Patents

Literature

884 results about "Propylene Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasticized polyolefin compositions

InactiveUS20060135699A1Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

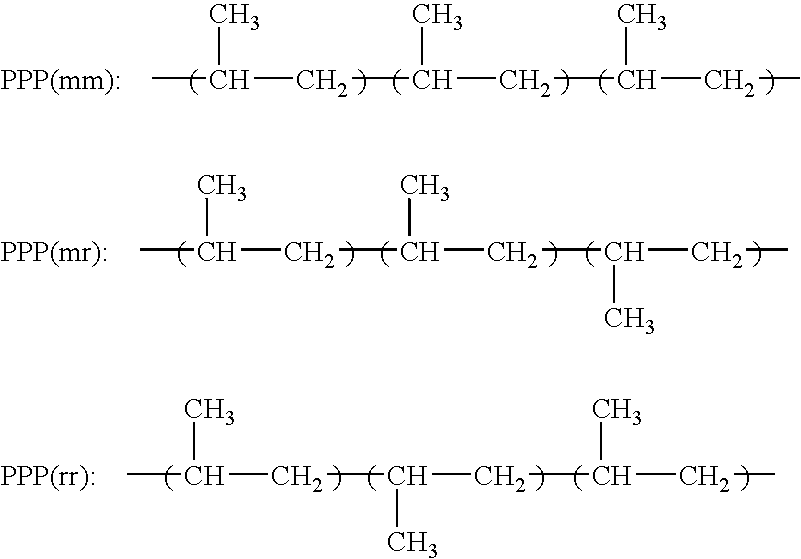

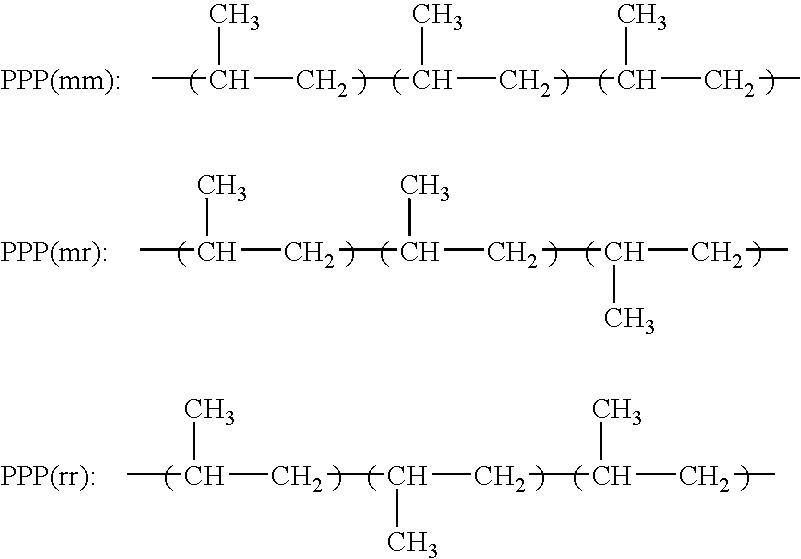

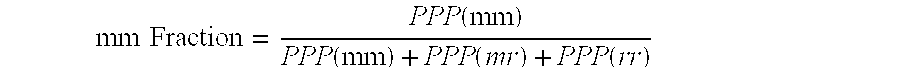

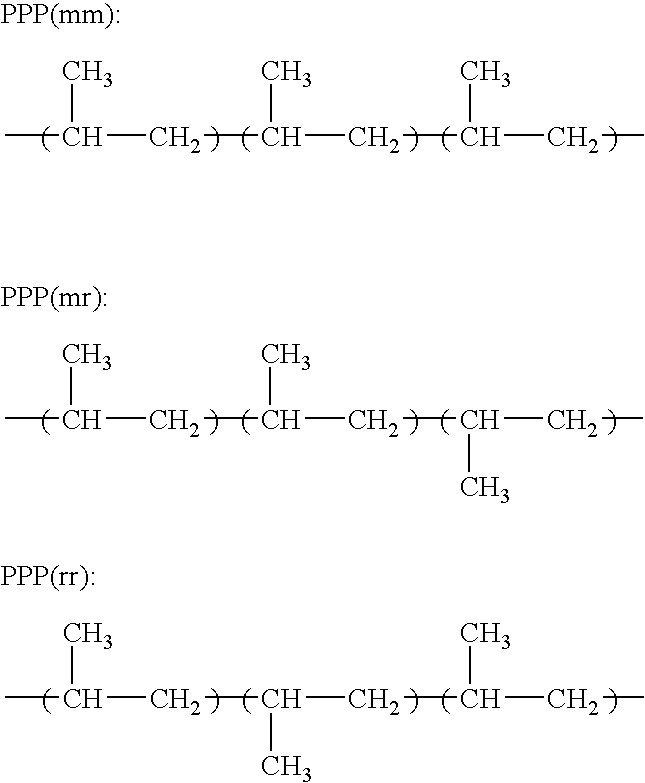

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

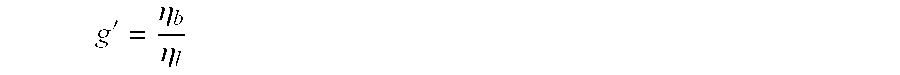

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

Propylene block copolymer

InactiveUS20050009993A1Extensive and intensive investigationImprove heat resistancePolymer scienceHeat resistance

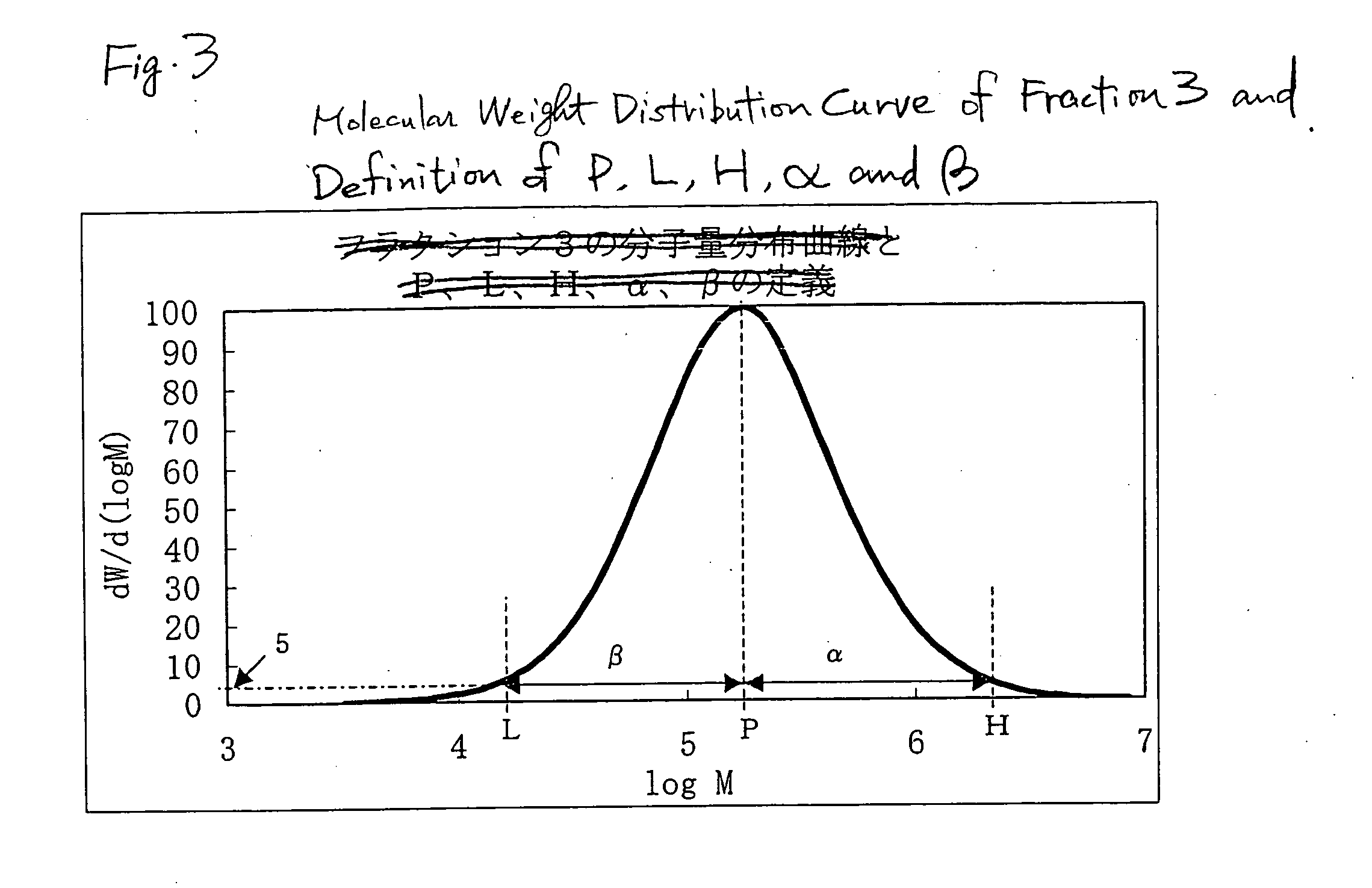

To provide a propylene based block copolymer that, when used as a molding material, exhibits an extremely good stiffness-impact resistance balance and has good heat. resistance and excellent moldability, and therefore, in molding, good appearance is revealed. That is, the invention provides a propylene based block copolymer obtained through a preceding stage step of producing a propylene polymer component (PP) and a subsequent stage step of producing a propylene-ethylene copolymer component (EP) using a metallocene catalyst, wherein the block copolymer satisfies specific requisites.

