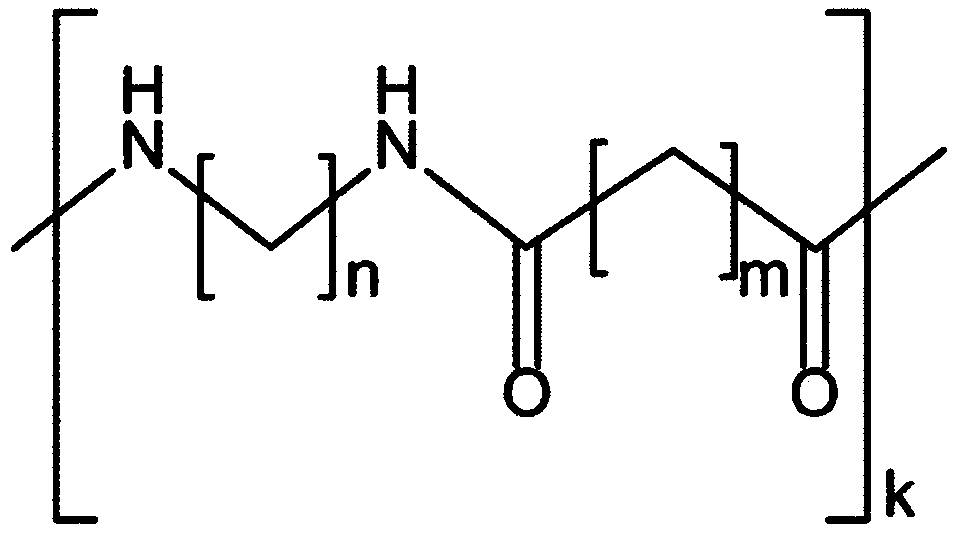

Method for preparing polyamide by using molecular weight control agent having double active group, and polyamide prepared thereby

A technology of molecular weight regulator and dual active groups, applied in the field of polyamide, can solve problems such as low efficiency and uneven reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

