Patents

Literature

42 results about "Weight control agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agent used to regulate body weight.

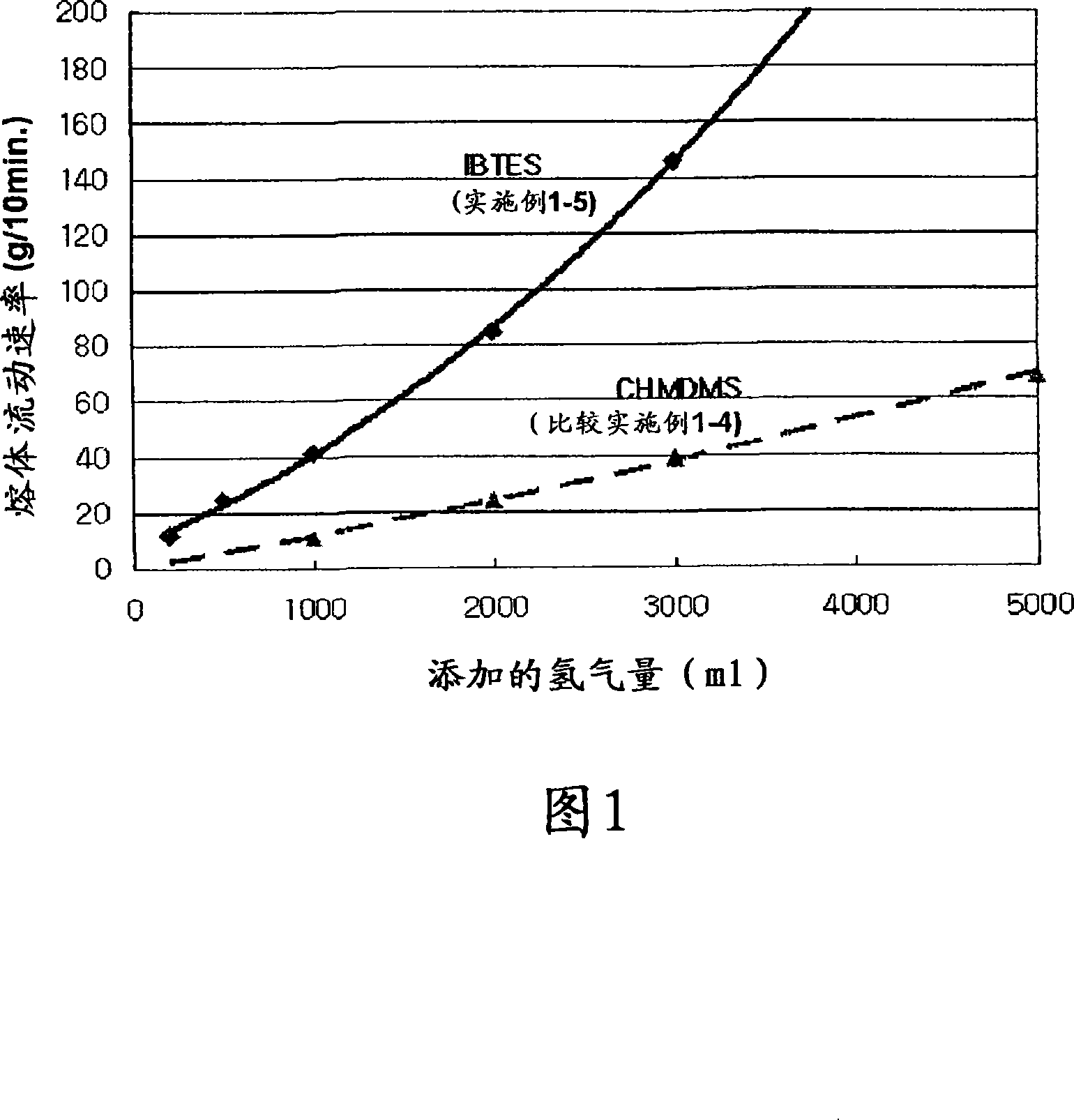

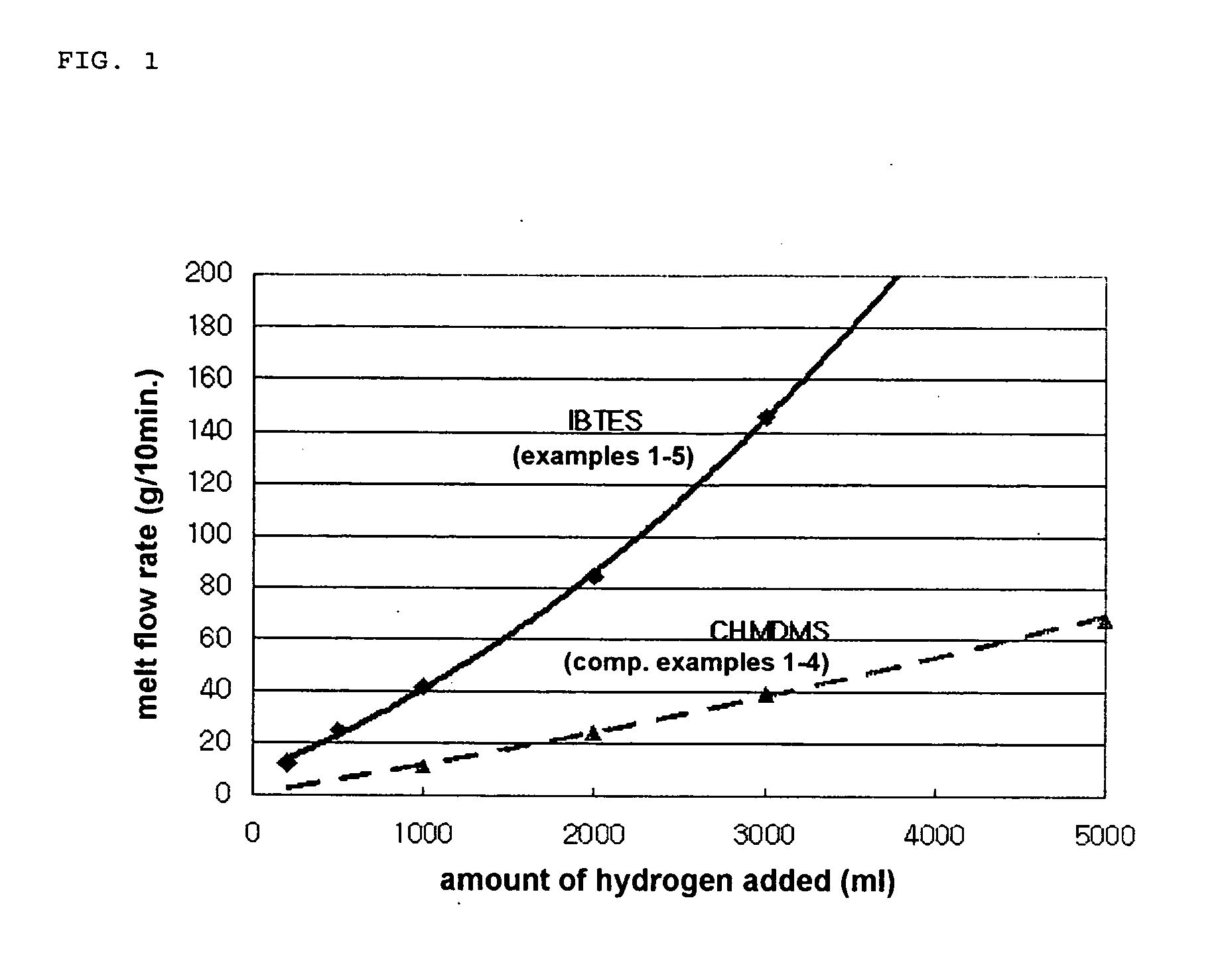

Method for producing propylene polymer having a very high melt-flowability

ActiveUS7244794B2Ensure effective applicationHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

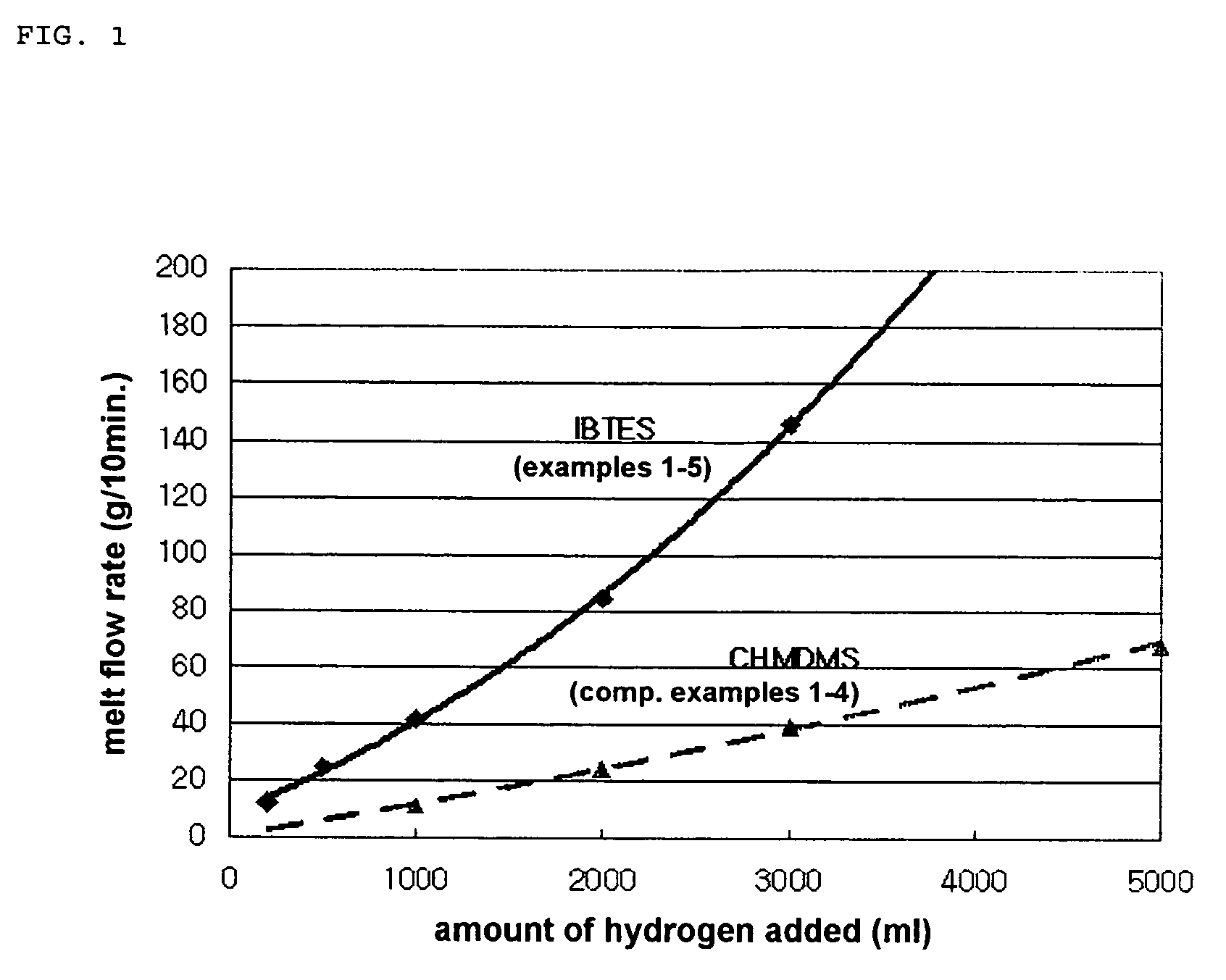

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

Salt-resistant and calcium-resistant filtrate reducer applied to drilling fluid and preparation method of filtrate reducer

ActiveCN104497995AAnti-calciumMagnesium and other divalent ions are strongDrilling compositionMeth-Propylsulfonic acid

