Patents

Literature

36results about How to "Control molar ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

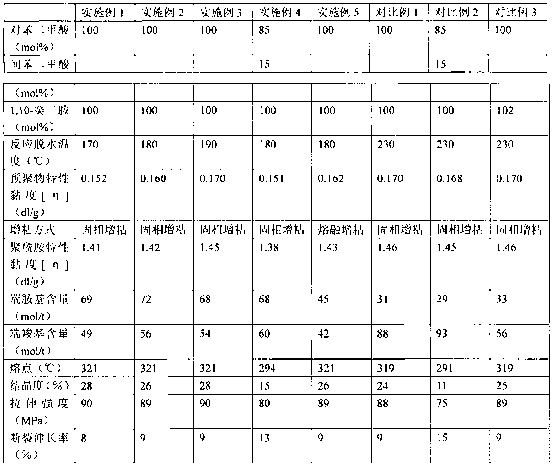

Process for preparing semi-aromatic polyamides

The invention discloses a method for preparing semi-aromatic polyamide. The method adopts low temperature of 170 DEG C to 190 DEG C for dehydration firstly, and then adopts a method for temperature-raising and prepolymerization to prepare the semi-aromatic polyamide, thus avoiding the loss of diamine and being capable of accurately controlling the molar ratio of the dicarboxylic acids and the diamine, obtaining the polyamide with high intrinsic viscosity and improving the quality of semi-aromatic polyamide. By the prepolymerization reaction, the prepolymer which is measured in 96 percent of sulphuric acid with the temperature of 25 DEG C and has the intrinsic viscosity Eta of 0.06 to 0.3dl / g can be obtained. After viscosifying reaction, the intrinsic viscosity Eta of the semi-aromatic polyamide is 0.8 to 2.5 dl / g and the melting point of the semi-aromatic polyamide is 270 to 330 DEG C; the content of terminal carboxyl group is 15 to 80 mol / t; and the content of amino-terminated group is 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

Semi-aromatic polyamide and preparation method thereof

The invention discloses a semi-aromatic polyamide and a preparation method thereof. The method of the invention uses the aromatic dicarboxylic acid and aliphatic diamine containing 4 to 14 carbon atoms as the raw materials in order to prepare the semi-aromatic polyamide and acquire a new structure of the semi-aromatic polyamide. The semi-aromatic polyamide is prepared by combining high purity semi-aromatic polyamide salt so the polyamine loss is avoided and the mole ratio of the dicarboxylic acid and the diamine can be accurately controlled so as to acquire the high viscosity semi-aromatic polyamide. The monomer is purified in the salifying process, so the melting point, the crystallinity and the mechanical property of the semi-aromatic polyamide are promoted. The pre-polymerized material which has a viscosity eta ranged from 0.06 to 0.3 dl / g tested in 96% sulfuric acid at 25 DEG C by performing the pre-polymerization reaction is acquired. After the tackifying reaction is performed, the viscosity eta of the semi-aromatic aromatic polyamide is ranged from 0.8 to 2.5 dl / g, the melting point of the semi-aromatic aromatic polyamide is ranged from 270 to 330 DEG C, the content of the end carboxyl is ranged from 15 to 80 mol / t and the content of the end amino is ranged from 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

