Device and method realizing synergic effects of waste heat utilization, desulfurization wastewater zero-emission and smoke plume removal

A technology of desulfurization wastewater and zero discharge, applied in chemical instruments and methods, separation methods, heating water/sewage treatment, etc., can solve the problems of easy blockage of pipelines, high operating costs, high operating costs, etc., and achieve high operating costs. Low, the effect of investment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

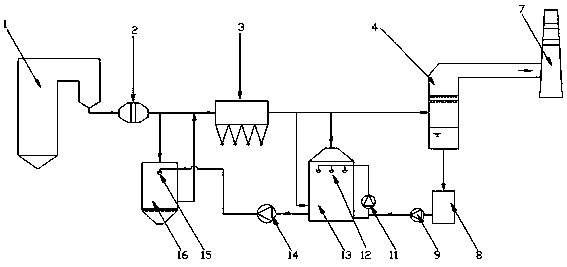

[0047] The specific implementation of the present invention based on a waste heat utilization collaborative desulfurization wastewater zero discharge and smoke plume removal method will be described in detail below with reference to the accompanying drawings.

[0048] like figure 1 As shown in the figure, it is a schematic diagram of the waste heat utilization cooperative desulfurization waste water zero discharge and smoke plume removal device provided in this embodiment. The device includes a boiler 1, an air preheater 2, a dust collector 3, a desulfurization tower 4 and a chimney connected by pipelines in sequence 7. The desulfurization wastewater outlet of the desulfurization tower 4 is connected to the wastewater sedimentation tank 8, and the wastewater outlet of the wastewater sedimentation tank 8 is connected to the wastewater concentration tower 13 through a pipeline, and the concentrated wastewater outlet of the wastewater concentration tower 13 is connected to the was...

Embodiment 2

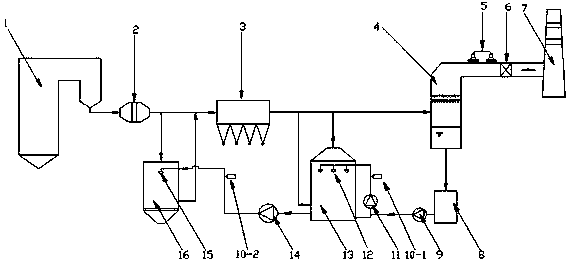

[0052] This embodiment is a further improvement on the basis of Embodiment 1, as figure 2 As shown, in the connecting pipe between the desulfurization tower 4 and the chimney 7, a sonic agglomeration device 5 and a demister 6 are arranged in sequence along the direction from the desulfurization tower 4 to the chimney 7, and the sound waves emitted by the sonic agglomeration device are used to stimulate the small liquid in the flue gas flow. The droplets undergo acoustic wave reunion to form a large liquid, which is then removed by the demister 6, thereby achieving a good plume reduction effect.

[0053] A circulation pump 11 is arranged on the pipeline between the wastewater sedimentation tank 8 and the wastewater concentration tower 13, and the circulation pump 11 is connected to the water supply pump 9 through the pipeline, and the circulation pump 11 transports the wastewater provided by the water supply pump 9 to the ultrasonic atomizing nozzle 12 for further concentration...

Embodiment 3

[0056] Utilize the device provided by the invention to carry out the method for zero discharge of desulfurization wastewater and smoke plume removal, comprising the following steps:

[0057] Step 1, the desulfurization wastewater generated after desulfurization of the flue gas in the desulfurization tower is first transported to the wastewater sedimentation tank, and the suspended matter sedimentation process is completed in the sedimentation tank;

[0058] Step 2: The waste water supernatant after preliminary precipitation enters the waste water concentration tower at night and is atomized through the ultrasonic atomizing nozzle. The atomized solid-liquid mixed droplets are mixed with the low-temperature flue gas after the dust collector to exchange heat and complete part of the waste water. evaporative concentration;

[0059] Step 3: The wastewater concentrate at the outlet of the wastewater concentration tower enters the wastewater flash tower and is atomized into small dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com