Owner:JAPAN POLYPROPYLENE CORP

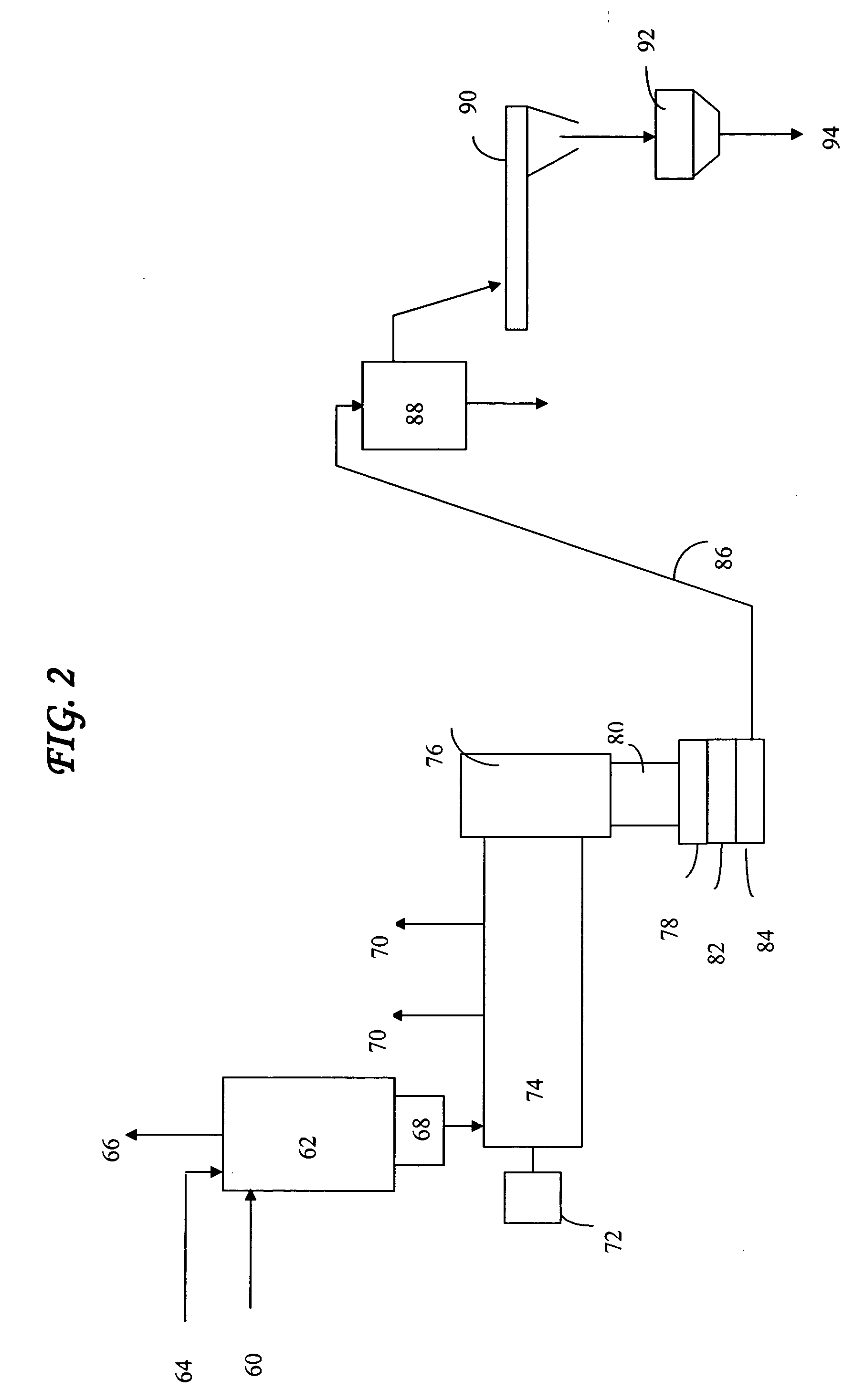

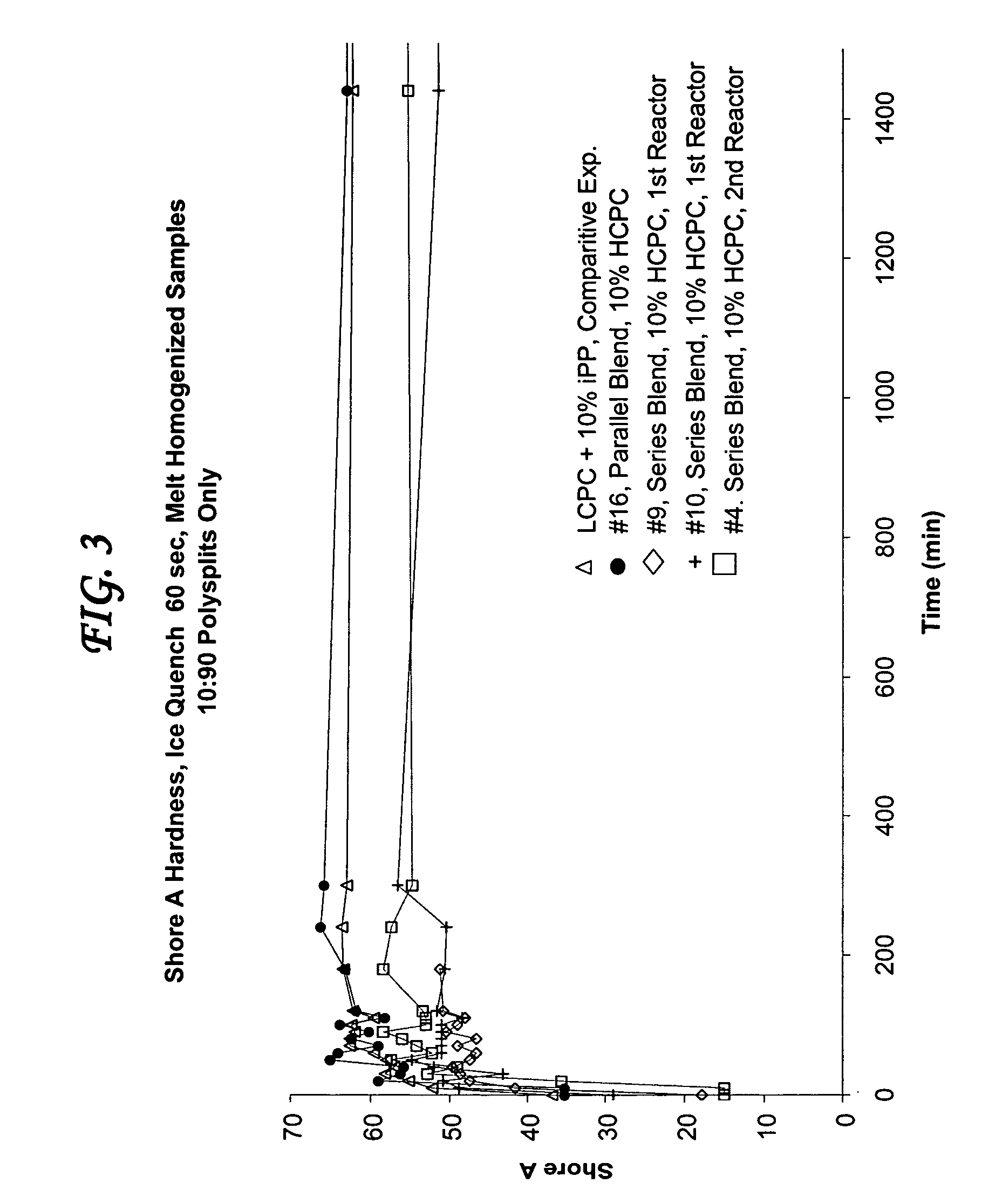

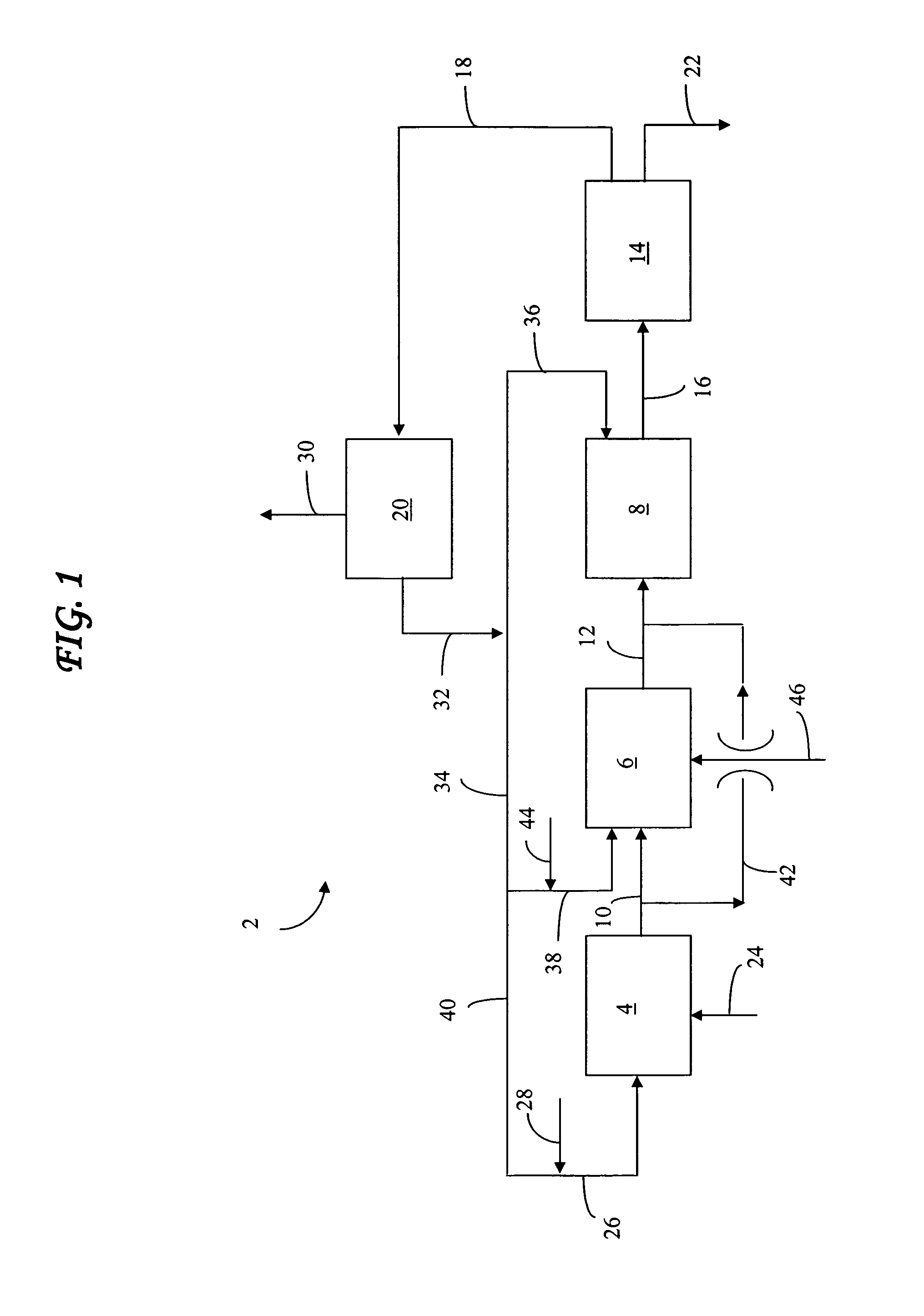

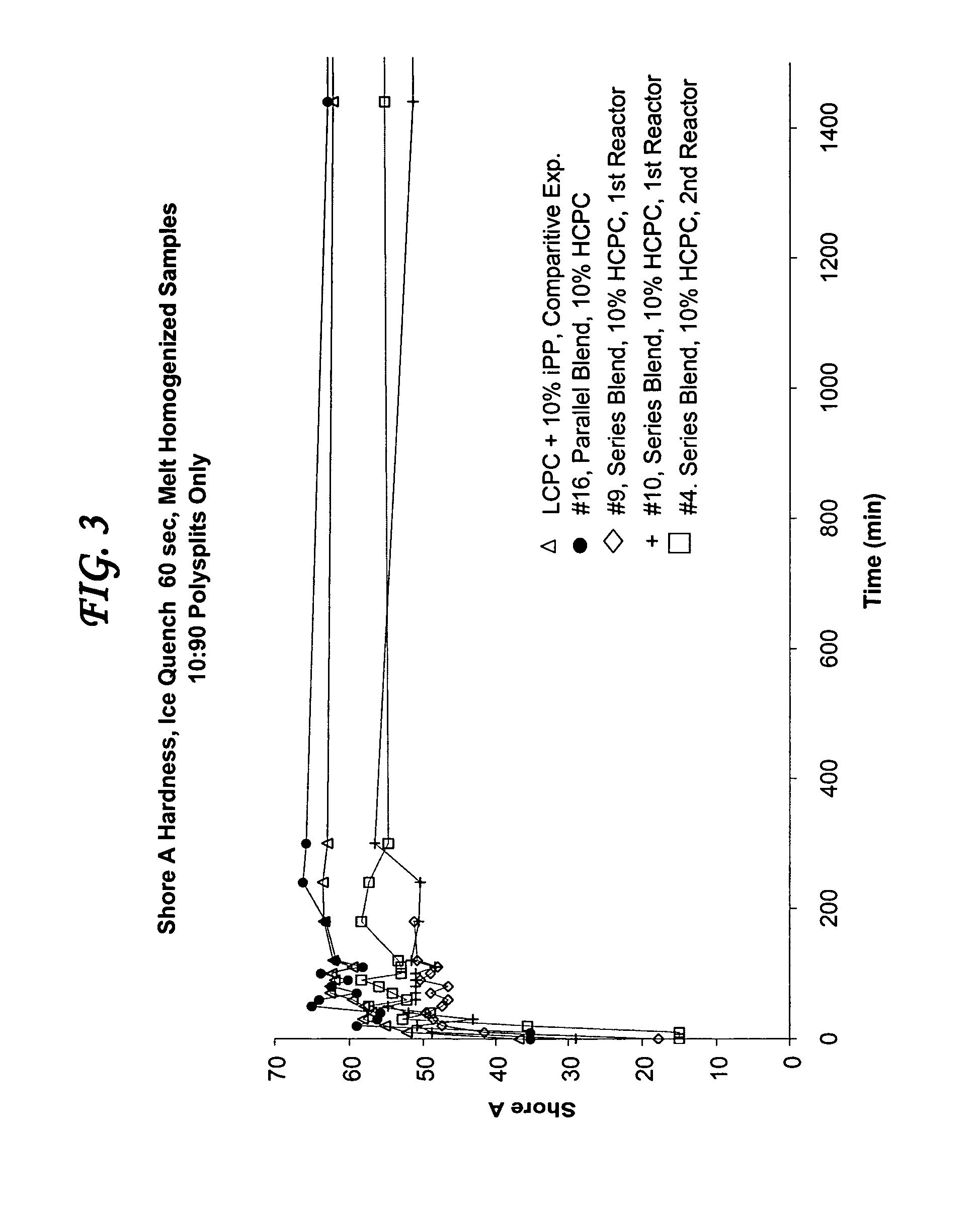

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

Plasticized polyolefin compositions

InactiveUS20080227919A9Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

Functionalized propylene copolymer adhesive composition

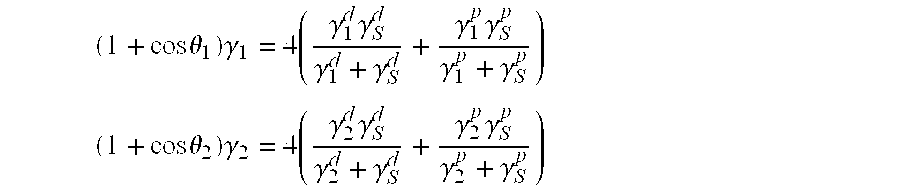

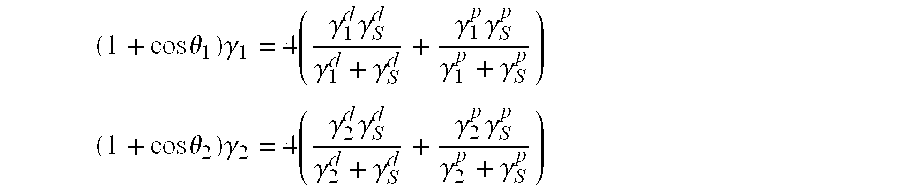

This invention relates to an adhesive composition comprising a functionalized random propylene polymer (FRPP) having at least 0.1 wt % of a functional group, a heat of fusion of between 0.5 and 70 J / g, and an mm triad tacticity index of at least 75%, where the adhesive has a T-Peel adhesion on a polar substrate at 20° C. of at least 175 N / m (1 lb / in) and a T-Peel adhesion on a non-polar substrate at 20° C. of at least 175 N / m (1 lb / in) where the polarity of the polar substrate is at least 0.10 units higher than the polarity of the non-polar substrate. Methods to produce the adhesive and articles comprising the adhesive are also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

Plasticized functionalized propylene copolymer adhesive composition

Disclosed herein is an adhesive composition comprising: a random propylene polymer component having a heat of fusion of between 1 and 70 J / g and an mm triad tacticity index of at least 75%; and a functionalized polymer component comprising a C2-C20 olefin comprising at least 0.1 wt % of a functional group; wherein the adhesive composition has a T-Peel adhesion on a polar substrate at 20° C. of at least 175 N / m (1 lb / in) and a T-Peel adhesion on a non-polar substrate at 20° C. of at least 175 N / m Pa (1 lb / in) and where the polarity of the polar substrate is at least 0.10 units higher than the polarity of the non-polar substrate. Methods to produce the adhesive and articles comprising the adhesive are also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Thermoplastic blend compositions

Described herein is a thermoplastic physical blend composition comprising (a) from 20 to 95 wt. % based on the total polymer content of a first polymer component that includes polypropylene having a melting point (Tm)≧110° C.; and (b) from 80 to 5 wt. % based on the total polymer content of a second polymer component that includes a reactor blend obtainable from a solution process, the reactor blend including: (i) from 2 to 98 wt. % based on the total weight of the SPC of a propylene polymer having 60 wt. % or more units derived from propylene, including isotactically arranged propylene derived sequences and Tm<105° C. or a Heat of Fusion<45 J / g, or both; and (ii) from 98 to 2 wt. % based on the total weight of the SPC of an ethylene α-olefin elastomer having either no crystallinity or crystallinity derived from ethylene, wherein (c) the FPC and the SPC are physically blended together to form the composition.

