Patents

Literature

80results about How to "Ensure effective application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

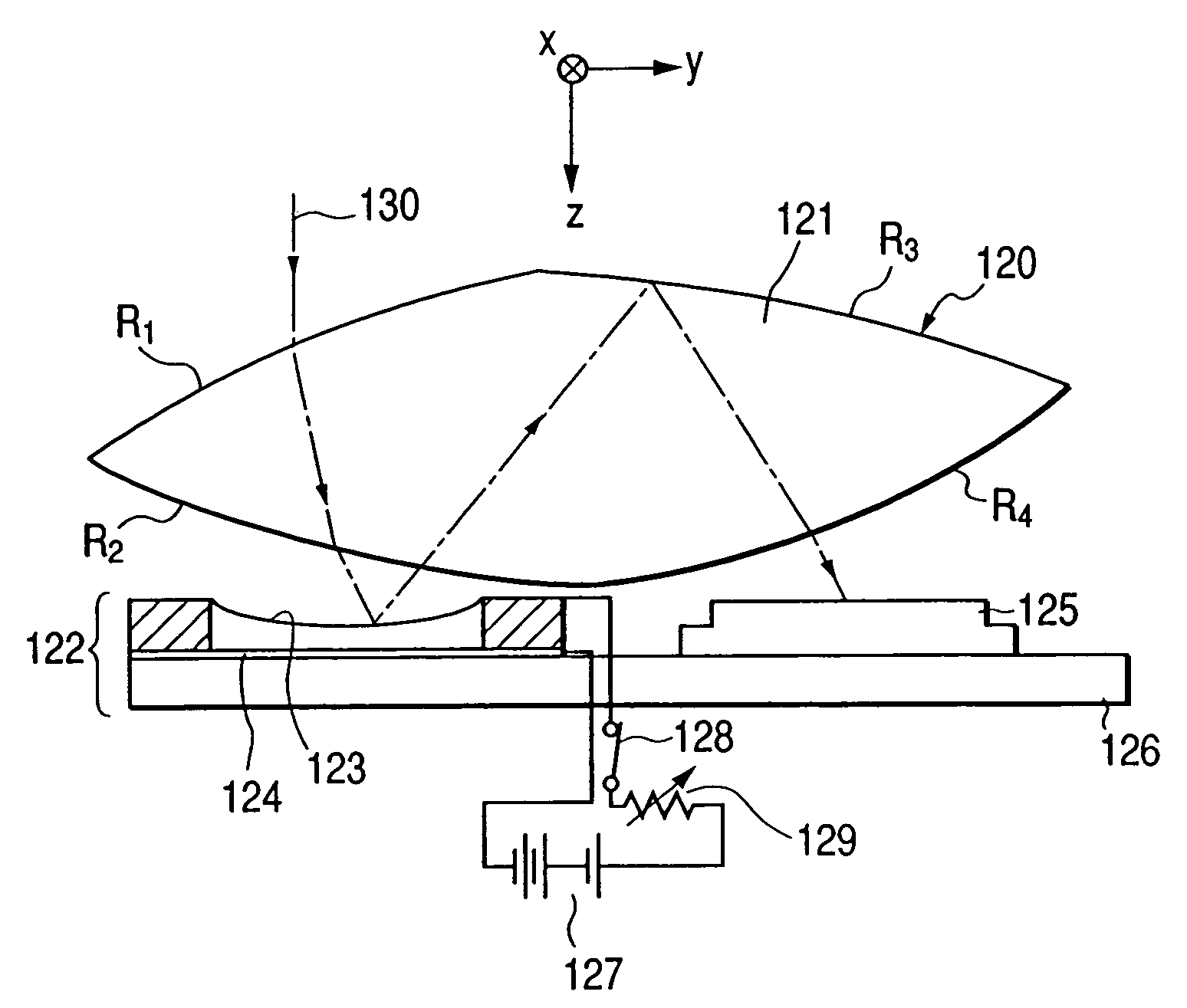

Optimal elements (such as vari focal lens component, vari-focal diffractive optical element and variable declination prism) and electronic image pickup unit using optical elements

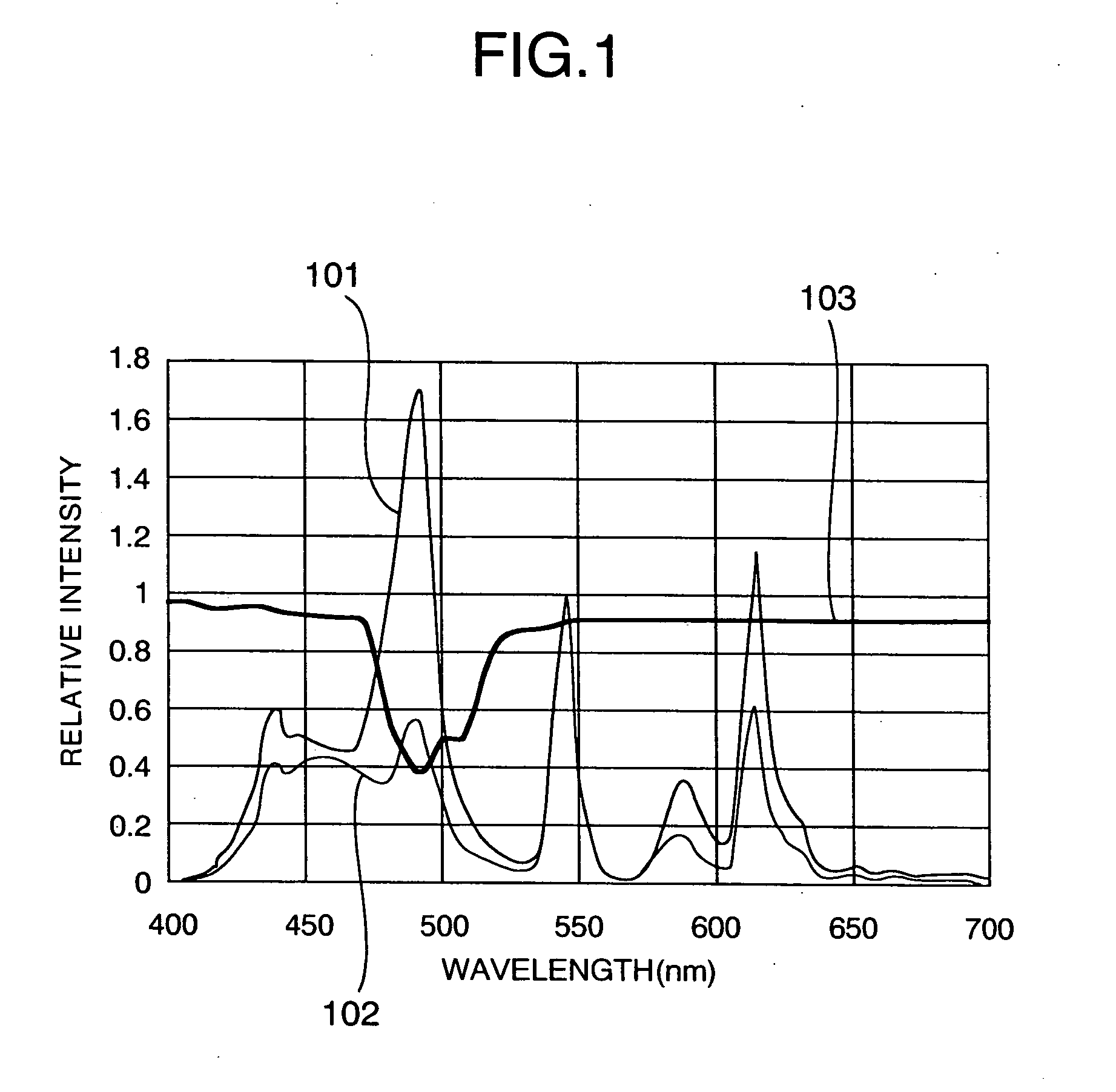

InactiveUS7009757B2Improve utilization efficiencyImprove versatilitySpectales/gogglesNon-optical partsUses eyeglassesEyeglass lenses

Optical elements such as a vari-focal lens element, a vari-focal diffractive optical element and a variable declination prism usable as spectacle lens elements and so on.

Owner:OLYMPUS CORP

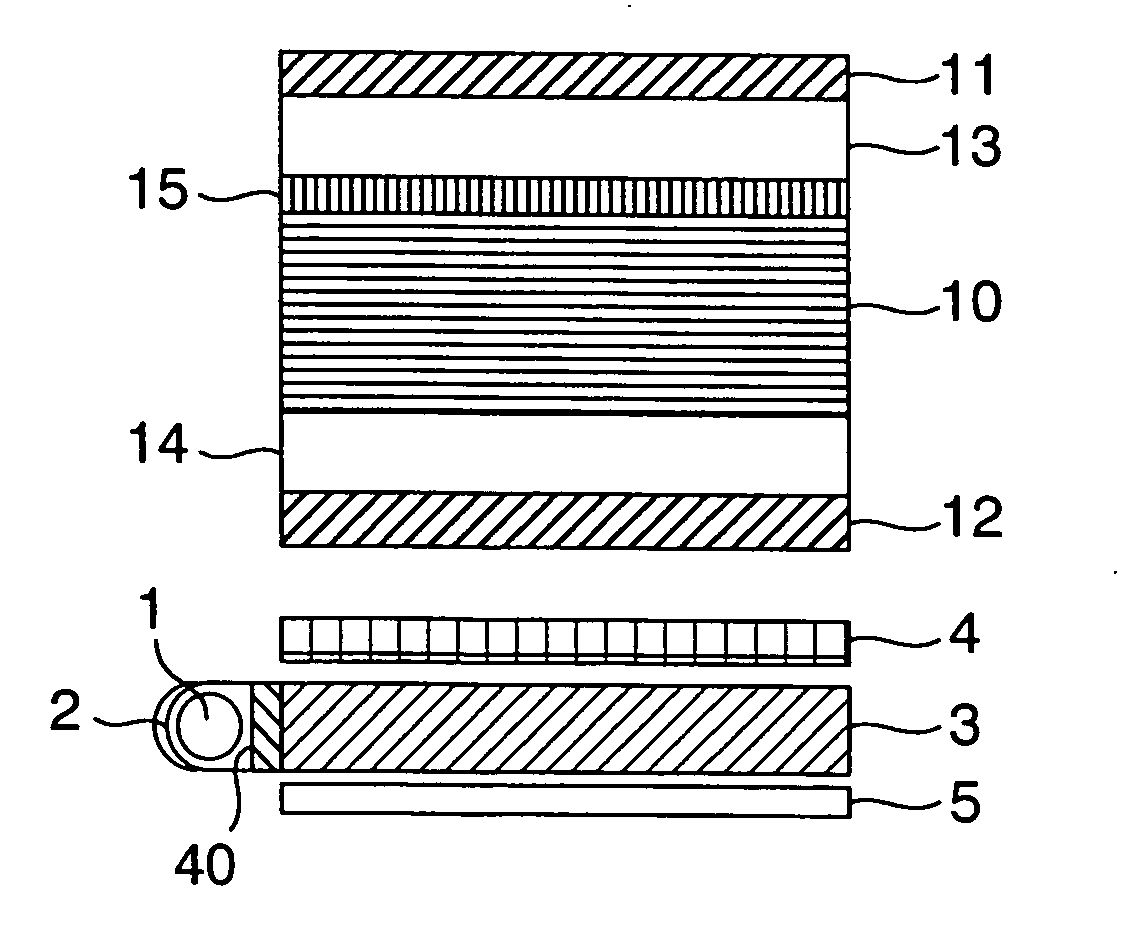

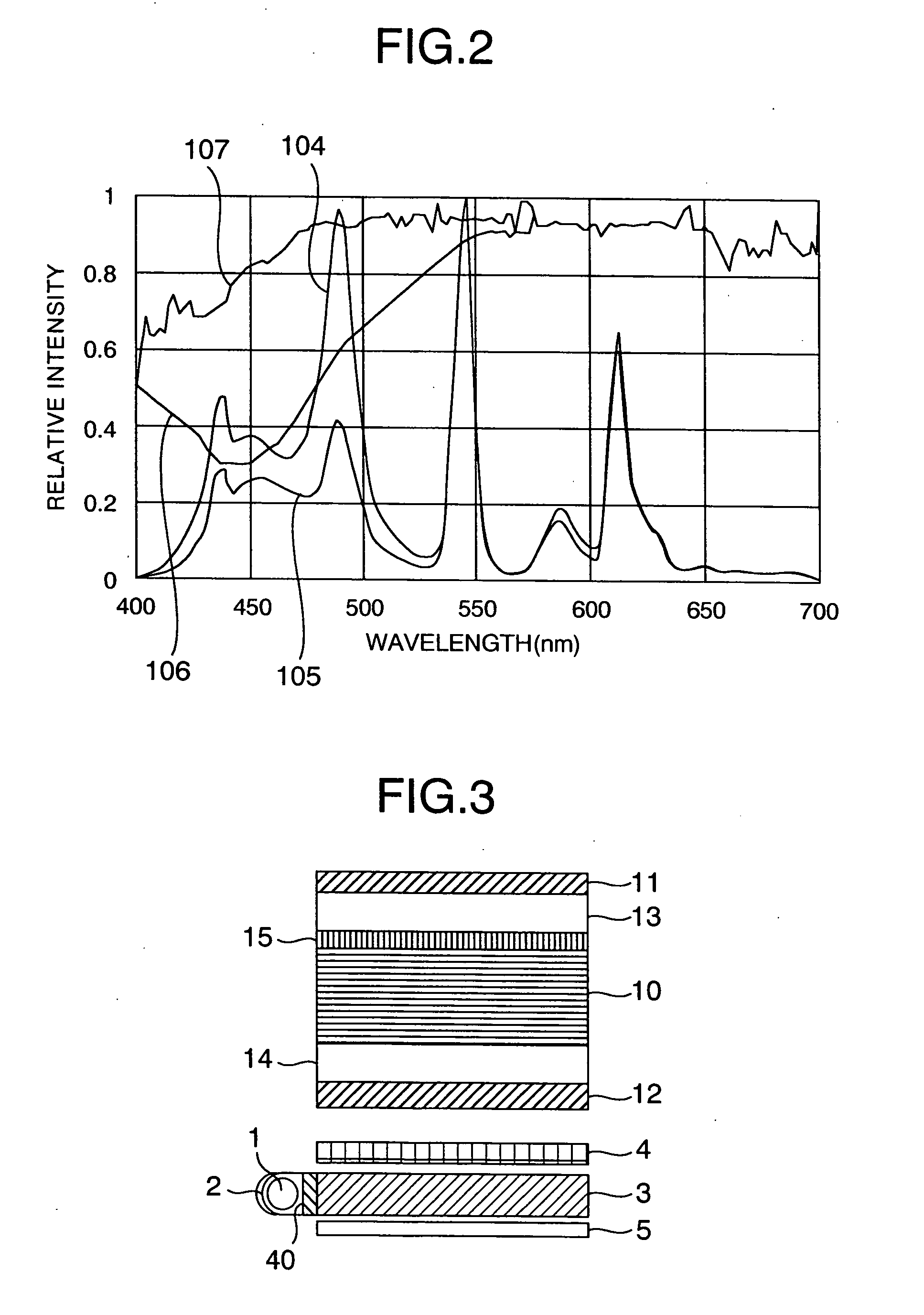

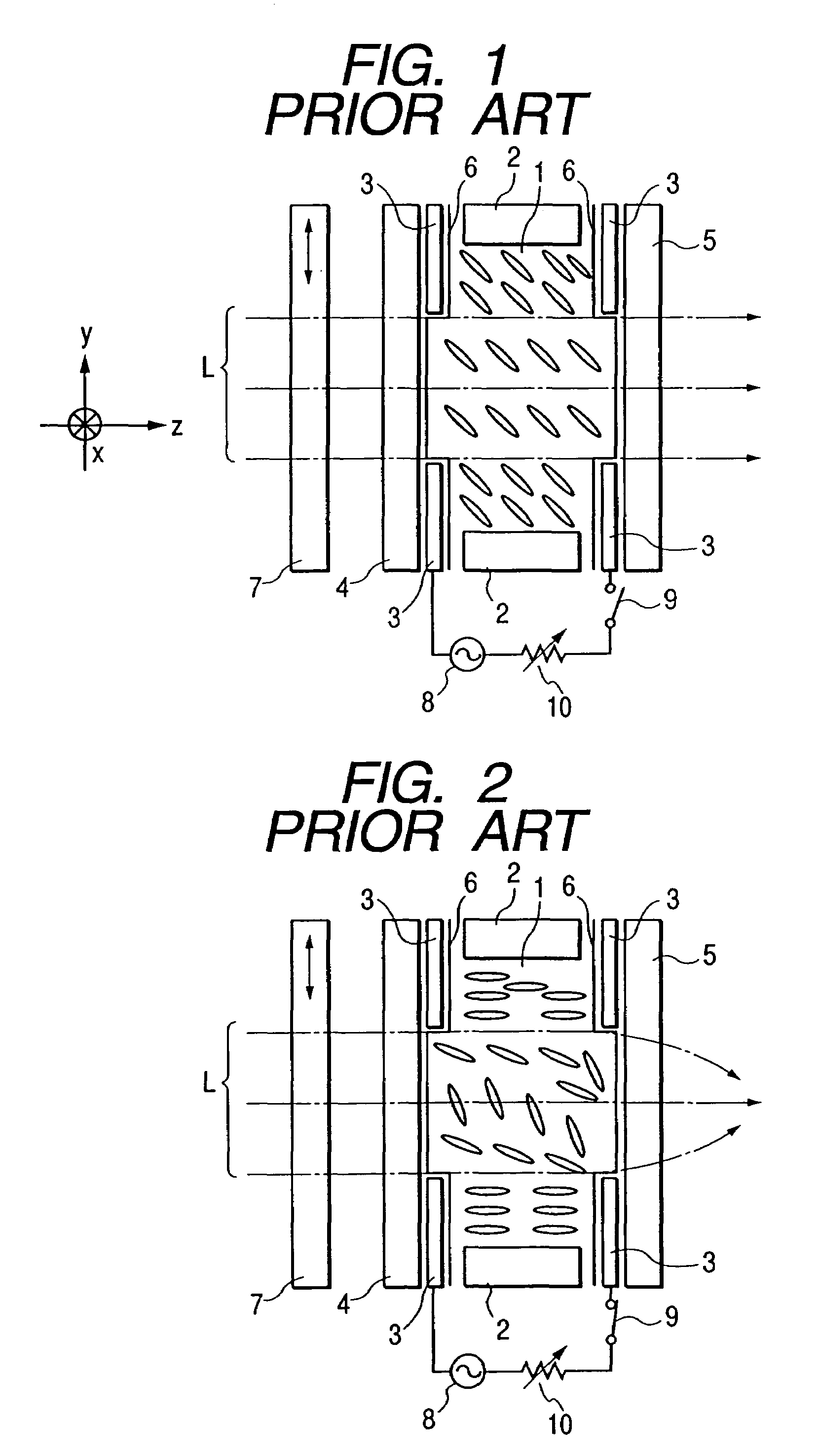

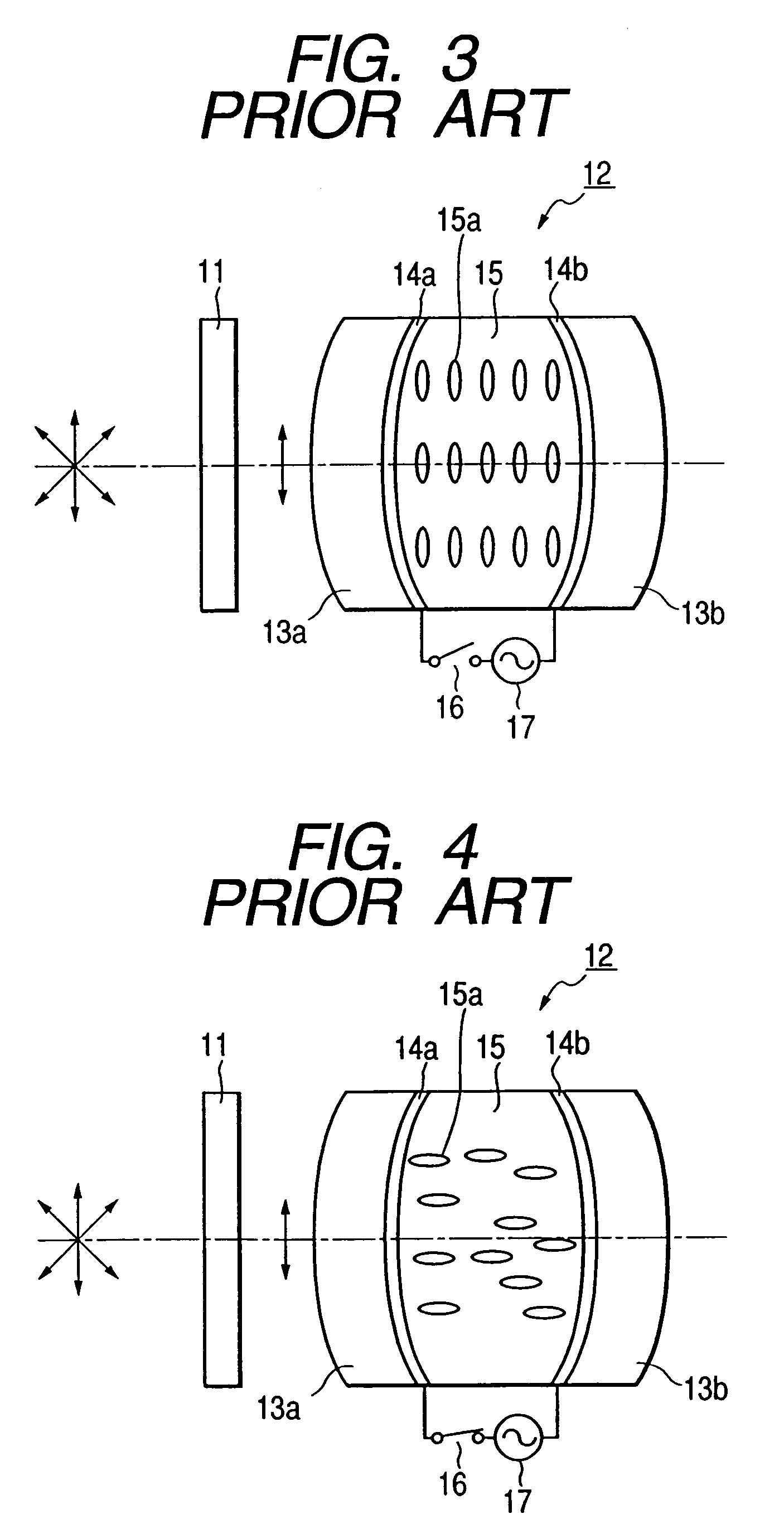

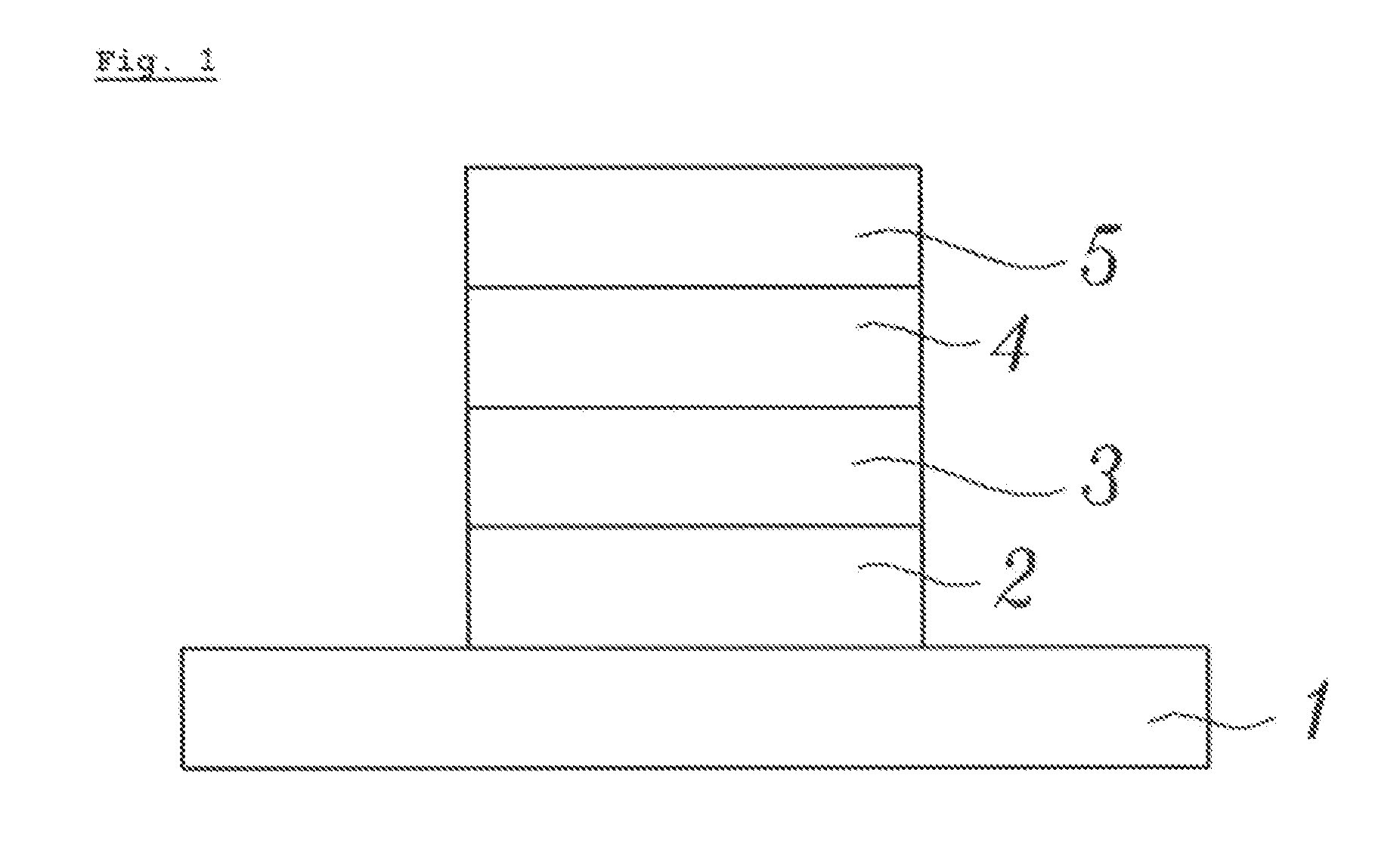

Liquid crystal display

ActiveUS20050140855A1Black luminance increaseContrast ratio is reducedNon-linear opticsLiquid-crystal displayDepolarization

A normally-closed liquid crystal display includes a component to selectively absorb characteristic leakage light occurring at black representation. Therefore, when black is displayed, occurrence of unnecessary leakage light due to partial depolarization of polarized light caused by a component of an LCD panel can be suppressed. It is therefore possible to provide a liquid crystal display in which display performance of black is improved to clearly display black.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

