Water-based inorganic filler dispersant and preparation method thereof

An inorganic filler and dispersant technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of high VOC, unfriendly environment, volatile organic solvent failure, etc., achieve good dispersion, obvious resistance The effect of strong ability and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

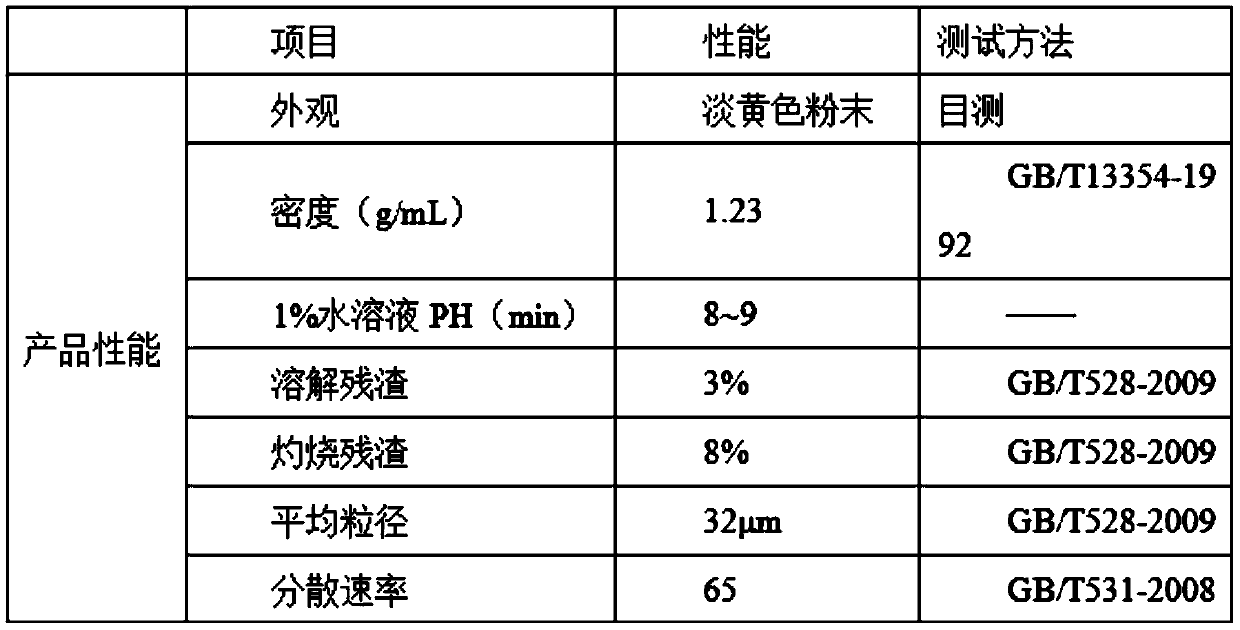

Embodiment 1

[0018] 500 parts of methacrylic acid used in the raw materials of this example, 10 parts of silsesquioxane particles, 100 parts of long-chain monomers, 100 parts of purified water, 40 parts of acrylic acid-1,3-sultone, and 15 parts of styrene 1.5 parts of initiator (potassium persulfate + dibenzoyl peroxide, the mixing mass ratio is 2:1), 0.2 parts of chiral phosphoric acid, and 0.5 parts of compatibilizer.

[0019] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and heat up to 50°C. When the temperature reaches 50°C, start stirring, set the stirring rate to 25rpm, keep for 35min, and then add Silsesquioxane, initiator and molecular weight control agent were kept stirring for 15 minutes, then heated to 80°C and kept for 3 hours, then chiral phosphoric acid was added dropwise and kept at 90°C for 1 hour to discharge. Add 2% toluene to the product and vacuum-dry it on a rotary evaporator...