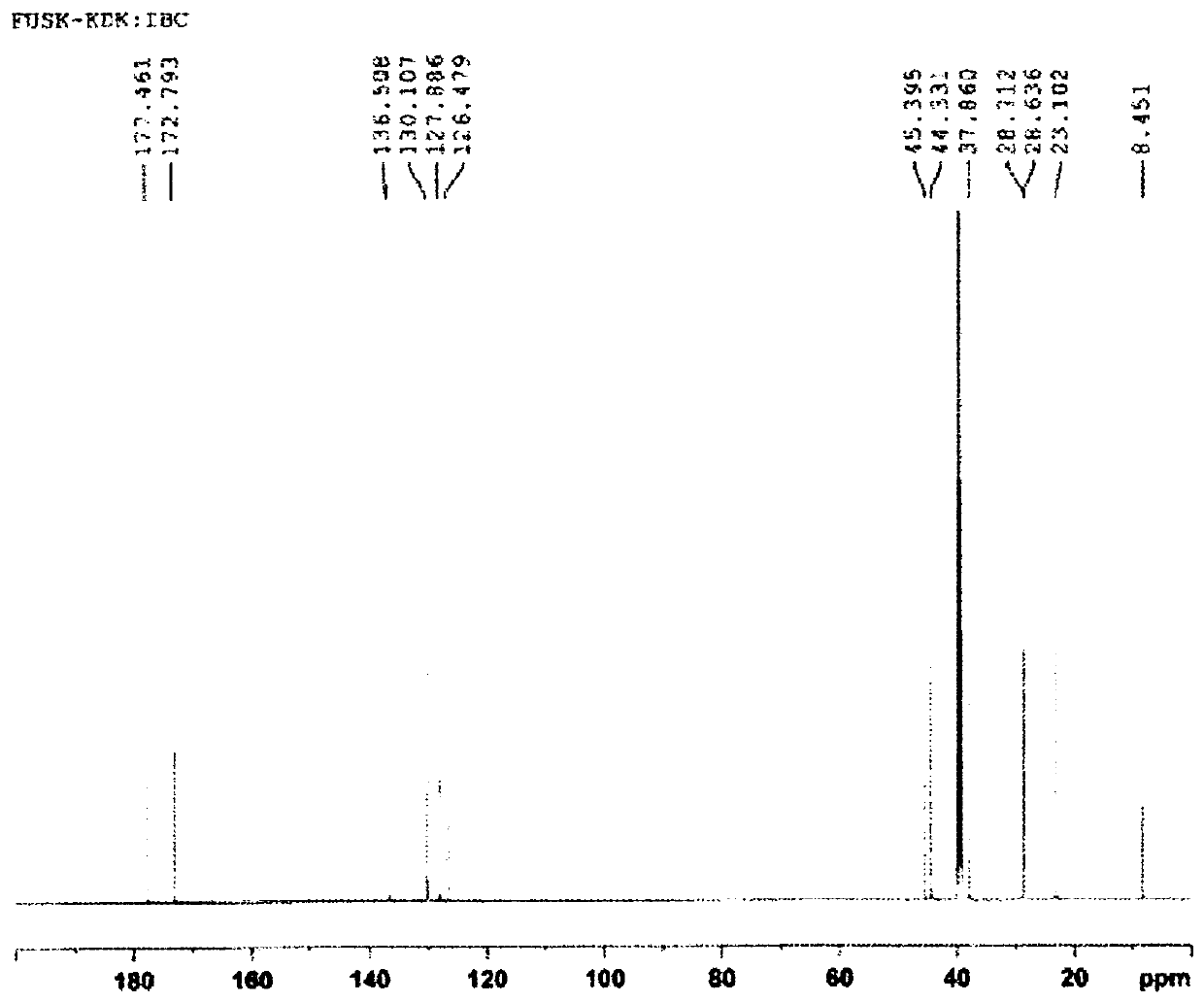

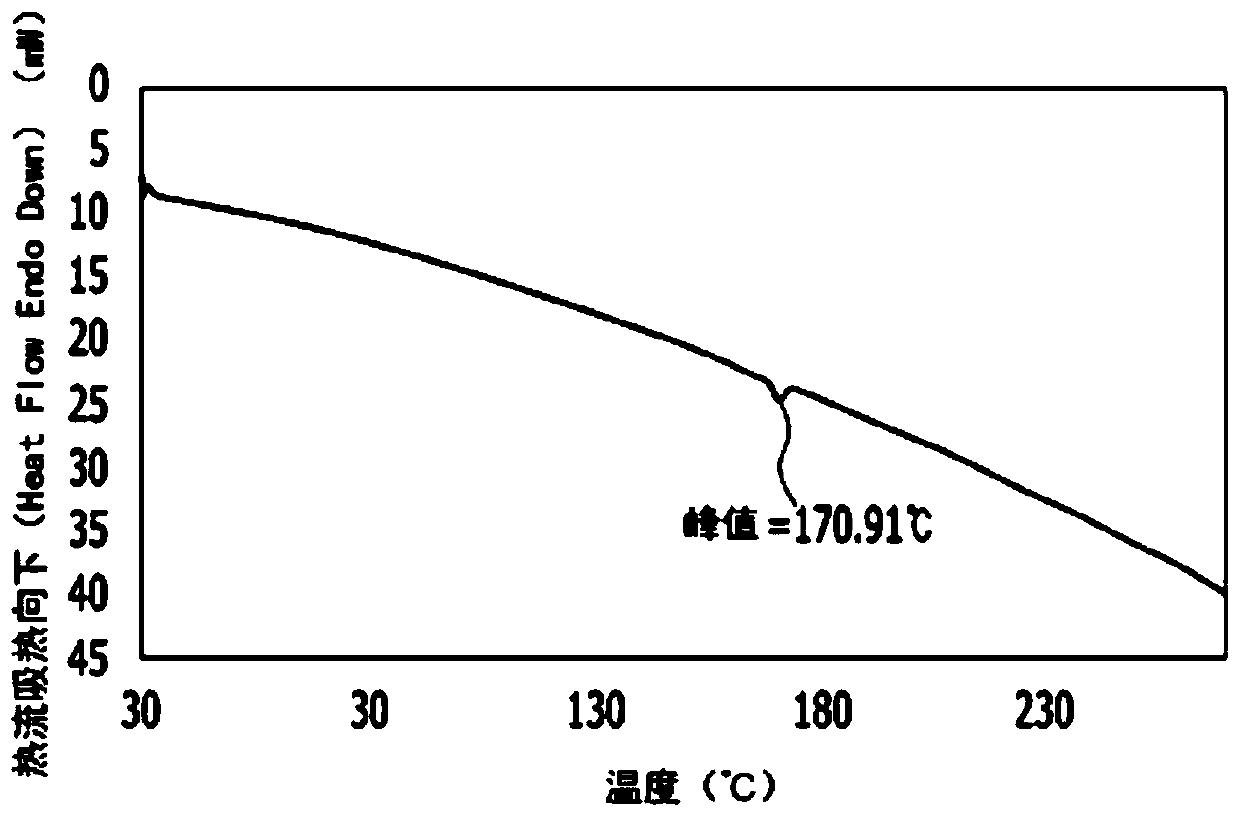

[0076] IBL (isophthaloyl-bis-laurolactam, isophthaloyl dilaurolactam) molecular weight regulator preparation of

[0077] Set the stirrer, reflux condenser tube and dropping funnel in the three-necked flask. At this point, all glasses were pre-dried under a nitrogen atmosphere in consideration of moisture-sensitive reactants. 1 mol equivalent of laurolactam (197.32 g) as a monomer, 1 mol of triethylamine, and 500 mL of THF were added to the flask and stirred. Among them, triethylamine (triethylamine) acts as a trapping agent for trapping hydrochloric acid generated by the reaction of laurolactam and isophthaloyl chloride. The prepared mixture was stirred and cooled on ice, and a solution obtained by dissolving 0.5 mol equivalent of isophthaloyl chloride in 150 mL of THF was slowly added dropwise for 40 minutes. After the addition was complete, the reaction mixture was stirred at room temperature for 30 minutes and then filtered. After drying the white solid under air, in...

Embodiment 1

[0080] Preparation of Polyamides Using Molecular Weight Regulators (IBL) with Bi-Reactive Groups

[0081] Caprolactam and laurolactam as a monomer and NaH as an initiator were weighed at a molar ratio of 50:50:1, respectively, and then put into a three-necked flask, and the temperature of the oil bath was adjusted to 160°C. After dissolving the monomer and the initiator once under a nitrogen atmosphere, and after confirming that the reactants are all dissolved, a vacuum is applied and hydrogen gas generated in the reactants is removed. After adjusting to a temperature of 230° C. at which the polymerization reaction actually occurs, 0.05 mol of a molecular weight modifier and 0.15 mol of an activator TDI were added to 100 parts by weight of lactam in total. When the polymerization was completed, after the reaction was terminated by adding a mixed solution of 1:1 formic acid and water, after washing with water and alcohol several times, and finally drying in a vacuum oven, the...

Embodiment 2

[0085] As shown in Table 1 above, a polyamide was prepared in the same manner as in Example 1 except that an end-capping agent was added in a molar ratio of 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com