Owner:EXXONMOBIL CHEM PAT INC

Thermoplastic Polyolefin In-Reactor Blends And Molded Articles Therefrom

This invention relates to a molded article comprising an in-reactor polymer blend comprising: (a) a first propylene polymer comprising 90 to 100 wt % propylene and from 0 to less than 10 wt % comonomer, said first propylene component having a Tm of 135° C. or more; and (b) a second propylene polymer comprising from 30 to 90 wt % propylene and 70 to 10 wt % comonomer, said second propylene polymer having an Mw of 30,000 g / mol or more, and said second propylene-containing polymer having a crystallinity different by at least 5% from the first polymer, wherein the polymer blend has:(a) a Tm of at least 135° C.,(b) a melt flow rate of at least 70 dg / min,(c) a tensile strength of at least 8 MPa,(d) an elongation at break of at least 200%,(e) a tensile strength at break of 10 MPa or more, and(f) a GME 60280 scratch resistance of less than 1.2 DL at a scratching load of 5 Newtons.

Owner:EXXONMOBIL CHEM PAT INC

Biaxially stretched multilayer polypropylene film and use thereof

InactiveCN101160209ALow densityLow surface smoothnessSynthetic resin layered productsCoatingsPolymer scienceFilm base

Disclosed is a biaxially stretched multilayer polypropylene film wherein a front layer and back layer composed of a propylene polymer (a1) are respectively arranged on both sides of a biaxially stretched polypropylene film base layer (B) which is composed of a propylene polymer composition (A) obtained by adding an inorganic compound powder (a2) to the propylene polymer (a1). This biaxially stretched multilayer polypropylene film is characterized in that the front and back layers have a surface roughness (three-dimensional center plane average roughness SRa) of less than 0.08 [mu]m and a glossiness (incident angle: 60 degrees) of not less than 114%, and the multilayer polypropylene film has a total light transmittance of not more than 20% and a density of 0.40-0.65 g / cm<3>.

Owner:TOHCELLO CO LTD (JP)

Polyethylene rich/polypropylene blends and their uses

InactiveUS6939919B2Good blocking performanceHigh modulusFlexible coversWrappersPropylene PolymersEthylene Polymers

The present invention includes a blend composition comprising at least one coupled propylene polymer and at least 55 weight percent of at least one ethylene polymer, based on the total weight of the coupled propylene polymer and the ethylene polymer. The invention also includes methods for making the coupled propylene polymer and methods for making the blend composition. The present invention further includes films made from the blend composition.

Owner:DOW GLOBAL TECH LLC

Catalyst for olefin polymerization, method for producing olefin polymer, method for producing propylene-based copolymer, propylene polymer, propylene-based polymer composition, and use of those

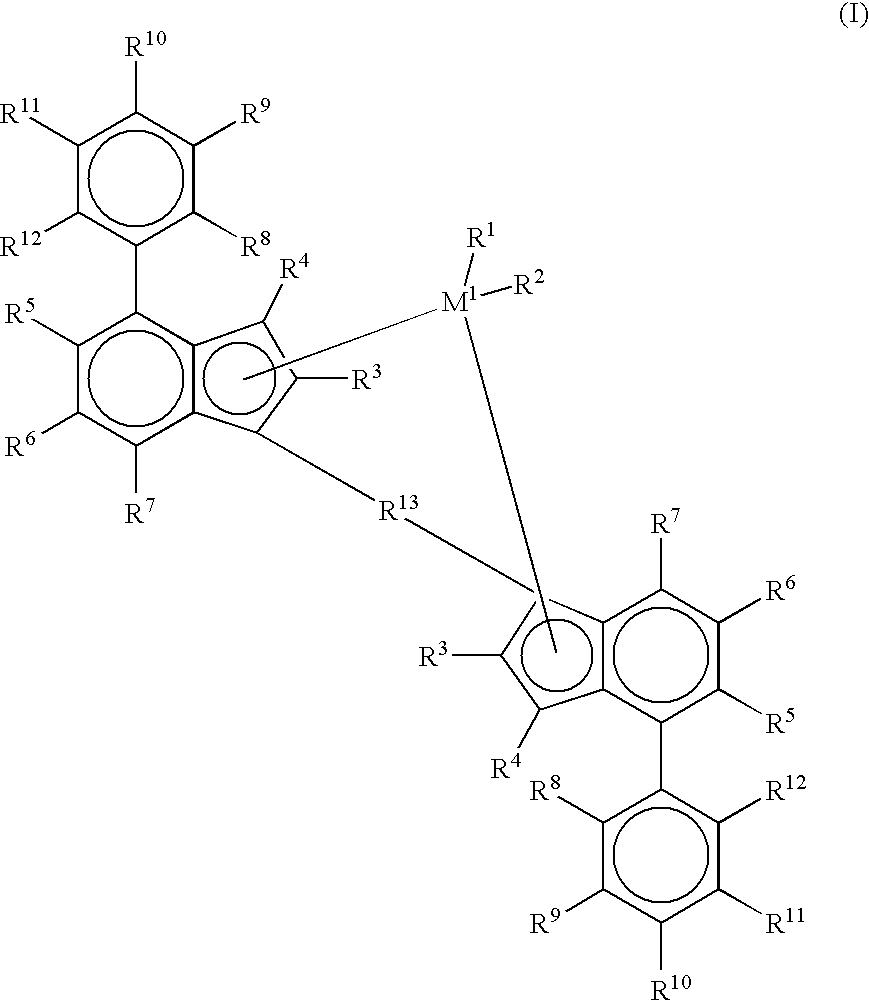

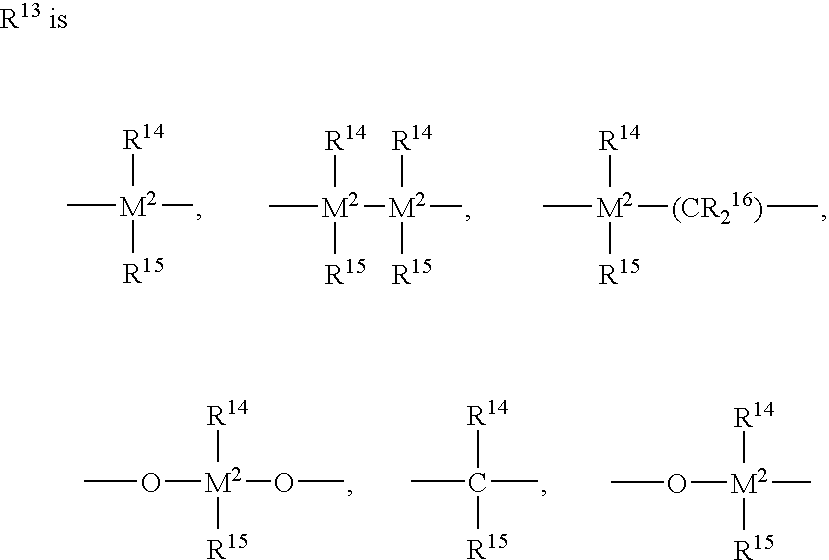

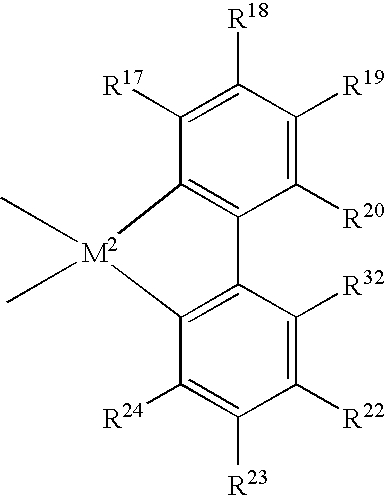

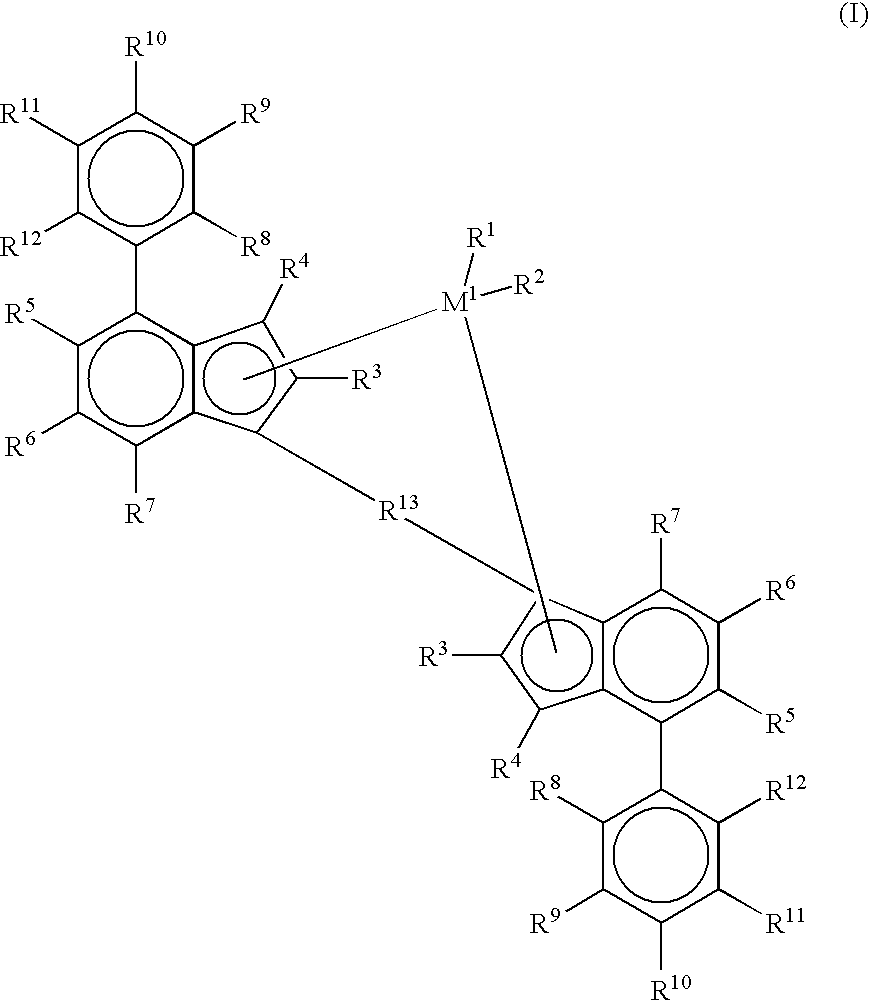

ActiveUS20080220193A1High molecular weightHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsBottlesMethyl groupAluminium