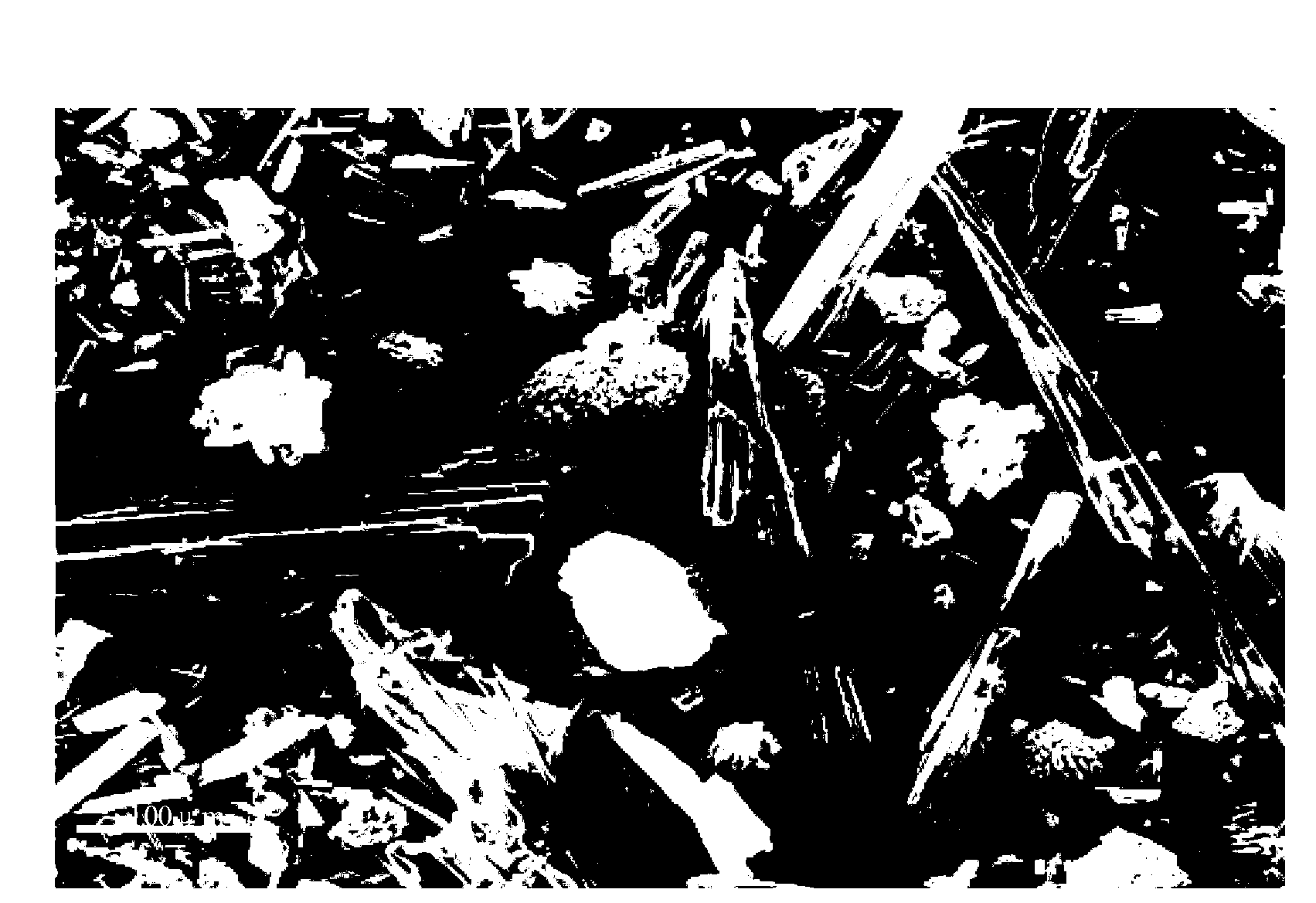

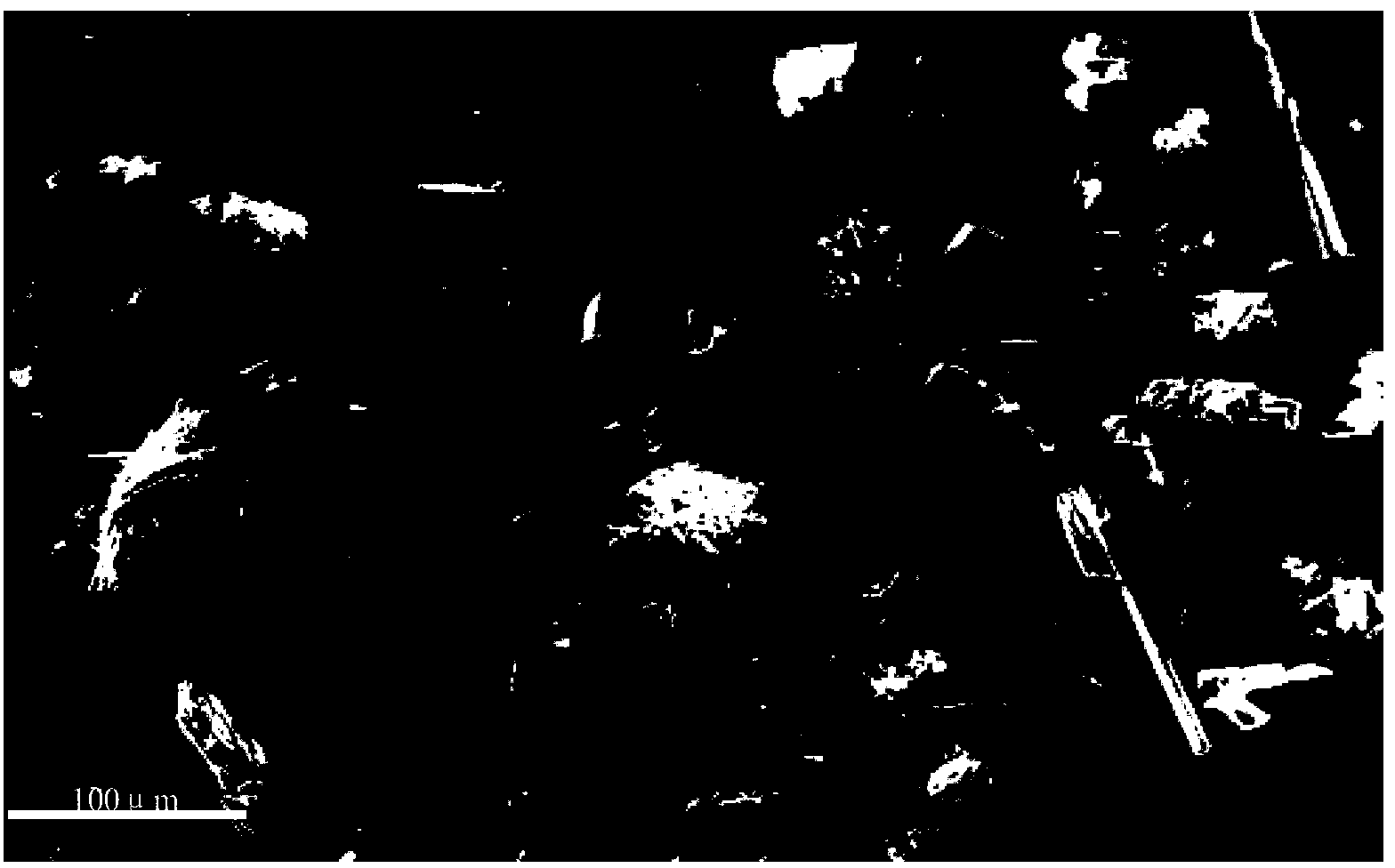

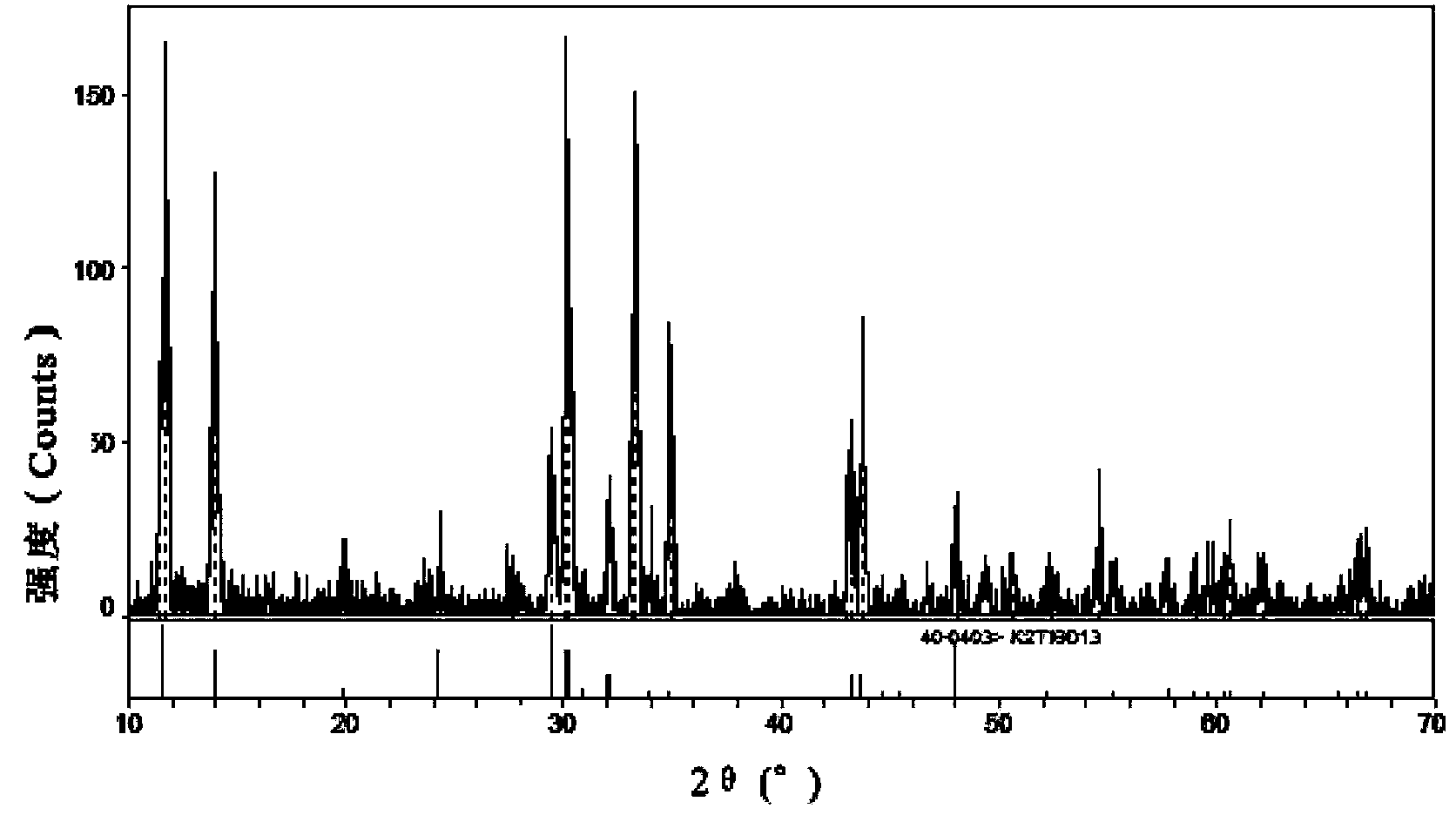

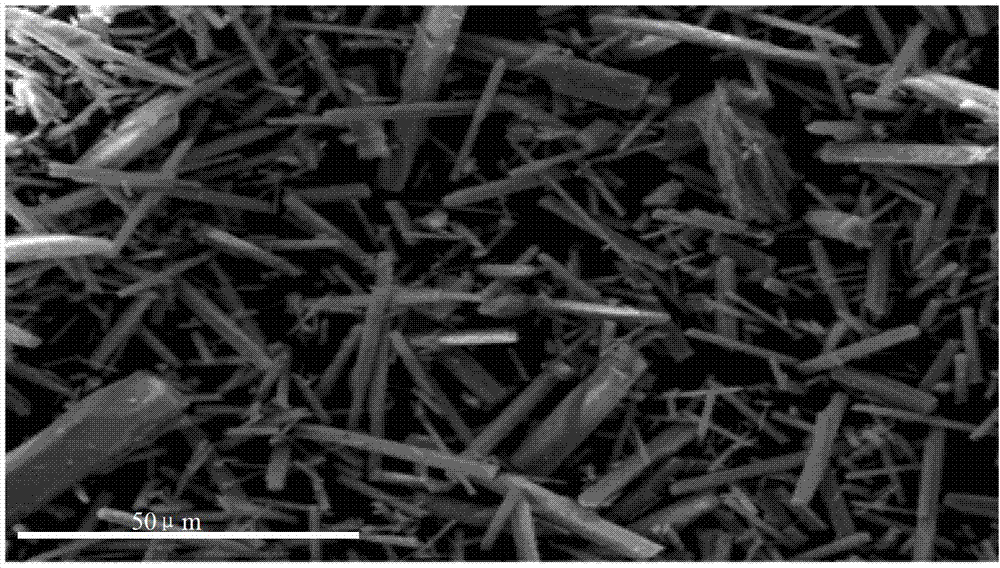

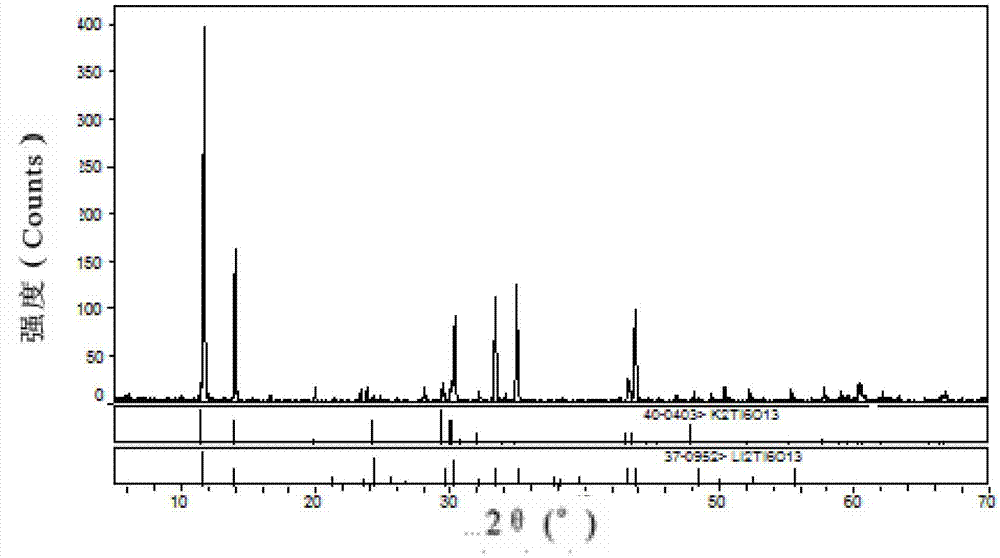

Preparation method of columnar hexagonal potassium titanate

InactiveCN102849790AControl molar ratioControlling the particle size of raw materials is beneficial to the molar ratioTitanium compoundsChemical industryDrawing ratio

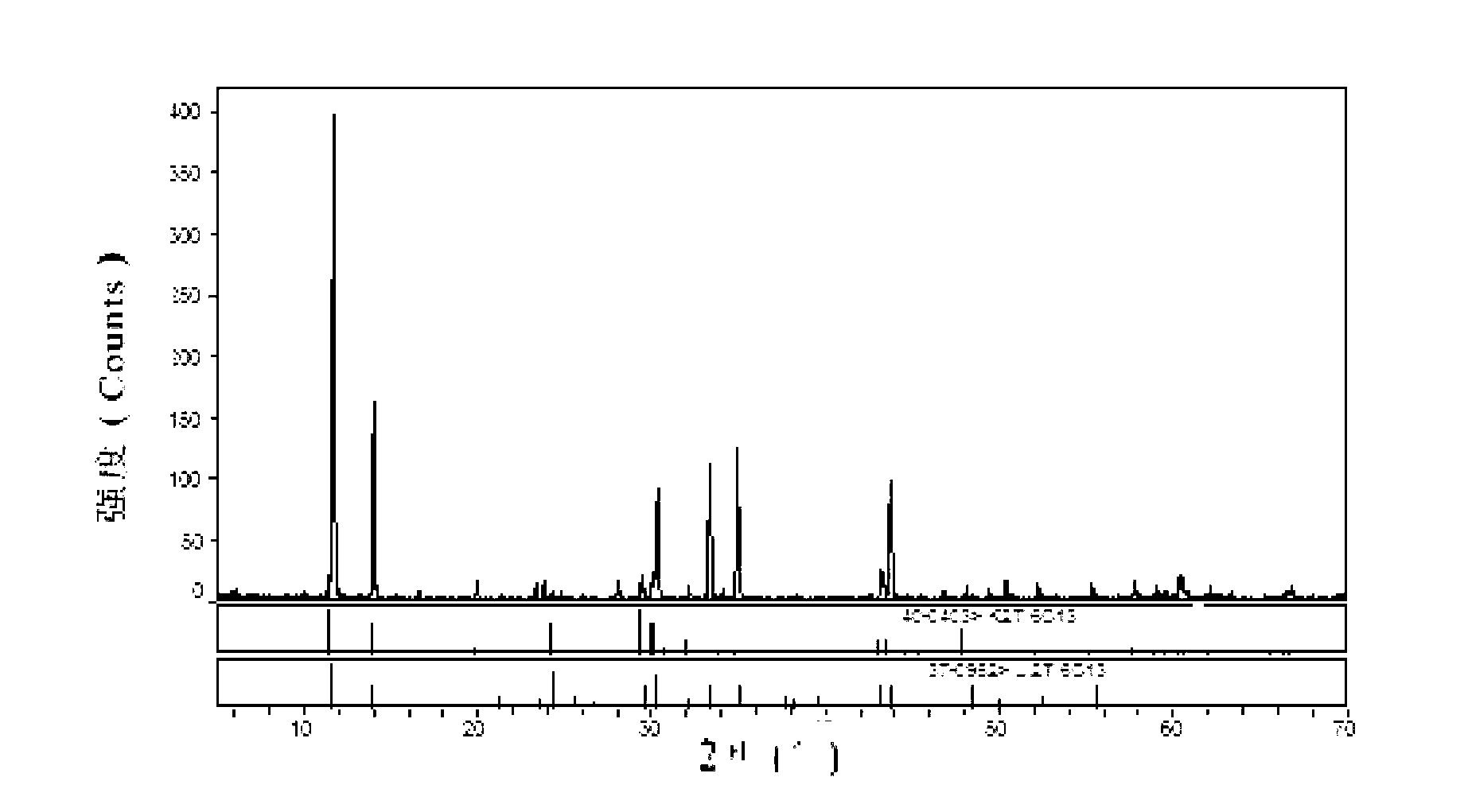

The invention discloses a preparation method of columnar hexagonal potassium titanate, which belongs to the field of the chemical industry. The method comprises the steps of: a, uniformly mixing a -100 mesh titaniferous containing material and a potassium containing material according to a molar ratio of TiO2:K2O=4-7; b, placing the material mixed uniformly in the step a in an environment at 1100-1300 DEG C for sintering for 1-4 hours for adequate reaction of the material; and c, quickly cooling the sintered material in the step b, then adequately dissociating the cooled material by water at a constant temperature of 60-80 DEG C, and finally filtering and drying to obtain a columnar hexagonal potassium titanate product. The method provided by the invention is simple in process flow, easy to operate, low in cost and high in yield, and the prepared columnar hexagonal potassium titanate is large in draw ratio and high in purity, and is suitable for industrial production.

Owner:PANZHIHUA UNIV

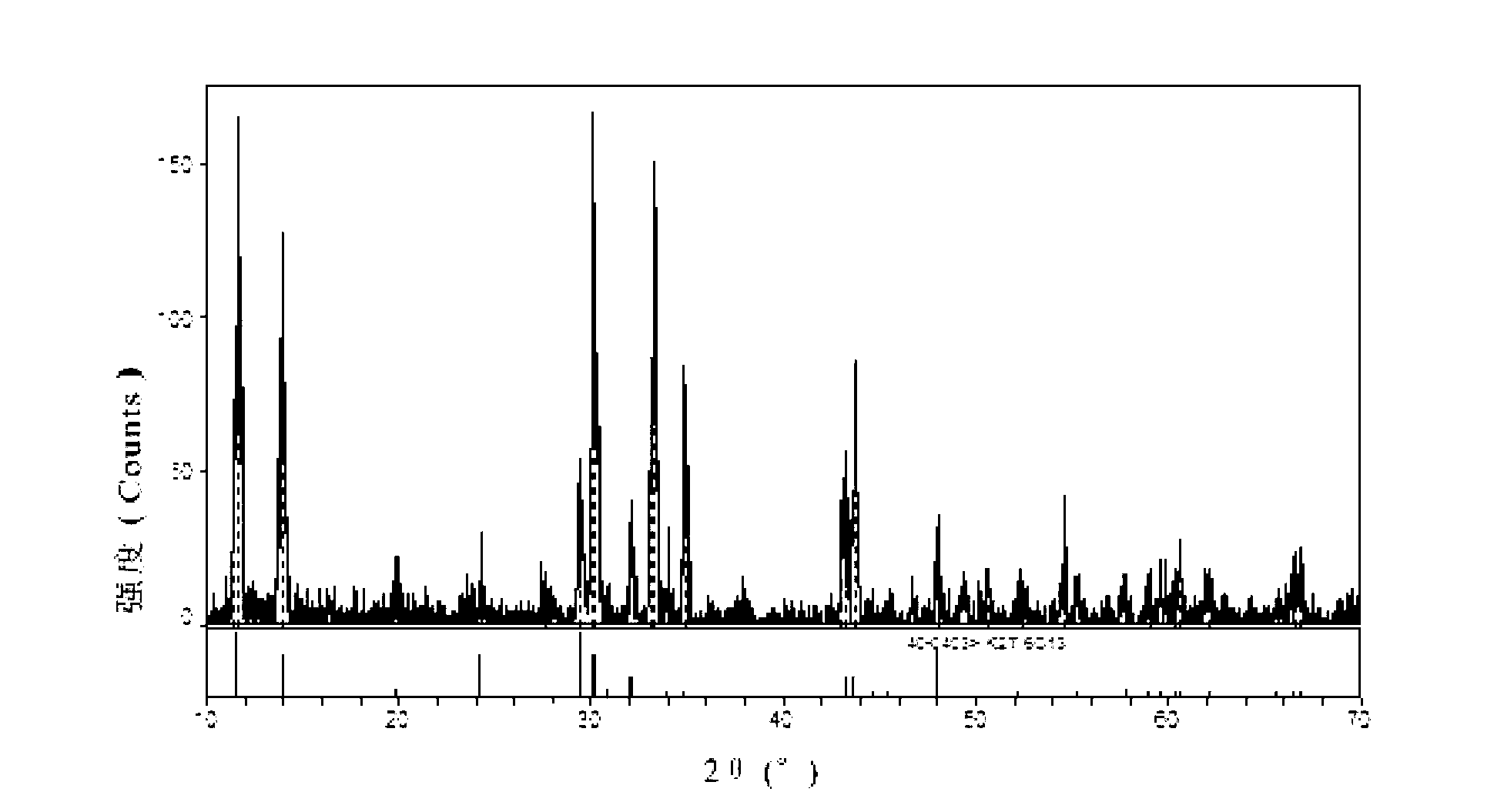

Method for preparing fine-grain low silica alumina ratio X zeolite

ActiveCN101254928ASimplify operation stepsSynthesis cost reductionFaujasite aluminosilicate zeoliteChemistryWater soluble

A preparation method of small-grain low-silica-content X zeolite includes mixing silicon-containing compound, sodium hydroxide, water and sulfuric acid solution or water soluble sulfate, stirring and adding aluminum-containing compound to obtain gel, adding the directing agent to the gel to obtain the mixture with the molar composition of (2.5-5.0)Na2O:Al2O3:(2.4-3.0) SiO2:(0.5-2.0)SO4<2->:(80-200)H2O, standing and crystallizing at 80-120 DEG C for 0.5-3.0 hours, water washing, filtering and drying. The obtained X zeolite has a crystal grain of 0.2-1.2 Mum, the molar ratio of silica / alumina is 2.07-2.3, and the crystallinity is more than 95%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing potassium hexatitanate whisker

InactiveCN102839424AControl molar ratioControlling the particle size of raw materials is beneficial to the molar ratioPolycrystalline material growthFrom solid stateChemical industryPotassium

The invention discloses a method for preparing a potassium hexatitanate whisker, belonging to the field of chemical industry. The method comprises the following steps of: a, uniformly mixing 100-mesh titanium-containing raw material and potassium-containing raw material according to mole rate of TiO2 to K2O being 3-6; b, placing the materials in an environment at temperature of 1100-1300 DEG C and sintering for 1-5 hours to make the materials fully reacted; and c, rapidly cooling the sintered materials, fully dissociating in an environment at constant temperature of 60-80 DEG C by using water, filtering, drying, and thus obtaining the potassium hexatitanate whisker. The process flow is simple, production period is short, yield is high, meanwhile, a production process of a precursor or a post-period recrystallization conversion process in the prior art is reduced, energy consumption is saved, and production cost is reduced. The cooled materials are fully dissociated in the environment at constant temperature of 60-80 DEG C by using the water, so that the potassium hexatitanate whisker has good purity and is suitable for industrial production.

