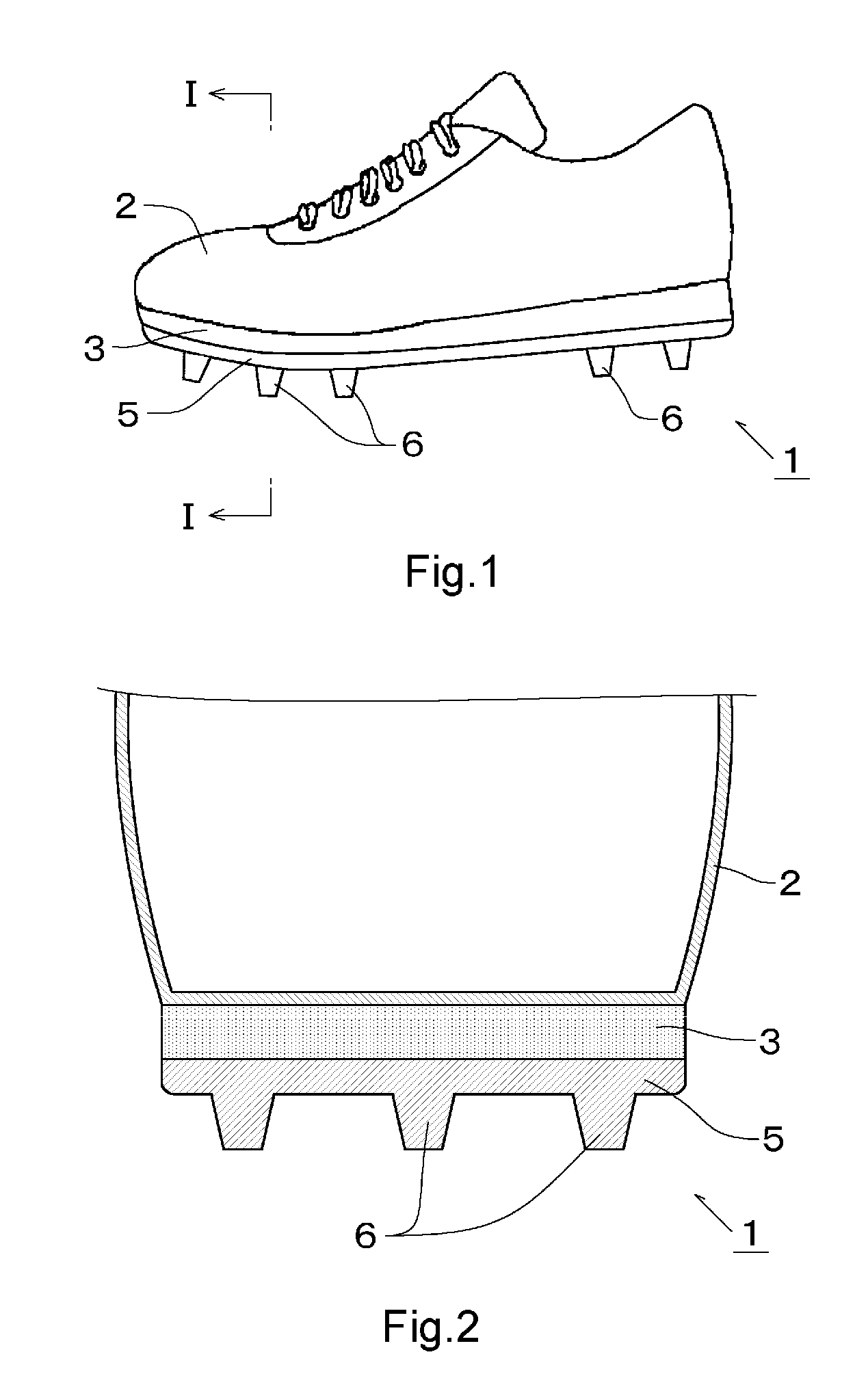

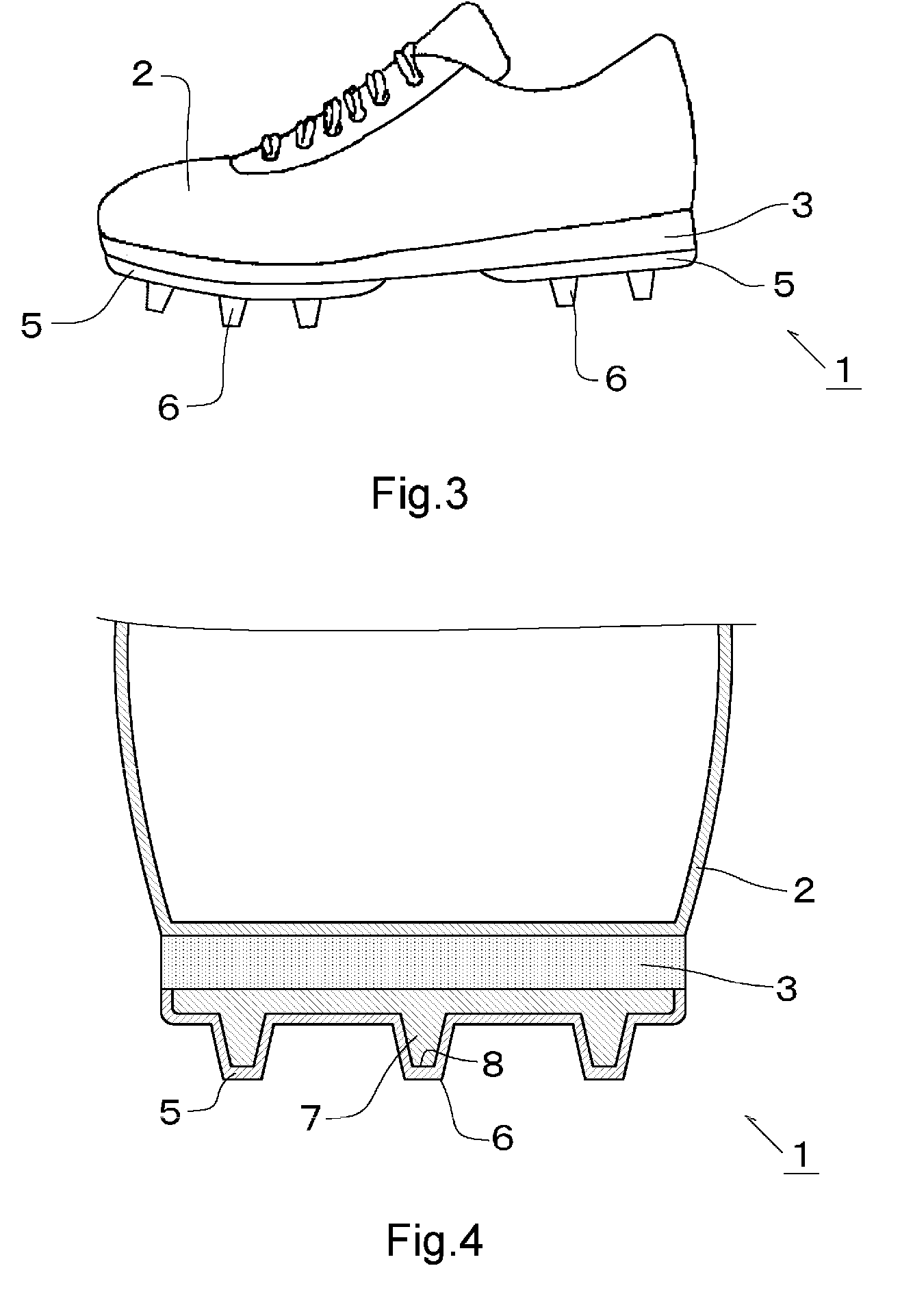

Outer sole and shoes

InactiveUS20100154253A1Light weightImprove wear resistanceSolesFasteningsElastomerDynamic viscoelasticity

The present invention provides an outer sole light in weight and excellent in abrasion resistance.The outer sole of the present invention is formed out of a polymer composition with a specific gravity of 0.95 or less, which contains an olefin resin and a styrene elastomer, wherein a storage elastic modulus [E′] and a loss coefficient [tan δ] in a dynamic viscoelasticity measurement (20±3° C., 10 Hz) are 100 MPa to 500 MPa and 0.2 or less respectively, and a maximum tensile stress is 30 MPa or more. The olefin resin contains an ethylene polymer and a propylene polymer, for example. The styrene elastomer contains an α-methyl styrene.butadiene copolymer, for example.A flaw is hardly occurred on the outer sole in use, so that the outer sole is excellent in abrasion resistance.

Owner:ASICS CORP

Rubber composition containing an alkoxysilane coupled in-chain functionalized elastomer and tire with component thereof

InactiveUS20060247360A1Improve propertiesLower Level RequirementsCosmetic preparationsPlastic/resin/waxes insulatorsElastomerSilicon dioxide

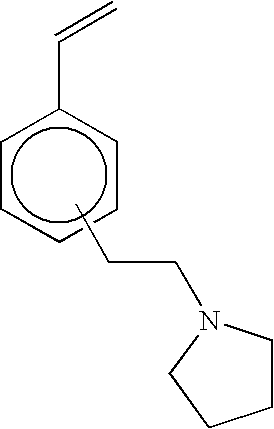

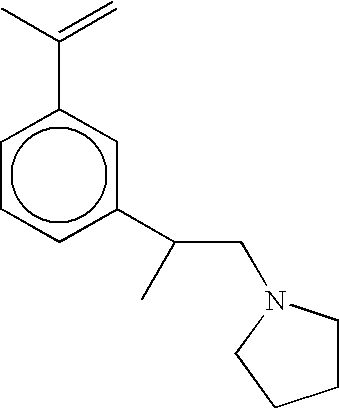

This invention relates to a precipitated silica reinforced conjugated diene-based elastomer composition containing an alkoxysilane coupled, in-chain functionalized, conjugated diene-based elastomer and to a tire having at least one component thereof. Said in-chain functionalized conjugated diene-based elastomer is a conjugated diene-based elastomer which contains a plurality of at least one of in-chain p- and m-(2-pyrrolidinoethyl) styrene (PES) and m-(2-pyrrolidino-1-methylethyl) alpha-methylstyrene (PAMS) groups.

