Sulphoaluminate cement composite reinforcing agent

A technology of sulphoaluminate cement and composite reinforcement, which is applied in the field of sulphoaluminate cement composite reinforcing agent, can solve the problem that there is no research report on sulphoaluminate cement reinforcing agent, the profit cannot be maximized, and the amount of mixed materials is limited. Limitation and other issues, to achieve the effect of improving plasticity, increasing compressive strength, and delaying cement hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of sulphoaluminate cement composite reinforcing agent that one embodiment of the present invention proposes, by weight, it comprises:

[0027] Diethylene glycol: 0.01 parts;

[0028] Calcium hydroxide: 0.1 parts;

[0029] Sodium gluconate: 0.1 parts.

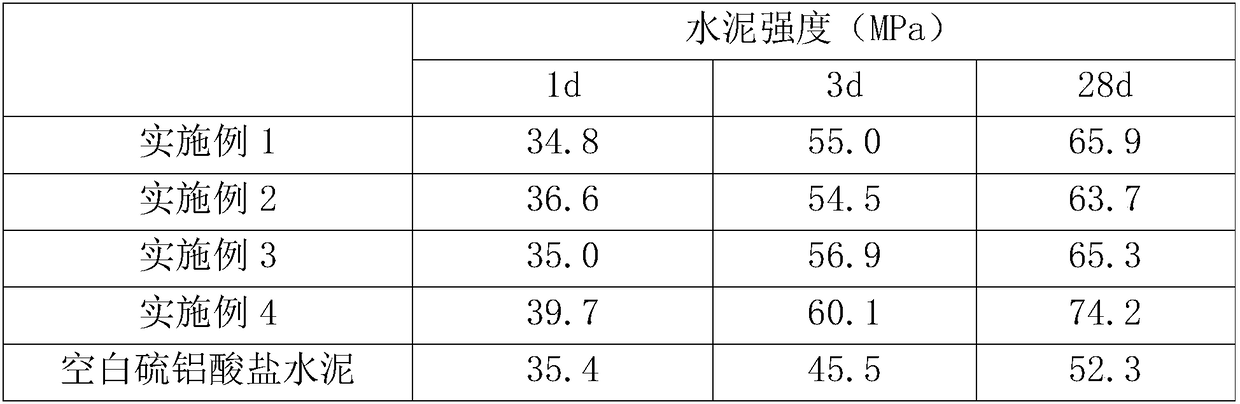

[0030] The sulphoaluminate cement reinforcing agent of Example 1 was mixed with 100 parts of blank sulphate cement, and the cement strengthening effect was tested as shown in Table 1.

Embodiment 2

[0032] A kind of sulphoaluminate cement composite reinforcing agent that one embodiment of the present invention proposes, by weight, it comprises:

[0033] Diethylene glycol: 0.007 parts;

[0034] Calcium hydroxide: 0.1 parts;

[0035] Sodium gluconate: 0.1 parts.

[0036] The sulphoaluminate cement reinforcing agent of Example 2 was mixed with 100 parts of blank sulphate cement, and the cement strengthening effect was tested as shown in Table 1.

Embodiment 3

[0038] A kind of sulphoaluminate cement composite reinforcing agent that one embodiment of the present invention proposes, by weight, it comprises:

[0039] Diethylene glycol: 0.008 parts;

[0040] Calcium hydroxide: 0.15 parts;

[0041] Sodium gluconate: 0.3 parts.

[0042] The sulphoaluminate cement reinforcing agent of Example 3 was mixed with 100 parts of blank sulphate cement, and the cement strengthening effect was tested as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com