Owner:PANZHIHUA UNIV

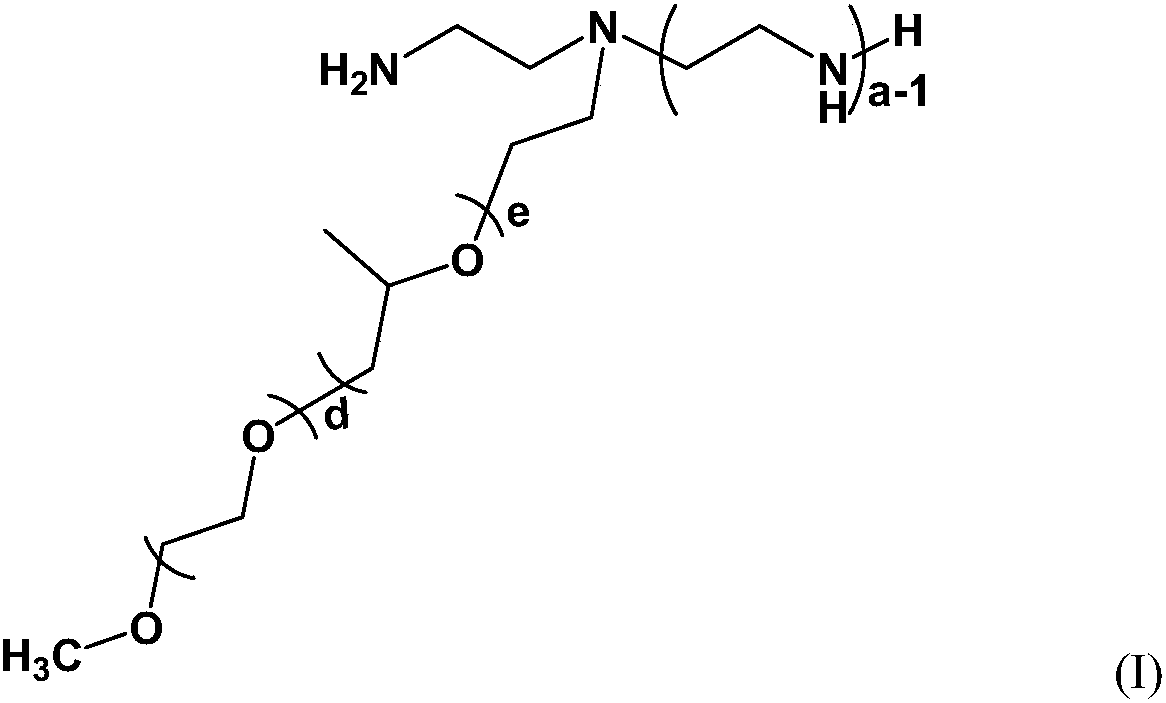

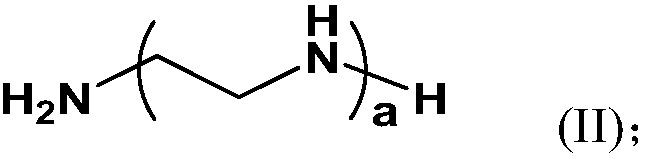

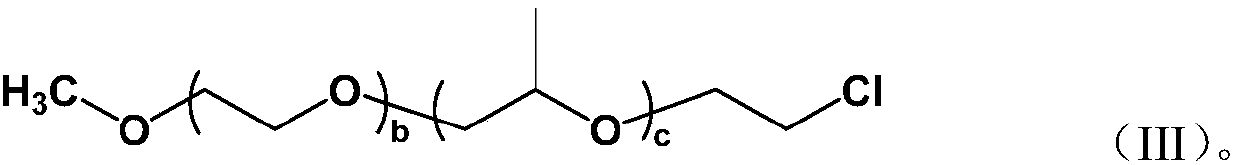

Polyether amine, preparation method of polycondensate containing phosphorous acid group and application of polycondensate as cement dispersing agent

ActiveCN107602870ASolve the chain transfer problemMolecular weight controlPhosphorous acidEndcapping

The invention discloses polyether amine, a preparation method of a polycondensate containing a phosphorous acid group and application of the polycondensate as a cement dispersing agent. The polyetheramine has a polyether chain segment with steric hindrance property and hydrophilic-hydrophobic property, one end of the polyether chain segment is methoxyl-terminated while the other end of the polyether chain segment is amine monomer-terminated; the polyether chain segment is connected to a primary amino group N-H or a secondary amino group N-H of an amine monomer so as to present the characteristic of random grafting. Polycondensation reaction on a polycondensation monomer formed by grafting polyether amine on a benzene ring of a phenolic monomer and an aldehyde monomer as well as a phosphorous acid is carried out, so that a phosphite polycondensate is obtained; moreover, the polycondensate can be used as the cement dispersing agent, so that the polycondensate has a better dispersion effect.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

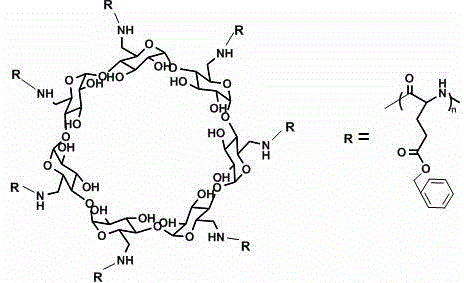

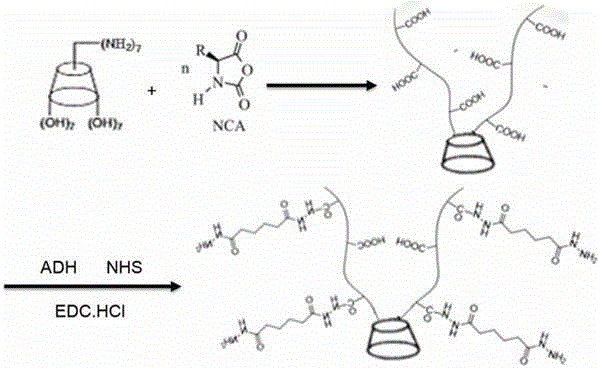

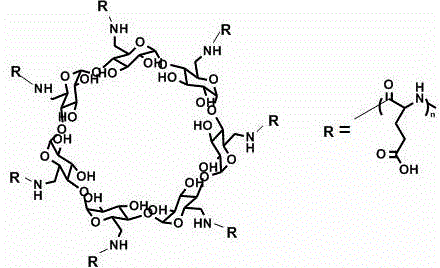

Star-shaped polyglutamic acid as well as injectable hydrogel and preparation method thereof

InactiveCN105482104ASpeed controlControl mechanical strengthAerosol deliveryOintment deliveryPolymer scienceCyclodextrin

The invention relates to a star-shaped polyglutamic acid as well as injectable hydrogel and a preparation method thereof. According to the preparation method, firstly, polyamino beta-cyclodextrin is stereospecifically synthesized, secondly, a plurality of polymerization reaction initiation sites are introduced so as to initiate ring-opening polymerization of L-glutamate-N-carboxylic acid anhydride, and finally the L-glutamate-N-carboxylic acid anhydride subjected to ring-opening polymerization is modified to be used as a first component of hydrogel; meanwhile, modified polysaccharide polymer is used as a second component of the hydrogel, the two components are mixed according to a certain ratio, through chemical crosslinking of the Schiff base reaction, the star-polyglutamic acid hydrogel is obtained, and the gelation time is 7-300 s. The hydrogel is characterized by having an excellent apparent appearance, mechanical properties, biocompatibility and biodegradability; in addition, beta-cyclodextrin is used as a core of the star-shaped polyglutamic acid, so that additional stable crosslinking sites are provided, the improvement of the mechanical strength of the hydrogel is facilitated, and the loading and controlled release properties to hydrophobic drugs are improved. The hydrogel has a wide application prospect in the fields of drug controlled release, tissue engineering, regenerative medicine and the like.

Owner:SHANGHAI UNIV

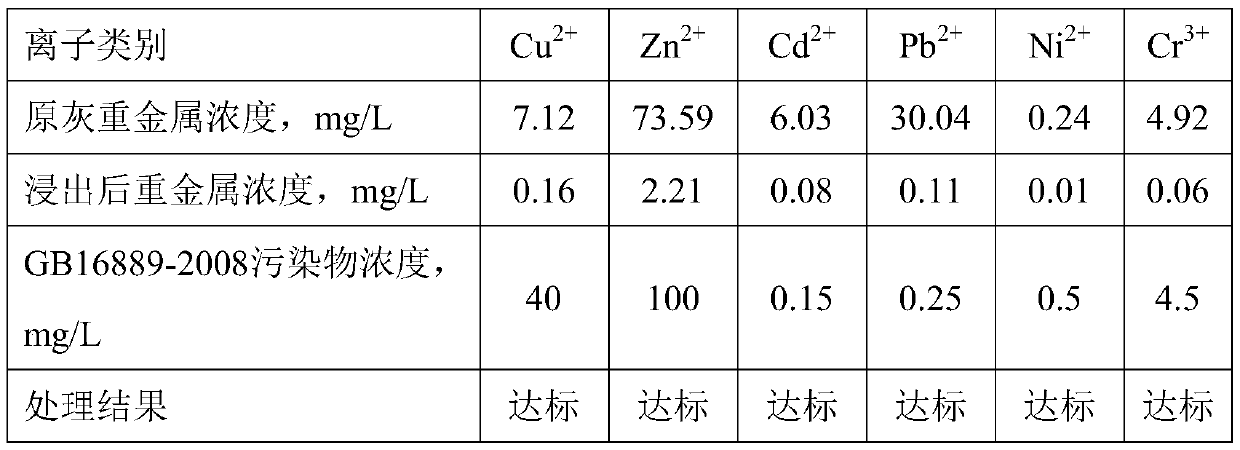

General bonderite used before spray coating of steel and aluminum combined shell body, and preparation method of general bonderite

The invention discloses general bonderite which is used before spray coating of a steel and aluminum combined shell body and by which phosphating films can be generated on the surfaces of steel and aluminum at the same time, and a preparation method of the general bonderite. The general bonderite is prepared by mixing a main agent, an additive No.1 and an additive No.2; the mass ratio of the main agent, the additive No.1 to the additive No.2 is 100:(3-8):(13-19); the main agent is prepared from the following raw materials in percentage by mass: 8 to 20 percent of phosphoric acid, 1 to 3 percent of room-temperature steel surface treatment agent, 0.5 to 2 percent of zinc oxide, 0.1 to 0.3 percent of 35 percent hydrogen peroxide, 0.6 to 2 percent of over 38 percent manganese carbonate, 2 to 4 percent of sodium carbonate, 4 to 7 percent of nickel nitrate of which Ni content is 20 percent, 0.1 to 0.2 percent of ferric nitrate and the balance of water; the additive No.1 is prepared from the following raw materials in percentage by mass: 40 to 70 percent of 40 percent silicofluoric acid, 3 to 5 percent of 50 percent hydrofluoric acid and the balance of water; and the additive No.2 is prepared from the following raw materials in percentage by mass: 30 to 70 percent of sodium nitrate and the balance of water.

