An air-entraining controllable polycarboxylate water reducer for pure machine-made sand concrete and its preparation method

A polycarboxylic acid-based and concrete technology, applied in the field of concrete admixtures, can solve the problems of large concrete pumping loss, poor bubble stability, poor water retention, etc. The effect of improving the slump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

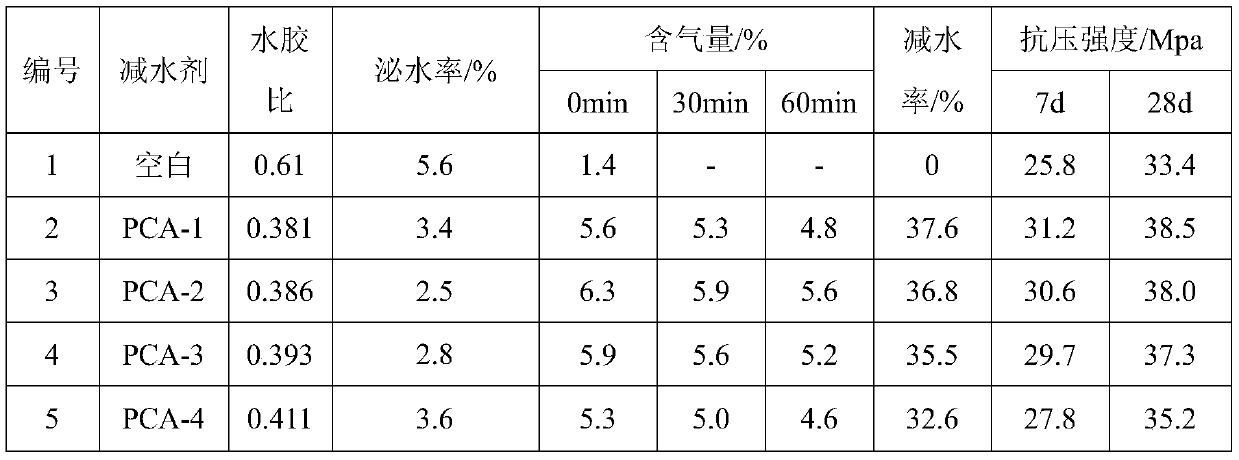

Examples

Embodiment 1

[0032] An air-entraining controllable polycarboxylate water-reducing agent for pure machine-made sand concrete is prepared by the following method:

[0033] (1) The octylphenol polyoxyethylene ether monomer (CH 3 (CH 2 ) x C 6 H 4 (OC 2 H 4 ) y OH x = 8, y = 7) was added to the flask, heated to 110 ~ 120 ℃, nitrogen under the liquid, stirred uniformly, and then added acrylic monomer (octyl phenol polyoxyethylene ether monomer and acrylic monomer The molar ratio is 1:1.1), oleum (accounting for 1% of the total amount of two monomers), phenothiazine (accounting for 0.02% of the total amount of two monomers) and hydroquinone (accounting for the total amount of two monomers) 0.02%), the temperature is controlled at 110~120℃, react for 4~6 hours, after the temperature is reduced to 80~85℃, add sodium hydroxide solution while stirring to neutralize to pH=6.5~7, obtain unsaturated carboxylic acid- Alkylphenol polyoxyethylene ether ester monomer, ready for use after cooling down;

[0034]...

Embodiment 2

[0038] An air-entraining controllable polycarboxylate water-reducing agent for pure machine-made sand concrete is prepared by the following method:

[0039] (1) The nonylphenol polyoxyethylene ether monomer (CH 3 (CH 2 ) x C 6 H 4 (OC 2 H 4 ) y OH x = 8, y = 11) was added to the flask, heated to 110 ~ 120 ℃, nitrogen under the liquid, stirred uniformly, and then added methacrylic acid monomer (nonylphenol polyoxyethylene ether monomer and methyl The molar ratio of acrylic monomer is 1:1.2), fuming sulfuric acid (accounting for 2% of the total amount of two monomers), phenothiazine (accounting for 0.05% of the total amount of monomers) and hydroquinone (accounting for the total amount of monomers 0.05%), the temperature is controlled at 110~120℃, react for 4~6 hours, when the temperature is reduced to 80~85℃, add sodium hydroxide solution while stirring to neutralize to pH=6.5~7, obtain unsaturated carboxylic acid- Alkylphenol polyoxyethylene ether ester monomer, ready for use aft...

Embodiment 3

[0044] An air-entraining controllable polycarboxylate water-reducing agent for pure machine-made sand concrete is prepared by the following method:

[0045] (1) The nonylphenol polyoxyethylene ether monomer (CH 3 (CH 2 ) x C 6 H 4 (OC 2 H 4 ) y OH x=8, y=9) Put it into the flask, raise the temperature to 110~120℃, pour nitrogen under the liquid, stir it evenly, and then add acrylic monomer (nonylphenol polyoxyethylene ether monomer and acrylic monomer The molar ratio is 1:1.15), oleum (accounting for 1.5% of the total amount of two monomers), phenothiazine (accounting for 0.04% of the total amount of two monomers) and hydroquinone (accounting for the total amount of two monomers) 0.04%), the temperature is controlled at 110~120℃, react for 4~6 hours, after the temperature is reduced to 80~85℃, add sodium hydroxide solution while stirring to neutralize to pH=6.5~7, to obtain unsaturated carboxylic acid- Alkylphenol polyoxyethylene ether ester monomer, ready for use after cooling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com