Owner:THE GOODYEAR TIRE & RUBBER CO

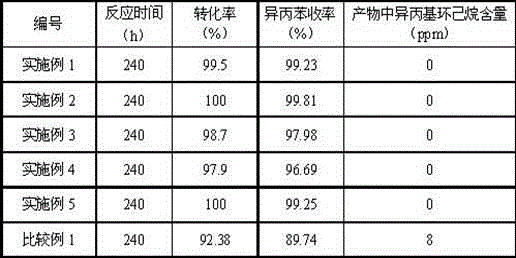

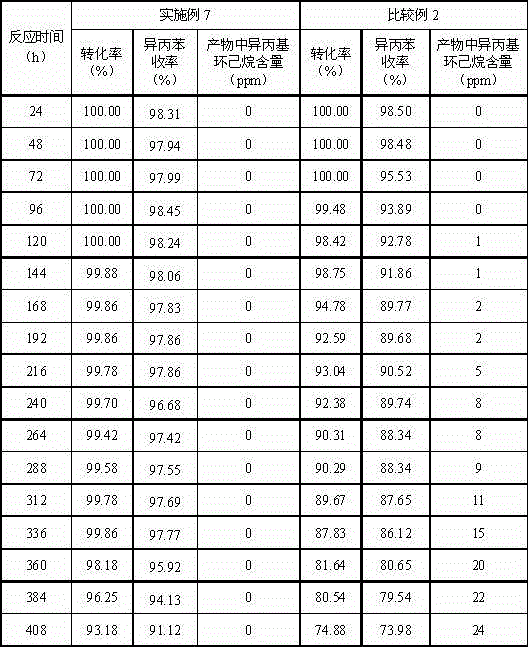

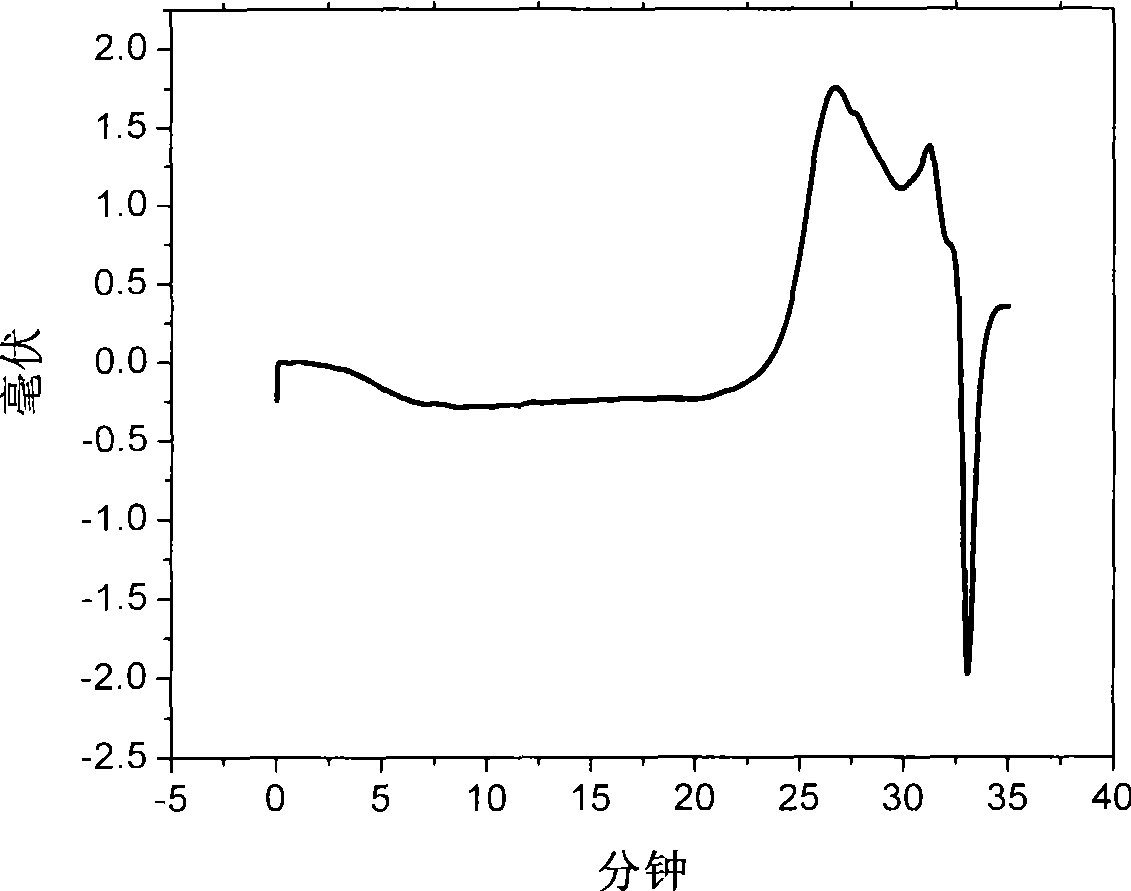

Alpha-methyl styrene selective hydrogenation method

ActiveCN104151129AGood activity at low temperatureGood choiceHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsState of artPalladium