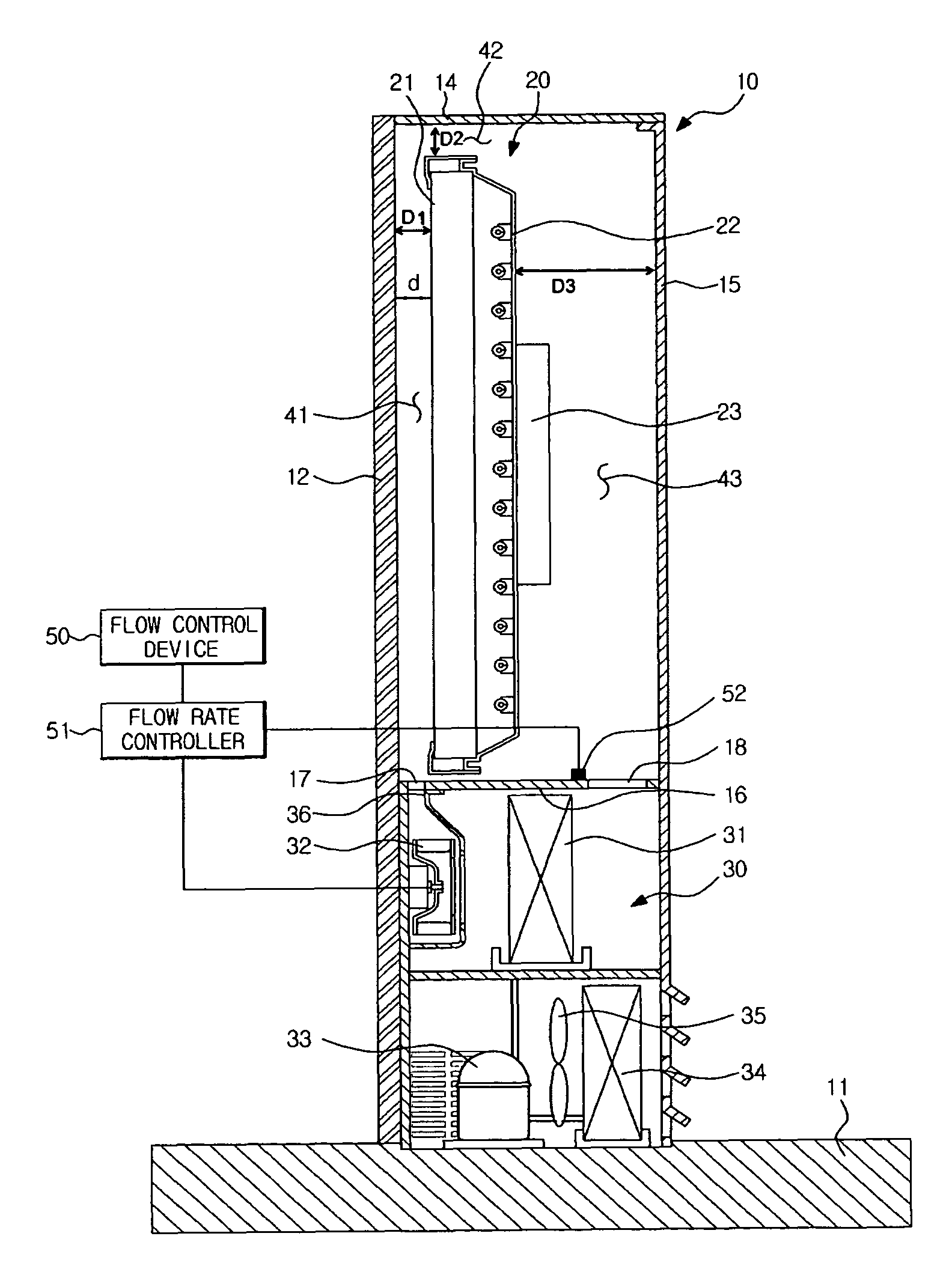

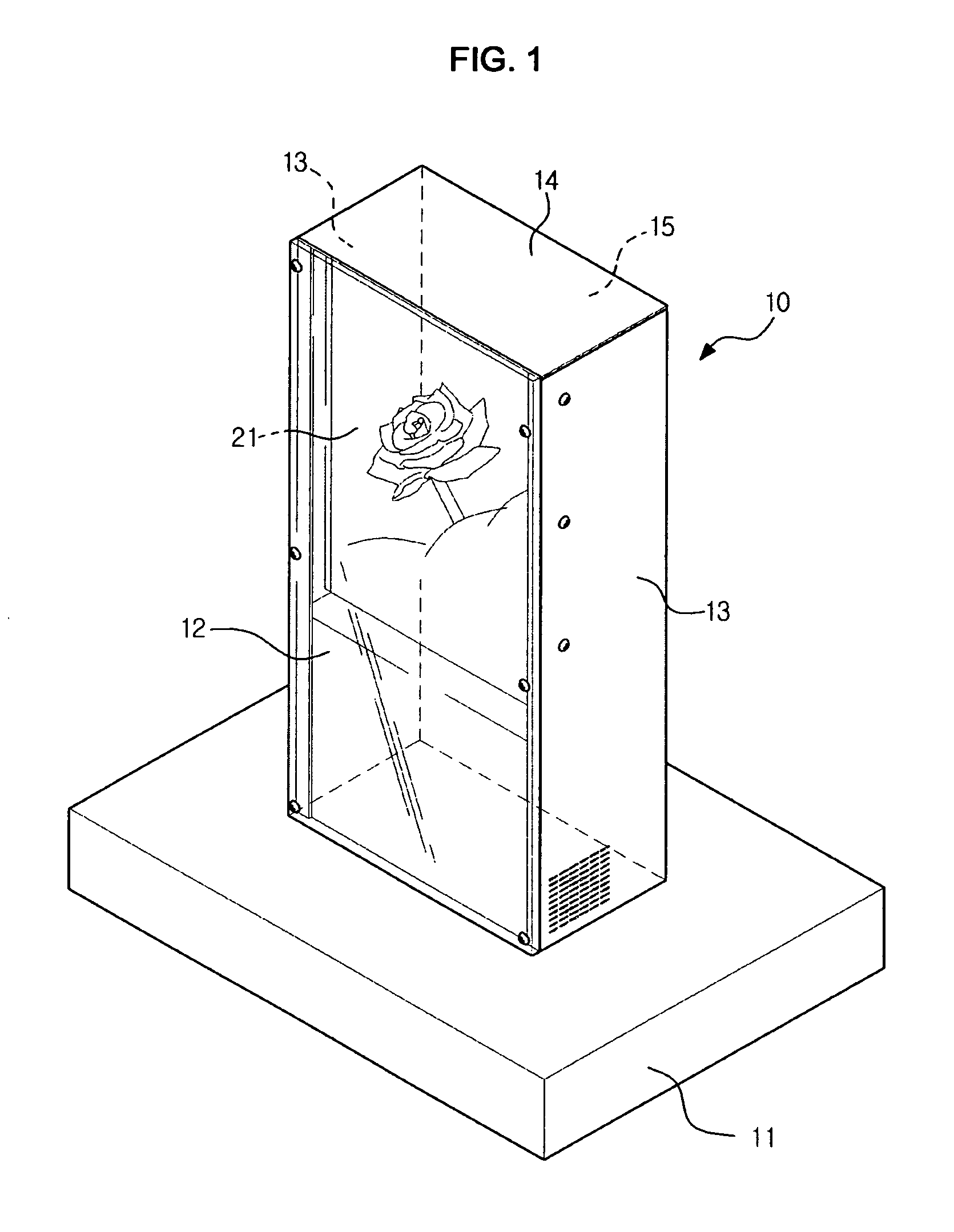

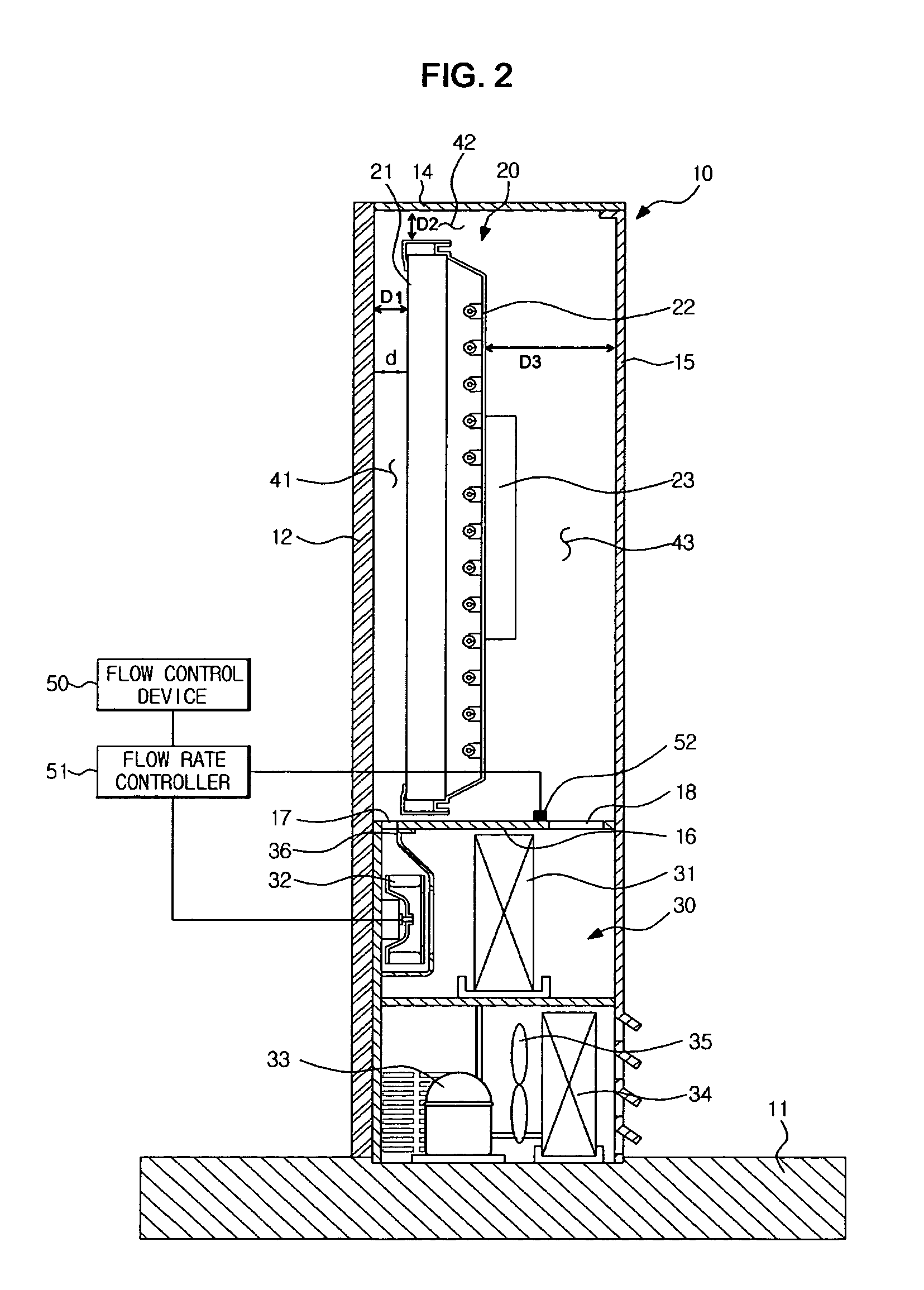

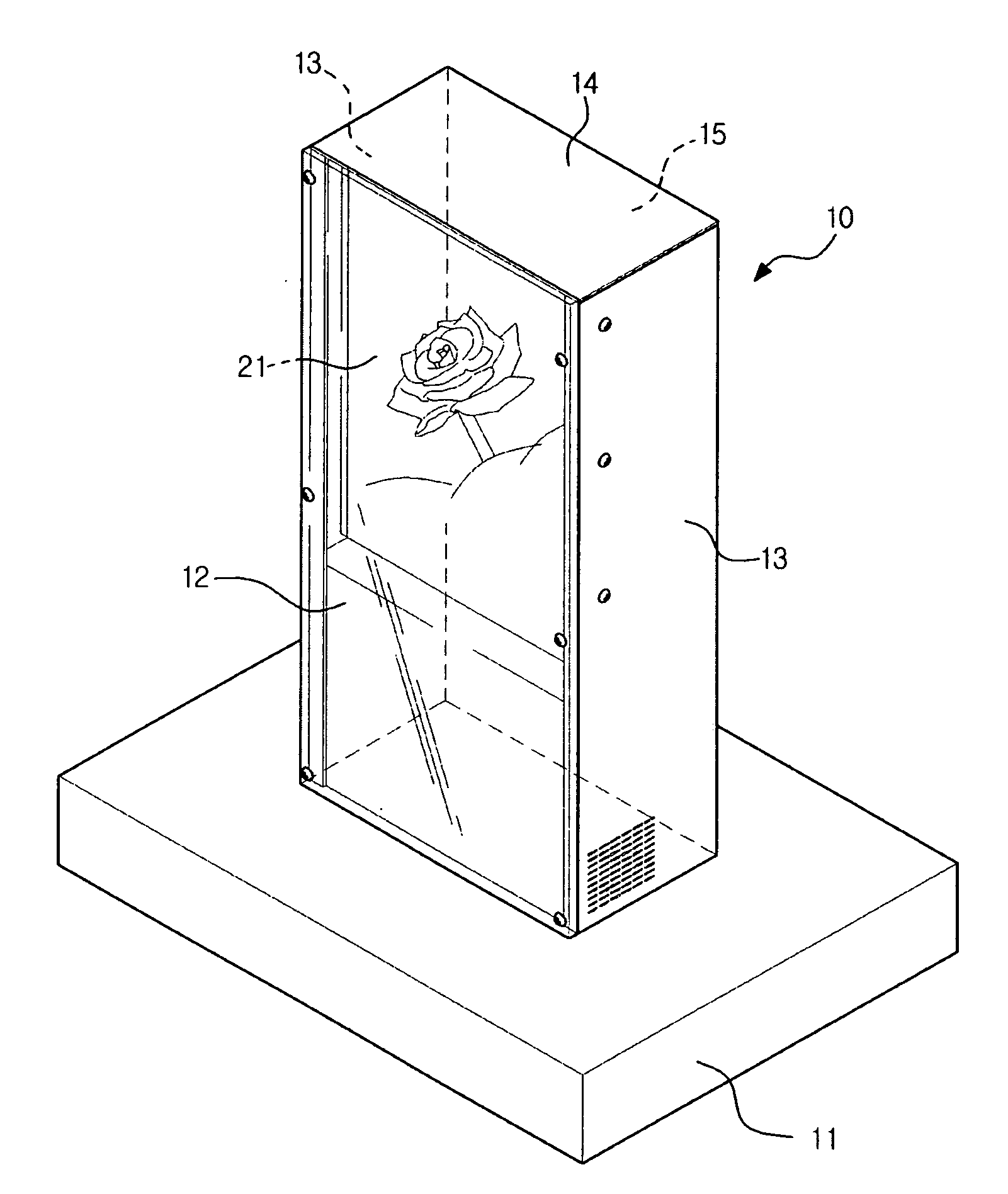

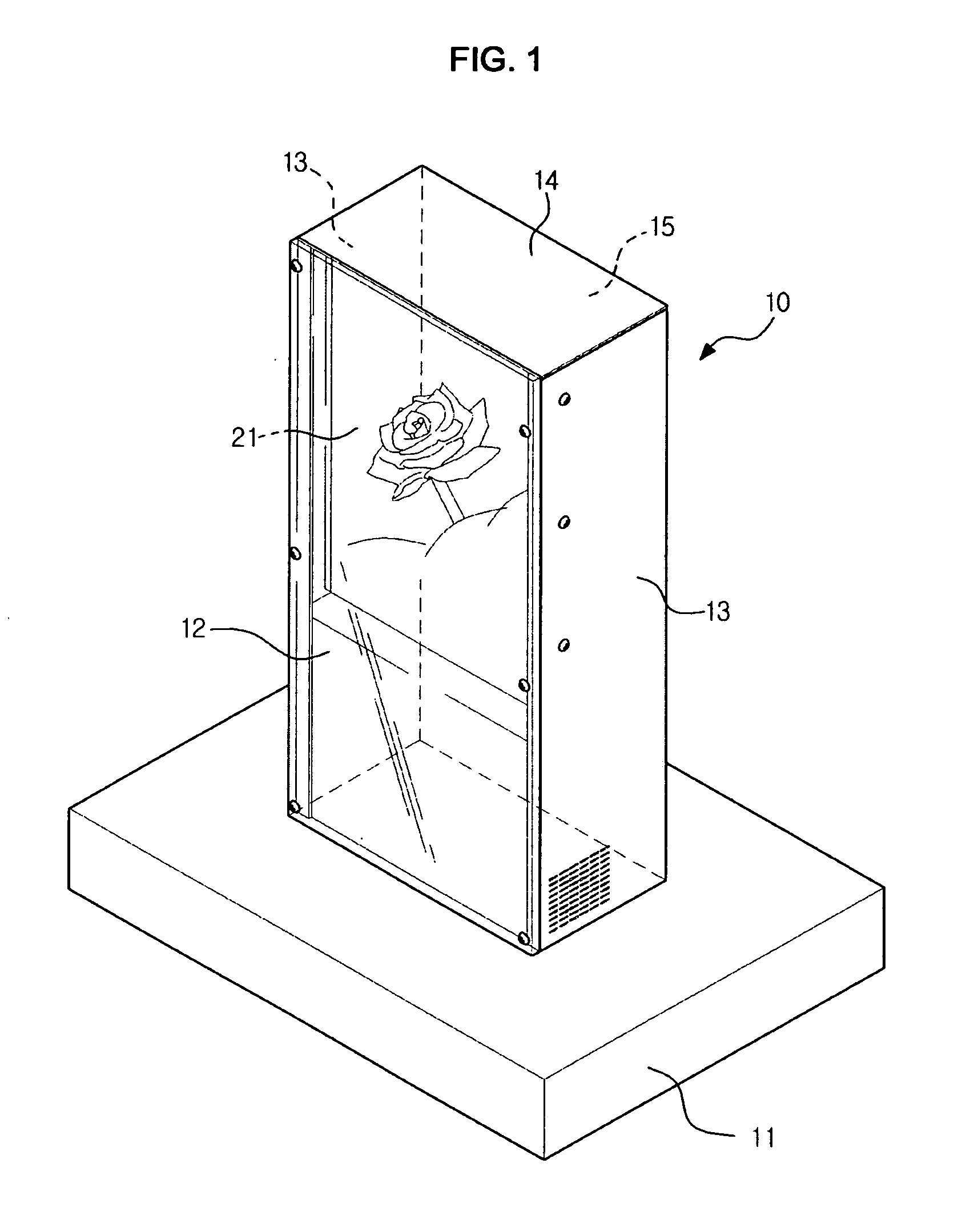

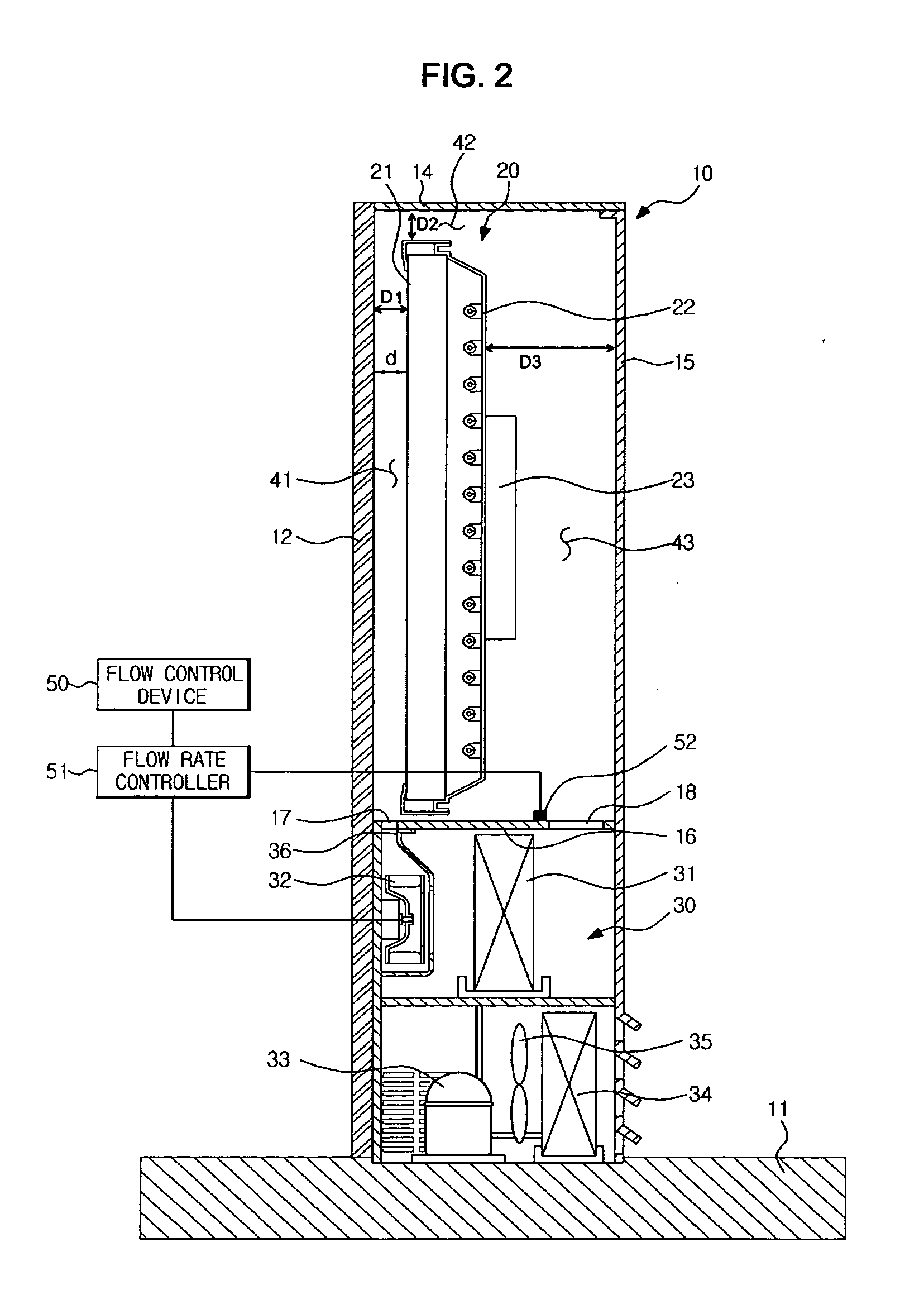

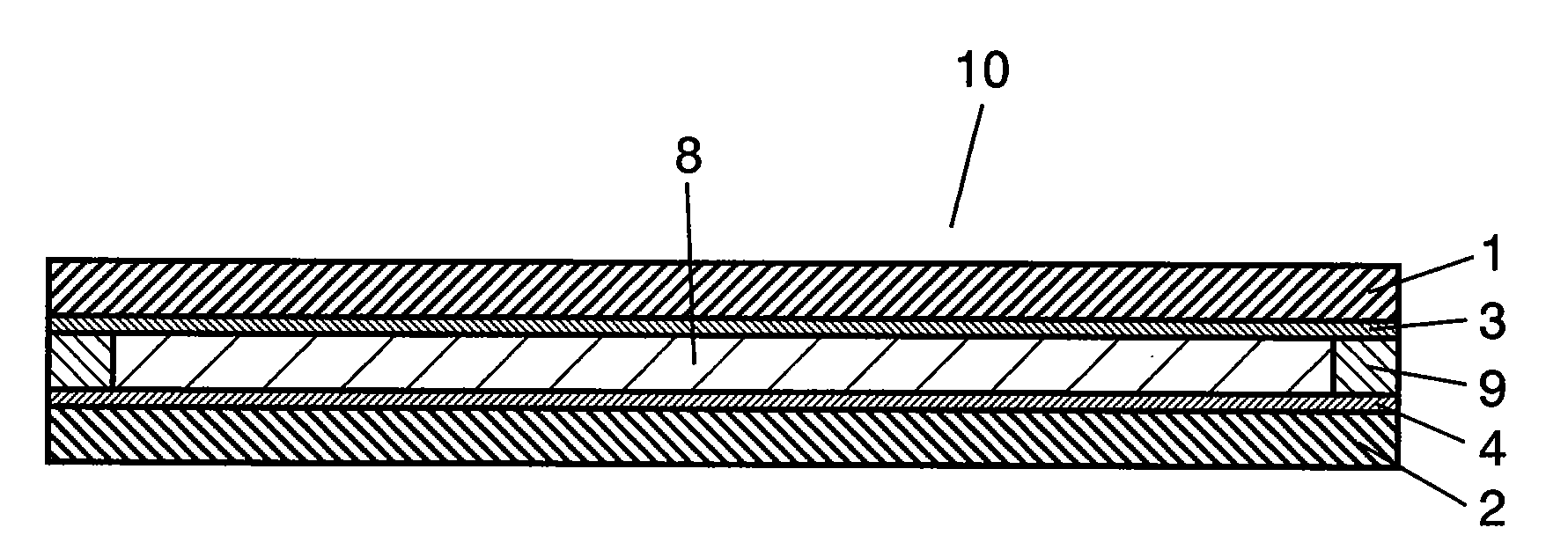

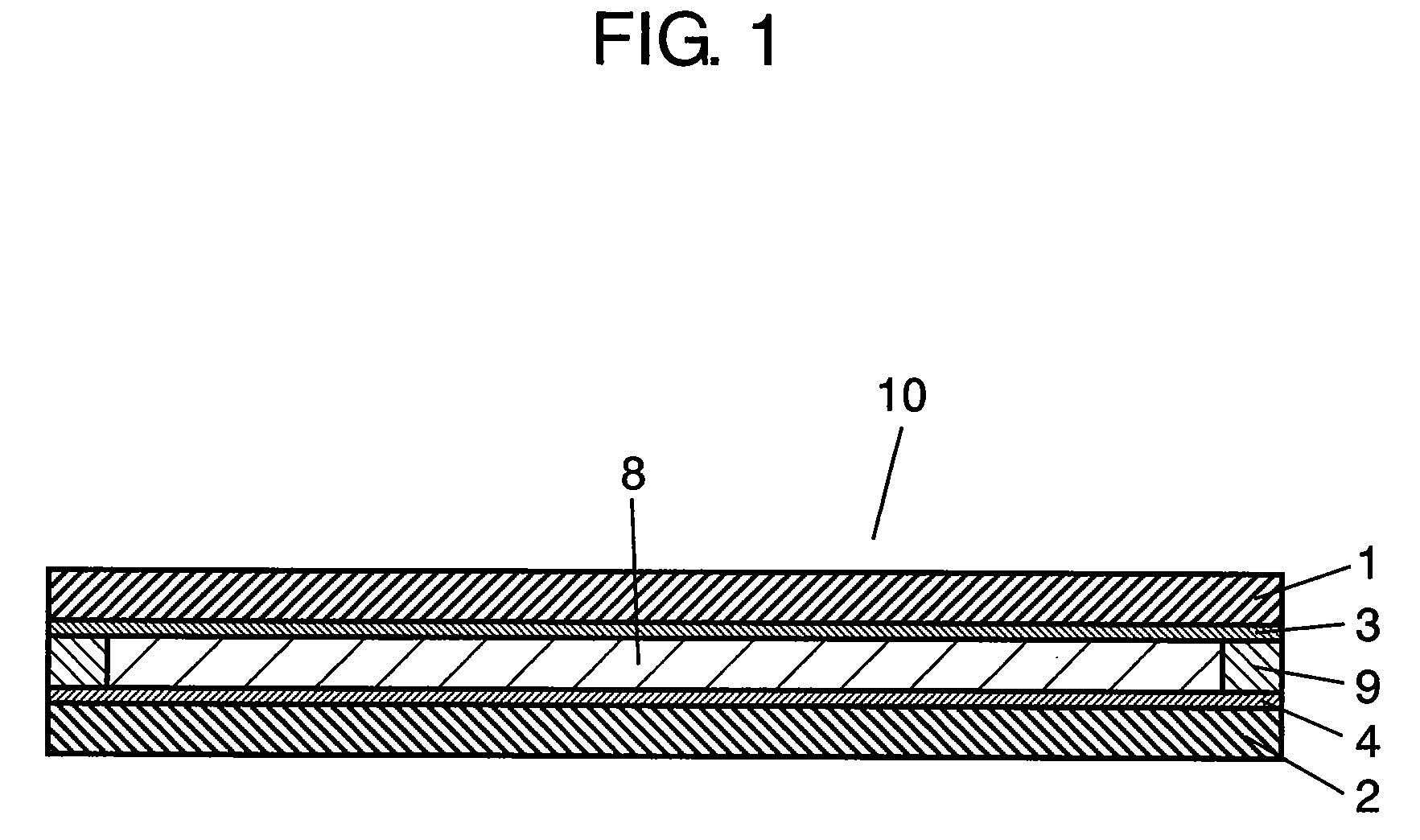

Liquid crystal display device including airflow channel

ActiveUS8223311B2Ensure effective applicationReduce power consumptionStatic indicating devicesElectrical apparatus contructional detailsLiquid-crystal displayEngineering

A liquid crystal display device includes a liquid crystal panel, a protection panel arranged a predetermined distant from the liquid crystal panel, and a flow control device to impart turbulence to an air flow in a channel, which is defined between the liquid crystal panel and the protection panel.

Owner:SAMSUNG ELECTRONICS CO LTD

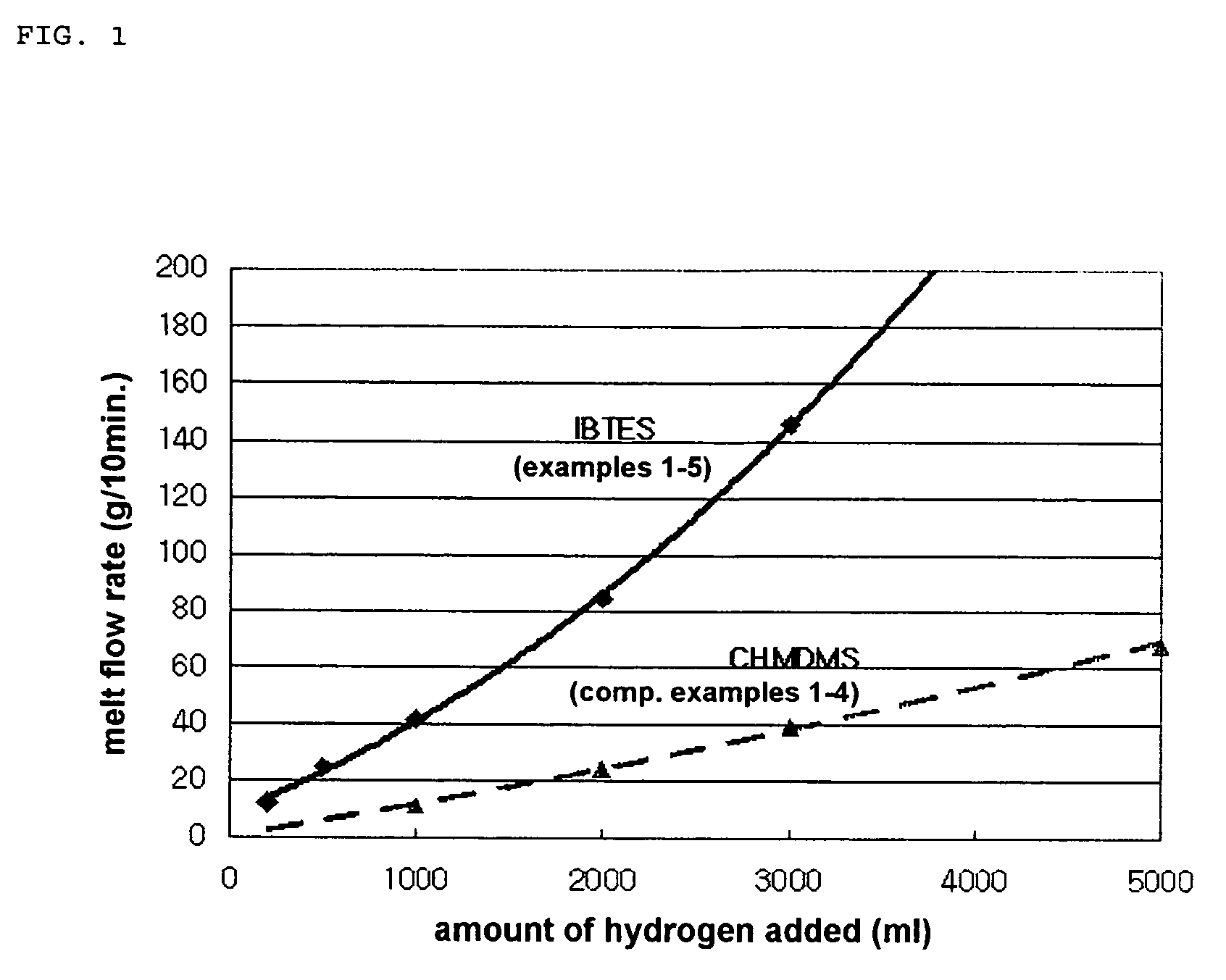

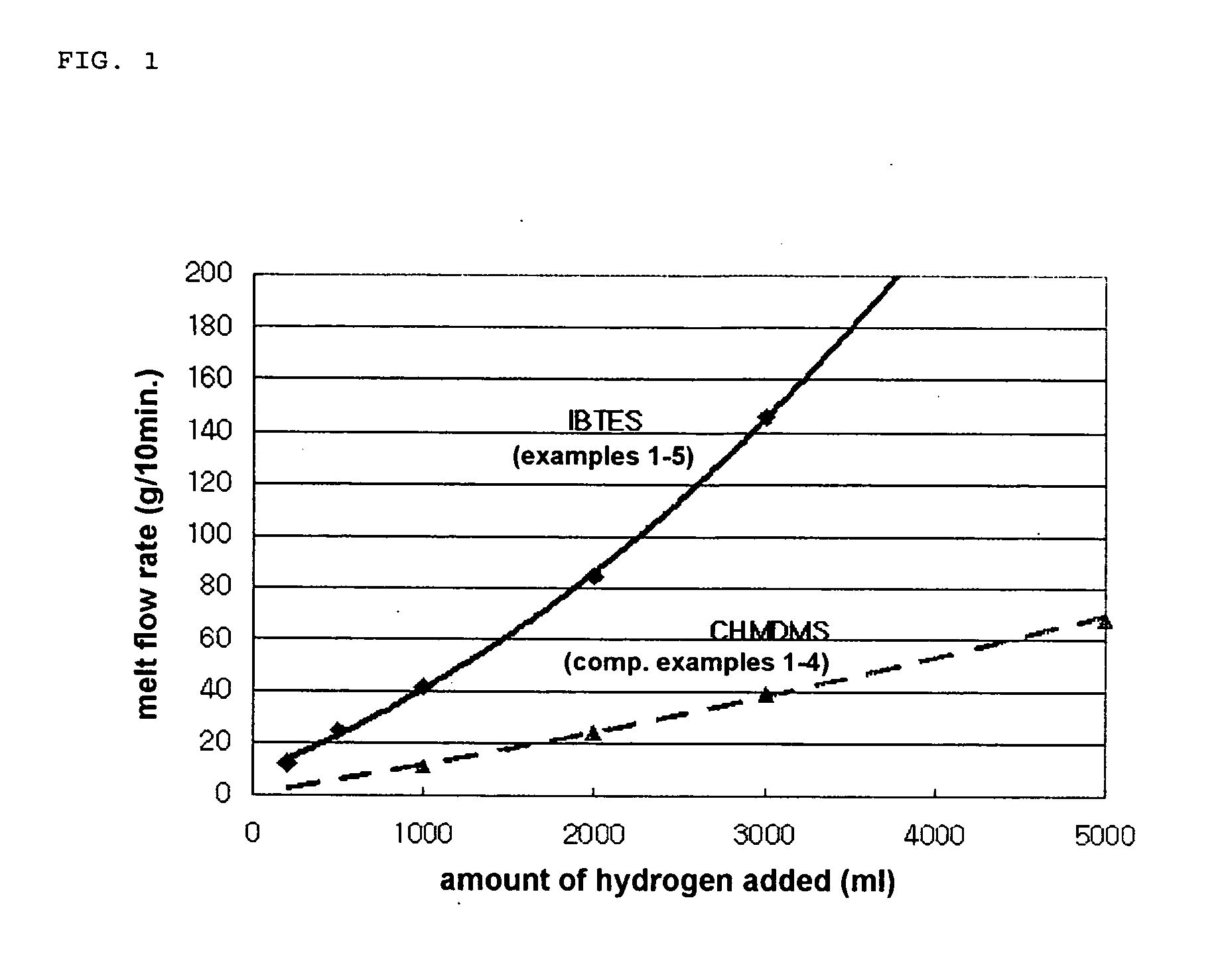

Method for producing propylene polymer having a very high melt-flowability

ActiveUS7244794B2Ensure effective applicationHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

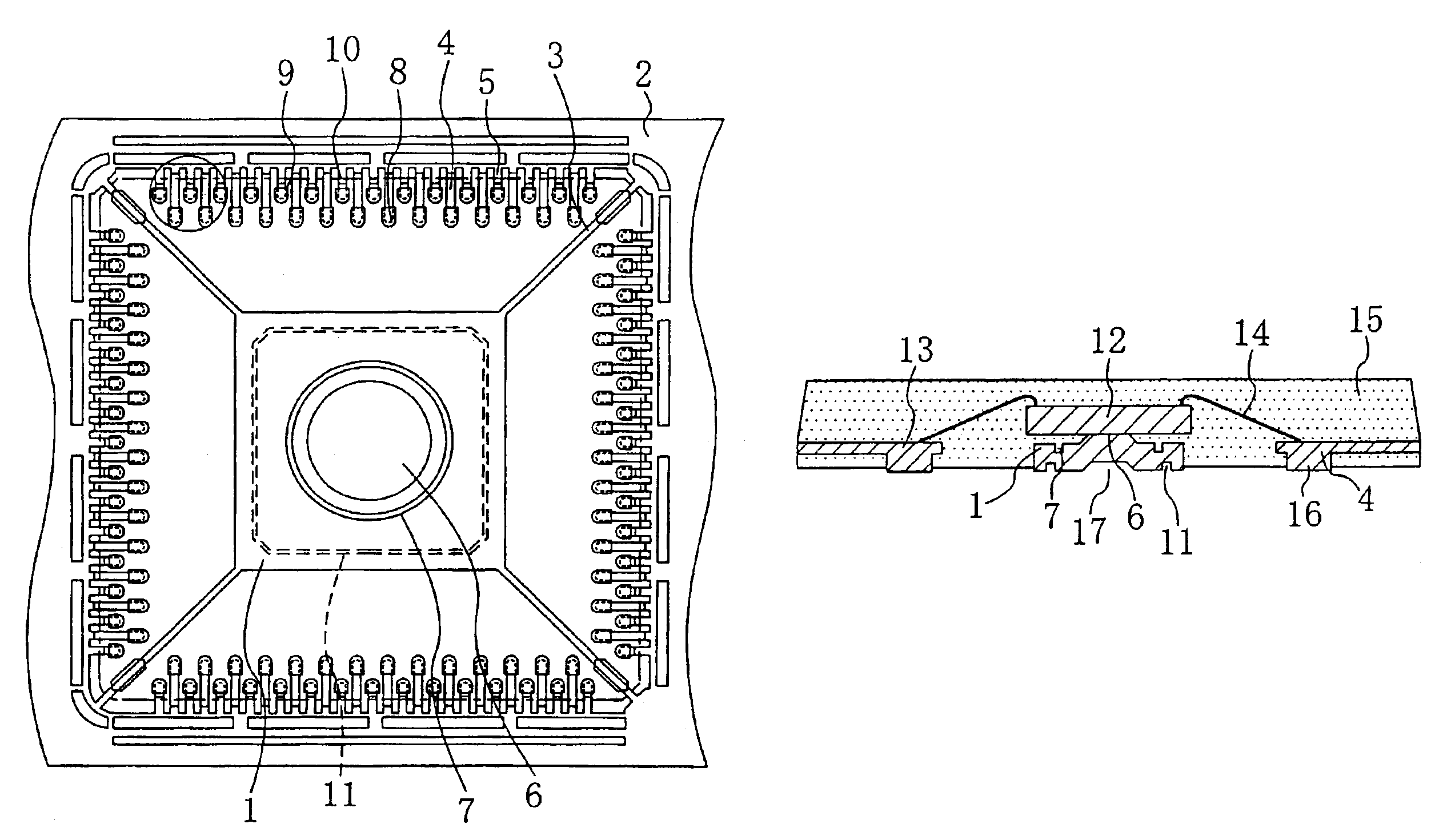

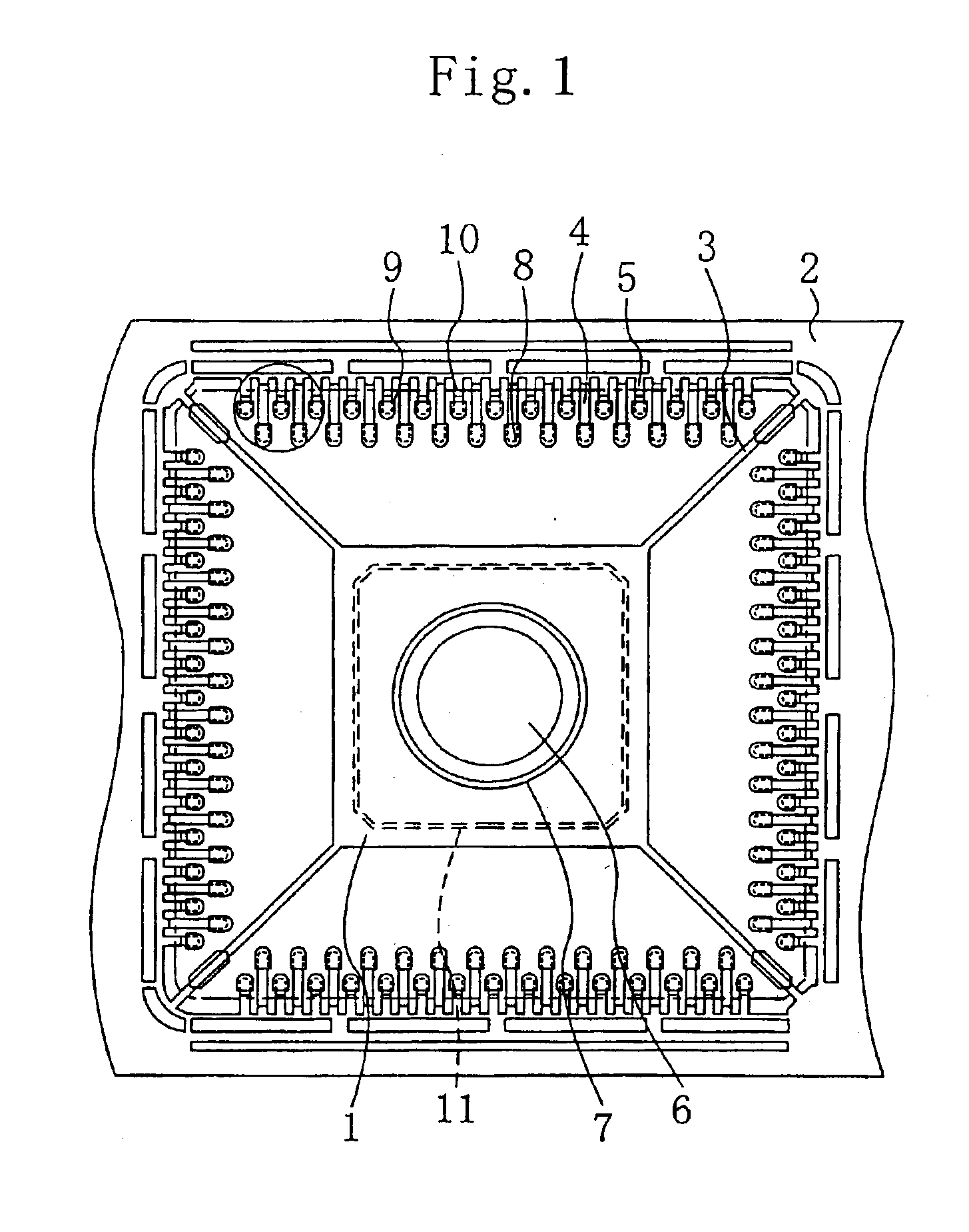

Resin-molded semiconductor device

InactiveUS6861734B2Ensure effective applicationPrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialEngineering

In a leadframe for an LGA package, a lead member is pressed downward to form a land lead with a half-cut portion and a land portion. The land portion, whose bottom will be a land electrode, is inclined at a predetermined angle and the bottom of the land portion is made lower than that of a lead. Thus, in a resin molding process using a seal sheet, the land electrode is forced into, and strongly adhered to, the seal sheet when pressure is applied through dies, and no resin encapsulant reaches the land electrode. As a result, no resin bur will be left on the land electrode of the land lead.