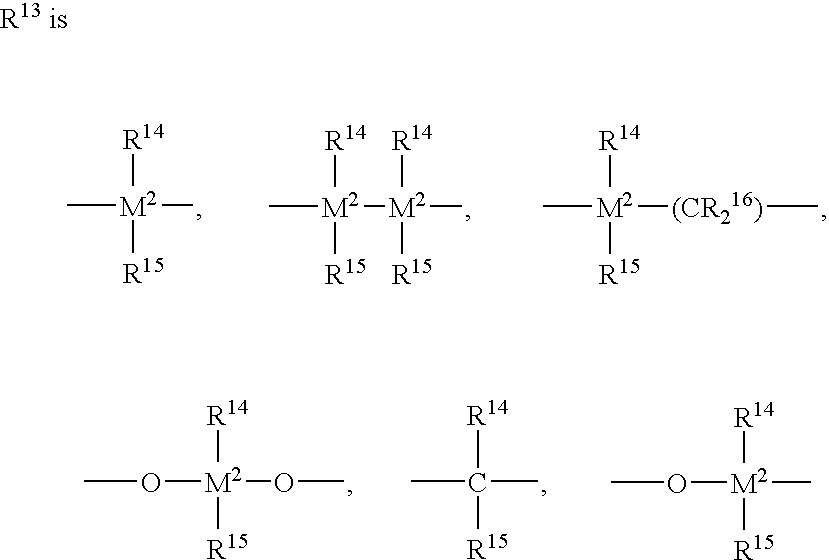

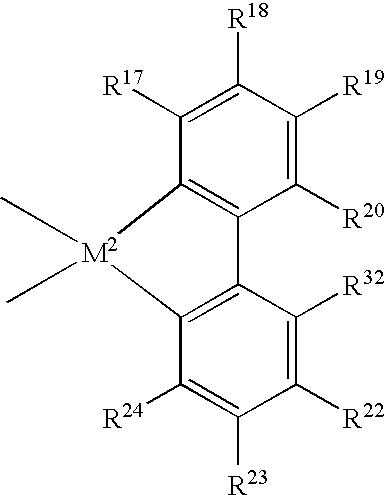

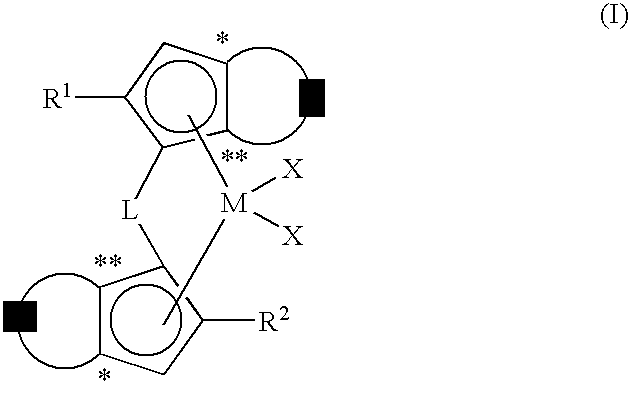

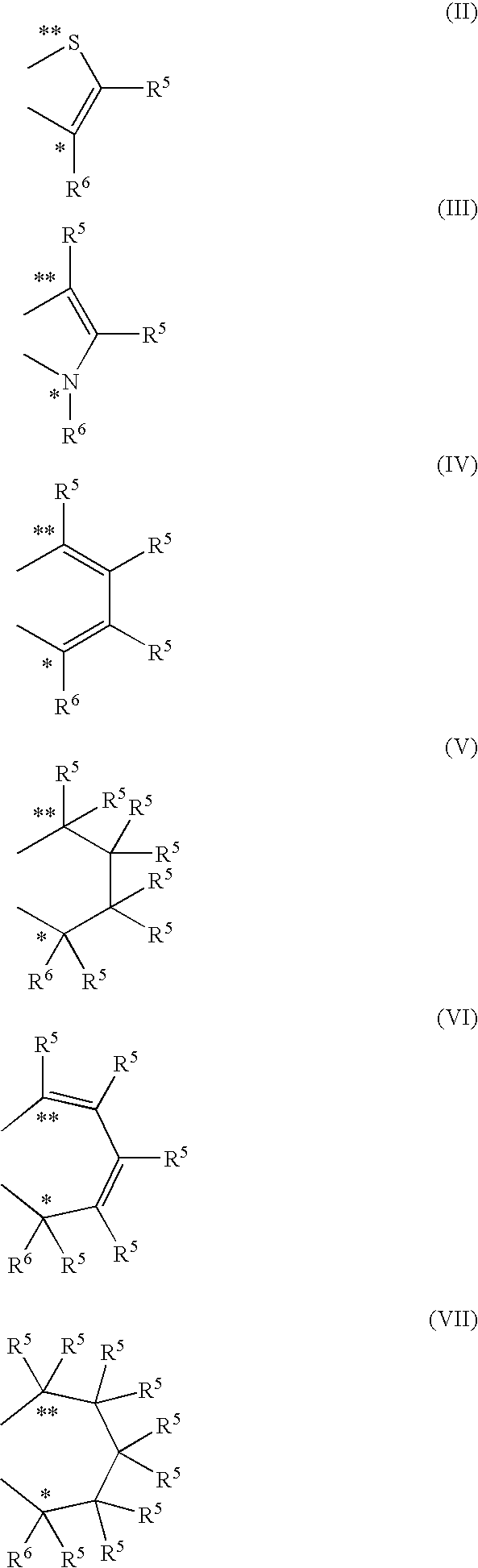

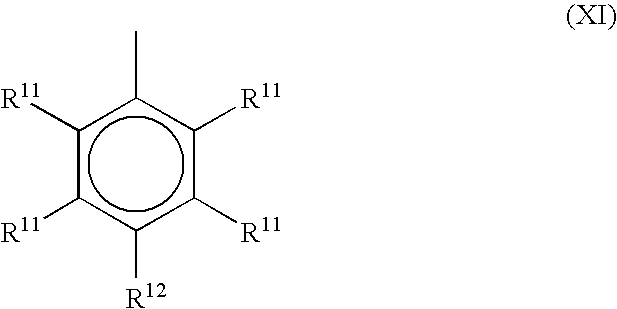

A catalyst for olefin polymerization, comprising:(A-1) a bridged metallocene compound represented by the following Formula [1-1], and (b) at least one compound selected from: (b-1) an organoaluminum oxy compound, (b-2) a compound which forms an ion pair, and (b-3) an organoaluminum compound:wherein in Formula [1-1], R1, R2, R3, R4, R5, R8, R9, and R12 are each selected from a hydrogen, a hydrocarbon group and a silicon-containing group; the four groups of R6, R7, R10, and R11 are not hydrogen atoms, and are each selected from a hydrocarbon group or a silicon-containing group; R13 and R14 are each a hydrocarbon group or the like, excluding a hydrogen atom and a methyl group; M is Ti, Zr or the like; Y is carbon or the like; Q is a halogen or the like; and j is an integer from 1

Owner:MITSUI CHEM INC

Solid catalyst component and catalyst for olefins polymerization

InactiveUS6770586B2Particles in good shapeImprove handlingOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropylene PolymersOlefin polymerization

Owner:TOHO TITANIUM CO LTD

Thermoplastic olefinic compositions

Thermoplastic olefinic compositions comprising (a) at least one ethylene / α-olefin polymer having a PRR between 8 and 70 and (b) at least one polypropylene polymer and an (a) / (b) weight ratio of greater than 50 / less than 50 to 90 / 10. The compositions are used in extrusion, calendering, blow molding, foaming and thermoforming processes to make a variety of articles, such as automotive instrument panel skins.

Owner:DOW GLOBAL TECH LLC

Process for the production of a propylene polymer having a broad molecular weight distribution and a low ash content

Owner:TOTAL RES & TECH FELUY

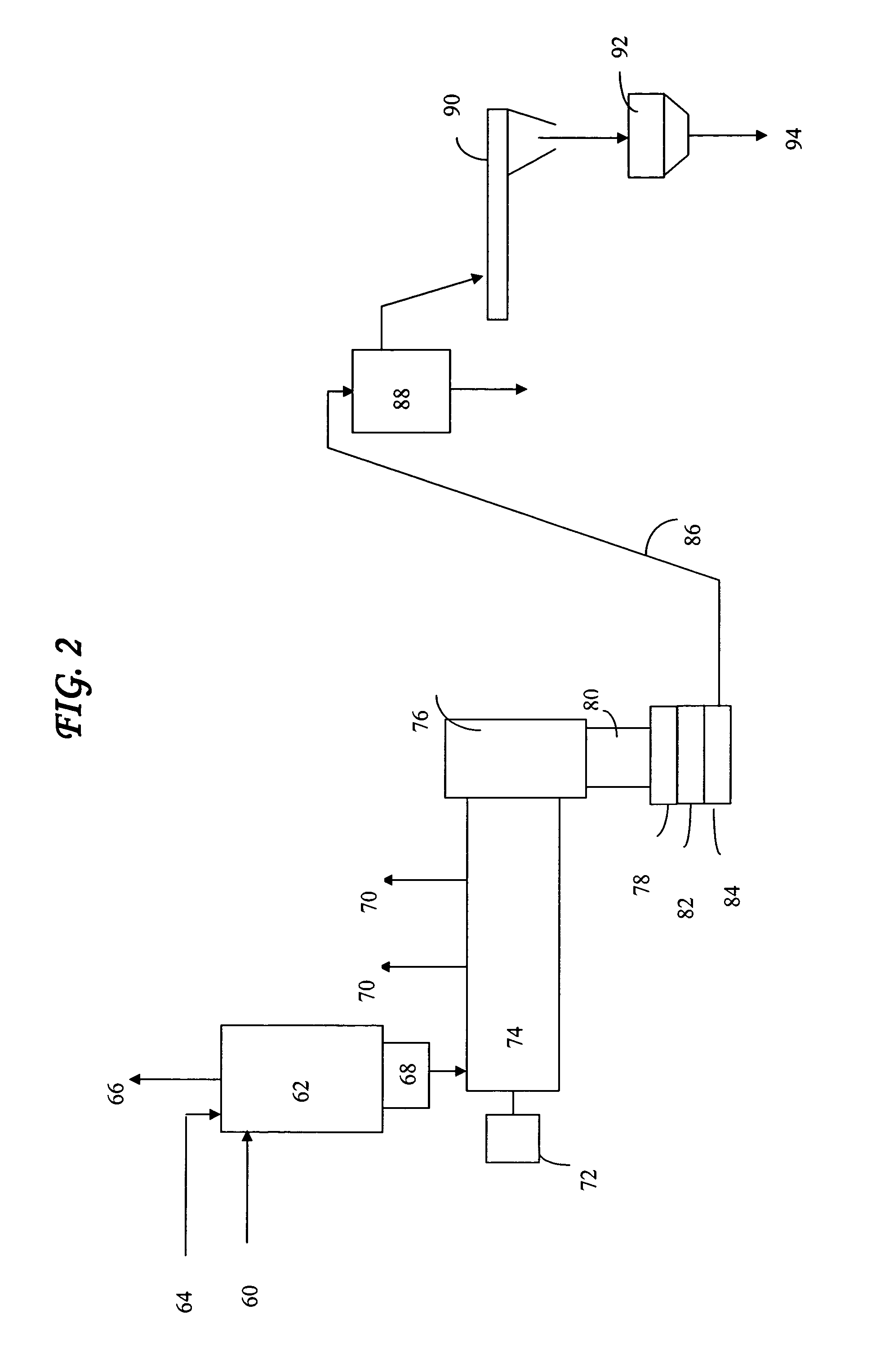

Supercritical polymerization process and polymers produced therefrom

ActiveUS20040122191A1High catalytic activityDrop in molecular weightBulk chemical productionPolymer sciencePtru catalyst

This invention relates to a process to produce propylene polymers comprising contacting a metallocene catalyst compound and an activator in a reaction medium comprising propylene, from 0 to 30 volume % of one or more solvents and from 0 to 30 mole % of one or more comonomers, under temperature and pressure conditions below the melting point of the propylene polymer and where: a) the temperature is at or above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium; or b) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at or above the critical pressure of the reaction medium; or c) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium.

