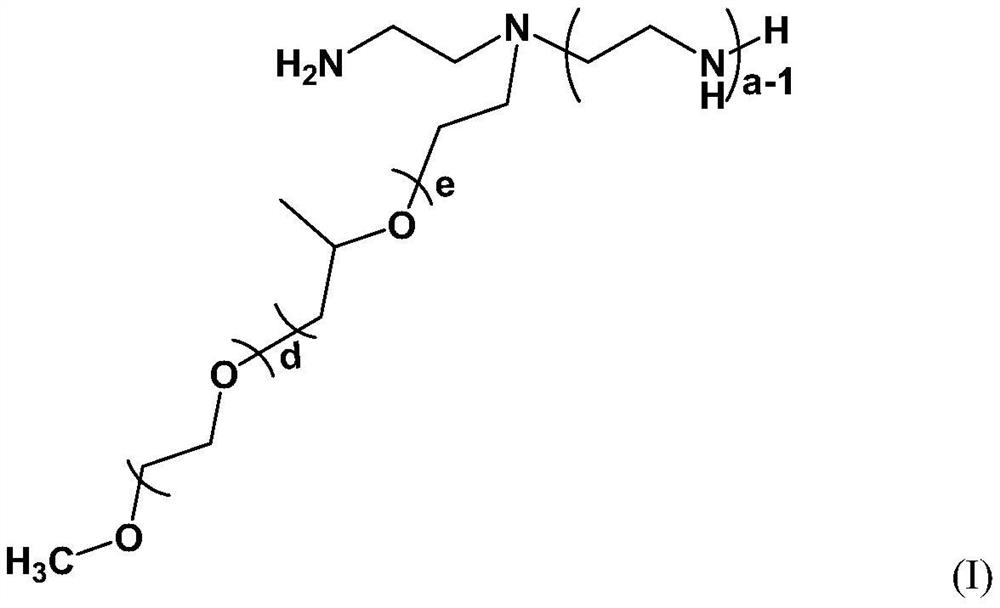

A kind of aminated polyether, the preparation method of its polycondensate containing phosphorous acid group and its application as cement dispersant

A phosphorous acid group, aminated polyether technology, used in the application of cement dispersant, aminated polyether field, can solve the problem that phosphorus-containing groups are prone to chain transfer, the molecular structure and molecular weight of water reducers cannot be controlled, and Problems such as uncontrollable side reactions of polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

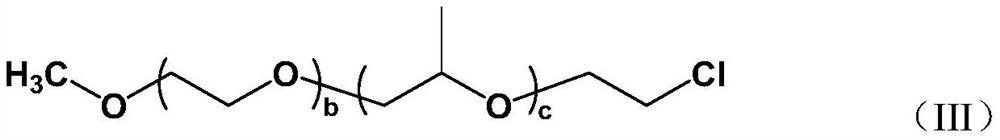

[0063] Preparation of Chlorinated Polyether M-1.

[0064] Weigh 1000 parts of methoxypolyether (M n =1000, b=18, c=3) into the reactor, under the condition of -0.08MPa~-0.1MPa, vacuumize for 1h to remove water and a little volatile components in the polyether. Cool down to 40~60℃, in N 2 Under protection conditions, add SOCl to the above reaction system 2 155 parts, the temperature of the reaction system is controlled not to exceed 60°C during the dropwise addition. After the dropwise addition is completed, connect the cooling reflux device, raise the temperature of the reaction system to 80-90°C, continue the heat preservation reaction for 3-5 hours, and then distill out the acidic volatile components in the reaction system under reduced pressure to obtain a light brown product, which is passed through Liquid phase test showed that the yield of chlorinated polyether M-1 was 98.7%. Similarly, the following chlorinated polyethers were prepared for the synthesis of aminated...

Embodiment 2

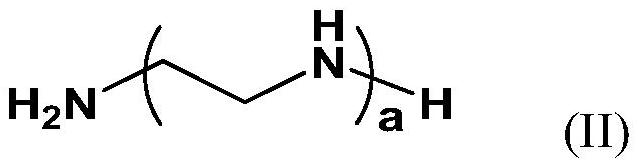

[0072] Preparation of Aminated Polyether N-1

[0073] Weigh 1952 parts of polyethyleneimine (a=45) as a primer, and heat up to 60-80°C. Weigh 1019 parts of M-1 and add 891 parts of water to dilute, then gradually add to the reaction system. After the addition was completed, the temperature was raised to 100° C., and the reaction was continued for 15 hours to obtain a wine-red liquid. The conversion rate of chlorinated polyether M-1 is close to 100% through liquid phase test.

[0074] Similarly, the following aminated polyether was prepared for the preparation of polycondensation monomers.

[0075]N-2: 877 parts of polyethyleneimine (a=20), 2221 parts of chlorinated polyether M-2, 1239 parts of solvent water, the reaction temperature is 120 °C, the reaction time is 10 h, the product is wine red liquid, and it is tested by liquid phase , the conversion rate of chlorinated polyether M-2 is close to 100%.

[0076] N-3: 275 parts of polyethylene polyamine (a=6), 3019 parts of c...

Embodiment 3

[0082] Weigh 94 parts of phenol as a primer, gradually add N-1 to the reaction system, stir evenly and then raise the temperature to 60-80°C. Weigh 81 parts of 37wt% formaldehyde, drop it completely within 2-4 hours, then raise the temperature to 85°C, and keep it warm for 6 hours.

[0083] After the reaction, turn on the circulating water at room temperature to cool, lower the temperature to 50-60°C, weigh 1952 parts of catalyst concentrated hydrochloric acid, gradually add to the above reaction system, then add 3772 parts of phosphorous acid, and finally add 3811 parts of 37wt% formaldehyde. The reaction temperature was raised to 100° C., and the reaction was continued for 10 h to obtain a reddish-brown liquid, which was tested by GPC with a molecular weight of 44497 and a PDI of 3.52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com