Owner:III HLDG 12 LLC

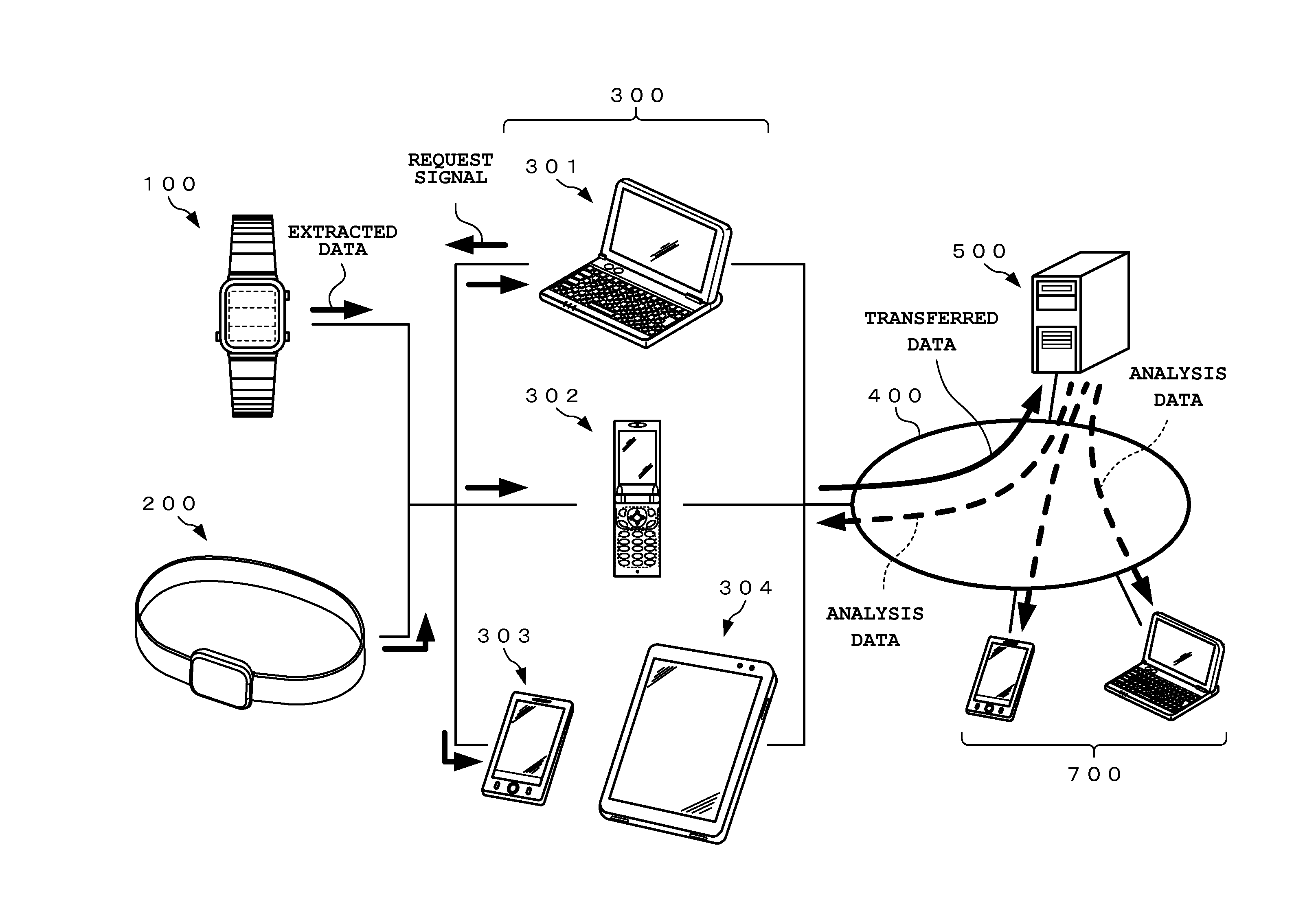

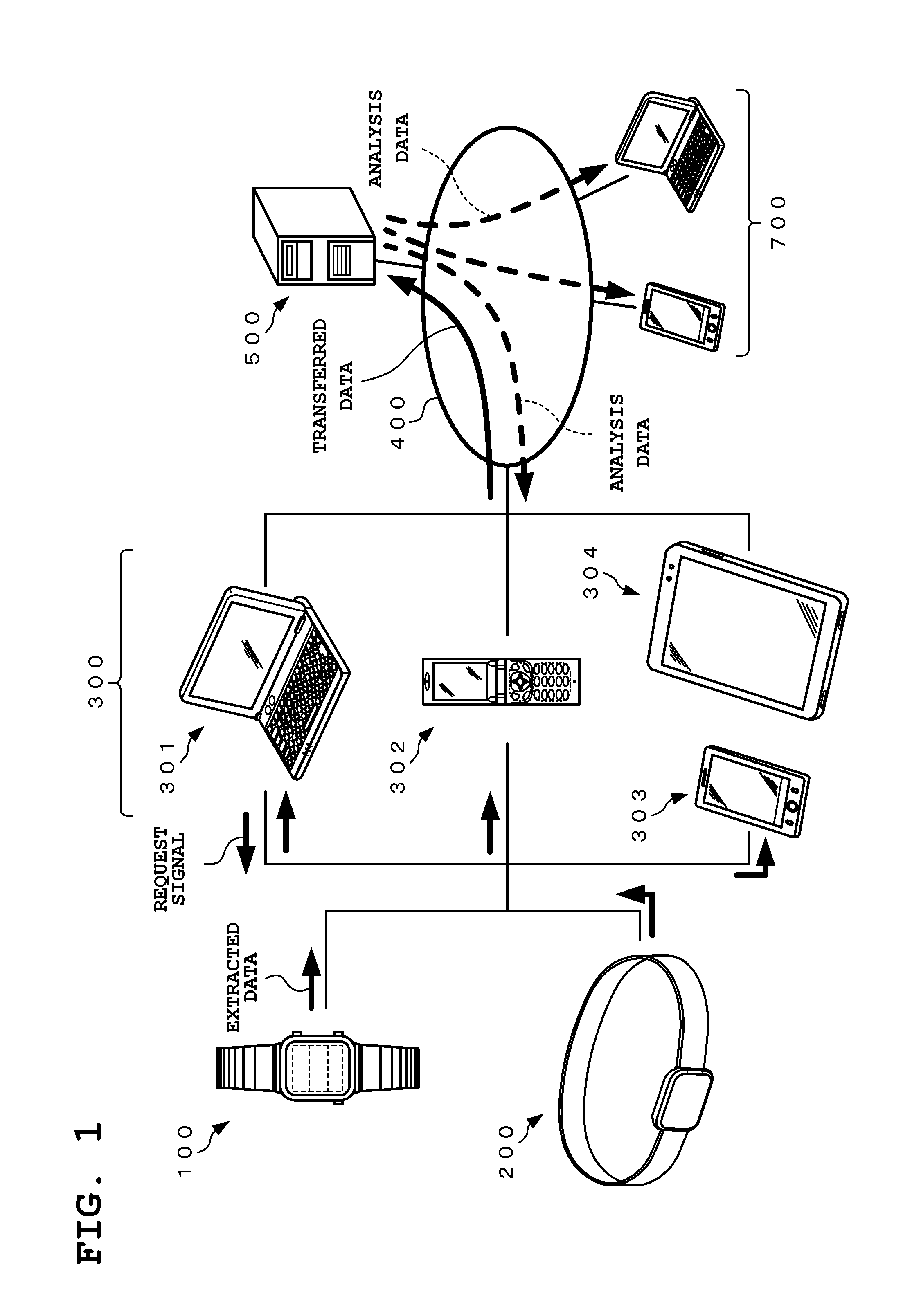

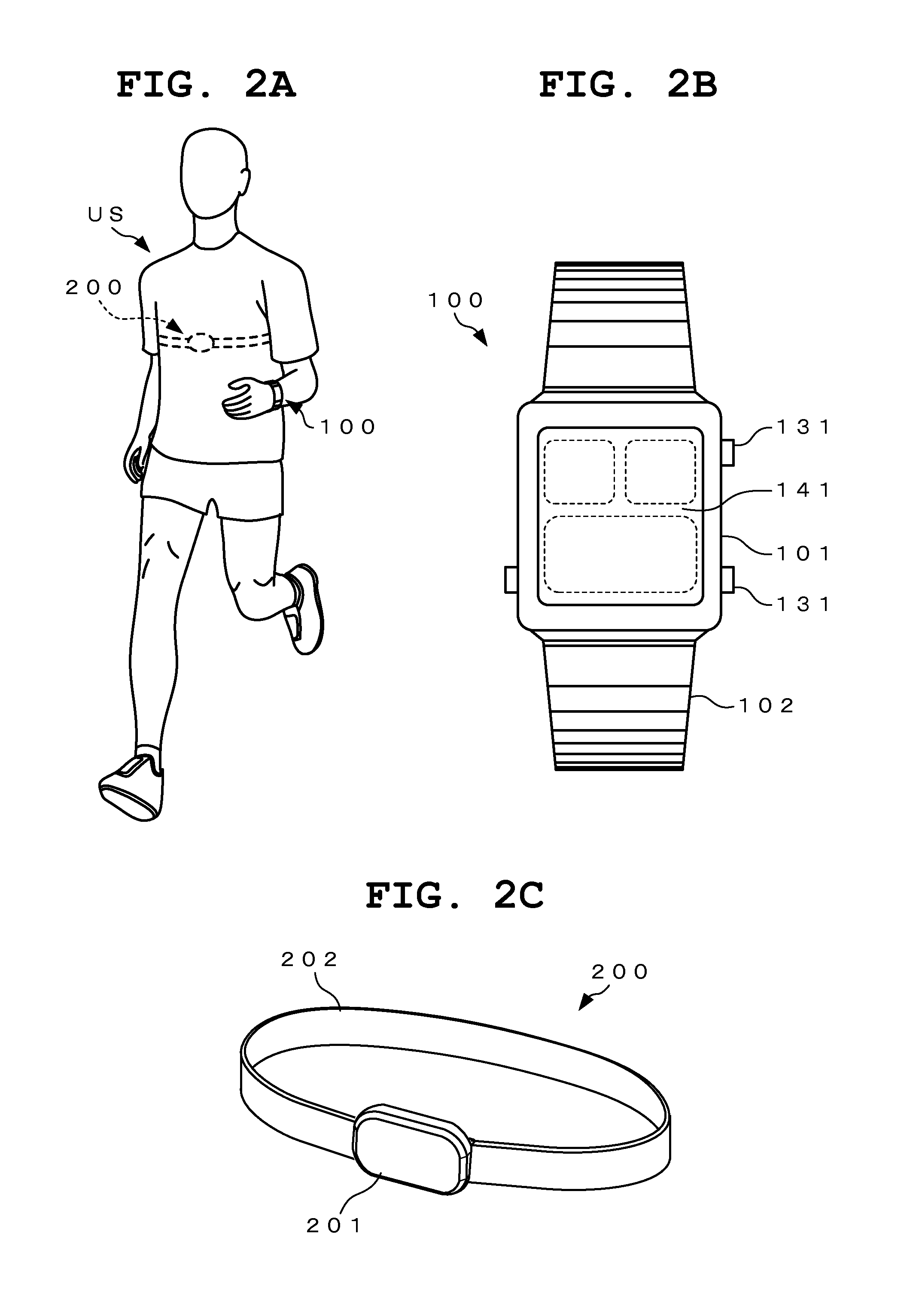

Sensor data extraction system, sensor data extraction method, and computer-readable storage medium having sensor data extraction program stored thereon

InactiveUS20140172132A1Ensure effective applicationPhysical therapies and activitiesPower managementData matchingData ingestion

A sensor data extraction system of the present invention includes an exercise data obtaining section which obtains exercise data related to an exercise status of a human body, an extraction condition specifying section which specifies an extraction condition for extracting a portion required for analysis processing using the exercise data, from among the exercise data obtained by the exercise data obtaining section, a data extracting section which extracts exercise data matching the extraction condition from among the exercise data obtained by the exercise data obtaining section, a data transfer section which transfers the extracted exercise data from the exercise data obtaining section, and a data analyzing section which performs the analysis processing by using the exercise data transferred by the data transfer section.

Owner:CASIO COMPUTER CO LTD

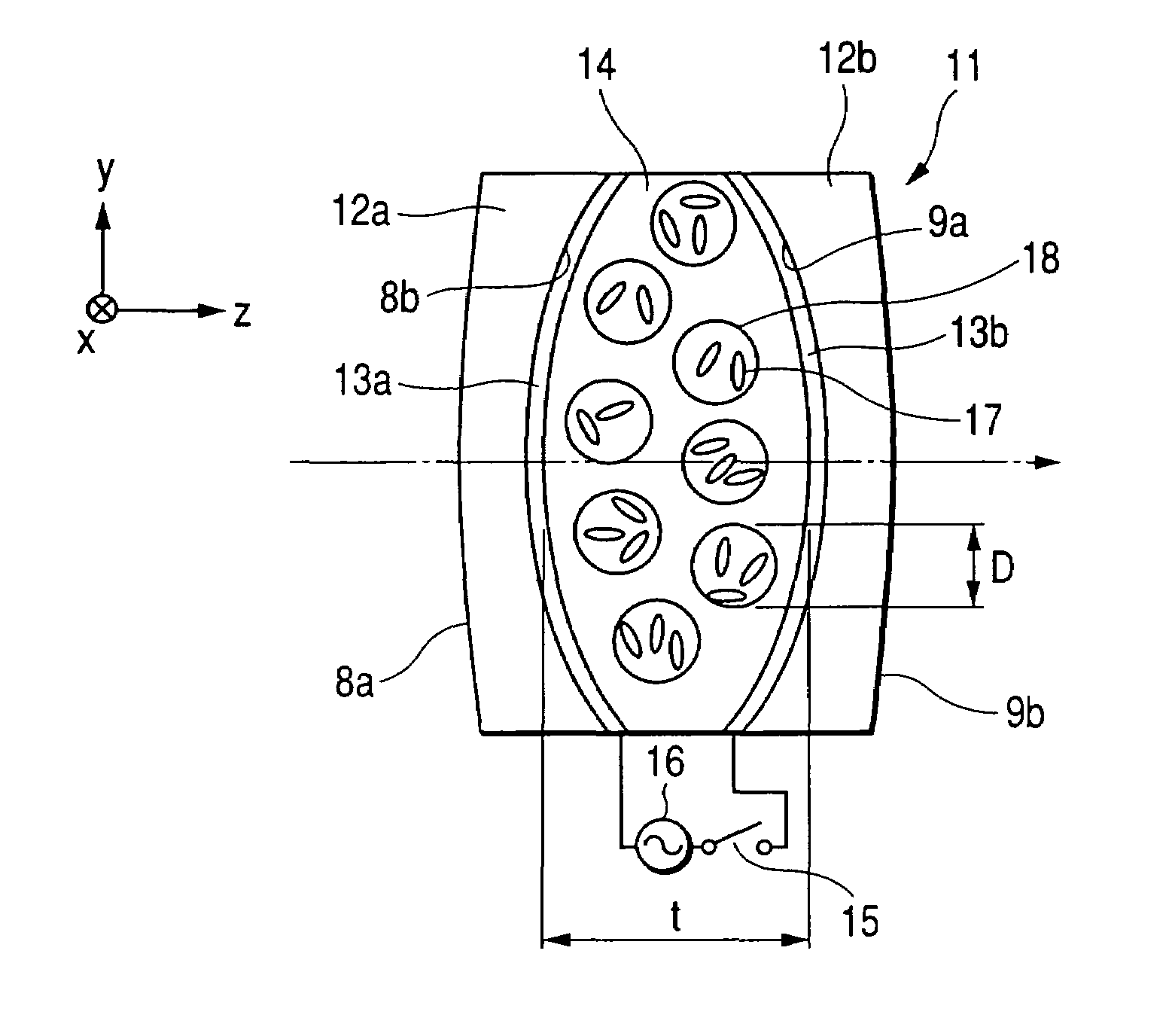

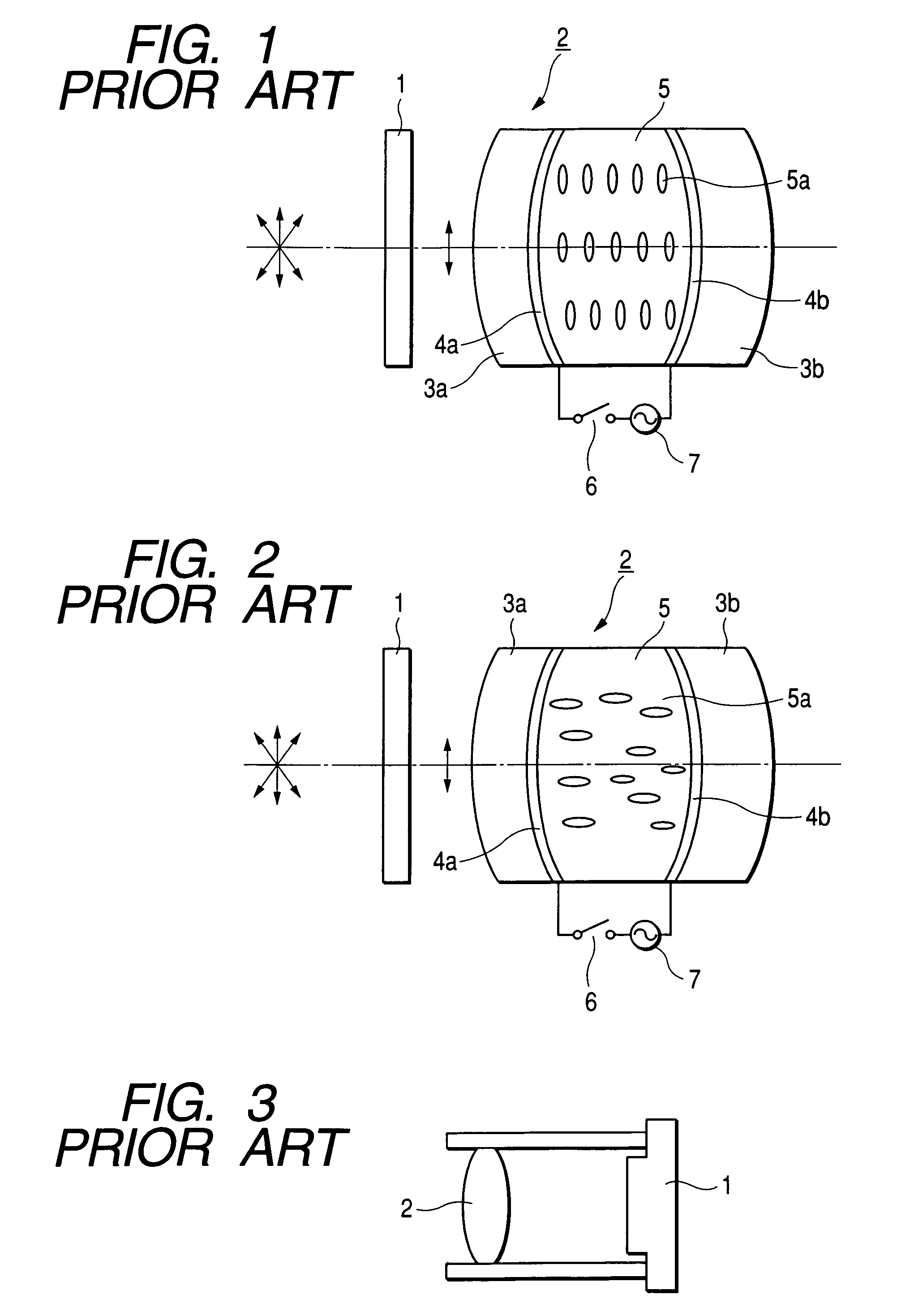

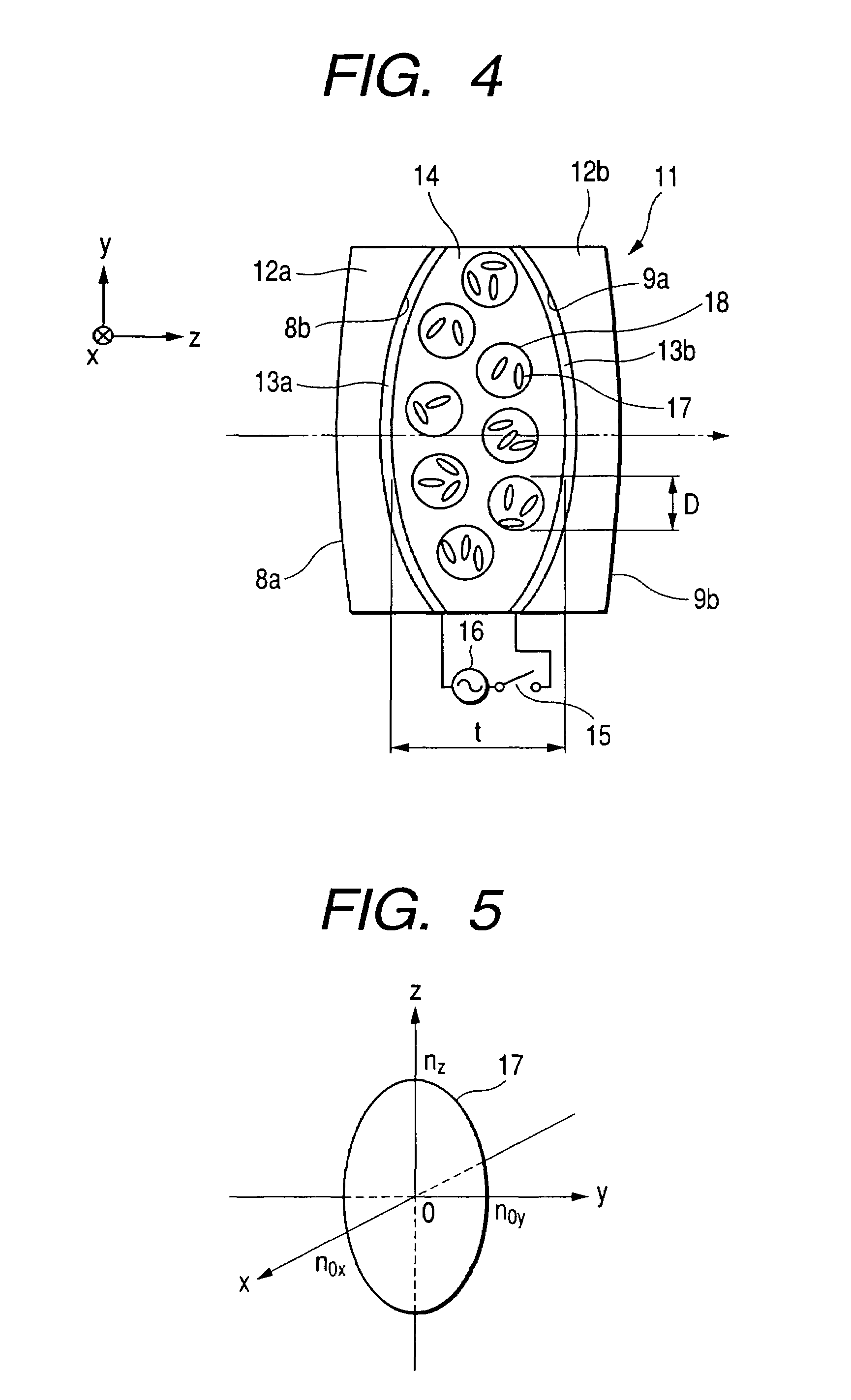

Variable optical-property element and optical apparatus including the same

InactiveUS7369327B1No loss in amountSimple structureEndoscopesCamera body detailsOptical propertyRefractive index

A variable optical-property element includes a liquid crystal the pitch of twist is less than 60 times the wavelength of light used, so that a spatially uneven electric or magnetic field or temperature is applied to the liquid crystal to thereby form an index distribution, and the electric or magnetic field or the temperature is changed to thereby alter the index distribution. In this way, the variable optical-property element is capable of changing its optical properties as a liquid crystal lens and is used in an optical apparatus.

Owner:OLYMPUS CORP

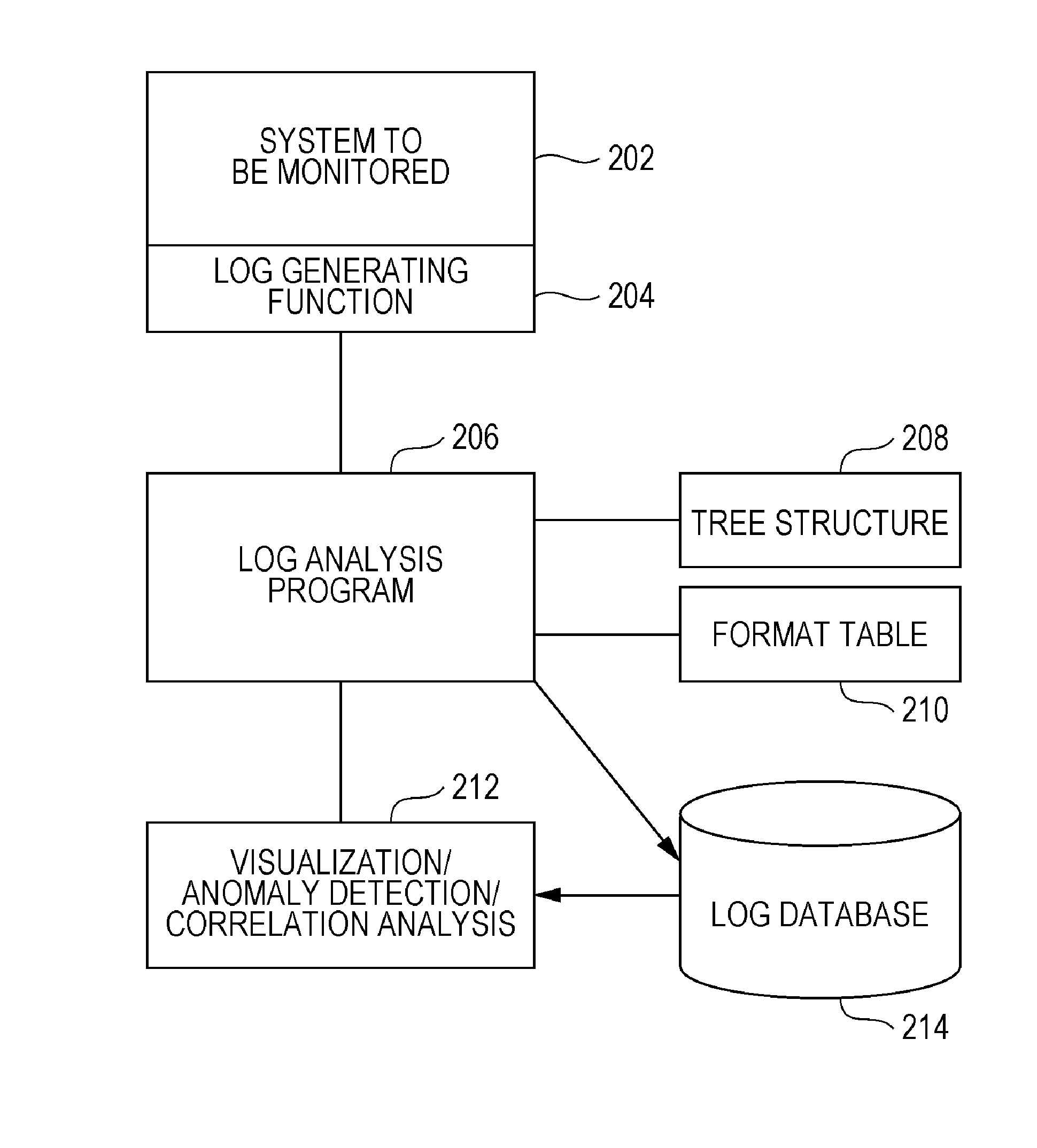

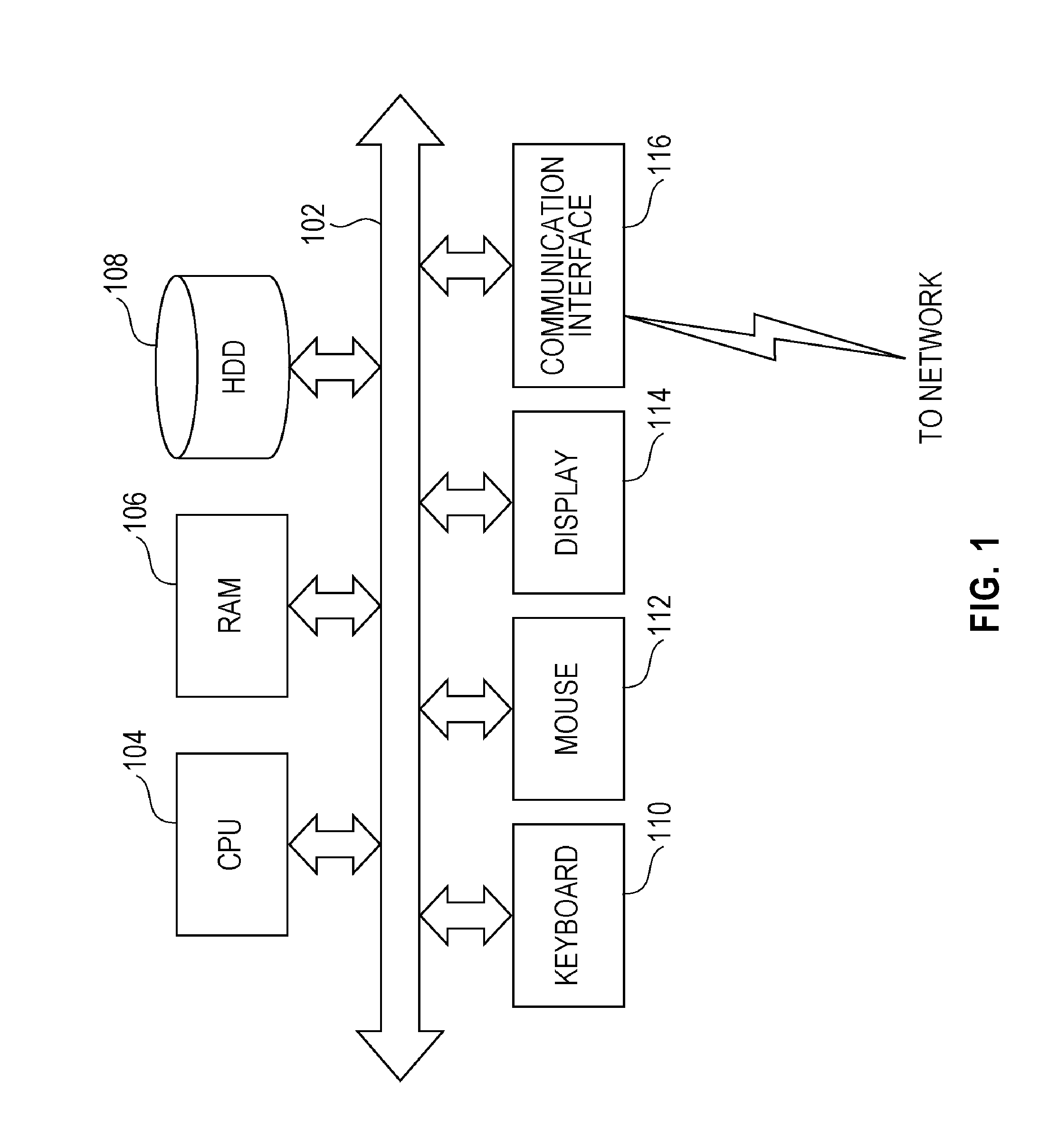

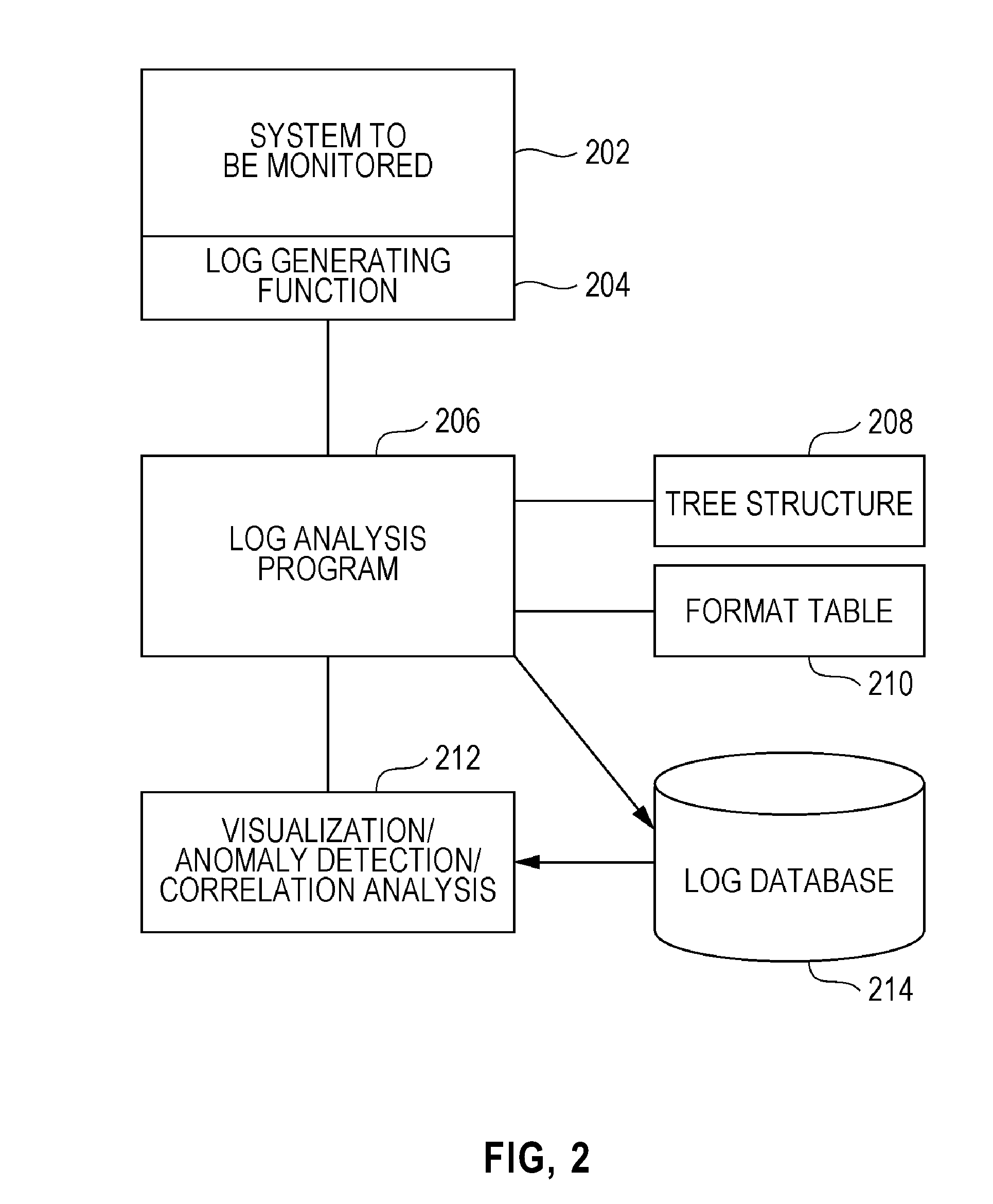

Method, program, and system for classification of system log

InactiveUS20140324865A1Avoid excess performanceEnsure effective applicationDigital data processing detailsNon-redundant fault processingData processing systemData mining

Method and system for classifying system logs. A data processing system reads a message in one line of a system log; prepares a root node of a tree structure in which each node holds a format; calculates a similarity between a log of the root node and the message; generates and stores a first format in the root node if the calculated similarity is equal to or greater than a threshold value; adds the message to a child node of the root node, in accordance with a given condition; searches for, after the first format is created, a second format similar to the first format in a format storage table; combines the first format and the similar format to produce a combined parent format, where the combined parent format holds a plurality of formats; and stores the combined parent format in the format storage table to produce a classified format.

Owner:IBM CORP

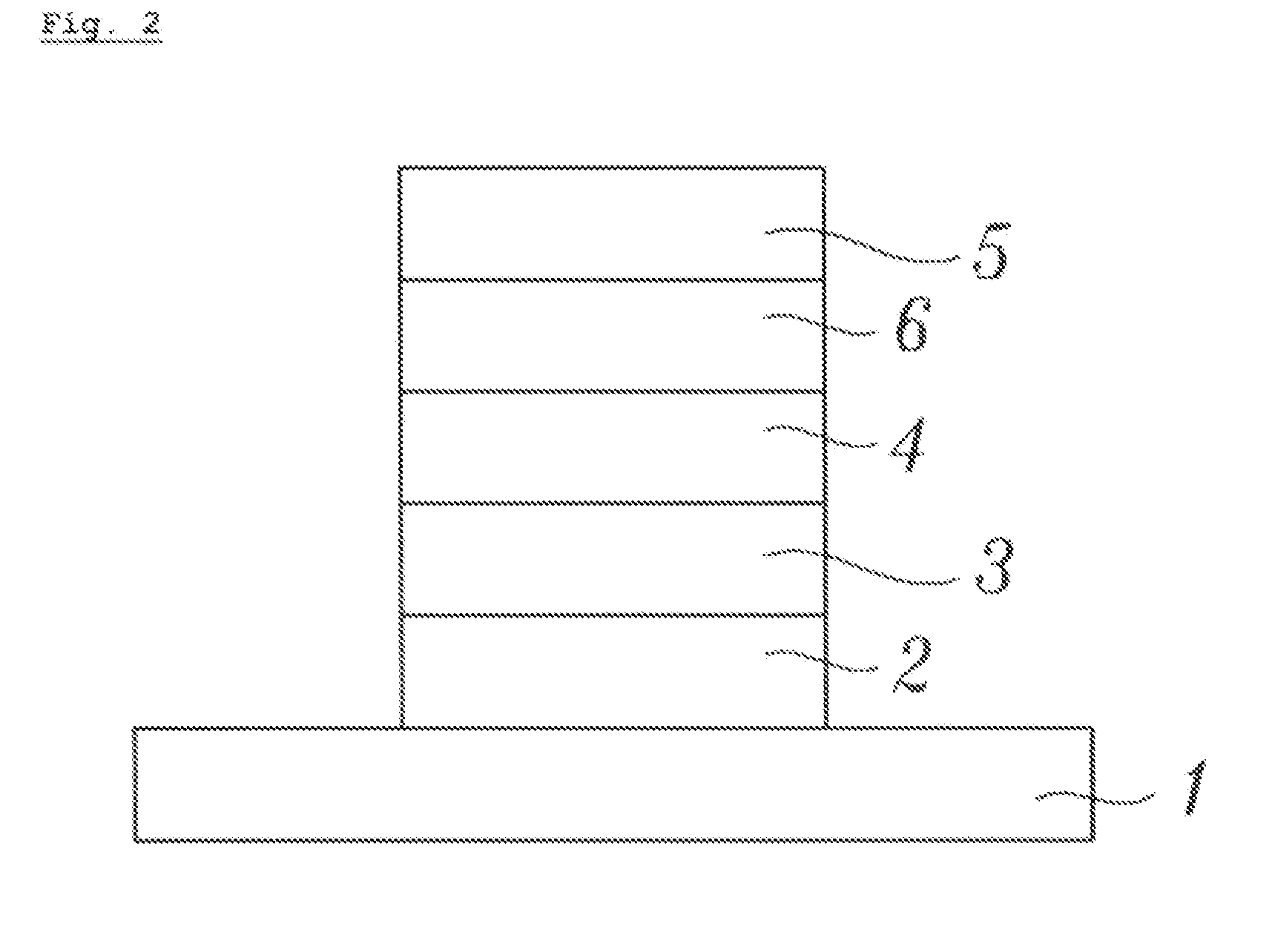

Liquid crystal display device

ActiveUS20090310059A1Reduce power consumptionEnsure effective applicationStatic indicating devicesElectrical apparatus contructional detailsLiquid-crystal displayEngineering

A liquid crystal display device includes a liquid crystal panel, a protection panel arranged a predetermined distant from the liquid crystal panel, and a flow control device to impart turbulence to an air flow in a channel, which is defined between the liquid crystal panel and the protection panel.