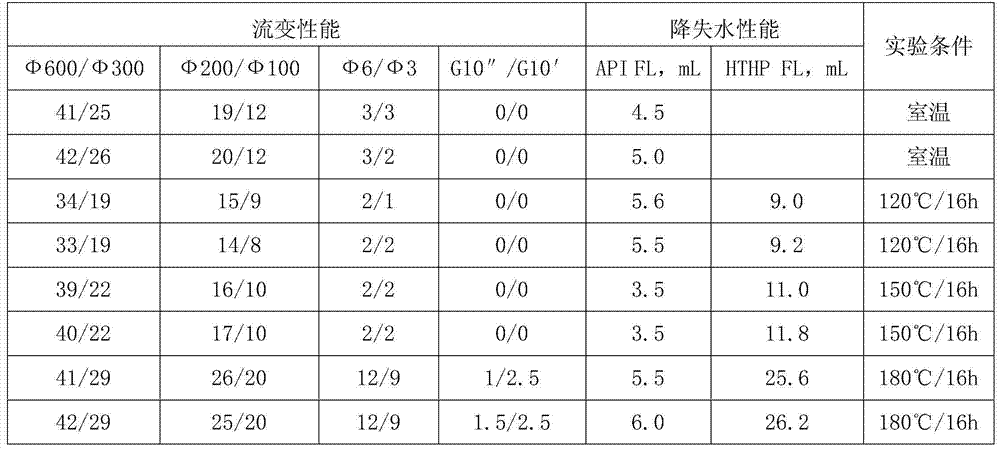

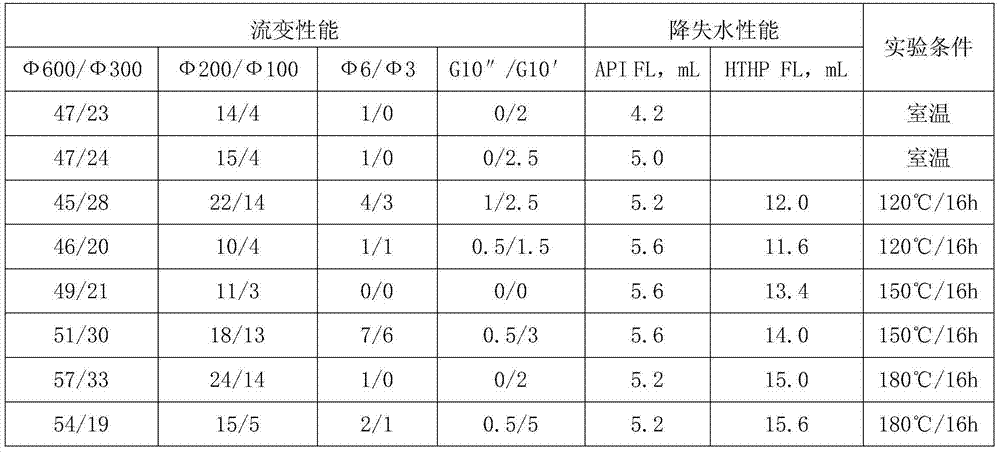

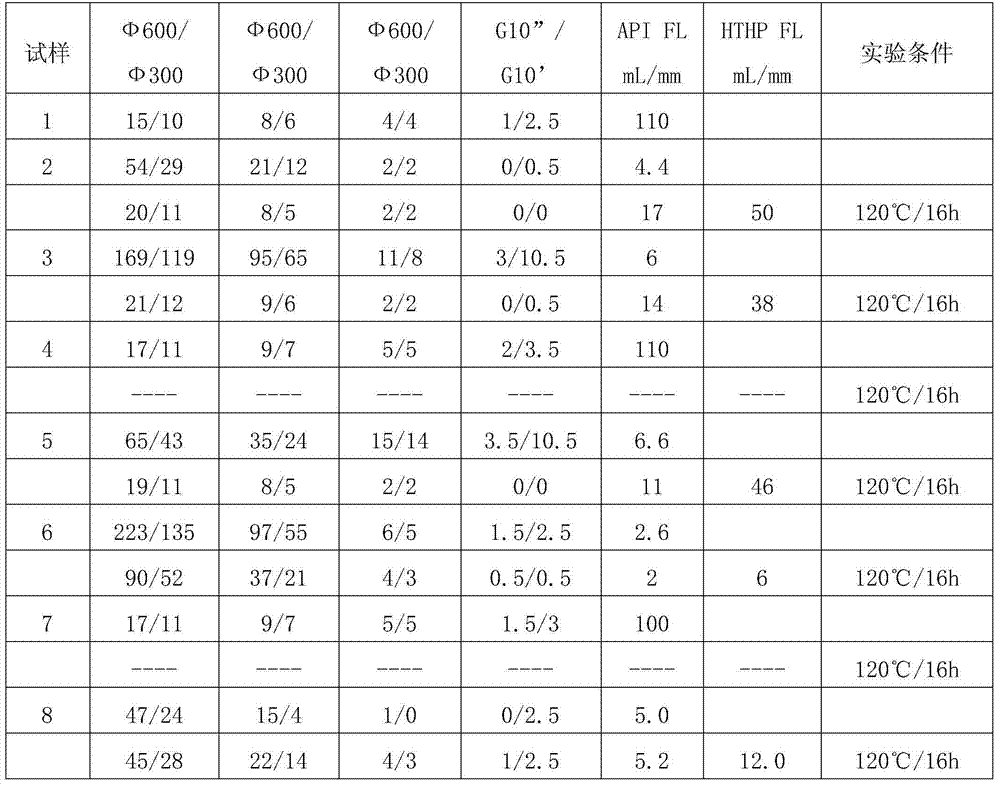

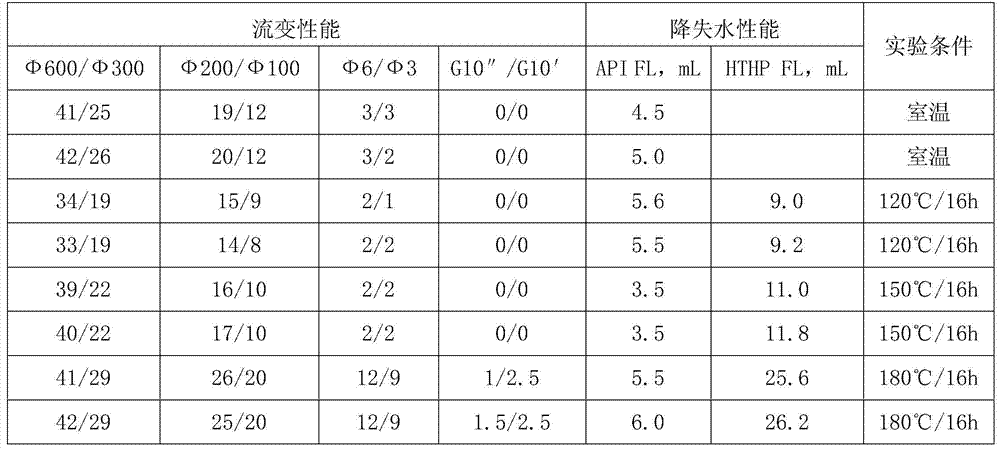

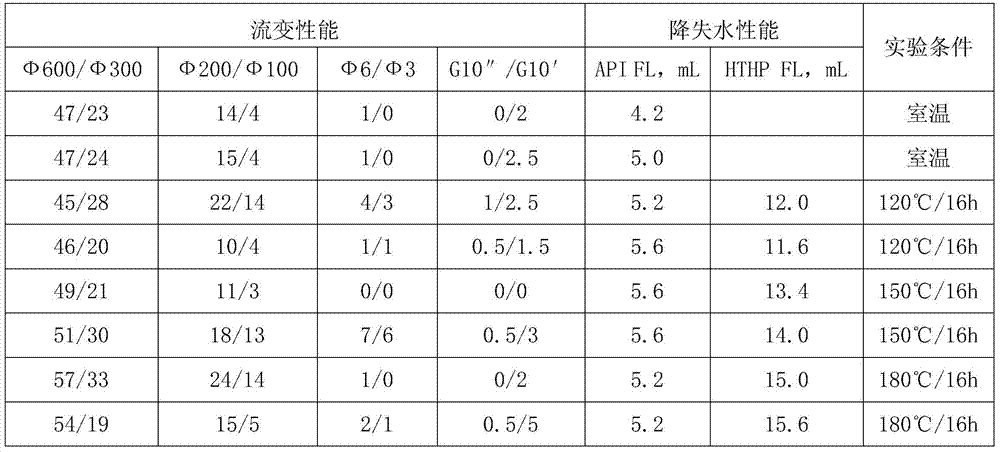

The invention discloses a salt-resistant and calcium-resistant filtrate reducer applied to a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer is prepared from raw materials and water, wherein the raw materials comprise 2-acrylamide-2-methyl propane sulfonic acid, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride; the ratio of m(2-acrylamide-2-methyl propane sulfonic acid) to m(acrylic acid) to m(acrylamide) to m(dimethyl diallyl ammonium chloride) to m(initiator) to m(molecular weight control agent) is (40-60) to (6-10) to (30-40) to (5-9) to (1-2) to (0.1-0.5). The molecular weight of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid and prepared by the preparation method is greatly improved; the coating property, the inhibition property, the heat stability and the salt-resistant and calcium-resistant pollution capacity of the filtrate reducer are greatly improved; by virtue of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid, the rheological property of the drilling fluid can be greatly improved; the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid also has a high temperature-resistant effect at 150-180 DEG C.

Owner:北京奥凯立科技发展股份有限公司

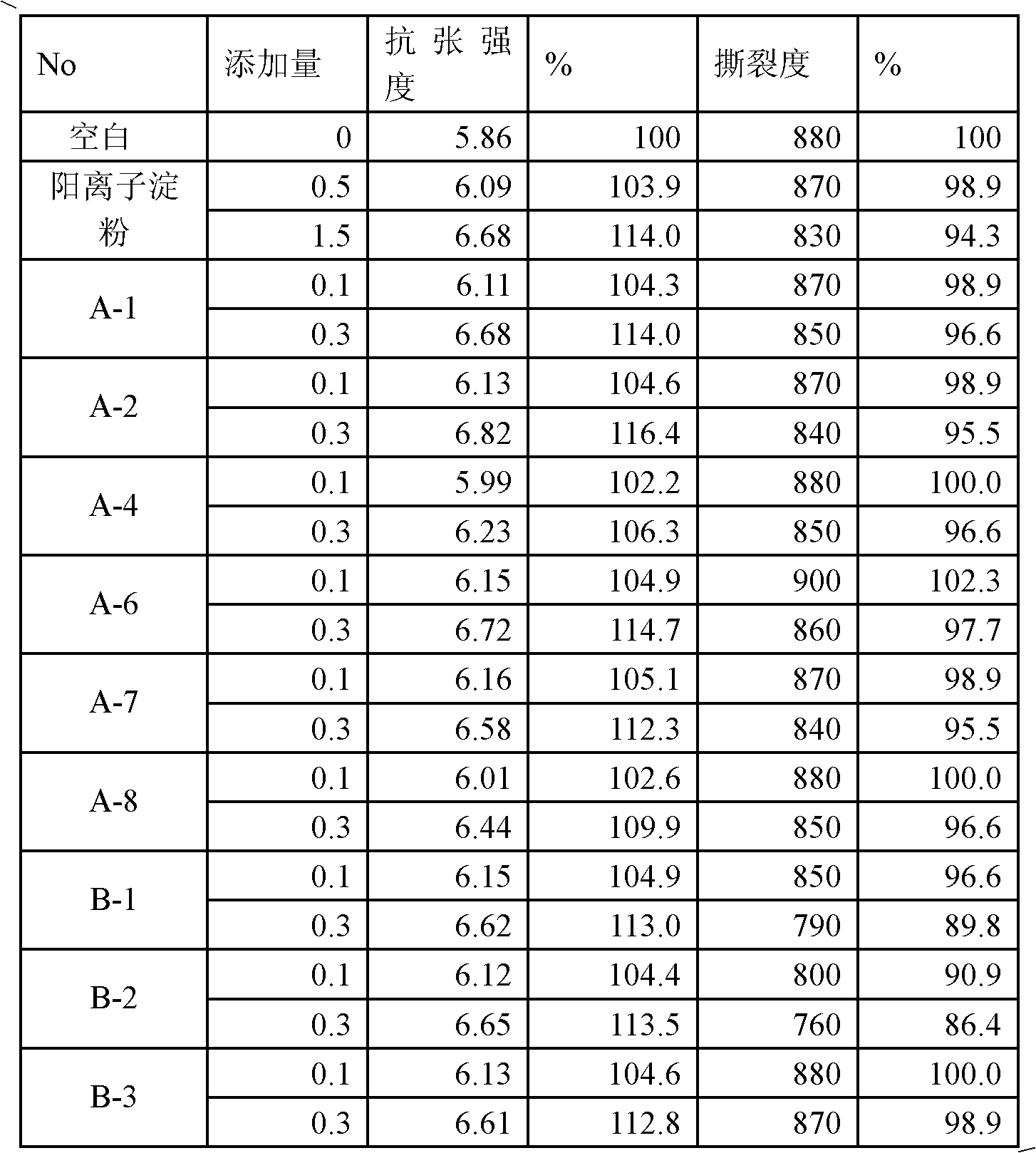

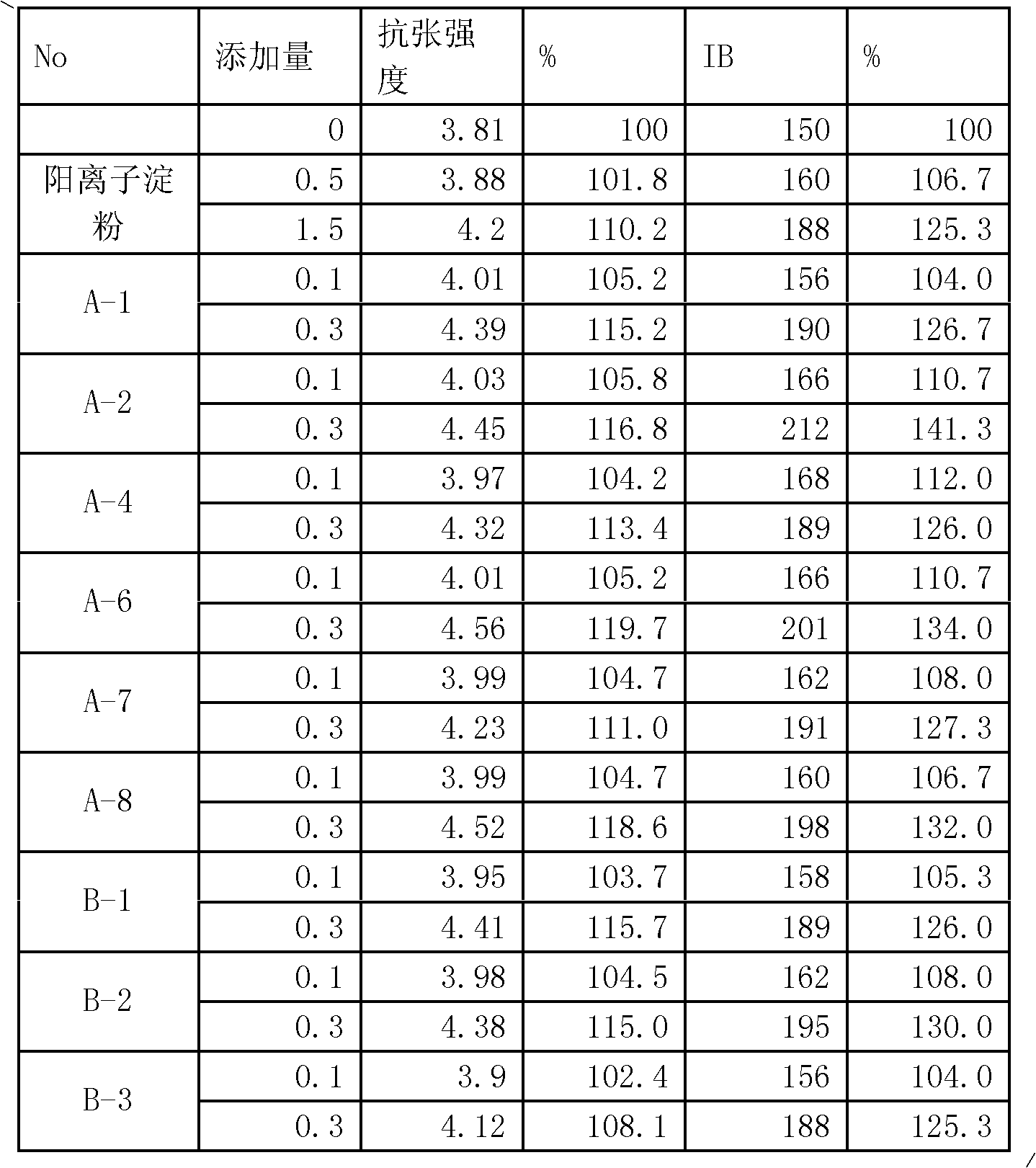

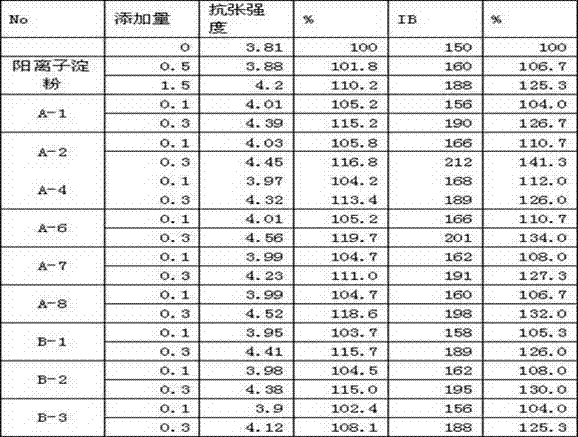

Preparation method of water-solubility amylum-acrylamide copolymer and application of water-solubility amylum-acrylamide copolymer

ActiveCN102603977AStrong enhancementLow costReinforcing agents additionPaper/cardboardSolubilityWeight control agent

The invention relates to the field of papermaking production, aims at solving the problem that the current papermaking industry needs a comprehensive dry strength resin concurrently having super enhanced effect of polyacrylamide and low cost feature of amylum, and provides a preparation method of a water-solubility amylum-acrylamide copolymer and application of the water-solubility amylum-acrylamide copolymer. The water-solubility amylum-acrylamide copolymer is prepared by the following components in parts by weight: 25-90 parts of monomer A, 0-20 parts of monomer B, 0-20 parts of monomer C, 0.02-1.5 parts of molecular weight control agents, 0.005-3.5 parts of crosslinking monomers, 5-30 parts of the amylum, 0.1-1 parts of catalyst and 0.2-2 parts of terminating agents, wherein water is added until product solid content is adjusted to be 10%-30%. The water-solubility amylum-acrylamide copolymer is used as the dry strength resin, and has strong enhanced effect, lower cost than the currently ordinary polyacrylamides dry strength resin and better economic benefit.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

