Process for preparing semi-aromatic polyamides

A semi-aromatic and polyamide technology, applied in the field of semi-aromatic polyamide preparation, can solve problems such as influence and poor product application, and achieve the effect of avoiding loss and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

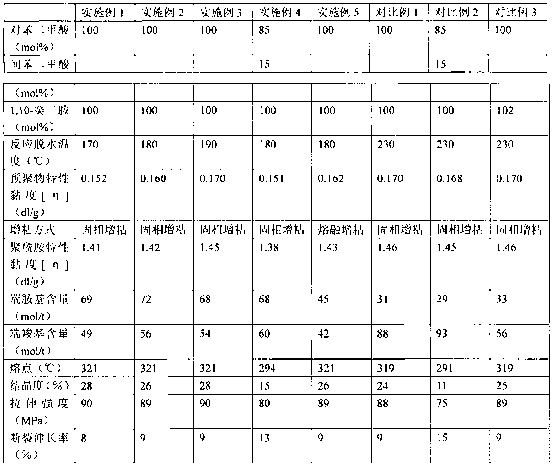

Examples

Embodiment 1

[0042] Add 3323g (20mol) of terephthalic acid, 3446g (20mol) of decanediamine, and 73.27g (0.6mol) of benzoic acid into a 20L autoclave equipped with magnetic coupling stirring, condenser, gas phase port, feed port, and pressure explosion-proof port , 6.77g (0.1wt% based on the total weight of the raw material) sodium hypophosphite, 2.2L deionized water, and the temperature was raised after nitrogen purging. The temperature was raised to 170° C. under stirring to start dehydration, and the temperature was raised to 220° C. after dehydration, and the reaction mixture was stirred at 220° C. for 1 hour, and then the temperature of the reactant was raised to 230° C. under stirring. The reaction was continued for 2 hours at a constant temperature of 230° C. and a constant pressure of 2.5 MPa. After the reaction was completed, the material was discharged to obtain a prepolymer with an intrinsic viscosity [η] of 0.152 dl / g. The prepolymer was vacuum-dried at 80°C for 24 hours, and th...

Embodiment 2

[0044] Repeat Example 1, except that the dehydration temperature is changed to 180°C. The results are shown in Table 1.

Embodiment 3

[0046] Repeat Example 1, except that the dehydration temperature is changed to 190°C. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com