Owner:SAMSUNG ELECTRONICS CO LTD

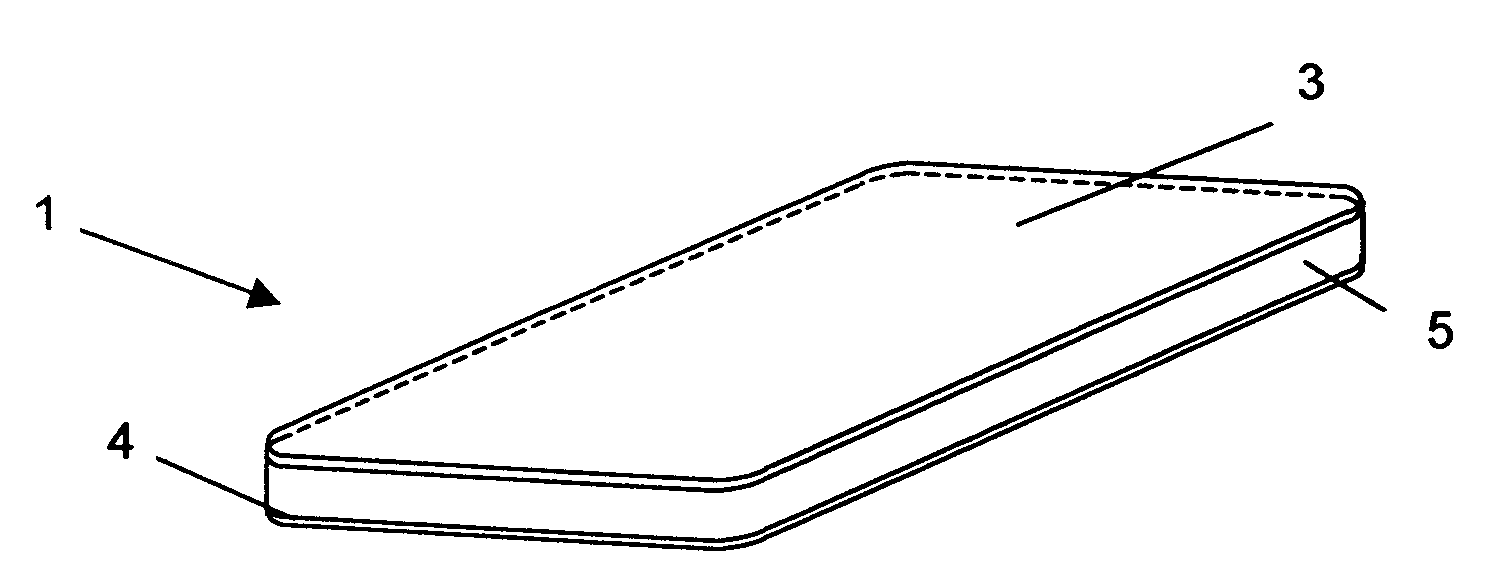

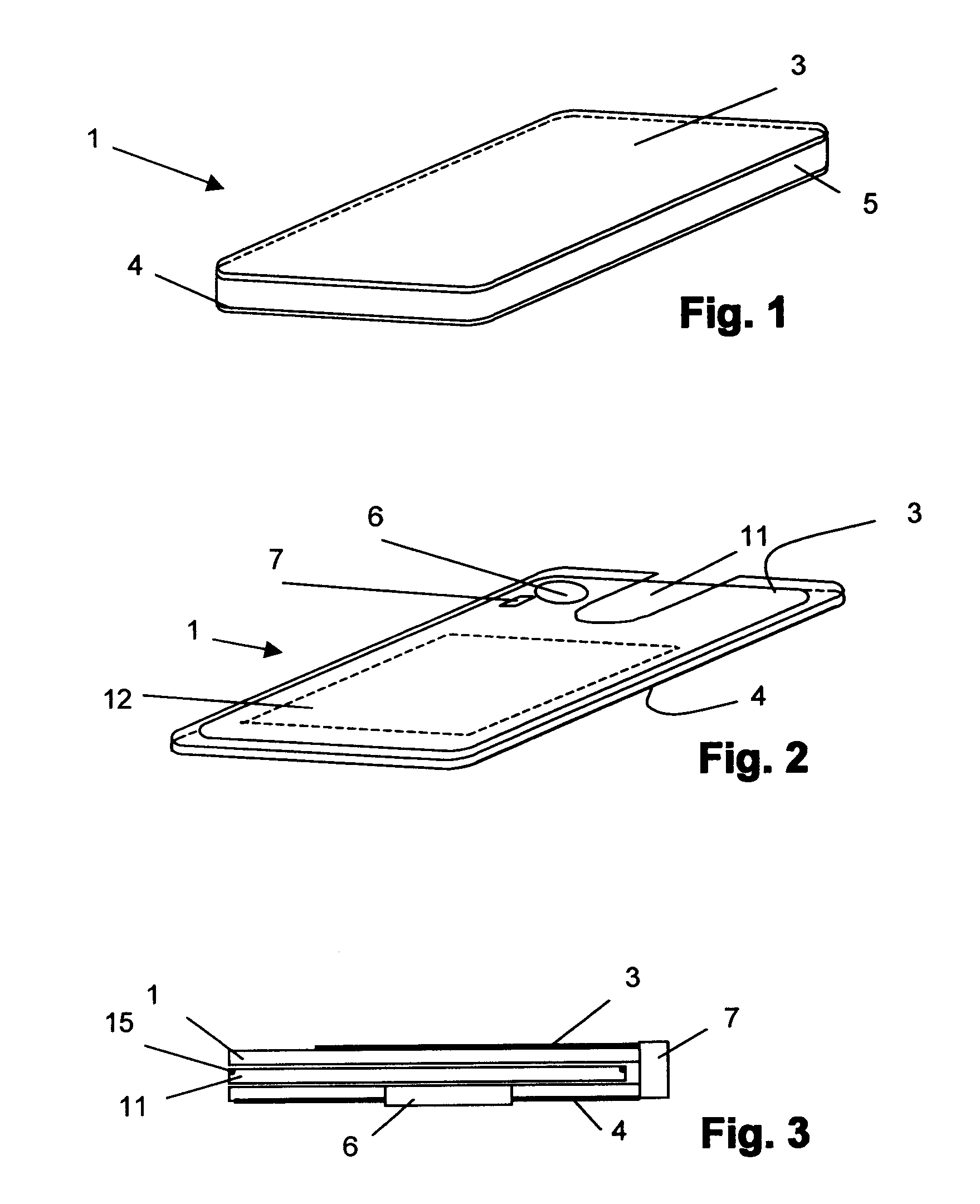

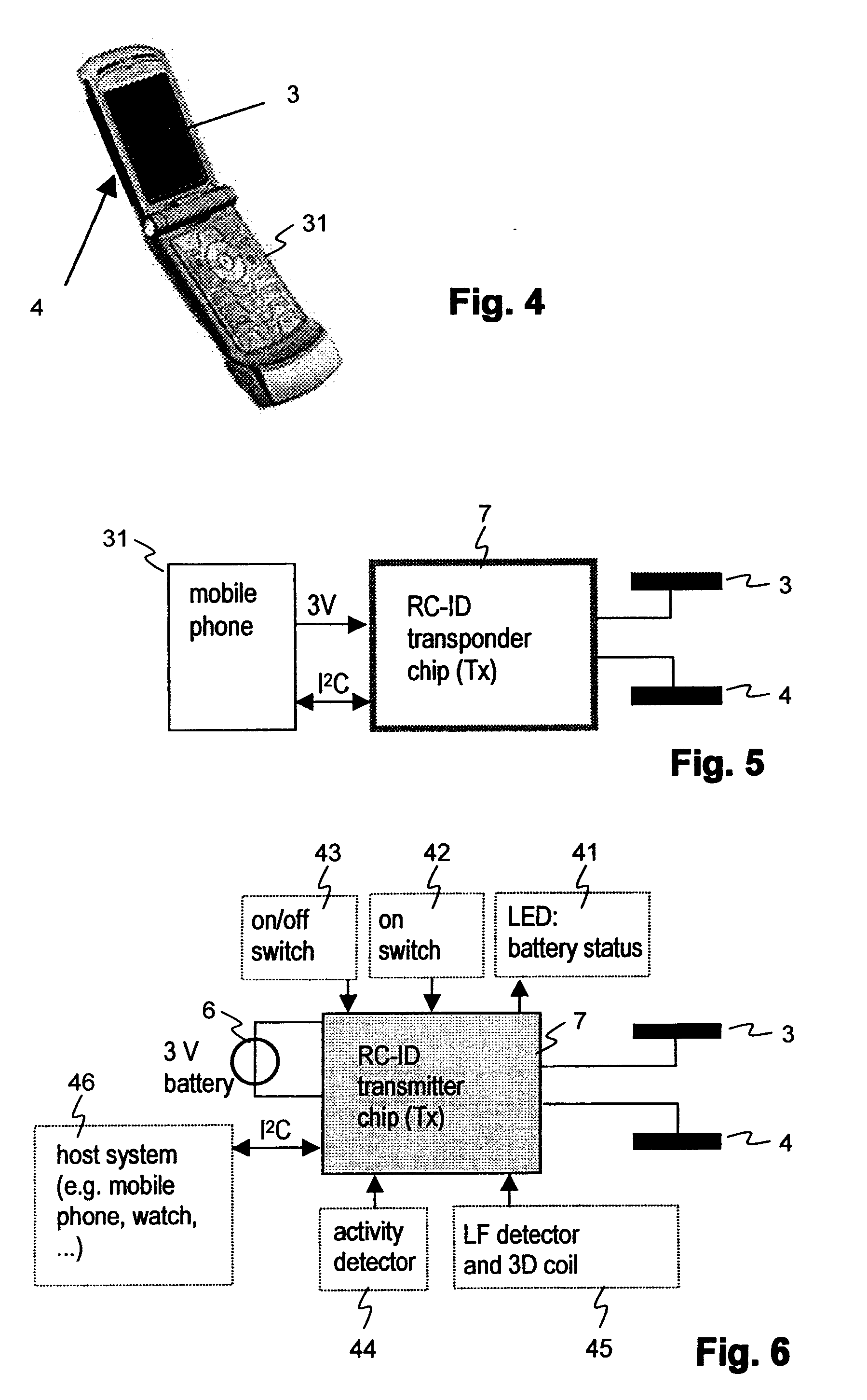

System and portable device for transmitting identification signals

InactiveUS20100048127A1Extend battery lifeSaving in power consumptionNear-field transmissionIndividual entry/exit registersElectricityApplication-specific integrated circuit

A system is provided with a portable device (31) for the transmission of signals to a second device, wherein the portable device (31) is wearable on the body of a user. The portable device (31) includes at least two electrodes (3, 4) and transmitter electronics (7) for applying an electrical signal between the electrodes, in such a way that the signal between the electrodes (3, 4) is able to be coupled into the body of the user and detected by at least one electrode of the second device. The transmitter electronics are an application specific integrated circuit and thus include both means for the production of electrical signals that are dependent upon specified data, as well as means for applying the electrical signal between the electrodes. The means for generating electrical signals that are dependent upon specified data are typically digital circuits for the encoding of specified data that are to be transmitted and for the modulation of the data that are so encoded.

Owner:DORMAKABA SCHWEIZ AG

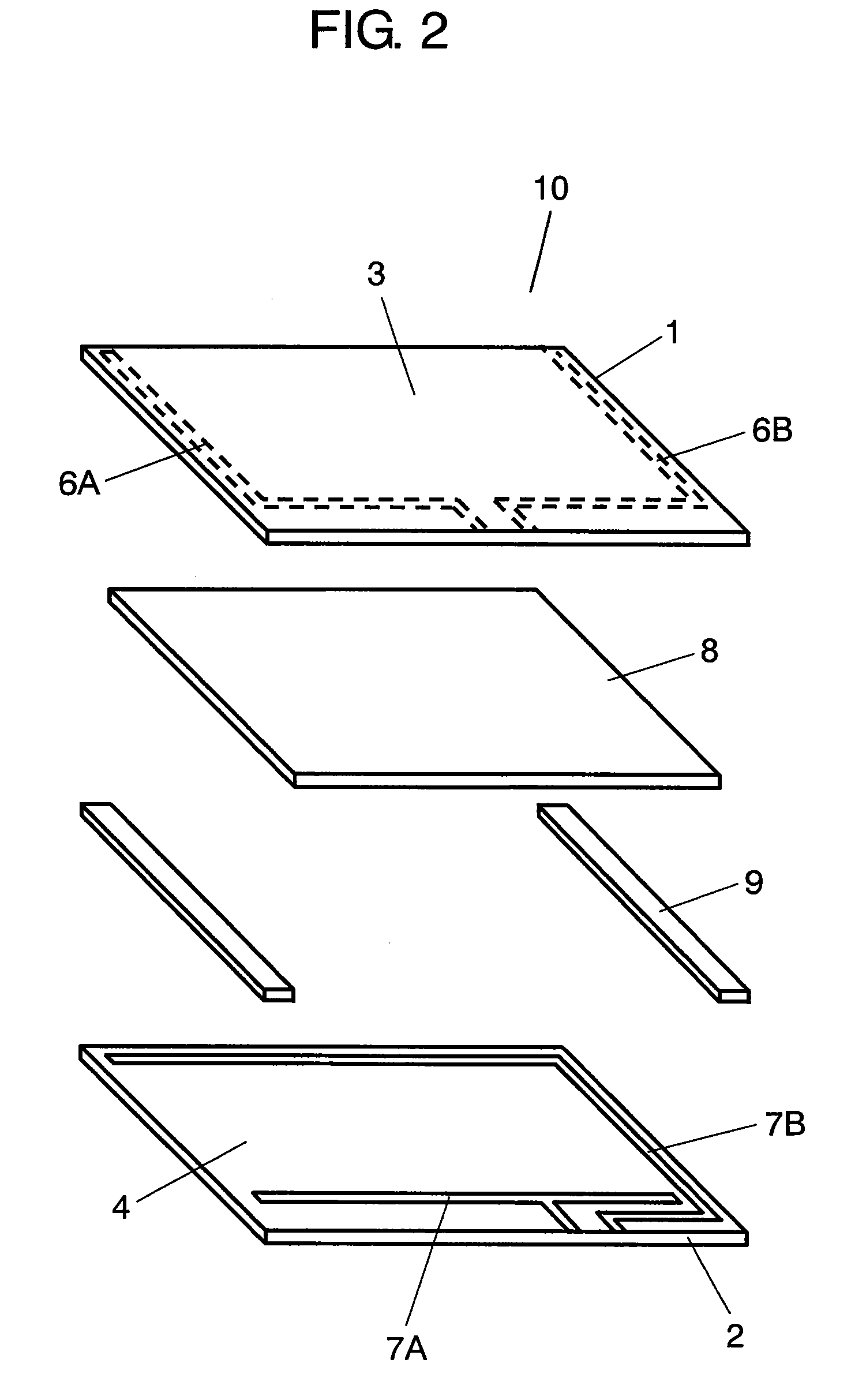

Touch panel

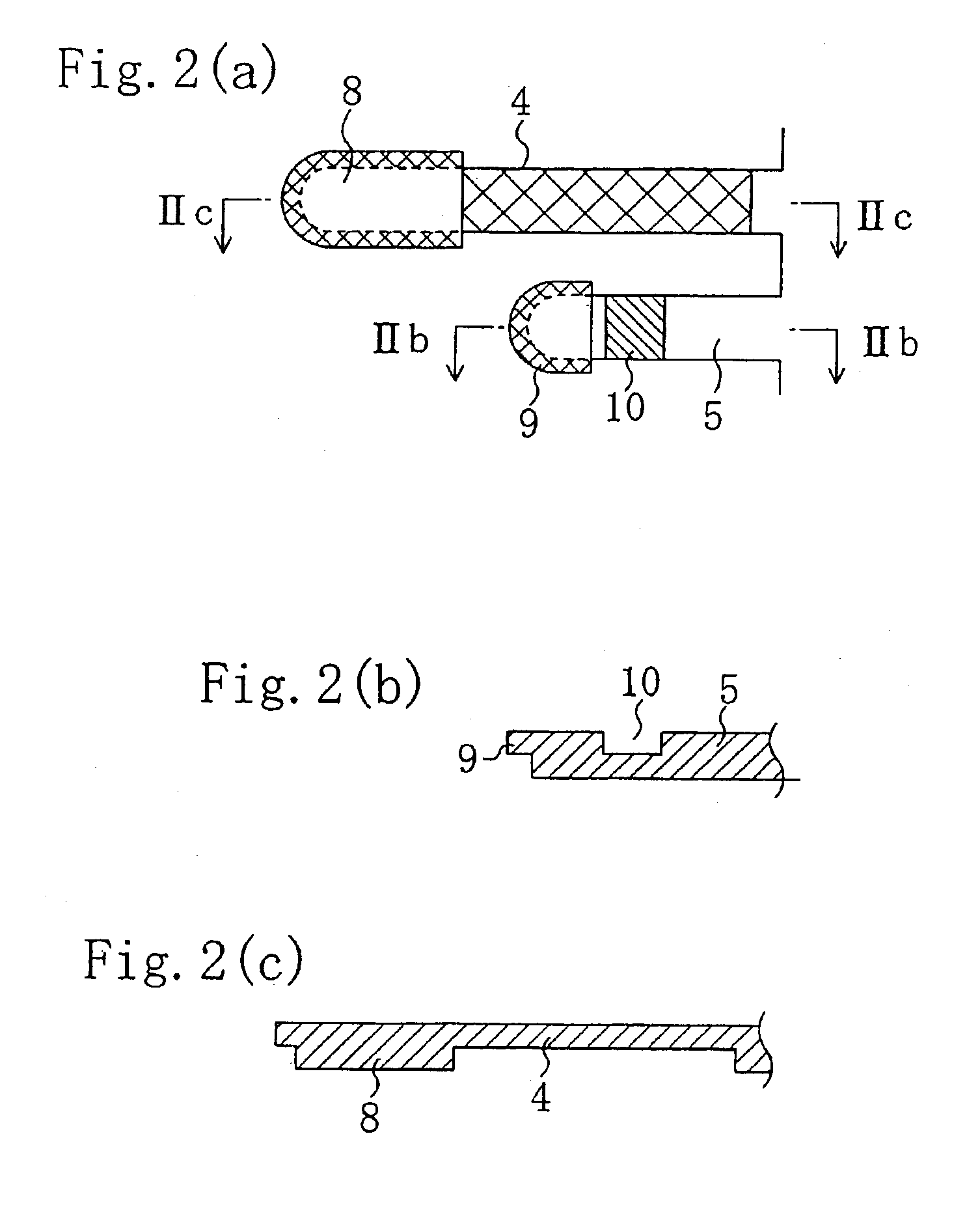

InactiveUS20080018201A1Improve visibilityEnsure effective applicationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTouchpadEngineering

A touch panel that sandwiches a light transmitting piezoelectric material, which generates a voltage by a pressing force, between an upper conductive layer formed on a bottom face of an upper substrate and a lower conductive layer formed on a top face of a lower substrate. Since there is no space between the upper conductive layer and the lower conductive layer, reflection of external light can be reduced. This achieves good viewability. In addition, the touch panel can be easily manufactureable just by sequentially superimposing and attaching components

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

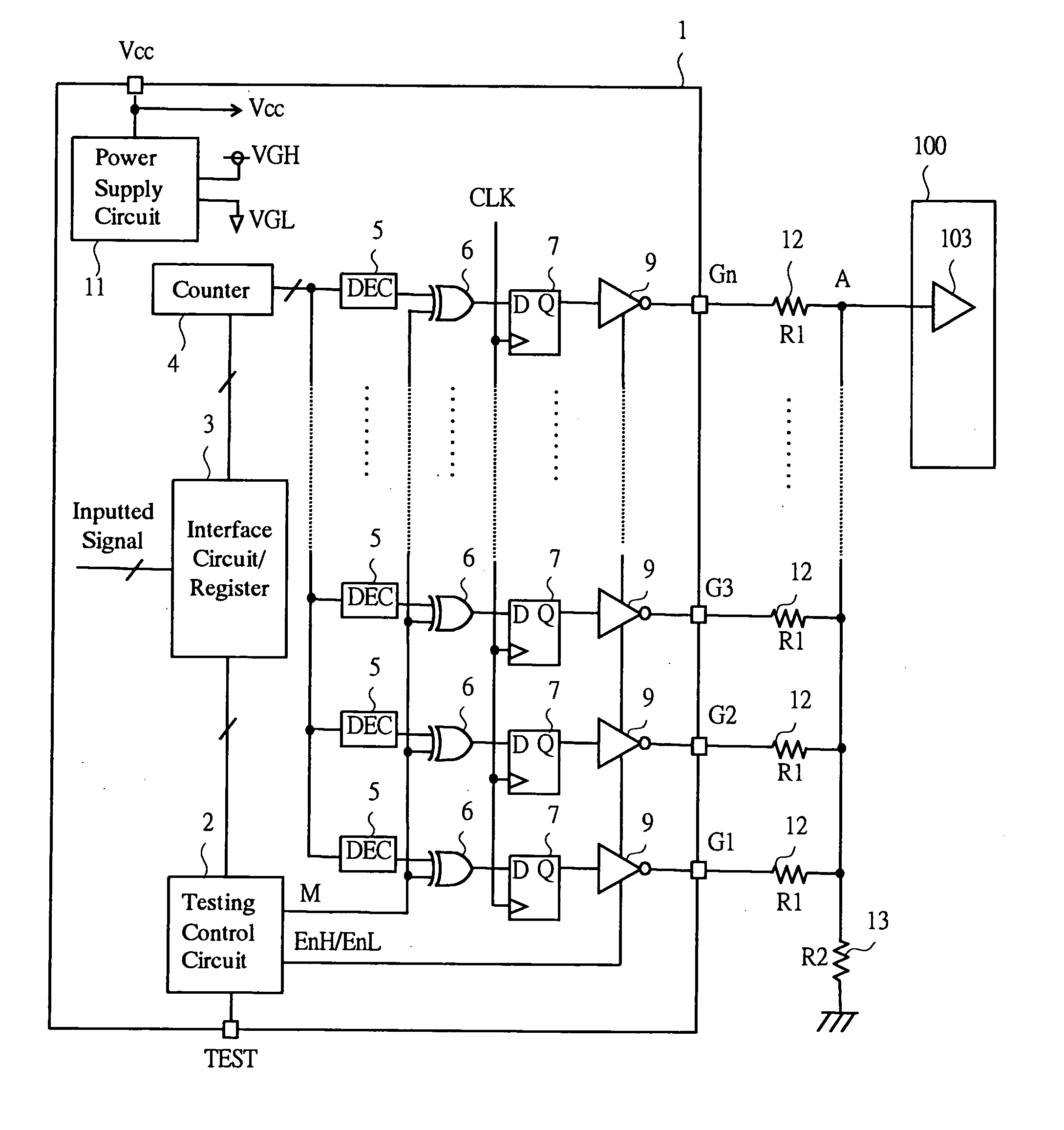

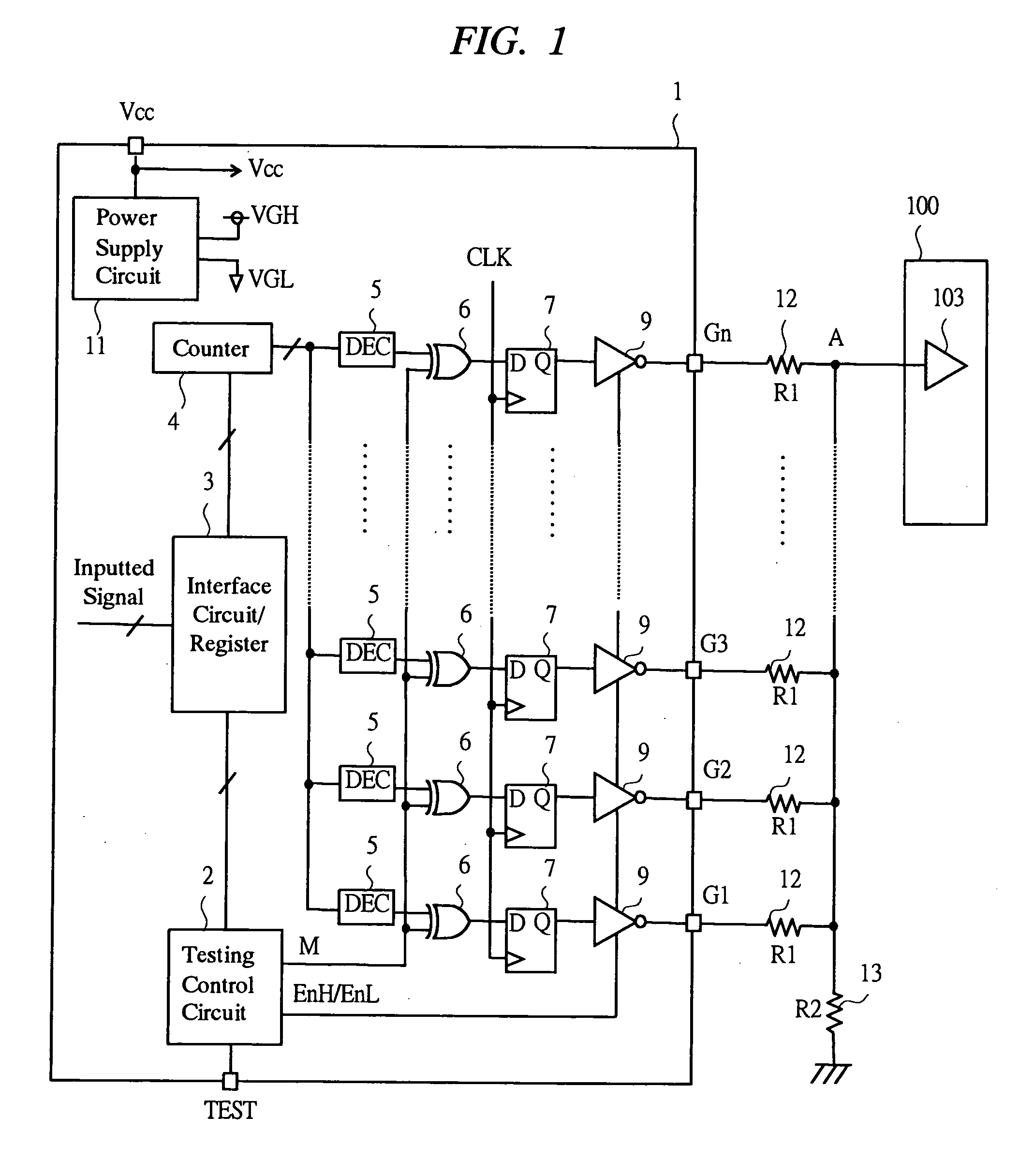

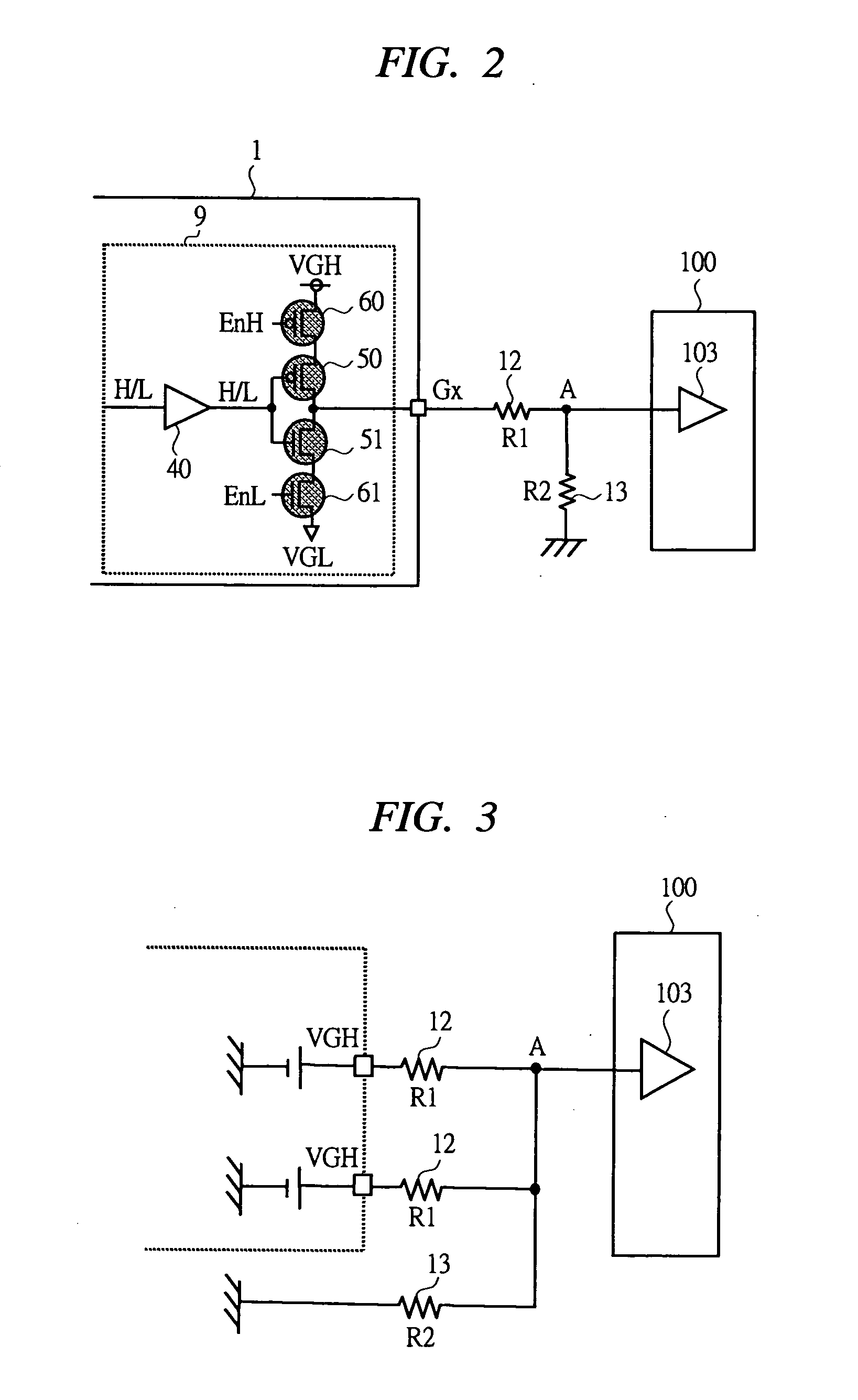

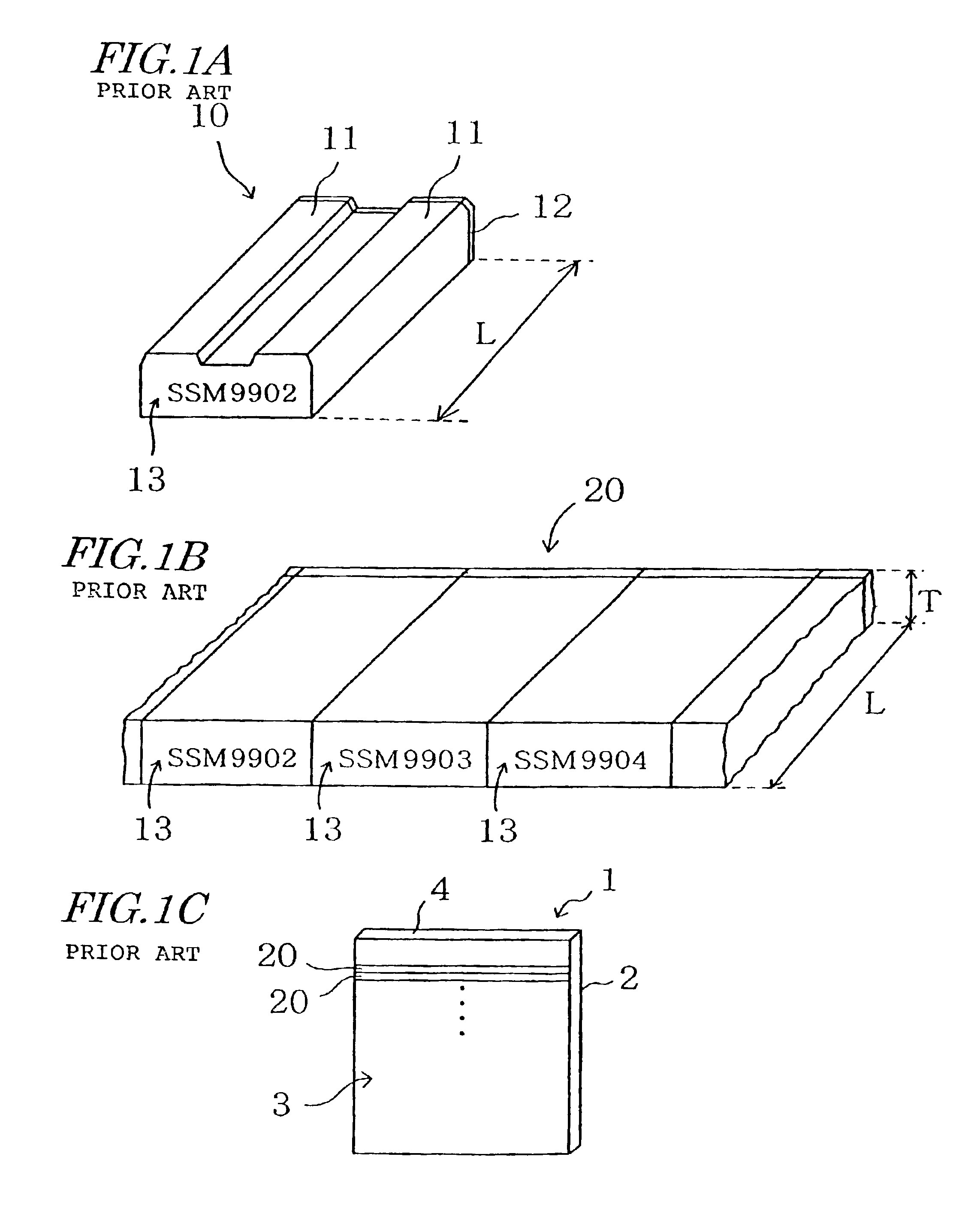

Semiconductor device and the method of testing the same

ActiveUS20050122297A1Efficient use ofEnsure effective applicationElectronic circuit testingStatic indicating devicesLiquid-crystal displayDevice material

A problem, which one of the inventions included in the present application solves, is to provide a semiconductor device that can simultaneously test a plurality of output pins by less channels of a semiconductor test equipment in number than the integrated output pins of the semiconductor device. Representative one of the inventions has such a configuration that an LCD driver, which is the semiconductor device having a function of driving a gate line of a liquid crystal display panel, comprises: an exclusive-OR circuit for inverting polarities of positive and negative voltages for driving the gate line; a tri-state type inverter circuit capable of changing and controlling, to a high-impedance state, an output circuit for driving the gate line; and at least one of test control terminals TEST for controlling the exclusive-OR circuit and the tri-state type inverter circuit. When a test is conducted, only one terminal of the gate output outputs a positive voltage VGH or negative voltage VGL and the other terminal is set to a high-impedance state, whereby the plurality of gate outputs are simultaneously tested.