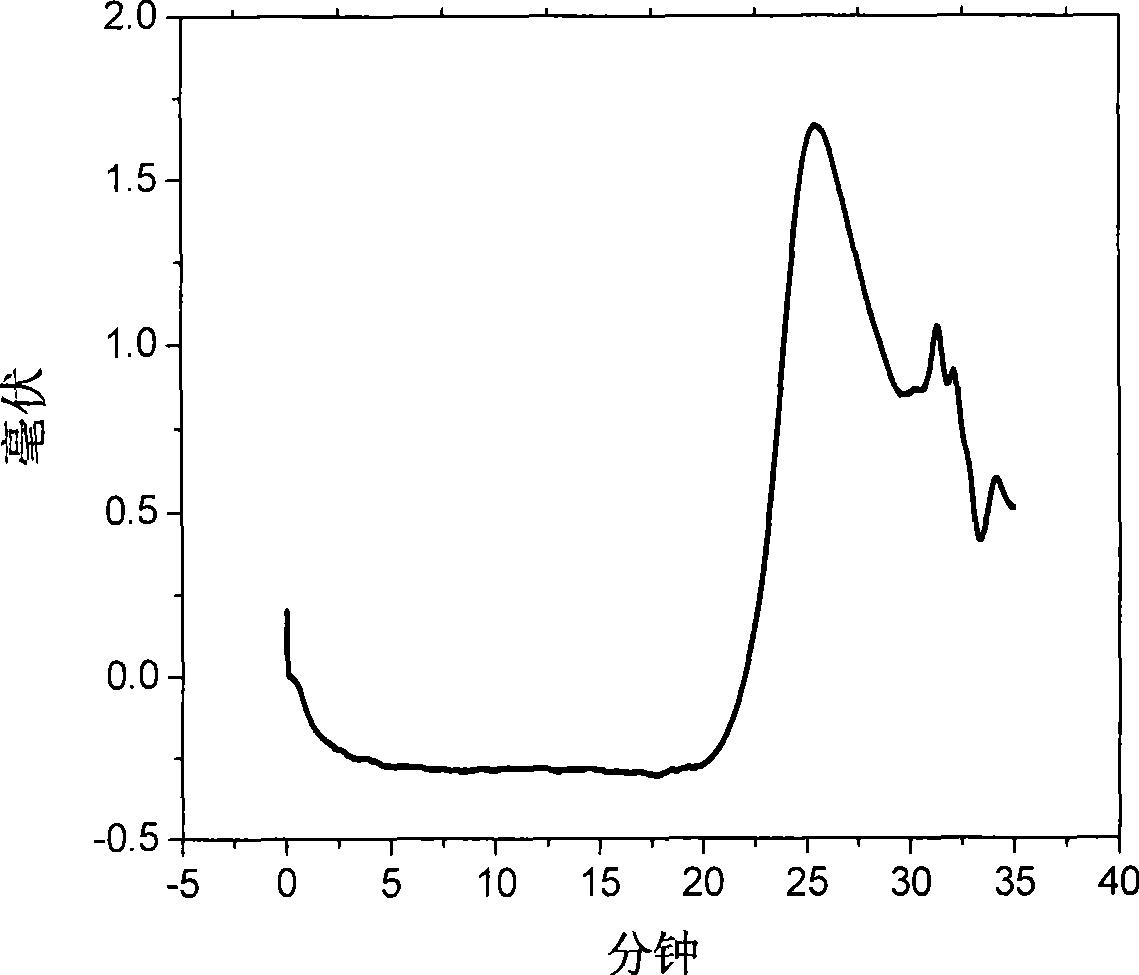

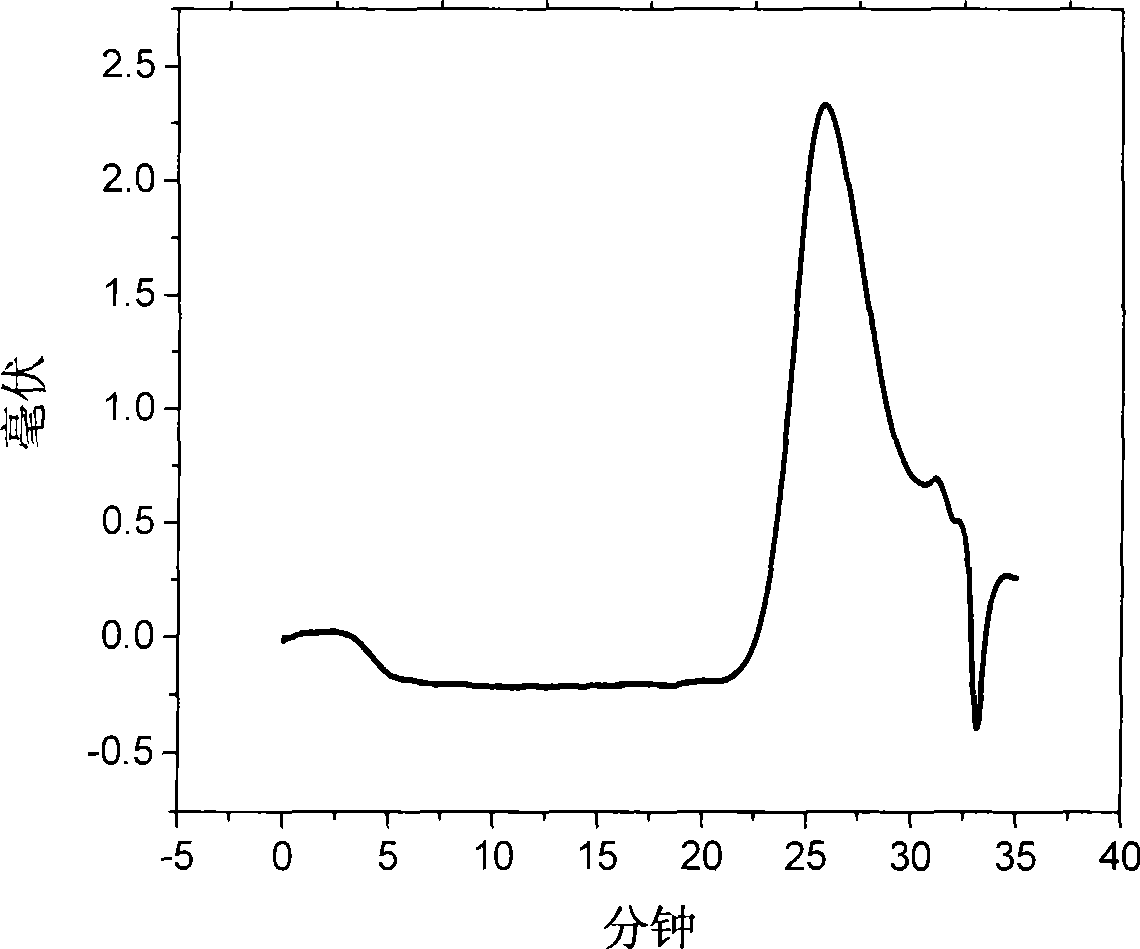

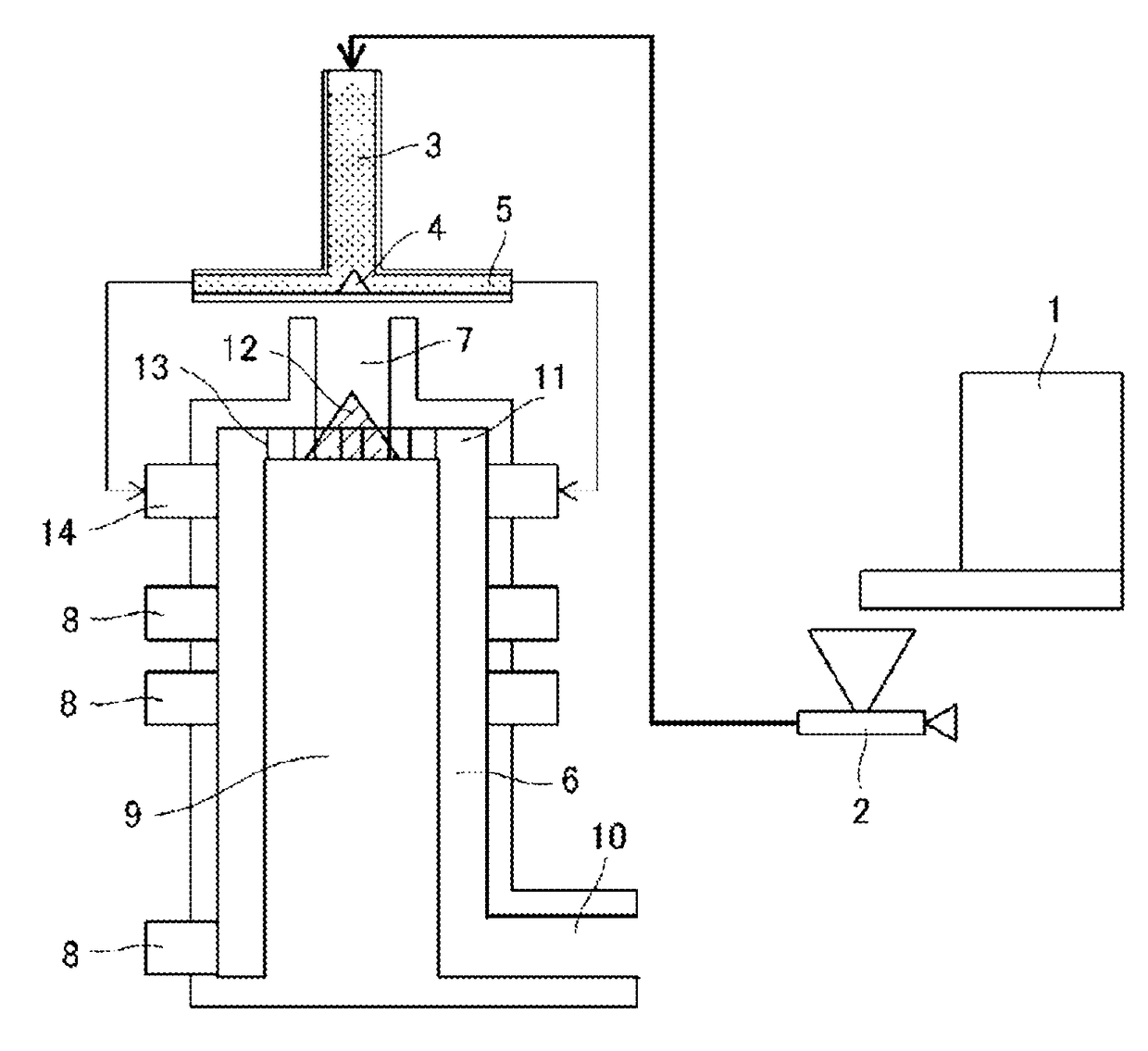

The invention relates to an AMS (Alpha Methyl Styrene) selective hydrogenation method which mainly solves the problems of poor low-temperature activity and bad selectivity and stability of a catalyst in the prior art. According to the technical scheme, the used catalyst comprises the following components in parts by weight: (a) 0.01-1.0 part of metal palladium or oxide thereof, (b) 0.01-2.0 parts of at least one element of IA or IIA selected from the periodic table of elements or oxide thereof, (c) 0.01-20.0 parts of at least one element of IVA or VA selected from the periodic table of elements or oxide thereof and (d) 77-100 parts of alumina carriers, so that the problems are better solved. The AMS selective hydrogenation method disclosed by the invention can be used for the industrial production of AMS selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functionalized block copolymers, method for making same, and various uses for such block copolymers

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to lithiation and each B block is a polymer block susceptible to lithiation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers not having hydrogen on a para benzylic carbon center, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) para-substituted styrene having hydrogen on a para benzylic carbon center (vi) 1,1-diphenylethylene, (vii) 1,2-diphenylethylene and (viii) mixtures thereof. After lithiation, the lithiated polymer is reacted with at least one graftable functional molecule selected from the group consisting of an electrophilic graftable molecule containing a functional group and an electrophile. Preferred are carbon monoxide and ethylene oxide. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Method for synthesizing low molecular weight phenylethylene / maleic anhydride alternate copolymer

A synthetic method of a styrene / maleic anhydride alternating copolymer with low molecular weight belongs to the field of macromolecular precipitation polymerization. Media and chain transfer agents used in the existing methods for preparing styrene / maleic anhydride copolymers by precipitation polymerization have disadvantages. In the synthetic method, the styrene / maleic anhydride alternating copolymer is prepared by taking a mixed solvent of organic acid alkyl ester and alkane as a reaction medium for the precipitation polymerization, alpha-methylstyrene or vinyl acetate as a molecular weight regulator and organic peroxide or an azo compound as an initiator for initiating a copolymerization reaction between styrene monomers and styrene. The synthetic method has simple process, the synthesized copolymer has good properties, and the method has the advantages of being economical, environment-friendly and the like.

Owner:BEIJING UNIV OF CHEM TECH

Toner production method and polymer

A toner production method including: a melt-kneading step of melt-kneading a resin composition including a binder resin, a colorant, a wax, and a wax dispersant to obtain a melt-kneaded product; and a pulverizing step of pulverizing the melt-kneaded product. Where the temperature of the melt-kneaded product at the end of the melt-kneading step is Tk (° C.), and the softening point of the wax dispersant is Tm (° C.), the relationship of −18≤[Tk−Tm]≤10 is satisfied. The wax dispersant is a polymer in which a styrene acrylic polymer is graft-polymerized to a polyolefin. The styrene acrylic polymer has a monomer unit derived from α-methylstyrene and a monomer unit derived from a cycloalkyl (meth)acrylate.

Owner:CANON KK

Transparent polyvinyl chloride material, and preparation and application thereof

The invention relates to a polyvinyl chloride material prepared from a composition containing 100 parts by weight of a polyvinyl chloride resin having the weight-average molecular weight of 100000-200000 and used as a basic resin and the following components: A) 1-10 parts by weight of a styrene analogue which is a grafted copolymer of rubber or an elastomer and alpha-methyl styrene; B) 5-30 parts by weight of a vinyl terpolymer with an America DuPont Co commodity name of Elvaloy; C) 5-20 parts by weight of low-molecular-weight polyvinyl chloride with the weight-average molecular weight of 20000-40000; D) a heat stabilizer; and E) and a plasticizer. The invention also relates to preparation and an application of the polyvinyl chloride material. The material can ensure the good transparency of PVC, improves cold resistance of PVC in the premise without sharp decrease of the hardness, moreover, reduces the plasticizing temperature of PVC, improves the performance of PVC, and broadens the application field of PVC.

Owner:BEIJING UNIV OF CHEM TECH +1

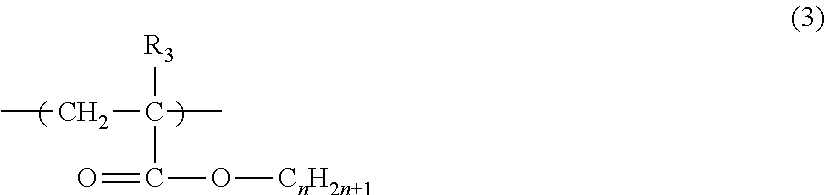

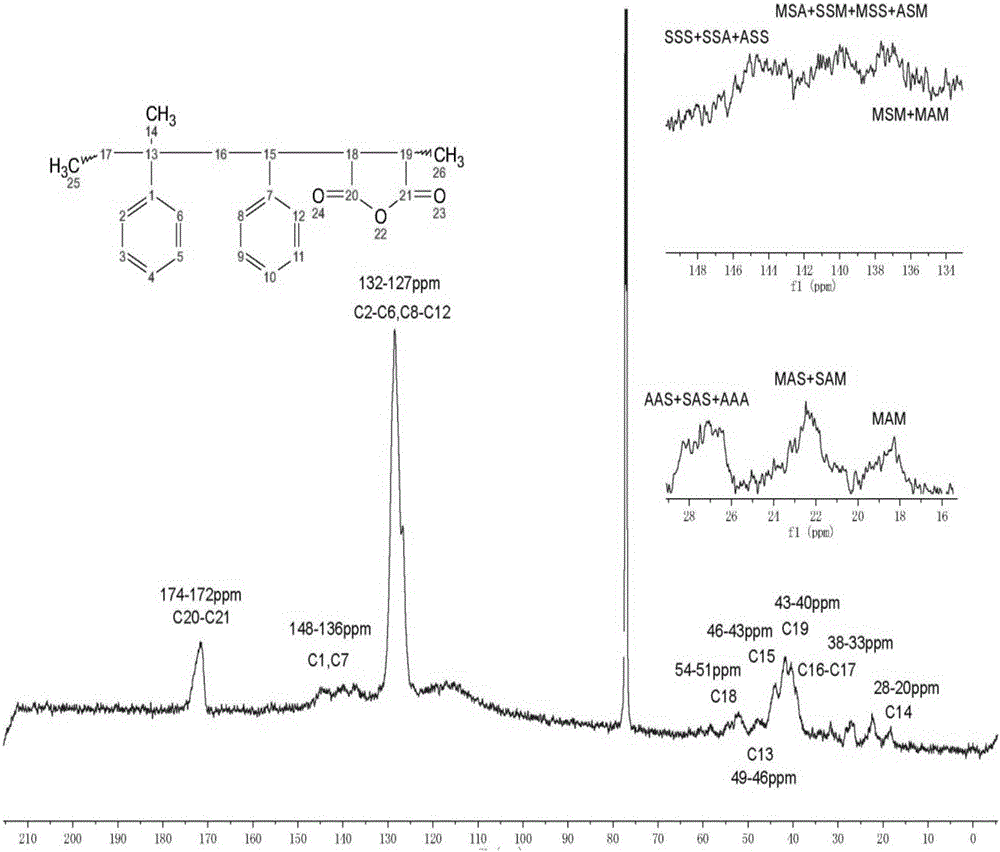

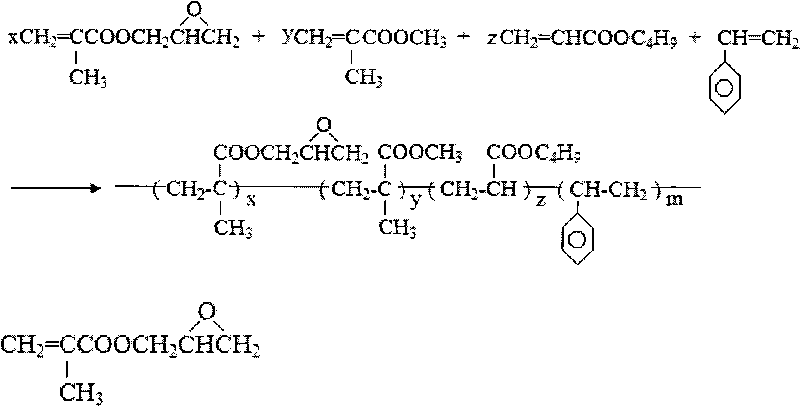

Preparation method of water-soluble solid styrene-acrylic resin

The invention discloses a preparation method of water-soluble solid styrene-acrylic resin. The preparation method comprises the following steps: under atmospheric pressure and low temperature, choosing N2 aura as a protective gas, adopting the polymerization process of atmospheric pressure semi-continuous solution, taking peroxide as an evocating agent and mercaptan acid as a chain transfer agent, and obtaining the water-soluble solid styrene-acrylic resin with an adjustable weight mean molecular weight, acid value and glass transition temperature (Tg) through multi components copolymerization of alpha-methyl styrene (AMS) and / or styrene (St), acrylic acid ester monomer and acrylic acid (AA) copolymer. The polymerization process of the method is simple, with the atmospheric pressure environment and low temperature, weight mean molecular weight, the acid value and the Tg value are controllable, the polymerization process is simple; and the polymerization reaction is carried out under atmospheric pressure environment and low temperature (110-120 DEG C), thereby being safe and energy saving for production.

