Water-based single-component baking type polysiloxane coating and preparation method thereof

A polysiloxane, one-component technology, applied in coatings and other directions, can solve the problems of complicated construction of baking polysiloxane coatings, increase in coating viscosity, etc., and achieve improved storage stability and freeze-thaw stability, Improve dispersibility and compatibility, reduce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058] A polysiloxane prepolymer, each component and its weight are shown in Table 1, and prepared by the following preparation steps:

[0059] The nano-silica sol was added dropwise to the alkoxysilane at 50 °C, and after stirring and mixing for 2 hours at 600 r / min, the silane end-capping agent was added, and the polysilane was stirred and mixed at 200 r / min for 0.3 hours to obtain a polysilane pre-polymer. aggregates.

[0060] Nano silica sol, the average particle size is 10nm, the pH value is 8-11, and the silica content is 30%.

[0061] After testing, the molecular weight of the polysiloxane prepolymer was 150,000.

preparation example 2

[0063] A polysiloxane prepolymer, each component and its weight are shown in Table 1, and prepared by the following preparation steps:

[0064] The silane end-capping agent was added to the alkoxysilane, and after stirring and mixing for 0.3 h at 50° C. and 200 r / min, the nano-silica sol was added dropwise, and the polysilane prepolymer was obtained by stirring and mixing for 2 h.

[0065] After testing, the molecular weight of the polysiloxane prepolymer was 100,000.

preparation example 3-5

[0067] A polysiloxane prepolymer differs from Preparation Example 2 in that the components and their weights are shown in Table 1.

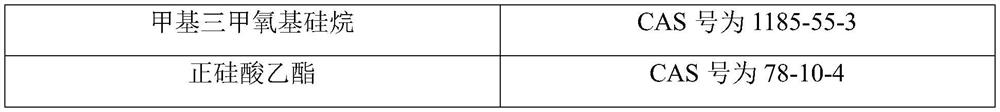

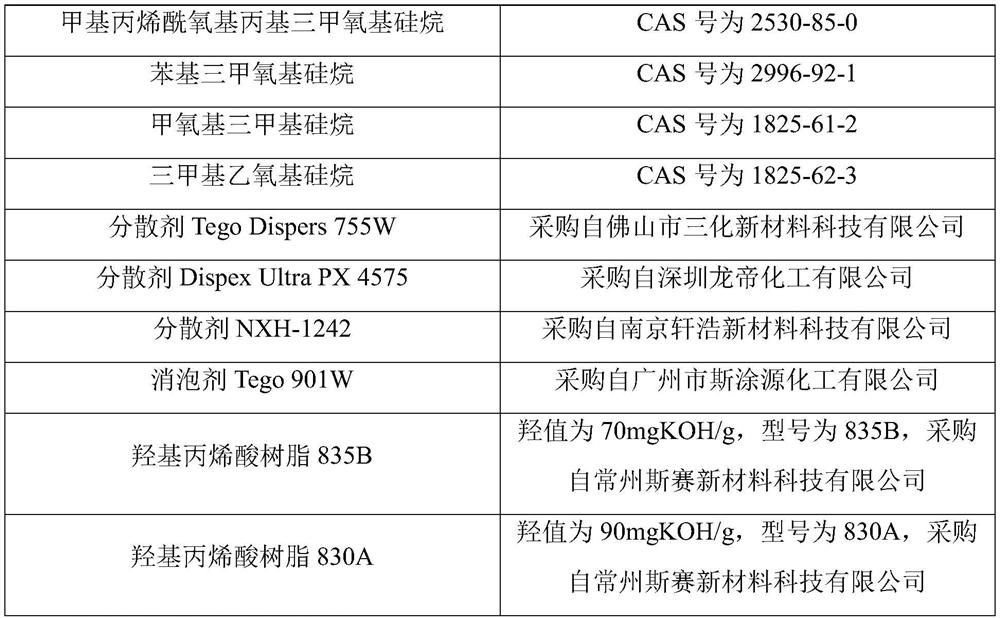

[0068] Components and their weights (kg) in Table 1 Preparation Examples 1-5

[0069]

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com