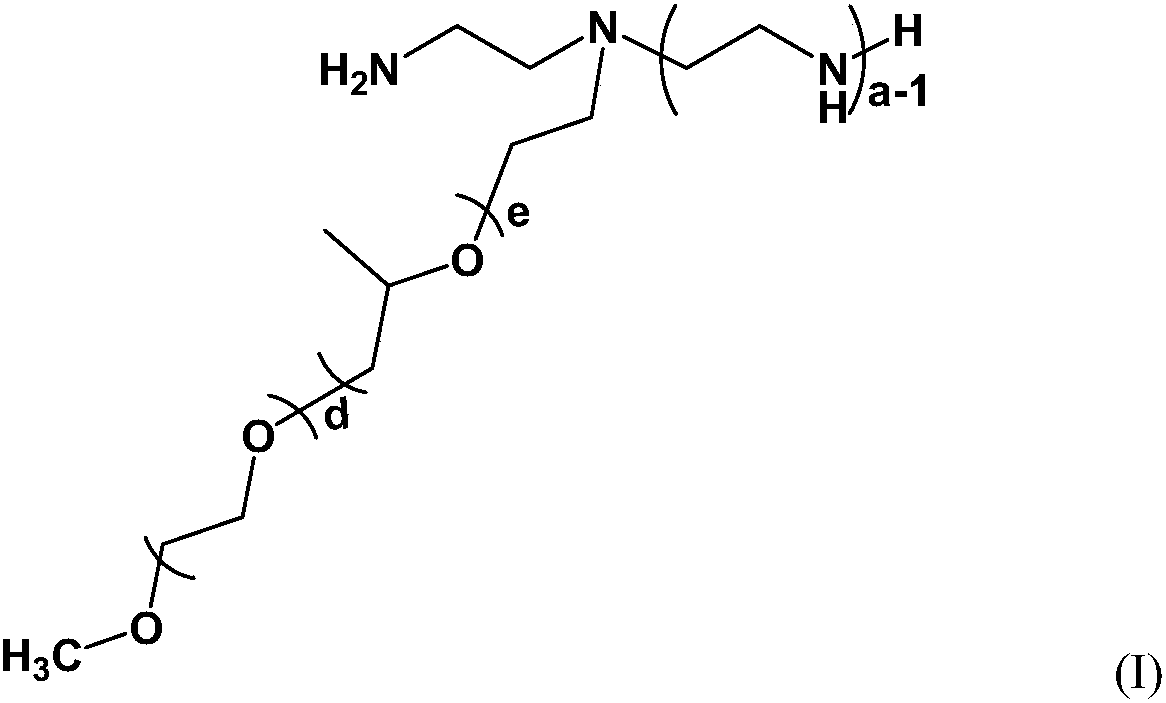

Polyether amine, preparation method of polycondensate containing phosphorous acid group and application of polycondensate as cement dispersing agent

A technology of aminated polyether and polycondensate, which is applied in the field of preparation of concrete admixtures, can solve problems such as uncontrollable side reactions of copolymerization reactions, easy chain transfer of phosphorus-containing groups, uncontrollable molecular structure and molecular weight of water reducers, etc. , to achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

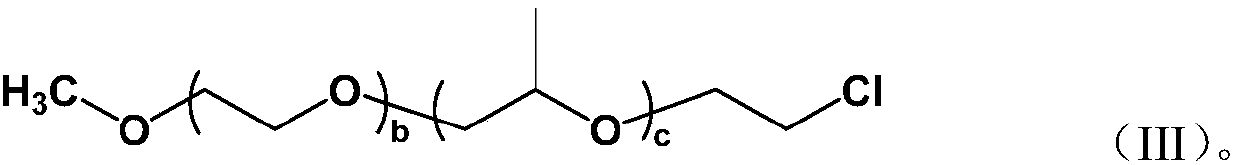

[0062] Preparation of Chlorinated Polyether M-1.

[0063] Weigh 1000 parts of methoxypolyether (M n =1000, b=18, c=3) into the reactor, under the condition of -0.08MPa~-0.1MPa, vacuumize for 1h to remove water and a little volatile components in the polyether. Cool down to 40~60℃, in N 2 Under protection conditions, add SOCl to the above reaction system 2 155 parts, the temperature of the reaction system is controlled not to exceed 60°C during the dropwise addition. After the dropwise addition is completed, connect a cooling reflux device, raise the temperature of the reaction system to 80-90°C, continue the heat preservation reaction for 3-5 hours, and then distill out the acidic volatile components in the reaction system under reduced pressure to obtain a light brown product, which is passed through Liquid phase test showed that the yield of chlorinated polyether M-1 was 98.7%. Similarly, the following chlorinated polyethers were prepared for the synthesis of aminated p...

Embodiment 2

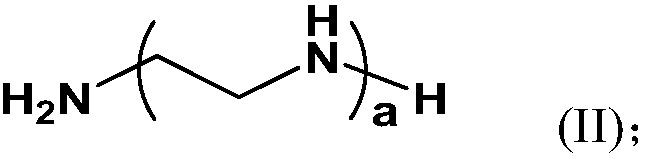

[0071] Preparation of Aminated Polyether N-1

[0072] Weigh 1952 parts of polyethyleneimine (a=45) as a primer, and heat up to 60-80°C. Weigh 1019 parts of M-1 and add 891 parts of water to dilute, then gradually add to the reaction system. After the addition was completed, the temperature was raised to 100° C., and the reaction was continued for 15 hours to obtain a wine-red liquid. The conversion rate of chlorinated polyether M-1 is close to 100% through liquid phase test.

[0073] Similarly, the following aminated polyether was prepared for the preparation of polycondensation monomers.

[0074]N-2: 877 parts of polyethyleneimine (a=20), 2221 parts of chlorinated polyether M-2, 1239 parts of solvent water, the reaction temperature is 120 °C, the reaction time is 10 h, the product is wine red liquid, and it is tested by liquid phase , the conversion rate of chlorinated polyether M-2 is close to 100%.

[0075] N-3: 275 parts of polyethylene polyamine (a=6), 3019 parts of c...

Embodiment 3

[0081] Weigh 94 parts of phenol as a primer, gradually add N-1 to the reaction system, stir evenly and then raise the temperature to 60-80°C. Weigh 81 parts of 37wt% formaldehyde, drop it completely within 2-4 hours, then raise the temperature to 85°C, and keep it warm for 6 hours.

[0082] After the reaction, turn on the circulating water at room temperature to cool, lower the temperature to 50-60°C, weigh 1952 parts of catalyst concentrated hydrochloric acid, gradually add to the above reaction system, then add 3772 parts of phosphorous acid, and finally add 3811 parts of 37wt% formaldehyde. The reaction temperature was raised to 100° C., and the reaction was continued for 10 h to obtain a reddish-brown liquid, which was tested by GPC with a molecular weight of 44497 and a PDI of 3.52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com