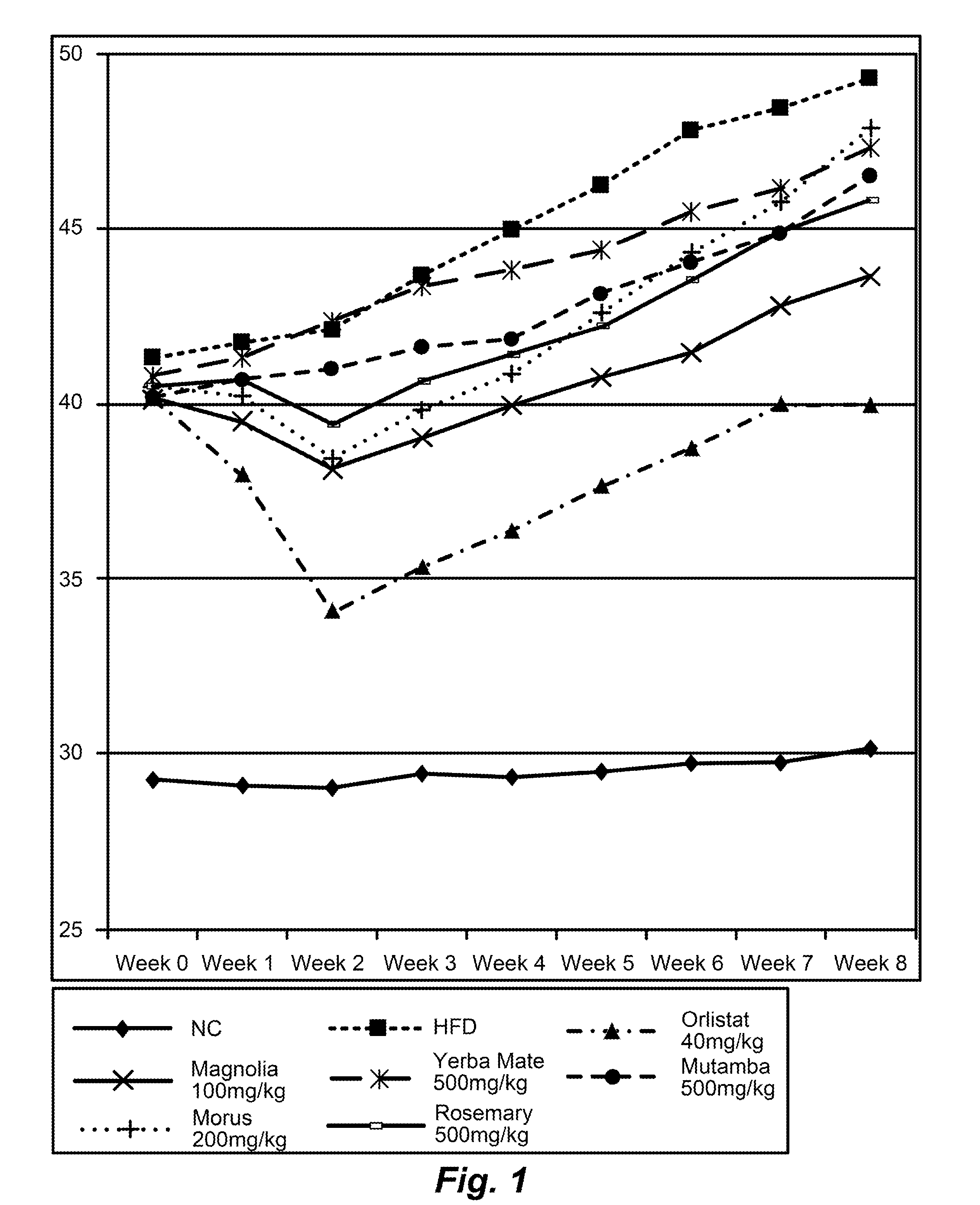

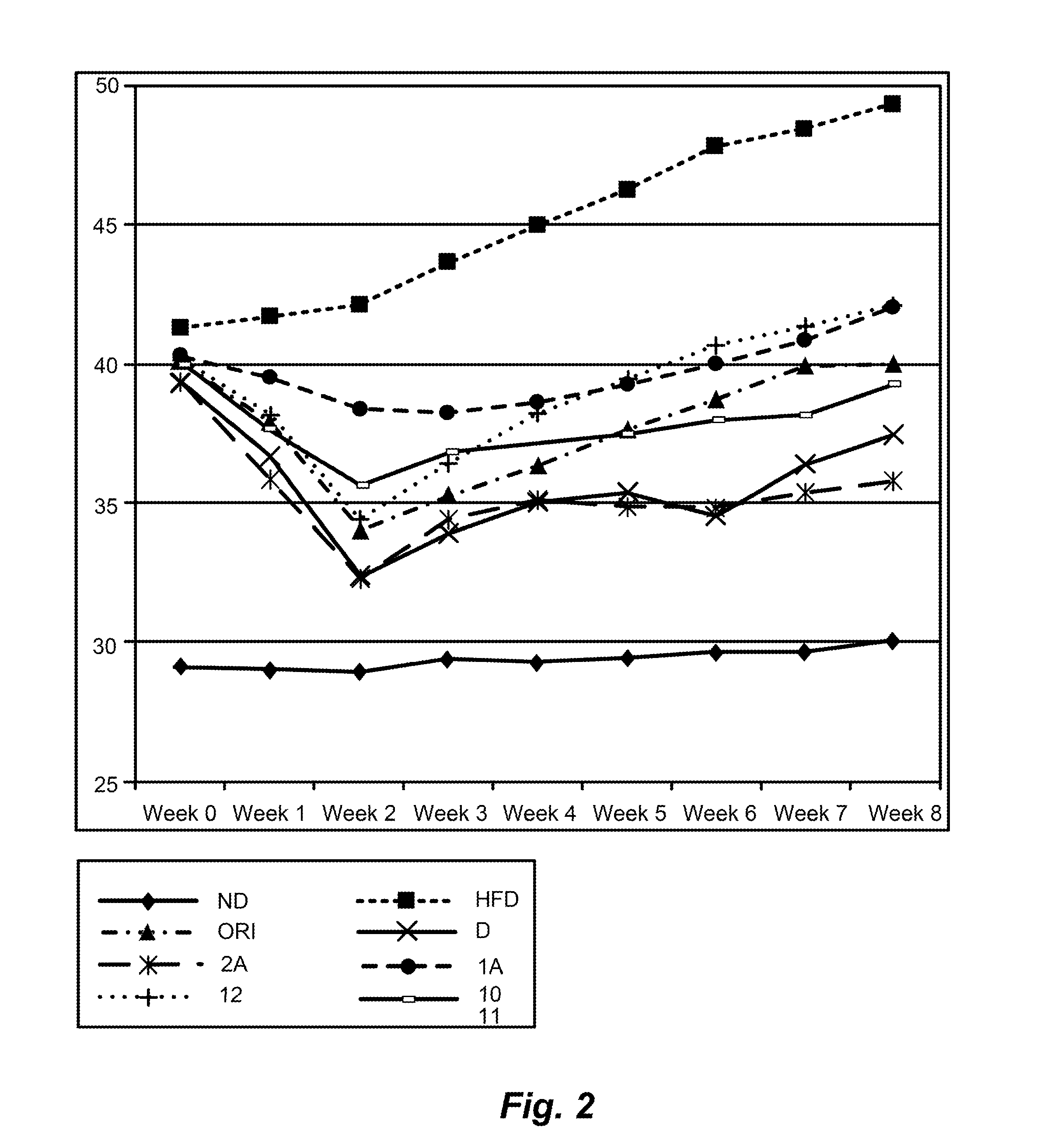

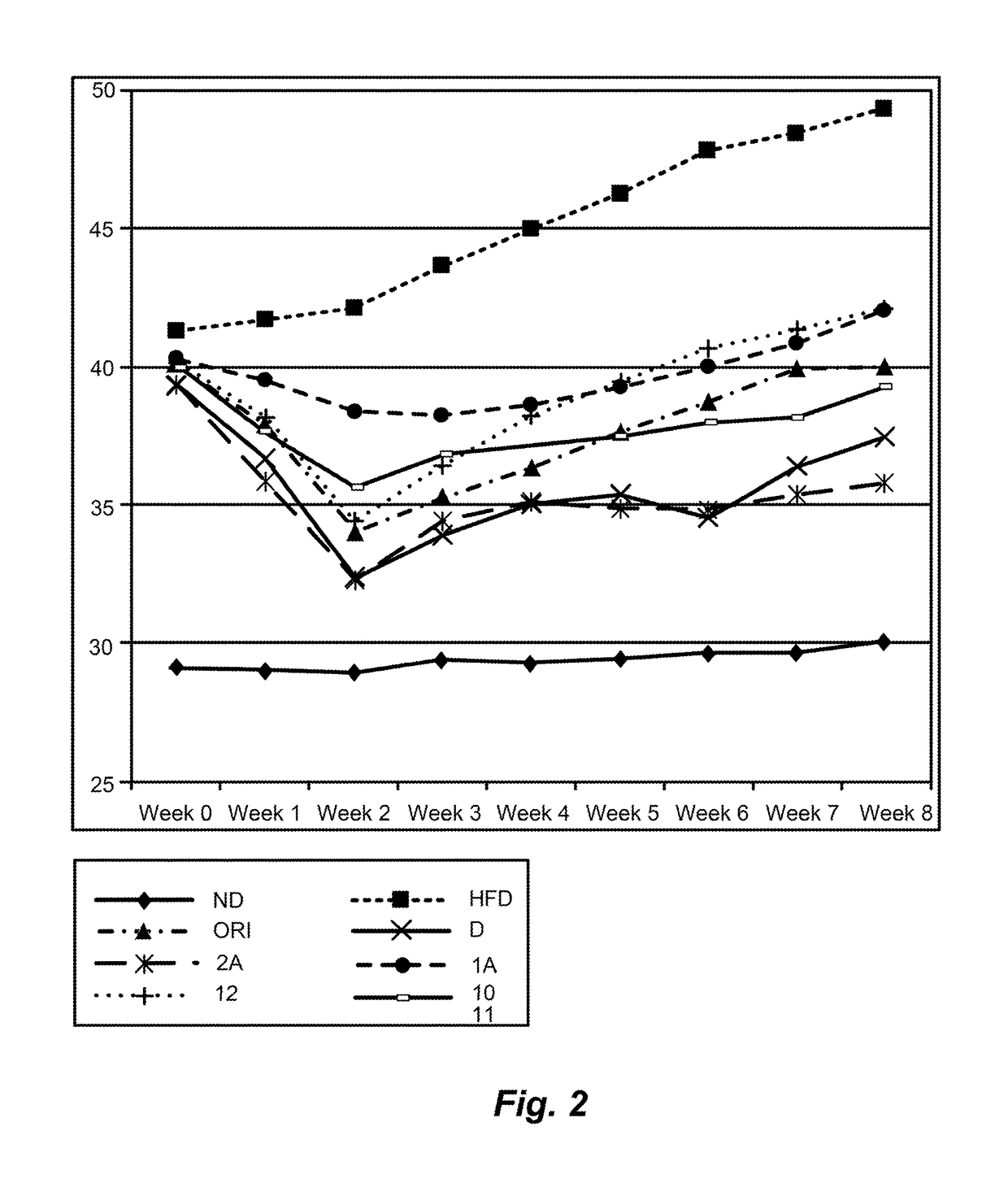

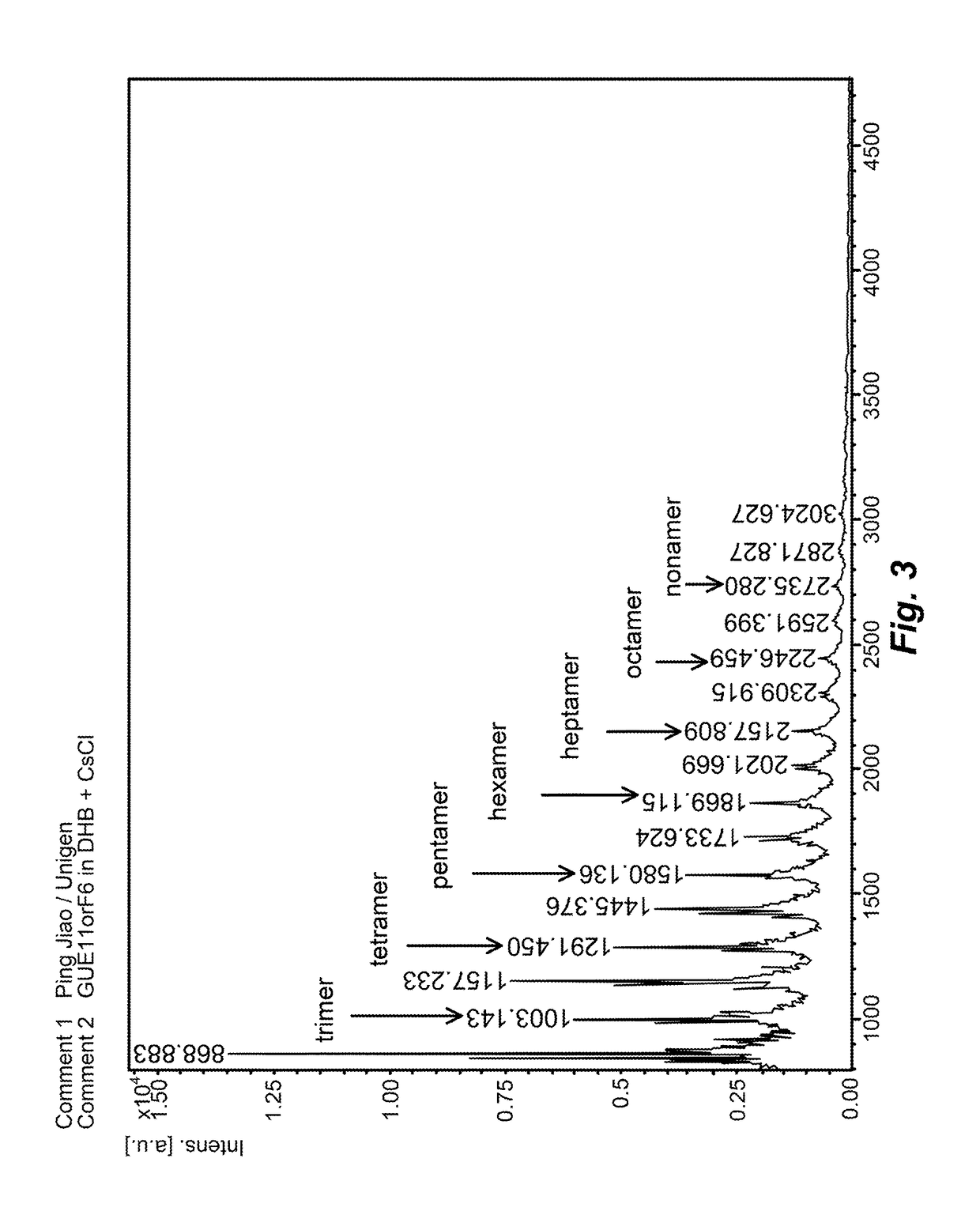

Compositions and methods for managing weight

ActiveUS20140004215A1Promoting and managing weight lossMaintain weightBiocideNervous disorderPsychotropic AgentStimulant

The present disclosure provides Diels-Alder adducts of chalcone and prenylphenyl moieties capable of modulating the activity of cannabinoid receptors, and to oligomers of flavan-3-ol capable of modulating fat absorption and storage. Such Diels-Alder adducts of chalcone and prenylphenyl moieties or oligomers of flavan-3-ol can optionally be used in combination with other weight management agents, such as anorectic agents, a lipase inhibitors, other cannabinoid receptor modulators, psychotropic agents, insulin sensitizers, stimulants, or satiety agents, as well as to methods of use thereof such as treating or preventing weight gain or obesity, promoting weight loss, appetite suppression, modifying satiety, or the like.

Owner:UNIGEN

Process for manufacturing cycloolefin addition polymer

ActiveUS20080085979A1Excellently balanced processabilityExcellently balanced mechanicalPolymer scienceAddition polymer

A process for manufacturing a cycloolefin addition polymer includes polymerizing monomers containing a cycloolefin compound using a catalyst containing a nickel compound or a palladium compound by addition polymerization in the presence of a molecular weight controlling agent in two steps, that is a step of a initiating the polymerization reaction using the monomers in an amount of not more than 80 wt % of the total monomers and a step of supplying the remaining monomers to the reaction system during the polymerization reaction. A cycloolefin addition polymer with a uniform quality, having a narrow molecular weight distribution and a controlled molecular weight, and excellently balanced processability and mechanical strength can be obtained at a high polymerization conversion rate using the process. The process can be operated at a highly controlled polymerization temperature, and is thus suitable for industrially manufacturing a cycloolefin addition polymer.

Owner:JSR CORPORATIOON

Method for producing a propylene polymer having a very high melt flowability

InactiveCN101155838AHigh stereoregular indexImprove melt fluidityPolymer scienceWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:SAMSUNG TOTAL PETROCHEMICALS CO LTD