Owner:EXXONMOBIL CHEM PAT INC

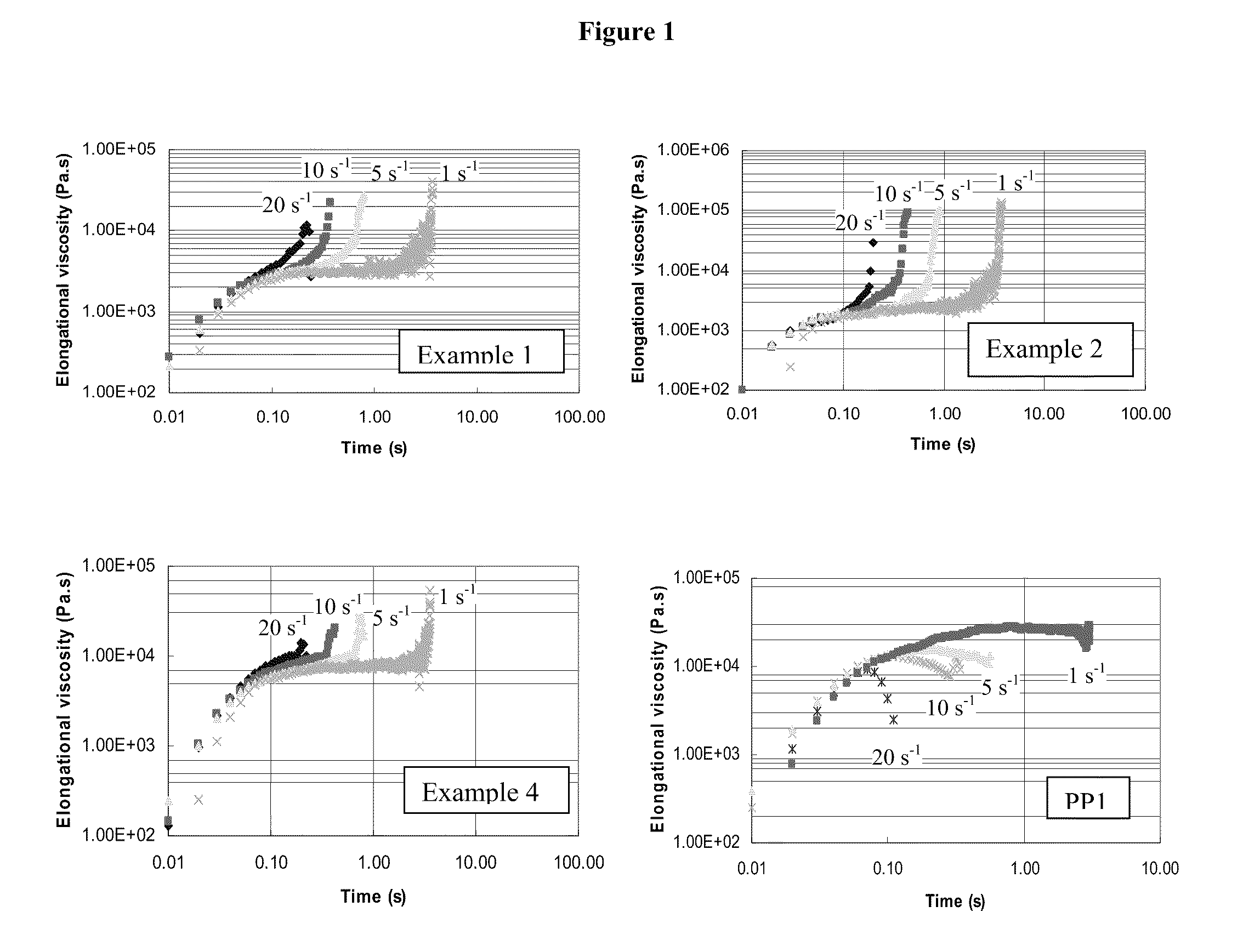

Foamable Thermoplastic Reactor Blends and Foam Article Therefrom

This invention relates to a foamable blend comprising an in-reactor polymer blend comprising: (a) a first propylene polymer component comprising 90 to 100 wt % propylene and from 0 to less than 10 wt % comonomer, said first propylene component having a Tm of 120° C. or more; and (b) a second propylene polymer component comprising from 30 to 90 wt % propylene and 70 to 10 wt % comonomer, said second propylene polymer having an Mw of 30,000 g / mol or more, and said second propylene-containing polymer having a crystallinity different by at least 5% from the first polymer, wherein the polymer blend, prior to combination with a foaming agent, has: (i) a Tm of at least 120° C.; (ii) a MFR of 10 dg / min or more; (iii) a tensile strength of at least 8 MPa; (iv) an elongation at break of at least 200%, and (v) a ratio of elongational viscosity at break to linear viscosity of 5 or more when the elongational viscosity is measured at a strain rate of 1 sec−1 and temperature of 180° C.; and where when the blend is foamed with a foaming agent, the foamed article has a density of 800 kg / m3 or less.

Owner:EXXONMOBIL CHEM PAT INC

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

InactiveUS20020006993A1High crystallinityLong mesochainLayered productsPolymer scienceHindered amine light stabilizers

Disclosed are a propylene polymer having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain (continuous propylene units wherein directions of alpha-methyl carbons are the same as each other), and a process for preparing said polymer. Also disclosed are a propylene block copolymer containing a crystalline polypropylene portion having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain, and a process for preparing said copolymer. Further disclosed is a propylene polymer composition comprising the above propylene polymer or propylene block copolymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene polymer of the invention is excellent in rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc. The propylene block polymer of the invention is well-balanced between rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance. The propylene polymer composition can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc.

Owner:MITSUI CHEM INC

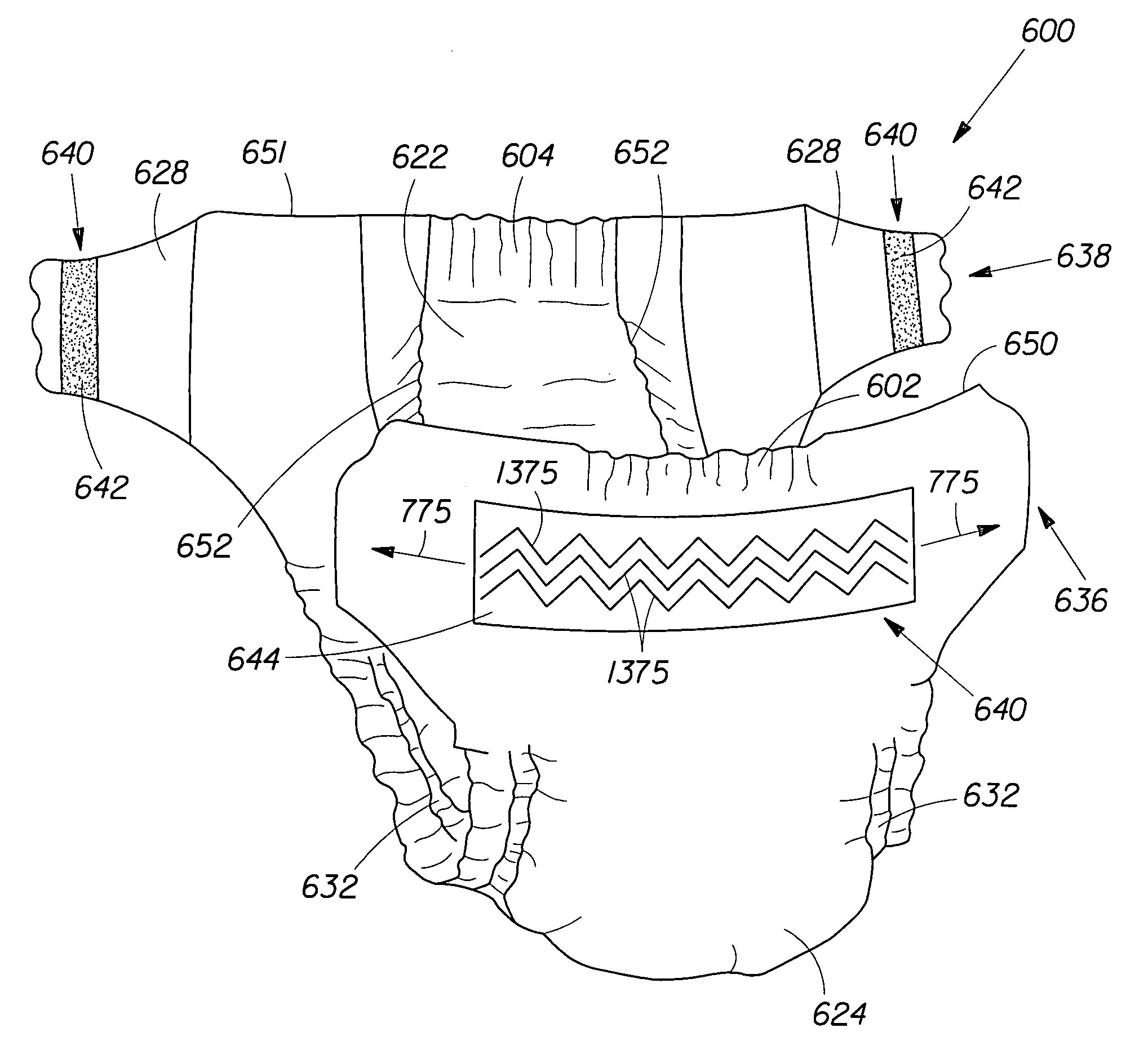

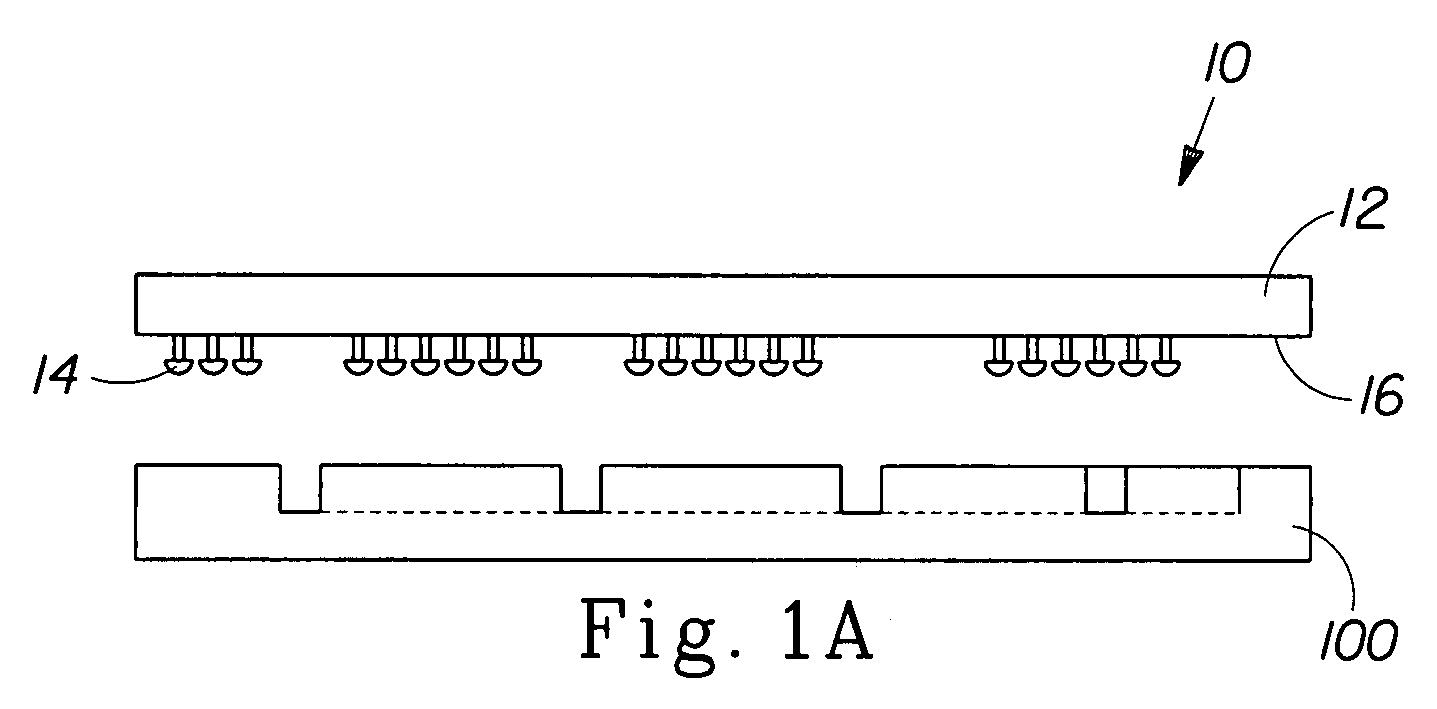

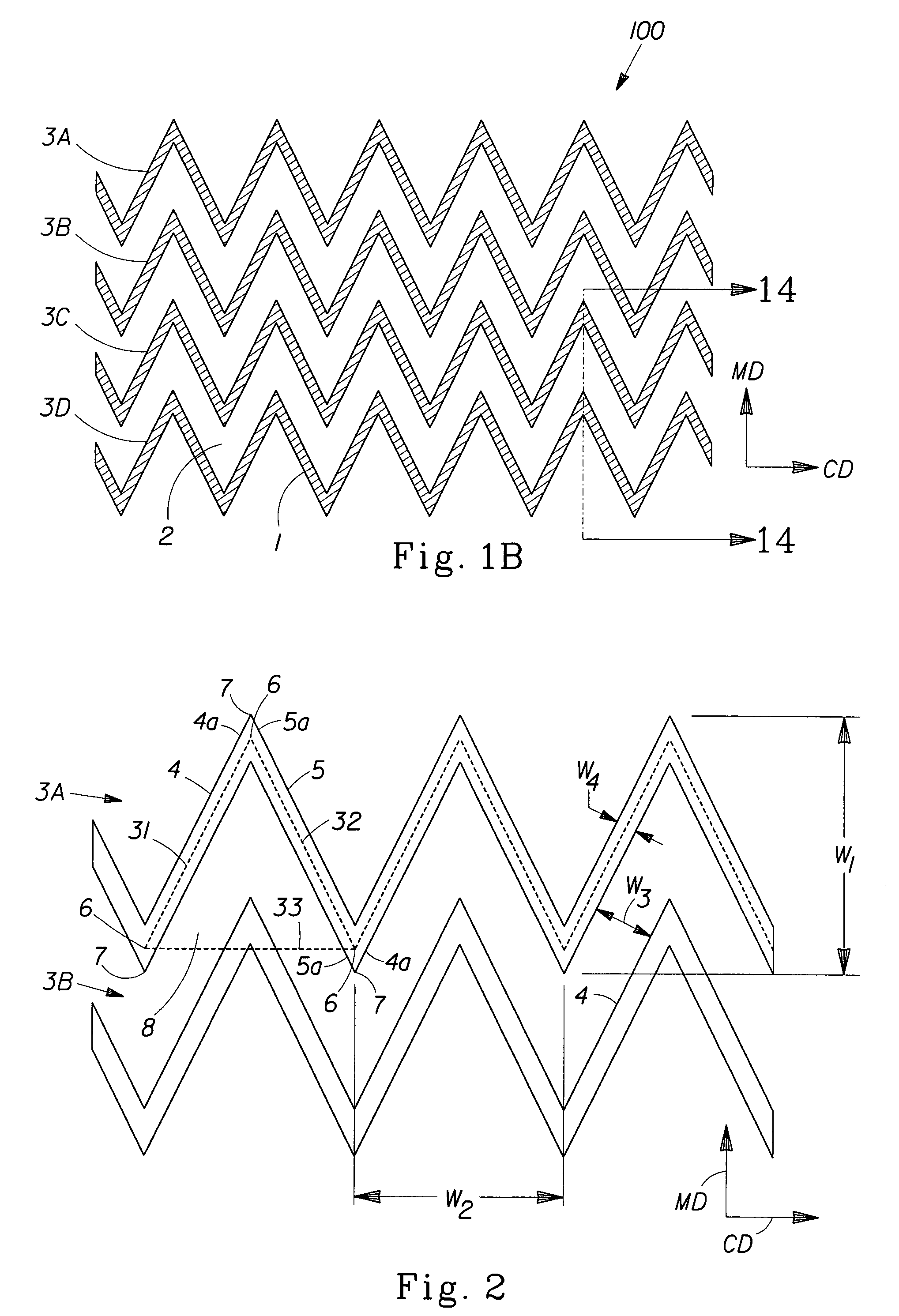

Nonwoven fabric for a female component of a fastening system

InactiveUS7789870B2High bonding strengthHigh mechanical strengthLayered productsBaby linensEngineeringNonwoven fabric

A fastening system includes an engaging component and a receiving component. The engaging component has a plurality of engaging elements capable of engaging the receiving component. The receiving component includes a nonwoven fabric having composite fibers, an embossed section, and a non-embossed section. The composite fibers are bonded together in the embossed sections. The composite fibers include a first propylene polymer and a second propylene polymer, wherein the first and second propylene polymers extend continually in a longitudinal direction and are arranged such that the second propylene polymer is associated with the first propylene polymer such that the composite fiber forms a crimp therein. The embossed sections have a plurality of zigzag unit patterns arranged in a machine direction which have a ratio of W1 / W2 in the range of about 0.5 to about 2.0.

