Comprehensive dispersing agent capable of adjusting construction time in refractory material and preparation method of comprehensive dispersing agent

A construction time and refractory technology, applied in the field of comprehensive dispersants and dispersants, can solve the problems of affecting construction completion, short construction time, affecting construction efficiency, etc., and achieve the effect of reducing solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

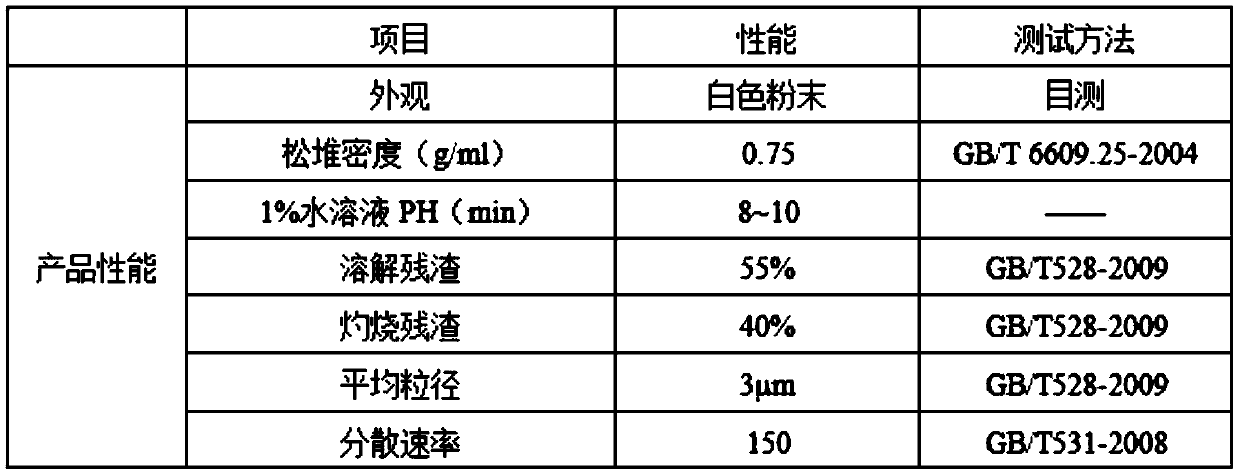

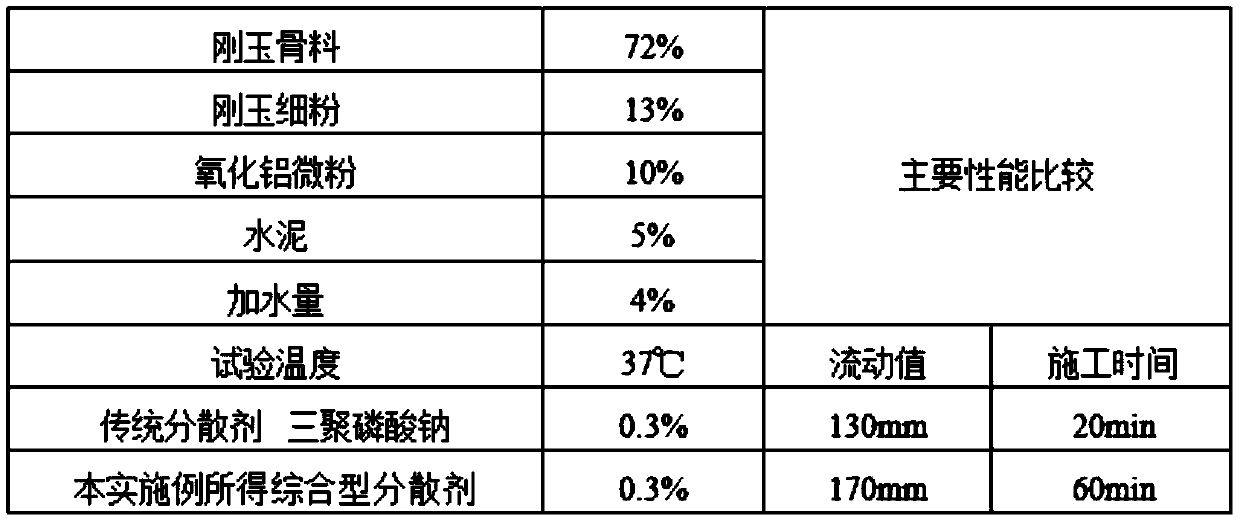

Embodiment 1

[0016] 700 parts of carboxylic acid monomers (methacrylic acid) used in the raw materials of this example, 15 parts of potassium vinyl trifluoroborate, 5 parts of calcium 4-vinylbenzenesulfonate, 50 parts of long-chain monomers, hydroxyethyl methacrylate 100 parts of ester, 60 parts of purified water, 3.5 parts of acrylic acid-1,3-sultone, 1.5 parts of initiator, and 500 parts of slow-release powder.

