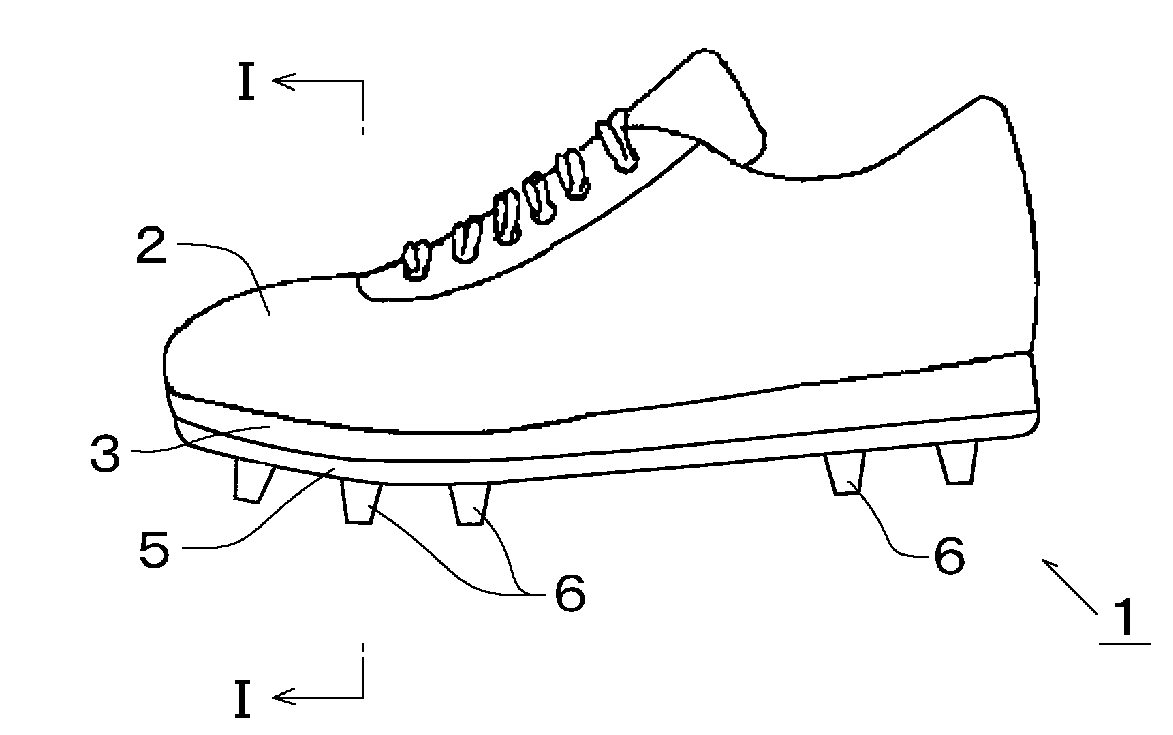

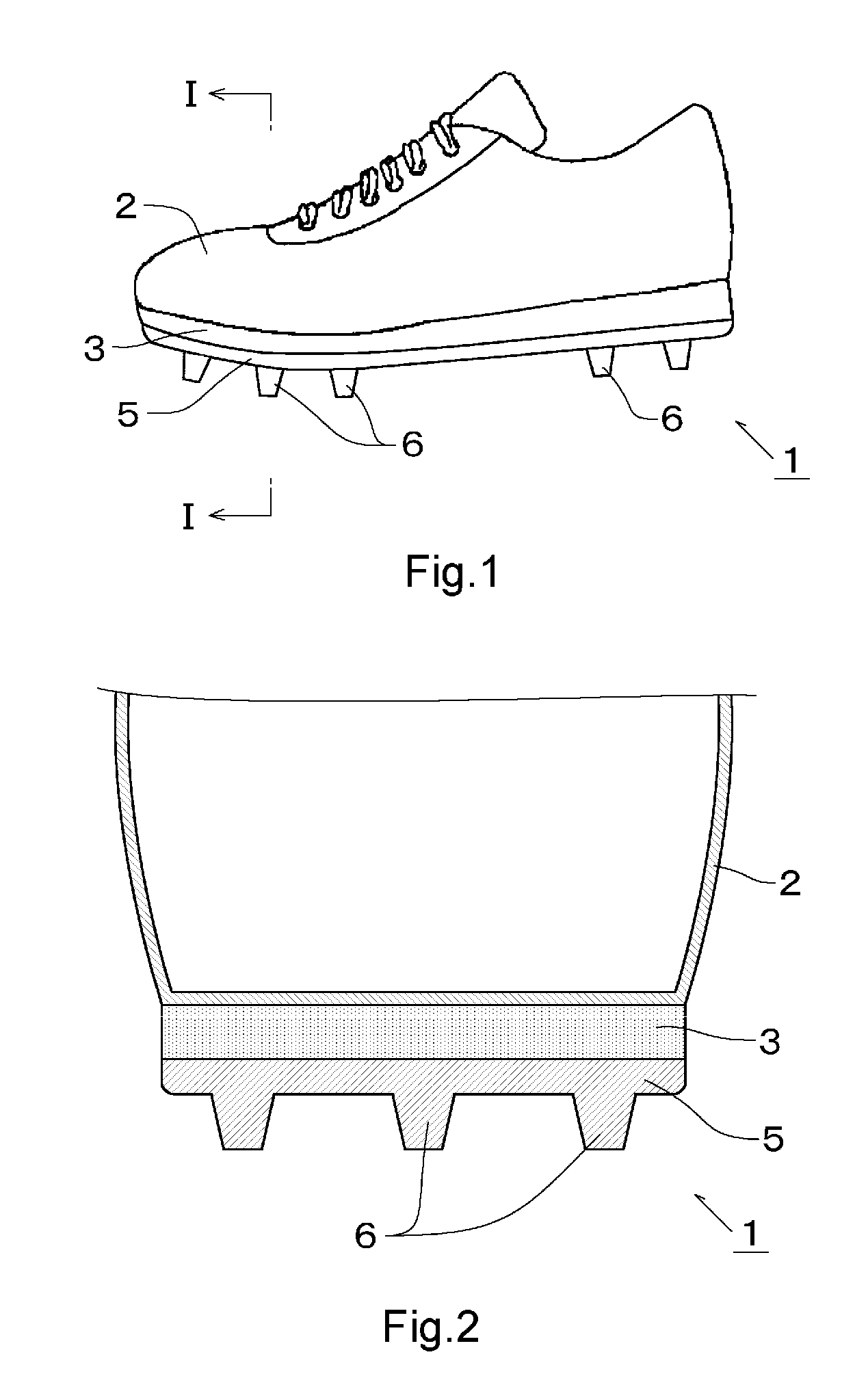

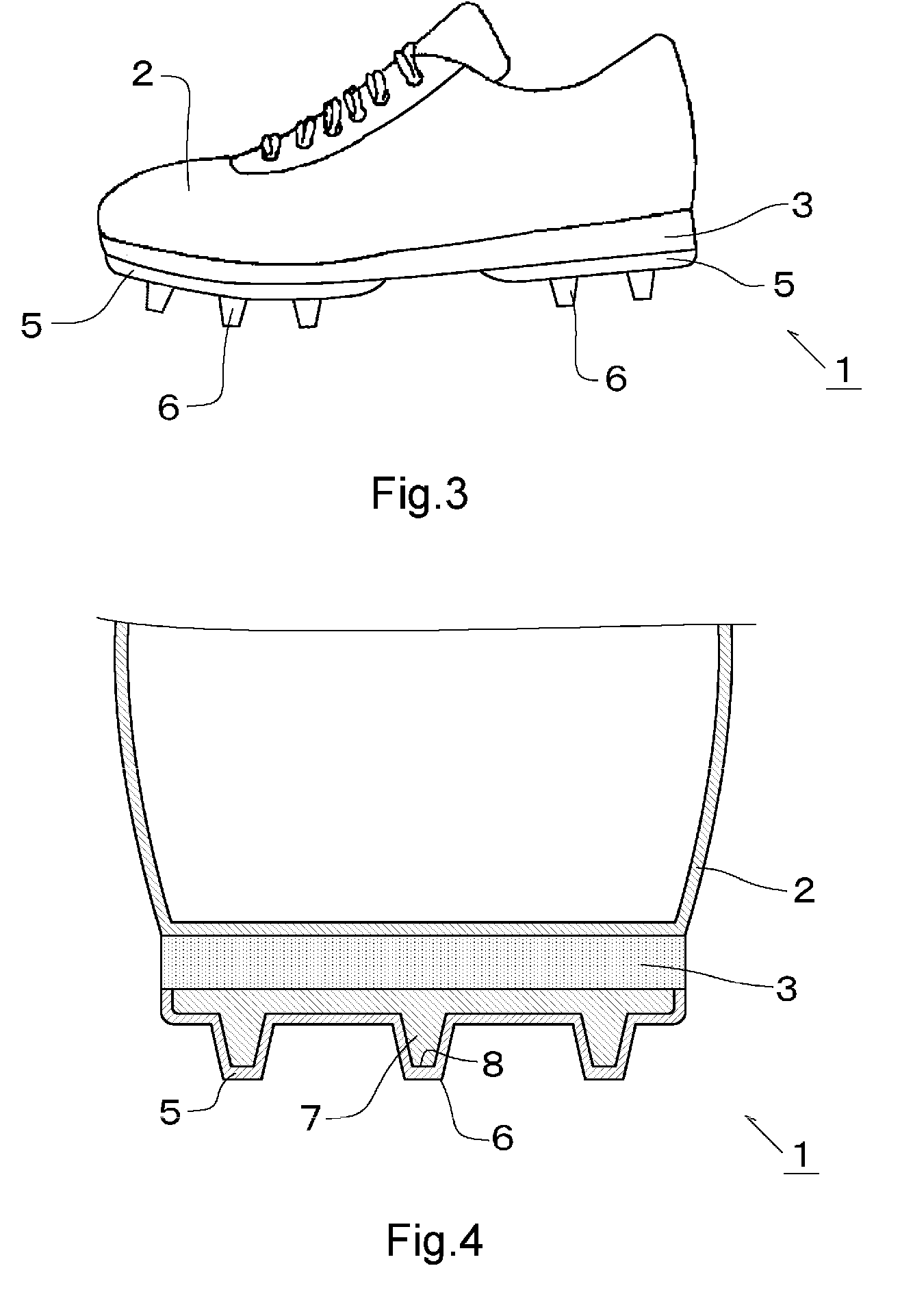

Outer sole and shoes

a technology of outer soles and shoes, applied in the field of outer soles of shoes and shoes, can solve the problems of inferior abrasion resistance of the outer sole of patent document 1, insufficient abrasion resistance of the grounding layer, and inferior abrasion resistance of the outer sole of the patent document 1, and achieve excellent abrasion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0094]PE, PP, and aSBS were blended at the ratio shown in Table 1, sufficiently mixed by a mixer and thereafter kneaded by a twin-screw extruder (180 to 230° C.) to prepare a polymer composition. The specific gravity of the polymer composition (20° C.±3° C.) is as shown in Table 1. In Table 1, the blending ratio of each material is denoted as part by mass.

[0095]The above-mentioned polymer composition was injected into a metallic mold by using an injection molding machine (maker: manufactured by Nissei Resin Industry Co., product name: FE160S type hydraulic injection molding machine, clamping force: 160 ton, screw diameter: 45 mm, injection speed: 21 cm3 / s, injection pressure: 60 MPa: injection temperature (nozzle portion): 230° C.) to produce a sample for physical tests and a sample for abrasion tests.

[0096]The above-mentioned sample for physical tests was used for the measurement of specific gravity, the measurement of dynamic viscoelasticity, and the measurement of tensile strengt...

examples 2 to 5

[0098]A sample for physical tests and a sample for abrasion tests were produced in the same manner as the above-mentioned Example 1 except for blending PE, PP, and aSBS at the ratio shown in Table 1. The specific gravity of each polymer composition (20° C.±3° C.) of Examples 2 to 5 is as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific gravity | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com