Sugar modified silicone oil and application thereof

A technology of modifying silicon and silicone oil, applied in the field of daily chemicals, can solve the problems of skin physiology and metabolic function obstruction, airtight and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

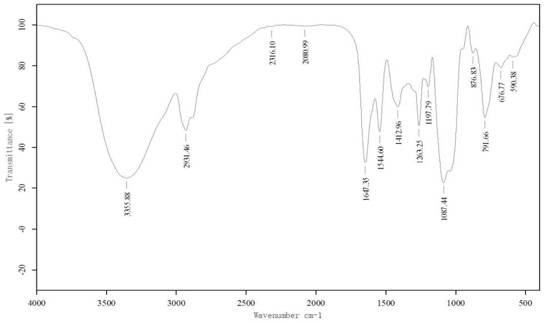

Image

Examples

Embodiment 1

[0033] S1. Preparation of aminopolysiloxane

[0034] Add 8.0g of aminopropylmethyldimethoxysilane to the reaction flask in the nitrogen atmosphere, 4.23g of silicone oil containing hydroxyl groups with a molecular weight of 400, catalyst potassium hydroxide and diethylene glycol ether are 0.0005g and 0.1g respectively . The reaction was carried out under stirring condition at 80° C. for 3 hours, and silicon-based phosphate was added to neutralize potassium hydroxide. Aminopolysiloxane A1 was prepared. The amino group content of the aminopolysiloxane A1 was 3.9mmol / g, and the viscosity was 300mpa·s.