[0017] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and heat up to 70°C. When the temperature reaches 70°C, start stirring, set the stirring rate at 25rpm, keep for 35min, and then add Keep stirring the metal monomer, hydroxyl monomer, initiator and molecular weight control agent for 15 minutes and raise the temperature to 90°C for 5 hours, then pour into the granulator and slowly add the slow-release powder. After all the slow-release powder is added, keep it for 10-20 minutes before...

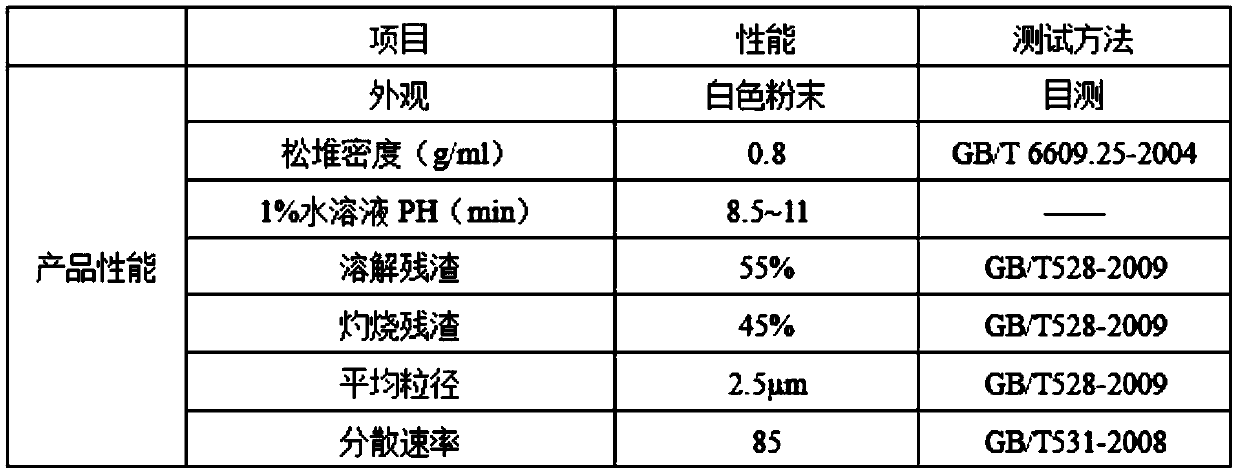

Embodiment 2

[0025] The components used in the raw materials of this example and the weight ratio are: 500 parts of carboxylic acid monomer (methacrylic acid+acrylic acid), 50 parts of vinyl boric acid pinacol ester, 100 parts of long-chain monomer, 200 parts of hydroxyethyl acrylate parts, 60 parts of purified water, 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.5 parts of initiator, and 300 parts of slow-release powder.

[0026] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and heat up to 70°C. When the temperature reaches 70°C, start stirring, set the stirring rate to 25rpm, keep for 15min, and then add Keep stirring the metal monomer, hydroxyl monomer, initiator and molecular weight control agent for 15 minutes and raise the temperature to 90°C for 5 hours, then pour into the granulator and slowly add the slow-release powder. After all the slow-release powder is added and kept for 1...

Embodiment 3

[0034] The components and weight ratios of the raw materials in this example are: 550 parts of carboxylic acid monomer (maleic anhydride + fumaleic acid), 28 parts of vinyl boric acid pinacol ester, 2 parts of vinyl lithium, long chain monomer 100 parts of body, 150 parts of hydroxypropyl methacrylate, 60 parts of purified water, 2 parts of molecular weight control agent (thioglycolic acid + mercaptopropionic acid), 1.5 parts of initiator, and 400 parts of slow-release powder.

[0035] The preparation method in this example is as follows: Add carboxylic acid monomers, purified water, and long-chain monomers into the reactor and heat up to 70°C. When the temperature reaches 70°C, start stirring, set the stirring rate at 25rpm, keep for 35min, and then add Keep stirring the metal monomer, hydroxyl monomer, initiator and molecular weight control agent for 15 minutes and raise the temperature to 90°C for 5 hours, then pour into the granulator and slowly add the slow-release powder....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com