Multipurpose, multifunctional complex cleaning and washing agent

A technology for cleaning degreasers and auxiliaries, which is applied in the directions of cleaning methods using liquids, detergent compounding agents, detergent compositions, etc., and can solve problems such as poor removal of grease and pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

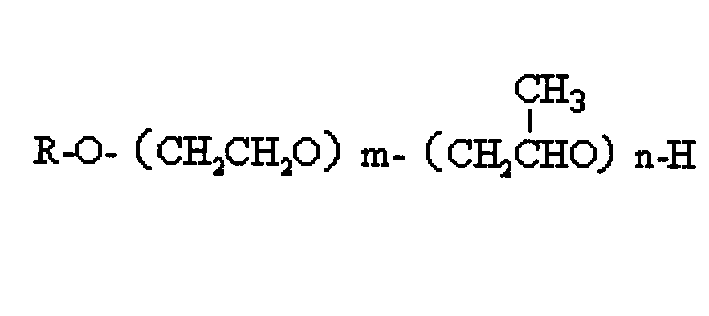

Method used

Image

Examples

Embodiment

[0049] 2) Manufacture of board

[0050] The sheets used in the present invention are steel sheets, zinc-coated steel sheets, alloy zinc-coated steel sheets, tin-coated steel sheets, zinc, nickel, titanium, aluminum, and aluminum alloys. The plates were cut to a size of 1.5 x 8 cm and the cut surface was rubbed. After immersing the rubbed board in 3% sodium hydroxide solution for one minute, use pure water to remove the alkaline solution on the rubbed board, and clean it with a first-class ordinary alcohol. After drying the cleaned board in an oven at 120 °C for 60 minutes, the cleaned board was cooled to room temperature and dried in a vacuum desiccator under vacuum.

[0051] 3) Sample plate

[0052] After weighing, the boards were stored in a vacuum desiccator and stretched depending on the type of board. Use a roller coater to evenly spray synthetic oil, such as rolling oil, anti-rust oil, etc., and silicone oil on the board (1-2g / m 2 ), heat the plate in an oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com