Owner:THE PROCTER & GAMBLE COMPANY

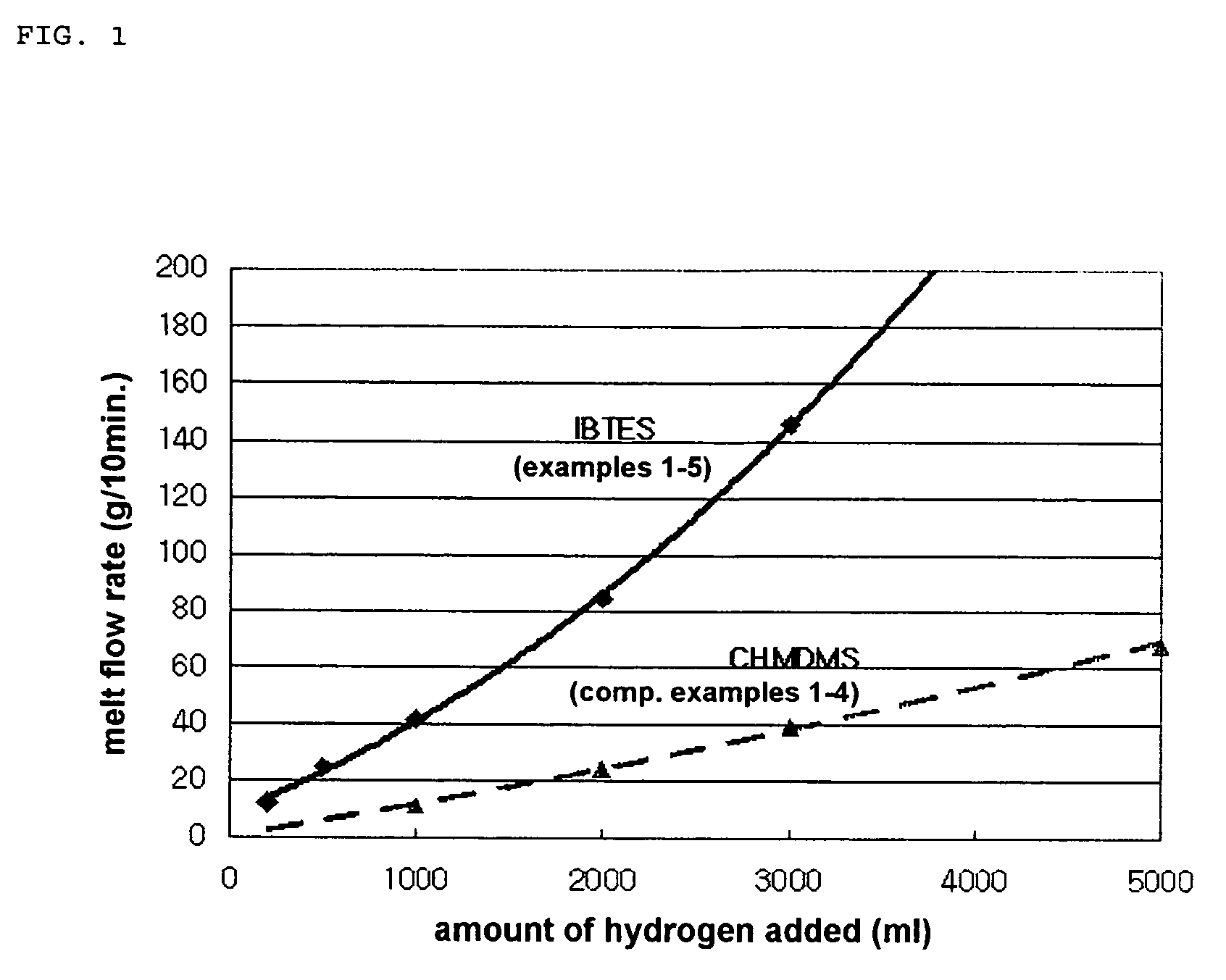

Method for producing propylene polymer having a very high melt-flowability

ActiveUS7244794B2Ensure effective applicationHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