[0035] S2. Preparation of sugar-modified silicone oil

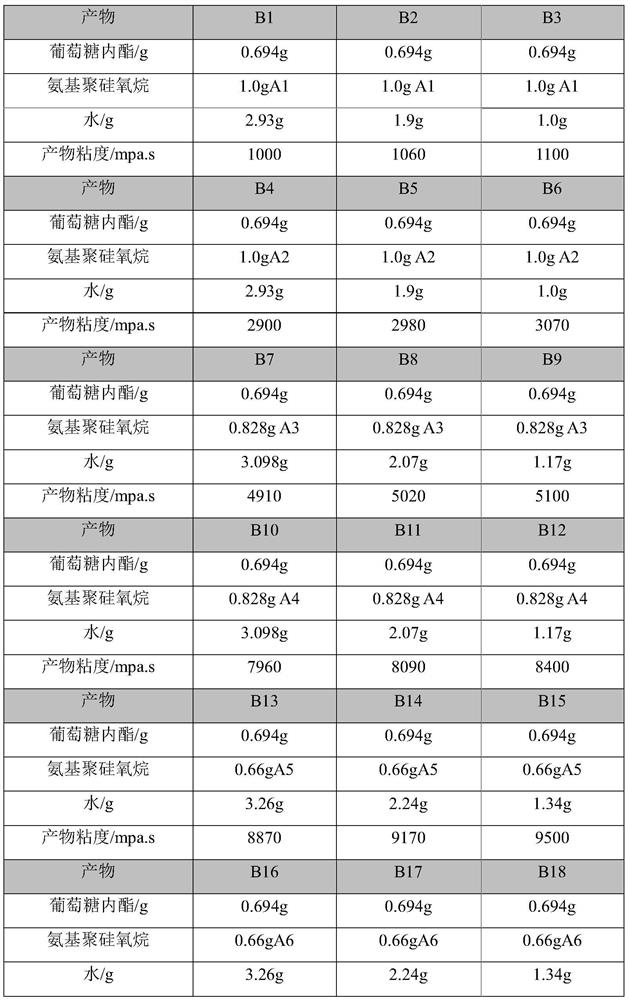

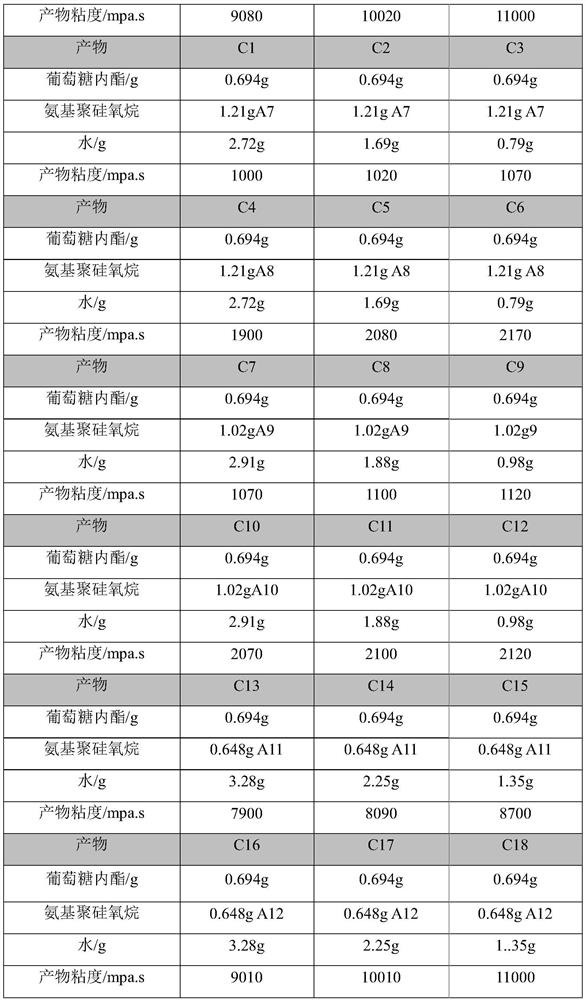

[0036] Add 0.694g of gluconolactone, 1.0g of aminopolysiloxane A1 prepared by S1, and 2.93g of pure water into a reaction flask in a nitrogen atmosphere, and react for 3 hours under stirring at 70°C to obtain the sugar-modified Silicone oil B1, pH is neutral.

[0037] Add 0.694g of gluconolactone, 1.0g of aminopolysiloxan...

Embodiment 2

[0040] S1. Preparation of aminopolysiloxane

[0041] Add 8.0g of aminopropylmethyldimethoxysilane to the reaction flask in the nitrogen atmosphere, 4.23g of silicone oil containing hydroxyl groups with a molecular weight of 400, catalyst potassium hydroxide and diethylene glycol ether are 0.0005g and 0.1g respectively . The reaction was carried out under stirring condition at 80° C. for 5 hours, and silicon-based phosphate was added to neutralize potassium hydroxide. Aminopolysiloxane A2 was prepared, the amino group content of the prepared aminopolysiloxane A2 was 3.9 mmol / g, and the viscosity was 600 mPa·s.

[0042] S2. Preparation of sugar-modified silicone oil

[0043] Add 0.694g of gluconolactone, 1.0g of aminopolysiloxane A2 prepared by S1, and 2.93g of pure water into a reaction flask in a nitrogen atmosphere, and react for 3 hours under stirring at 70°C to obtain the sugar-modified Silicone oil B4, pH is neutral.

[0044]Add 0.694g of gluconolactone, 1.0g of aminop...

Embodiment 3

[0047] S1. Preparation of aminopolysiloxane

[0048] Add 8.0g of aminopropylmethyldimethoxysilane to the reaction flask in the nitrogen atmosphere, 2.23g of silicone oil containing hydroxyl groups with a molecular weight of 400, catalyst potassium hydroxide and diethylene glycol ether are 0.0005g and 0.8g respectively . The reaction was carried out under stirring condition at 80° C. for 3 hours, and silicon-based phosphate was added to neutralize potassium hydroxide. Aminopolysiloxane A3 was prepared, the amino group content of the prepared aminopolysiloxane A3 was 4.7mmol / g, and the viscosity was 3000mpa·s.

[0049] S2. Preparation of sugar-modified silicone oil

[0050] Add 0.694g of gluconolactone, 0.828g of amino polysiloxane A3 prepared by S1, and 3.098g of pure water into a reaction flask in a nitrogen atmosphere, and react for 3 hours under stirring at 70°C to obtain the sugar-modified Silicone oil B7, pH is neutral.

[0051] Add 0.694g of gluconolactone, 0.828g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com