Owner:BEIJING UNIV OF CHEM TECH

Binder composition for positive electrodes

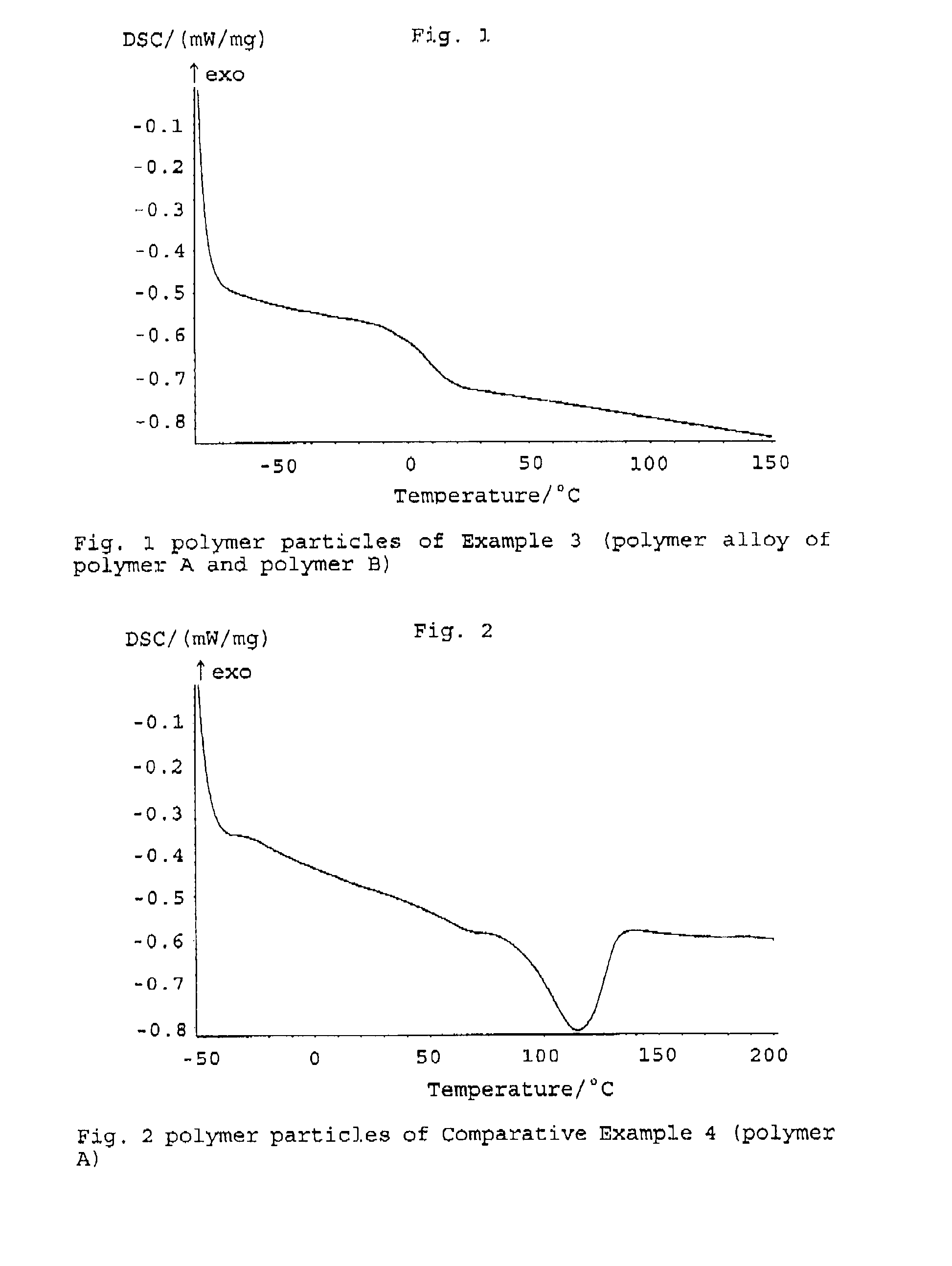

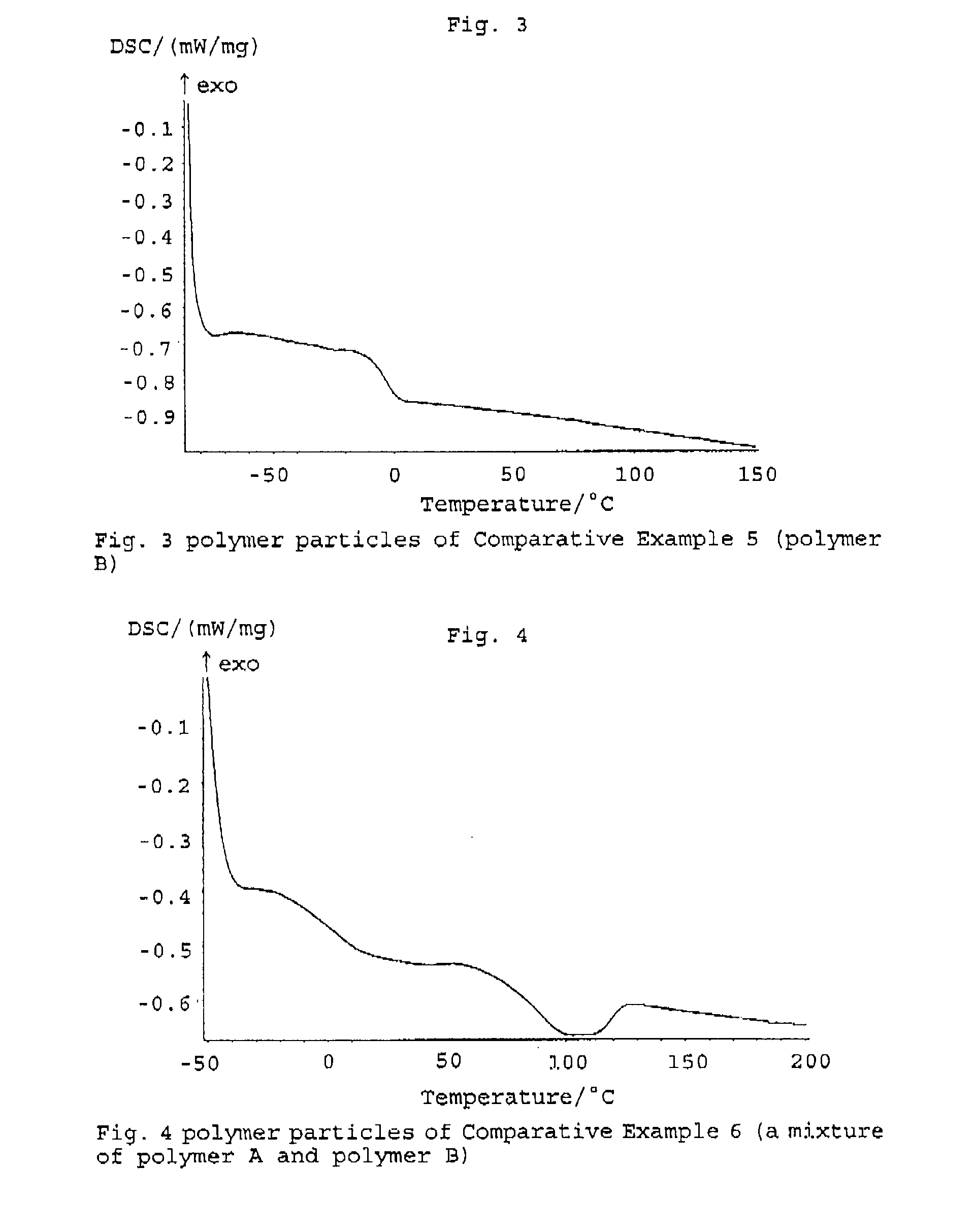

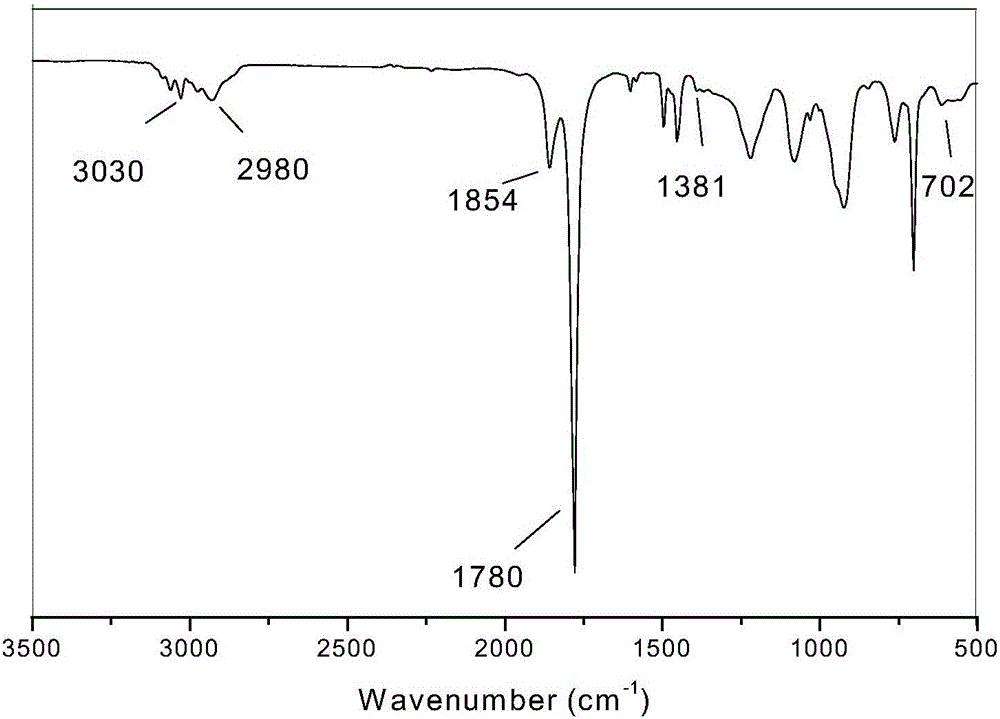

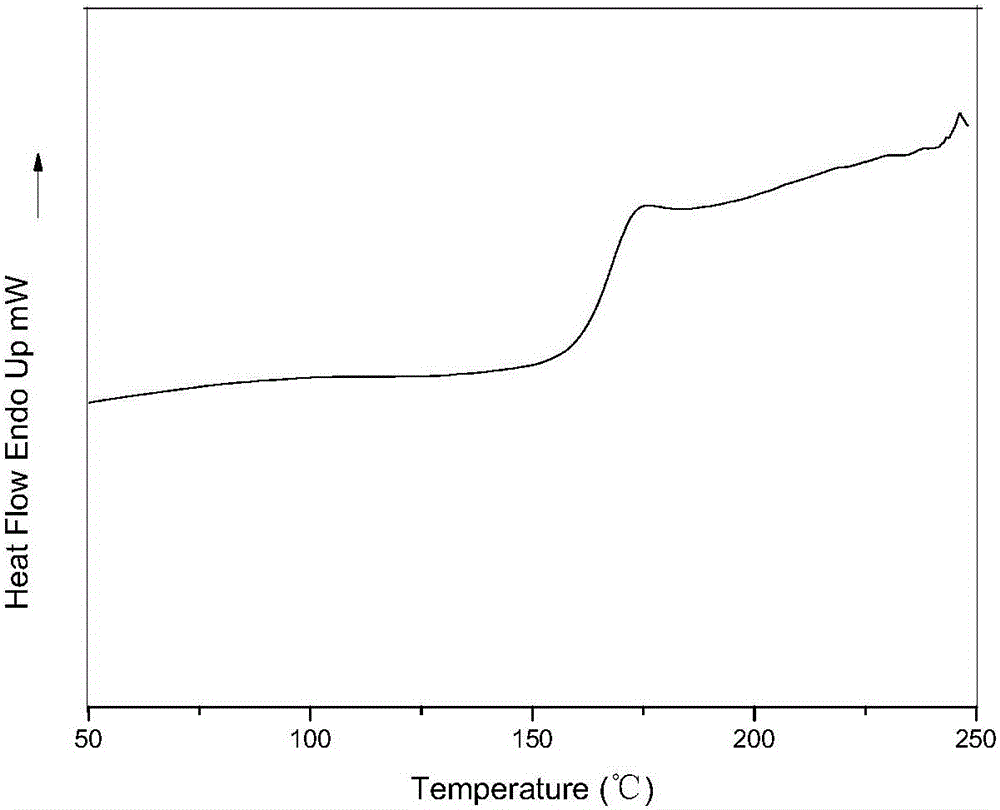

ActiveUS20120309892A1Positive electrodesNon-aqueous electrolyte accumulator electrodesPolymer sciencePolymer alloy

A binder composition for the positive electrode of an electric storage device. The composition contains polymer alloy particles composed of: a polymer (A) having a recurring unit derived from vinylidene fluoride, ethylene tetrafluoride, propylene hexafluoride, or mixtures thereof; a polymer (B) having a recurring unit derived from an unsaturated carboxylic acid ester; and water. The average diameter of the polymer alloy particles is 50 to 400 nm. The polymer alloy particles are synthesized by absorbing a monomer (b) to the polymer (A) and polymerizing the monomer (b) to synthesize the polymer (B). The monomer (b) is an unsaturated carboxylic acid ester, or a mixture of an unsaturated carboxylic acid ester and one or more of the following monomers: an α,β-unsaturated nitrile compound, an unsaturated carboxylic acid, a conjugated diene compound, styrene, α-methylstyrene, p-methylstyrene, vinyltoluene, chlorostyrene, divinylbenzene, a carboxylic vinyl ester, and an acid anhydride of an ethylenically unsaturated dicarboxylic acid.