Owner:DALIAN SANDAAOKE CHEM

Preparation method of palladium nano-clusters with sizes controllable

InactiveCN108145173AControl molar ratioEasy to operateMaterial nanotechnologyTransportation and packagingThiolOrganic solvent

The invention discloses a preparation method of palladium nano-clusters with the sizes being controllable. The method can be used for preparing the palladium nano-clusters of different sizes on a large scale. The method specifically comprises the steps that firstly, palladium chloride is dissolved into a trace amount of concentrated hydrochloric acid; secondly, an obtained mixture is added into anorganic solvent and stirred for a period of time; and thirdly, mercaptan ligands with different mole ratios are added for reaction, after one hour of reaction, sodium borohydride is added for reduction, and non-valent palladium nano particles are obtained. The sizes of the nano-clusters are controlled by changing the ratios of the ligands. The preparation method related by the invention is feasible and easy to operate, and the palladium nano particles of different sizes can be obtained by adjusting and controlling the ligands with the different mole ratios.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing semi-aromatic polyamide

The invention discloses a method for preparing a semi-aromatic polyamide. The method comprises the steps of adding aromatic dicarboxylic acid and aliphatic diamine containing 4 to 14 carbon atoms into a high-pressure autoclave, applying nitrogen pressure in the autoclave under a condition of water existence, rising the temperature so as to pre-polymerize, and then preparing high viscosity semi-aromatic polyamide resin by performing tackifying reaction on the pre-polymerized materials. The method of the invention prepares the semi-aromatic polyamide by applying nitrogen pressure, the diamine loss is avoided and the mole ratio of the dicarboxylic acid and the diamine can be accurately controlled so as to acquire the high viscosity semi-aromatic polyamide. The pre-polymerized material which has a viscosity eta ranged from 0.06 to 0.3 dl / g tested in 96% sulfuric acid at 25 DEG C by performing the pre-polymerization reaction is acquired. After the tackifying reaction is performed, the viscosity eta of the semi-aromatic aromatic polyamide is ranged from 0.8 to 2.5 dl / g, the melting point of the semi-aromatic aromatic polyamide is ranged from 270 to 330 DEG C, the content of the end carboxyl is ranged from 15 to 80 mol / t and the content of the end amino is ranged from 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

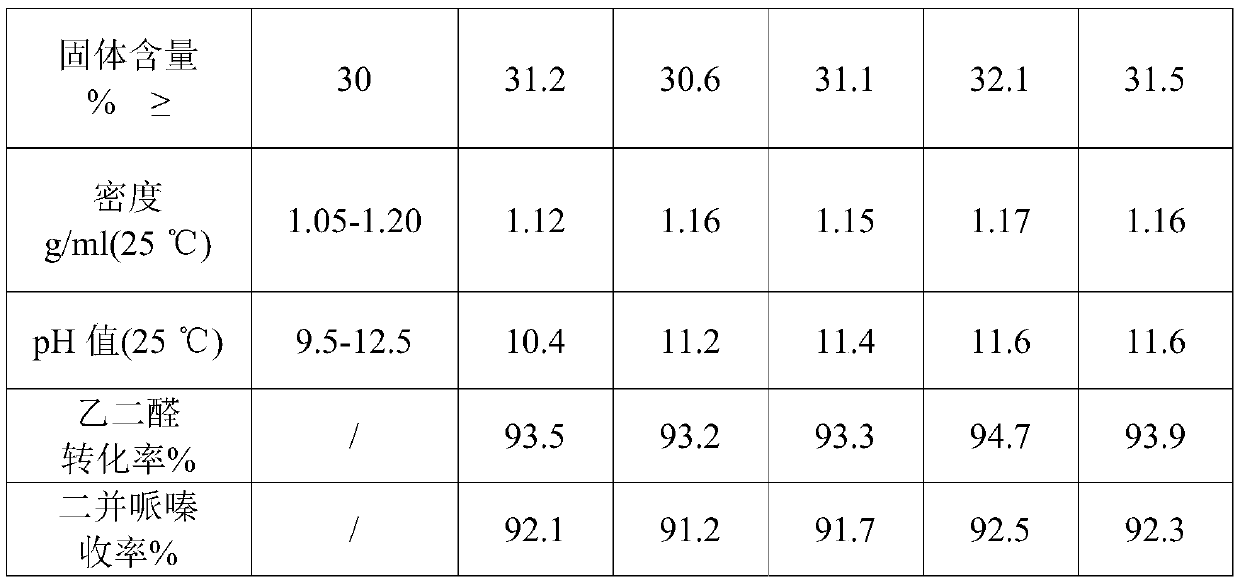

Synthesis process of composite piperazine heavy metal chelating agent TDDP

ActiveCN111057060AImprove economic efficiencyHigh yieldOrganic chemistryWater/sewage treatmentOrganic baseHeavy metal chelation

The invention discloses a synthesis process of a composite piperazine heavy metal chelating agent TDDP, which comprises the following steps: by using ethylenediamine and glyoxal as raw materials, carrying out a condensation reaction in the presence of a catalyst to generate dipiperazine; taking organic alkali tetramethyl guanidine as a catalyst, and reacting dipiperazine with carbon disulfide andsodium hydroxide to generate TDDP; and meanwhile, reacting ethylenediamine with carbon disulfide and sodium hydroxide to generate EDTC. Compared with the prior art, the beneficial effects of the invention are that: under a designed reaction condition, a solution obtained after dipiperazine is synthesized is used for preparing TDDP, excessive ethylenediamine reacts with carbon disulfide and sodiumhydroxide to generate another heavy metal precipitant EDTC; therefore, the prepared heavy metal chelating agent target product can obtain a removing agent with the function of removing heavy metal ions of a cyclic structure and a linear structure at the same time without secondary compounding, the application field is expanded, and the heavy metal ion removing effect is particularly obvious.

Owner:YANTAI ZHONGKE RONGDA NEW MATERIAL CO LTD

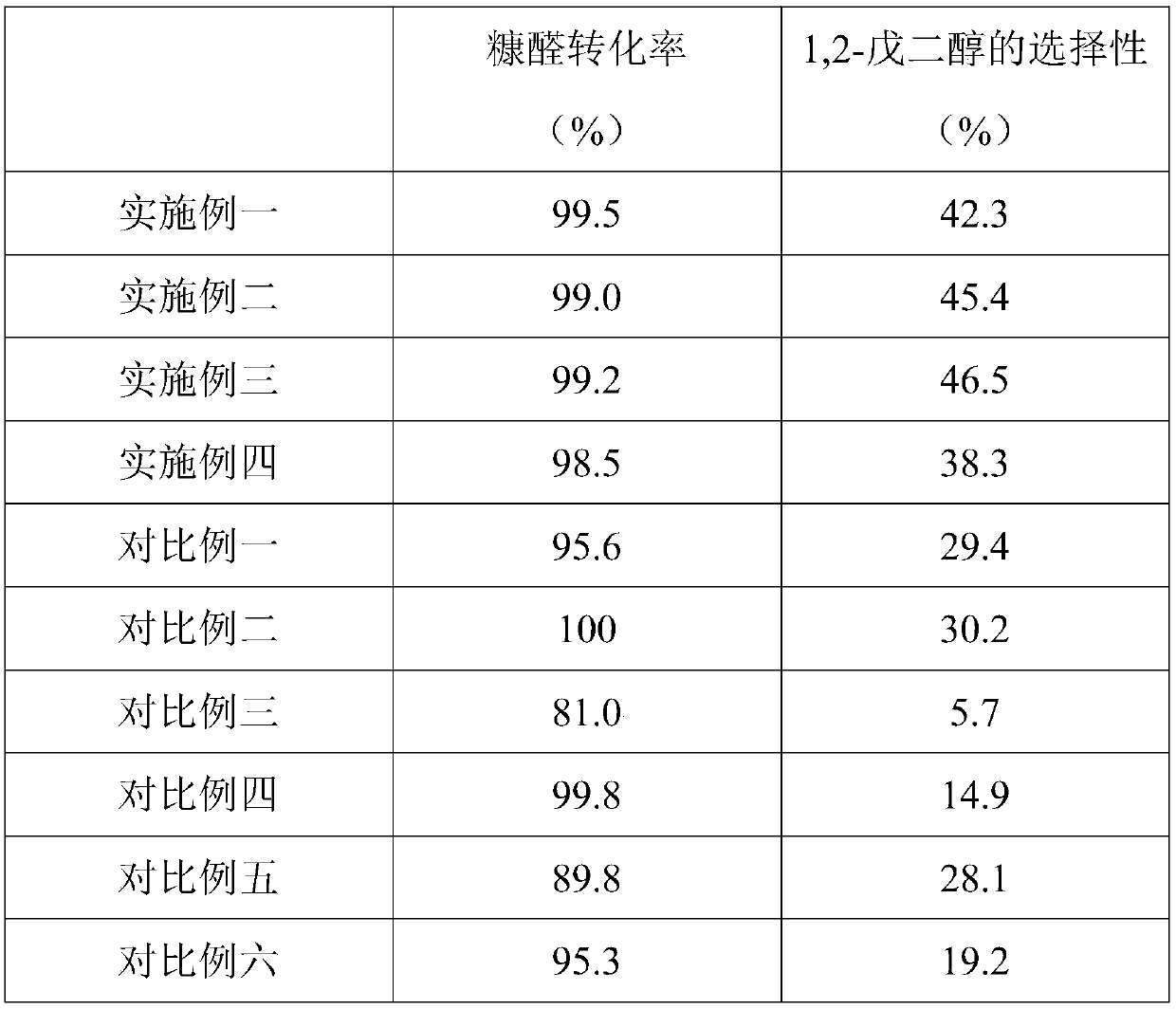

Method for directly producing 1,2-pentanediol through furfural hydrogenation

ActiveCN109608304ARich sourcesLow costOrganic compound preparationHydroxy compound preparationHydrogen pressureHydrogenation reaction

The invention relates to a method for directly producing 1,2-pentanediol through furfural hydrogenation. The method includes the step of conducting a hydrogenation reaction under certain reaction temperature and hydrogen pressure conditions with the presence of solvents with furfural as the raw material and amorphous alloy as the catalyst to generate 1,2-pentanediol through one step. The method has the advantages of being mild in catalytic reaction condition, low in catalyst preparing cost and simple in after-reaction catalyst separation; the problems are solved that in the existing process ofdirectly preparing 1,2-pentanediol through furfural hydrogenation, the preparing cost of noble metal catalysts is high, the reaction pressure of Cu-series catalysts is high, the requirements for devices and operation are high and existing catalysts are complicated to recover after reaction; the method has good industrial application prospects.

Owner:JIAXING UNIV

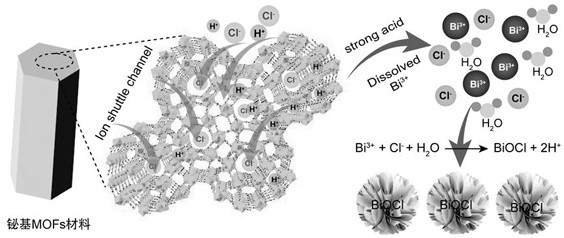

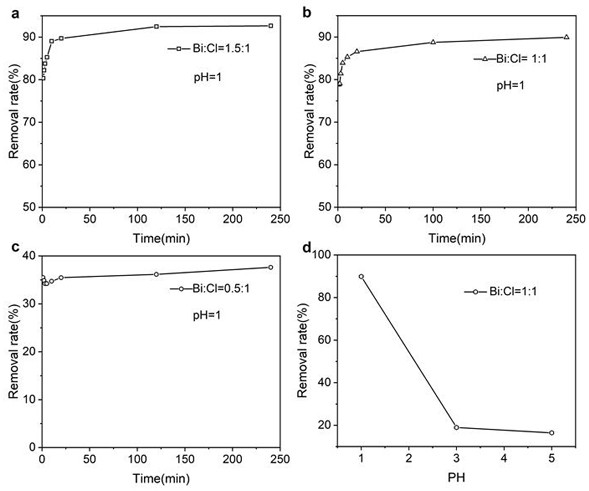

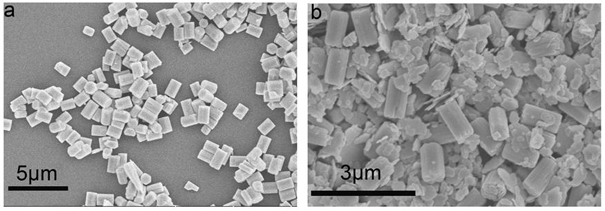

Method for rapidly removing chloride ions in wastewater by using bismuth-based metal organic framework material

ActiveCN114835233AControl molar ratioHave economic effectGeneral water supply conservationWater contaminantsOrganic acidFiltration

The invention provides a method for rapidly removing chloride ions in wastewater by using a bismuth-based metal organic framework material. According to the method, soluble bismuthate and non-toxic organic acid are utilized to form a porous bismuth-based metal organic framework material as a dechlorination reagent, the bismuth-based MOFs material is added into chlorine-containing wastewater, the pH value and stirring time of the wastewater are adjusted, the molar ratio of bismuth ions to chloride ions is controlled, and qualified filtrate with low-concentration chlorine content and a bismuth oxychloride product are obtained after filtration.

Owner:MINJIANG UNIV

Titanium dioxide photocatalysis material and preparation method thereof

ActiveCN104667941AImprove photocatalytic performanceControl the photocatalytic rangeMetal/metal-oxides/metal-hydroxide catalystsTolueneMaterials science

The invention provides a modified titanium dioxide photocatalysis material. The modified titanium dioxide photocatalysis material comprises titanium dioxide and doping elements, and the doping elements comprise Fe, Ce, B, Ni, V, Co, La and Nd; and a molar ratio of Fe to V is 0.01-10:1, and a molar ratio of Ce to Co is 0.1-10:1. The invention also provides a preparation method of the modified titanium dioxide photocatalysis material, a photocatalysis glass containing the modified titanium dioxide photocatalysis material, and a preparation method of the photocatalysis glass. The modified titanium dioxide photocatalysis material has a very good photocatalysis effect on formaldehyde, amines and toluene.

