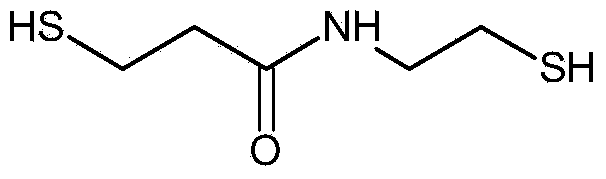

Catalyst for synthesizing amide and method for synthesizing N-mercaptoethyl-3-sulfydryl-propanamide

A technology for synthesizing amides and catalysts, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of N-mercaptoethyl-3-mercapto-propionamide The synthetic method has no problems such as reports, and achieves the effects of reducing the generation of by-products, controlling molecular weight, and having high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1, prepare SO 4 2- / TiO 2 -ZnO Mixed Crystal Solid Acid Support Coordination Catalyst

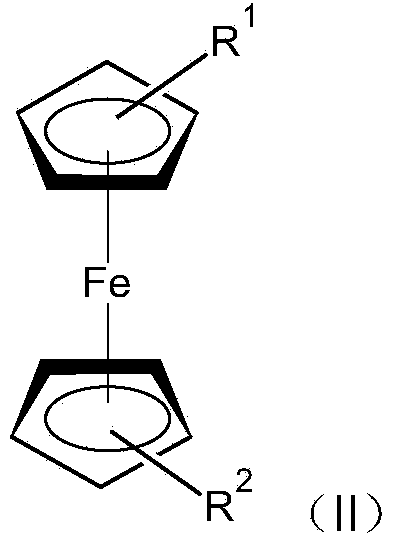

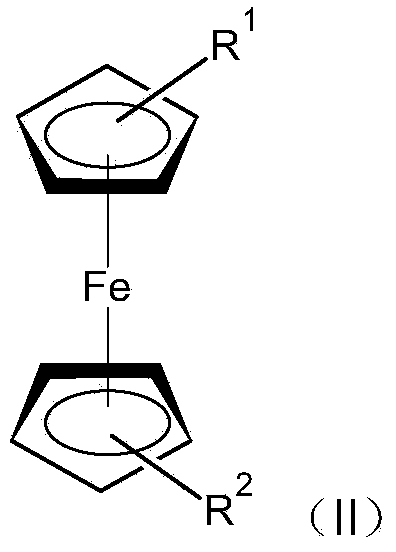

[0062] (a) Chemical composition: 100 parts of deionized water, TiCl 4 20 parts, 20 parts of zinc nitrate, 50 parts of 25wt% ammonia water, 5 parts of sodium tetraborate, 3 parts of basic nickel carbonate, 1 part of triphenyl cobalt phosphide, and 3 parts of ferrocene.

[0063] (b) TiCl 4 1. Add zinc nitrate to deionized water. In a high-speed disperser (1500 rpm), the temperature rises to 95°C. Add ammonia water to the mixture, then add sodium tetraborate and basic nickel carbonate, and continue to keep warm for 3 hours. , stop stirring, lower to normal temperature, let stand, filter to collect the precipitate, wash with deionized water, and vacuum dry at 120°C.

[0064] (c) Calcining the product of (b) process at 850° C. for 3 hours.

[0065] (d) The product of (c) process is immersed in 10wt% sulfuric acid solution for 2 hours, and then put into 550 ° C ...

Embodiment 2

[0067] Embodiment 2, prepare SO 4 2- / TiO 2 -ZnO Mixed Crystal Solid Acid Support Coordination Catalyst

[0068] (a) Chemical composition: 100 parts of deionized water, TiCl 4 28 parts, 15 parts of zinc nitrate, 60 parts of 25wt% ammonia water, 7 parts of sodium tetraborate, 4 parts of basic nickel carbonate, 3 parts of triphenyl cobalt phosphide, and 2 parts of ferrocene.

[0069] (b) TiCl 4 1. Add zinc nitrate to deionized water. In a high-speed disperser (1500 rpm), the temperature rises to 90°C. Add ammonia water to the mixture, then add sodium tetraborate and basic nickel carbonate, and continue to keep warm for 2 hours. , stop stirring, lower to normal temperature, let stand, filter to collect the precipitate, wash with deionized water, and vacuum dry at 120°C.

[0070] (c) Calcining the product of (b) process at 900° C. for 3 hours.

[0071] (d) The product of the (c) process is immersed in a 10wt% sulfuric acid solution for 2 hours, and then baked at ...

Embodiment 3

[0073] Embodiment 3, prepare SO 4 2- / TiO 2 -ZnO Mixed Crystal Solid Acid Support Coordination Catalyst

[0074] (a) Chemical composition: 100 parts of deionized water, TiCl 4 24 parts, 19 parts of zinc nitrate, 80 parts of 25wt% ammonia water, 7 parts of sodium tetraborate, 3 parts of basic nickel carbonate, 2 parts of triphenyl cobalt phosphide, and 2 parts of ferrocene.

[0075] (b) TiCl 4 1. Add zinc nitrate to deionized water. In a high-speed disperser (1500 rpm), the temperature rises to 90°C. Add ammonia water to the mixture, then add sodium tetraborate and basic nickel carbonate, and continue to keep warm for 2 hours. , stop stirring, lower to normal temperature, let stand, filter to collect the precipitate, wash with deionized water, and vacuum dry at 120°C.

[0076] (c) Calcining the product of (b) process at 970° C. for 3 hours.

[0077] (d) The product of the (c) process is immersed in 10wt% sulfuric acid solution for 2 hours, and then baked at 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com