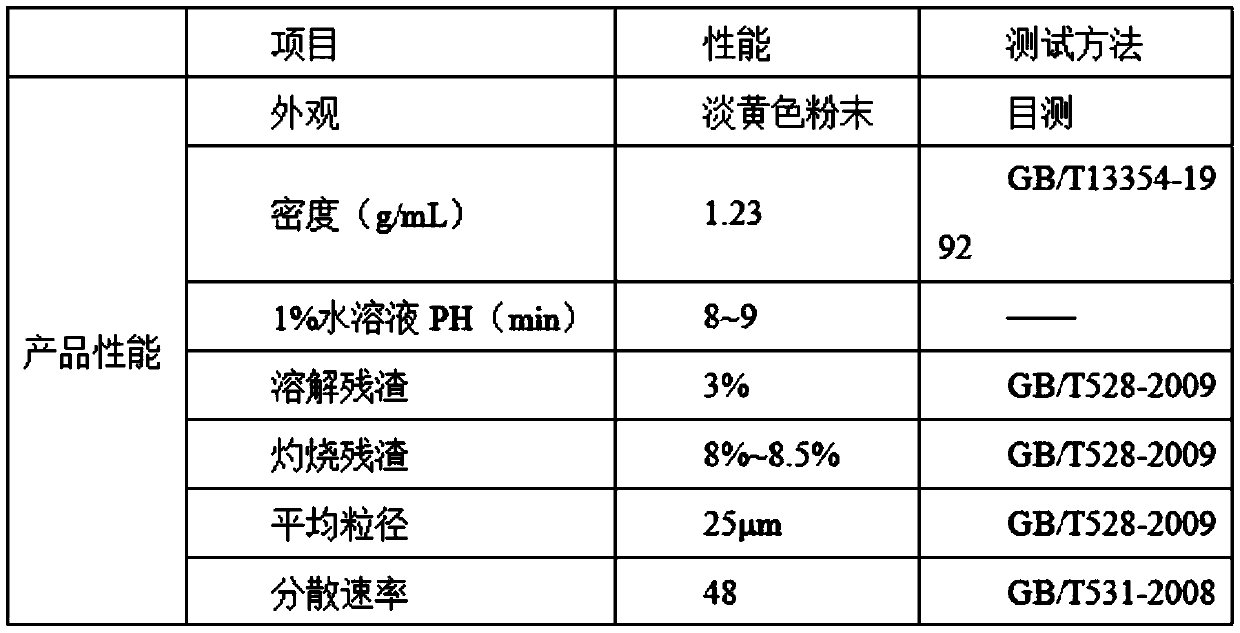

Embodiment 2

[0024] The components used in the raw materials of this example and the weight ratio are: 480 parts of methacrylic acid + acrylic acid, 15 parts of silsesquioxane particles, 80 parts of long-chain monomers, 90 parts of purified water, 20 parts of sodium methacrylic acid 1 part, initiator (potassium persulfate + dibenzoyl peroxide, mixing mass ratio is 3:1), 0.15 part of chiral phosphoric acid, 0.3 part of compatibilizer; and prepared by special synthesis process and powder making process It is a powder dispersant, which is characterized in that the powder shape is uniform and spherical, which is convenient and simple to use, and it will not fail after being stored at room temperature for 24 months. It has good dispersion effect on general inorganic materials and anti-interference ability powerful.

[0025] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and heat up to 50°C. When the te...

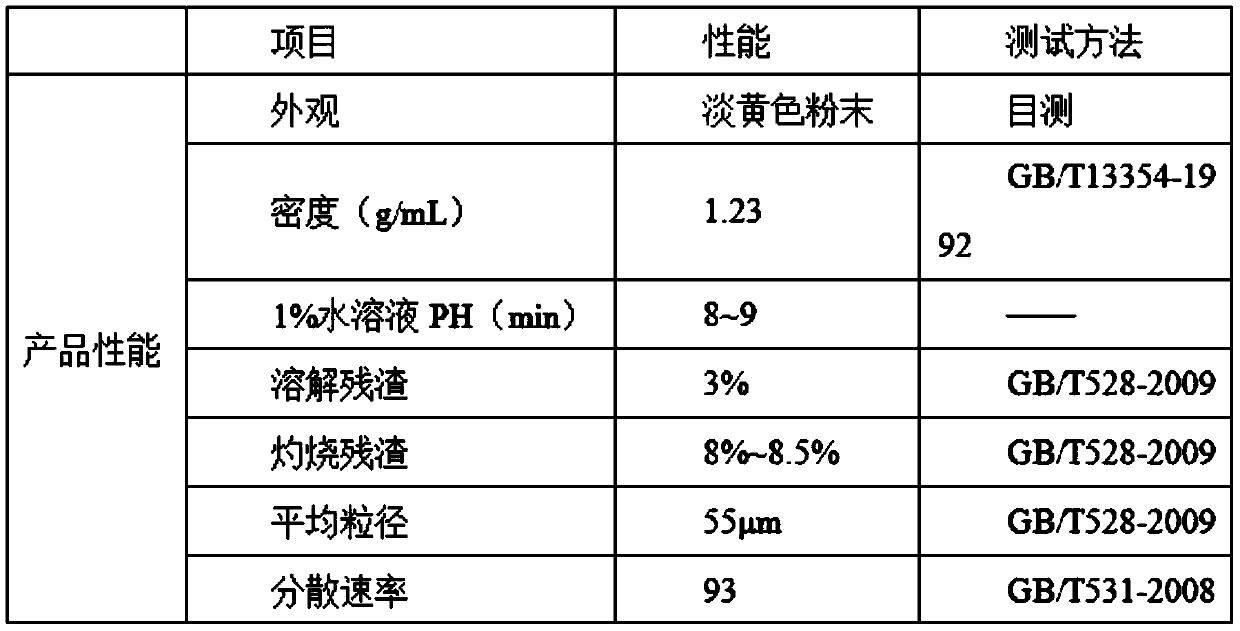

Embodiment 3

[0030] The components and weight ratios of the raw materials in this example are: 420 parts of acrylic acid + maleic anhydride, 12 parts of silsesquioxane particles, 50 parts of long-chain monomers, 80 parts of purified water, sodium methacrylate + 26 parts of 2-acrylamide-2-methylpropanesulfonic acid, 0.8 parts of initiator (potassium persulfate + azobisisobutyronitrile, mixing mass ratio of 3.5:1), 0.1 parts of chiral phosphoric acid, 0.15 parts of compatibilizer It is a kind of powder dispersant prepared by a special synthesis process and powder making process. It is characterized in that the powder shape is uniform and spherical, which is convenient and simple to use, and it will not fail when stored at room temperature for 24 months. General inorganic materials have good dispersion and strong anti-interference ability.

[0031] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com