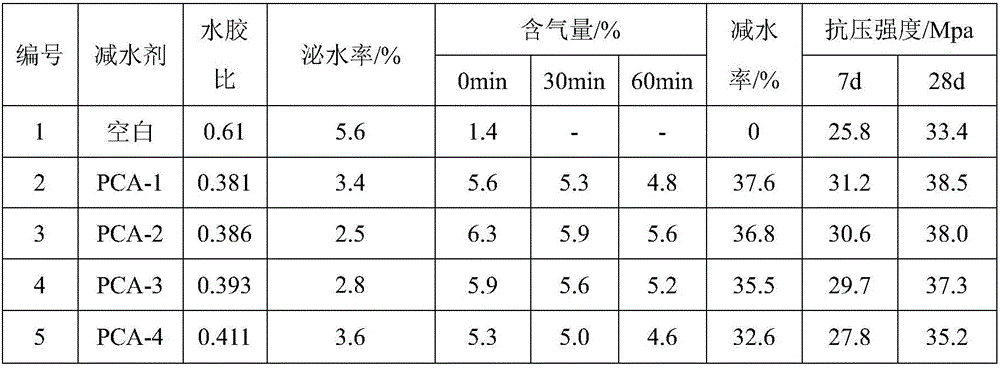

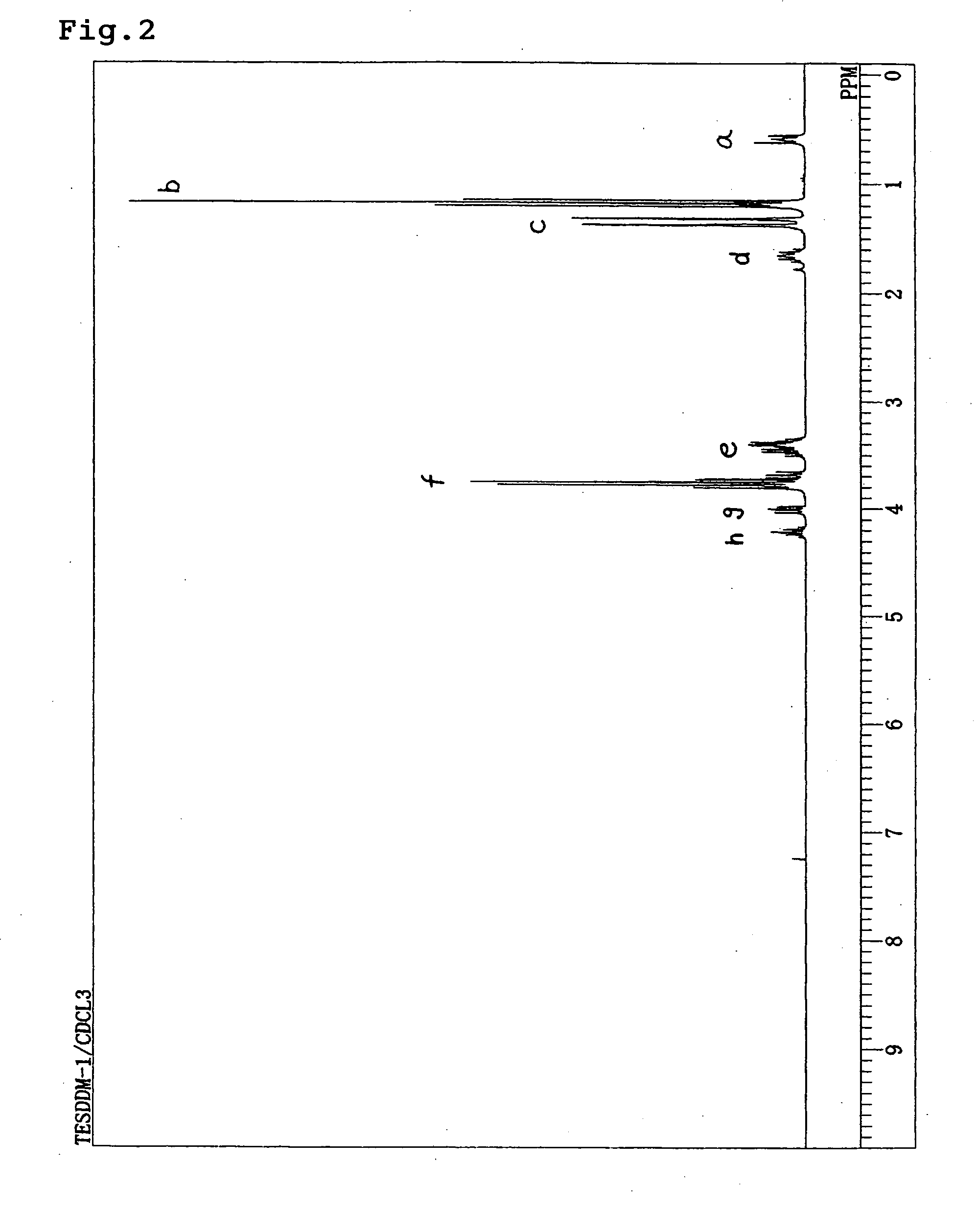

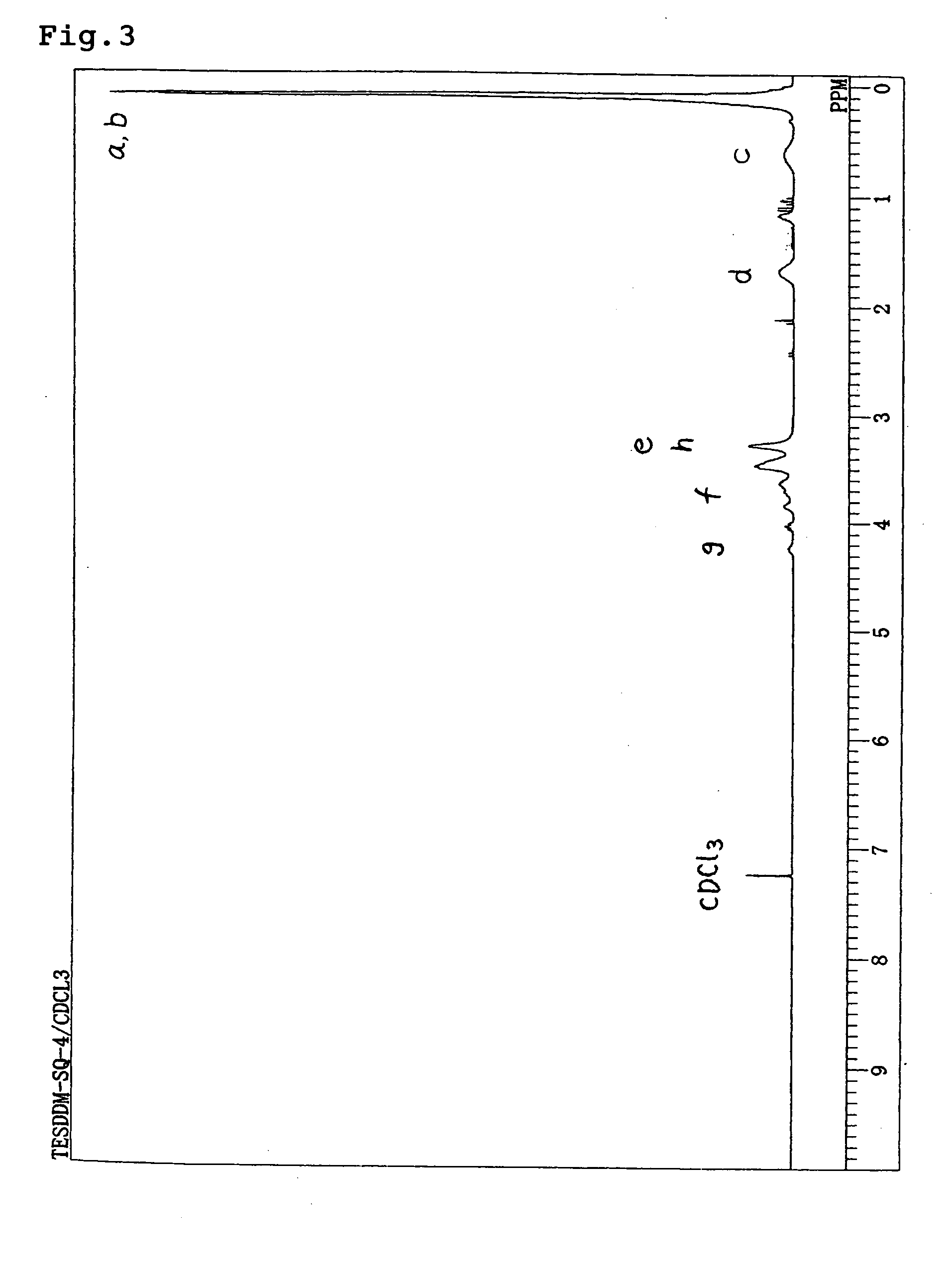

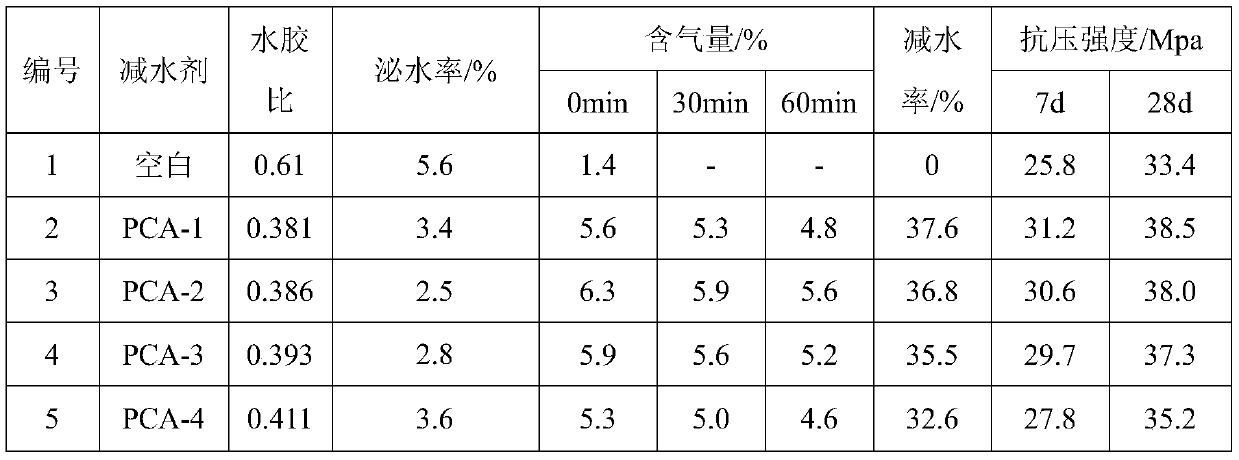

Air entrainment-controllable polycarboxylic water reducer used for purely machine-made sand concrete, and preparation method thereof

The invention belongs to the field of concrete additives, and concretely relates to an air entrainment-controllable polycarboxylic water reducer used for purely machine-made sand concrete, and a preparation method thereof. The preparation method comprises the following steps: carrying out an esterification reaction on an alkylphenol polyoxyethylene monomer and an unsaturated carboxylic acid to generate an unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, carrying out an aqueous solution copolymerization reaction on the unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, an unsaturated polyether monomer and an unsaturated sulfonic acid monomer through an oxidation-reduction initiation system, and adding a proper amount of a molecular weight control agent to control the molecular weight in order to obtain the air entrainment-controllable polycarboxylic water reducer. The water reducer prepared in the invention has the advantages of high water reduction rate, good adaptability, small bubble diameters, stable sealing property and controllable air entrainment when applied to the purely machine-made sand concrete, and well solves the problems of difficult air entrainment, poor bubble stability and large concrete pumping loss of the purely machine-made sand concrete.