Owner:BYD CO LTD

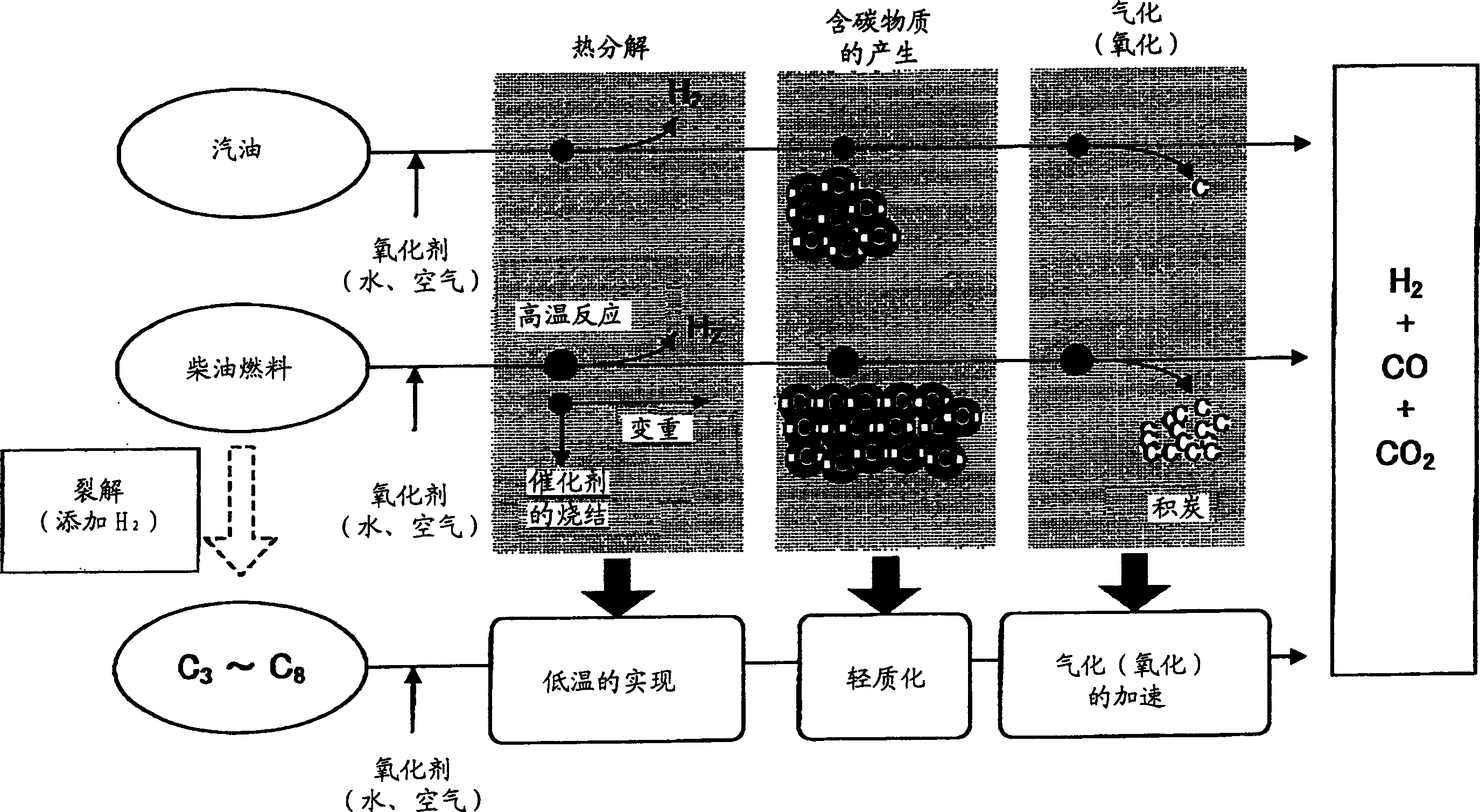

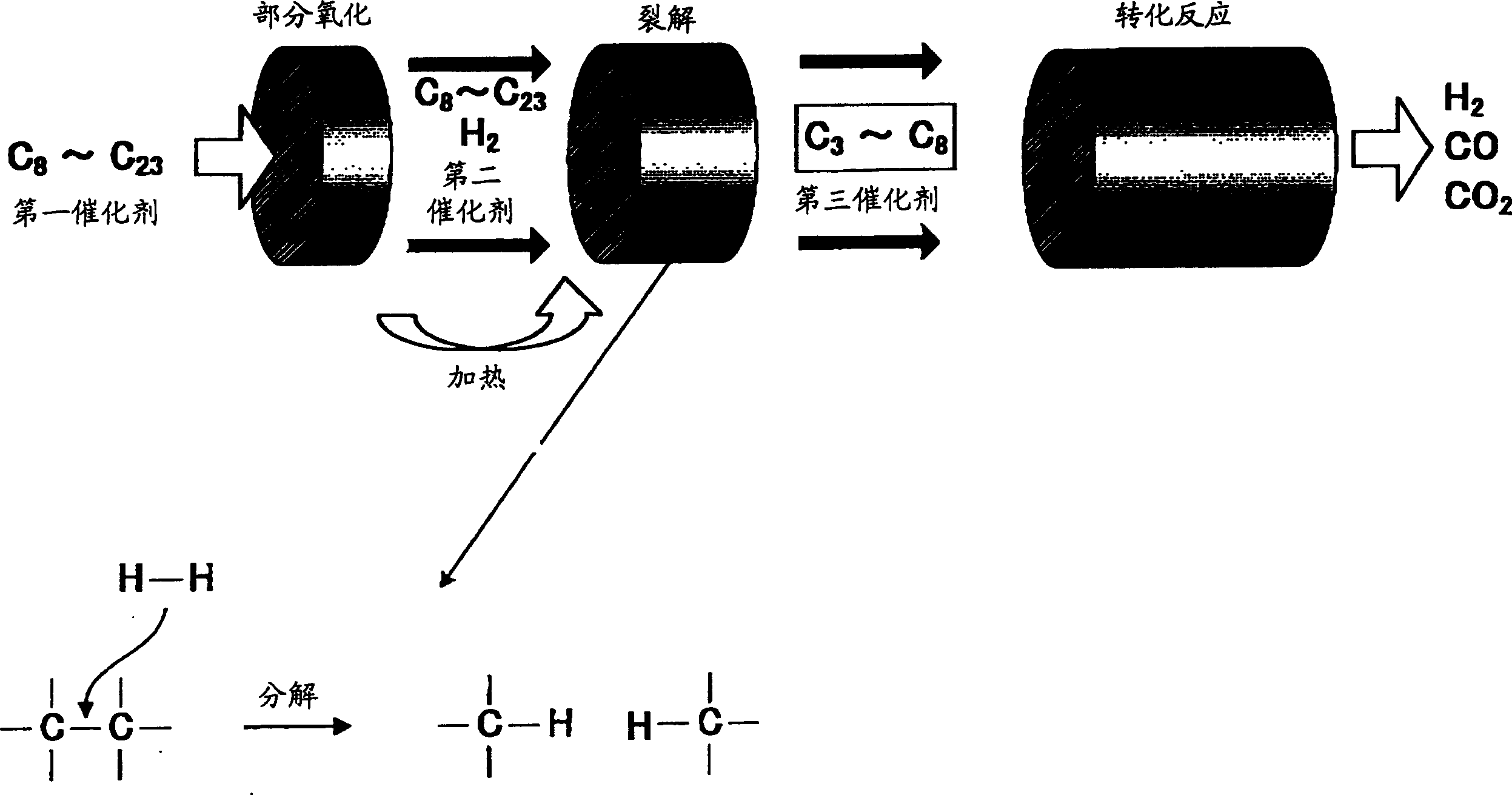

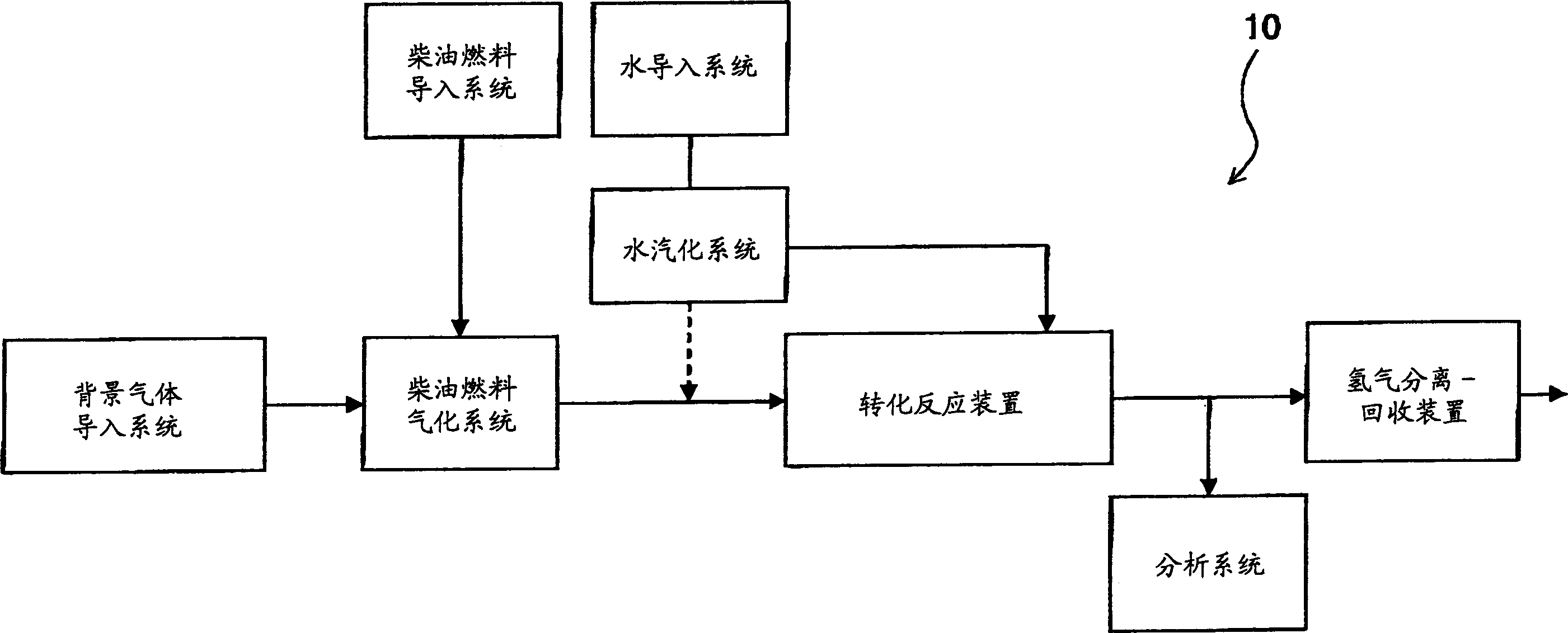

Method for producing hydrogen and apparatus for producing hydrogen

InactiveCN1640812AAvoid inactivationSmall pressure lossHydrogenHydrogen/synthetic gas productionHydrogenGasoline

A method for reforming a diesel fuel with high efficiency under a same condition as that of gasoline or the like to continuously produce hydrogen with high selectivity and high yield is provided. By allowing three catalysts having different functions from one another to be in a composite state and, then, controlling a reforming reaction of the diesel fuel, the diesel fuel is reformed with high efficiency under a same condition as that of gasoline or the like and, accordingly, hydrogen can continuously be produced with high efficiency and high yield.

Owner:HONDA MOTOR CO LTD

Preparation method of columnar potassium hexatitanate

InactiveCN102849790BControl molar ratioControlling the particle size of raw materials is beneficial to the molar ratioTitanium compoundsChemical industryPotassium

The invention discloses a preparation method of columnar hexagonal potassium titanate, which belongs to the field of the chemical industry. The method comprises the steps of: a, uniformly mixing a -100 mesh titaniferous containing material and a potassium containing material according to a molar ratio of TiO2:K2O=4-7; b, placing the material mixed uniformly in the step a in an environment at 1100-1300 DEG C for sintering for 1-4 hours for adequate reaction of the material; and c, quickly cooling the sintered material in the step b, then adequately dissociating the cooled material by water at a constant temperature of 60-80 DEG C, and finally filtering and drying to obtain a columnar hexagonal potassium titanate product. The method provided by the invention is simple in process flow, easy to operate, low in cost and high in yield, and the prepared columnar hexagonal potassium titanate is large in draw ratio and high in purity, and is suitable for industrial production.