Owner:RENESAS ELECTRONICS CORP

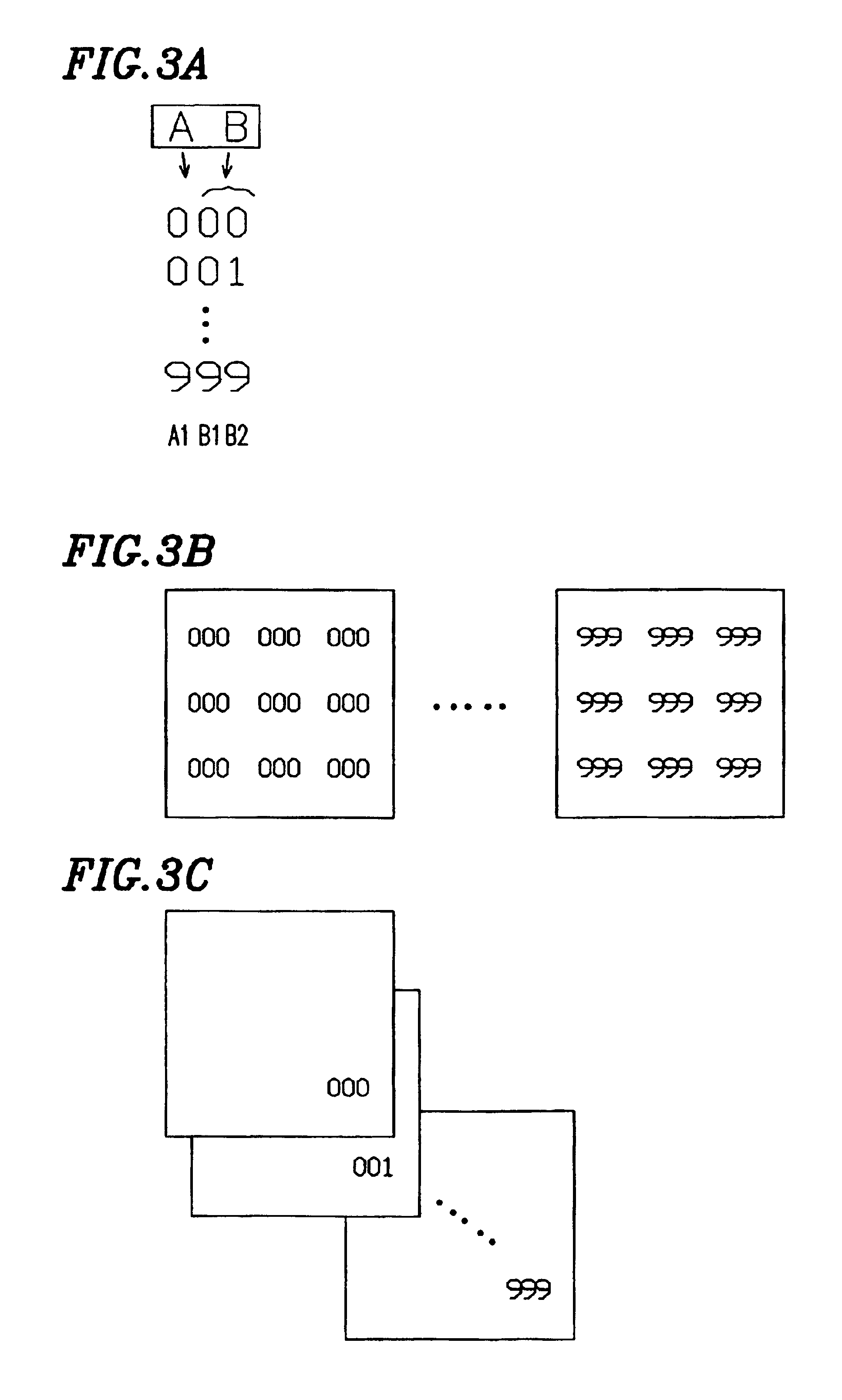

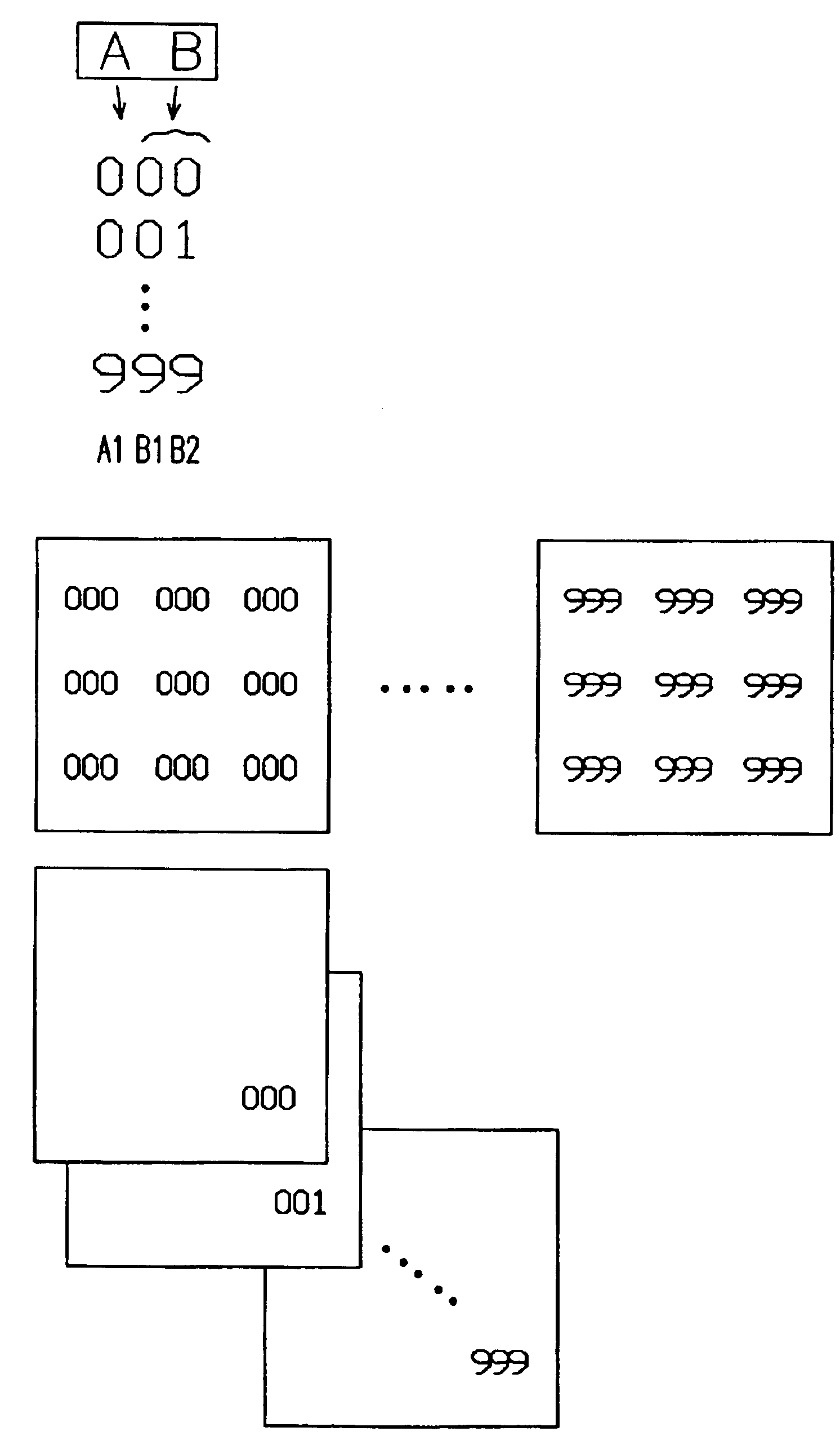

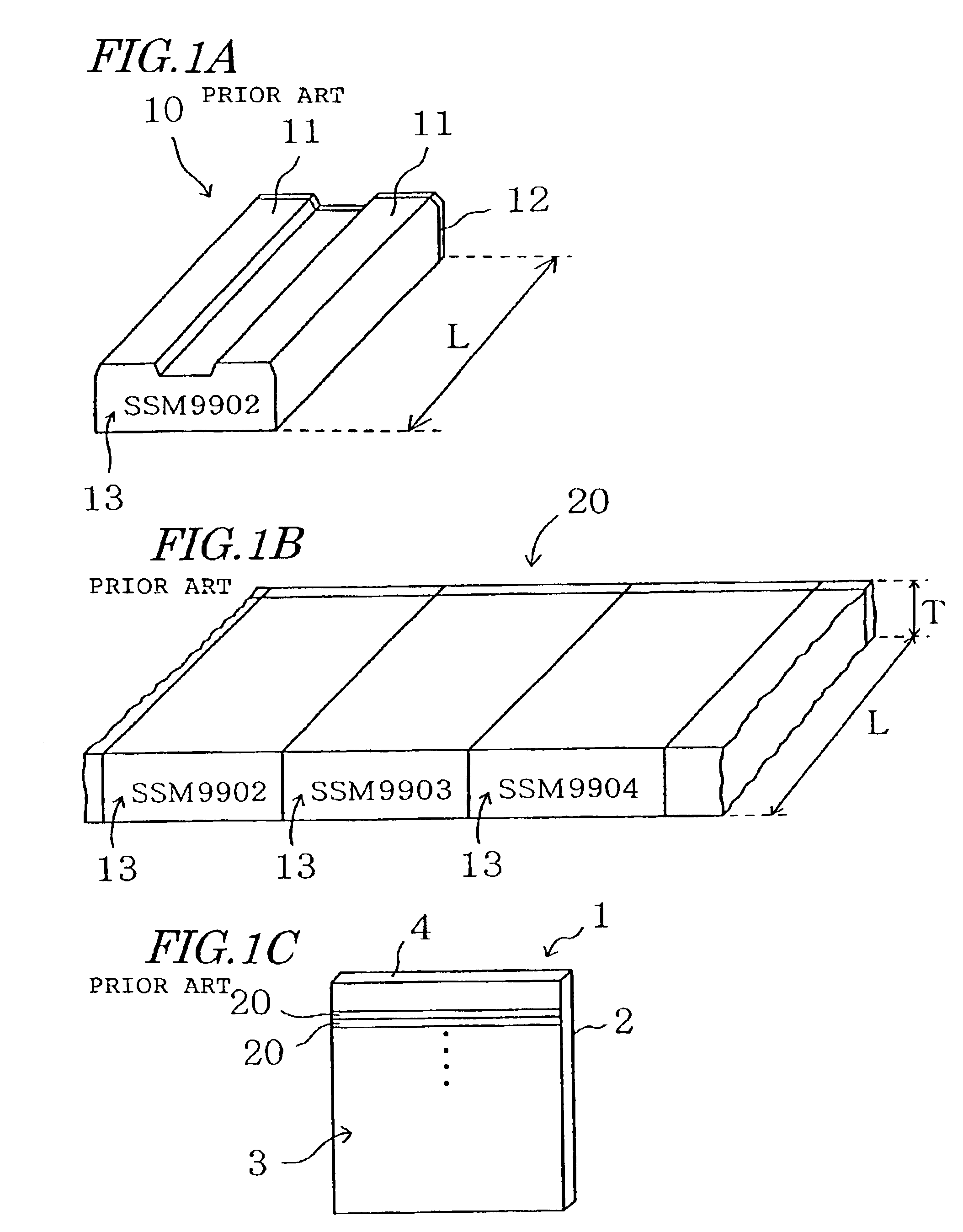

Method of recording identifier and set of photomasks

InactiveUS6924090B2Reduce the numberEnsure effective applicationPhoto-taking processesSemiconductor/solid-state device manufacturingLatent imageComputer science

A method of recording different identifiers, each including at least one character, on multiple plate-type members, involves the use of a photomask of a first type and at least two photomasks of a second type. The photomask of the first type has an opaque pattern that defines a blank region to write the identifier thereon. Each of the photomasks of the second type has an opaque pattern defining the at least one character. The method further includes the steps of forming a photoresist layer on the surface of one of the plate-type members, exposing the photoresist layer, except the blank region, to a radiation through the photomask of the first type, and forming a latent image of the at least one character in the blank region through at least one of the photomasks of the second type.

Owner:SUMITOMO SPECIAL METAL CO LTD

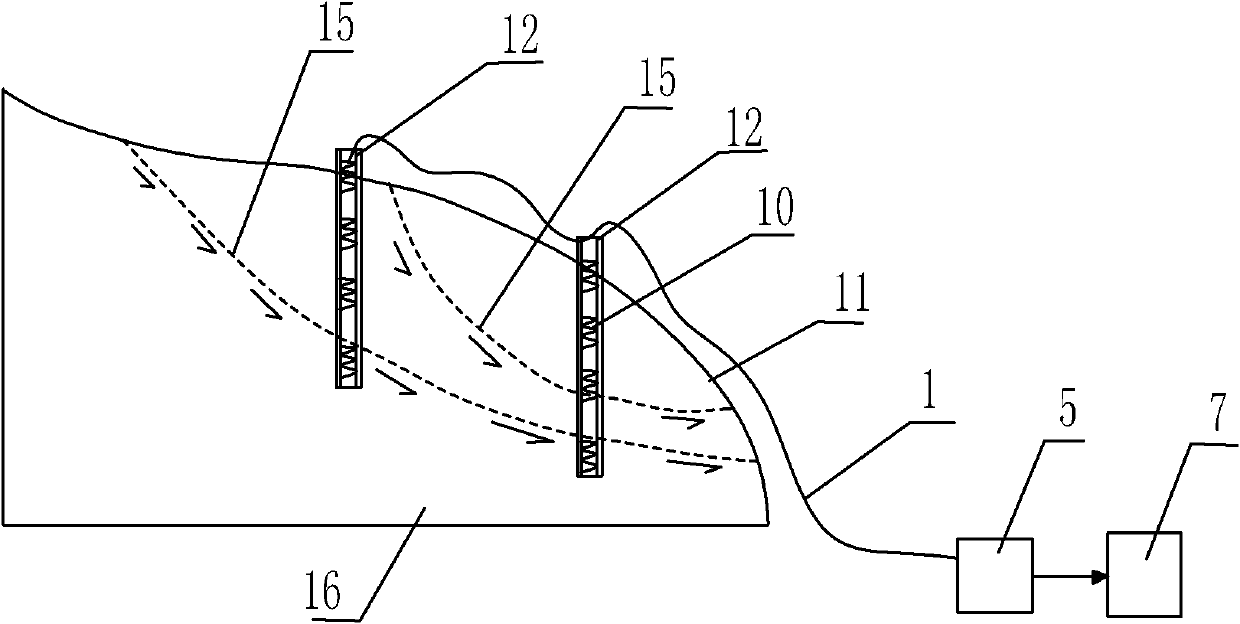

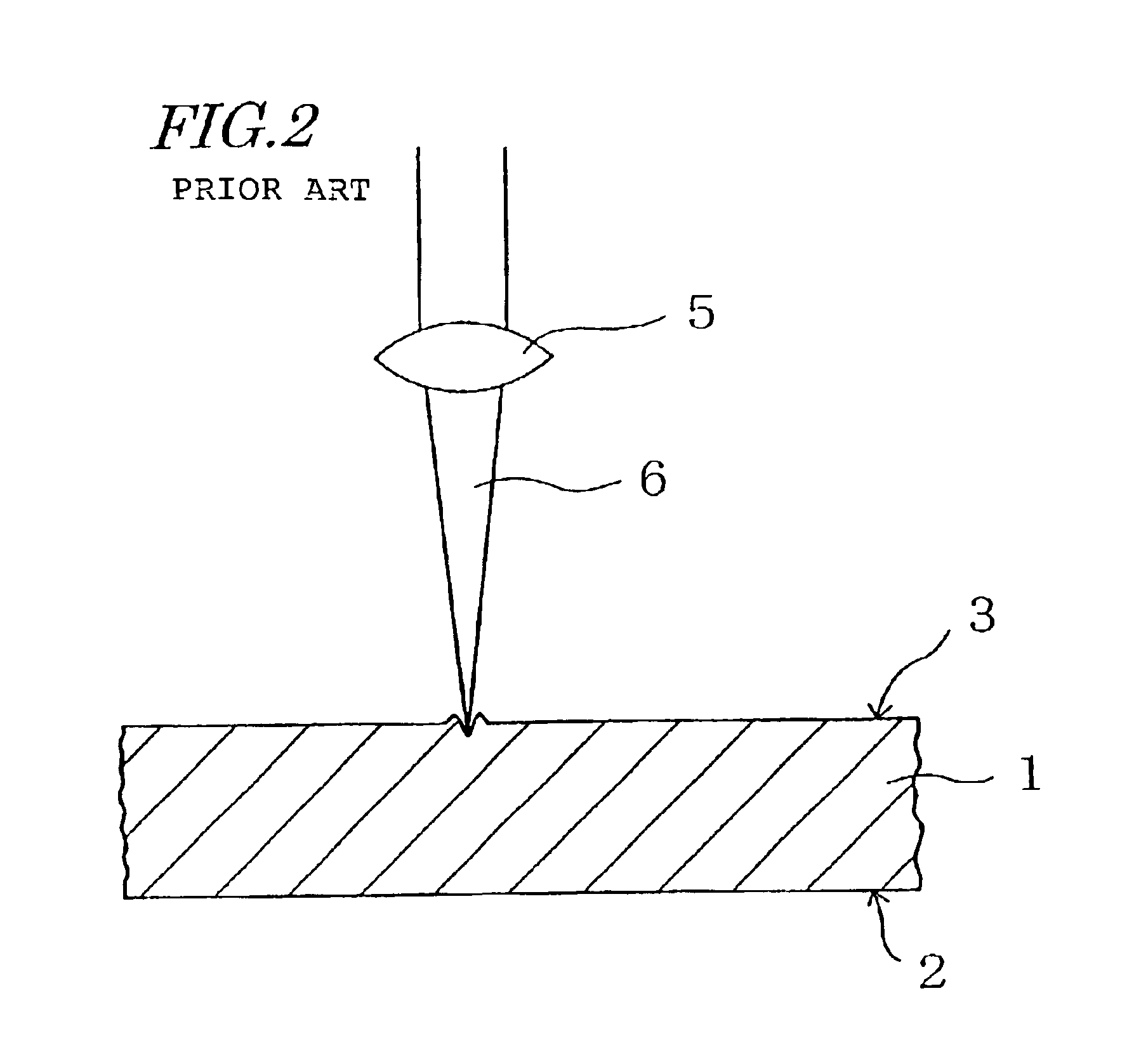

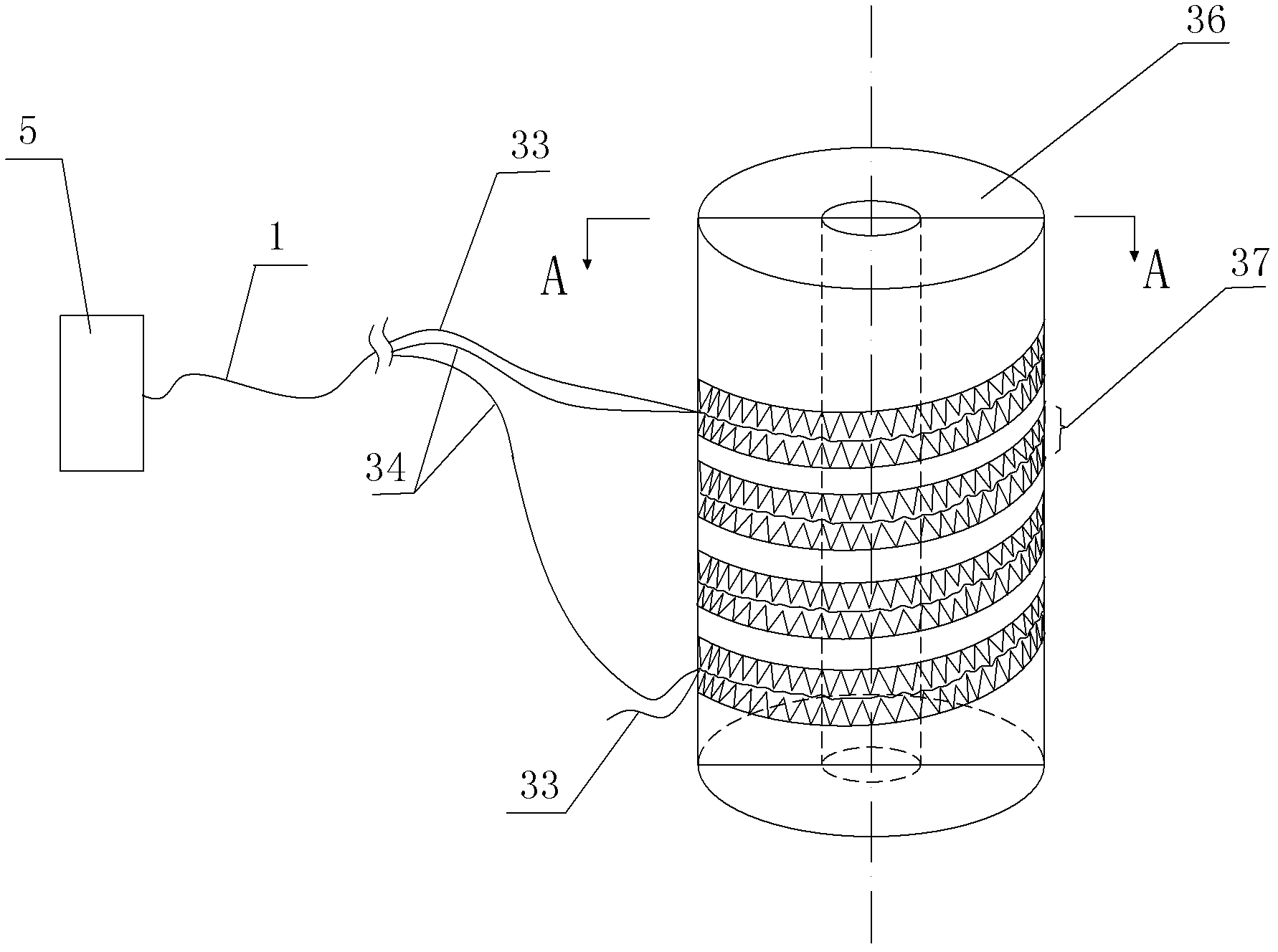

Landslide depth displacement monitoring device

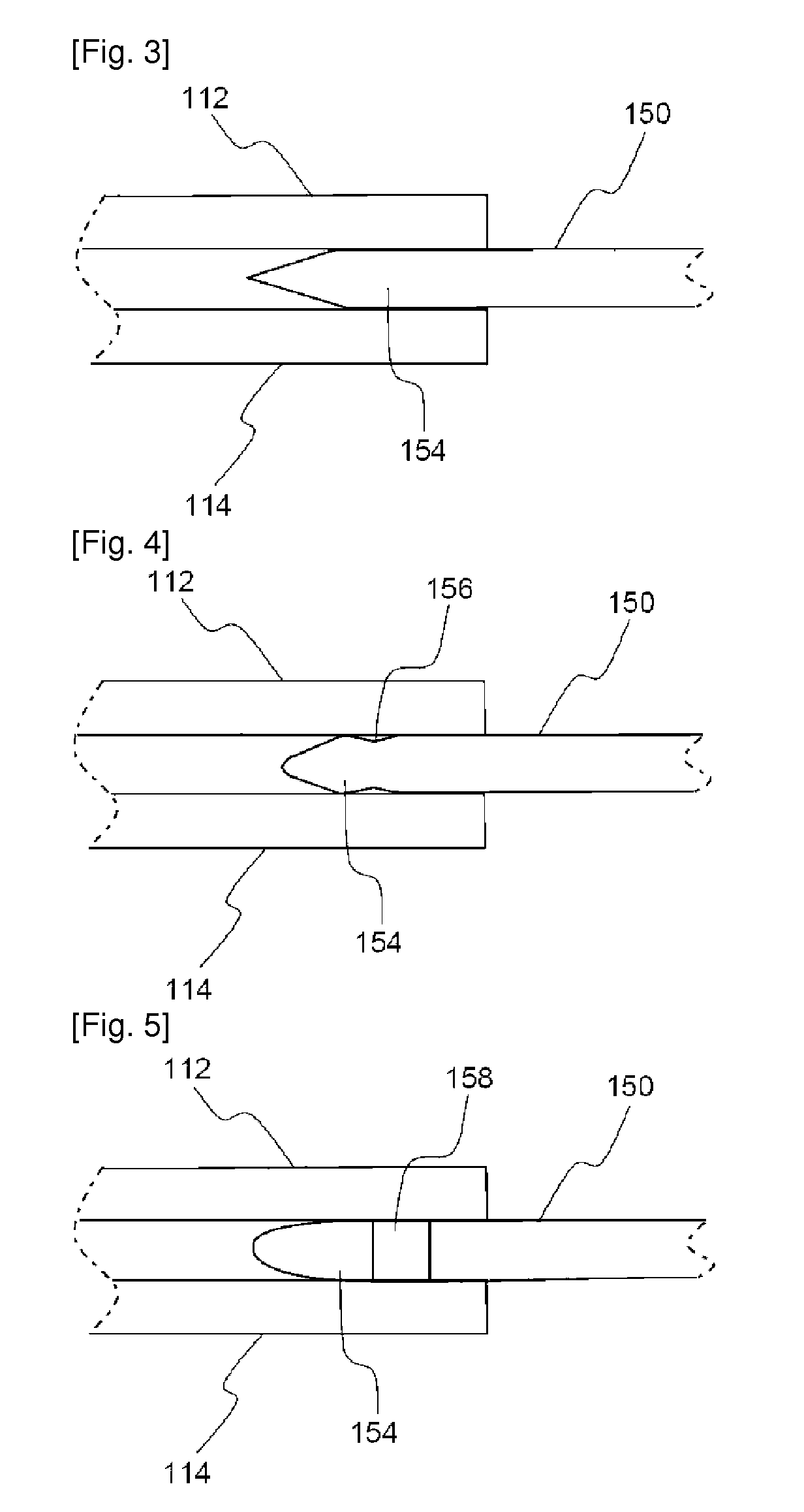

InactiveCN102564312ASimple structureEasy to processUsing optical meansConverting sensor output opticallyTest channelBedrock

The invention discloses a landslide depth displacement monitoring device, which comprises an inclinometer pipe, wherein the inclinometer pipe is inserted on a landslide, and the end part of the inclinometer pipe passes through a potential sliding surface and extends into a drill hole below a bedrock surface; a curved test channel for a signal optical fiber I to pass through is arranged in the inclinometer pipe; the curved test channel comprises a curved support, a plurality of deformation teeth I and a plurality of deformation teeth II which are continuously arranged at the upper side and lower side which are opposite in the curved support; the deformation teeth I and the deformation teeth II are correspondingly arranged in a staggered way; the signal optical fiber I is arranged at the inner part of the curved channel in a penetrating way; at least one row of the corresponding deformation teeth of the deformation teeth I and the deformation teeth II share the same height, pitch and bending curvature of the top part contacted with the signal optical fiber I; the joint of the signal optical fiber I is connected with one end of an optical cable; the other end of the optical cable is led to a monitoring station and is connected with a testing unit; and the testing unit is further connected with an upper processing unit. The landslide depth displacement monitoring device can effectively realize remote monitoring of the landslide depth displacement change.

