UPS battery charger and UPS

A battery charger and electrolytic capacitor technology, applied in the field of UPS, can solve the problems of the influence of the input current index of the whole machine, the increase of the ripple current, and the increase of the cost of the whole machine, so as to improve the quality of the output current, stabilize the input voltage, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

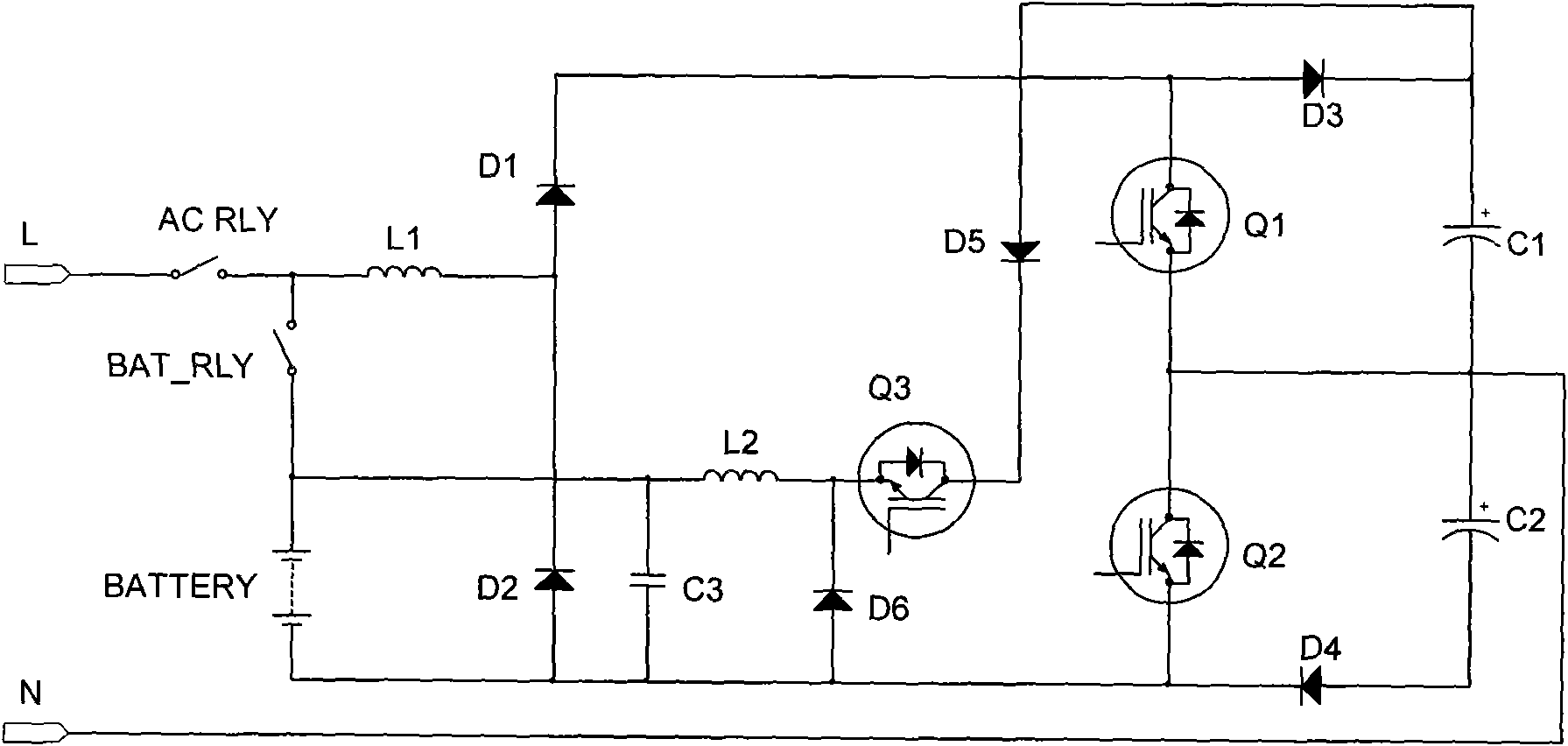

[0024] Please refer to figure 1 , the UPS battery charger includes a rectifier circuit, a PFC chopper circuit and a BUCK (step-down) converter. The output terminal of the wave circuit is coupled to the AC input zero line N through the positive and negative busbars, the input terminal of the BUCK converter is coupled to the positive busbar, and the output terminal of the BUCK converter is coupled to the positive and negative poles of the rechargeable battery BATTERY.

[0025] The rectifier circuit includes a first inductor L1, a first diode D1, and a second diode D2, and the PFC chopper circuit includes a third diode D3, a fourth diode D4, a first electrolytic capacitor C1, and a second electrolytic capacitor Capacitor C2 and the first switching tube Q1 and the second switching tube Q2 with anti-parallel diodes, one end of the first inductor L1 is coupled to the AC input live line L through the mains input switch AC_RLY, the other end of the first inductor L1 is connected to th...