Owner:中建商品混凝土(福建)有限公司 +1

Method for producing propylene polymer having a very high melt-flowability

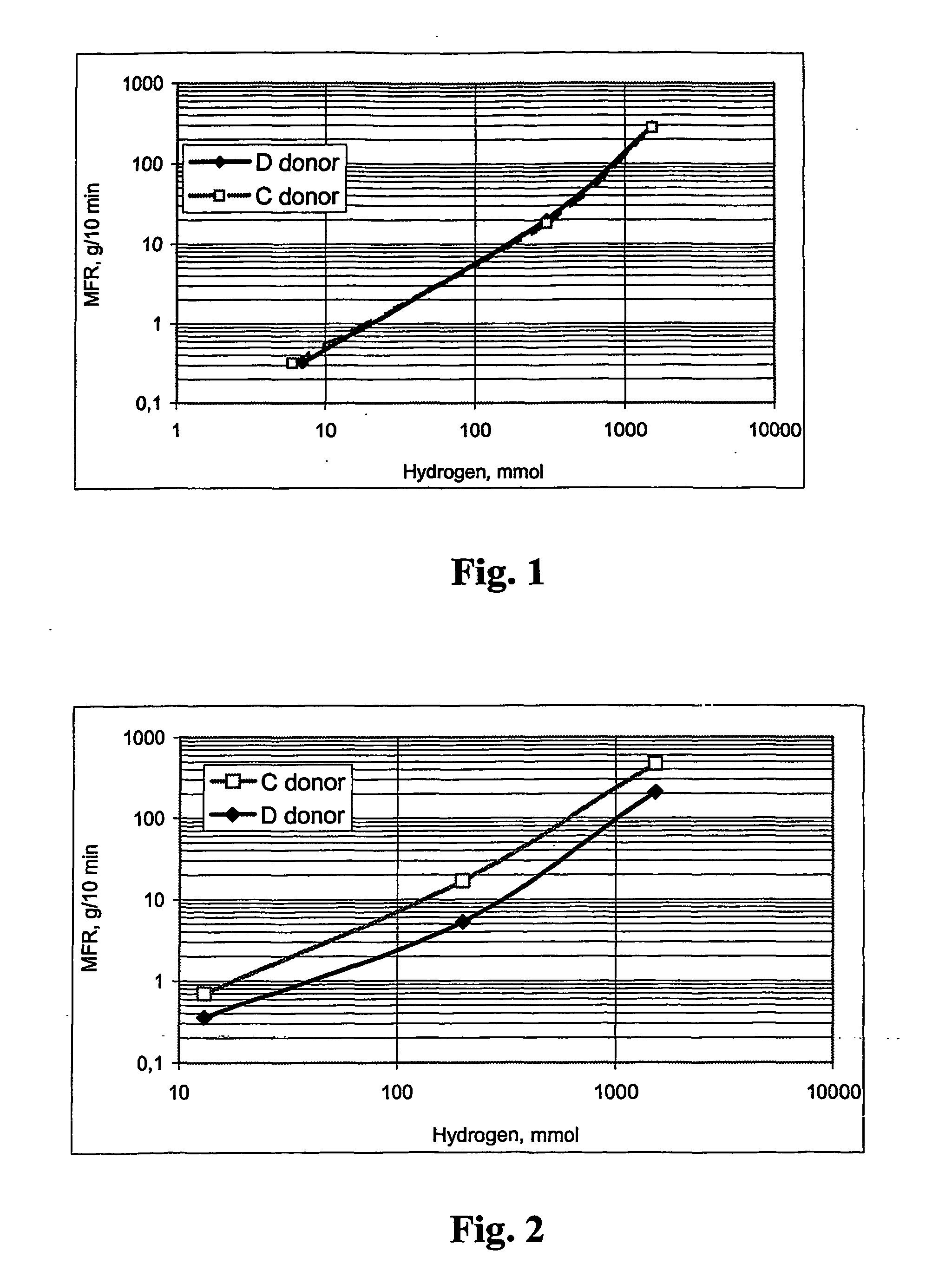

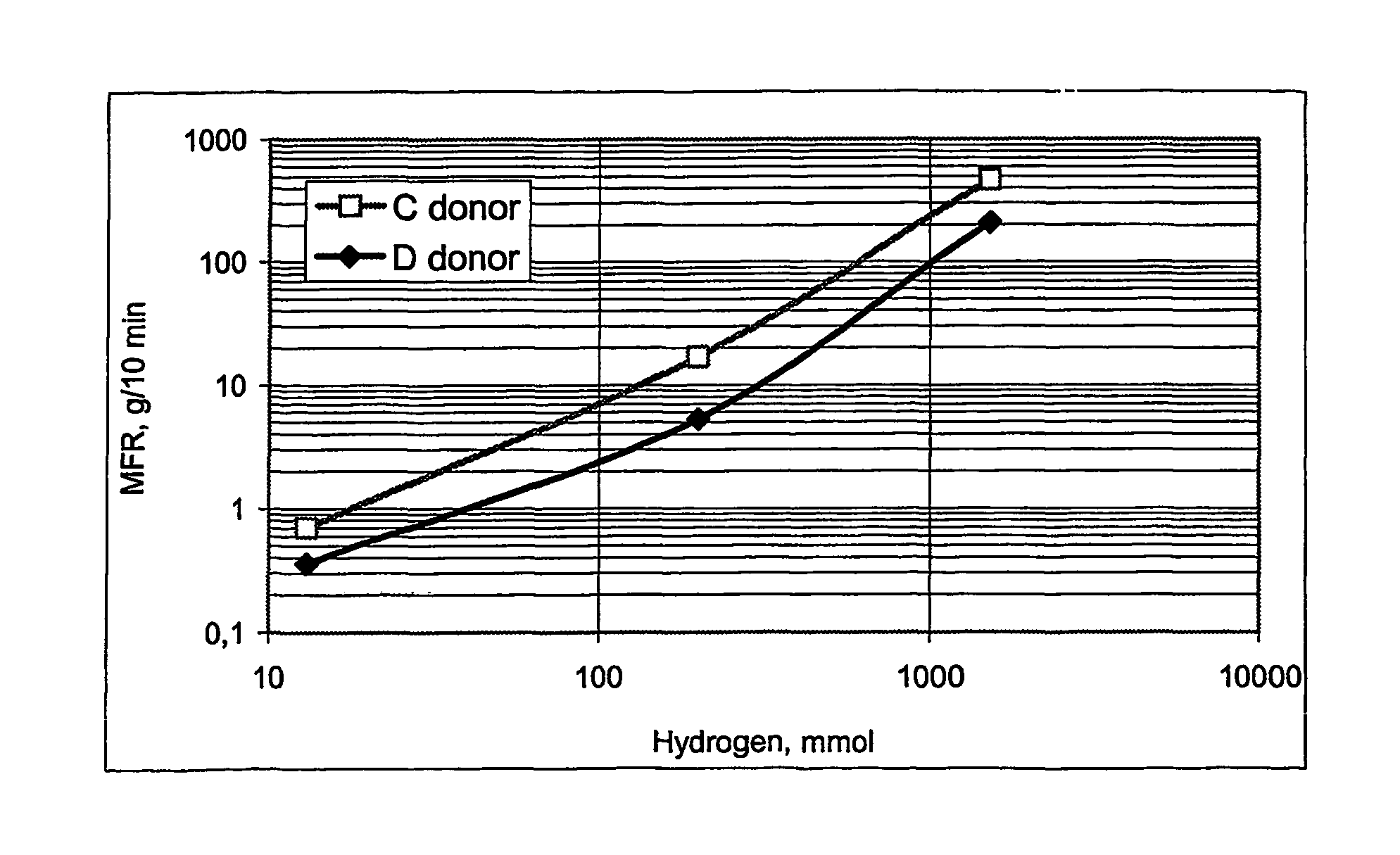

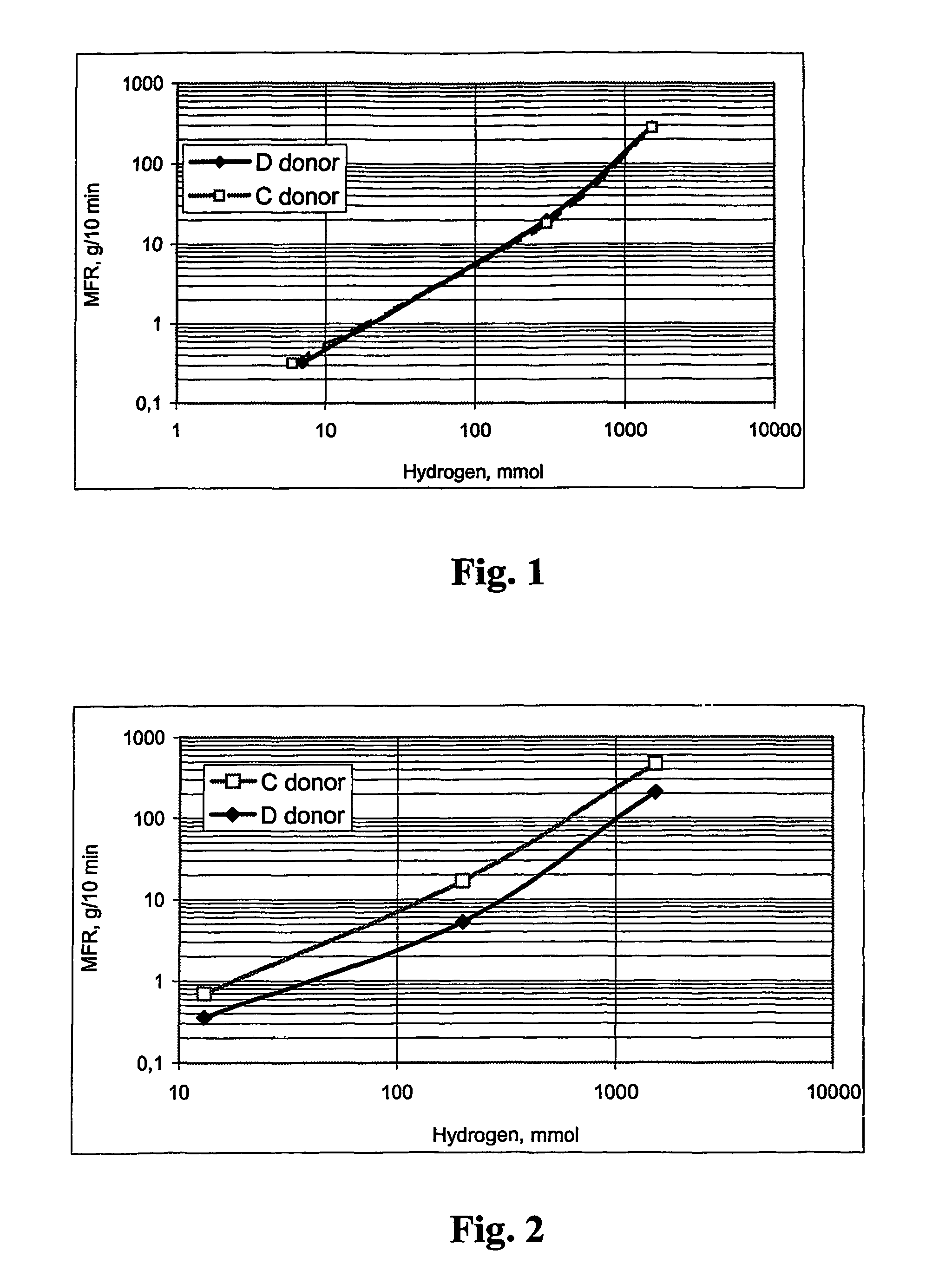

ActiveUS20060223959A1Improve production yieldIncreased melt flow rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

Method for preparing low-viscosity polymer polyol

The invention relates to a method for preparing a low-viscosity polymer polyol. According to the method, a continuous process is adopted, namely a polymer polyol with solid content equal to or lower than that of a target product is adopted as a base material, all remaining raw materials are blended and then are dropwise added continuously, a polyoxyalkylene polyether polyol serves as a continuous phase during reaction, a mixture of styrene and acrylonitrile is subjected to in-situ polymerization in the presence of a certain amount of an azo free radical initiator, a maleate-polyether half-ester unsaturated macromolecular monomer and an alcohol molecular weight control agent so as to form a stable polymer polyol system, and the polymer polyol is provided with the continuous phase containing a polyoxyalkylene polyol and a disperse phase containing vinyl polymer solids. According to the method, a polymer polyol product, of which the particle morphology of the disperse phase is approximately spherical, the surface is more smooth and the particle diameter distribution of particles is wider, can be obtained, and the obtained polymer polyol product has the characteristic of low viscosity.

Owner:CHINA PETROLEUM & CHEM CORP

Process for producing olefin polymers

InactiveUS20070149728A1Faster and easy to controlEasy to controlPolymer scienceZiegler–Natta catalyst

A process for producing at least two different propylene polymer grades, in which process the isotacticity of the polymer is changed while keeping the melt flow rate of the polymer at a predetermined level during a transition of production from a first polymer grade to a second. The process is carried out in a polymerization arrangement comprising at least one polymerization reactor, where propylene is polymerized, optionally with comonomers, under polymerization conditions in the presence of hydrogen as a molecular weight controlling agent and a Ziegler-Natta catalyst system. The catalyst system comprises a catalyst component and an external donor. During a transition of production from the first polymer grade to the second, the external donor is changed, but the hydrogen feed is kept at a predetermined level.

Owner:BOREALIS TECH OY

Process for producing olefin polymers

A process for producing at least two different propylene polymer grades, in which process the isotacticity of the polymer is changed while keeping the melt flow rate of the polymer at a predetermined level during a transition of production from a first polymer grade to a second. The process is carried out in a polymerization arrangement comprising at least one polymerization reactor, where propylene is polymerized, optionally with comonomers, under polymerization conditions in the presence of hydrogen as a molecular weight controlling agent and a Ziegler-Natta catalyst system. The catalyst system comprises a catalyst component and an external donor. During a transition of production from the first polymer grade to the second, the external donor is changed, but the hydrogen feed is kept at a predetermined level.

Owner:BOREALIS TECH OY

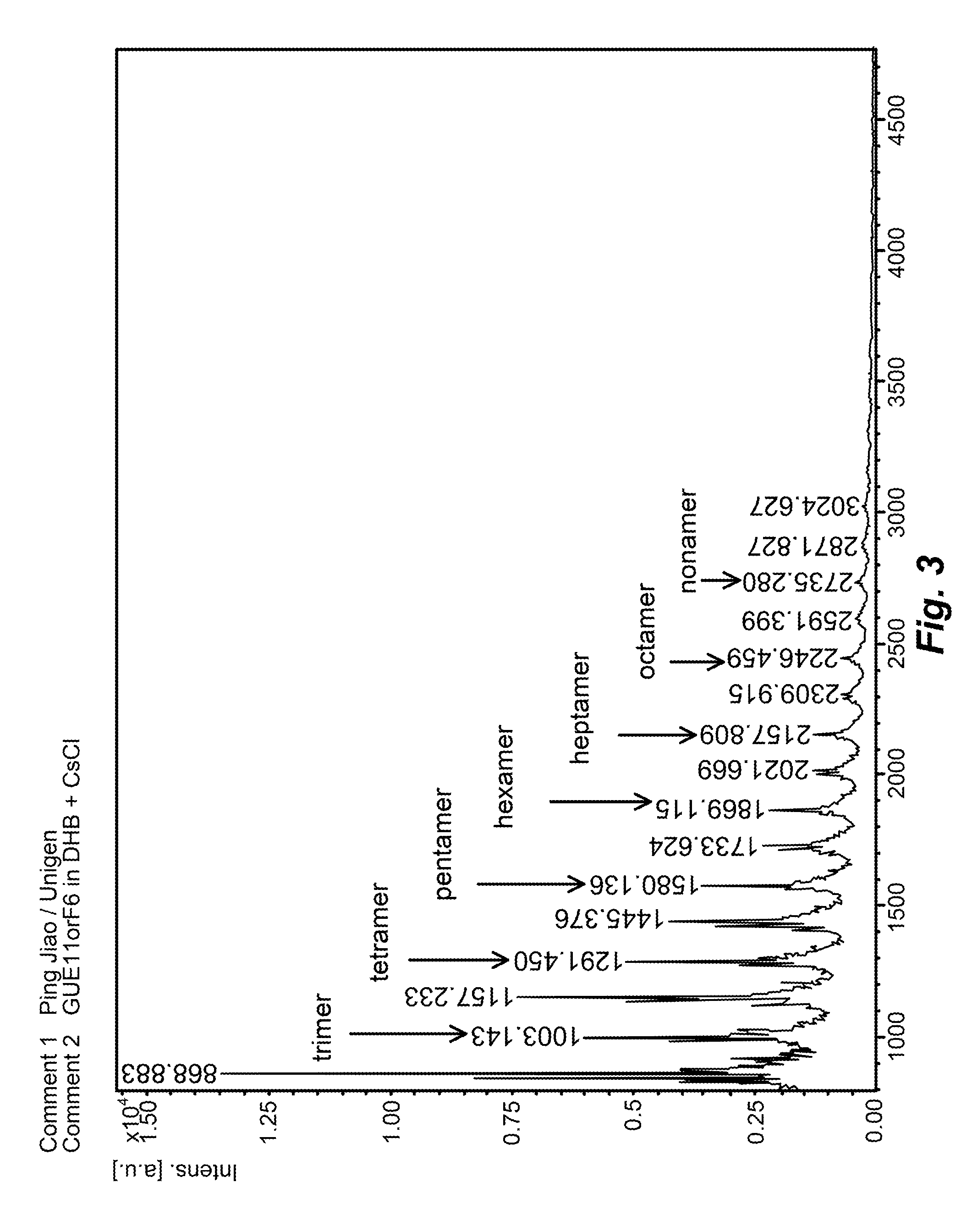

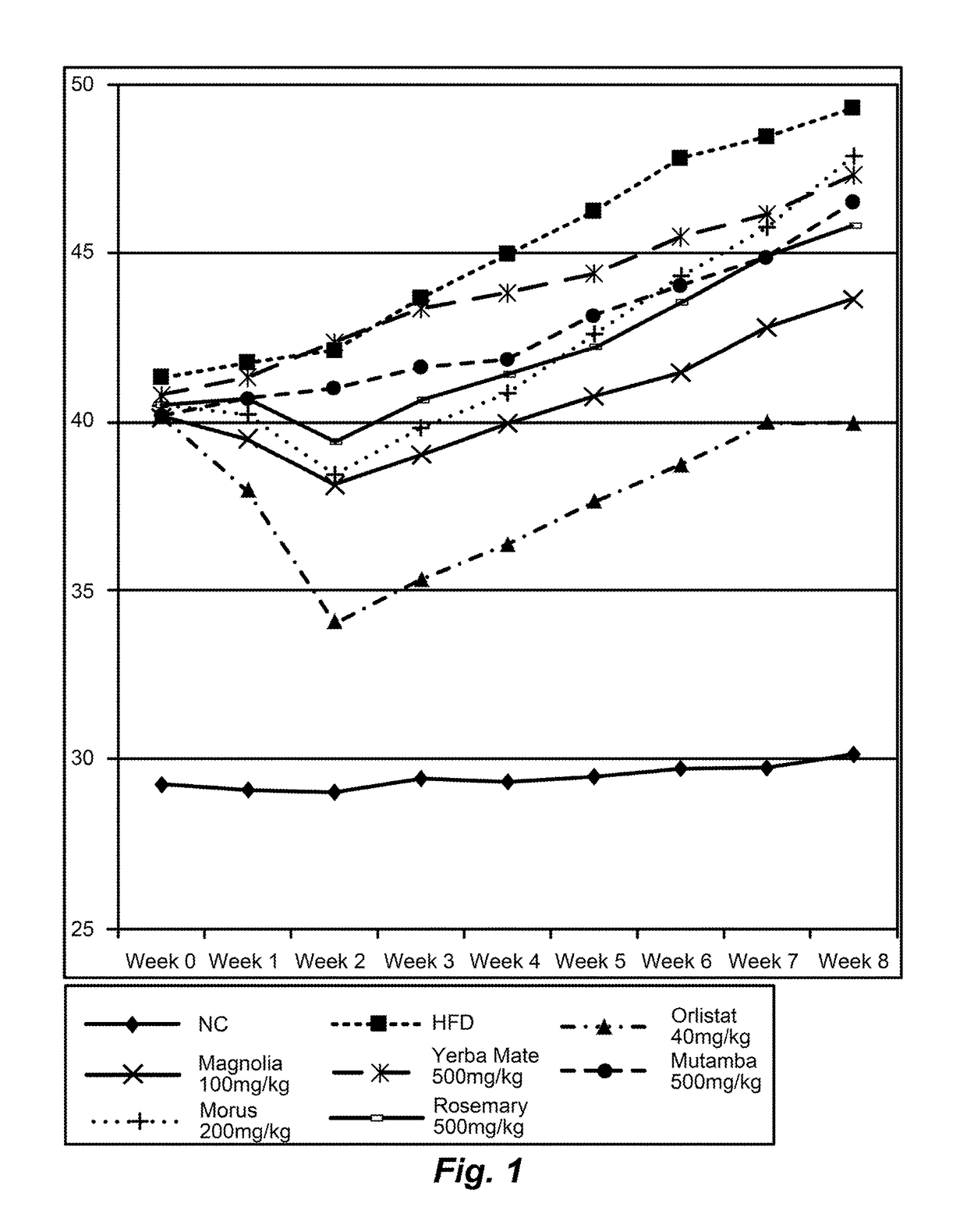

Compositions and methods for managing weight

ActiveUS9844576B2Less weight gainImprove the level ofNervous disorderHydroxy compound active ingredientsPsychotropic AgentStimulant

The present disclosure provides Diels-Alder adducts of chalcone and prenylphenyl moieties capable of modulating the activity of cannabinoid receptors, and to oligomers of flavan-3-ol capable of modulating fat absorption and storage. Such Diels-Alder adducts of chalcone and prenylphenyl moieties or oligomers of flavan-3-ol can optionally be used in combination with other weight management agents, such as anorectic agents, a lipase inhibitors, other cannabinoid receptor modulators, psychotropic agents, insulin sensitizers, stimulants, or satiety agents, as well as to methods of use thereof such as treating or preventing weight gain or obesity, promoting weight loss, appetite suppression, modifying satiety, or the like.