Owner:XIAN JINHE OPTICAL TECH

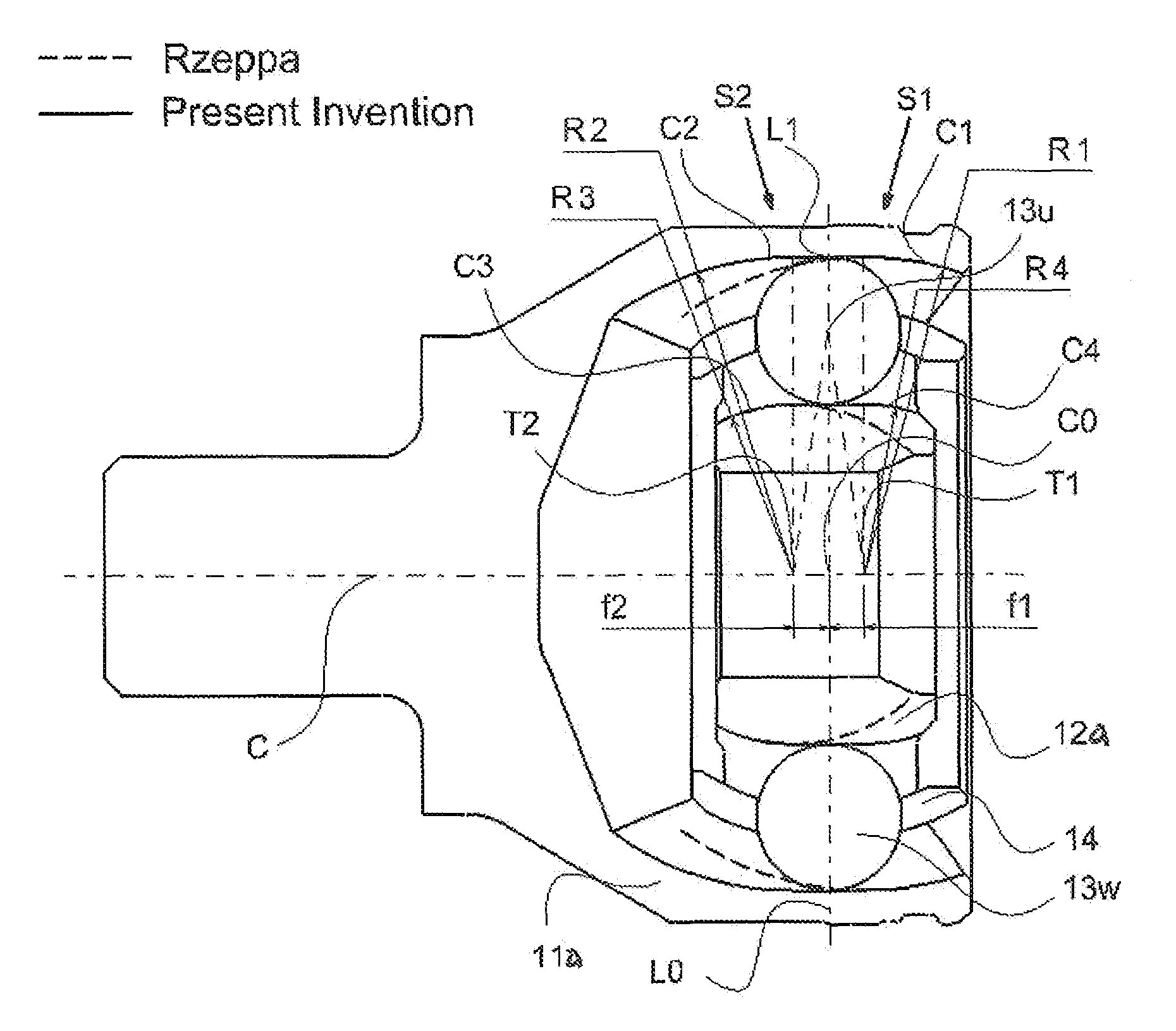

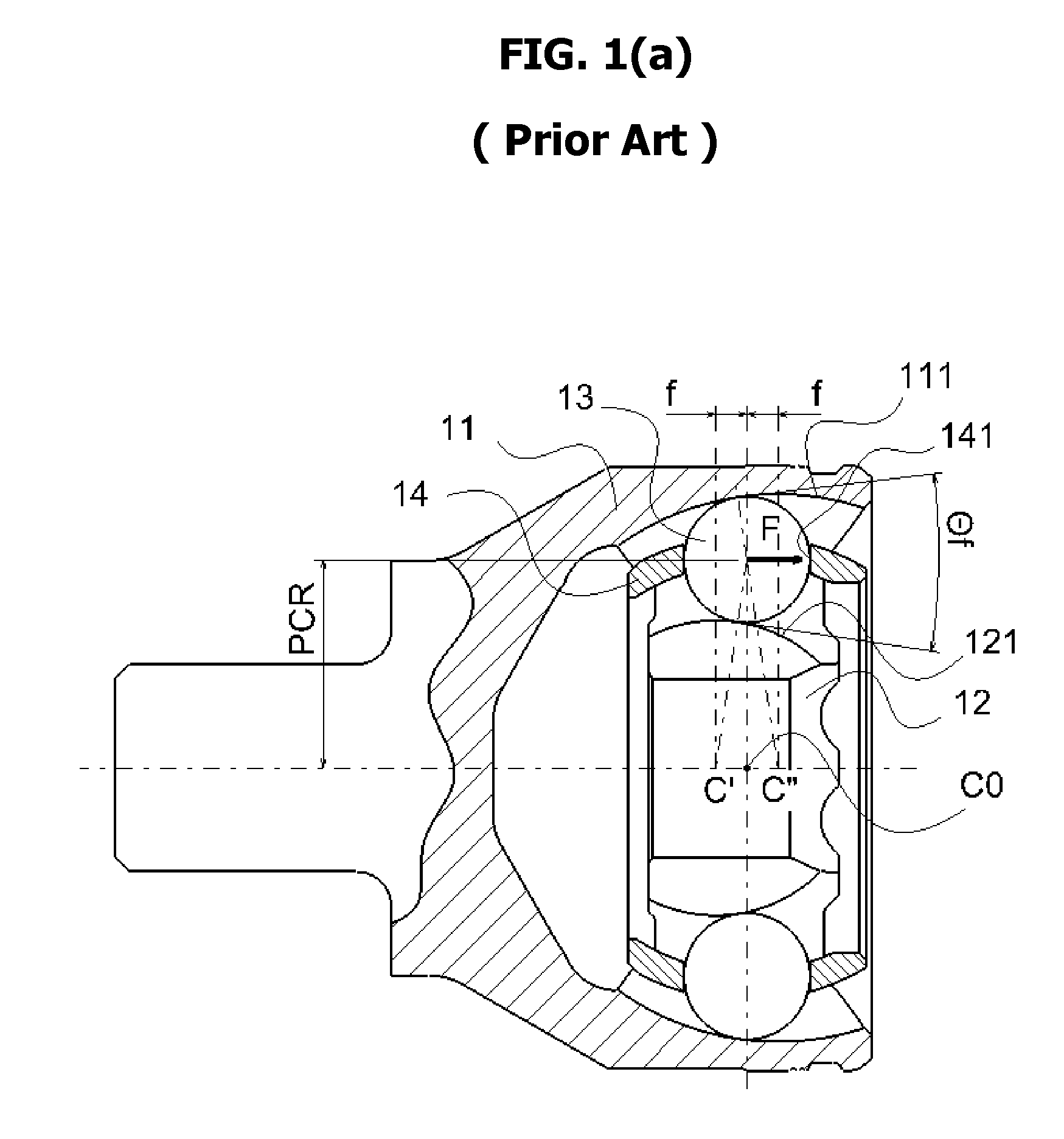

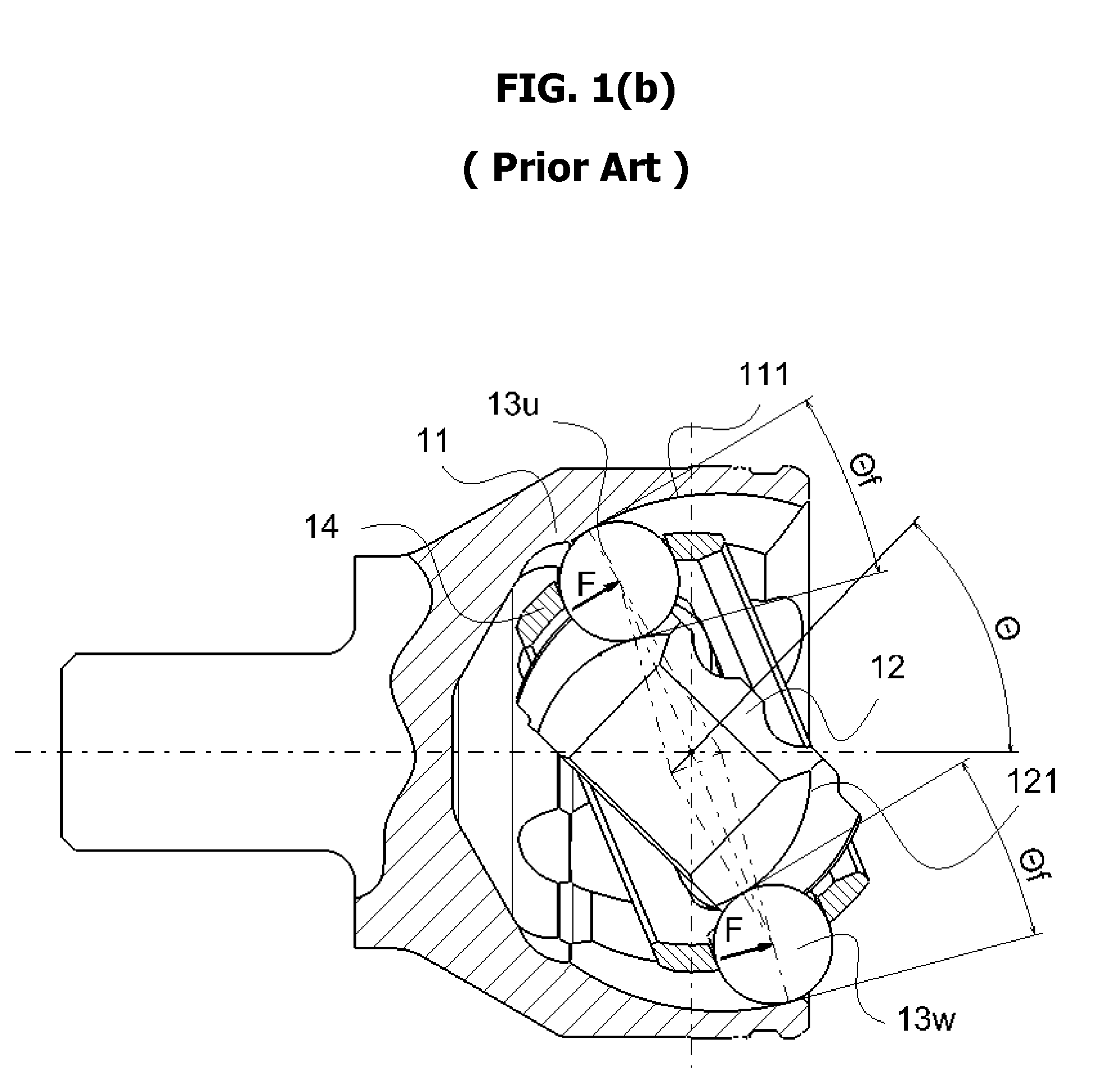

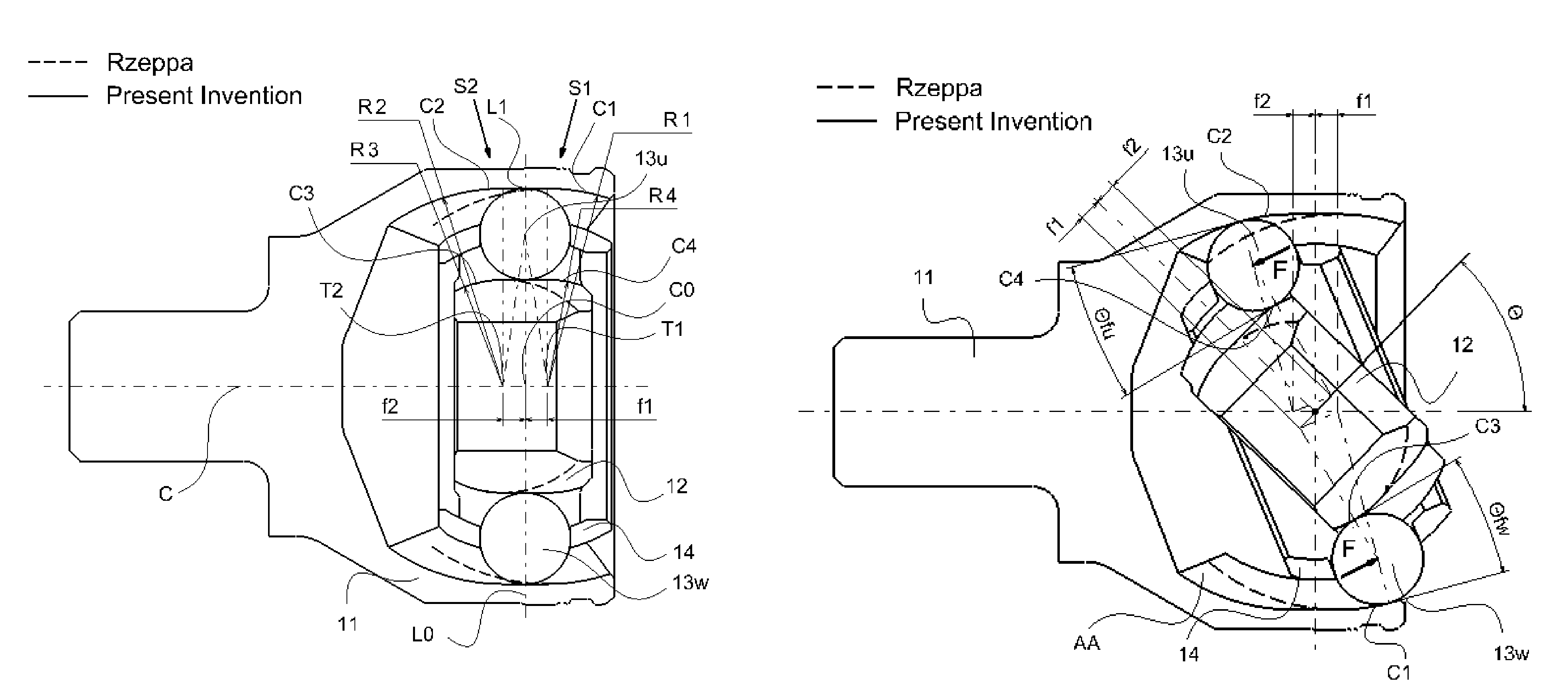

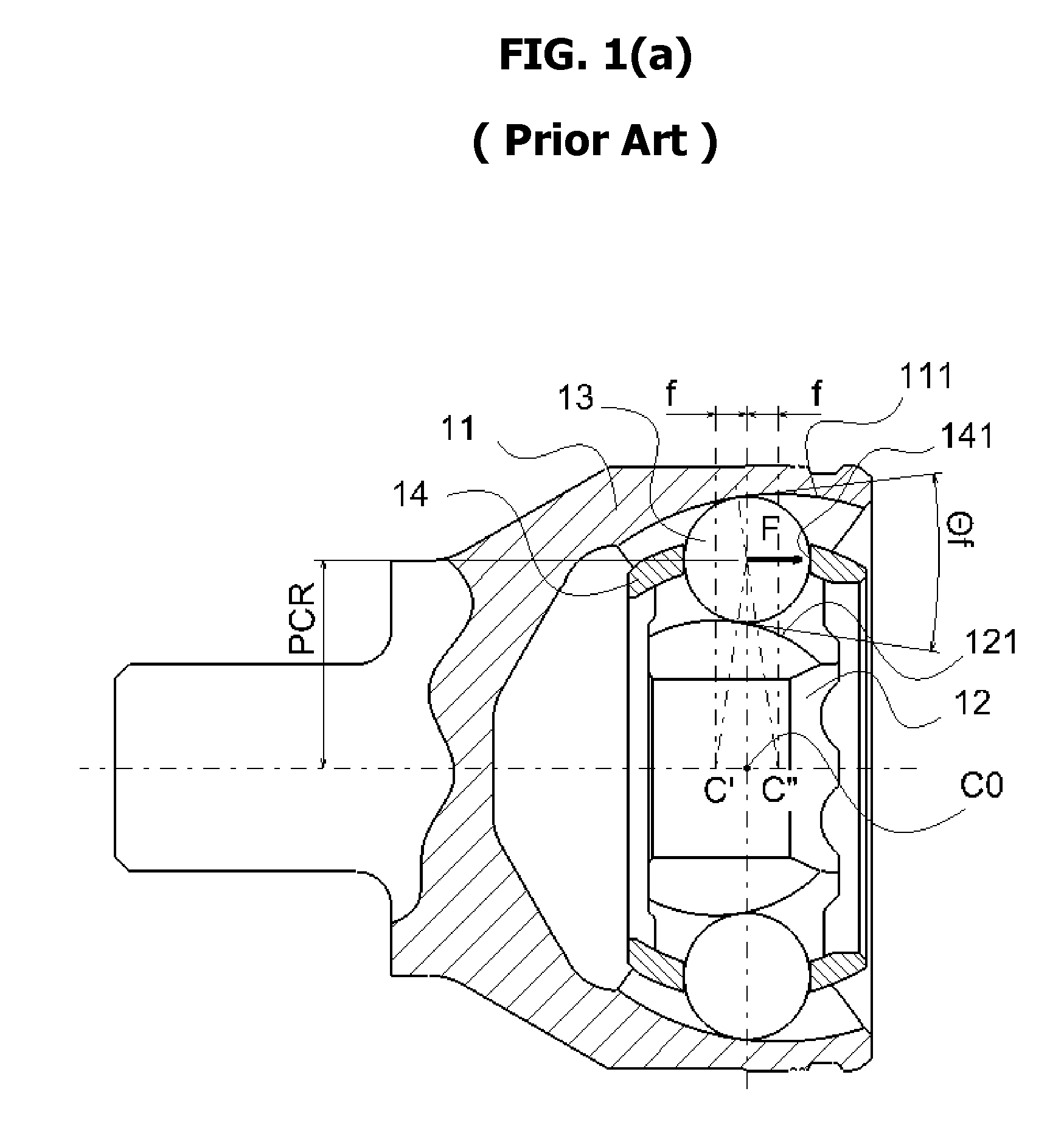

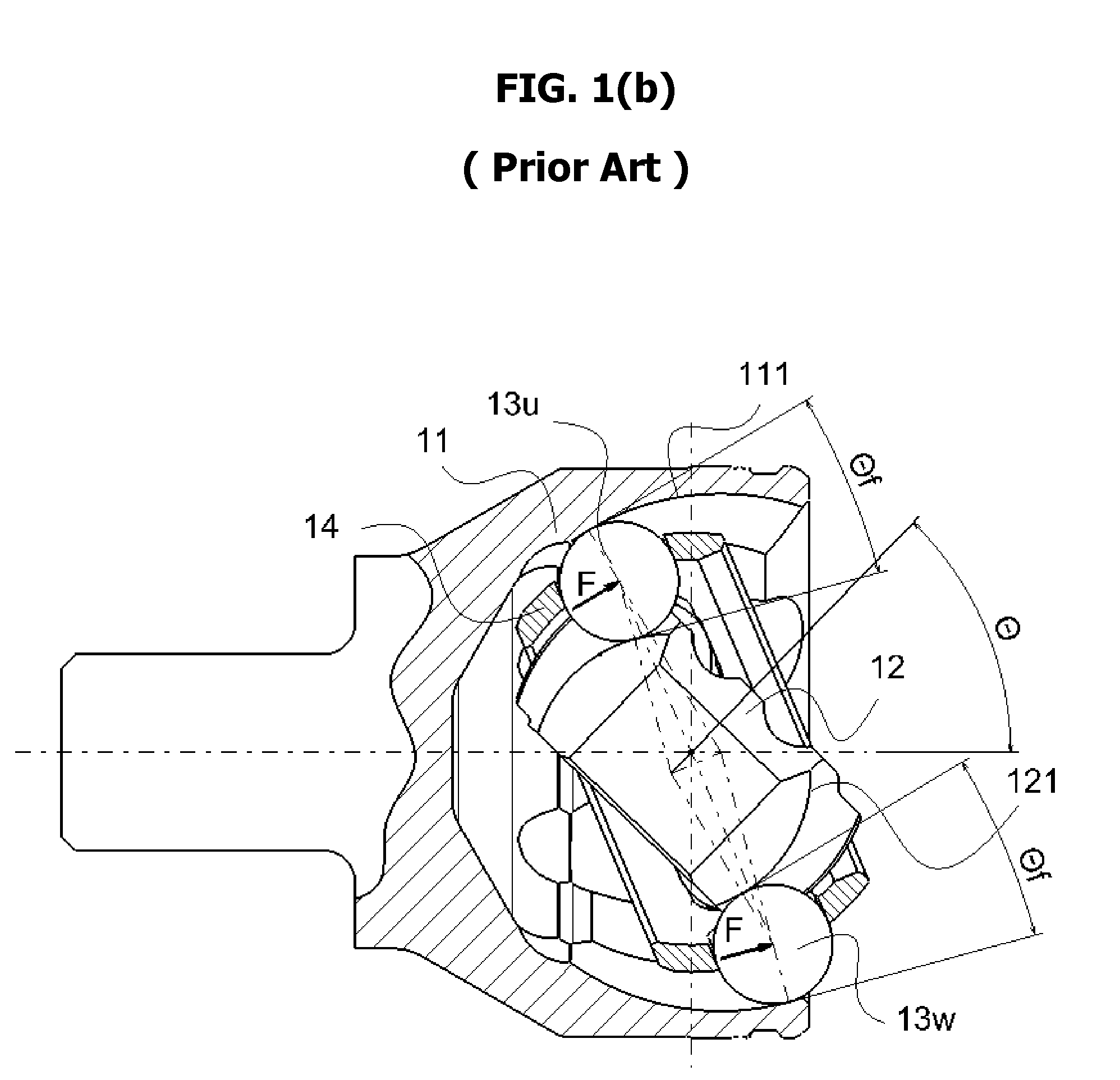

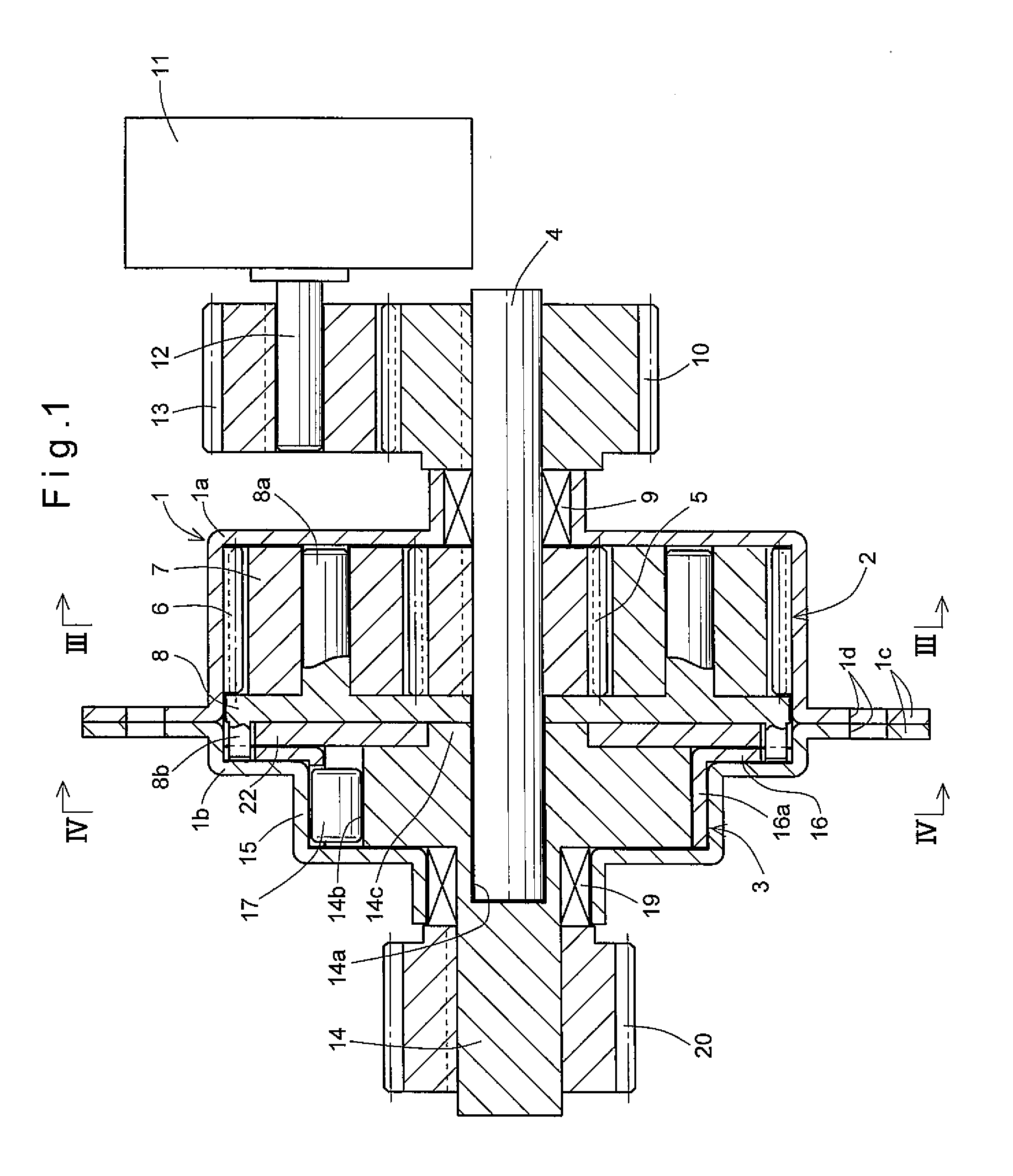

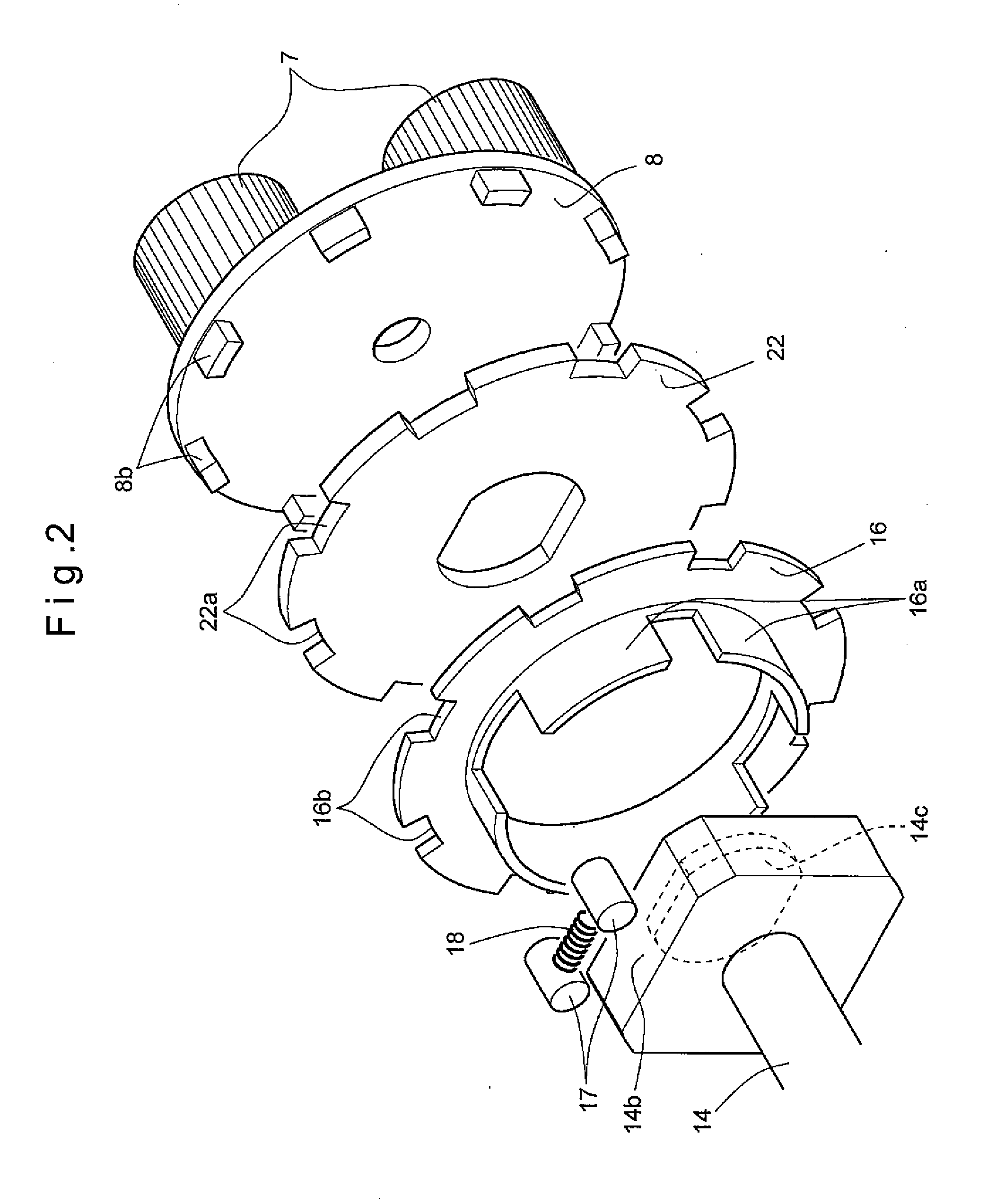

Fixed type constant velocity joint

ActiveUS8096887B2Durable in constructionSuitable strength and durabilityYielding couplingRotary machine partsLinear regionEngineering

A constant velocity joint for a drive system comprises: an outer race having a plurality of guide grooves formed in an axial direction in the inner spherical surface of the outer race; an inner race having a plurality of guide grooves formed in an axial direction in the outer spherical surface of the inner race, said guide grooves of the outer race and the inner race together forming a plurality of ball guide tracks; a plurality of balls disposed in the ball guide tracks; and a cage installed between the inner spherical surface of the outer race and the outer spherical surface of the inner race, said cage having a plurality of windows for retaining the balls therein. Each guide groove of the outer race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the outer race and a second circular region disposed at a second lateral side of the outer race, and a linear region tangentially extending between these two circular regions, and each guide groove of the inner race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the inner race and a second circular region disposed at a second lateral side of the inner race, and a linear region tangentially extending between these two circular regions.

Owner:WIA CORP

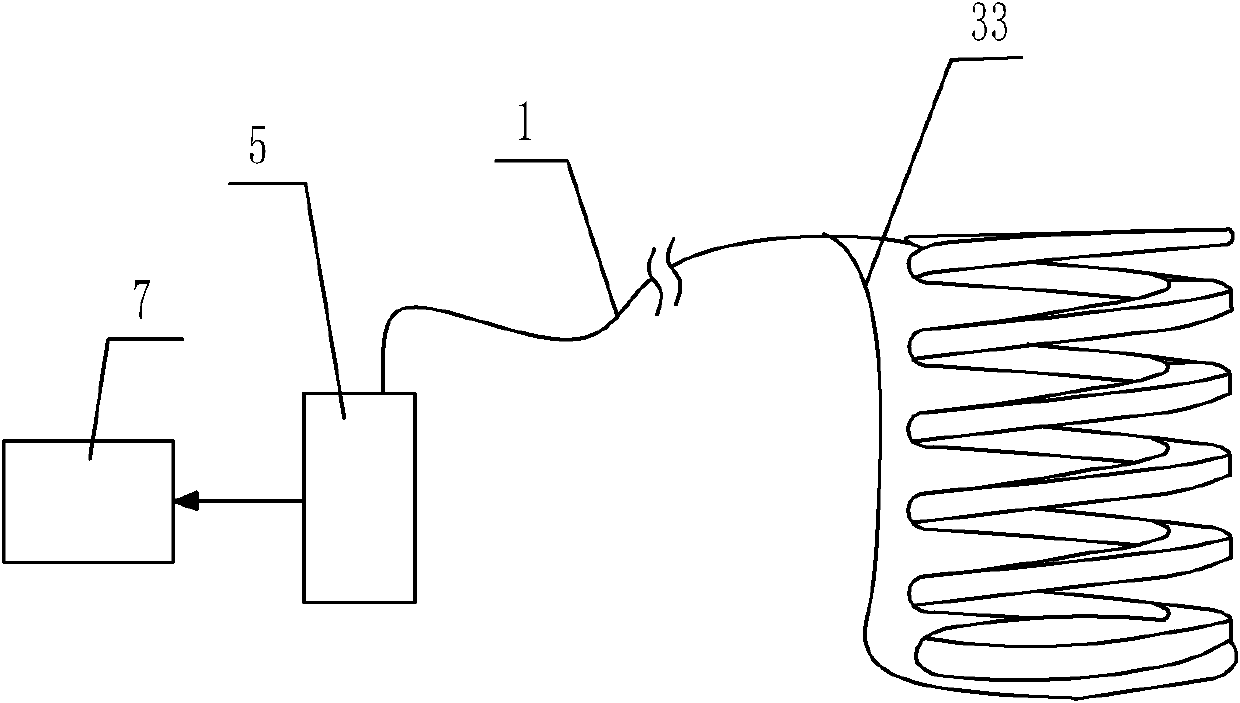

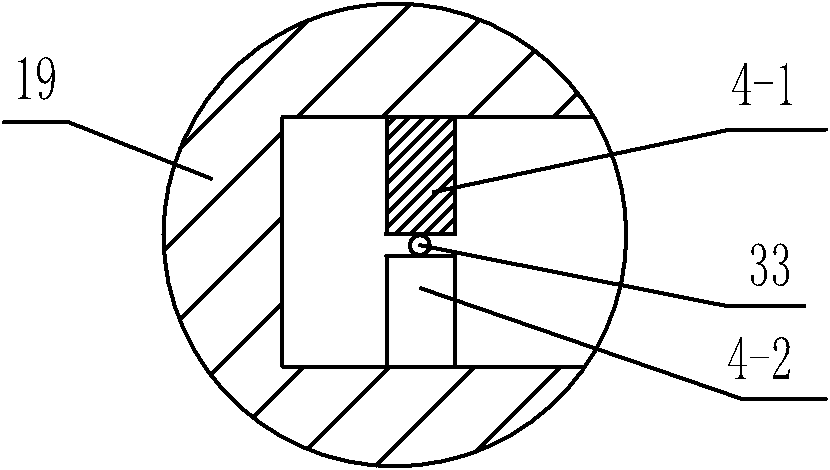

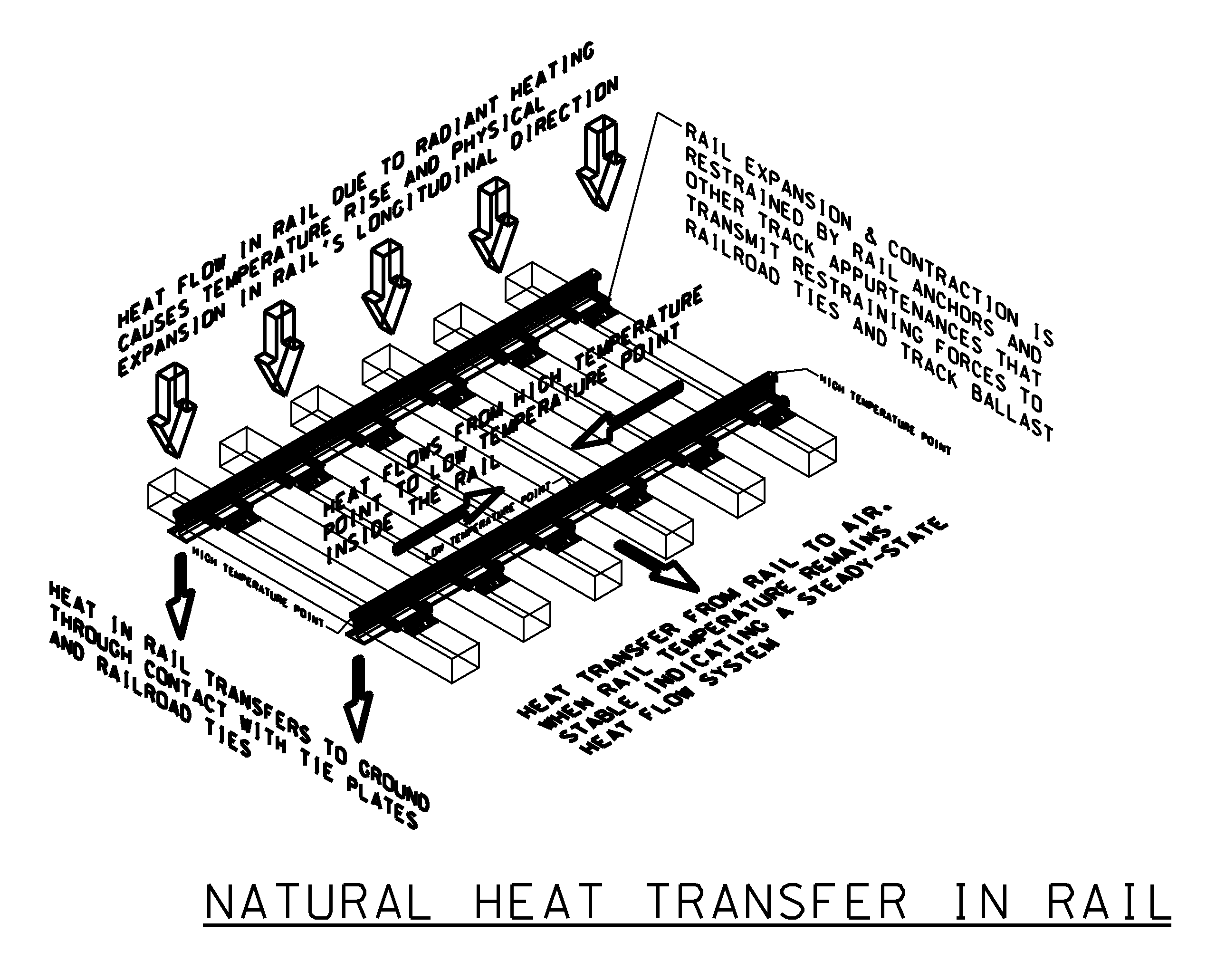

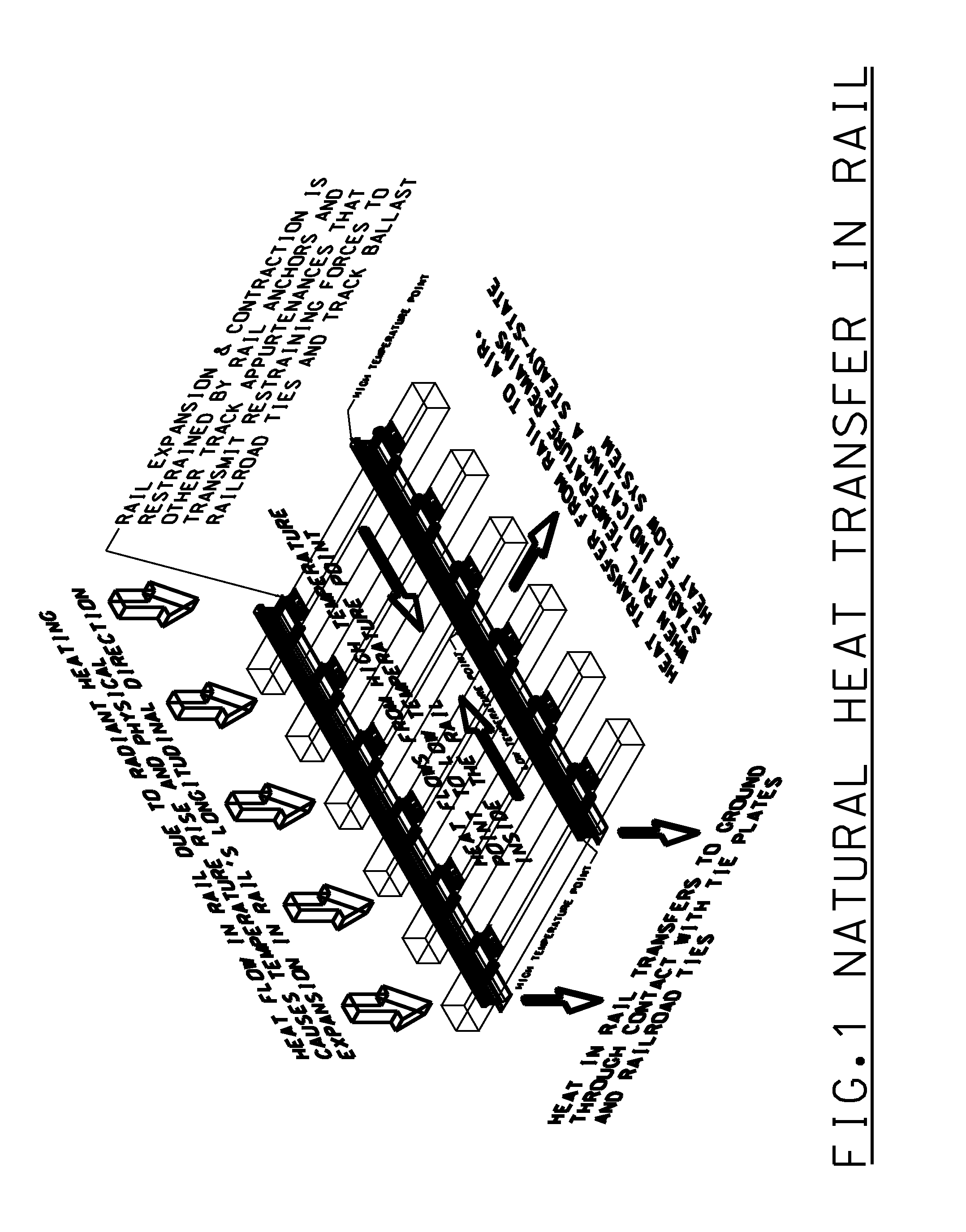

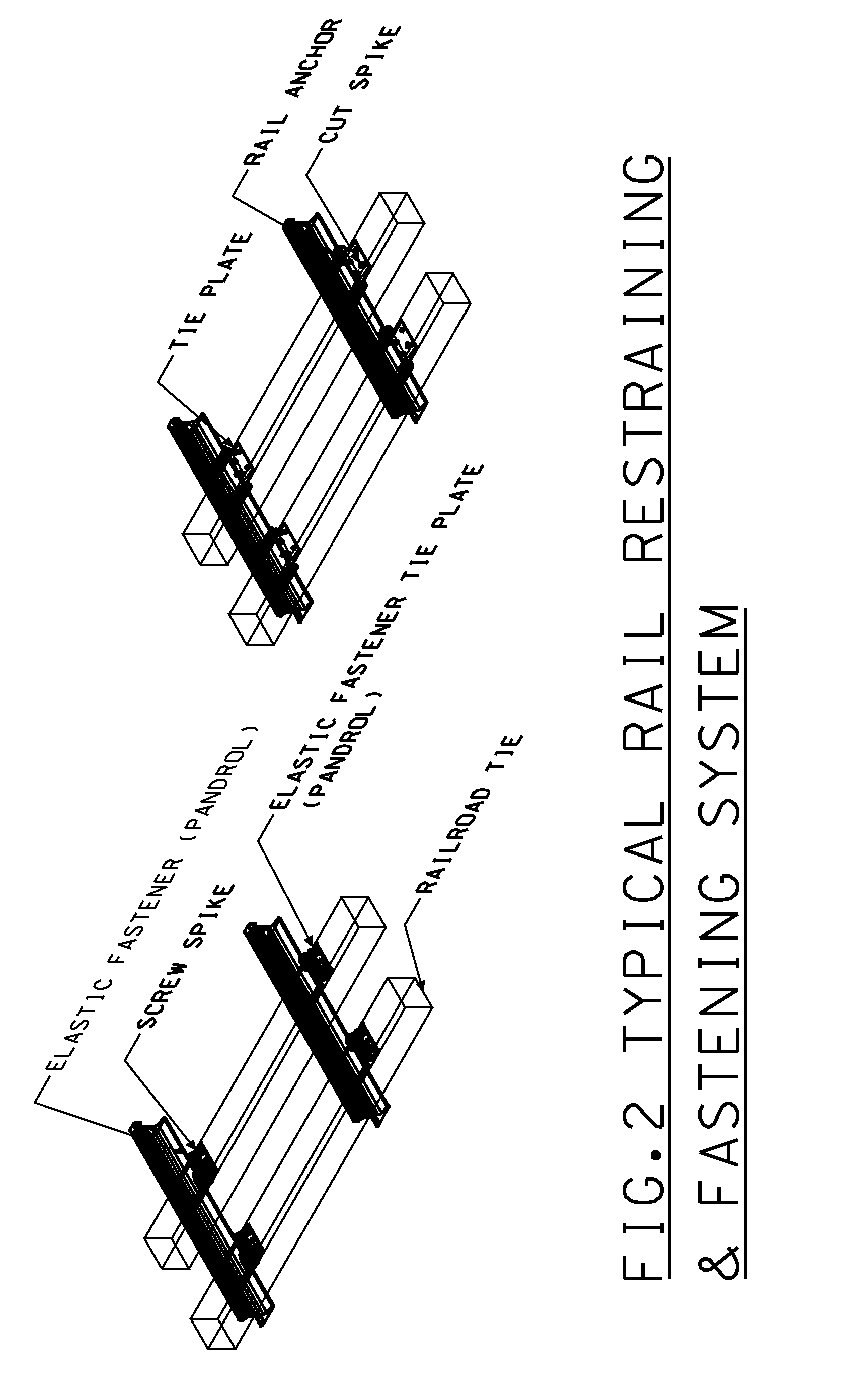

Geothermal Rail Cooling and Heating System

InactiveUS20140033755A1Ensure effective applicationReduce heatRail switchesGeothermal energy generationCooling effectEngineering

A Geothermal Rail Cooling and Heating System is a reversible system process that accelerates heat transfer between the steel rail used in railway track and the adjacent earth. It is comprised of the Rail Heat Exchangers specially shaped to fit tightly inside the rail web, a refrigerant cycling on its physical condensing and evaporative characteristics, a mechanical and power supply system, and an underground tubing loop system for heat dissipation or absorption. When the railroad track undergoes a range of temperature changes that results in rapid rail expansion, it may cause track buckling or sun kink. Upon detection of such occurrence, the system responds with cooling effect to slow down expansion, and simultaneously reduce the risk of track failure. By switching the direction of refrigerant flow utilizing the system built-in reversing valve, the function is alternated for the evaporator and condenser to enable heating instead of cooling.

