Computer numerical control machining center based on quick and automatic tool changing system

An automatic tool change and machining center technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems affecting the processing efficiency of CNC machine tools, cannot be completed synchronously, and the tool change time is long, and achieves high practical value. , to achieve the effect of convenient, short tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

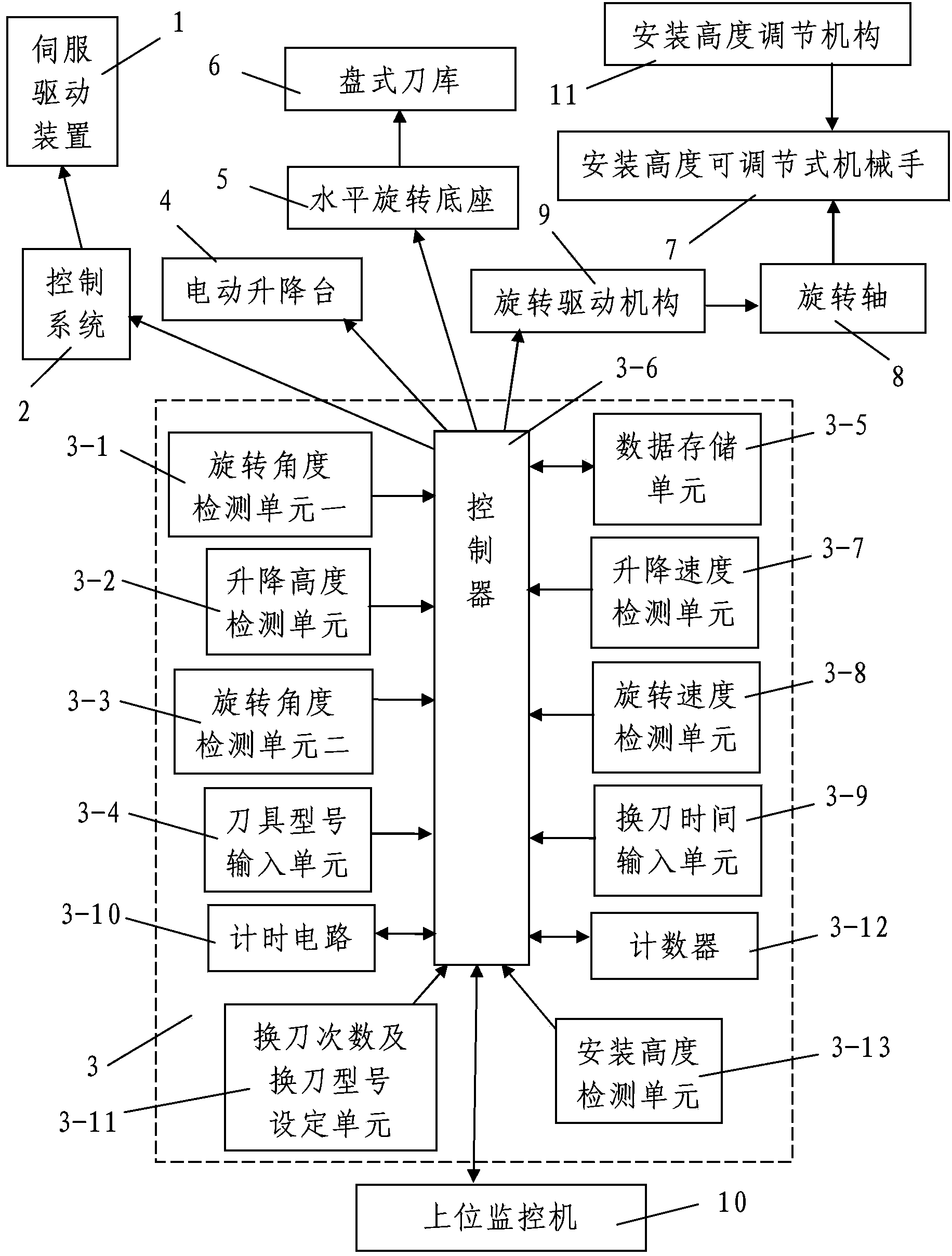

[0032] Such as figure 1As shown, the present invention includes a machine tool body, an automatic tool change system installed on the machine tool body, a servo drive device 1 for driving the machine tool main shaft, and a control system 2 arranged on the machine tool body. The servo drive devices 1 are connected through a transmission mechanism, and the servo drive device 1 is controlled by a control system 2 and connected to the control system 2 . The automatic tool change system includes an automatic tool change control device 3, an electric lifting platform 4, a horizontal rotating base 5 installed on the electric lifting platform 4 through bearings, a disc tool magazine 6 installed on the horizontal rotating base 5, and a The installation height adjustable manipulator 7 for changing the tool is provided with a rotating shaft 8 below the middle part of the installation height adjustable manipulator 7 . The rotating shaft 8 is provided with an installation height adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com