Owner:UNIGEN

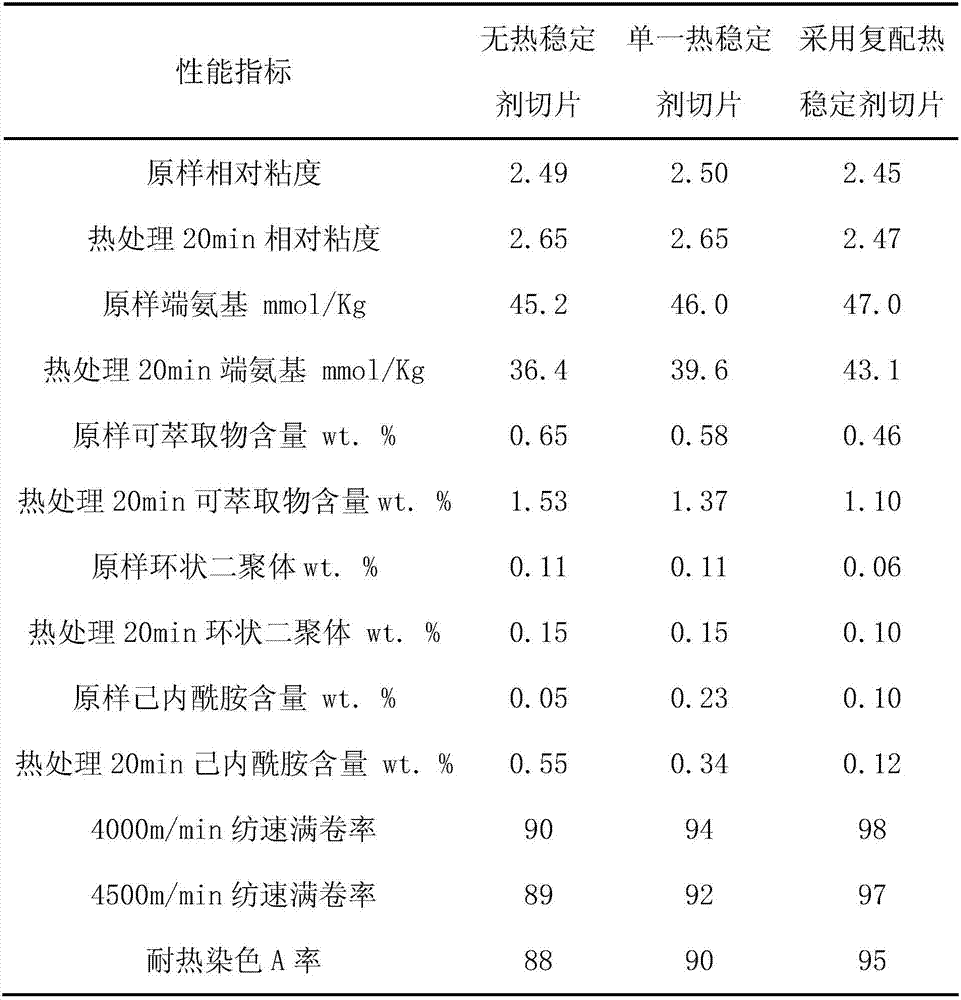

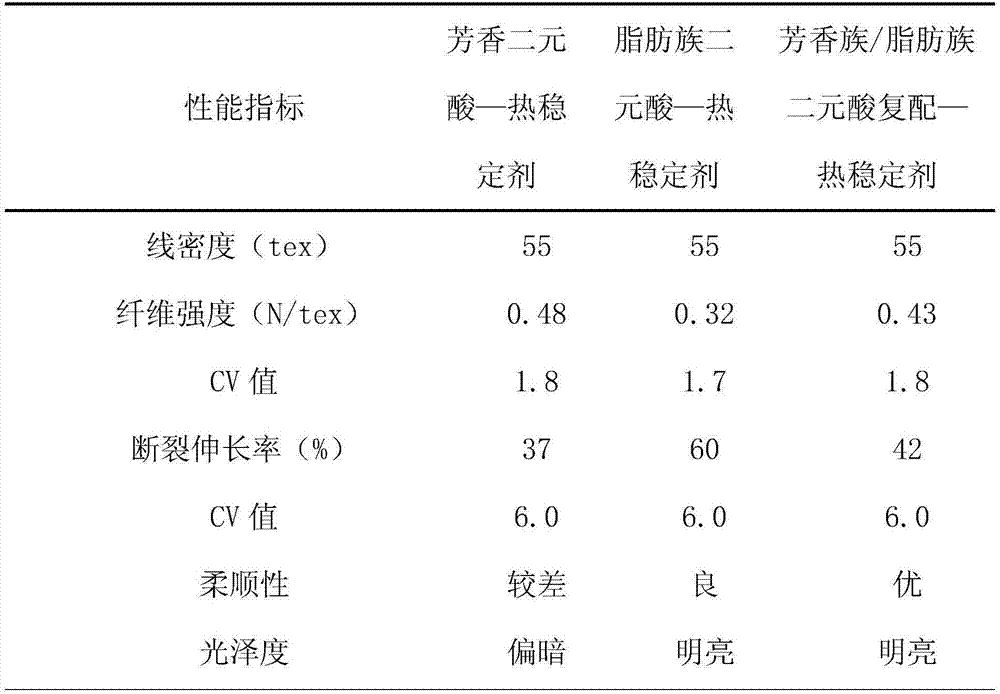

Chinlon 6 for spinning and manufacturing method thereof

InactiveCN106977712AImprove thermal stabilityReduce concentrationMonocomponent polyamides artificial filamentWeight control agent4-methylpiperidine

The invention relates to chinlon 6 for spinning. The chinlon 6 is prepared from the following raw materials in parts by mass: 96 to 98 parts of caprolactam, 2 to 4 parts of desalted water, 0.28 to 0.3 part of molecular weight controlling agents and 0.05 to 0.15 part of thermal stabilizers, wherein the molecular weight controlling agents are any one kind of materials from terephthalic acid, m-phthalic acid and 1.4-phenylenediacetic acid; the thermal stabilizers are 4-amino-2,2,6,6-4 methyl piperidine and N,N'-bis(2,2,6,6- tetramethyl-4 piperidyl)-1,3-benzenedicarboxamide.

Owner:FUJIAN ZHONGJIN NEW MATERIALS

OCA optical adhesive, and preparation method and application of OCA optical adhesive

InactiveCN112195003AControl conversion rateEster polymer adhesivesFilm/foil adhesives without carriersPolymer scienceAdhesive

The invention discloses an OCA optical adhesive, a preparation method and application of the OCA optical adhesive. The OCA optical adhesive comprises 2-ethylhexyl acrylate, isobornyl acrylate, 2-hydroxyethyl acrylate, 1-hydroxycyclohexyl benzophenone and a molecular weight control agent dodecanethiol. The preparation method of the OCA optical adhesive comprises the following steps of 1, mixing 2-ethylhexyl acrylate, isobornyl acrylate, 2-hydroxyethyl acrylate, 1-hydroxycyclohexyl benzophenone and dodecanethiol to obtain a monomer prepolymer, 2, exposing the monomer prepolymer to ultraviolet radiation in a nitrogen protection environment, and adding a photoinitiator and a cross-linking agent to obtain an OCA optical adhesive. The application of the OCA optical adhesive comprises the following steps of A, unwinding a release film, B, coating the release film with OCA optical adhesive to obtain the release film coated with the OCA optical adhesive, C, curing the release film coated with the OCA optical adhesive under illumination to obtain a cured optical adhesive film, and D, winding the cured optical adhesive film.

Owner:世星科技股份有限公司

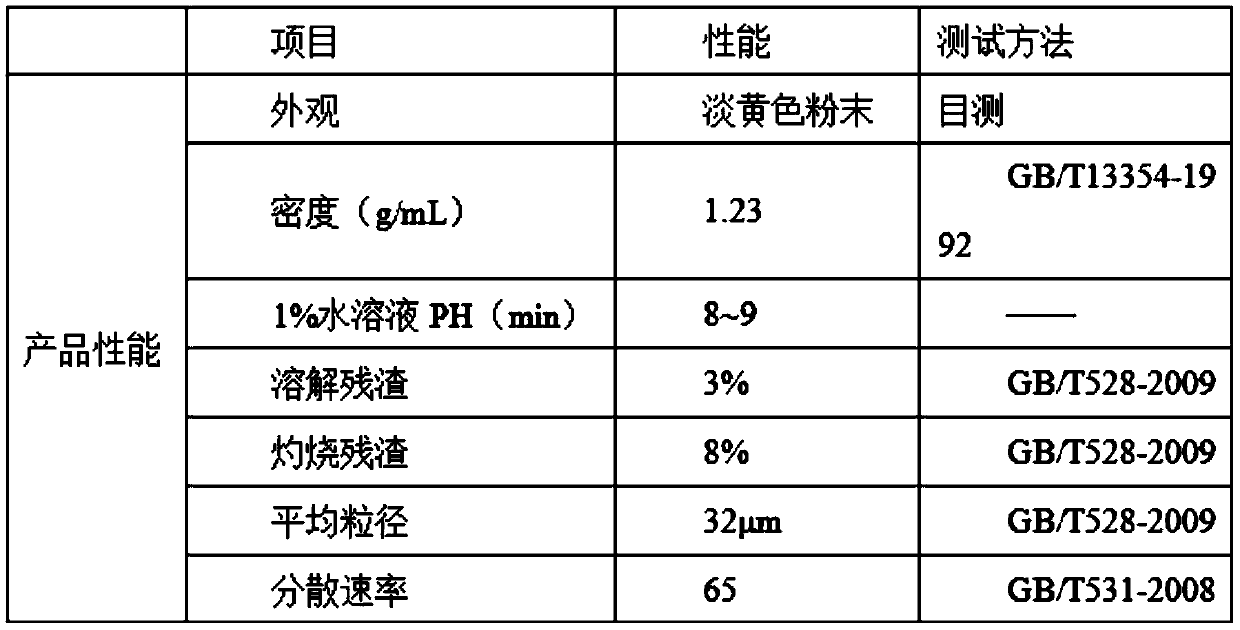

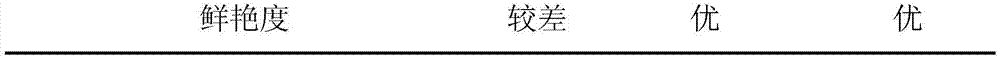

Water-based inorganic filler dispersant and preparation method thereof

ActiveCN110721632AGood dispersionStrong resistanceTransportation and packagingMixingPolymer scienceO-Phosphoric Acid

The invention provides a water-based inorganic filler dispersant. The raw materials of the water-based inorganic filler dispersant include the following components: in parts by mass, a carboxylic acidmonomer, silsesquioxane particles, a long-chain monomer, purified water, a molecular weight control agent, an initiator, chiral phosphoric acid and a compatibilizer, and the water-based inorganic filler dispersant is of a powder form, has a microscopic morphology of uniform spherical particles with an average particle diameter of 12-25 [mu]m. The prepared water-based inorganic filler dispersant has uniform powder and convenient and simple use, and does not fail after storage is performed for 24 months in a normal temperature environment, and a good dispersing effect on common inorganic materials and high anti-interference performance are achieved.

Owner:武汉善达化工有限公司

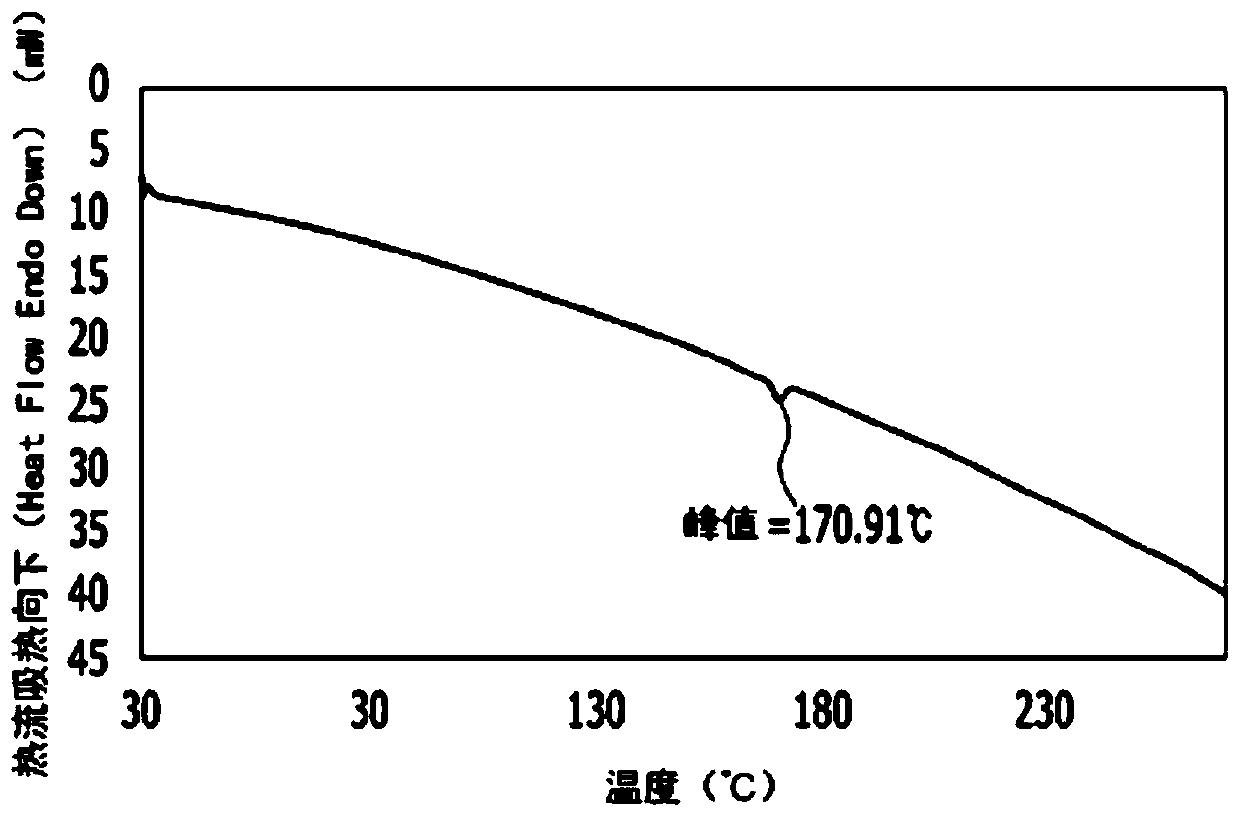

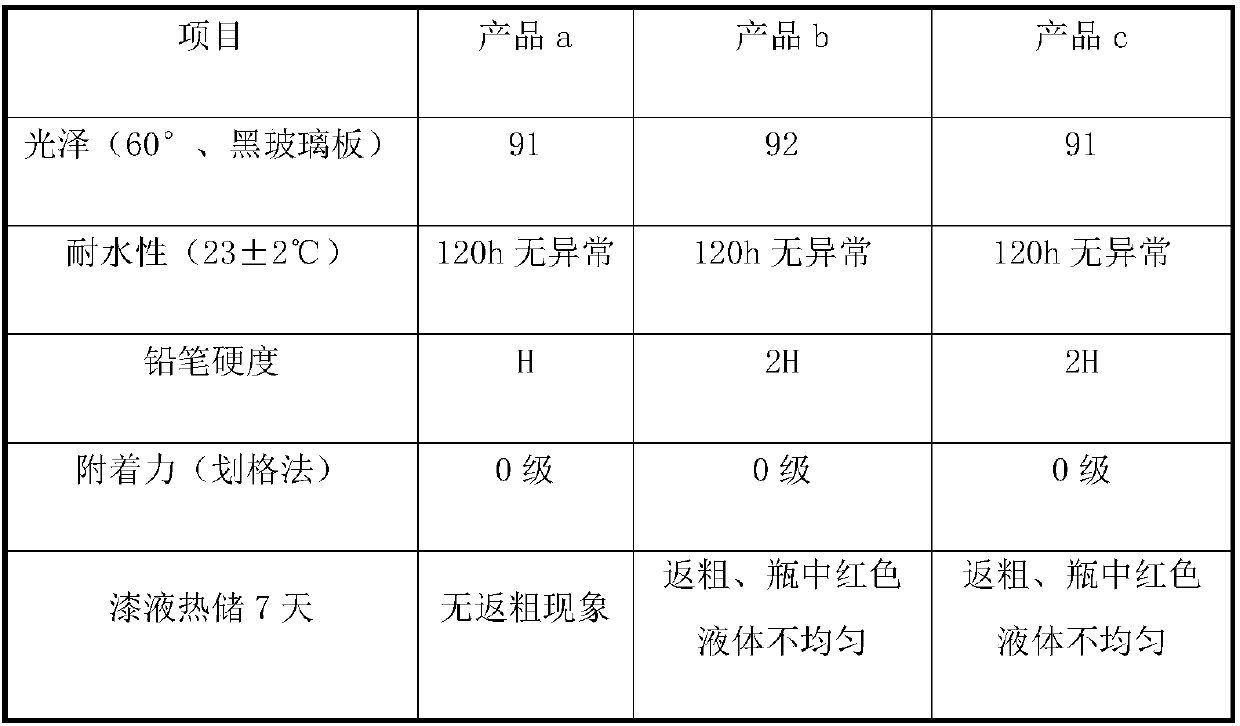

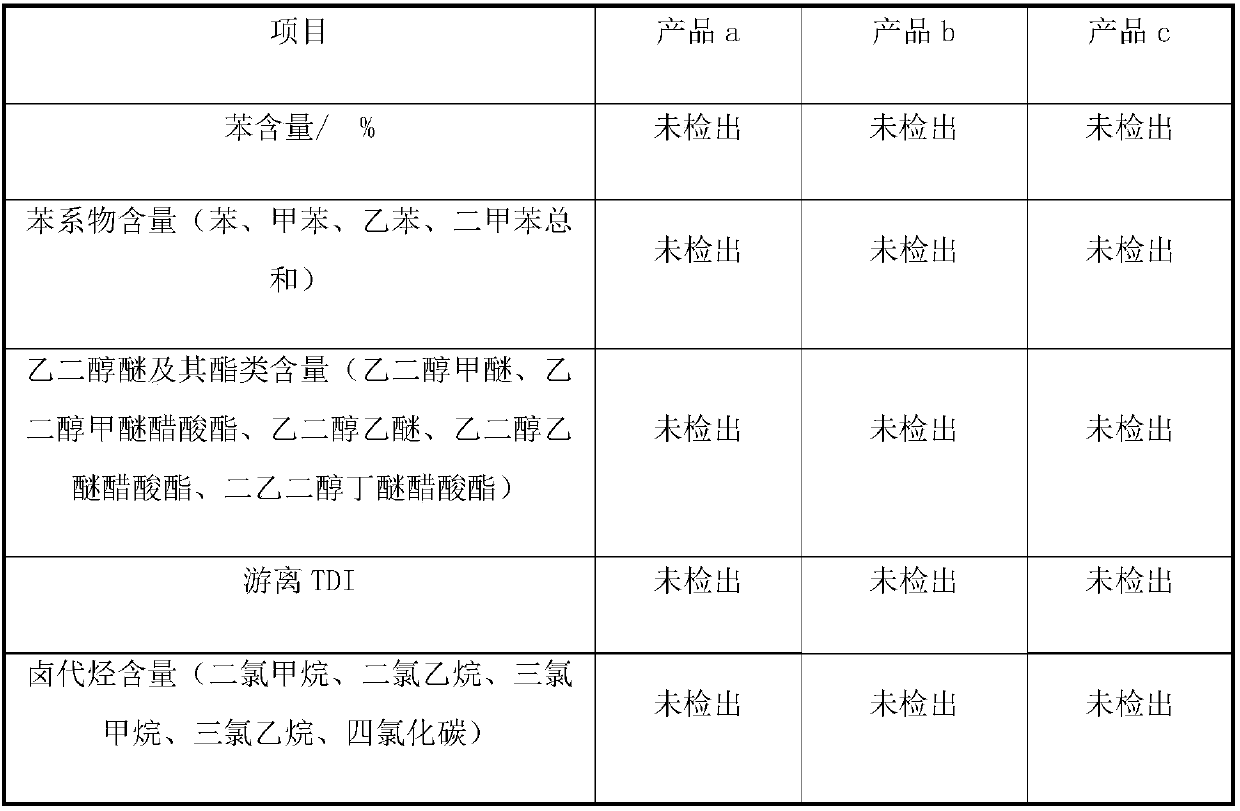

Synthetic resin for water-borne fishing rod finishing varnish as well as preparation method and application thereof

The invention relates to synthetic resin for water-borne fishing rod finishing varnish as well as a preparation method and application thereof. The synthetic resin is prepared from the following raw materials in parts by mass: 20 to 50 parts of alkyl methacrylate, 2 to 20 parts of alkyl acrylate, 5 to 25 parts of a functional monomer, 0.1 to 5.0 parts of a molecular weight controlling agent, 0.5 to 4.0 parts of an initiator and 1 to 10 parts of a pH (Potential of Hydrogen) value regulation agent. Water, a de-foaming agent and a leveling agent are added into the synthetic resin so as to obtain the water-borne fishing rod finishing varnish. After the water-borne fishing rod finishing varnish provided by the invention is used for coating a fishing rod, the fishing rod has high glossiness, good distinctness, yellowing resistance, good water resistance, high rigidity, good wearing resistance and excellent anti-scratching performance.