Owner:ENEOS MATERIALS CORP

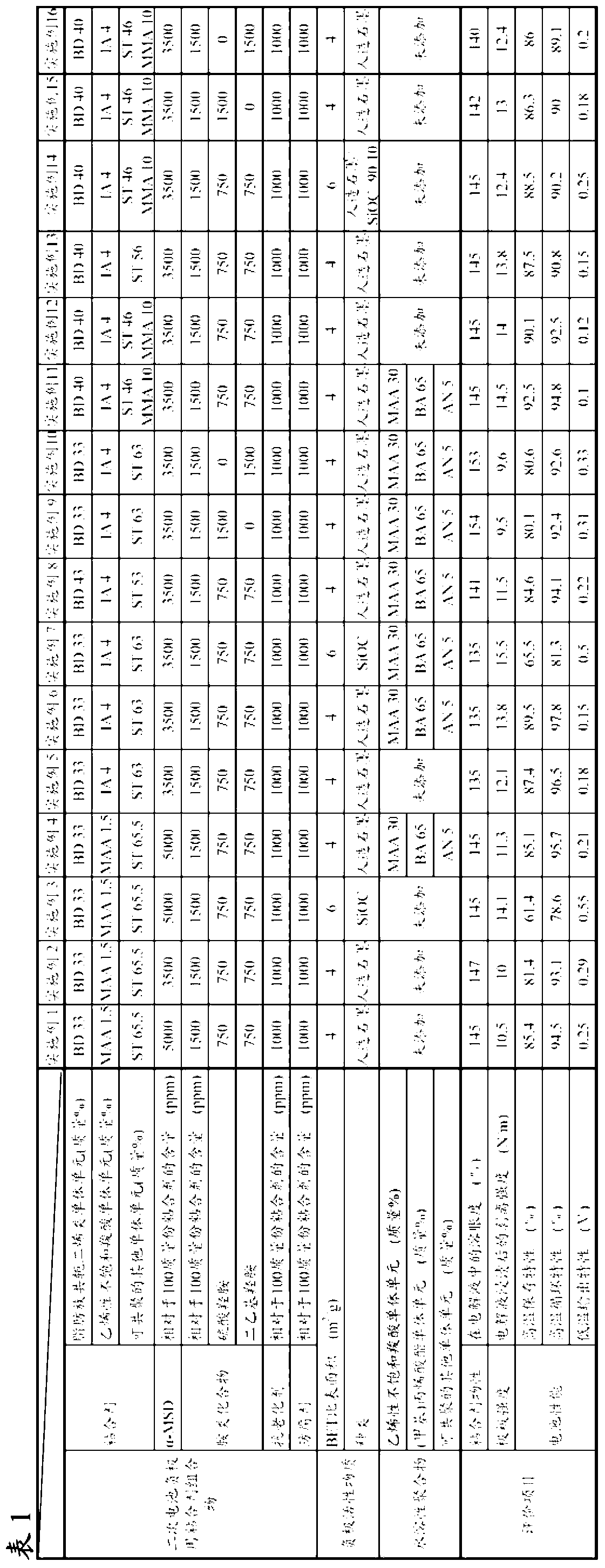

Thermoplastic polymer composition

ActiveUS20100152386A1Good flexibility propertyGood lightweight propertyPolymer scienceHeat resistance

A thermoplastic polymer composition has good flexibility, lightweight properties, moldability, and heat resistance, and in particular, is excellent in wear resistance. The thermoplastic polymer composition includes: at least one block copolymer (a) selected from among an α-methylstyrene based block copolymer having a number average molecular weight of 30,000 to 500,000 and a hydrogenated product thereof, the α-methylstyrene based block copolymer including a polymer block A mainly composed of an α-methylstyrene unit and a polymer block B mainly composed of a conjugated diene unit; a propylene-based polymer (b); and an ethylene-based polymer (c) having a density of 0.94 g / cm3 or less, in a ratio satisfying the following inequalities (1) and (2):0.1≦W(a) / [W(a)+W(b)+W(c)]≦0.8 (1)1≦W(b) / W(c) (2)wherein W(a), W(b), and W(c) represent the masses of the block copolymer (a), the propylene-based polymer (b), and the ethylene-based polymer (c), respectively.

Owner:KURARAY CO LTD

Alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer and preparation method thereof

The invention discloses an alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer and a preparation method thereof, and belongs to the field of macromolecular polymerization.The preparation method comprises the steps that firstly, a monomer alpha-vinyltoluene, styrene and an initiator are added to a solvent to be dissolved, and the solution is heated to 80 DEG C to 110 DEG C; then, a semicontinuous sample introduction method is adopted for dropwise adding a solution containing maleic anhydride to a reaction system for 1 h to 3 h, and the reaction continues to be carried out for 30 min to 60 min after the solution is dropwise added; after the reaction is finished, the system is subjected to methyl alcohol precipitation, suction filtration and drying, and the alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer is obtained.The prepared alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer has the advantages that the content of maleic anhydride is high, and the glass transition temperature is low (low Tg facilitates machine shaping); meanwhile, an alpha-vinyltoluene structural unit is contained in the polymer chain of the ternary random copolymer, depolymerization occurs at high temperature to generate free radicals, and the alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer can be used as a macroinitiator to be applied to polyolefin grafting and polyolefin melt blending modification.

Owner:BEIJING UNIV OF CHEM TECH

Binder composition for secondary battery negative electrode, slurry composition for secondary battery negative electrode, secondary battery negative electrode, secondary battery, and method for producing binder composition for secondary battery negat

ActiveCN103181008AImprove high temperature storage characteristicsImprove featuresNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh temperature storageSlurry

To provide a binder composition for a secondary battery, capable of improving the high temperature storage characteristics, high temperature cycle characteristics, and low temperature output characteristics of the secondary battery because the degree of swelling for the electrolyte of the secondary battery is small and the peel strength is large after immersion of the negative electrode in the electrolyte solution, and also to provide a slurry composition for a secondary battery negative electrode that uses this binder composition, a secondary battery negative electrode, and a secondary battery. [Solution] The binder composition for a secondary battery negative electrode according to the present invention is characterized by containing: a binder comprising 25 - 55% by mass of an aliphatic conjugated diene monomer unit, 1 - 10% by mass of an ethylenically unsaturated carboxylic acid monomer unit, and 35 - 74% by mass of another monomer unit copolymerizeable with these; and more than 3000 ppm and less than 7000 ppm of an alpha-methyl styrene dimer and 100 - 5000 ppm of an amine compound to 100 parts by weight of the binder.

Owner:ZEON CORP

Inkjet pigment ink

ActiveUS20140066550A1Improve featuresImprove hydrophobicityDuplicating/marking methodsInksMeth-Glycol ethers

Provided is an inkjet pigment ink which contains a pigment that is selected from the group consisting of C.L. Pigment Yellow 74 having a transmittance of 70% or more, C.I. Pigment Red 269 having a transmittance of 70% or more, C.I. Pigment Red 122 having a transmittance of less than 70% and C.I. Pigment Yellow 150; a water-soluble solvent that is selected from the group consisting of glycol ethers and diols; water; and a pigment dispersing resin that is a copolymer which contains a monomer A, a monomer B and a monomer C as unit components. The monomer A is an alkyl (meth)acrylate ester; the monomer B is styrene, α-methyl styrene or benzyl (meth)acrylate; and the monomer C is (meth)acrylic acid.

Owner:TOYO INK SC HOLD CO LTD +1

Abrasive material

InactiveUS7001252B2Good polishing performanceReduce generationOther chemical processesAbrasion apparatusEmulsionItaconic acid

An object of the present invention is to provide a polishing body, wherein the abrasive in the polishing body are extremely dispersed well, which provides stable polishing performance in the polishing process, and which can effectively reduce the occurrence of scratches even in a case a large quantity of the abrasive are contained. A polishing part constituting the polishing body in the invention is produced obtained by loading predetermined amounts of butadiene, styrene, methyl methacrylate, itaconic acid, acrylic acid, α-methylstyrenedimer, and t-dodecylmercaptan in an autoclave, making the mixture react for 16 hours at 75° C. to obtain an emulsion wherein a copolymer is dispersed, adjusting this emulsion to pH8.5, incorporating cerium oxide powder with an average primary particle diameter of 0.3 μm and stirring to obtain an aqueous dispersion, drying this aqueous dispersion by spreading it thinly across a film, and mold pressing the dried product obtained. The above-mentioned polishing part may have a crosslinked structure. The polishing body in the invention can be used favorably in a polishing pad and the like, for polishing the surface of a semiconductor wafer or the like.

Owner:JSR CORPORATIOON

Method for the production of alpha-alane

A method of forming α-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous diethyl ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a first crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The first crystallization additive is selected from the group consisting of polystyrene, polybutadiene, polystyrene-co-polybutadiene, polyisoprene, poly-alpha-methylstyrene, polystyrene-co-polyindene, poly-alpha-pinene, and mixtures thereof. Optionally, a second crystallization additive is added to the crystallization solution. The second crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbornylene, norbornadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof. Solvents are removed from the crystallization solution to crystallize the α-alane.

