Preparation method of non-linear structure organosilicon polymer

A silicone, polymer technology, applied in the polymer field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

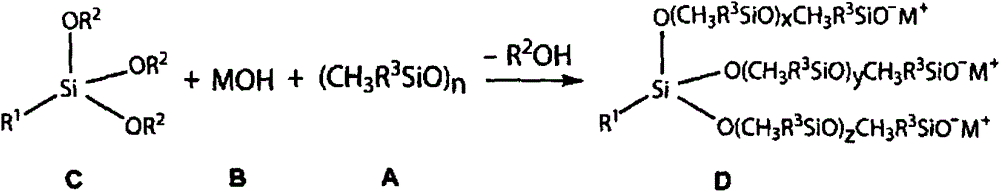

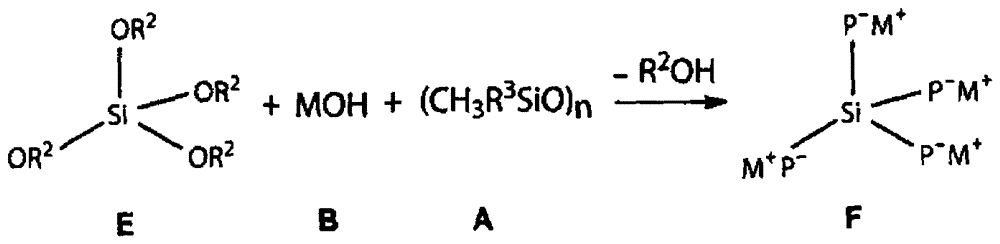

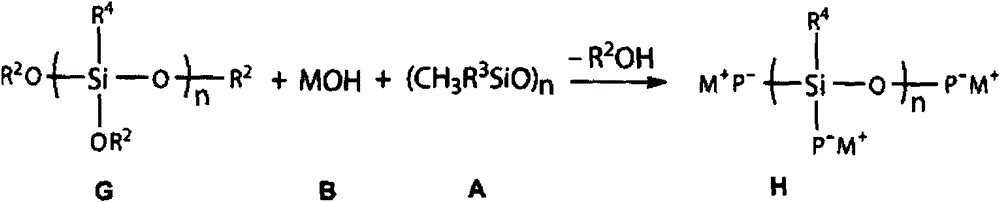

Method used

Image

Examples

Embodiment 1

[0039] Prepare three active species initiators: with 100 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 4 parts by weight (CH 3 ) 4 NOH and 4 parts by weight of methyltriethoxysilane were reacted at 110° C. for 2 hours to obtain a transparent oily three-active species initiator with a viscosity of 100 mPa·s.

[0040] Preparation of three-arm star silicone rubber: with 100 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 1.5 parts by weight of the above-mentioned three active species initiators, 0.5 parts by weight of hexamethyldisiloxane and 0.15 parts by weight of tetramethyltetravinyl cyclotetrasiloxane (V 4 ) at 120° C. for 4 hours of polymerization reaction, after the polymerization reaction was completed, 0.2 parts by weight of trimethylchlorosilane was added for devolatilization to obtain a nonlinear silicone rubber raw rubber. Yield by D 4 The meter is 90%, the molecular weight is 700,000, and the vinyl content is 0.15%.

Embodiment 2

[0042] Prepare three active species initiators: with 100 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 4 parts by weight of NaOH and 4 parts by weight of phenyltriethoxysilane were reacted at 130° C. for 5 hours to obtain a three-active species initiator with a transparent oily viscosity of 100 mPa·s.

[0043] Prepare three-arm star-shaped fluorosilicone rubber: with 100 parts by weight of methyl trifluoropropyl cyclotrisiloxane (D 3 F), 2 parts by weight of the above-mentioned three active species initiators, 0.5 parts by weight of hexamethyldisiloxane and 0.01 to 2 parts by weight of tetramethyltetravinyl cyclotetrasiloxane (V 4 ) at 130° C. for 8 hours, and after the polymerization, 0.2 parts by weight of trimethylchlorosilane was added for devolatilization to obtain nonlinear fluorosilicone rubber. Yield by D 3 The F count is 85%, the molecular weight is 850,000, and the vinyl content is 0.15%.

Embodiment 3

[0045] Prepare three active species initiators: with 100 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 2.5 parts by weight of KOH and 4 parts by weight of ethyltrimethoxysilane were reacted at 120° C. for 5 h to obtain a three-active species initiator with a transparent oily viscosity of 200 mPa·s.

[0046] Prepare three-arm star-shaped phenyl silicone rubber: with 100 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 20 parts by weight of tetramethyltetraphenylcyclotetrasiloxane (P 4 ), 2 parts by weight initiator, 0.5 parts by weight hexamethyldisiloxane and 0.15 parts by weight tetramethyltetravinyl cyclotetrasiloxane (V 4 ) at 120° C. for 4 hours of polymerization reaction, after the polymerization reaction was completed, 0.2 parts by weight of trimethylchlorosilane was added for devolatilization to obtain a nonlinear phenyl silicone rubber raw rubber. Yield by P 4 The meter is 90%, the molecular weight is 700,000, and the vinyl content is 0.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com