High-activity admixture slurry made of wet fly-ash and method for preparing same

A technology for wet discharge of fly ash and admixtures, which is applied in the field of high-activity admixture slurry and its preparation, can solve the problems of high energy consumption and impossibility of popularization, and achieve pollution reduction, significant social and economic benefits, and production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

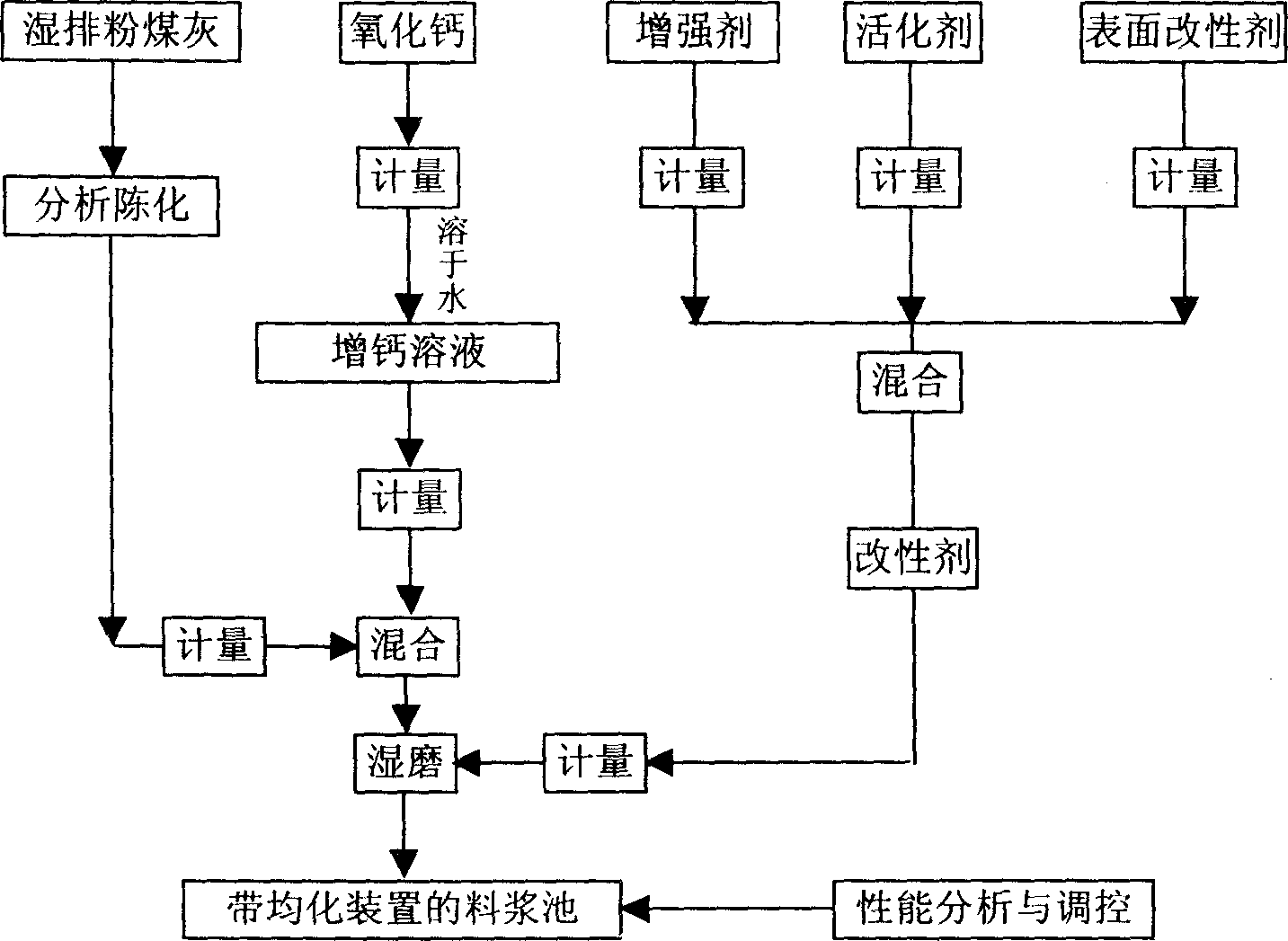

[0037] Embodiment 1: as figure 1 Shown, a kind of highly active wet discharge fly ash admixture slurry preparation method, it comprises the steps:

[0038] 1) Raw material selection: select wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age for later use; the moisture content of the wet-discharged fly ash is 25-35%, free calcium oxide (f -CaO) content ≤ 2.5%, sulfur trioxide (SO 3 ) content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-400m 2 / Kg;

[0039] 2) Select reinforcing agent, surface modifier and activator according to Table 1 and mix to form modifier, set aside;

[0040]3) Select the wet-discharged fly ash, calcium-increasing solution and modifier according to Table 1. The calcium-increasing solution contains the mass of water in the wet-discharged fly ash; mix and grind for 10-30 minutes to obtain the product.

[0041] See Table 1 for the slurry mix ratio of a high-activity wet-...

Embodiment 2

[0049] A kind of preparation method of high activity wet row fly ash admixture slurry, it comprises the steps:

[0050] 1) Raw material selection: select wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age for later use; the moisture content of the wet-discharged fly ash is 25-35%, free calcium oxide (f -CaO) content ≤ 2.5%, sulfur trioxide (SO 3 ) content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-400m 2 / Kg;

[0051] 2) Modifier preparation: according to the mass percentages of the reinforcing agent, surface modifier and activator in the modifier: reinforcing agent 20, surface modifying agent 35, and activator 45, select the reinforcing agent, surface modifying agent and activator Agents are mixed and set aside; the enhancer is Na 2 CO 3 , the surface modifier is a high-efficiency naphthalene-based water reducer; the activator is Na 2 SO 4 ;

[0052] 3) According to the mass percent...

Embodiment 3

[0054] A kind of preparation method of high activity wet row fly ash admixture slurry, it comprises the steps:

[0055] 1) Raw material selection: select wet-discharged fly ash, measure the actual moisture content and carbon content of the wet-discharged fly ash, and age for later use; the moisture content of the wet-discharged fly ash is 25-35%, free calcium oxide (f -CaO) content ≤ 2.5%, sulfur trioxide (SO 3 ) content ≤ 3%, carbon content ≤ 12%; Blaine specific surface area is 350-400m 2 / Kg;

[0056] 2) Modifier preparation: according to the mass percentages of the reinforcing agent, surface modifier and activator in the modifier: reinforcing agent 20, surface modifying agent 35, and activator 45, select the reinforcing agent, surface modifying agent and activator Agents are mixed and set aside; the enhancer is Na 2 CO 3 , the surface modifier is a high-efficiency naphthalene-based water reducer; the activator is sodium hydroxide;

[0057] 3) According to the mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com