Owner:NORTHROP GRUMMAN SYST CORP

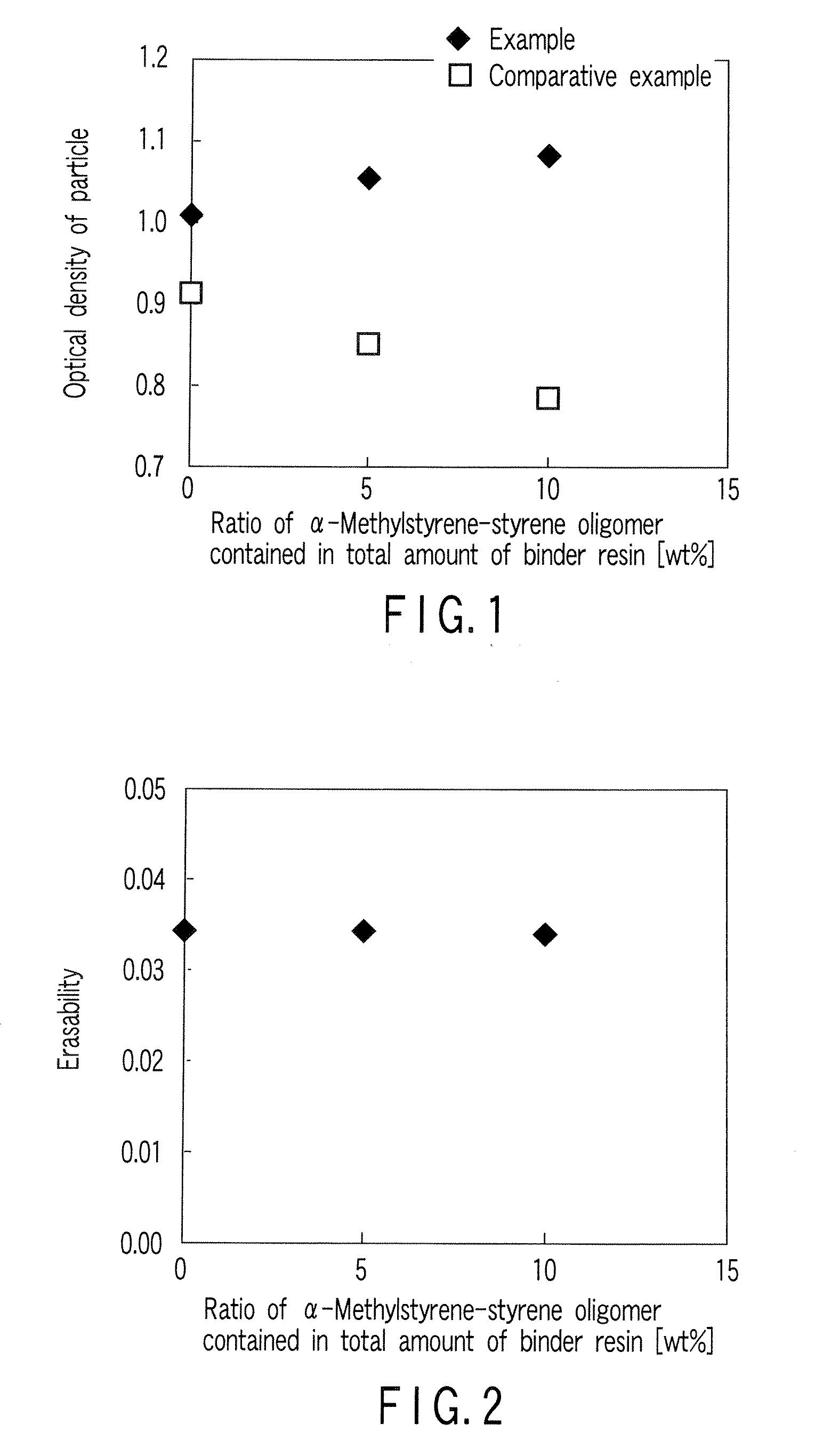

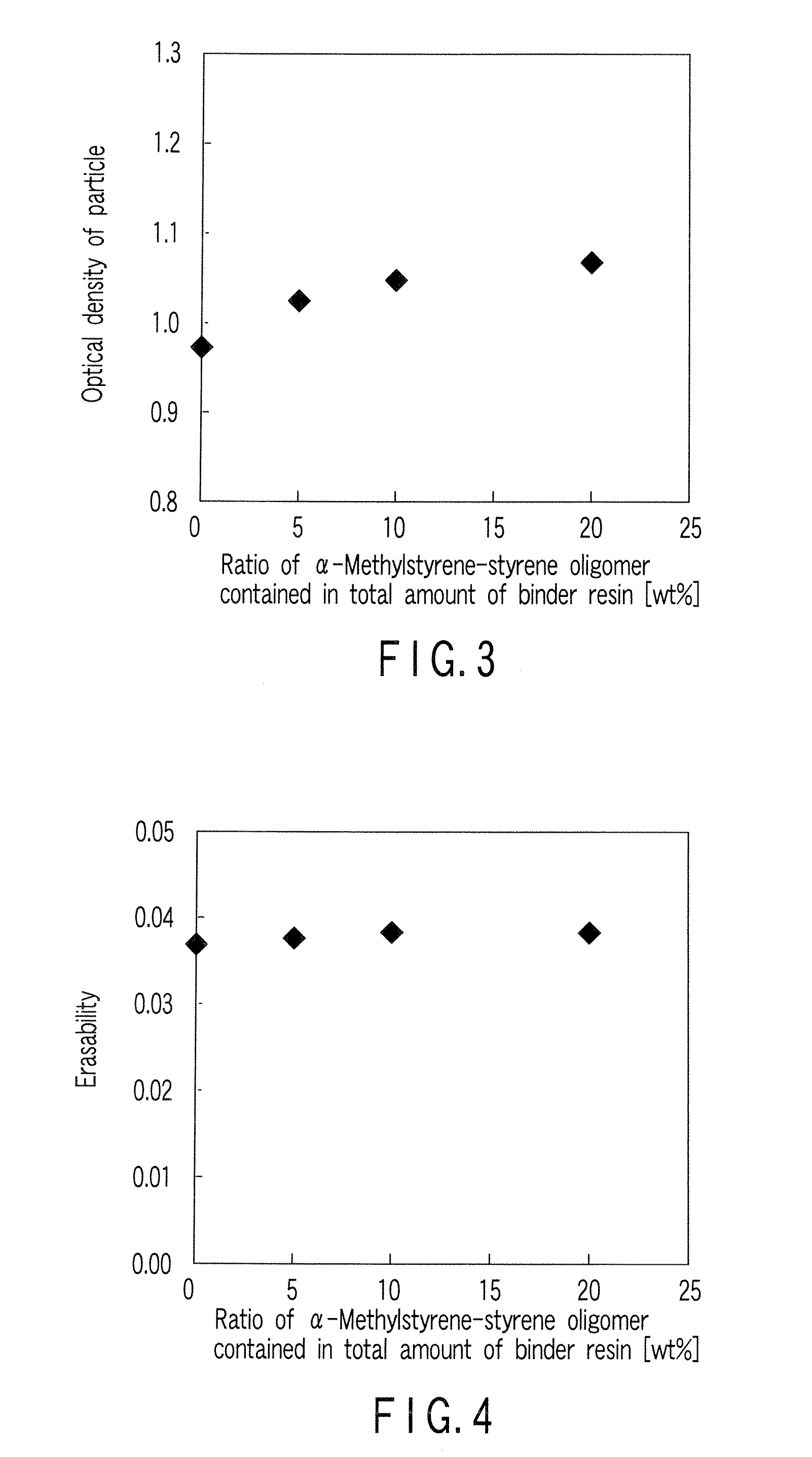

Erasable image forming material

An erasable image forming material includes a color former containing crystal violet lactone, a developer, a first binder resin of styrene-butadiene copolymer and a second binder resin of a styrene-based resin containing a-methylstyrene, the first and second binder resins being in a compatible state.