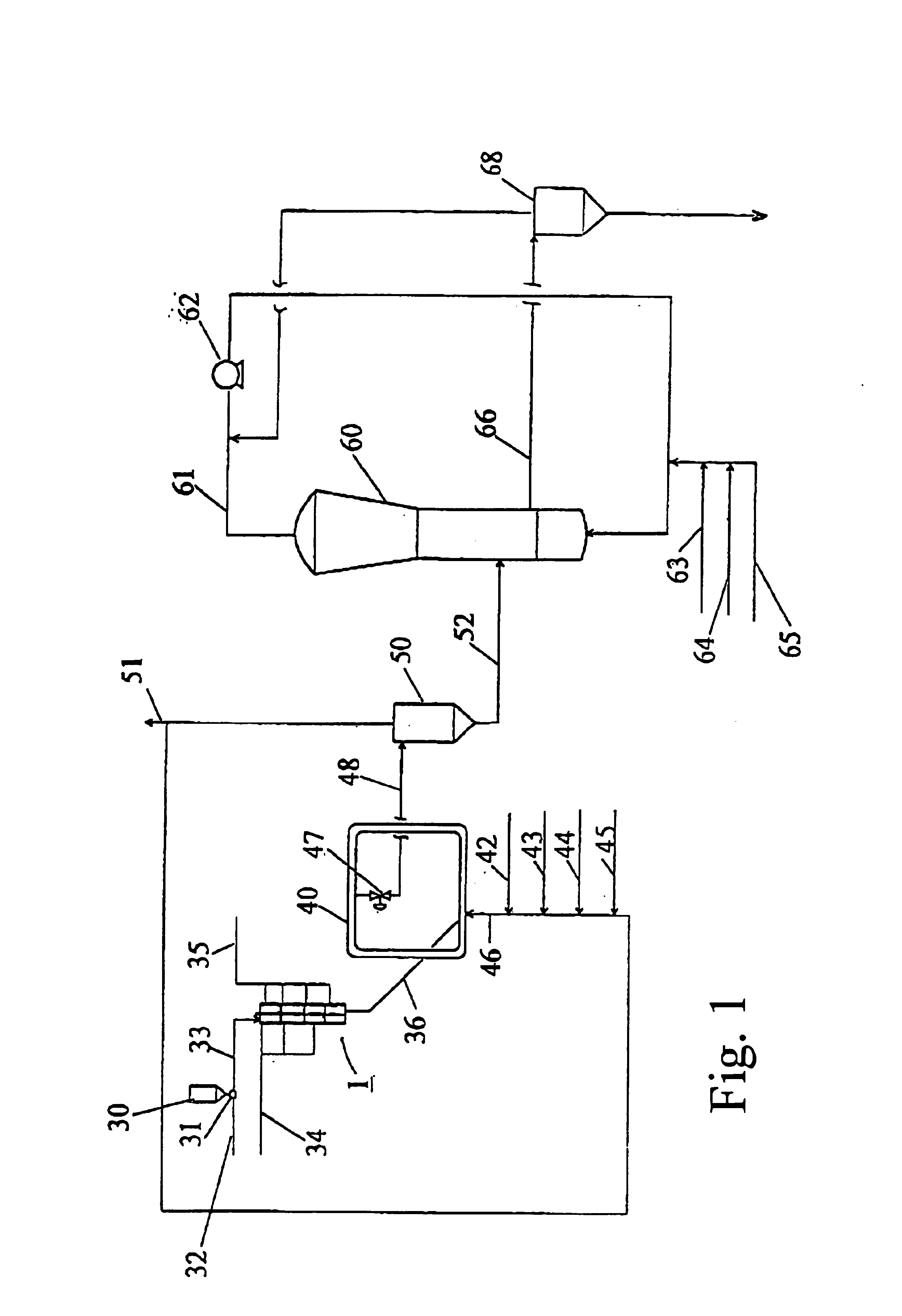

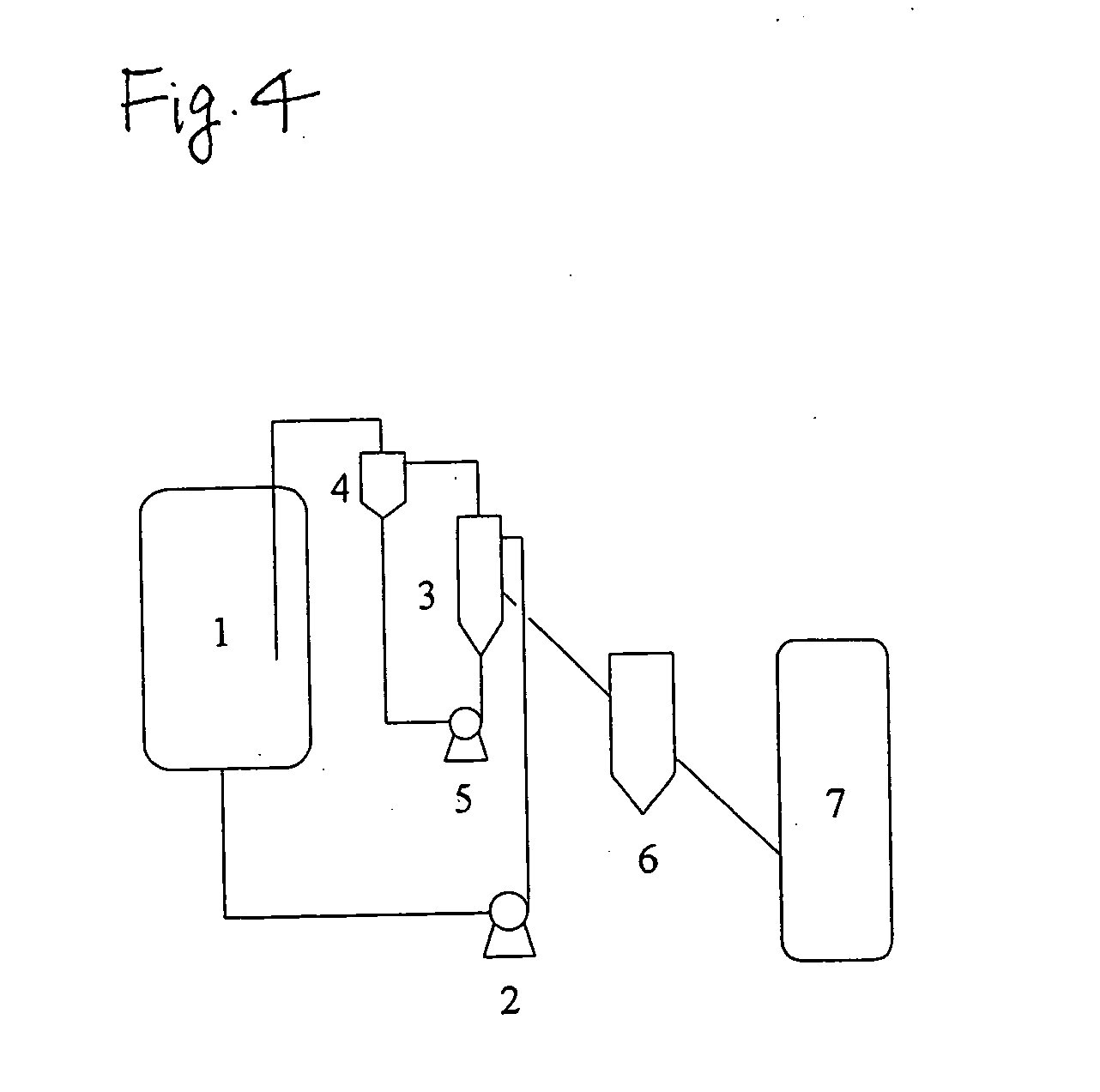

Propylene homopolymer having high melt strength and preparation method thereof

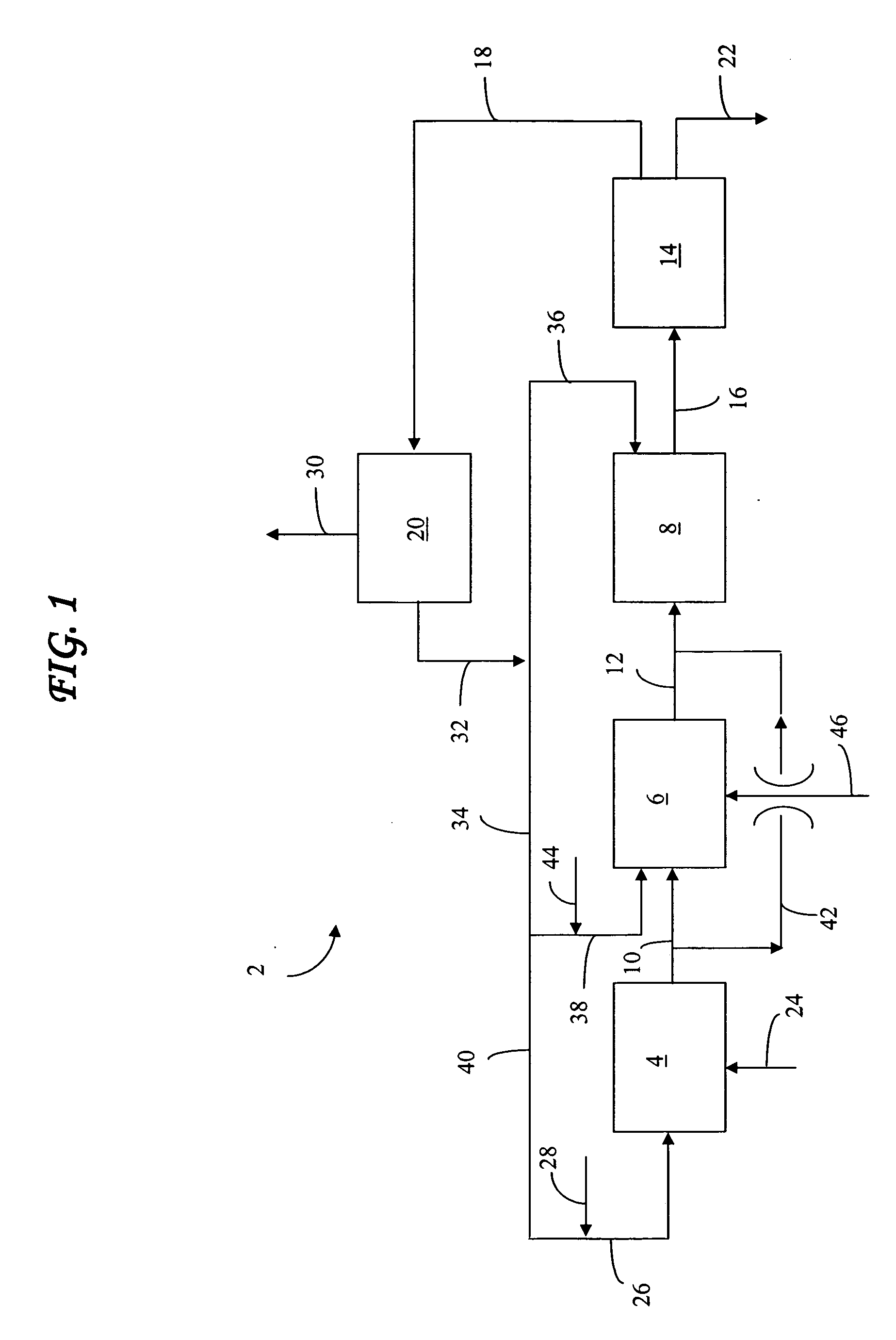

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirment for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechnical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

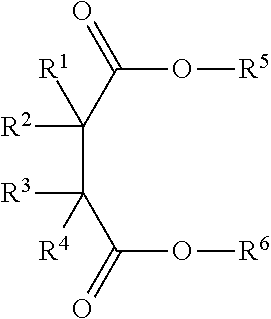

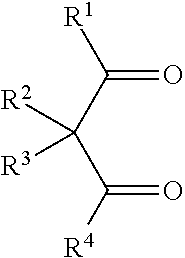

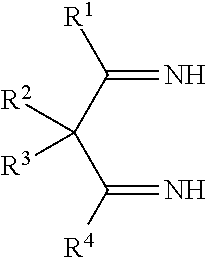

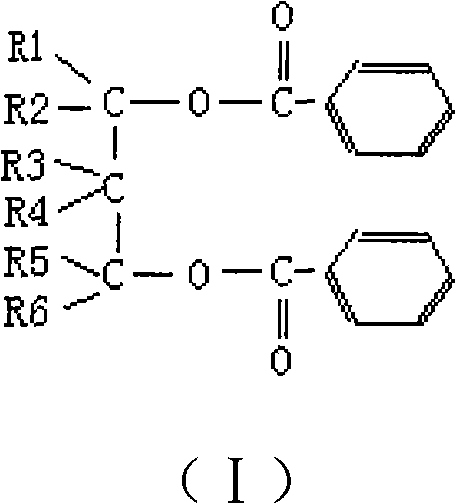

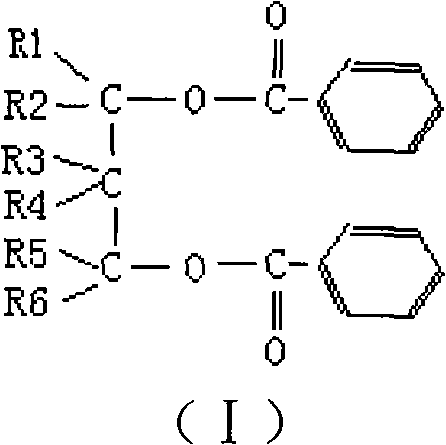

Propylene polymer catalyst donor component

ActiveUS7491781B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsElectron donorTitanium

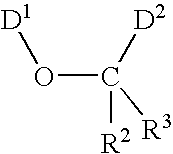

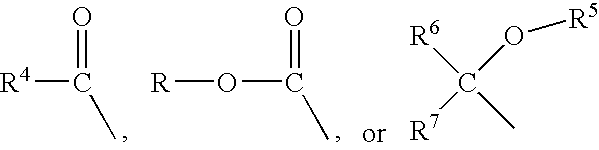

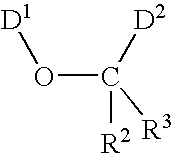

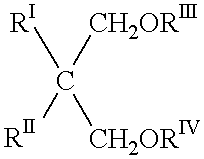

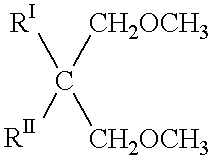

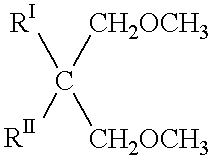

A solid, hydrocarbon-insoluble, catalyst component useful in polymerizing olefins containing magnesium, titanium, and halogen further contains an internal electron donor comprising a compound containing electron donating substituents with a structure:wherein D1 and D2 are selected individually fromand R, R2, R3, R4, R5, R6, and R7 individually are hydrocarbon or substituted hydrocarbon groups containing 1 to 20 carbon atoms and R2, R3, R4, R6, and R7 may be hydrogen; R4 may be —NR2; andwherein groups R1 and R2, R2 and R3, R3 and R4, R3 and R5, and groups R6 and R7 may be joined to form a cyclic structure.

Owner:INEOS TECH USA

Supercritical polymerization process and polymers produced therefrom

This invention relates to a process to produce propylene polymers comprising contacting a metallocene catalyst compound and an activator in a reaction medium comprising propylene, from 0 to 30 volume % of one or more solvents and from 0 to 30 mole % of one or more comonomers, under temperature and pressure conditions below the melting point of the propylene polymer and where:a) the temperature is at or above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium; orb) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at or above the critical pressure of the reaction medium; orc) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium.

