CO conversion treatment device in coke-oven gas and conversion treatment method thereof

A conversion treatment, coke oven gas technology, applied in the direction of steam generation method, removal of gas pollutants, and catalytic treatment of combustible gas, etc., can solve the problem of affecting the output of chemical products, the scale of products cannot be adjusted in time, and the economic level of device operation impact and other issues, to achieve the effect of reducing energy consumption and equipment investment, increasing operational flexibility, and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

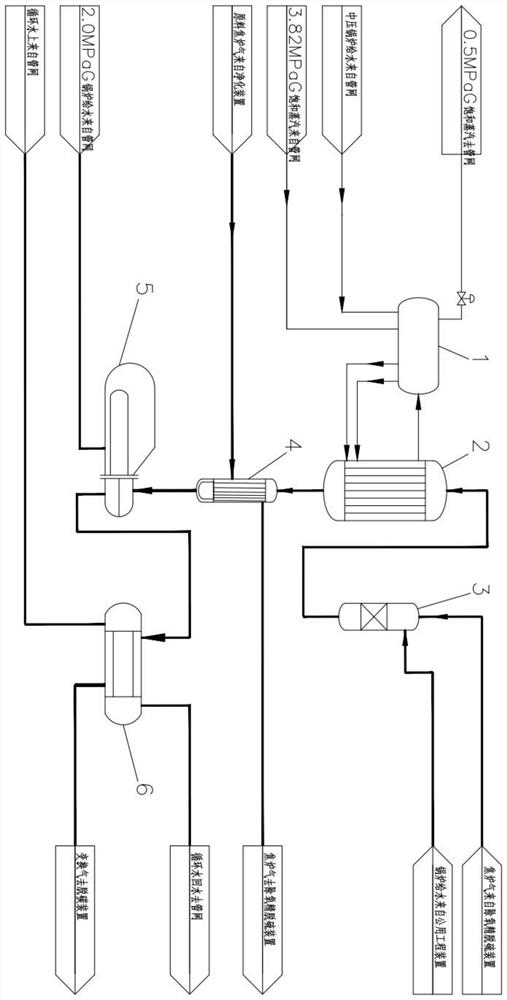

[0032] like figure 1 As shown, a CO conversion treatment device in coke oven gas is installed at the outlet of the desulfurization tank of the coke oven gas deoxygenation fine desulfurization device, including a steam drum 1, an isothermal conversion furnace 2, a cooling humidifier 3, and a heat exchanger for entering and exiting materials 4. 0.5MPa waste pot 5, water cooler 6, the cooling humidifier 3 is used to mix the coke oven gas from the deoxygenation and fine desulfurization unit with the boiler water from the utility installation, the cooling humidifier 3 The outlet is connected to the inlet of the isothermal heat exchange furnace 2, and the first outlet of the isothermal heat exchange furnace 2 is connected to the rising pipe of the steam drum 1, which is used to combine the reaction heat generated in the isothermal heat exchange furnace 2 with the hot water in the tube side The heat exchange is sent to the steam drum 1, the steam drum 1 receives the medium-pressure b...

Embodiment 2

[0034] A method for utilizing the device described in Embodiment 1 to convert and treat CO in coke oven gas, comprising the following steps:

[0035] Step 1, the raw coke oven gas passes through the crude desulfurization device, the benzene and naphthalene removal device, and then enters the deoxygenation and fine desulfurization device after being heated by the incoming and outgoing material heat exchanger 4;

[0036] Step 2, the coke oven gas from the deoxygenation fine desulfurization unit and the boiler water sent by the public works unit enter the cooling humidifier 3, and its coke oven gas volume (raw gas) is 100000Nm 3 / h, the raw material gas pressure is 3.2MPaG, the raw material gas temperature is 275°C, the main component of the raw material gas is CO: volume concentration 7%, total sulfur: 0.1ppm, O 2: 10ppm, the flow rate of its boiler water is 3.5t / h, the coke oven gas is mixed with the boiler water in the cooling humidifier 3 to obtain 190°C cooling and saturated...

Embodiment 3

[0042] A method for utilizing the device described in Embodiment 1 to convert and treat CO in coke oven gas, comprising the following steps:

[0043] Step 1, the raw coke oven gas passes through the crude desulfurization device, the benzene and naphthalene removal device, and then enters the deoxygenation and fine desulfurization device after being heated by the incoming and outgoing material heat exchanger 4;

[0044] Step 2, the coke oven gas from the deoxygenation fine desulfurization unit and the boiler water sent by the public works unit enter the cooling humidifier 3, and its coke oven gas volume (raw gas) is 100000Nm 3 / h, the raw material gas pressure is 3.3MPaG, the raw material gas temperature is 285°C, the main component of the raw material gas is CO: volume concentration 7%, total sulfur: 0.1ppm, O 2 : 10ppm, the flow rate of its boiler water is 4t / h, the coke oven gas is mixed with the boiler water in the cooling humidifier 3, and the coke oven gas of 200 ℃ coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com