Fiberglass flow-guiding cloth and vacuum adsorption

A glass fiber and diversion cloth technology, applied in textiles, papermaking, woven fabrics, etc., can solve the problems of high price and prolong process time, and achieve the effect of reducing the use of expensive consumables, shortening the process, and increasing strength and stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

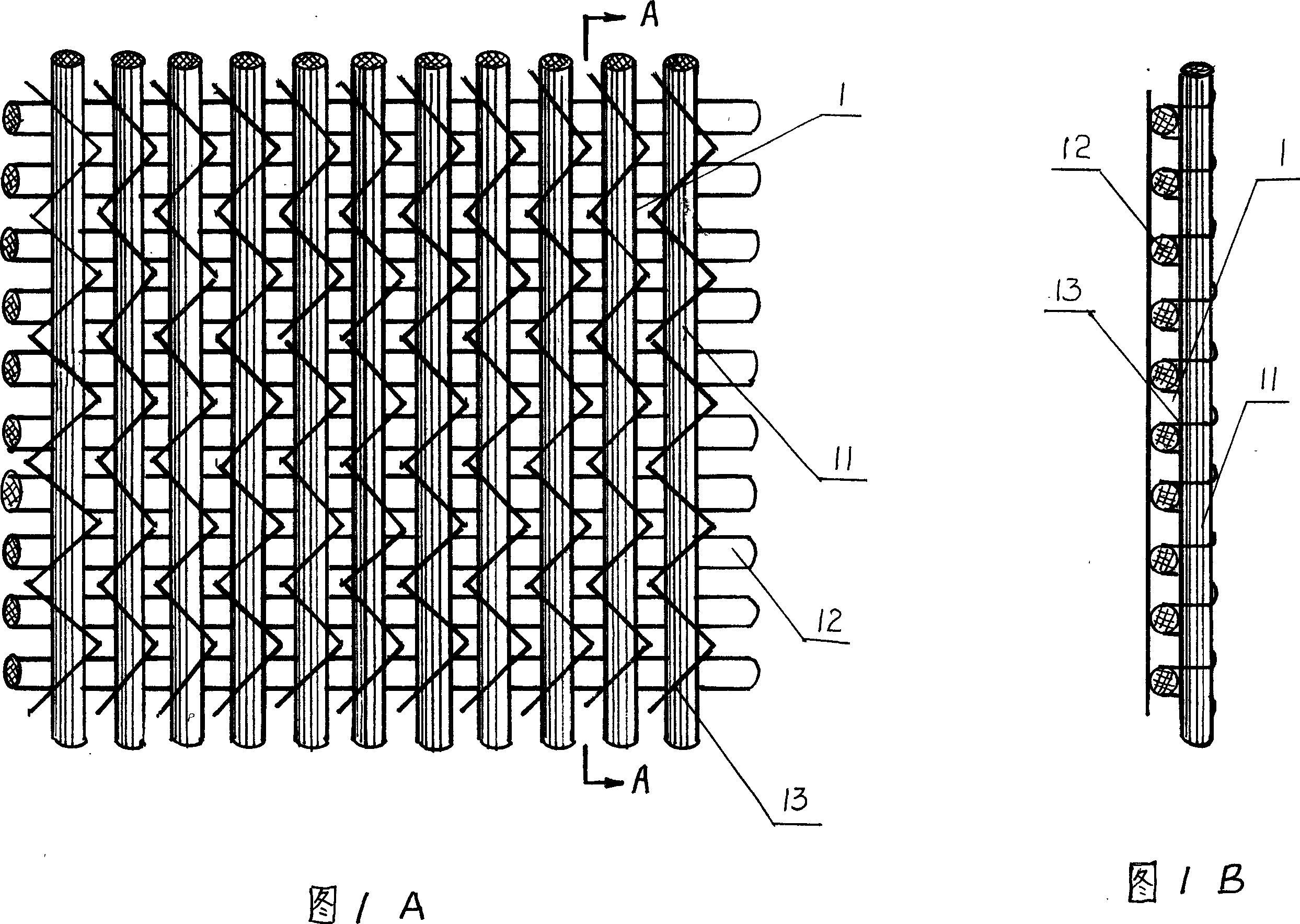

[0024] As shown in Figure 1A and Figure 1B, a glass fiber guide cloth 1 is mainly composed of radial glass fiber yarns 11, weft glass fiber yarns 12 and stitched organic fiber yarns 13, wherein: radial glass fiber yarns Yarns 11 and weft glass fiber yarns 12 are laid up and down each other, and they are arranged in a straight line and parallel to each other, and then stitched with organic fiber yarns 13 perpendicular to the plane of the cloth.

[0025] The glass fiber guide cloth of the present invention has the following main specifications:

[0026] Specification code

Characteristic description

FC-1A

Double-layer, weft-directed flow, moderate flow speed

FC-1B

Double-layer, weft-directed flow, fast flow

FC-2A

Double layer, meridian diversion, moderate diversion speed

FC-2B

Double layer, meridional flow guide, fast flow guide

FC-3A

Three-layer, meridional diversion, moderate diversion speed

FC-3B

Thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com