Owner:PANZHIHUA UNIV

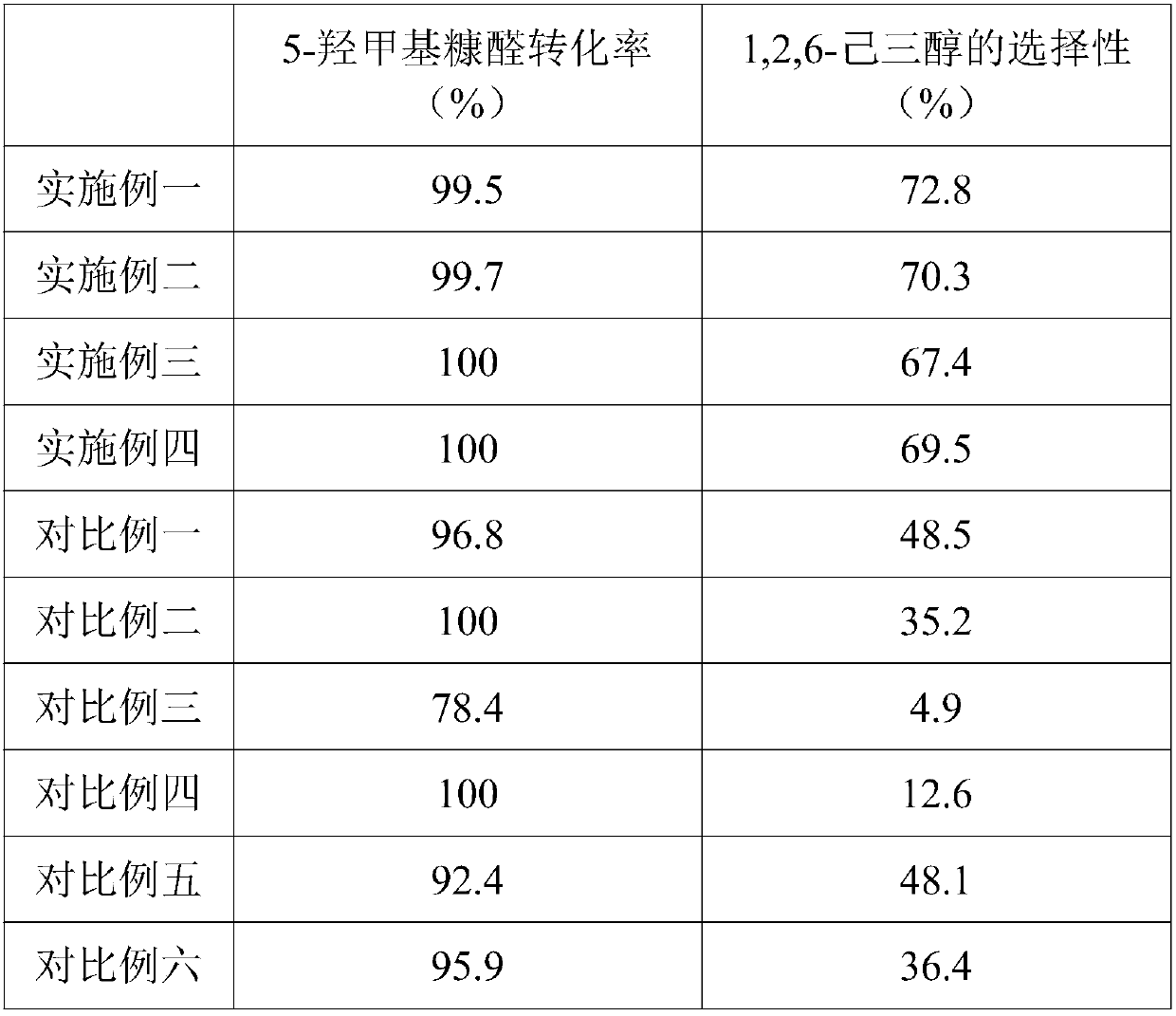

Method for directly producing 1,2,6-hexanetriol by performing hydrogenation on 5-hydroxymethylfurfural

ActiveCN109678654AReduce manufacturing costHigh yieldOrganic compound preparationHydroxy compound preparationSolventRaw material

The invention relates to a method for directly producing 1,2,6-hexanetriol by performing hydrogenation on 5-hydroxymethylfurfural. The method comprises the following steps: adopting 5-hydroxymethylfurfural as a raw material under the existence of the solvent, taking amorphous alloy as catalyst, performing hydrogenation under a certain reaction temperature and hydrogen pressure condition, generating 1,2,6-hexanetriol through one-step method. The method disclosed by the invention has the advantages of being high in hexanetriol yield, mild in reaction condition, low in catalyst preparation cost and simple in separation after reaction, and has good industrial application prospect.

Owner:JIAXING UNIV

Method for preparing semi-aromatic nylon salt

The invention discloses a method for preparing a semi-aromatic nylon salt. The method is to make aromatic dibasic acid and aliphatic diamine subjected to neutralization reaction in an organic solvent, perform centrifugal separation, wash obtained deposit, and obtain the semi-aromatic nylon salt. The semi-aromatic nylon salt prepared by the method has high purity, and the method can accurately control the mol ratio of the dibasic acid to the diamine to be equal under the condition of polycondensation. The organic solvent selected by the method can dissolve the aromatic dibasic acid and the aliphatic diamine but can not dissolve the semi-aromatic nylon salt, so that the generated nylon salt can be easily separated and purified. Moreover, the solvent used for preparing the semi-aromatic nylon salt can be recycled.

Owner:KINGFA SCI & TECH CO LTD +1

Method for preparing fine-grain low silica/alumina ratio X zeolite

ActiveCN101254928BLower structural silicon/aluminum ratioReduce post-processing stepsFaujasite aluminosilicate zeoliteSilicon oxideCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Semi-aromatic polyamide and preparation method thereof

Owner:KINGFA SCI & TECH CO LTD +1

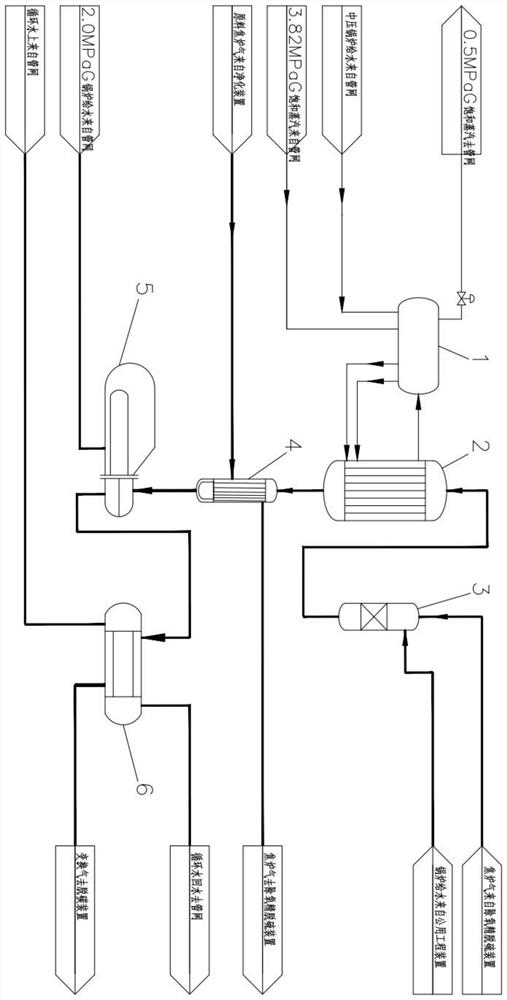

CO conversion treatment device in coke-oven gas and conversion treatment method thereof

InactiveCN112980519AReduce in quantityLess investmentSteam generation heating methodsCombustible gas catalytic treatmentPtru catalystProcess engineering

The invention belongs to the field of coke-oven gas purification, and particularly relates to a CO conversion treatment device in coke-oven gas and a conversion treatment method thereof The CO conversion treatment device is arranged at an outlet of a desulfurization tank of a coke-oven gas deoxidization and fine desulfurization device and comprises a steam pocket, an isothermal conversion furnace, a cooling humidifier, a material inlet and outlet heat exchanger, a 0.5 MPa waste heat boiler and a water cooler. According to the method, the molar ratio of coke-oven gas to boiler water is controlled by adjusting the amount of boiler water sprayed by the cooling humidifier, so that the effect of controlling the conversion rate is achieved; and according to coke-oven gas components and shift catalyst operation process conditions, a copper shift catalyst is selected, a heat exchanger does not need to be arranged at an inlet of an isothermal shift converter, and heat coupling utilization of a deoxidization fine desulfurization device and a shift treatment device is achieved.

Owner:山西沃能化工科技有限公司

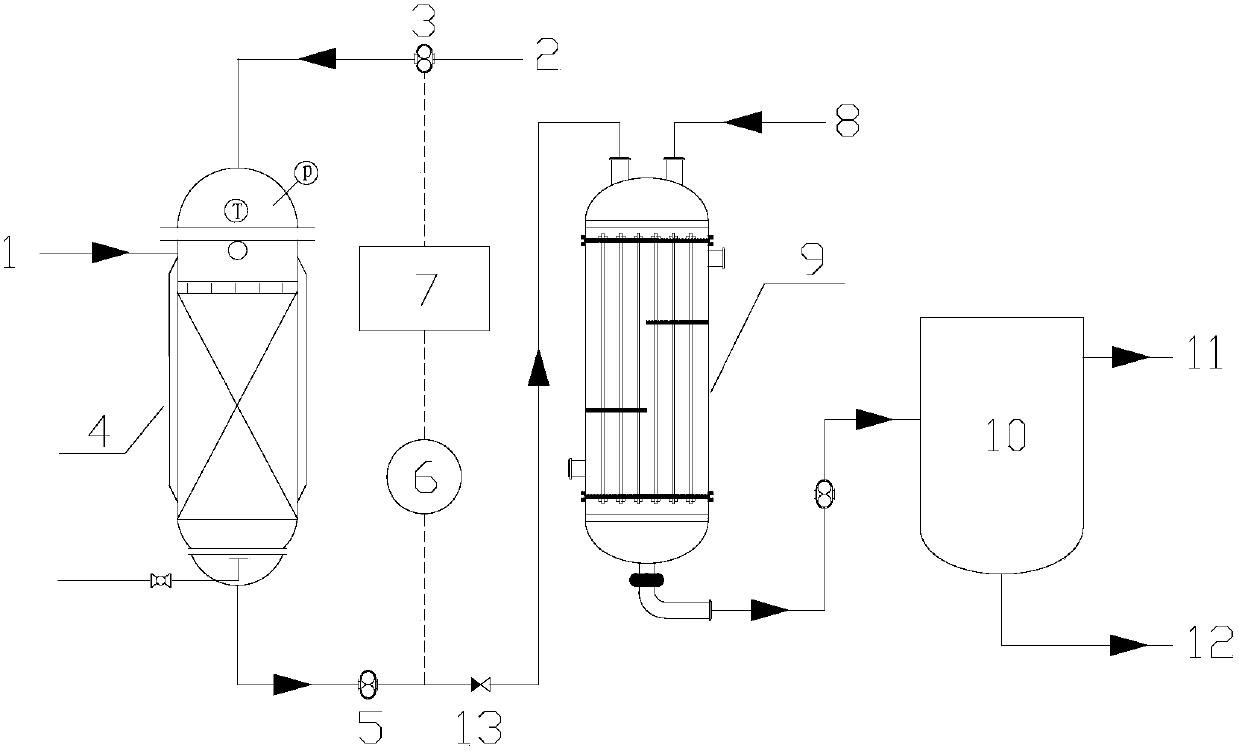

Novel preparation process of synthetic fatting agent and device

InactiveCN105950797AExcellent fatliquoring performanceControl molar ratioLeather impregnationAutomatic controlMeasuring instrument

The invention relates to a novel preparation process of a synthetic fatting agent and a device, and aims at achieving the effects that according to the provided process, the sulfonation degree of a final product can be automatically controlled, and the provided device can realize the continuous production of products. The preparation process of the novel synthetic fatting agent has the technical scheme that the novel preparation process of the synthetic fatting agent is performed according to the following steps of (1) synthesizing an oleic acid glycol monoester and diester mixture; (2) measuring the density of an esterification product by an automatic control system; (3) continuously inputting an oleic acid glycol ester mixture into a sulfonator for taking a diaphragm type sulfonation reaction; and (4) obtaining a leather fatting agent product, wherein tail gas is absorbed by a tail gas treatment system. A novel production device of the synthetic fatting agent comprises an esterification reactor, an organic material pump, a back pressure valve, a sulfonation reactor and a gas-liquid separator, wherein the esterification reactor is provided with an oleic acid inlet and a glycol inlet; a measuring instrument is also arranged in a connecting pipeline arranged between the organic material pump and the back pressure valve; and a data converter is communicated with the measuring instrument and a raw material pump.

Owner:JIAXING ZANYU TECH DEV CO LTD +1

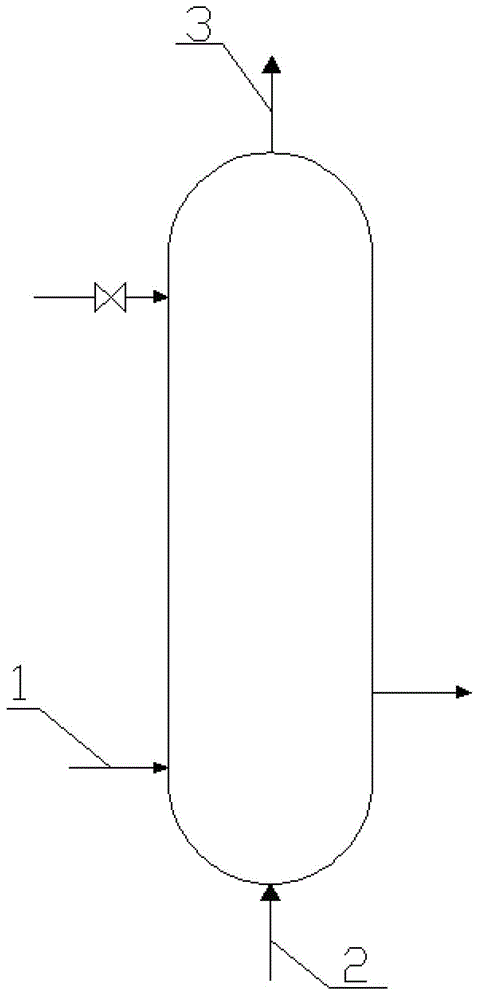

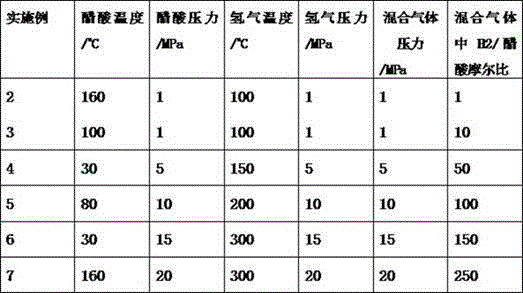

Method for mixing and gasifying liquid-phase acetic acid and hydrogen

ActiveCN102908958AGasification GuaranteeSolve the problem of high temperature corrosionOrganic compound preparationHydroxy compound preparationAcetic acidHydrogen pressure

The invention provides a method for mixing and gasifying liquid-phase acetic acid and hydrogen, comprising the steps of mixing and gasifying acetic acid and gas containing hydrogen in an evaporator, wherein the temperature of the hydrogen before mixing is 100-300 DEG C, the temperature of the acetic acid is 30-160 DEG C and the pressure of the acetic acid and the hydrogen is 1.0-20.0 MPa; and controlling the temperature of mixed gas of the top of the evaporator to obtain the mixed gas with an H2 / acetic acid mol ratio of 1-250 and the pressure of 1.0-20.0 MPa. According to the method disclosed by the invention, the acetic acid can be gasified at the temperature which is lower than an acetic acid boiling point under operation pressure and the problem of high-temperature corrosion of the liquid-phase acetic acid is solved; and the H2 / acetic acid mol ratio in the mixed gas can be well controlled. Furthermore, in a process of mixing and gasifying the liquid-phase acetic acid and the gas containing the hydrogen, the acetic acid is heated by an external heat source to provide gasification latent heat of the acetic aid, and the requirement on an external heat supply can be reduced.