Owner:WONG ROBERT HON SING

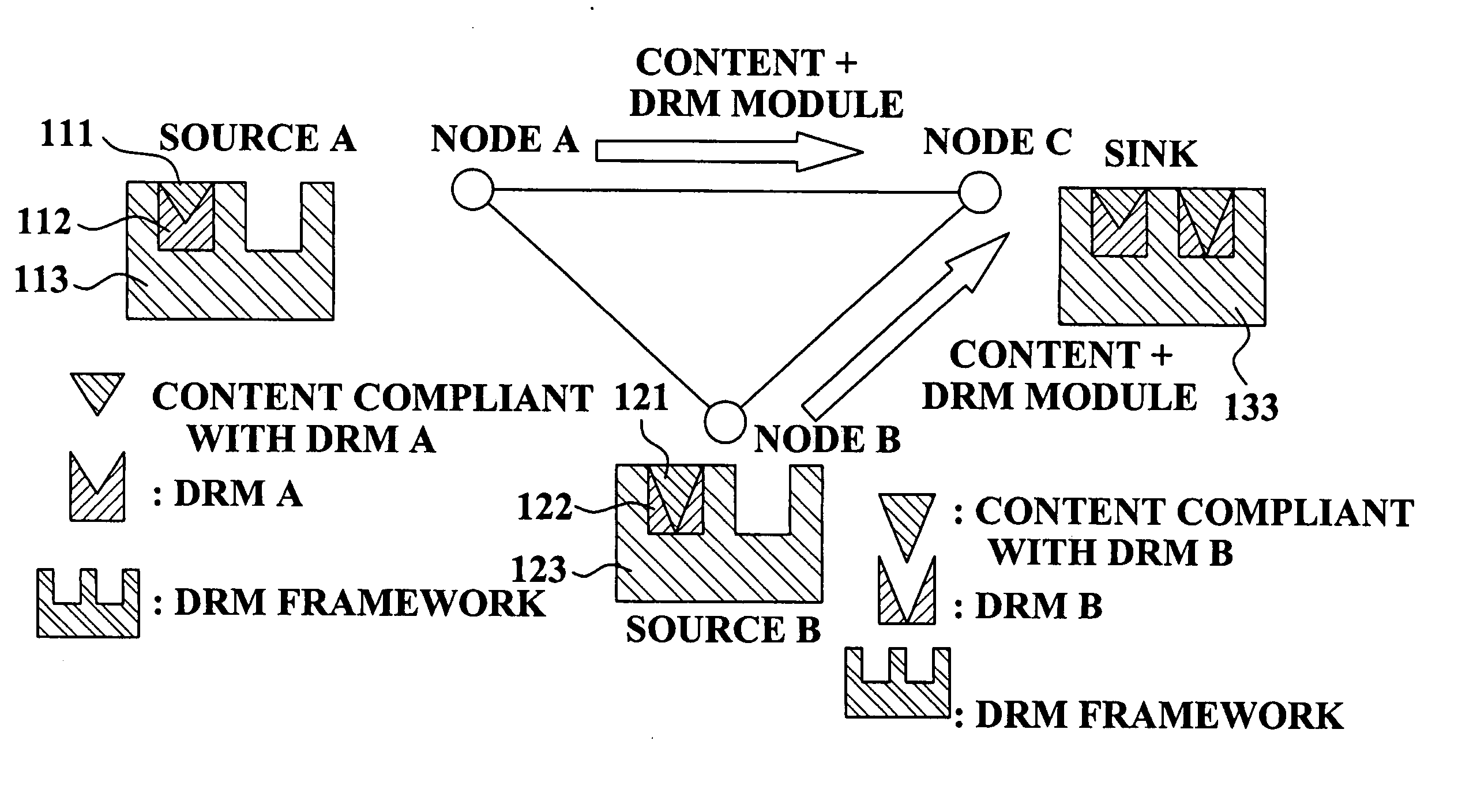

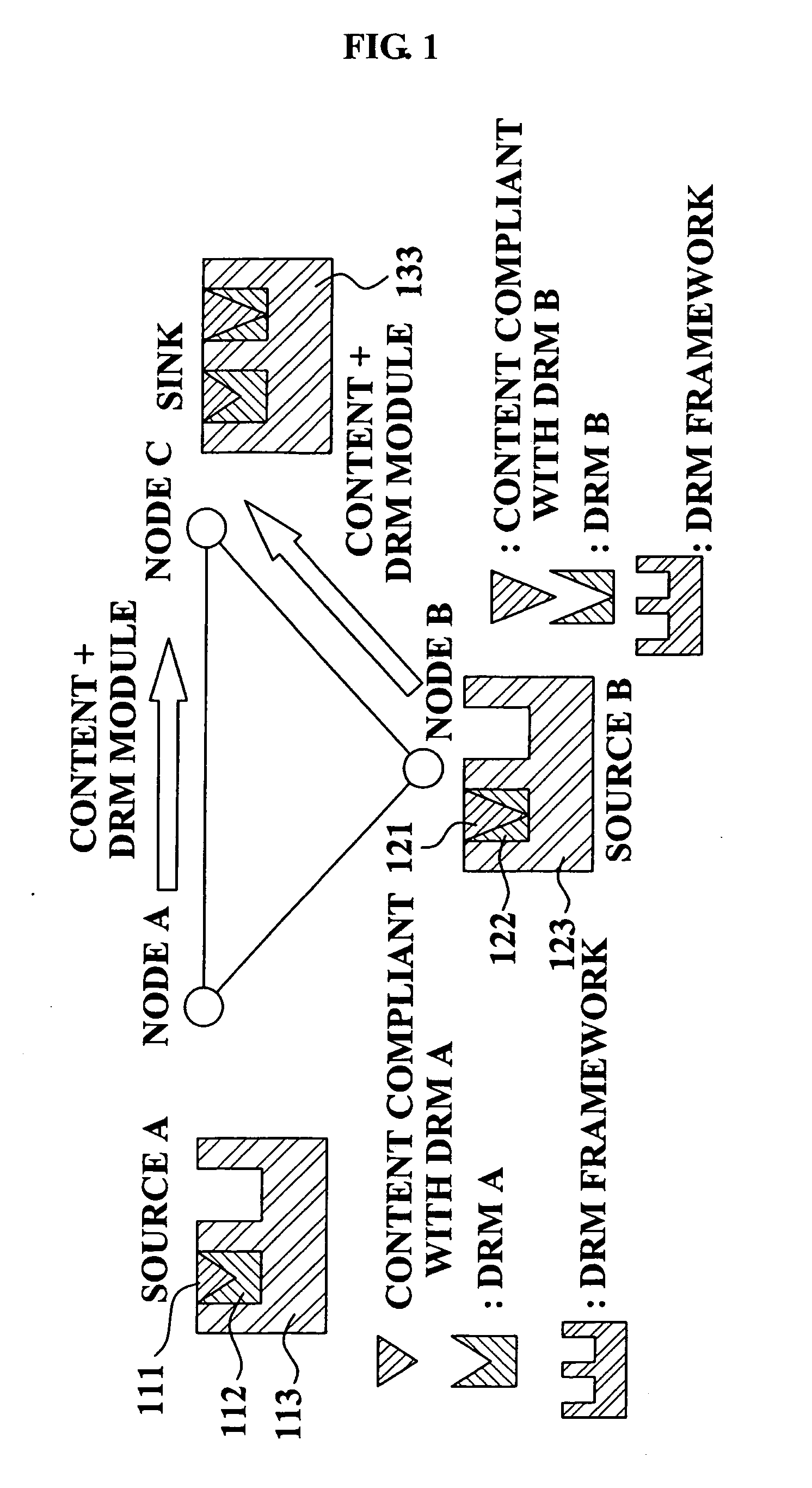

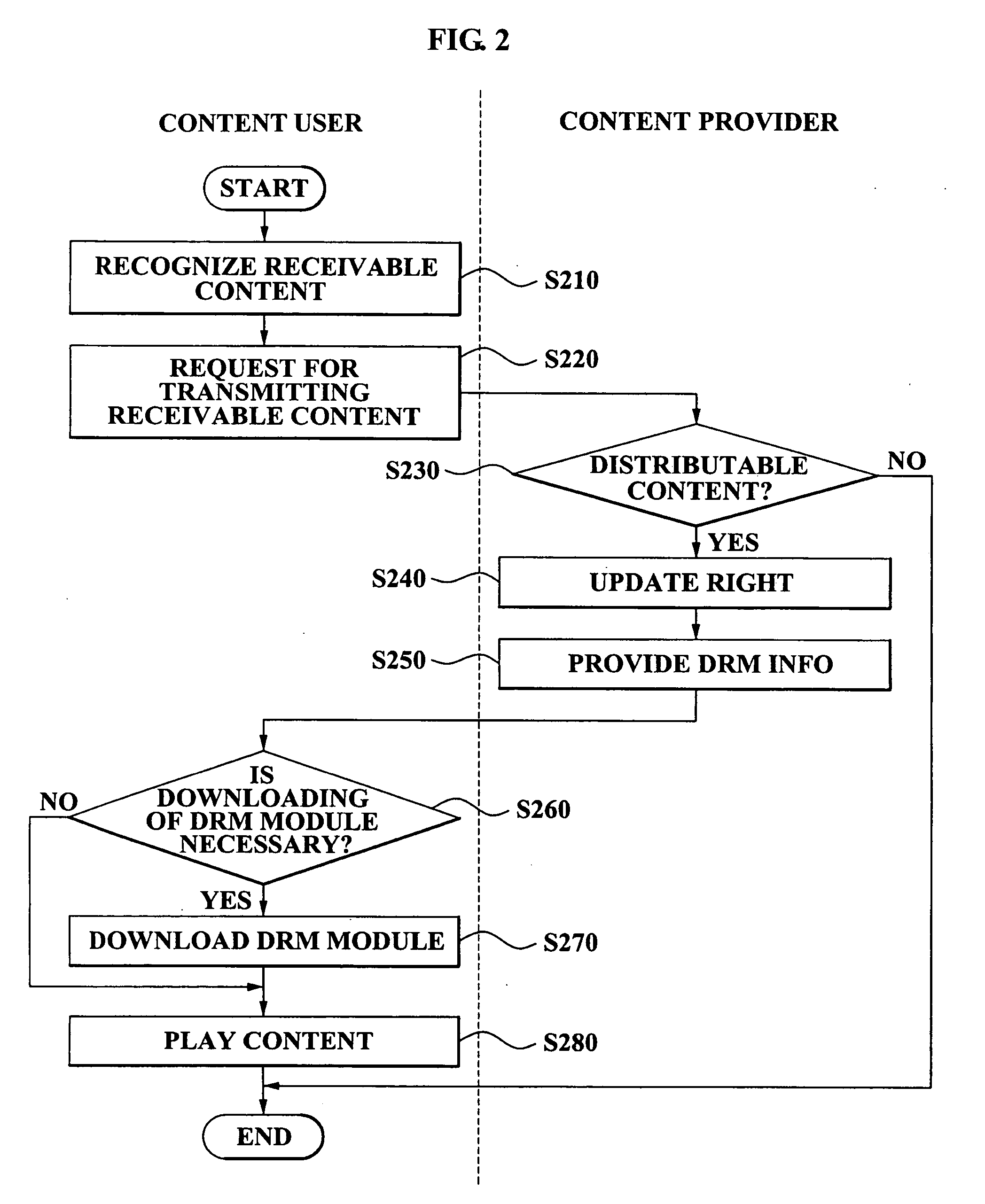

Method of providing DRM interoperability and ad hoc network device using the same

InactiveUS20070130076A1Efficiently share contentFacilitating content sharingData processing applicationsUser identity/authority verificationDigital rights managementInteroperability Problem

A method of providing digital rights management (DRM) interoperability and an ad hoc network device are provided where. a sink device requests a source device to transmit a receivable content in an ad hoc network, the source device provides DRM information corresponding to the requested receivable content, the sink device determines whether downloading of a DRM module is necessary using the DRM information, and the DRM module is downloaded as necessary, from the source device, to bind the DRM module to the requested receivable content. Accordingly, contents with different applied DRM technologies may be effectively shared in an ad hoc network.

Owner:SAMSUNG ELECTRONICS CO LTD

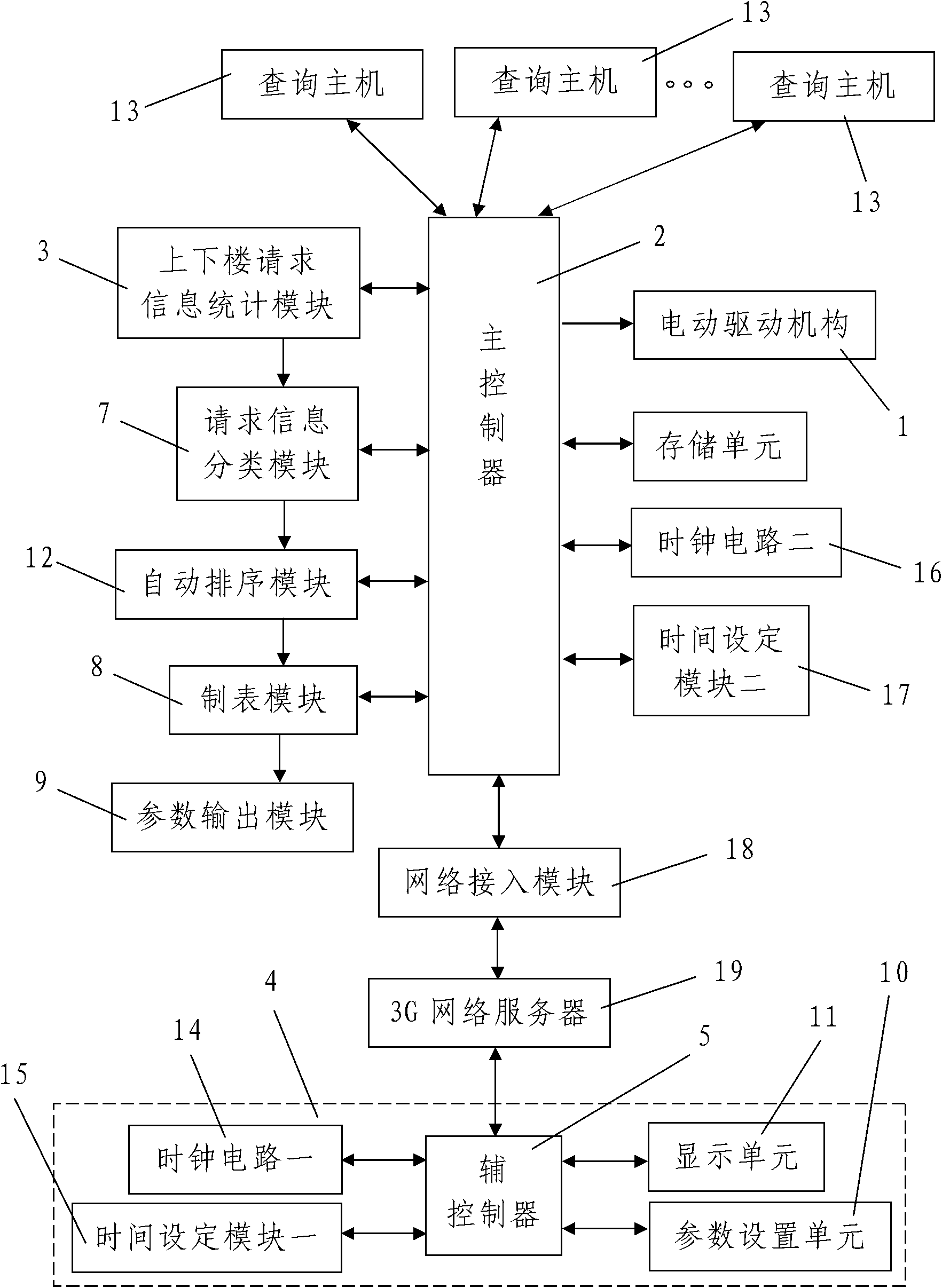

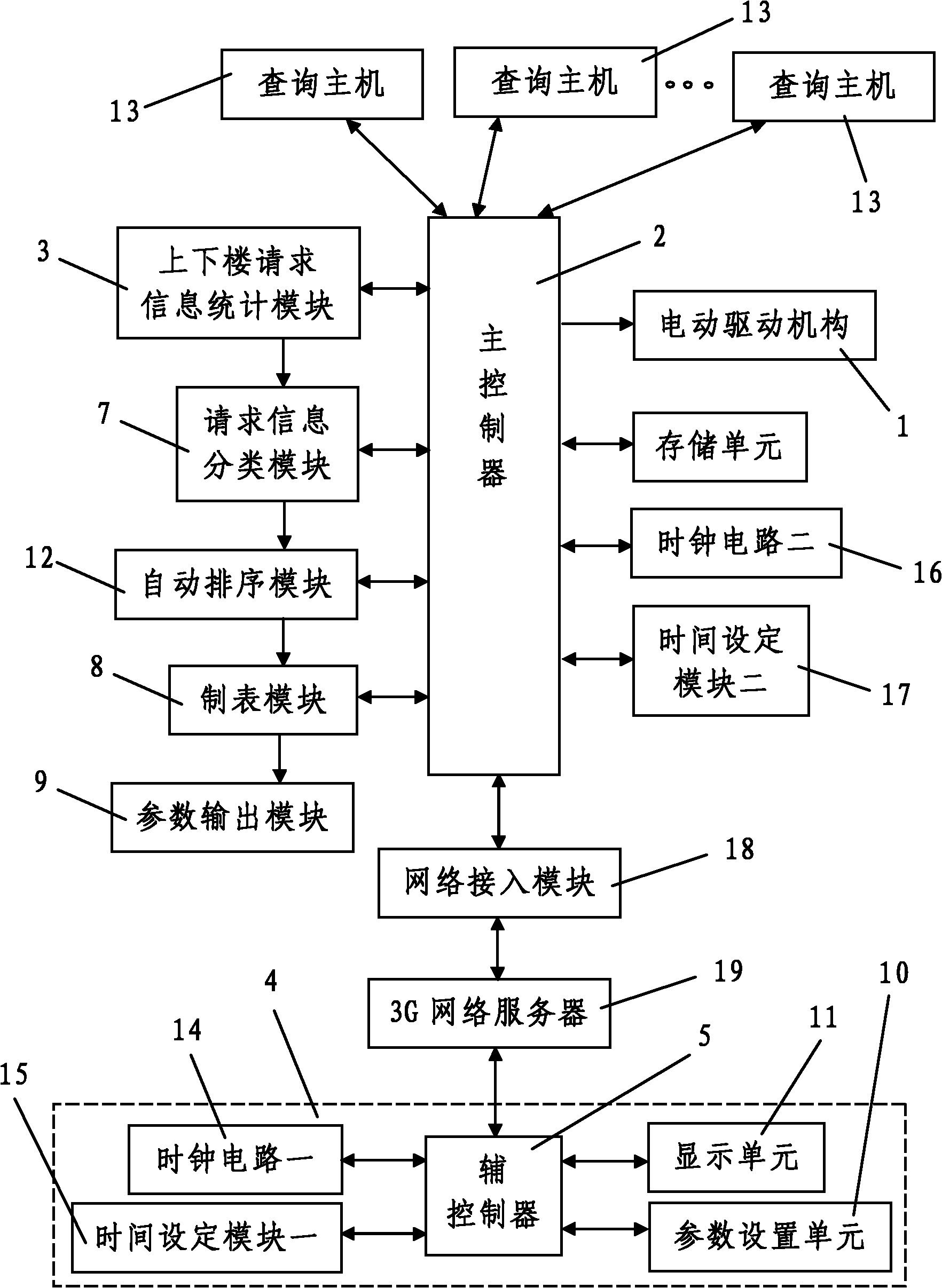

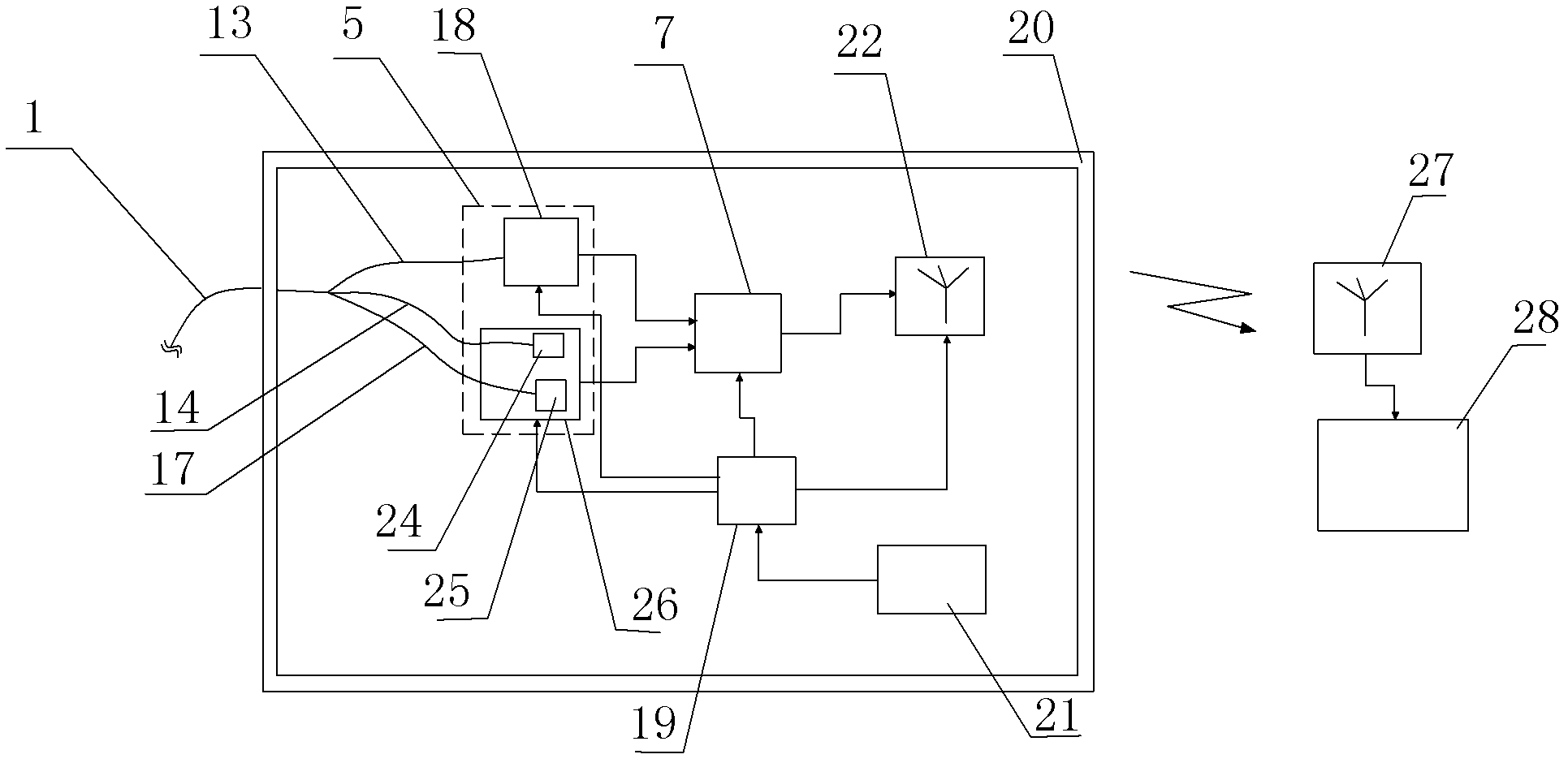

Remote control type elevator reservation device

The invention discloses a remote control type elevator reservation device, which comprises a main controller, an auxiliary controller, a upstairs / downstairs request information statistical module, a storage unit, a request information classification module, an automatic sequencing module, a parameter setting unit and a display unit. The main controller is used for controlling an electric drive mechanism used for driving an elevator car to lift, the auxiliary controller is carried by an elevator user, the a upstairs / downstairs request information statistical module is used for automatic statistics of all upstairs / downstairs requests submitted to the main controller through elevator floor control keys and the auxiliary controller, the automatic sequencing module is used for automatically sequencing upstairs request information and downstairs request information, the parameter setting unit and the display unit are connected with the auxiliary controller, and bidirectional communication is carried out between the auxiliary controller and the main controller in a wireless communication way. The remote control type elevator reservation device has a reasonable design, good use effects and a high degree of intelligence and can be operated easily, and the problems of the existing elevator that the degree of intelligence is low, the upstairs / downstairs keys need to be operated manually, the current operating status of the elevator cannot be mastered fully and the waiting time is long can be solved effectively.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

P-type NiO conducting film for organic solar cell, a method for preparation of NiO conducting film, and an organic solar cell with enhanced light-to-electric energy conversion using the same

InactiveUS20110108116A1Improve power conversion efficiencyEasy to prepareSynthetic resin layered productsVacuum evaporation coatingSputteringOrganic light emitting device

A p-type NiO conducting film for an organic solar cell, a preparation method thereof, and an organic solar cell using the same and having enhanced power conversion efficiency, are provided, wherein the NiO conducting film is fabricated by vacuum sputtering in which nickel or nickel oxide is used as a target material, and argon, oxygen or the mixed gas of the argon and the oxygen is supplied. The p-type NiO conducting film may be easily prepared by vacuum sputtering, and since a n-type conducting film is prepared by simply coating sol-phase precursor solution, the NiO conducting film and the organic solar cells having the NiO conducting film in the order of the NiO conducting film, a photoactive layer, and a n-type conducting film, have enhanced electric energy conversion. As a result, the provided disclosure is useful particularly when applied in organic solar cells and organic light emitting devices.

Owner:KOREA INST OF MASCH & MATERIALS

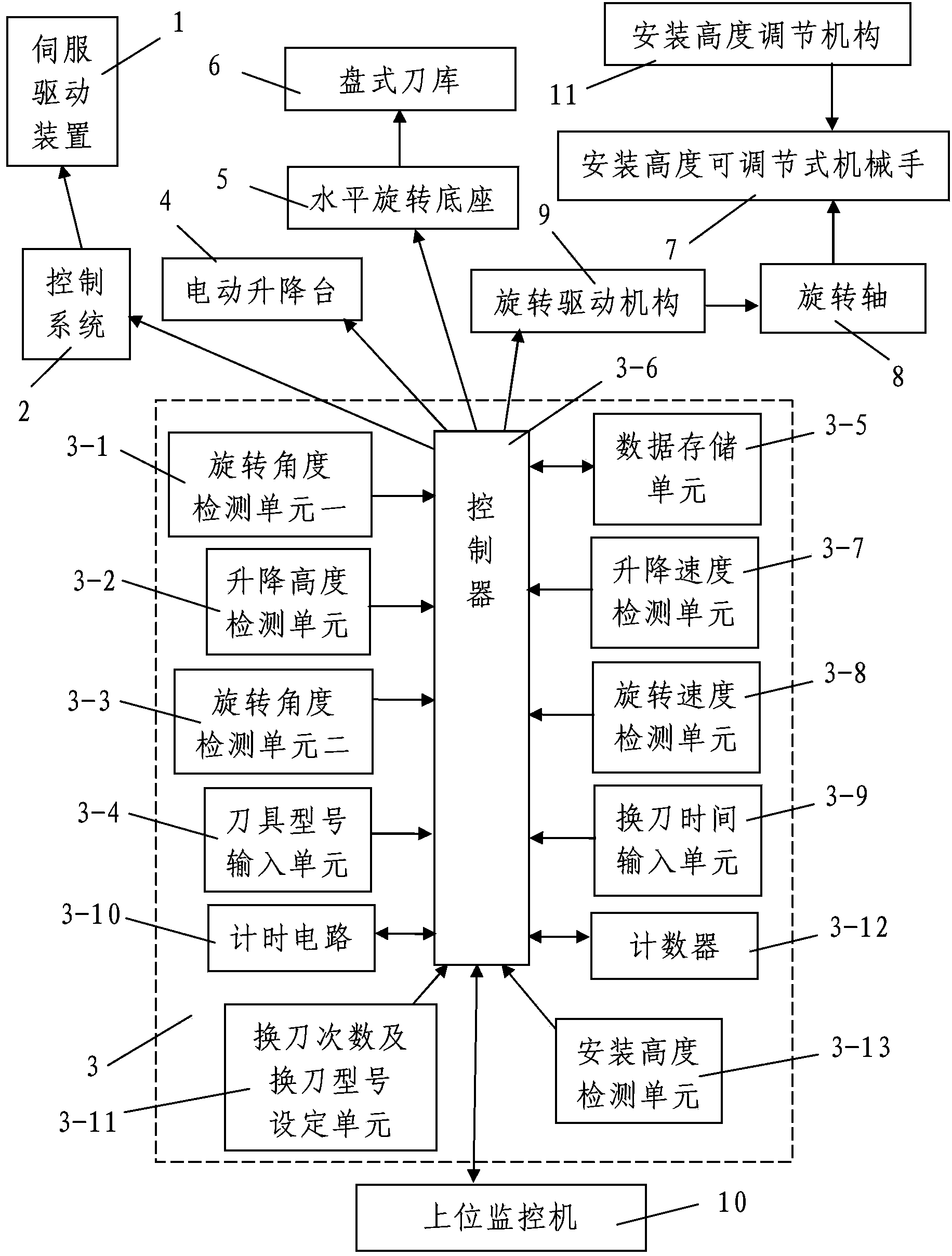

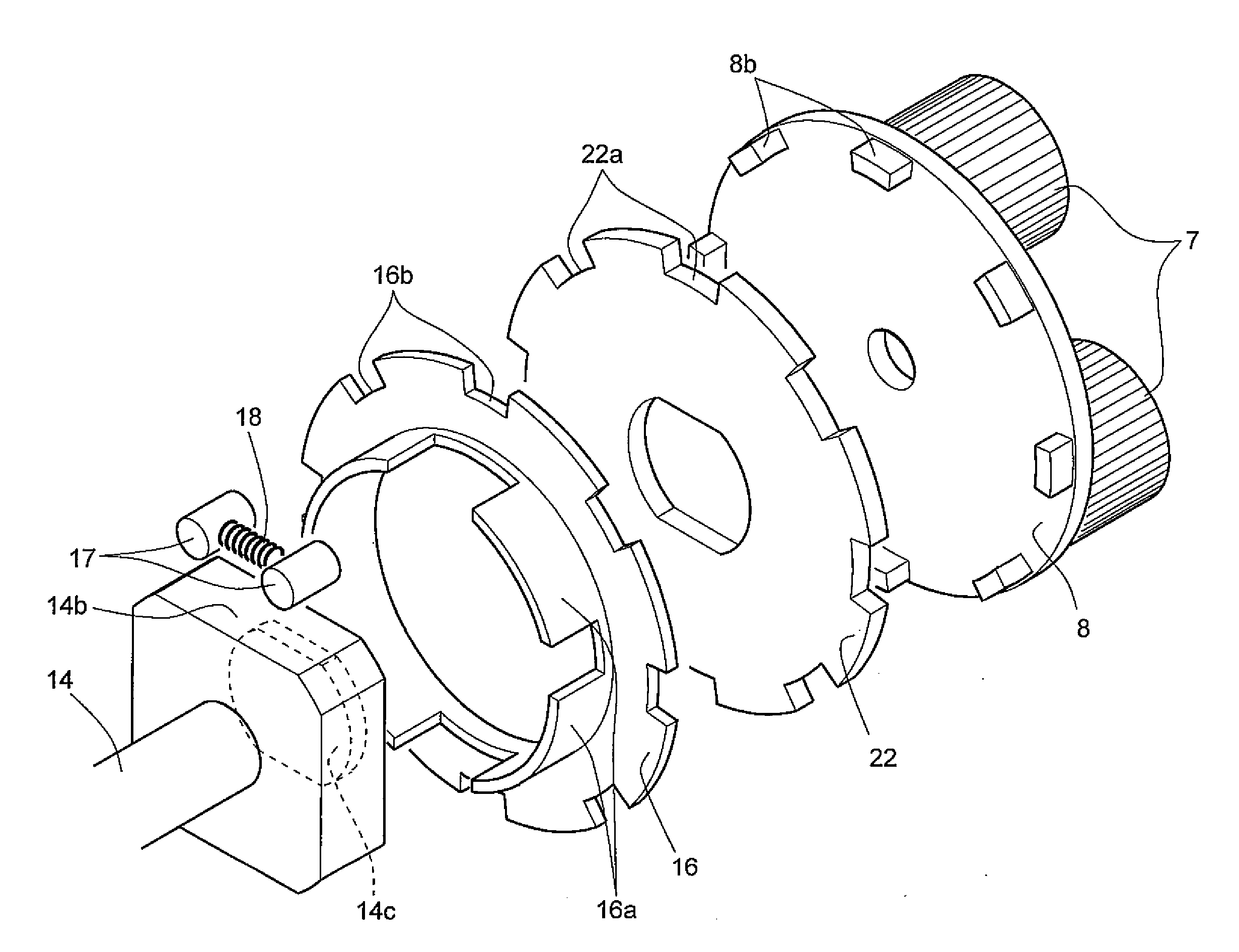

Computer numerical control machining center based on quick and automatic tool changing system

InactiveCN103801969AReasonable designLow costPositioning apparatusMetal-working holdersNumerical controlControl system

The invention discloses a computer numerical control machining center based on a quick and automatic tool changing system. The computer numerical control machining center comprises a machine tool body, an automatic tool changing system, a servo driving device and a control system, wherein the automatic tool changing system comprises an automatic tool changing control device, an electric lifting platform, a horizontal rotating base, a disc-type tool magazine, and an installation-height-adjustable manipulator which is used for changing tools; a rotating shaft is arranged below the middle of the installation-height-adjustable manipulator; an installation height adjusting mechanism which is used for adjusting the installation height of the installation-height-adjustable manipulator is arranged on the rotating shaft; the automatic tool changing control device comprises an automatic tool changing controller, a rotation angle detection unit I, a lifting height detection unit, a rotation angle detection unit II, a tool model input unit, an installation height detection unit and a data storage unit. The computer numerical control machining center is reasonable in design, simple and convenient to operate, high in intelligence degree, good in using effect, and shorter in tool changing time. The installation height of the manipulator is adjustable, a control mode is simple, and adjustment of the installation height can be conveniently realized.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

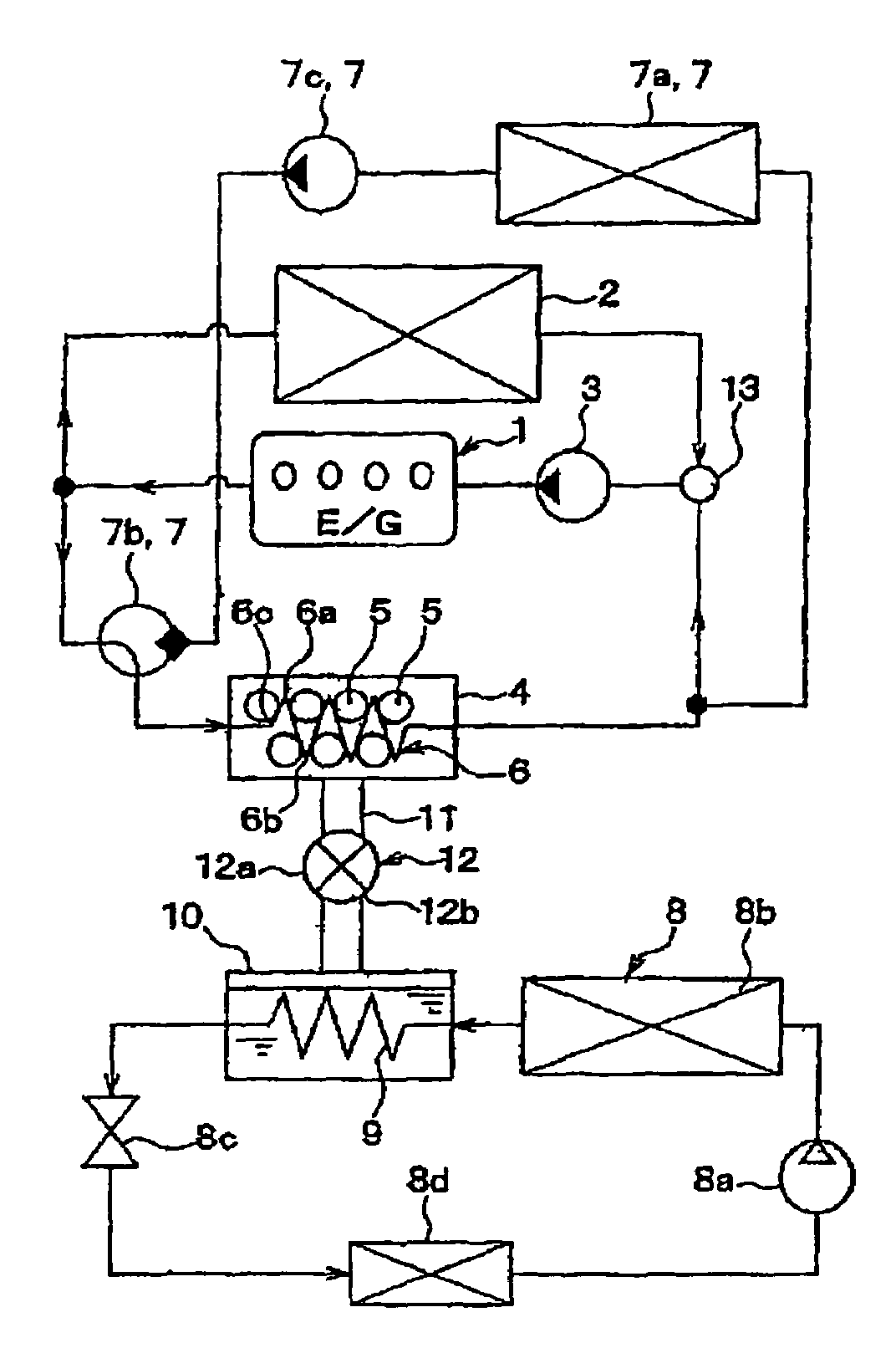

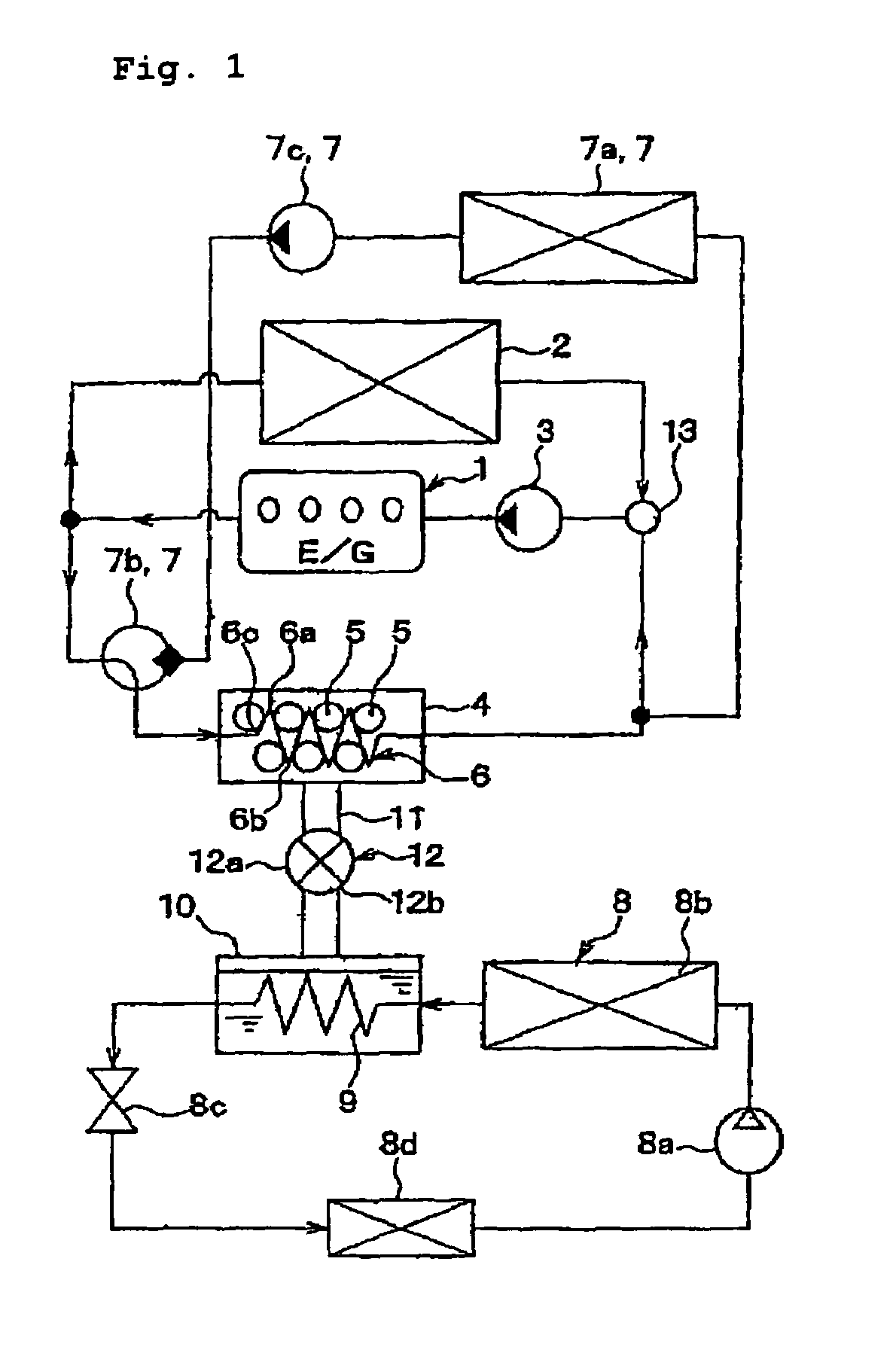

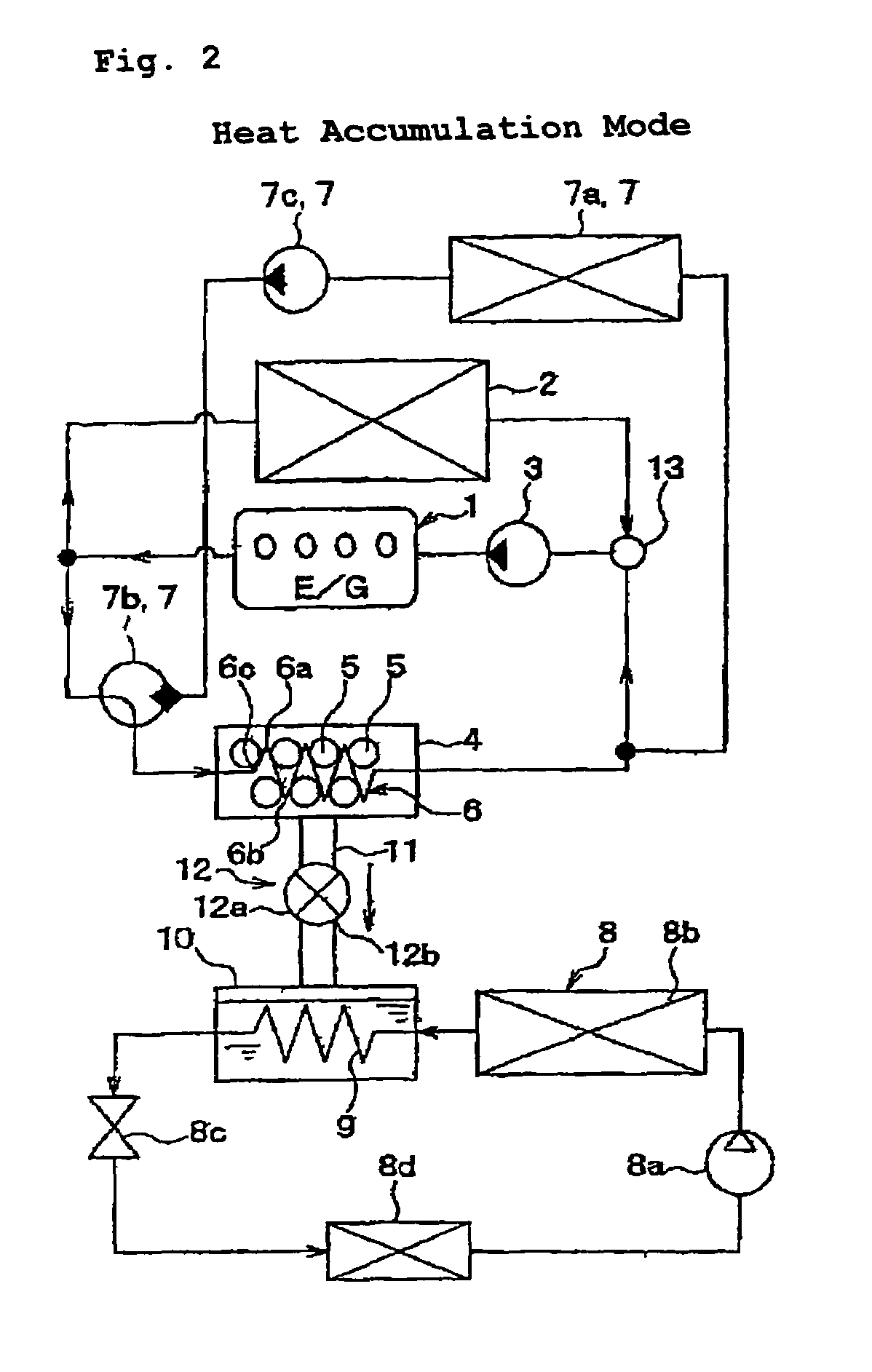

Adsorbent for heat utilization system, adsorbent for regenerator system, regenerator system comprising the adsorbent, ferroaluminophosphate and method for production thereof

ActiveUS7037360B2Excellent adsorbentImprove the desorption effectCombination devicesInternal combustion piston enginesSorbentEngineering

An adsorbent for regenerator systems, to a heat utilization system and a regenerator system that comprise the adsorbent, and to a ferroaluminophosphate and a method for production thereof. More precisely, the invention relates to an adsorbent favorable for regenerator systems, which efficiently utilizes the heat source obtainable from cars and the like to thereby realize efficient regenerator systems, to a regenerator system that comprises the adsorbent, to a ferroaluminophosphate to be the adsorbent favorable for regenerator systems, and to a method for production thereof.