Owner:新元化学(山东)股份有限公司

Spinning polyamide 6 and manufacture method thereof

InactiveCN106905517AWith strengthHigh strengthMonocomponent polyesters artificial filamentArtifical filament manufactureAcetic acidWeight control agent

Spinning polyamide 6 comprises the following raw materials, by mass part, 96-98 parts of caprolactam, 2-4 parts of desalted water, 0.28-0.3 part of a molecular weight control agent, and 0.05-0.15 part of a heat stabilizer, wherein the molecular weight control agent is any two of adipic acid, terephthalic acid and acetic acid, and the heat stabilizer is any one of 4-amino-2,2,6,6-4-methyl piperidine and N,N'-di(2,2,6,6-tetramethyl-4-piperidyl)-1,3-benzenedicarboxamide.

Owner:FUJIAN ZHONGJIN NEW MATERIALS

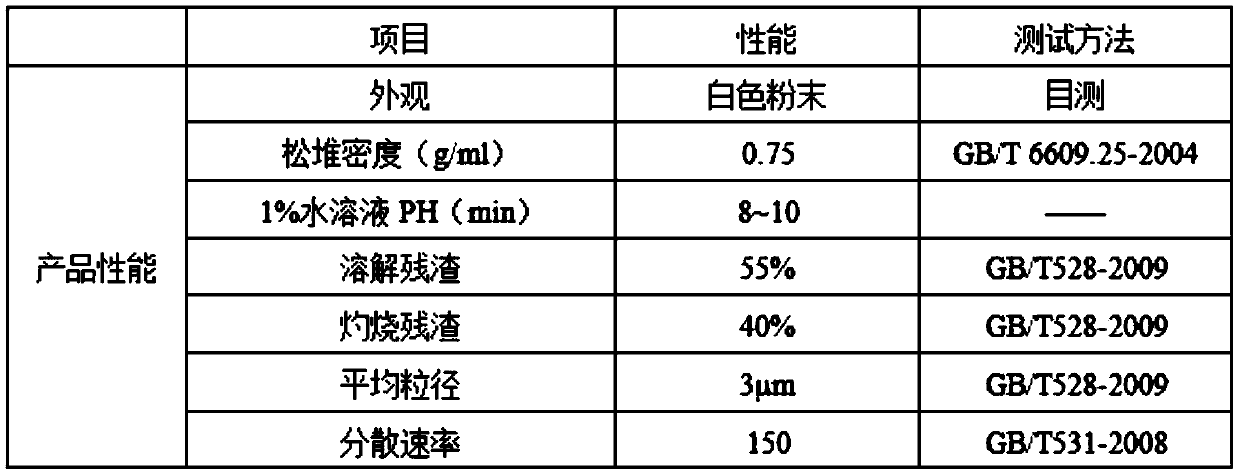

Comprehensive dispersing agent capable of adjusting construction time in refractory material and preparation method of comprehensive dispersing agent

The invention provides a comprehensive dispersing agent capable of adjusting construction time for a refractory material. The comprehensive dispersing agent comprises the following components in partsby mass: 500-700 parts of a carboxylic acid monomer, 20-50 parts of a metal monomer, 50-100 parts of a long-chain monomer, 100-200 parts of a hydroxyl monomer, 40-80 parts of purified water, 1-4 parts of a molecular weight control agent, 0.5-1.5 parts of an initiator and 300-500 parts of slow-release powder, wherein the metal monomer is one or a mixture of two or more of vinyl potassium trifluoroborate, vinyl boronic acid pinacol ester, vinyl lithium and 4-vinyl benzene sulfonic acid calcium. The comprehensive dispersing agent is uniform in powder and convenient and simple to use, does not lose efficacy after being stored for 24 months in a normal-temperature environment, has a good dispersing effect on alumina and high-silicon system refractory castables, and can adjust the constructiontime according to an external construction environment.

Owner:武汉善达化工有限公司

Anti-salt and anti-calcium fluid loss reducer for drilling fluid and preparation method thereof

ActiveCN104497995BGood filter loss reduction effectImprove salt resistanceDrilling compositionCalcium EDTAPollution

The invention discloses a salt-resistant and calcium-resistant filtrate reducer applied to a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer is prepared from raw materials and water, wherein the raw materials comprise 2-acrylamide-2-methyl propane sulfonic acid, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride; the ratio of m(2-acrylamide-2-methyl propane sulfonic acid) to m(acrylic acid) to m(acrylamide) to m(dimethyl diallyl ammonium chloride) to m(initiator) to m(molecular weight control agent) is (40-60) to (6-10) to (30-40) to (5-9) to (1-2) to (0.1-0.5). The molecular weight of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid and prepared by the preparation method is greatly improved; the coating property, the inhibition property, the heat stability and the salt-resistant and calcium-resistant pollution capacity of the filtrate reducer are greatly improved; by virtue of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid, the rheological property of the drilling fluid can be greatly improved; the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid also has a high temperature-resistant effect at 150-180 DEG C.

Owner:北京奥凯立科技发展股份有限公司

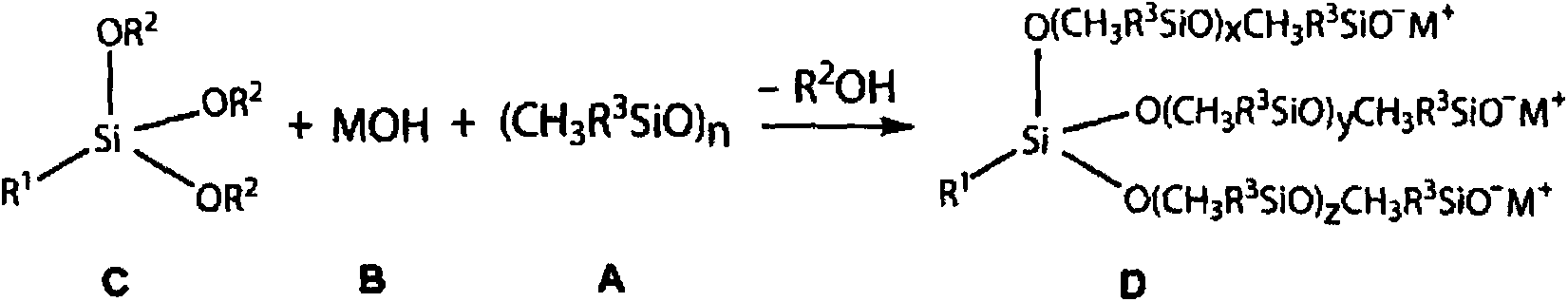

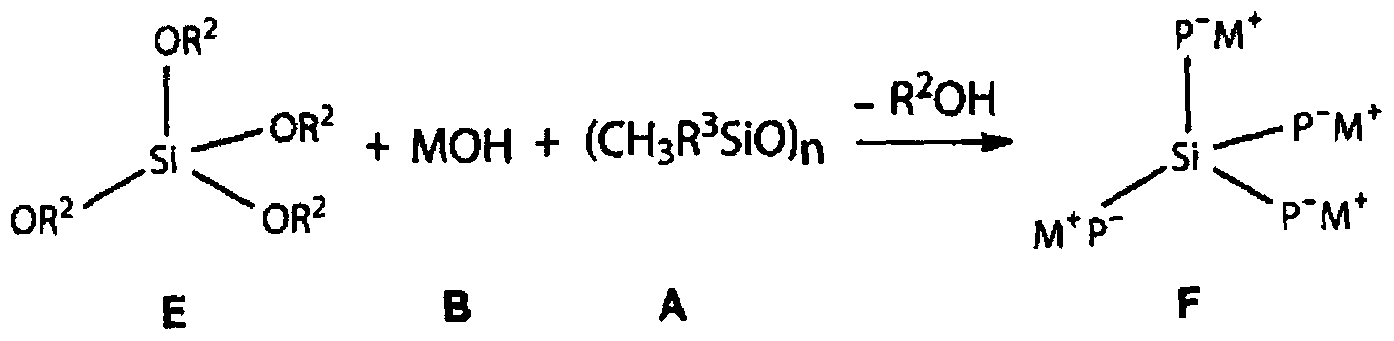

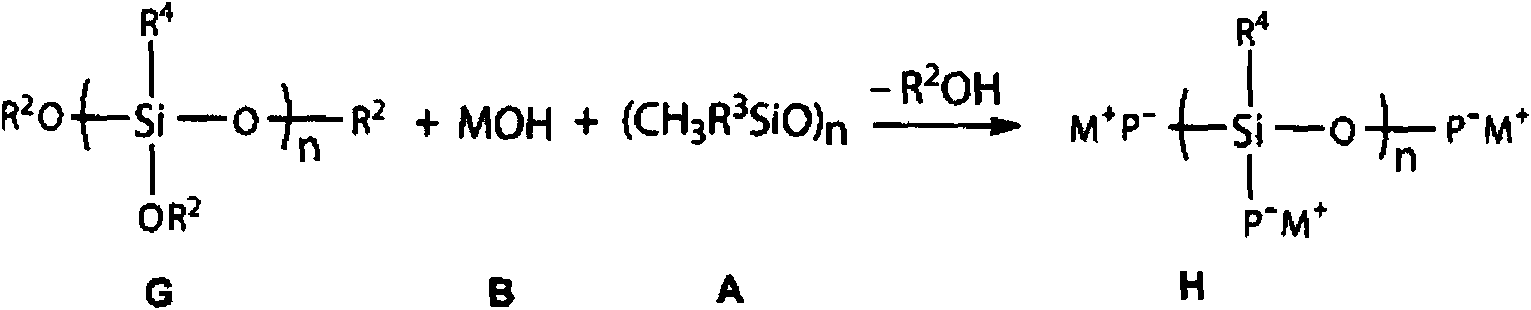

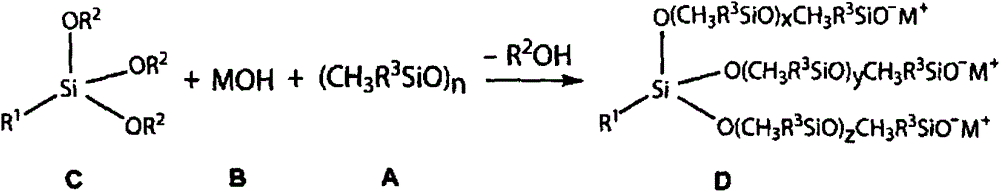

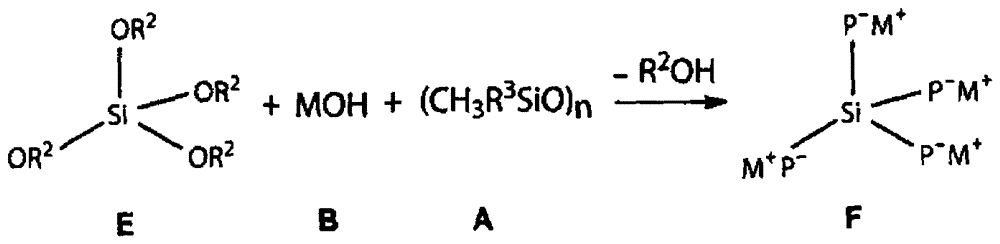

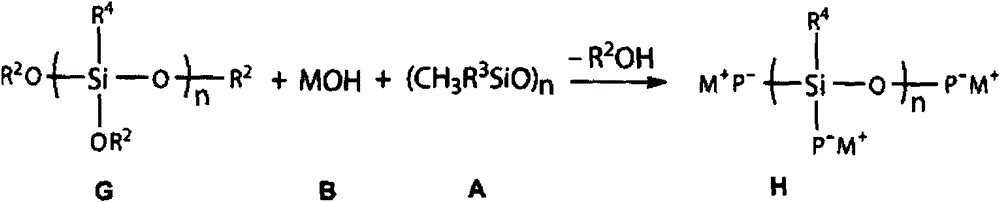

Preparation method of organosilicon polymer with nonlinear structure

The invention relates to a preparation method of an organosilicon polymer with a nonlinear structure. The organosilicon polymer with the nonlinear structure is obtained by carrying out polymerization reaction on a cyclic organosilicon monomer, a multi-active species anionic initiator, a molecular weight control agent and a vinyl monomer, wherein the multi-active species anionic initiator is prepared by reaction among the cyclic organosilicon monomer, a base and alkoxysilane. According to the preparation method of the multi-active species anionic initiator, the cyclic organosilicon monomer is initiated by virtue of the multi-active species anionic initiator to carry out ring-opening polymerization and thus the organosilicon polymer with the nonlinear structure is prepared. The organosilicon polymer, compared with a linear polymer, has higher melt elasticity and higher viscosity and the mixed rubber prepared from the organosilicon polymer has good rebound elasticity and low-compression permanent deformation.

Owner:EAST CHINA UNIV OF SCI & TECH

Silicon micropowder dispersing agent based on carboxylic acid monomer

PendingCN114349911AGood water solubilityReduce the probability of forming hydrogen bondsTransportation and packagingMixingWeight control agentAcrylate ester

The invention provides a silicon micropowder dispersing agent based on a carboxylic acid monomer. The silicon micropowder dispersing agent is prepared by the following steps: firstly, weighing the following components in parts by weight: 500-700 parts of carboxylic acid monomer, 20-50 parts of polyurethane modified acrylate, 50-100 parts of long-chain monomer, 100-200 parts of sacrificial monomer, 50-70 parts of water, 1-5 parts of molecular weight control agent, 0.5-1.5 parts of initiator and 300-500 parts of slow-release powder; the preparation method comprises the following steps: adding a carboxylic acid monomer, water and a long-chain monomer into a reaction kettle, heating and stirring, adding a polyurethane modified acrylate macromonomer, a sacrificial monomer, an initiator and a molecular weight control agent after stirring, continuously stirring and preserving heat, putting into a granulator after heat preservation is finished, adding the slow-release powder, and discharging after granulation is finished. The dispersing agent overcomes the defects in the prior art, and has the advantages of being convenient to use and good in dispersing effect for inorganic material slurry with the high silica powder content.

Owner:WUHAN UNIV OF SCI & TECH +1

Poly(pentabromobenzyl acrylate) synthesizing method

The invention discloses a poly(pentabromobenzyl acrylate) synthesizing method and belongs to the technical field of brominated flame retardant synthesis. The synthesizing method comprises the steps of adding acrylic acid and an emulsifier into a water phase, warming to 60 DEG C to 80 DEG C, gradually dropwise adding an alkali metal alkoxide solution, adjusting a pH to be equal to 9 to 10, fully stirring and evenly mixing, adding a phase transfer catalyst and a polymerization inhibitor, maintaining a temperature as 60 DEG C to 80 DEG C, adding a pentabromobenzyl chloride solution dissolved by dichloropropane, keeping the temperature for 1 to 5 hours after dropwise adding the pentabromobenzyl chloride solution, standing and layering, taking an organic layer to be washed by water, filtering to obtain an intermediate solution, warming the solution to 90 DEG C, adding a dispersant, an initiator and a molecular weight control agent to perform polymerization reaction, adding a stabilizer and a pH modifier in a center control process, programmably warming, finally curing in high temperature and filtering and drying to obtain a poly(pentabromobenzyl acrylate) product with even molecular weight distribution.