Owner:JIANGSU SOPO CHEM +1

Method for preparing potassium hexatitanate whisker

InactiveCN102839424BControl molar ratioControlling the particle size of raw materials is beneficial to the molar ratioPolycrystalline material growthFrom solid stateChemical industryPotassium

The invention discloses a method for preparing a potassium hexatitanate whisker, belonging to the field of chemical industry. The method comprises the following steps of: a, uniformly mixing 100-mesh titanium-containing raw material and potassium-containing raw material according to mole rate of TiO2 to K2O being 3-6; b, placing the materials in an environment at temperature of 1100-1300 DEG C and sintering for 1-5 hours to make the materials fully reacted; and c, rapidly cooling the sintered materials, fully dissociating in an environment at constant temperature of 60-80 DEG C by using water, filtering, drying, and thus obtaining the potassium hexatitanate whisker. The process flow is simple, production period is short, yield is high, meanwhile, a production process of a precursor or a post-period recrystallization conversion process in the prior art is reduced, energy consumption is saved, and production cost is reduced. The cooled materials are fully dissociated in the environment at constant temperature of 60-80 DEG C by using the water, so that the potassium hexatitanate whisker has good purity and is suitable for industrial production.

Owner:PANZHIHUA UNIV

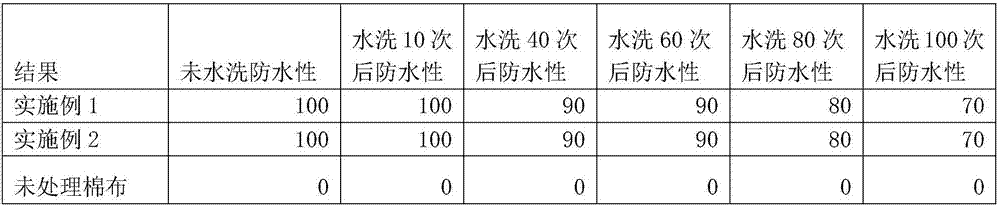

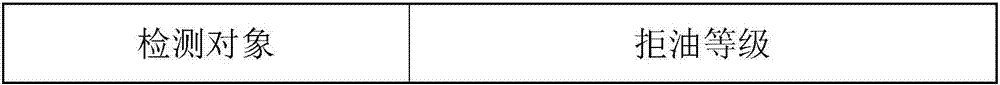

Anti-fouling textile finishing method

InactiveCN107964783AGood water and oil repellencyImprove smoothnessStain/soil resistant fibresSucessive textile treatmentsCooking & bakingPolymer science

The invention provides an anti-fouling textile finishing method. The method includes steps: subjecting textiles to corona treatment; adding butyl titanate, oxalic acid and sodium dihydrogen phosphateinto an ethyl alcohol and water mixed solvent, performing hermetical heating reaction, cooling to the room temperature, soaking the treated textiles, adopting a twice-soaking twice-dewatering process,and drying; soaking the treated textiles into water-repellent oil-repellent finishing agent solution, adopting a twice-soaking twice-dewatering process, drying and baking. Compared with the prior art, the anti-fouling textile finishing method has advantages that great water and oil repelling effects are achieved, fouling is prevented, high firmness of a waterproof layer and high light degradation efficiency are realized, and the self-cleaning performance is improved; in addition, a preparation method is simple and low in cost.

Owner:WUHU WANJIANG INTPROP OPERATION CENT CO LTD

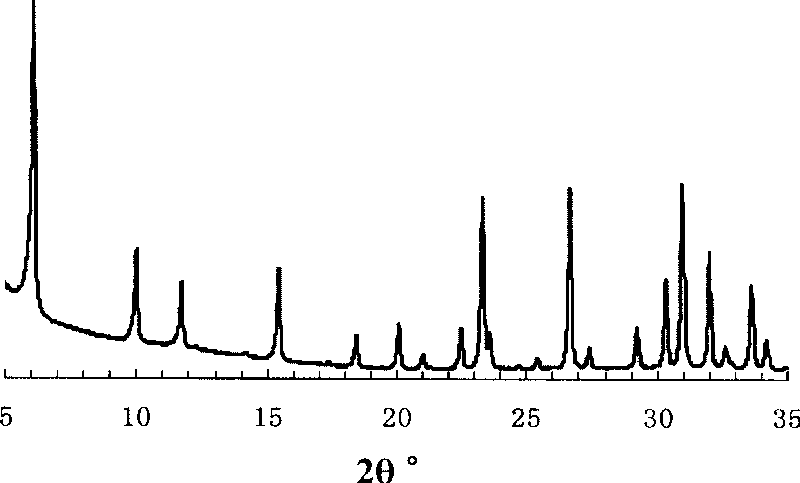

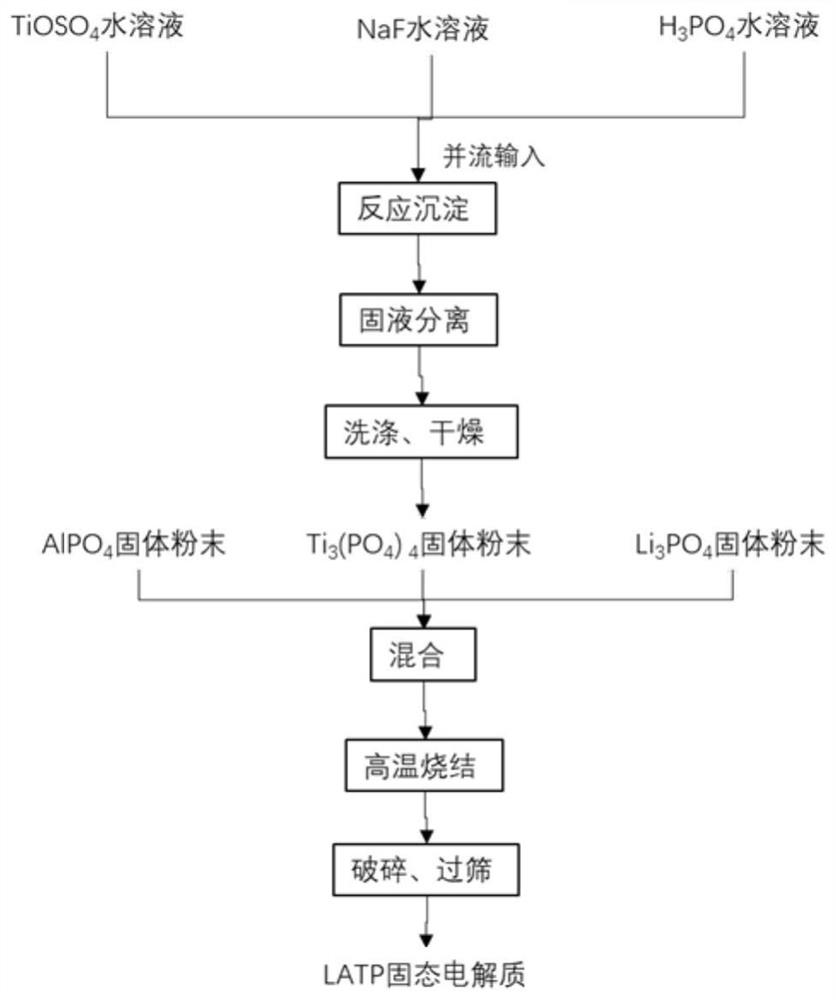

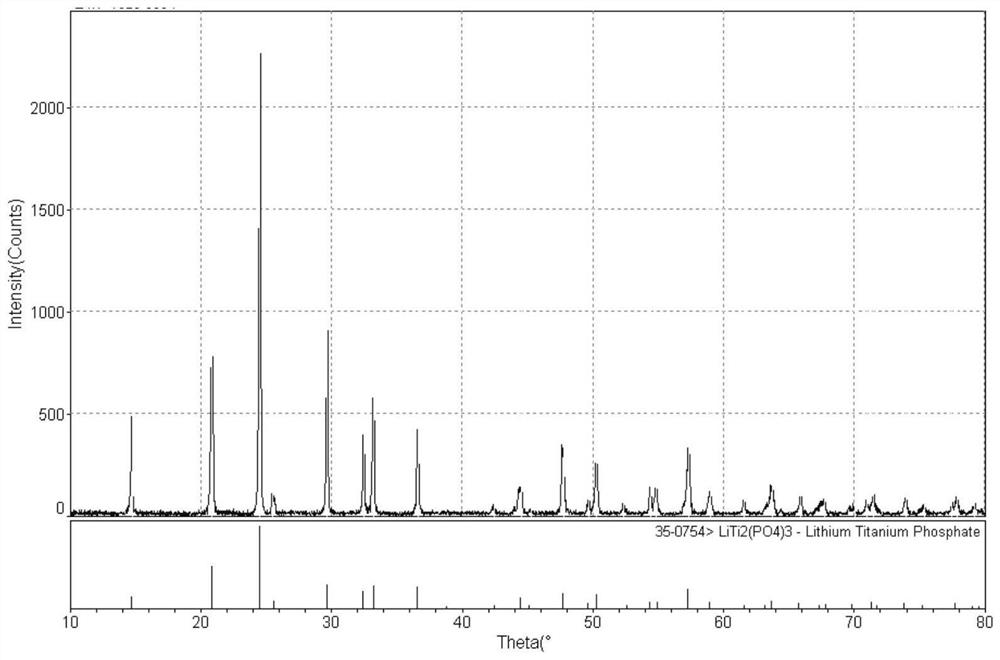

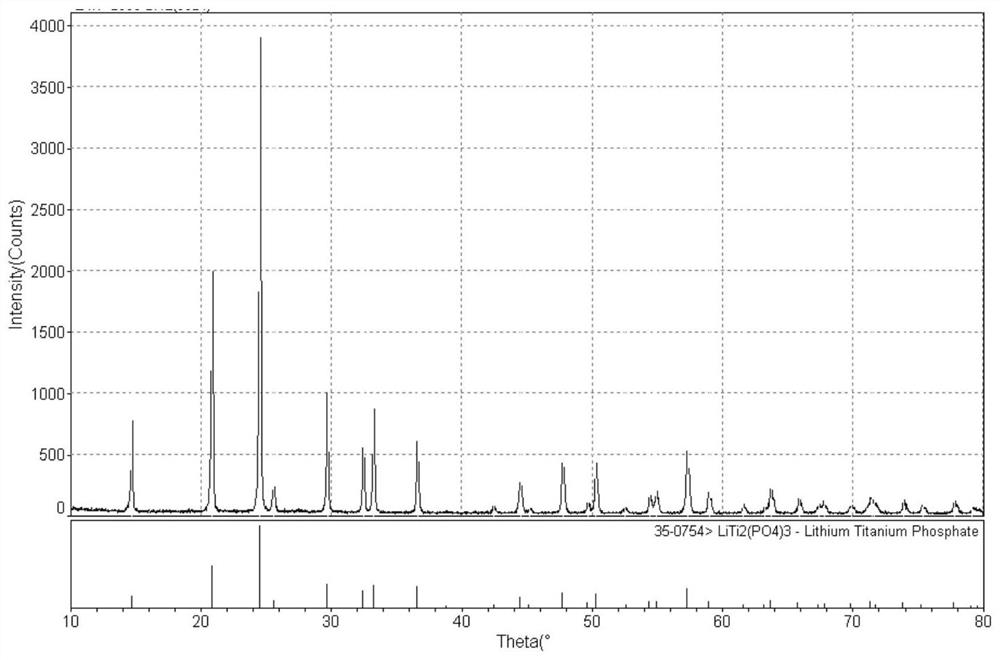

Preparation method of LATP solid electrolyte

PendingCN113178615AControl molar ratioGood crystal formSolid electrolytesSecondary cellsSolid state electrolyteAqueous solution

The invention discloses a preparation method of an LATP solid electrolyte, and relates to the technical field of lithium ion secondary battery solid electrolyte preparation, the preparation method comprises the following steps: S1, adding TiOSO4 into deionized water, mixing to prepare a TiOSO4 aqueous solution, adjusting the pH value, and preparing the TiOSO4 aqueous solution with the adjusted pH value for later use; S2, adding NaF into deionized water to prepare a NaF aqueous solution for later use; S3, adding H3PO4 into deionized water to prepare an H3PO4 aqueous solution for later use; S4, adding deionized water, NaF and H2SO4 into a reaction kettle, preparing and heating a mixed bottom water solution, adding a TiOSO4 solution, a NaF solution and a H3PO4 solution into the mixed bottom water solution at the same time, conducting solid-liquid separation, washing and drying prepared solids, and preparing Ti3 (PO4) 3 solid powder; and S5, adding an AlPO4 solid and a Li3PO4 solid into the Ti3 (PO4) 3 solid powder, mixing, sintering, crushing and sieving to obtain the LATP solid electrolyte.