Owner:MITSUBISHI PLASTICS INC +2

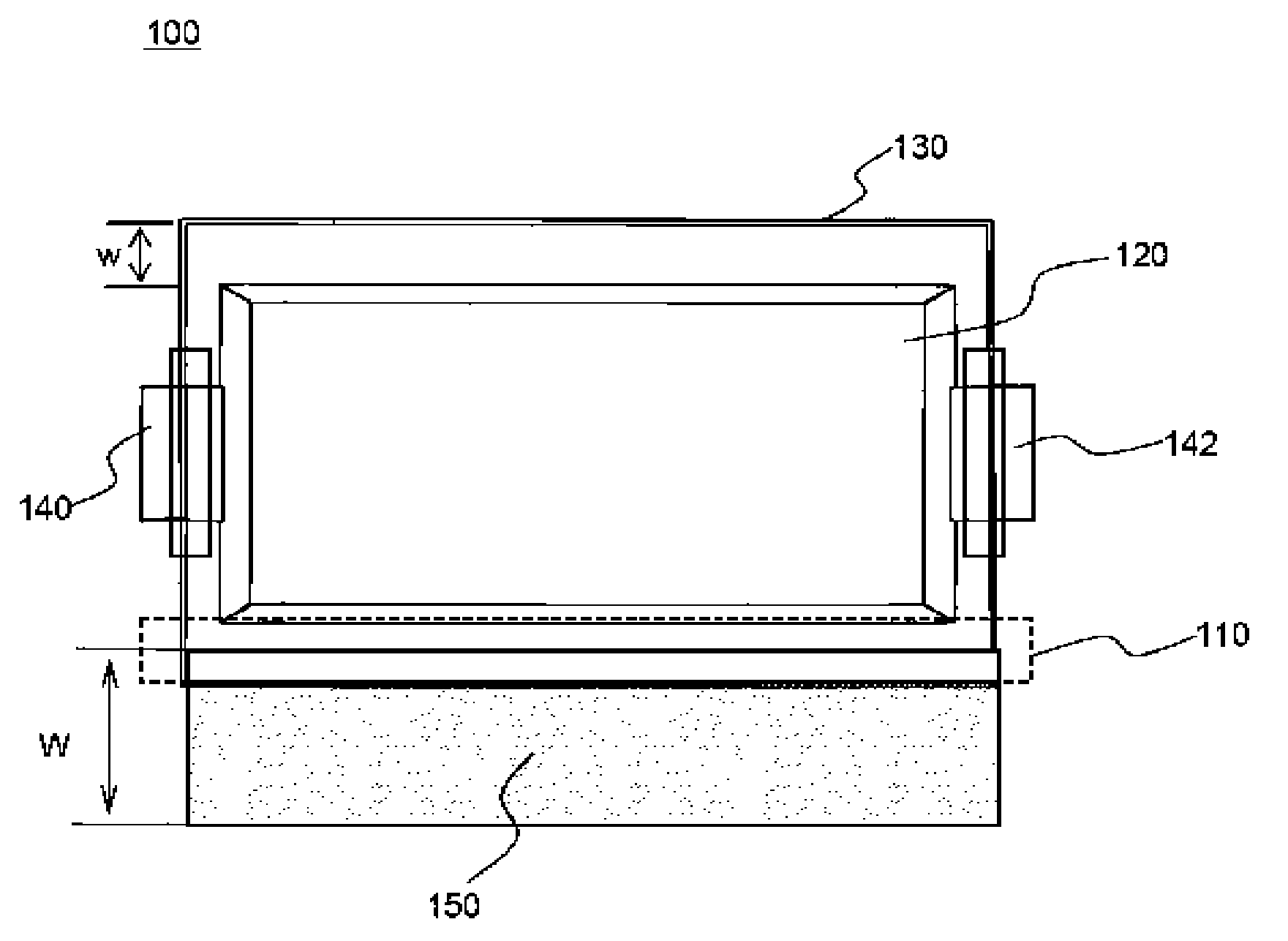

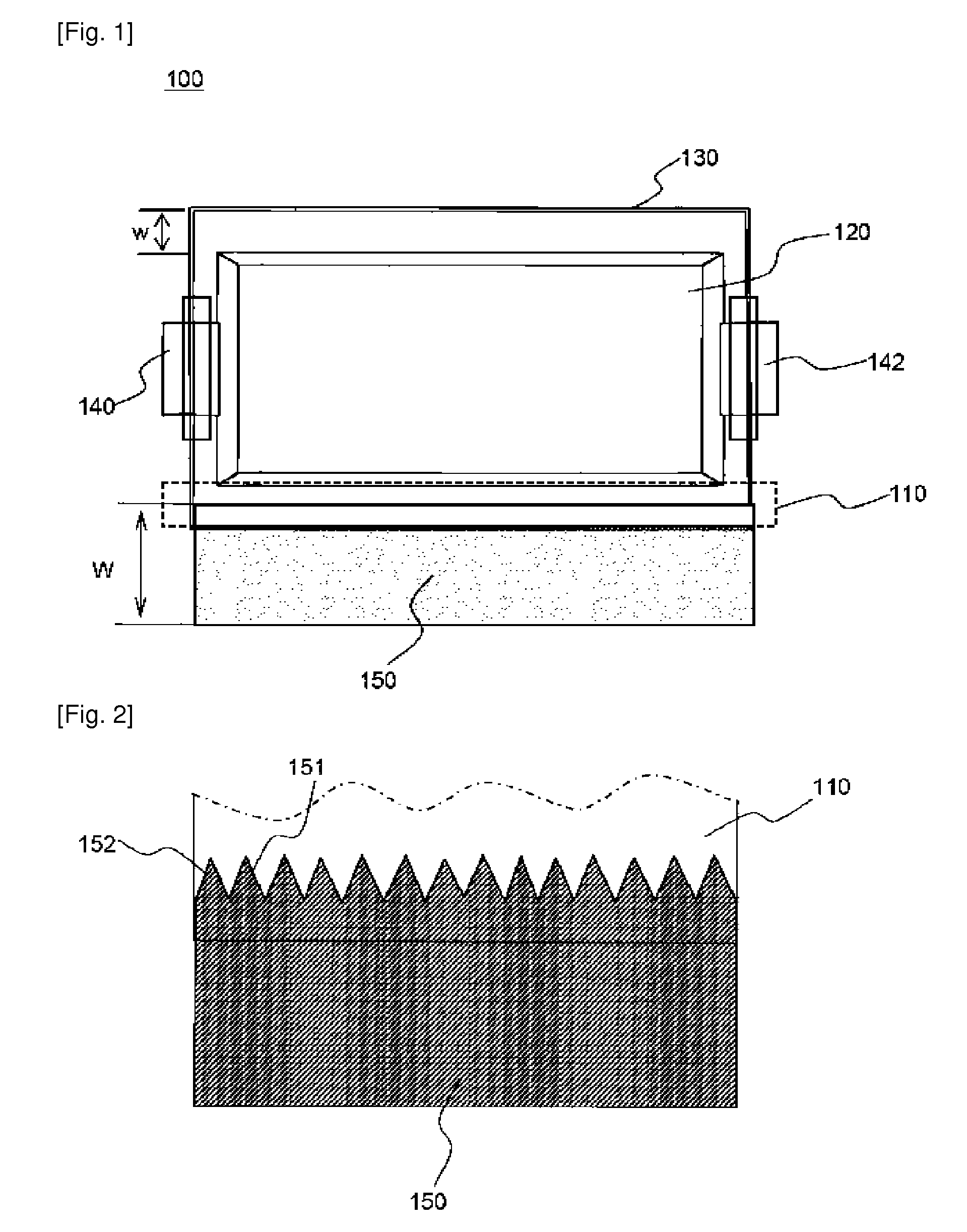

Battery cell of excellent heat dissipation property and middle or large-sized battery module employed with the same

ActiveUS20110008666A1Improve cooling effectEnsure effective applicationCell temperature controlJackets/cases materialsBattery cellMetal

Disclosed herein is a battery cell constructed in a structure in which an electrode assembly of a cathode / separator / anode structure is mounted in a battery case formed of a laminate sheet including a resin layer and a metal layer while the electrode assembly is connected to electrode terminals extruding out of the battery case, wherein the battery cell is constructed in a structure to accelerate heat dissipation by the heat conduction through at least some of a sealing part of the battery case where the electrode terminals are not located.

Owner:LG ENERGY SOLUTION LTD

Fixed type constant velocity joint

ActiveUS20100190558A1Reliable constructionSuitable strengthYielding couplingRotary machine partsLinear regionEngineering

A constant velocity joint for a drive system comprises: an outer race having an inner spherical surface, and a plurality of guide grooves formed in an axial direction in the inner spherical surface of the outer race; an inner race having an outer spherical surface, and a plurality of guide grooves formed in an axial direction in the outer spherical surface of the inner race, said guide grooves of the outer race and said guide grooves of the inner race together forming a plurality of ball guide tracks; a plurality of balls disposed in the ball guide tracks; and a cage installed between the inner spherical surface of the outer race and the outer spherical surface of the inner race, said cage having a plurality of windows for retaining the balls therein; wherein each of the guide grooves of the outer race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the outer race and a second circular region disposed at a second lateral side of the outer race, and a linear region tangentially extending between these two circular regions; and wherein each of the guide grooves of the inner race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the inner race and a second circular region disposed at a second lateral side of the inner race, and a linear region tangentially extending between these two circular regions.

Owner:WIA CORP

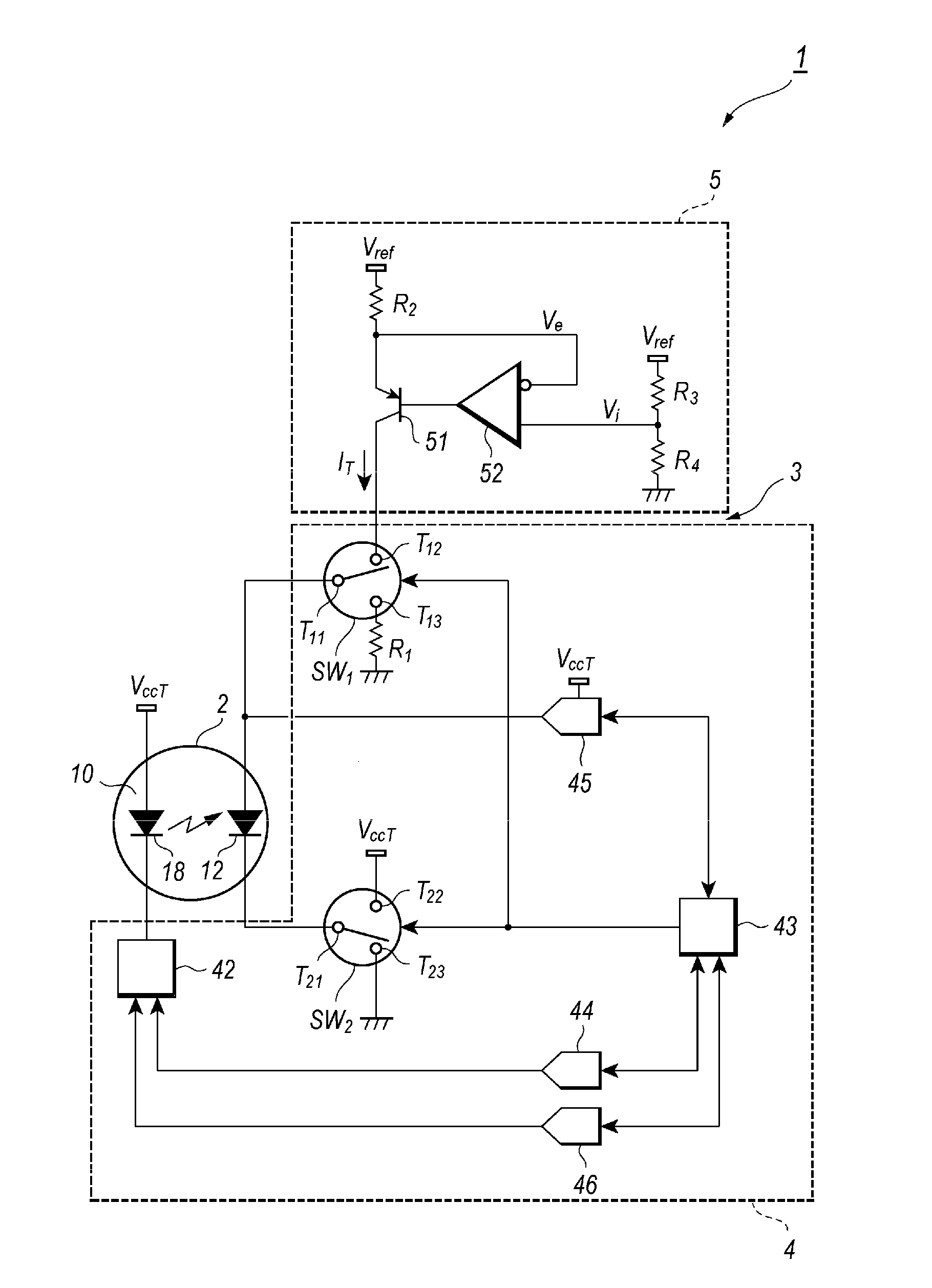

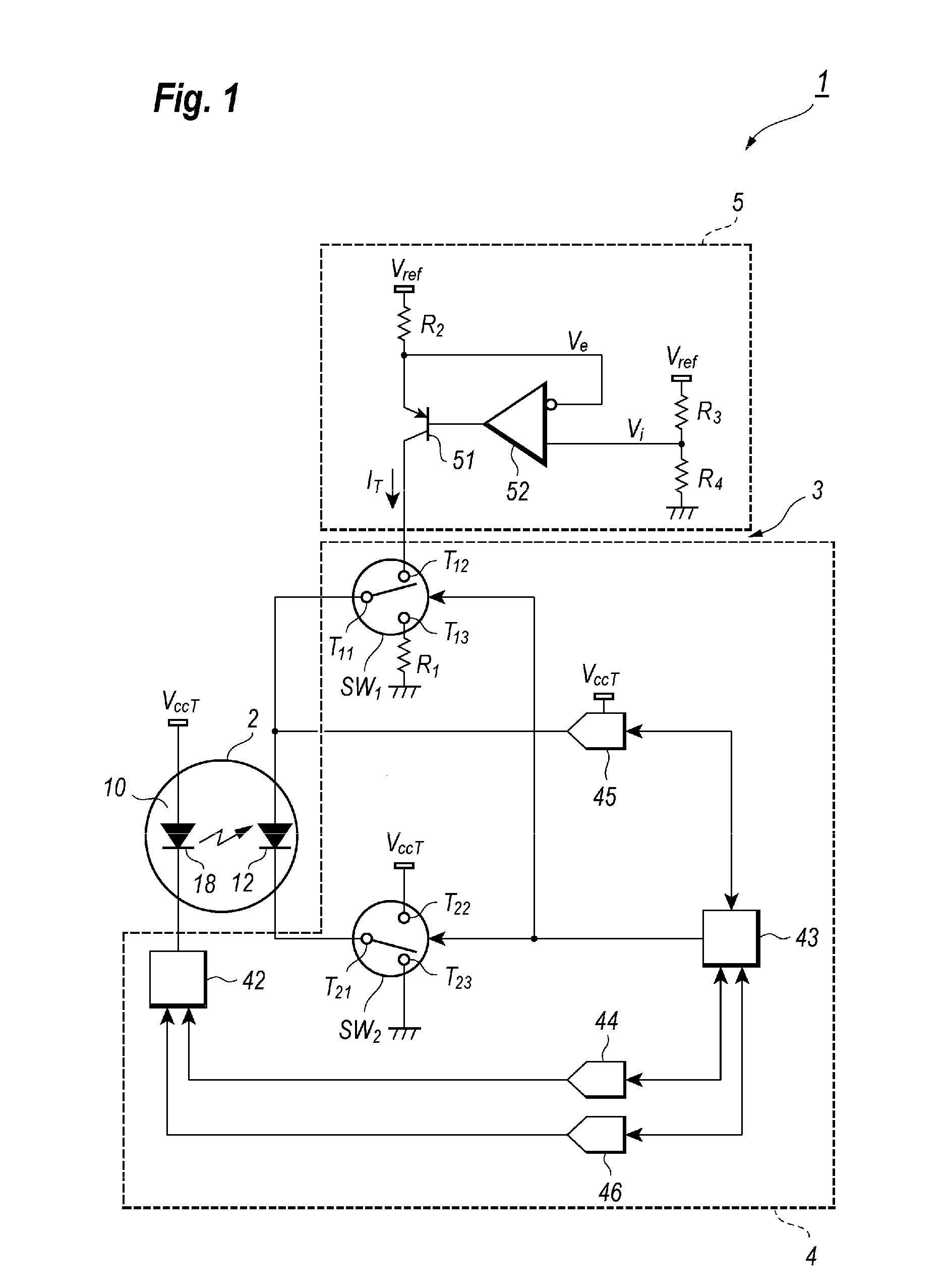

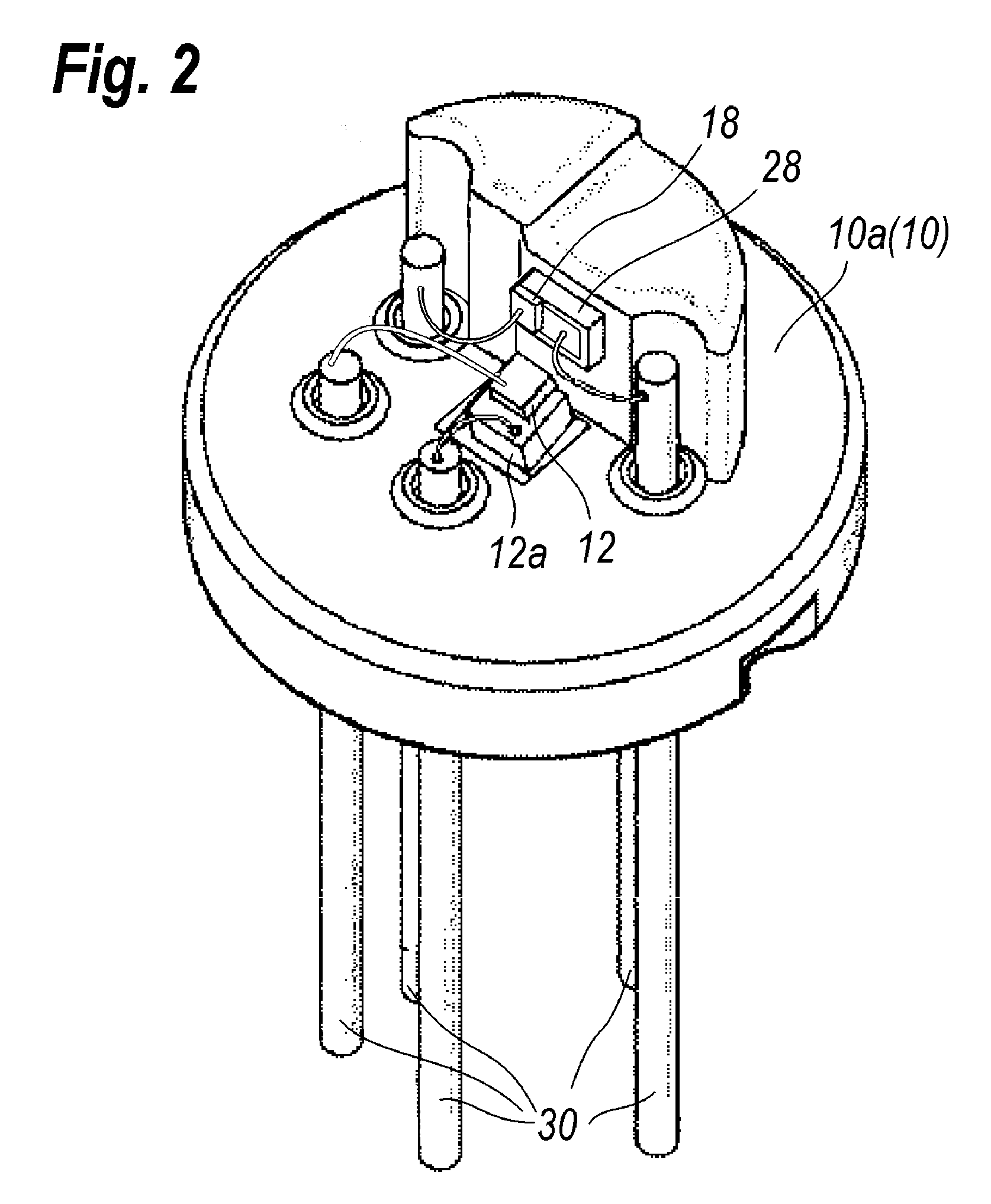

Optical transmitter module and optical bi-directional module with function to monitor temperature inside of package and method for monitoring temperature

InactiveUS20100265076A1Ensure effective applicationFire alarmsSemiconductor lasersMonitoring temperatureTemperature sense

An optical module with a function to monitor a temperature within the package without installing any specific temperature sensing device is disclosed. The optical module of the invention includes an LD and a monitor PD in a CAN type housing. When the LD is inactive or driven under a constant bias current, the monitor PD receives a constant current independent of the temperature. The forward voltage of the monitor PD indicates the temperature within the package.

Owner:SUMITOMO ELECTRIC IND LTD

Speed reducer with a brake

InactiveUS20160341267A1Easy to assembleLess electric powerBraking element arrangementsJointsReduction driveReducer

A device configured to actuate a driven member by driving a driving motor includes a brake which does not consume electric power and which can be easily mounted in the device. A speed reducer is mounted in the device, and includes a reduction mechanism for transmitting the rotation of the driving motor toward the driven member after reducing its speed, and a locking type reverse input shutoff mechanism, as the brake, which is configured to mechanically lock up when reverse input torque is applied from the driven member while the driving motor is not being driven, thereby retaining the position of the driven member. The reduction mechanism and the reverse input shutoff mechanism are combined to constitute a single unit.

Owner:NTN CORP

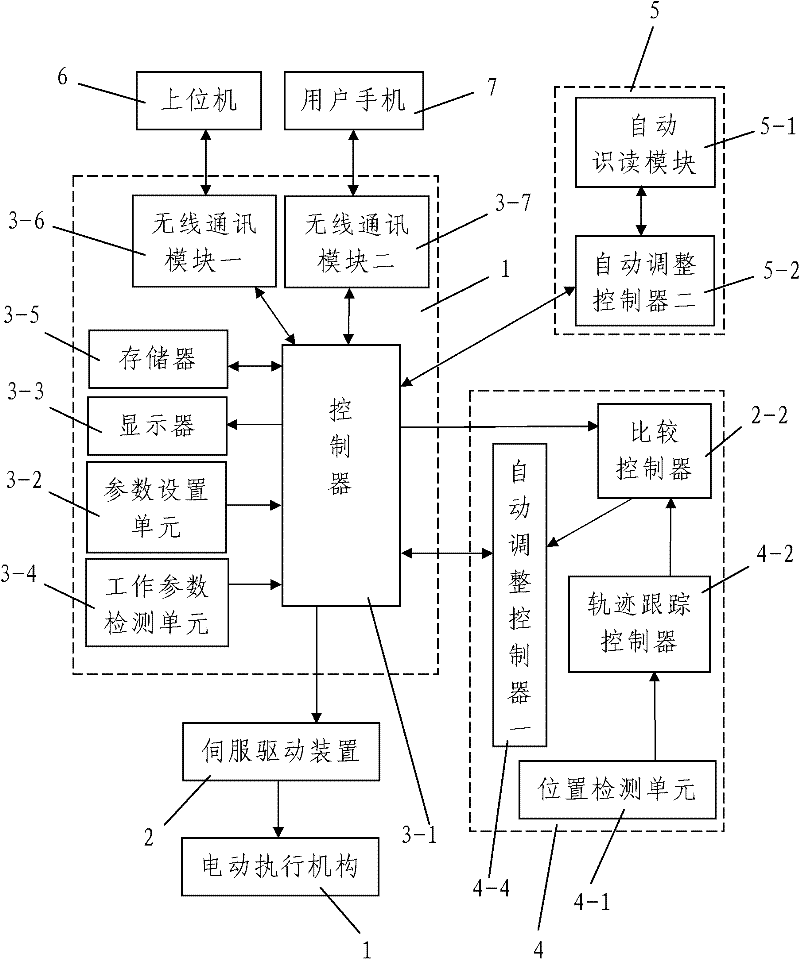

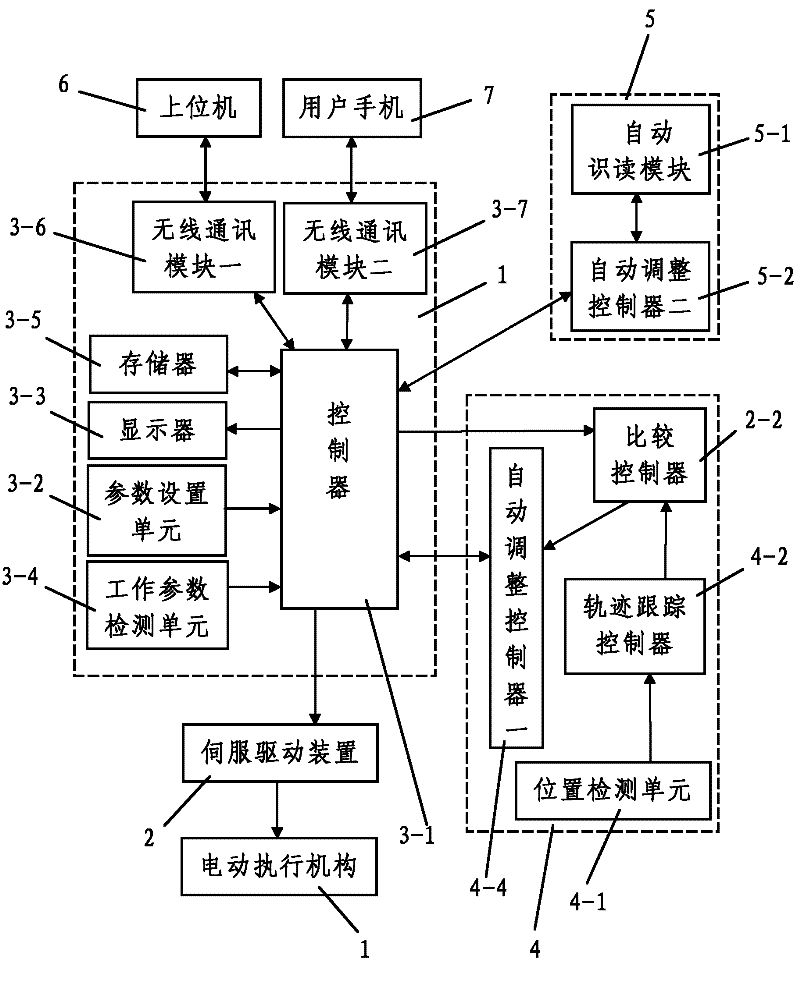

Novel straight-line control numerical control machine

InactiveCN102455680AReasonable designLow costTotal factory controlNumerical controlNumerical controlControl system

The invention discloses a novel straight-line control numerical control machine which comprises a machine tool body, an electric actuator, a servo driving device and a control system, wherein the control system comprises a controller used for controlling the electric actuator to process workpieces according to the pre-designed processing scheme, a storage device, a parameter setting unit, a display device and a working parameter detection unit; the novel straight-line control numerical control machine also comprises an internal processing scheme adjusting system and an external processing scheme adjusting system which are used for adjusting the predesigned processing scheme respectively in an automatic way and in an artificial way; the internal processing scheme adjusting system comprises a trajectory tracking controller, a position detecting unit, a comparison controller and an automatic adjustment controller I; and the external processing scheme adjusting system comprises an automatic indentifying and reading module and an automatic adjustment controller II. The novel straight-line control numerical control machine is reasonable in design, convenient in wiring, simple and convenient in use and operation and high machining precision, high intelligent degree, and is capable of effectively overcoming the defects that the existing straight-line control numerical control machine is difficult in adjustment for the processing scheme, poorer in using effect and lower in intelligent degree, can not realize unmanned operation in deed and the like.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Method of recording identifier and set of photomasks

InactiveUS6897010B2Reduce the numberEnsure effective applicationPhoto-taking processesSemiconductor/solid-state device detailsLatent imagePhotoresist

A method of recording identifiers, each including a group of character strings A and B including z1, and z2 characters, respectively, on plate members involves the use of a photomask of a first type and at least one photomask of a second type. The photomask of the first type has an opaque pattern defining the character string A. The photomask of the second type has an opaque pattern defining at least one of the characters of the character string B. The method further includes the steps of forming a photoresist layer on one of the plate members, selectively exposing the photoresist layer to a radiation through the photomask of the first type to form a latent image of the character string A in the photoresist layer, and forming a latent image of the character of the character string B in the photoresist layer through the photomask of the second type.

Owner:SUMITOMO SPECIAL METAL CO LTD

Landslide monitoring system

InactiveCN103134430ASimple structureEasy to processUsing optical meansTime-domain reflectometerLight source

The invention discloses a landslide monitoring system. The landslide monitoring system comprises an inclinometer pipe inserted into a landslide, a power supply system and a first wireless transceiver module, wherein the inclinometer pipe penetrates through a potential sliding surface of the landslide and extends into a drilling hole below a surface of a bed rock body; the inclinometer pipe is internally and continuously provided with curve-shaped testing channels allowing signal optical fibers to pass through; each curve-shaped testing channel comprises multiple A-side deformed teeth and multiple B-side deformed teeth; the testing unit comprises a light time domain reflectometer and a light source-light power meter; one end of a first signal optical fiber is connected to the light time domain reflectometer; a second signal optical fiber is connected to the light source-light power meter; the power supply system comprises a battery pack; and the first wireless transceiver module is wirelessly connected to a second wireless transceiver module. The landslide monitoring system has a simple structure, a rational design, convenience in processing and manufacturing, low cost, a flexible use way, high sensitivity, good use effects, a high practical value, strong adaptability, and capabilities of realizing long-distance monitoring and monitoring change of depth displacement of the landslide efficiently.

Owner:XIAN JINHE OPTICAL TECH

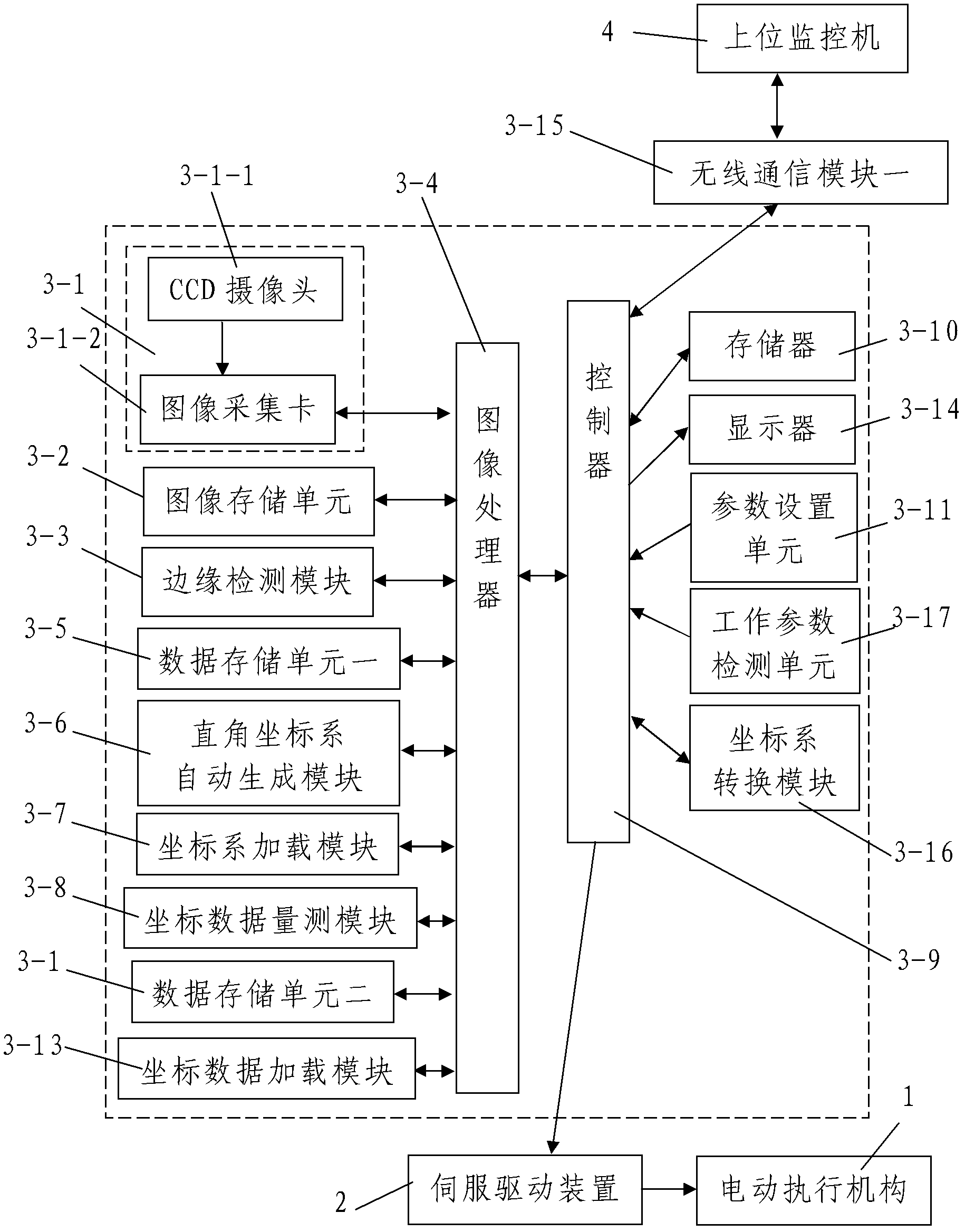

Intelligent numerical control machine tool based on image processing

InactiveCN103163834AReasonable designLow costProgramme controlComputer controlNumerical controlImaging processing

The invention discloses an intelligent numerical control machine tool based on image processing. The machine tool comprises a machine tool body, an electric execution mechanism, a servo drive device and a control system, wherein the control system comprises an image collecting device, an image storing unit, an edge detecting module, an image processing device, a first data storing unit, an automatic rectangular coordinate system generating module, a coordinate system loading module, a coordinate data measuring module, a second data storing unit, a coordinate data loading module, a coordinate system conversion module, a controller, a work parameter detecting unit, a memorizer, a parameter setting unit and a display device. The controller controls the electric execution mechanism to machine a workpiece according to the outline of a formed product after coordinate conversion. The memorizer, the parameter setting unit and the display are connected with the controller. The machine tool is reasonable in design, simple and convenient to use and operate, good in use effect and high in intelligent degree, and can effectively solve the problems that an existing numerical control machine tool is low in intelligent degree and low in machining efficiency and machining precision, and machining diagrams need to be drawn in advance.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Method for producing propylene polymer having a very high melt-flowability

ActiveUS20060223959A1Improve production yieldIncreased melt flow rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com