Preparation method of water-solubility amylum-acrylamide copolymer and application of water-solubility amylum-acrylamide copolymer

A technology of acrylamide copolymerization and water-soluble starch, which is applied in the field of papermaking, can solve problems such as low molecular weight, loss, and poor reinforcement effect, and achieve good economic benefits, low cost, and strong reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

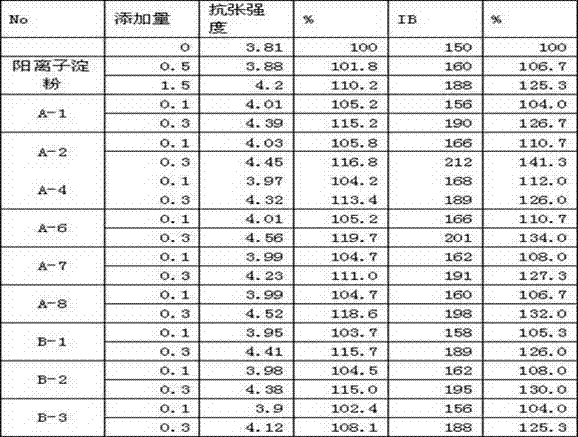

Examples

Embodiment 1

[0042] To a 1000ml four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a feeding port and a nitrogen conduit, add a monomer mixture: 152g of 40% acrylamide aqueous solution, 13.6g of dimethylaminoethyl methacrylate, methacrylic acid Acyloxyethyltrimethylammonium chloride 80% aqueous solution 7.5g, itaconic acid 5.2g, methylenebisacrylamide 1.97g, mercaptoethanol 0.13g, soluble starch 44g, deionized water 260g, and the solid content of the compound was 27.5 % of the primary monomer mixture, adjust the pH to 2.8 with 50% sulfuric acid, pass nitrogen into the reaction vessel for more than 30 minutes, and heat it to a temperature of 60°C, then add 10 g of deionized water and The aqueous catalyst solution prepared by catalyst hydrogen peroxide 0.2g initiates the polymerization reaction. The primary linear prepolymer A is obtained by controlling the temperature in a water bath at 60-70°C for 60 minutes.

[0043] 97.5g of 40% acrylamide aqueous solution, 1....

Embodiment 2

[0045] Add a monomer mixture to a 1000ml four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a feed port and an argon conduit: 170.4g of 40% acrylamide aqueous solution, 4.5g of dimethylaminoethyl methacrylate, N , N-dimethylaminopropyl acrylamide 1.0g, itaconic acid 2.8g, dimethylacrylamide 1.59g, sodium allyl sulfonate 0.46g, corn starch 25g, deionized water 260g, made into solid content It is a 22.4% primary monomer mixture, adjust the pH to 3.5 with 50% sulfuric acid, pass argon into the reaction vessel for more than 30 minutes, and heat it to a temperature of 70°C, then add it to the reaction vessel at one time. The catalyst aqueous solution prepared by ionized water and catalyst ammonium persulfate 0.2g initiates polymerization. The primary linear prepolymer A is obtained by controlling the temperature in a water bath at 80-90°C for 70 minutes.

[0046] 97.5g of 40% acrylamide aqueous solution, 0.5g of dimethylaminoethyl methacrylate, 0.2g of N,N...

Embodiment 3

[0048] Add a monomer mixture to a 1000ml four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a feed port and a nitrogen conduit: 62.6g of 40% acrylamide aqueous solution, 0.4g of dimethylaminoethyl methacrylate, and Conic acid 3.1g, dimethylacrylamide 0.32g and sodium methallyl sulfonate 0.2g, cationic starch 18g, deionized water 155.8g, made into a monomer mixture with a solid content of 20%, with 40% The concentration of sulfuric acid is adjusted to pH 3.5, nitrogen gas is passed into the reaction vessel for more than 30 minutes, and the temperature is 75°C, and then the reaction vessel is added at one time. Catalyst in water to initiate polymerization. The primary linear prepolymer A is obtained by controlling the temperature in a water bath at 80-90°C for 70 minutes.

[0049] 40% acrylamide aqueous solution 161.4g, methacrylamide 16.3g, dimethylaminoethyl methacrylate 3.4g, itaconic acid 7.3g, fumaric acid 2.8g, dimethylacrylamide 0.95g, methylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com