Embodiment 2

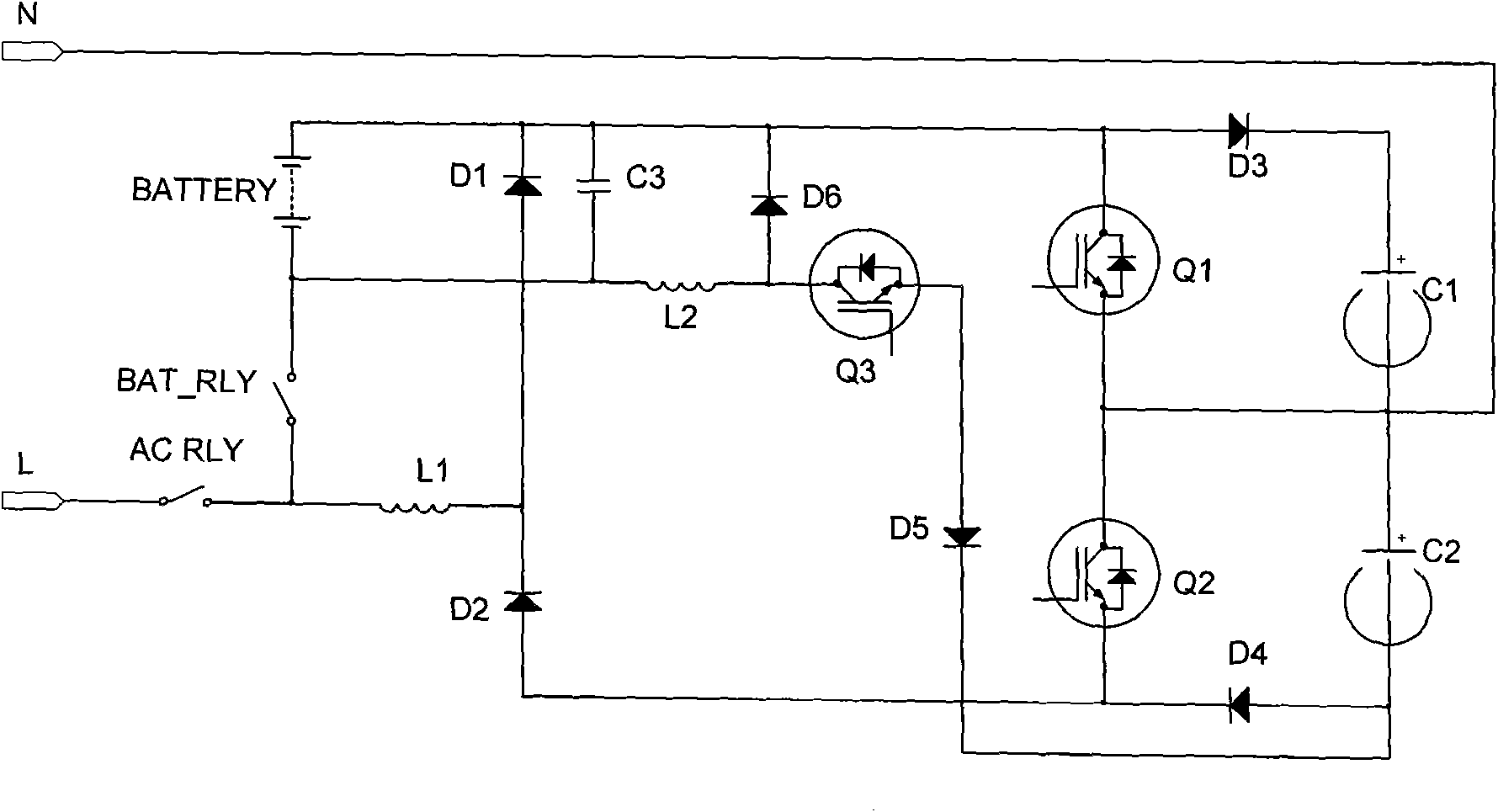

[0042] In Embodiment 1, the input terminal of the BUCK converter is coupled to the positive bus, the negative pole of the rechargeable battery is connected to the anode of the second diode D2, and the input terminal of the charger is connected to the cathode of the first diode D1. According to the symmetry of the circuit, the modification of the first embodiment can be obtained, please refer to figure 2 , this embodiment uses a negative Buck converter, and the difference from Embodiment 1 is that the cathode of the fifth diode D5 is the input terminal of the Buck converter, which is connected to the negative pole of the second electrolytic capacitor C2 and the fourth diode D4. Anode, so that the BUCK converter takes power from the negative bus; the anode of the fifth diode D5 is connected to the source of the third switching tube Q3, and the drain of the third switching tube Q3 is connected to one end of the second inductor L2 and the sixth diode The anode of the tube D6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com