Owner:KK TOSHIBA

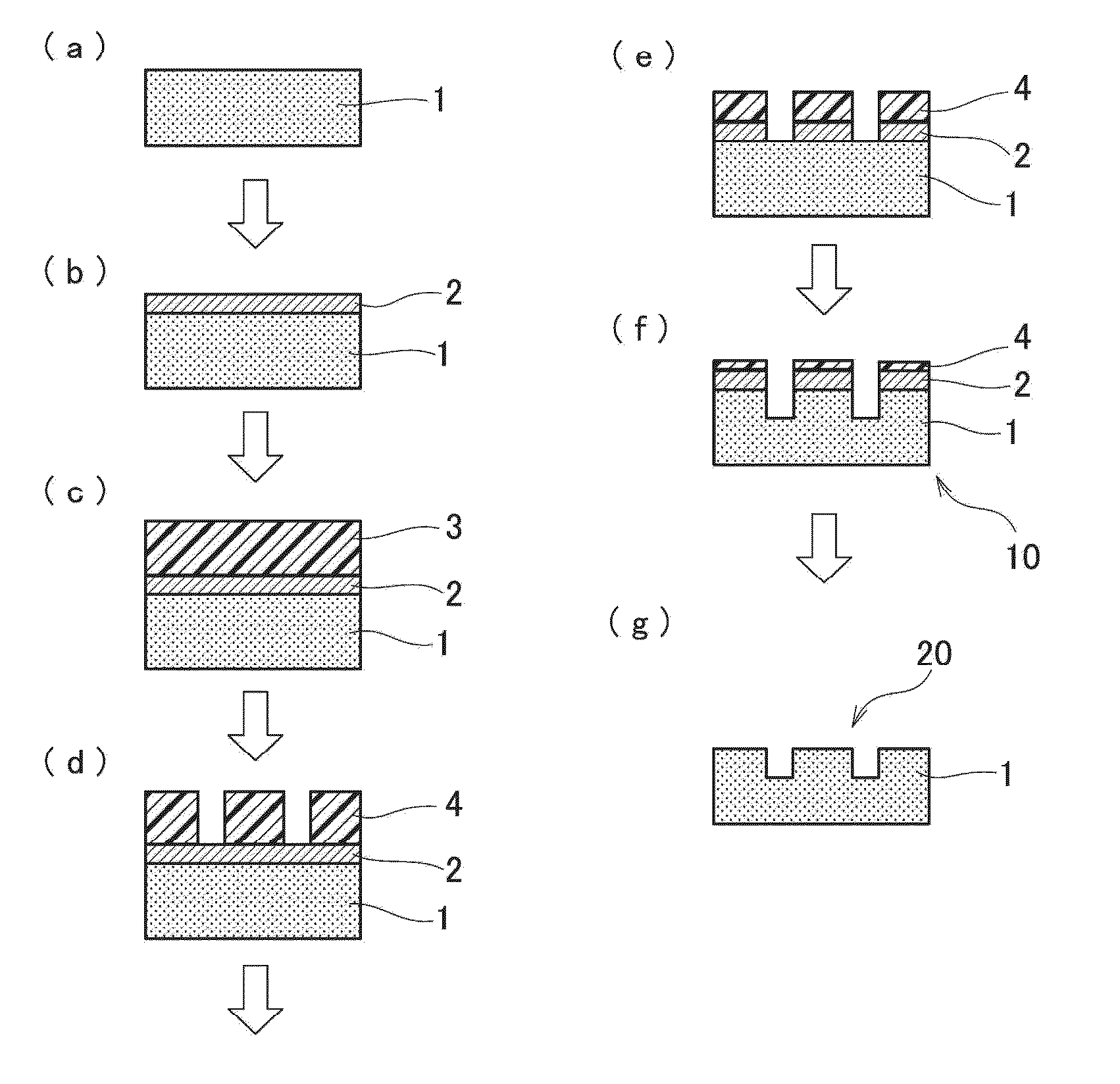

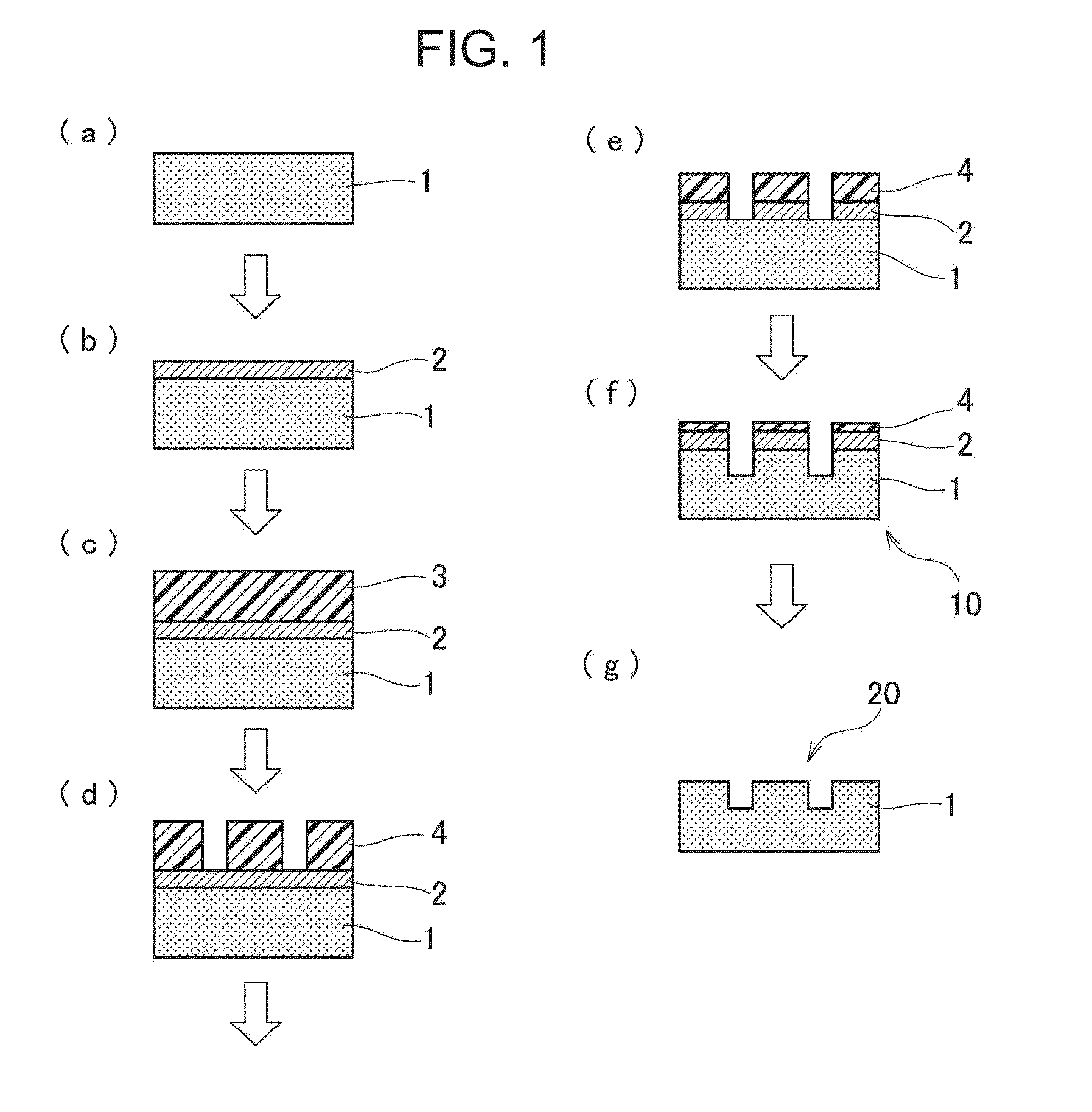

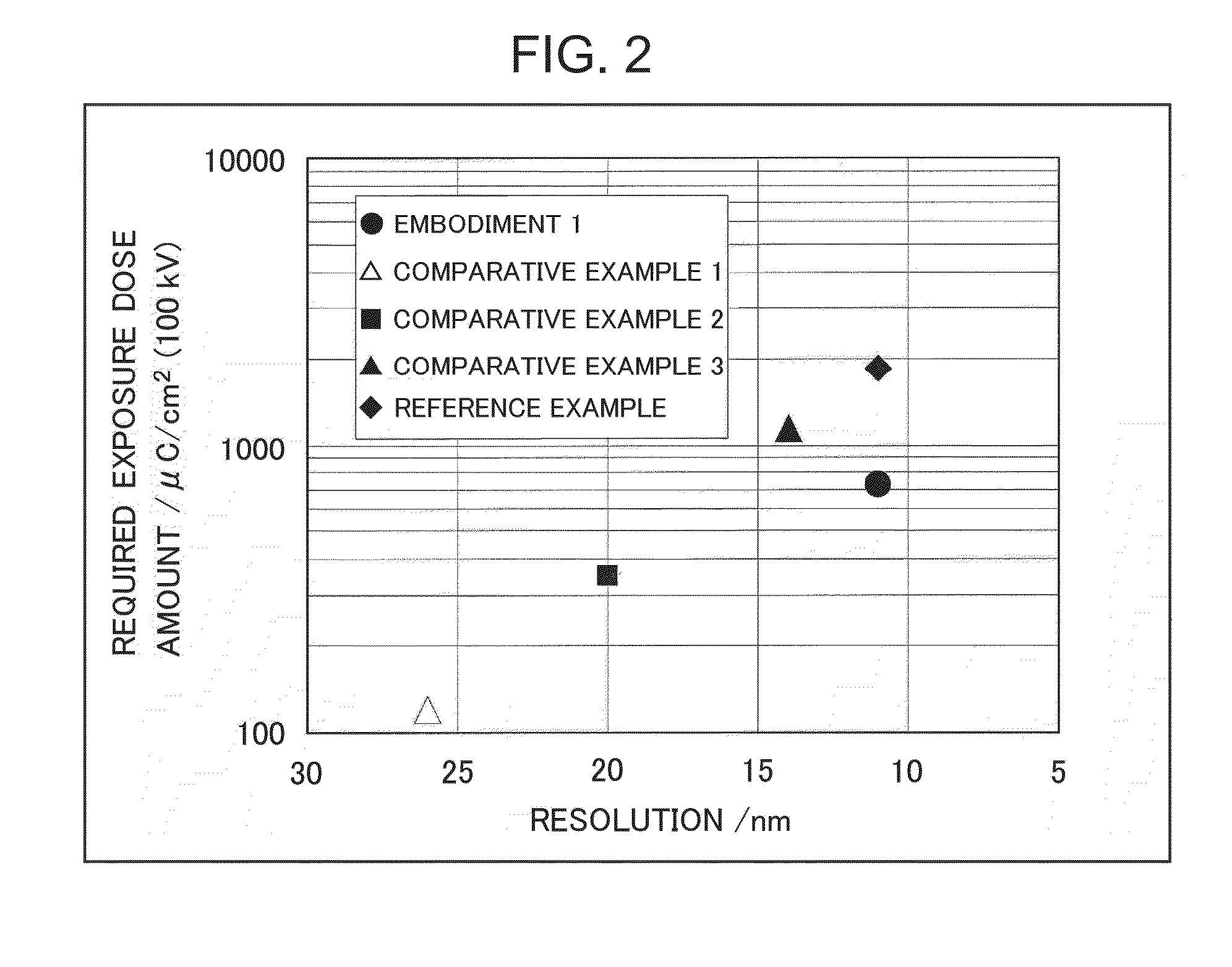

Resist developer, method for forming a resist pattern and method for manufacturing a mold

The disclosed resist developer is used when developing by irradiating an energy beam onto a resist layer containing a polymer of α-chloromethacrylate and α-methylstyrene for rendering or exposure, and contains a fluorocarbon-containing solvent (A) and an alcohol solvent (B), the latter of which has higher solubility relative to the resist layer than the former.

Owner:HOYA CORP

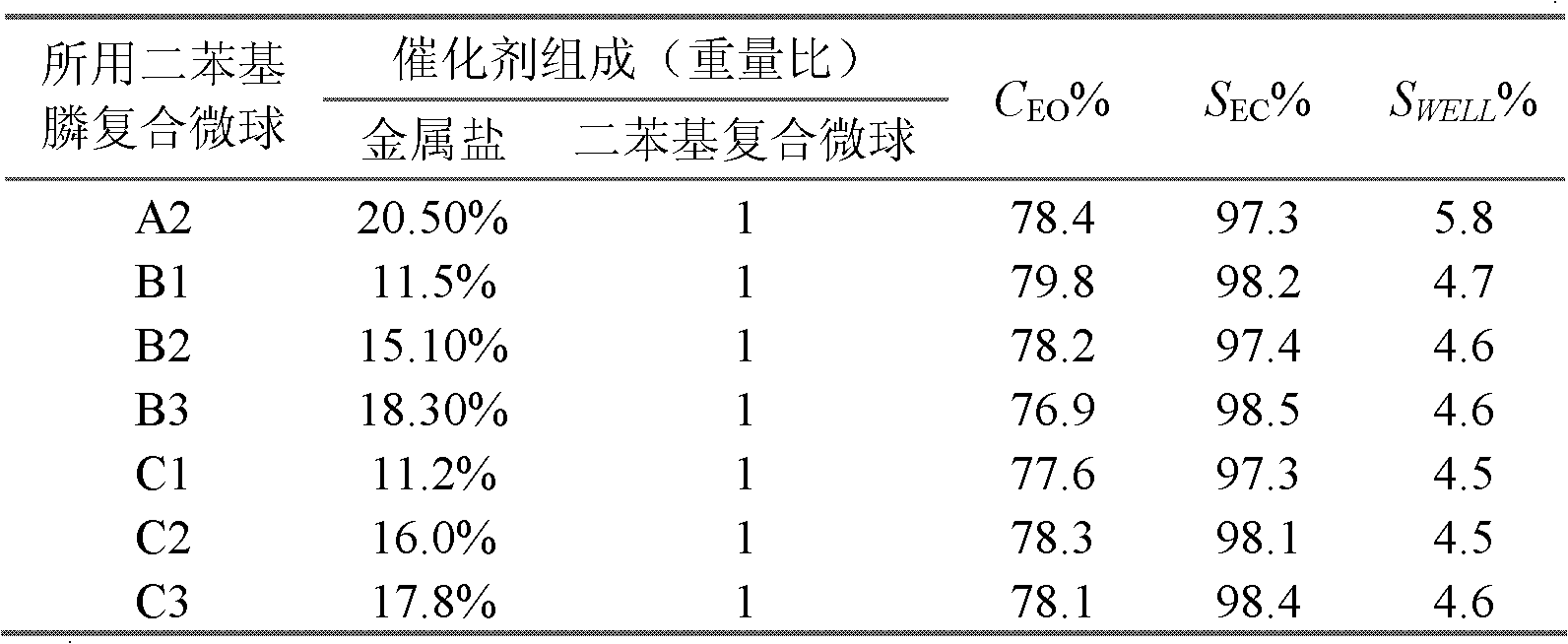

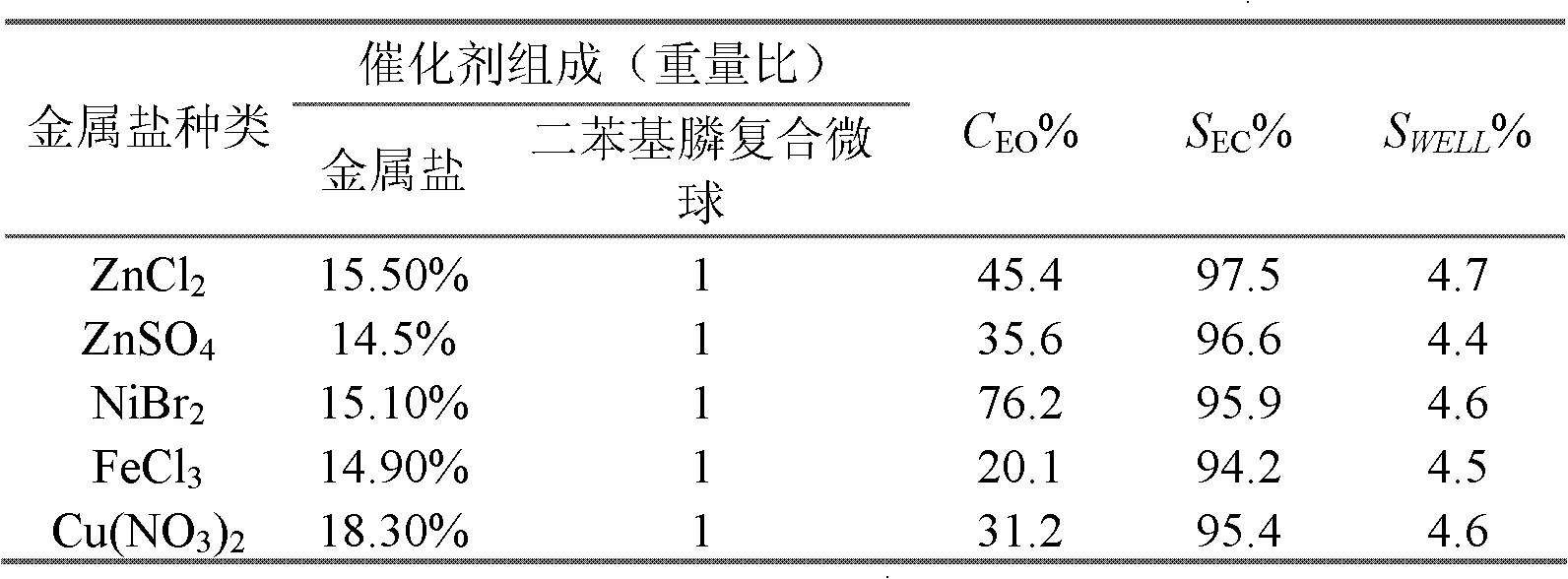

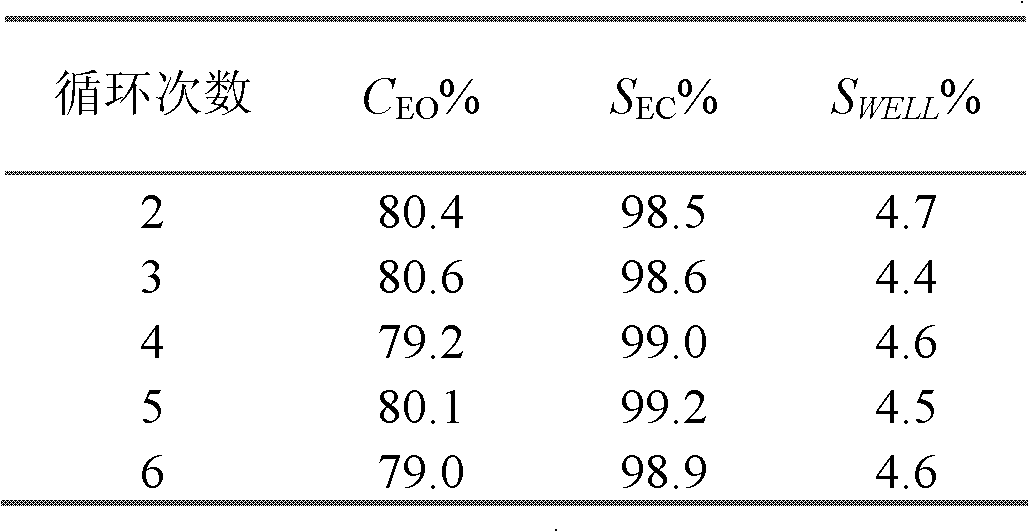

Macroporous resin catalyst for preparing alkyl carbonate

ActiveCN103028440ANot easy to inactivateHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsLithium metalMicrosphere

