Synthetic resin for water-borne fishing rod finishing varnish as well as preparation method and application thereof

A technology of synthetic resin and topcoat varnish, applied in the direction of coating, can solve the problems of water-based topcoat with less paint film and lack of luster on fishing rods, and achieve the effect of good storage stability and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

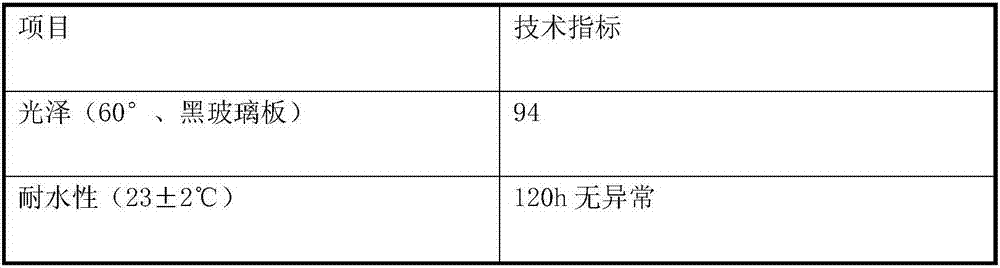

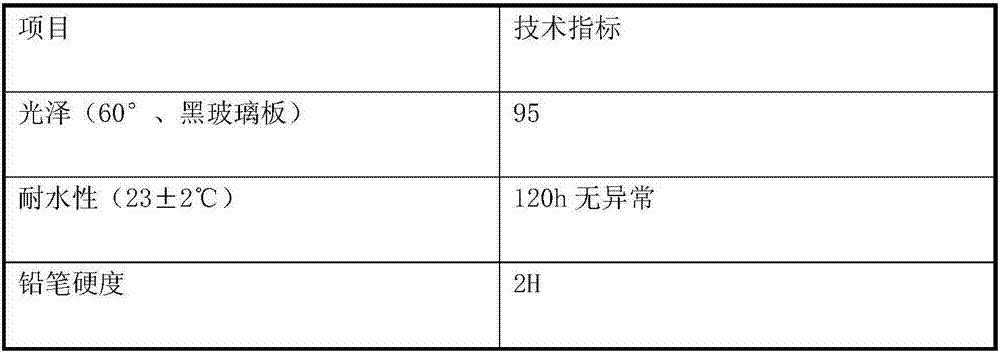

Embodiment 1

[0040] 1. Preparation of resin for water-based fishing rod finish varnish:

[0041] 11% methyl methacrylate, 4% isooctyl acrylate, 5% acrylic acid, 20% cyclohexyl methacrylate, 12% hydroxyethyl acrylate, 6% n-butyl acrylate, 2% Glycidyl methacrylate, 2% mercaptoethanol, and 1.5% azobisisoheptanonitrile were added to the autoclave and stirred evenly to obtain a mixed material; 8% ethanol, 6% N, N dimethyl formaldehyde Add the amide into the reaction kettle, raise the temperature to 60-70°C, start adding the mixed material at a constant speed, finish adding in 2-3 hours, react at constant temperature for 1-2 hours, add 0.15% azobisisoheptanonitrile solution, and continue the reaction for 1-3 hours. Cool down to 60°C, add 4.5% N-methylmorpholine, stir evenly, add deionized water, stir evenly, remove co-solvent, cool down below 35°C, and discharge.

[0042] 2. Preparation of water-based fishing rod finish varnish

[0043] Mix 95% resin for water-based fishing rod finish varnish, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com