Owner:深圳市新创材料科技有限公司

Process for preparing semi-aromatic polyamides

The invention discloses a method for preparing semi-aromatic polyamide. The method adopts low temperature of 170 DEG C to 190 DEG C for dehydration firstly, and then adopts a method for temperature-raising and prepolymerization to prepare the semi-aromatic polyamide, thus avoiding the loss of diamine and being capable of accurately controlling the molar ratio of the dicarboxylic acids and the diamine, obtaining the polyamide with high intrinsic viscosity and improving the quality of semi-aromatic polyamide. By the prepolymerization reaction, the prepolymer which is measured in 96 percent of sulphuric acid with the temperature of 25 DEG C and has the intrinsic viscosity Eta of 0.06 to 0.3dl / g can be obtained. After viscosifying reaction, the intrinsic viscosity Eta of the semi-aromatic polyamide is 0.8 to 2.5 dl / g and the melting point of the semi-aromatic polyamide is 270 to 330 DEG C; the content of terminal carboxyl group is 15 to 80 mol / t; and the content of amino-terminated group is 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

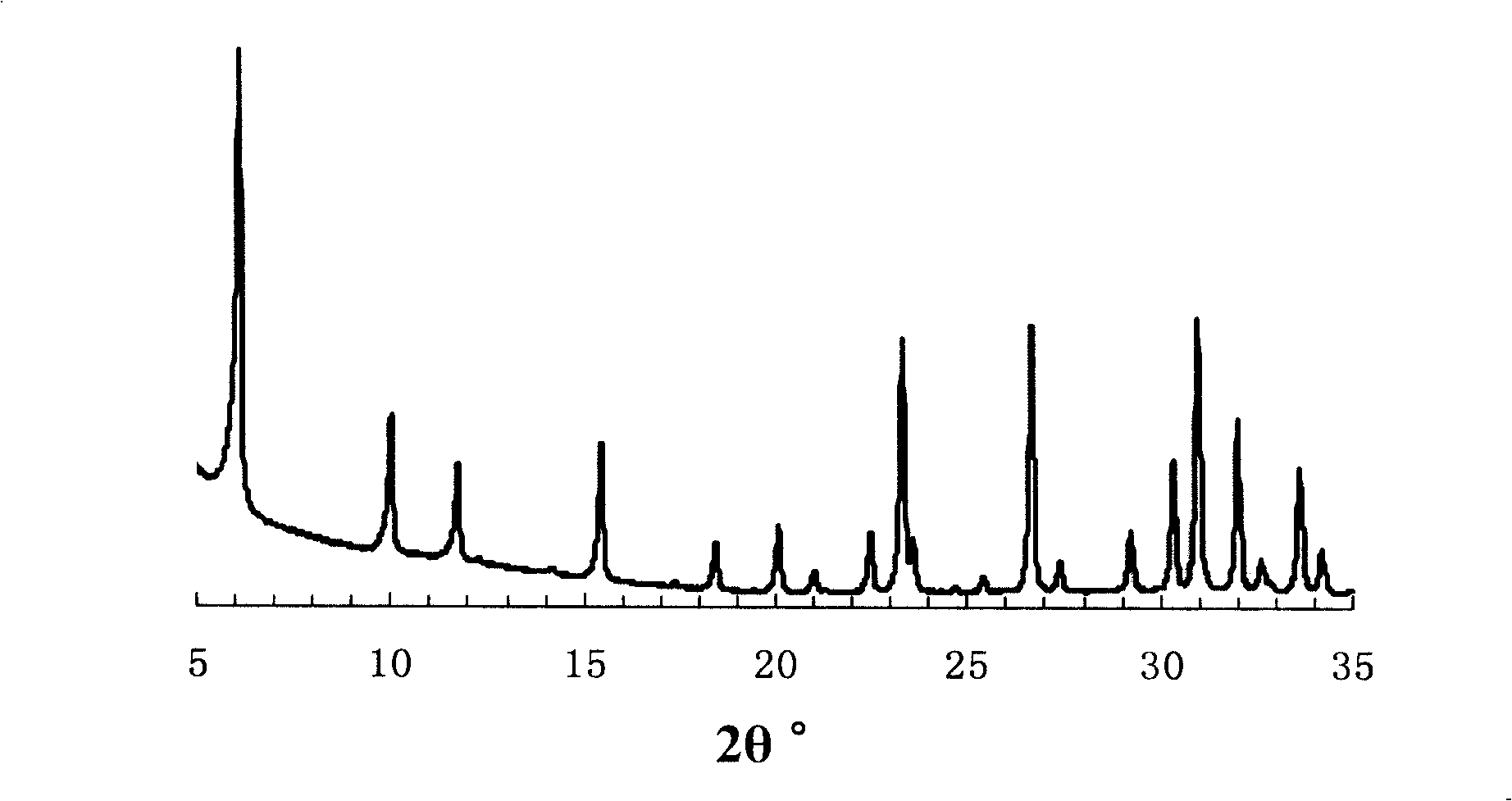

Method for synthesizing semi-aromatic nylon salt by using mixed solvent

ActiveCN103613505BReduce usagePromote formationOrganic compound preparationCarboxylic acid salt preparationOrganic solventReaction temperature

The invention discloses a method for synthesizing a semi-aromatic nylon salt by using a mixed solvent composed of water and an organic solvent. The method comprises the steps: mixing aliphatic diamine and water, pulping, and heating the aliphatic diamine solution to 60-98 DEG C, and remaining the aliphatic diamine solution for later use; mixing aliphatic diacid and an organic solution, heating the aliphatic diacid solution to 60-120 DEG C until the aliphatic diacid is completely dissolved, and remaining the aliphatic diacid solution for later use; slowly adding the aliphatic diacid solution into the aliphatic diamine solution, and carrying out neutral reaction at the temperature of 60-98 DEG C; and regulating the pH value to 7.0-7.5, then, cooling, centrifugally separating, washing by using deionized water, and drying to obtain the semi-aromatic nylon salt. The semi-aromatic nylon salt prepared by using the method disclosed by the invention is high in purity, favorable in particle crystal form, easy to separate and purify, low in consumption of organic solvent, mild in reaction condition and low in energy consumption. The organic solvent used in the method can be recycled.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

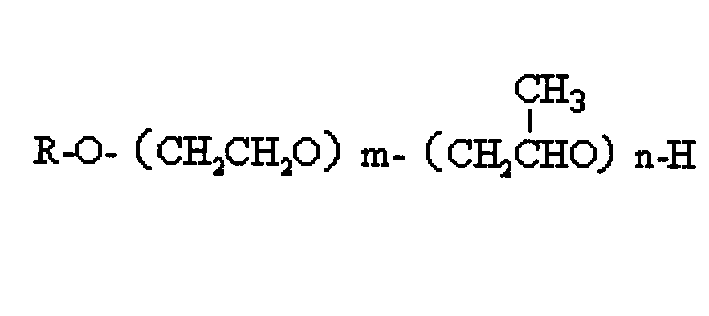

Multipurpose, multifunctional complex cleaning and washing agent

InactiveCN1406272AControl molar ratioCationic surface-active compoundsNon-ionic surface-active compoundsCarbon numberAlkalinity

The present invention is good for complex cleaning and degreasing agent which can save energy, and can shorten the cleaning time and show good cleaning and degreasing proficiency without changing the systems being used, and impairing the raw materials. The present invention is also for cleaning and degreasing agent that maintains the best alkalinity and can be used according to each characteristics of process, without being restrained under the scope of available temperature. The present invention includes the surfactant and alkaline builder of the below formula 1: R-O-(CH2CH2O)m-H, formula 2, formula 3: R-Ph-O-(CH2CH2O)-m-H, and formula 4: R-Ph-SO3<->M<+>. Wherein, from 1 to formula 4 R is alkyl group of which carbon number is 3-19, Ph is phenyl group, m is 1.5-12 mol for formula 1 and 2, and 13-19 moles for formula 3, n is 2-15 mol, and M is counter ion.

Owner:AMECHEM

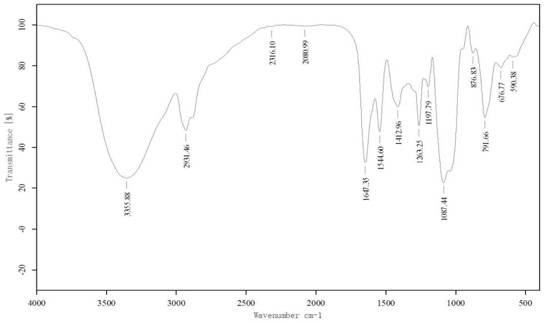

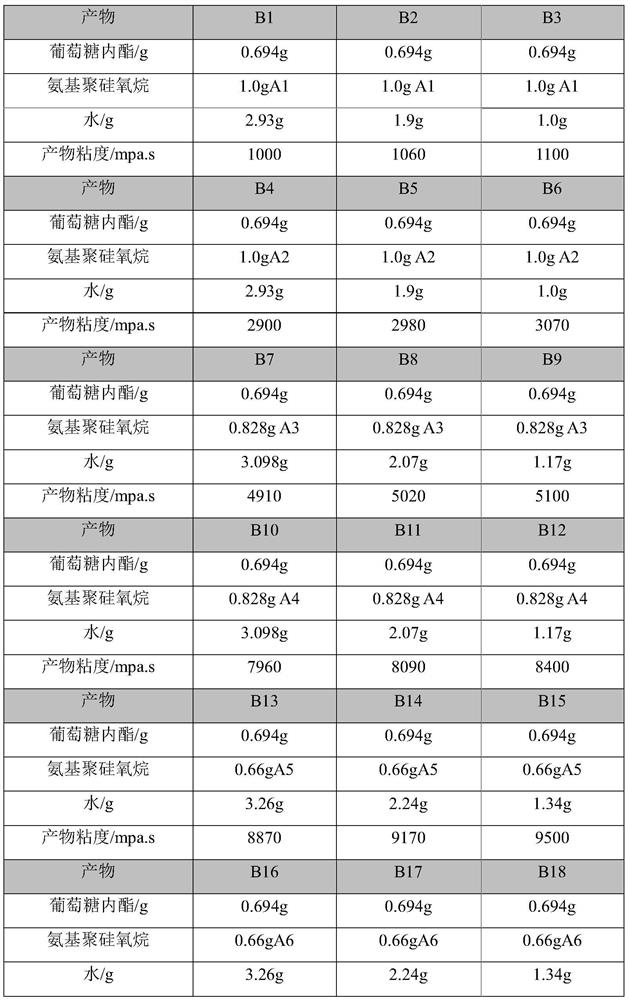

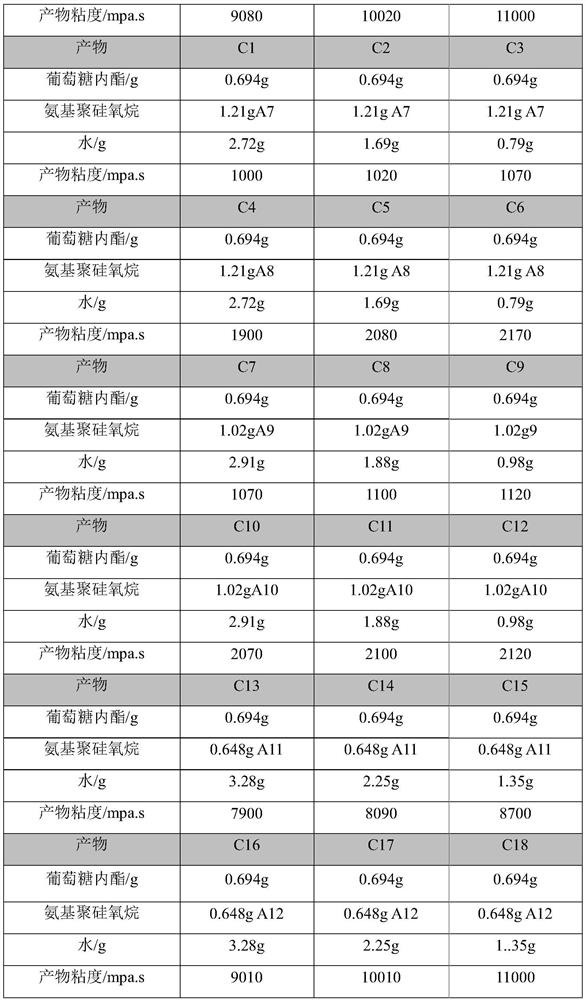

Sugar modified silicone oil and application thereof

ActiveCN111808289AHigh affinityGood moisturizing effectCosmetic preparationsToilet preparationsPolymer scienceSugar

The invention provides sugar modified silicone oil and application thereof. The sugar-modified silicone oil is prepared from the following components in percentage by weight through amidation reaction, 15 to 25.8% of sugar lactone, 11.4 to 45% of amino polysiloxane, and the balance water; wherein the content of amino groups in the amino polysiloxane is 3.9-5.9 mmoL / g, the pH value of the sugar-modified silicone oil is 7, and the molar ratio of ester groups in the sugar lactone to amino groups in the amino polysiloxane is 1: 1. The sugar-modified silicone oil has good affinity with water and also has good affinity with the skin surface, a uniform protective film is more easily formed on the skin surface by the sugar-modified silicone oil, and the sugar-modified silicone oil has a good moisturizing effect. In addition, the molar ratio of the sugar lactone to the amino polysiloxane can be controlled by adjusting the ratio of the sugar lactone to the amino polysiloxane silica chain link, the variety of the sugar lactone is changed, and the dissolving performance and the moisturizing performance of the sugar lactone in water are further adjusted.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com