Owner:EXXONMOBIL CHEM PAT INC

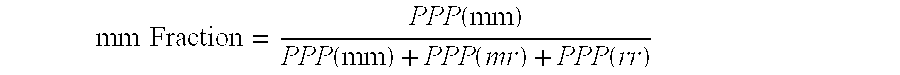

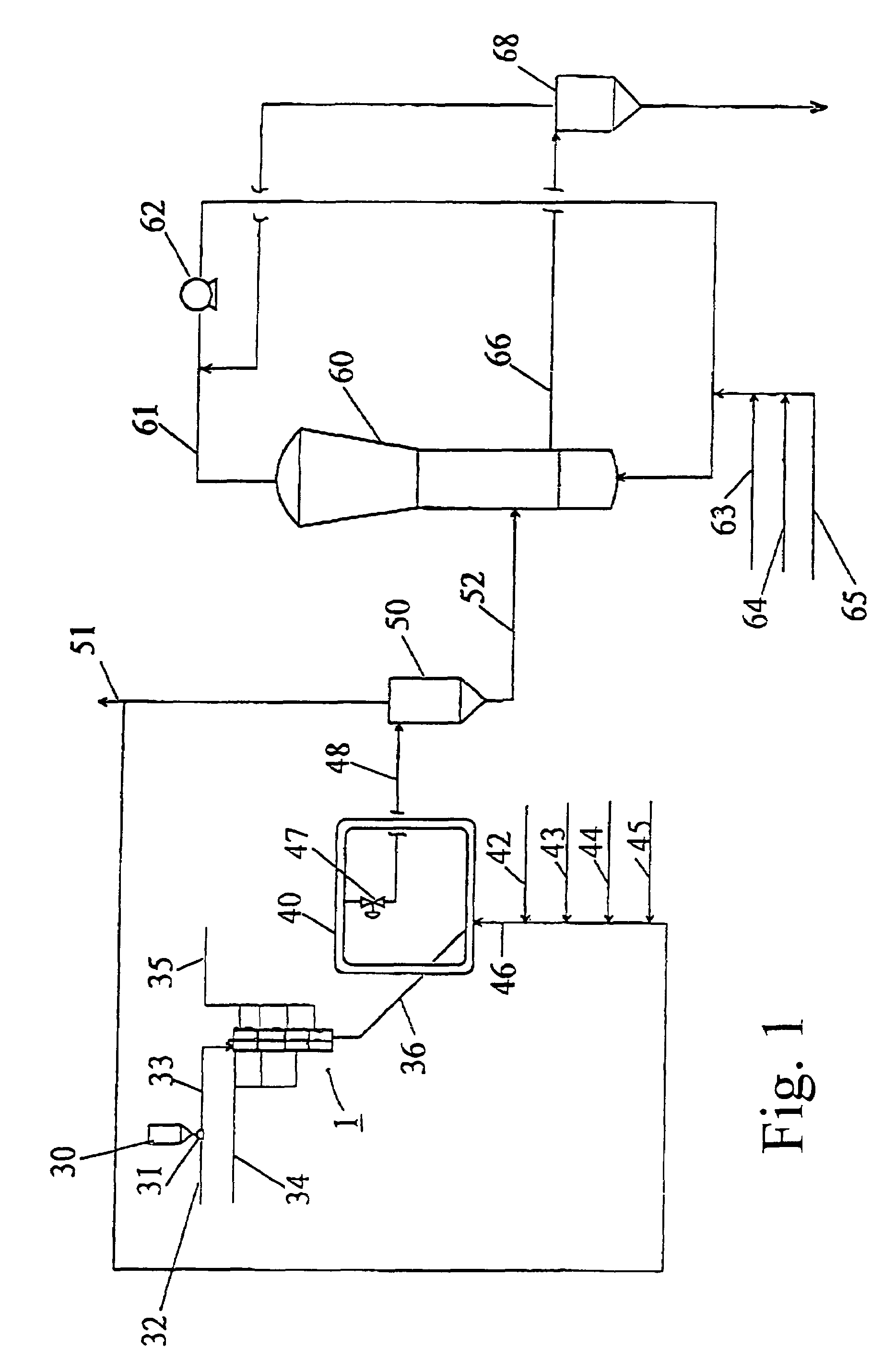

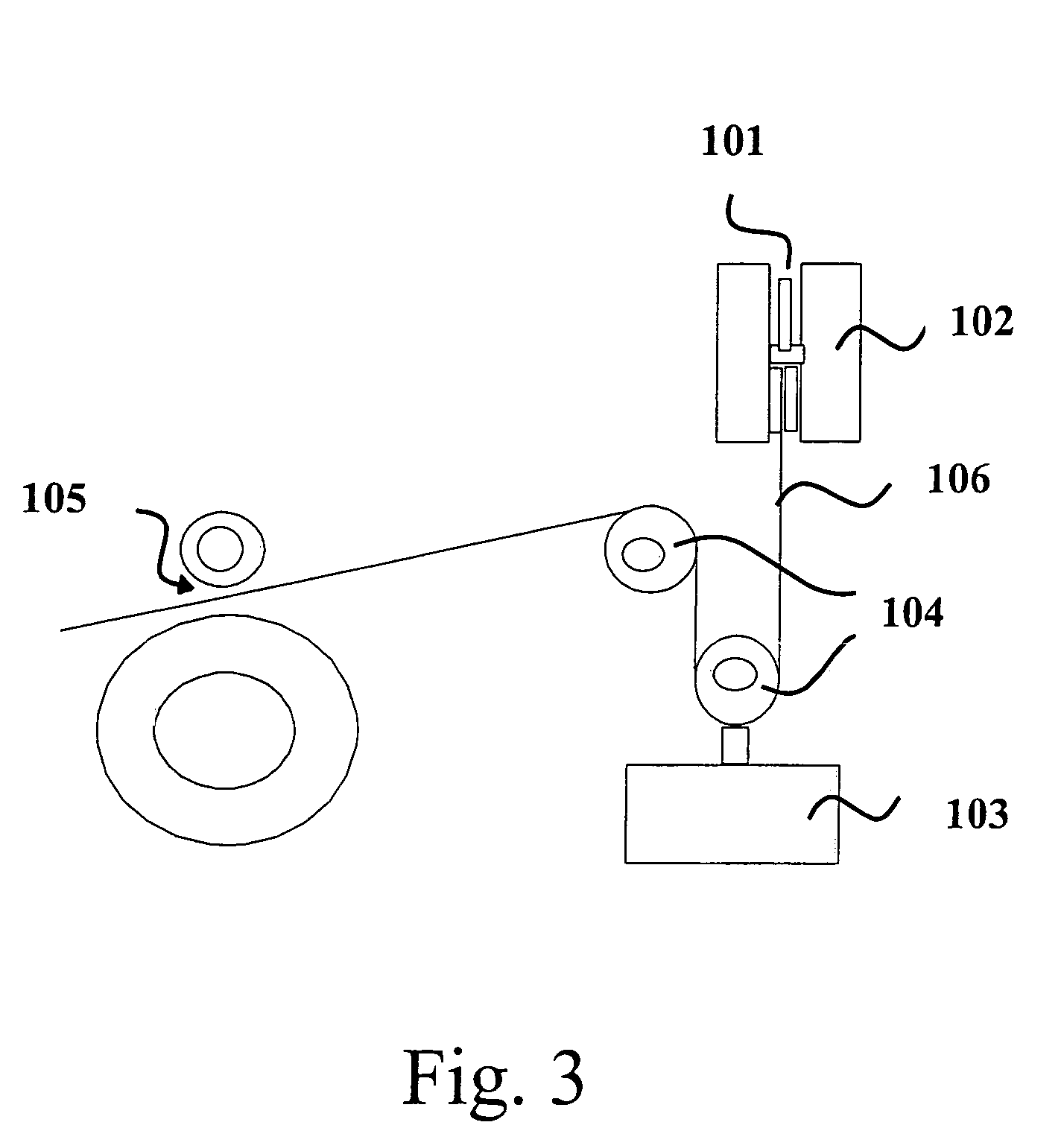

Process for the gas-phase polymerization of olefins

Process for the gas-phase polymerization of olefins of the formula CH2=CHR where R is hydrogen or an alkyl or aryl radical with 1 to 8 carbon atoms carried out in one or more reactors having a fluidized or mechanically agitated bed, using a catalyst obtained by reaction of a titanium halide or haloalcoholate and optionally an electron-donor compound supported on an active Mg-dihalide with an Al-trialkyl compound and optionally an electron-donor compound, comprising the steps of:a) contacting the catalyst components in the absence of polymerizable olefin or optionally in the presence of said olefin in an amount to from up to 3 g per g of solid catalyst component;b) prepolymerizing propylene or mixtures of propylene with ethylene or an alpha-olefin to form a propylene polymer having an insolubility in xylene of at least 60% by weight, in an amount of from 5 g of polymer per g of solid catalyst component to 10% by weight of the final catalyst yield; andc) polymerizing one or more CH2=CHR olefins in the gas phase in the presence of the prepolymer-catalyst system obtained in b), while maintaining in the gas phase an alkane in a molar concentration with respect to the total gases of from 20 to 90%.

Owner:MONTELL TECH CO BV

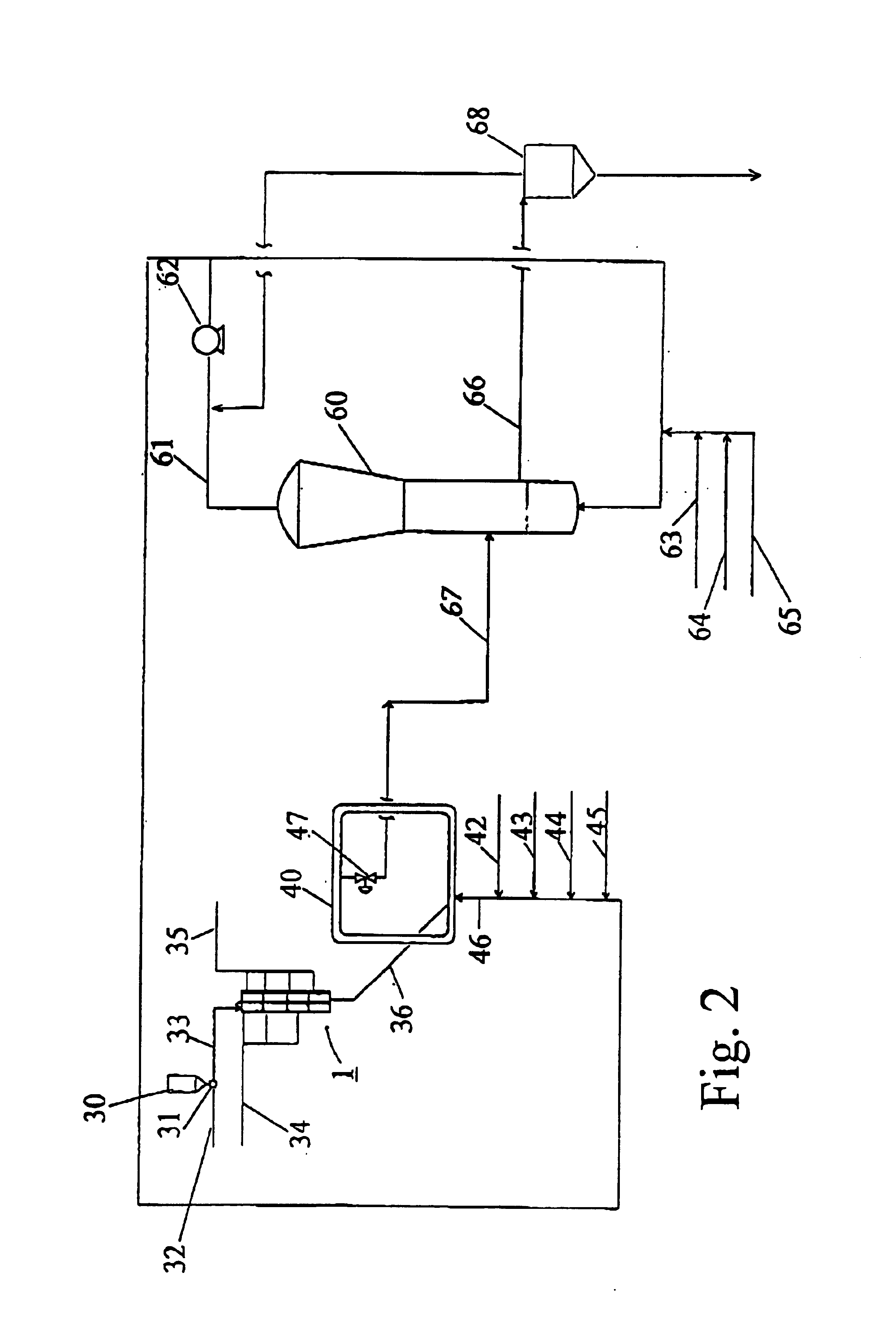

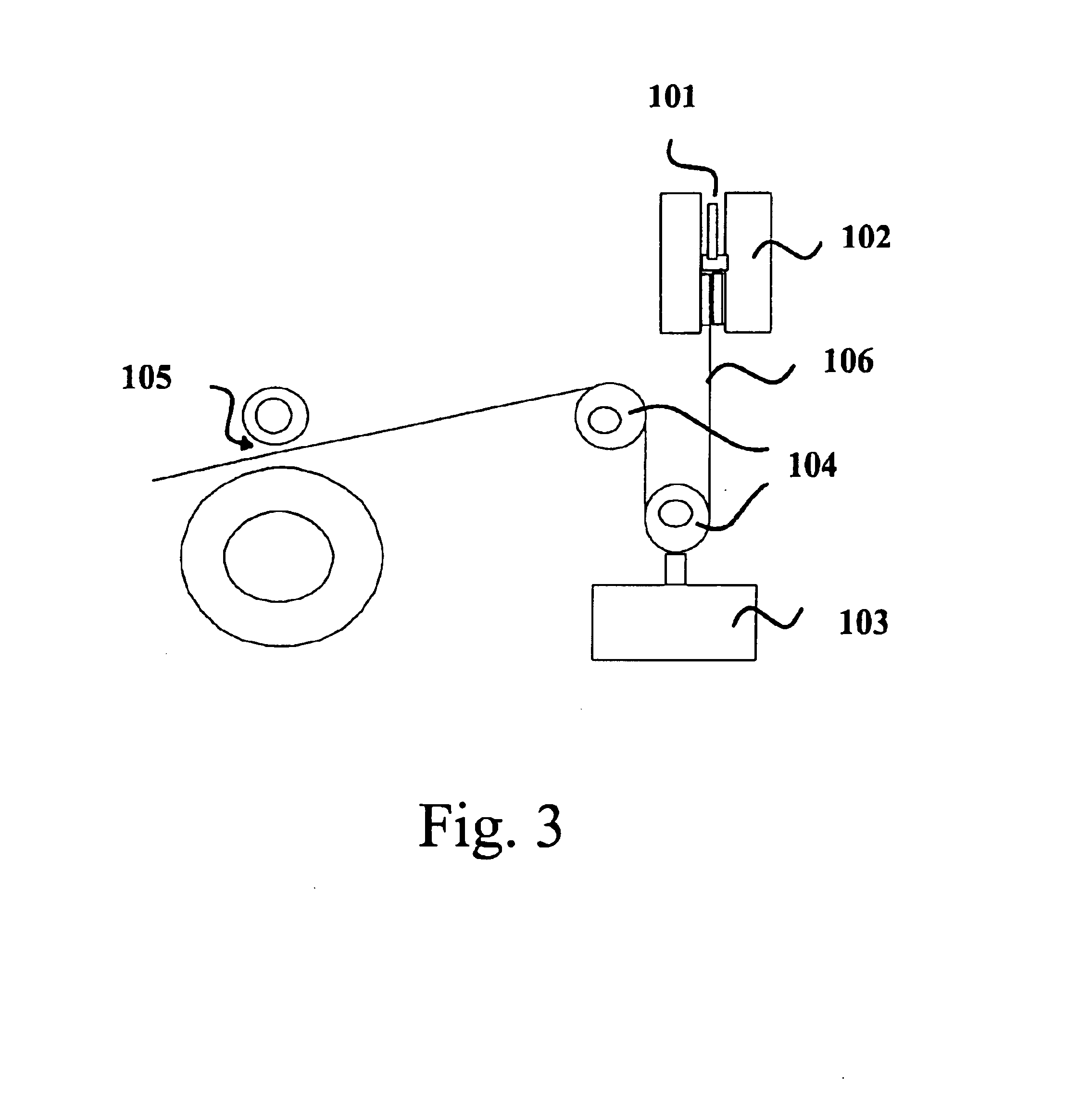

Process for producing high melt strength polypropylene

The present subject matter relates to processes for irradiating visbroken propylene polymer compositions or extrudates of propylene polymer compositions containing a propylene polymer having a low polydispersity index and a non-phenolic stabilizer.

Owner:BASSELL POLIOLEFINE ITAL SRL

High impact polymer compositions

Disclosed herein are various compositions that have particular utility in automotive components, including compositions that include: (a) polypropylene having a melting point of 110° C. or more; (b) ethylene a-olefin polymer in which the α-olefin is C4 or higher; and (c) propylene polymer, having 60 wt % or more units derived from propylene, including isotactically arranged propylene derived sequences and a heat of fusion less than 45 J / g.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of polypropylene with wide molecular weight distribution and polymer thereof

The invention provides a preparation method of molecular weight distribution polypropylene and a polymer thereof. By using the method, polymerization reaction is carried out in a single reactor or a plurality of series reactors in the presence of catalysts, wherein the catalysts are reactants containing the following components: (1) at least one solid catalyst component comprising magnesium, titanium, halogen and at least two electron donors of a and b, wherein the electron donor a is selected from a diol ester compound; the electron donor b is selected from unitary or multi-element aliphatic carboxylic ester, aromatic aliphatic carboxylic ester or diether compounds; and the weight ratio of the electron donor a to the electron donor b is 2-80; (2) an alkyl aluminum compound; and (3) optimally, an external electron donor component. The acrylic polymer has the advantages of wide molecular weight distribution, high isotacticity and the like; meanwhile, the preparation method has simple operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com