Owner:WEIFANG RIXING CHEM

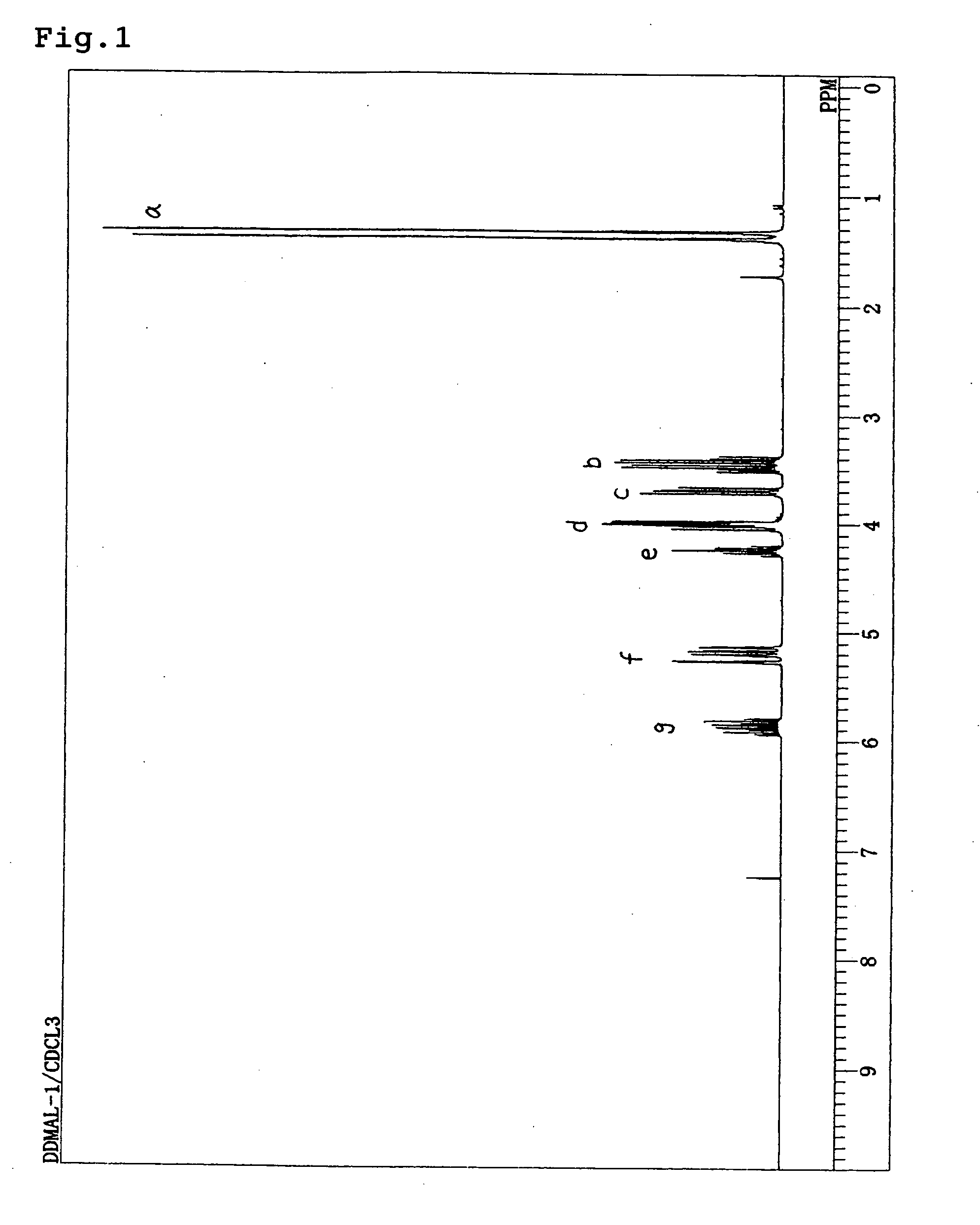

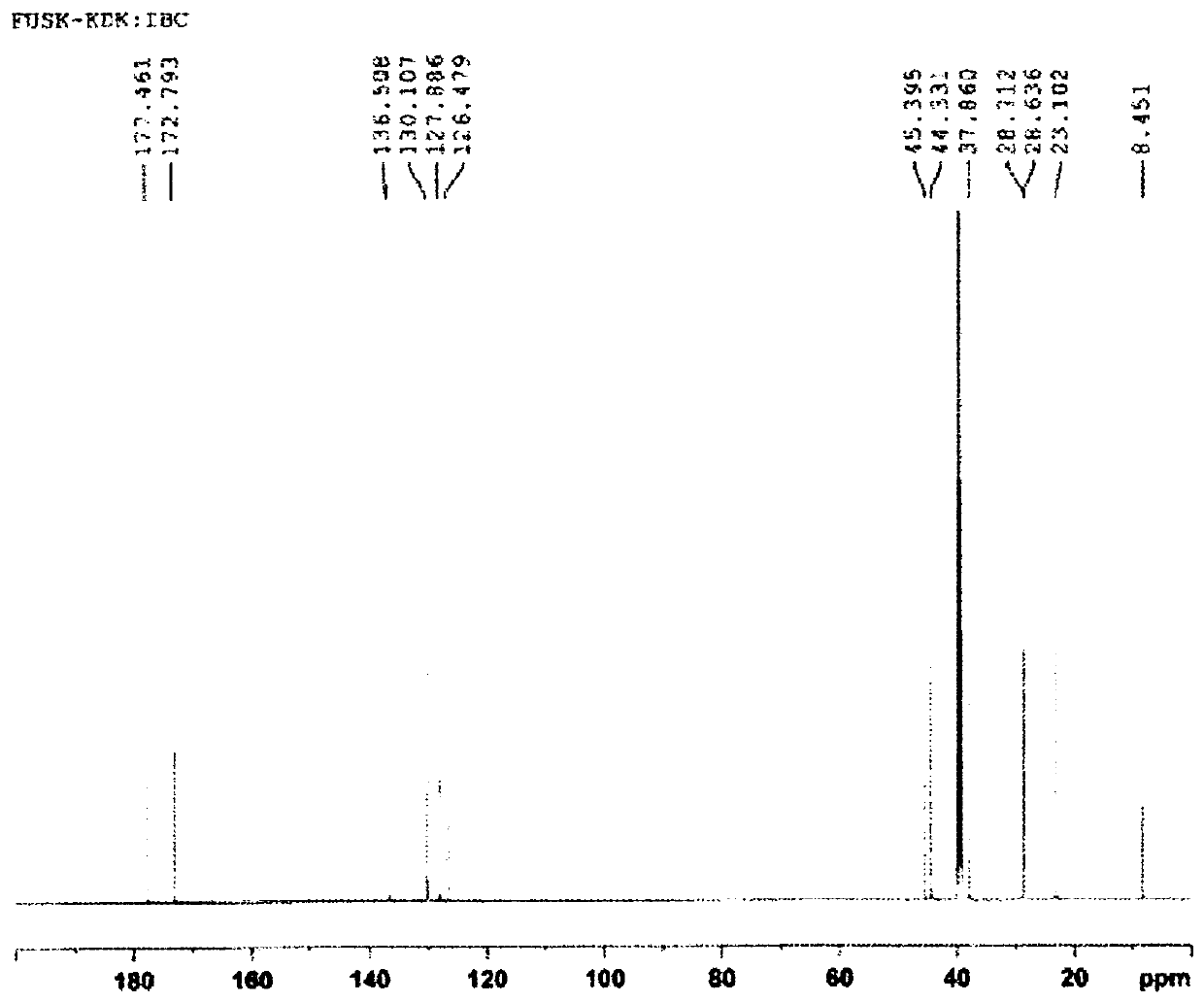

Novel organosilicon compound, organosilicon resin having diol, and processes for producing these

InactiveUS20070173625A1Strong hydrogen bondingEasy to controlSilicon organic compoundsCarbon numberSilanes

[Problems] To provide a novel alkoxysilane having a diol protected, an organosilicon resin which has a diol and the composition of which can be easily regulated, and to processes for producing these. [Means for solving problems] The alkoxysilane is an organosilicon compound represented by the following formula (1). The organosilicon resin having a diol is one obtained by hydrolyzing-condensing this compound with a multifunctional alkoxysilane. (In the formula, each of R1, R2 and R3 is an alkyl group or an alkoxy group each having carbon number from 1 to 6. R4 is an alkylene group having carbon number from 2 to 6. Z is an alkylene group having carbon number from 1 to 3.) The alkoxysilane of the present invention can be produced by a hydrosilylation reaction of a compound represented by the following formula (4) and a silane compound R1R2R3SiH. (In the formula, Z is an alkylene group having carbon number from 1 to 3 and R5 has a carbon-carbon double bond at the terminal.) The organosilicon resin of the present invention can be produced by a hydrolysis-condensation of a mixture comprising the organosilicon compound represented by the formula (1) above and a molecular weight-controlling agent.

Owner:TOAGOSEI CO LTD

OCA optical adhesive and preparation method and application thereof

InactiveCN112210327AMolecular weight controlChange the number of copiesEster polymer adhesivesFilm/foil adhesives without carriersPolymer scienceEthyl group

The invention discloses an OCA optical adhesive, a preparation method and application of the OCA optical adhesive. The OCA optical adhesive comprises 2-ethylhexyl acrylate, isobornyl acrylate, 2-hydroxyethyl acrylate, 1-hydroxycyclohexyl phenyl ketone and a molecular weight control agent dodecanethiol. The preparation method of the OCA optical adhesive comprises the following steps: step 1, mixing2-ethylhexyl acrylate, isobornyl acrylate, 2-hydroxyethyl acrylate, 1-hydroxycyclohexyl phenyl ketone and dodecanethiol to obtain a monomer prepolymer; and 2, exposing the monomer prepolymer to ultraviolet radiation in a nitrogen protection environment, and adding a photoinitiator and a cross-linking agent to obtain the OCA optical adhesive. The application of the OCA optical adhesive comprises the following steps: a, unwinding a release film; b, coating the release film with the OCA optical adhesive, and to obtain the release film coated with the OCA optical adhesive; c, curing the release film coated with the OCA optical adhesive under illumination to obtain a cured release film; and d, winding the cured release film.

Owner:世星科技股份有限公司

An air-entraining controllable polycarboxylate water reducer for pure machine-made sand concrete and its preparation method

The invention belongs to the field of concrete additives, and concretely relates to an air entrainment-controllable polycarboxylic water reducer used for purely machine-made sand concrete, and a preparation method thereof. The preparation method comprises the following steps: carrying out an esterification reaction on an alkylphenol polyoxyethylene monomer and an unsaturated carboxylic acid to generate an unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, carrying out an aqueous solution copolymerization reaction on the unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, an unsaturated polyether monomer and an unsaturated sulfonic acid monomer through an oxidation-reduction initiation system, and adding a proper amount of a molecular weight control agent to control the molecular weight in order to obtain the air entrainment-controllable polycarboxylic water reducer. The water reducer prepared in the invention has the advantages of high water reduction rate, good adaptability, small bubble diameters, stable sealing property and controllable air entrainment when applied to the purely machine-made sand concrete, and well solves the problems of difficult air entrainment, poor bubble stability and large concrete pumping loss of the purely machine-made sand concrete.

Owner:中建商品混凝土(福建)有限公司 +1

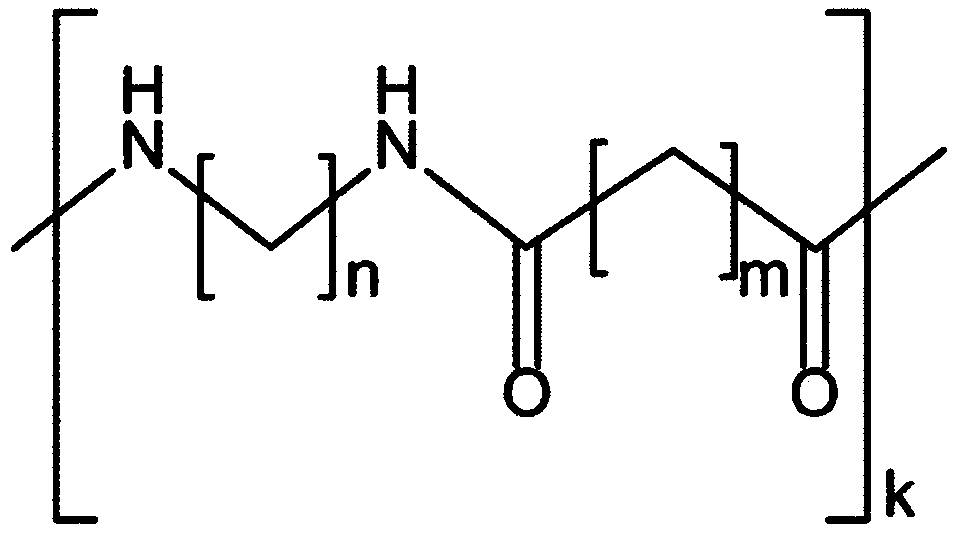

Method for preparing polyamide by using molecular weight control agent having double active group, and polyamide prepared thereby

The present invention provides: a method for preparing a polyamide by using a molecular weight control agent having a double active group, the method using a molecular weight control agent containinga double active group in the anionic ring-opening copolymerization of a polyamide, thereby enabling molecular weight to be controlled through the addition reaction of the molecular weight control agent; and a polyamide prepared thereby.

Owner:HANWHA SOLUTIONS CORP

Resin used for water-based fishing rod solid color paint, and preparation method thereof

The invention relates to a resin used for water-based fishing rod solid color paint, and a preparation method thereof. The resin is composed of, by mass, 5 to 15 parts of styrene or methylstyrene, 20to 50 parts of a main monomer, 5 to 30 parts of a functional monomer, 0.1 to 5.0 parts of a molecular weight controlling agent, 0.5 to 4.0 parts of an initiator, and 1 to 10 parts of a pH value conditioning agent. A preparation method of water-based fishing rod solid color paint comprises following steps: the resin is weighed; water, an anti-foaming agent, a leveling agent, a dispersant, and a pigment toner are added for uniform mixing; and an obtained mixture is grinded into powder with a particle size smaller than 20<mu>m. The resin is capable of solving the compatibility problem of pigmentwith resin, and especially the compatibility problem of high black degree carbon powder, organic red pigment, and organic yellow pigment, and the resin possesses excellent compatibility with pigments.

Owner:新元化学(山东)股份有限公司

Preparation method of non-linear structure organosilicon polymer

The invention relates to a preparation method of a non-linear structure silicone polymer, which is to obtain a non-linear structure silicone polymer through polymerization reaction of a cyclic organic silicon monomer, a multi-active anion initiator, a molecular weight control agent and a vinyl monomer. The multi-active anion initiator is prepared by reacting cyclic organosilicon monomer, alkali and alkoxysilane. The invention provides a preparation method of an anionic initiator with multiple active species, and uses the initiator to initiate ring-opening polymerization of organosilicon ring monomers to prepare organosilicon polymers with a nonlinear structure. These silicone polymers have greater melt elasticity and higher viscosity than linear polymers, resulting in compounds with better resilience and low compression set.

Owner:EAST CHINA UNIV OF SCI & TECH

Sweetener compositions for weight management

InactiveUS20210084955A1Maintain tasteMaintains feelNatural extract food ingredientsFood ingredient functionsWeight control agentMedicine

Sweetener compositions are provided, particularly tabletop sweeteners, comprising ground Hoodia as a weight control agent in combination with the non-caloric sweetener rebaudioside A and erythritol.

Owner:SUCRAZIT LTD

Preparation method of water-solubility amylum-acrylamide copolymer and application of water-solubility amylum-acrylamide copolymer

ActiveCN102603977BLarge molecular sizeLow costReinforcing agents additionPaper/cardboardSolubilityWeight control agent

The invention relates to the field of papermaking production, aims at solving the problem that the current papermaking industry needs a comprehensive dry strength resin concurrently having super enhanced effect of polyacrylamide and low cost feature of amylum, and provides a preparation method of a water-solubility amylum-acrylamide copolymer and application of the water-solubility amylum-acrylamide copolymer. The water-solubility amylum-acrylamide copolymer is prepared by the following components in parts by weight: 25-90 parts of monomer A, 0-20 parts of monomer B, 0-20 parts of monomer C, 0.02-1.5 parts of molecular weight control agents, 0.005-3.5 parts of crosslinking monomers, 5-30 parts of the amylum, 0.1-1 parts of catalyst and 0.2-2 parts of terminating agents, wherein water is added until product solid content is adjusted to be 10%-30%. The water-solubility amylum-acrylamide copolymer is used as the dry strength resin, and has strong enhanced effect, lower cost than the currently ordinary polyacrylamides dry strength resin and better economic benefit.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com