The invention relates to a macroporous resin catalyst for preparing alkyl carbonate, which mainly solves the problem of the prior art that the activity of the catalyst is low and is quickly reduced. Aiming at well solving the problem, the macroporous resin catalyst adopts the technical scheme that the macroporous resin catalyst is prepared by the following components in percentage by weight: (a) 10% to 20% of metal salts, and (b) 80% to 90% of diphenylphophine substituted composite microspheres. A method for preparing the diphenylphophine substituted composite microspheres comprises the following steps of (1) preparing an additive 1 into a water solution A; (2) preparing a monomer, a comonomer, a nano material, an initiator and an additive 2 into a solution B, wherein at least one of methyl methacrylate, butyl acrylate, styrene, alpha-methylstyrene, 4-butylstyrene or acrylonitrile is adopted as the monomer; (3) mixing the solution B and the solution A to obtain the microspheres; (4) adding a chloromethylation agent or zinc chloride into the microspheres to obtain composite chloride spheres; and (5) adding chlorinated diphenylphosphine and lithium metal into the composite chloride spheres to react, so as to obtain the diphenylphophine substituted composite microspheres. The macroporous resin catalyst can be used for the industrial production of the alkyl carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inkjet pigment ink

Provided is an inkjet pigment ink which contains a pigment that is selected from the group consisting of C.L. Pigment Yellow 74 having a transmittance of 70% or more, C.I. Pigment Red 269 having a transmittance of 70% or more, C.I. Pigment Red 122 having a transmittance of less than 70% and C.I. Pigment Yellow 150; a water-soluble solvent that is selected from the group consisting of glycol ethers and diols; water; and a pigment dispersing resin that is a copolymer which contains a monomer A, a monomer B and a monomer C as unit components. The monomer A is an alkyl (meth)acrylate ester; the monomer B is styrene, ±-methyl styrene or benzyl (meth)acrylate; and the monomer C is (meth)acrylic acid.

Owner:TOYO INK SC HLDG CO LTD +1

Method for preparing epoxybutane

The invention relates to a method for preparing epoxybutane so as to mainly solve problems of low selectivity of epoxybutane and short service life of a catalyst in the prior art The method provided by the invention comprises the following steps: a) an oxidation reaction between isopropyl benzene and molecular oxygen is carried out to obtain a cumyl hydroperoxide oxidation liquid; b) content of organic acid in the cumyl hydroperoxide oxidation liquid is controlled to be not more than 0.3 wt%, content of alkali metal or alkaline earth metal ions is controlled to be not more than 0.1 wt%, and content of water is controlled to be not more than 0.5 wt%; c) the cumyl hydroperoxide oxidation liquid and butylene react under the liquid-phase condition in the presence of a catalyst so as to generate epoxybutane and alpha, alpha-dimethyl-benzyl carbinol; d) alpha, alpha-dimethyl-benzyl carbinol undergoes dehydration to generate alpha-methyl styrene; and e) alpha-methyl styrene undergoes hydrogenation to generate isopropyl benzene. By the technical scheme, the above problems are solved well. The method provided by the invention can be used in industrial production of preparing epoxybutane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functional modified ABS (acrylonitrile butadiene styrene) profiled base station antenna housing and production method thereof

The invention discloses a functional modified ABS (acrylonitrile butadiene styrene) profiled base station antenna housing and a production method thereof; the addition to easy access to materials and low price, the functional modified ABS profiled base station antenna housing has the functions such as environmental friendliness, excellent mechanical properties, high heat resistance, excellent dielectric property, and stable resistance to ultraviolet irradiation, especially excellent solar reflectivity. The functional modified ABS profiled base station antenna housing is produced from, by weight, 75-80 parts of ABS resin, 5-10 parts of AS resin, 5-10 parts of high-mobility AS (acrylonitrile-styrene) resin, 5-10 parts of AlphaMSAN (Alpha-methylstyrene-acrylonitrile) heat-resistant modified resin, 1-2 parts of lubricant EBS, 2.0-3.0 parts of photostabilizer UV326, 0.3-0.5 part of antioxidant GM, and 5-10 parts of a surface-modified inorganic nonmetal compound.

Owner:NANJING UNIV OF TECH +1

Method for preparing multifunctional acrylic matting resin

InactiveCN101735543AImprove inherent advantagesGood compatibilityPowdery paintsBenzoyl peroxideFunctional monomer

The invention relates to a method for preparing a multifunctional acrylic matting resin. The method comprises the following steps: using xylol as a solvent, using three functional monomers, namely glycidyl methacrylate and butyl acrylate, styrene and methyl methacrylate, to synthesize low-molecular-weight matting resin homopolymer under the action of azodiisobutyronitrile and benzoyl peroxide initiator and regulation of an alpha-vinyltoluene formed dimer molecular chain, and mixing the low-molecular-weight matting resin homopolymer and hydroxyalkylamide or triglycidyl isocyanurate to finally obtain the multifunctional matting resin. The method has the advantages that: the inherent advantages of the matting resin is improved through homopolymerization of the plurality of functional monomers and the glycidyl acrylate and optimized improvement on the homopolymerization process, and simultaneously improves the compatibility between the matting resin and powder base stock and reduces the using amount of a flatting agent; and the mechanical strength and the surface scuff resistance of the matting resin are improved through combined actions of mixing other curing agents.

Owner:宁波维楷化学有限公司

A kind of polypropylene composition and preparation method thereof

The invention provides a polypropylene composition, comprising the following components in part by weight: 100 parts of polypropylene resin, 0.1-1.5 parts of petroleum resin and / or resin obtained by polymerization of alpha-methyl styrene, indenyl alkene, and terpene and 0.01-1 part of beta nucleating agent. In the polypropylene composition, the blocking property for oxygen is good; in the preparation method, the process is simple, the condition is easy to control, and the applicability is strong; and the invention can be used for the packaging fields such as medicines, foods and other aspects with requirements for blocking and sanitation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

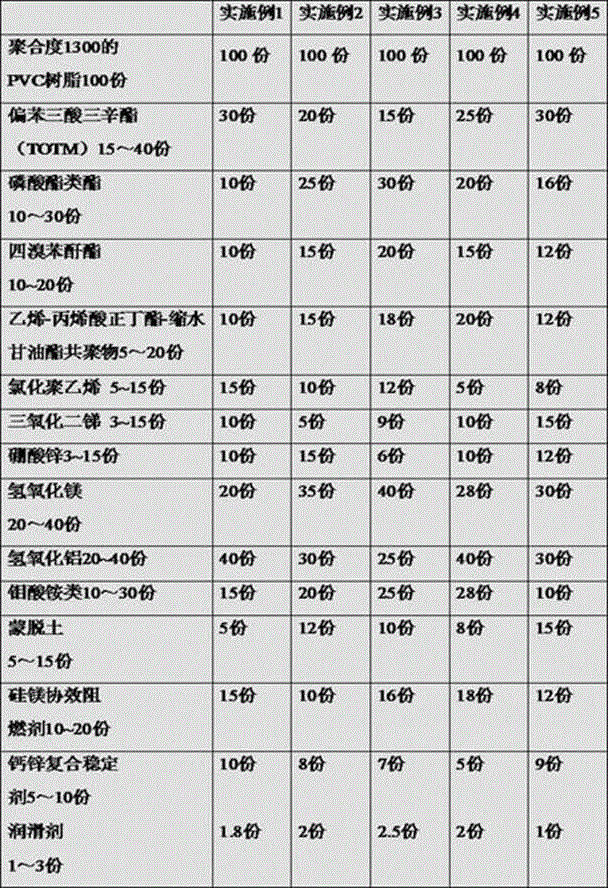

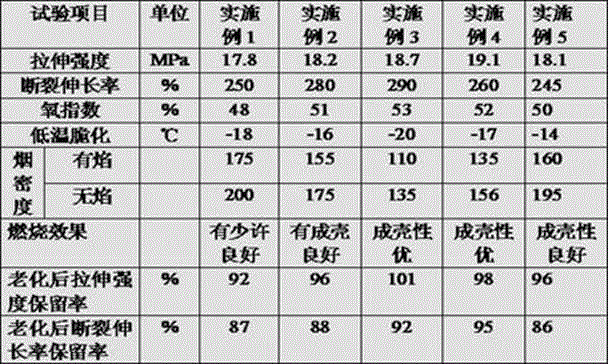

High-flame-retardation low-smoke composite cable material for boosting communication light cables, and preparation technology thereof

The invention relates to a high-flame-retardation low-smoke PVC composite material for boosting communication light cables, and a preparation technology thereof. The high-flame-retardation low-smoke PVC composite material for boosting communication light cables comprises, by weight, 100 parts of PVC resin with the polymerization degree of 1300, 15-40 parts of tricapryl trimellitate, 10-30 parts of phosphate ester, 10-20 parts of tetrabromophthalate, 10-30 parts of an ethylene-n-butyl acrylate-glycidyl ester copolymer, 5-15 parts of chlorinated polyethylene, 3-15 parts of diantimony trioxide, 3-15 parts of zinc stannate, 20-40 parts of magnesium hydroxide, 20-40 parts of aluminum hydroxide, 10-30 parts of ammonium molybdate, 5-15 parts of montmorillonite, 10-20 parts of a silicon-magnesium synergistic flame retardant, 5-10 parts of a calcium-zinc composite stabilizer, 1-3 parts of a lubricant, 0.2-1 part of an antioxidant, 2-4 parts of an acrylate polymer, and 1-3 parts of a linear polymer of alpha-methyl styrene. The high-flame-retardation low-smoke PVC composite material has the advantages of high flame retardation, good fire resistance, low smoke during combustion, unlikely propagation of flames, low heat release amount, and low release amount of toxic gases.

Owner:中广核三角洲(江苏)塑化有限公司

Preparation method of copolymer grafted carbon nano-tube super-hydrophobic material

The invention discloses a preparation method of a copolymer grafted carbon nano-tube super-hydrophobic surface. The method comprises the following steps: preparing a copolymer of alpha-vinyltoluene and butyl methacrylate by adopting a simple free radical polymerization method; grafting the copolymer to the surface of a multi-wall carbon nano-tube to obtain a alpha-vinyltoluene and butyl methacrylate copolymer grafted multi-wall carbon nano-tube; dispersing the alpha-vinyltoluene and butyl methacrylate copolymer grafted multi-wall carbon nano-tube into an organic solvent in an ultrasonic wave way to obtain a dispersing liquid; preparing resin paste by uisng resin, a promoting agent and an initiator; and coating the resin paste on the surface of a matrix of an inorganic or organic material, and coating the dispersing liquid to form a stable super-hydrophobic surface. The preparation method does not have special requirement on equipment, is low in cost, easy in implementation, and simple in process, has easily available raw materials, is environmental friendly, and can be used as a corrosion-resistance material, a pollution-prevention material, a self-cleaning material and the like.

Owner:QILU UNIV OF TECH

Weatherable colored resinous composition and method

Disclosed are weatherable compositions comprising (i) 25-45 wt. % of an acrylonitrile-styrene-acrylate graft copolymer (ASA) or acrylate-modified ASA, (ii) 75-55 wt. % of at least one rigid thermoplastic polymer comprising structural units derived from styrene and acrylonitrile; alpha-methylstyrene and acrylonitrile; alpha-methylstyrene, styrene, and acrylonitrile; styrene, acrylonitrile, and methyl methacrylate; alpha-methyl styrene, acrylonitrile, and methyl methacrylate; or alpha-methylstyrene, styrene, acrylonitrile, and methyl methacrylate, or mixtures thereof, (iii) at least one iron oxide-coated mica, and (iv) at least one organic or inorganic colorant. A process for making the compositions is also disclosed. Articles made from said compositions are also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com