Anti-fouling textile finishing method

A textile and anti-pollution technology, applied in the field of textiles, achieves the effects of high photodegradation efficiency, good water and oil repellency, and improved self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

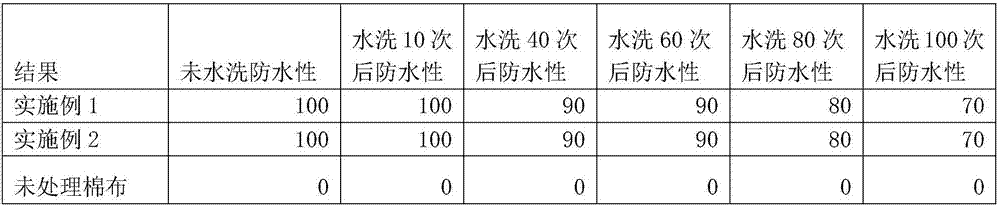

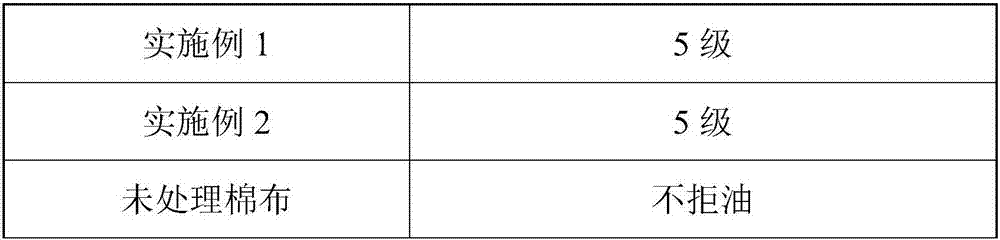

Examples

Embodiment 1

[0027] A method for finishing anti-pollution textiles, comprising the following steps:

[0028] 1) Corona treatment is performed on the cotton cloth: it is carried out under the condition of a mixed gas with a volume ratio of oxygen and nitrogen of 2:8, and the treatment is carried out under the condition of 6kV for 6s.

[0029] 2) Add 1 mol of butyl titanate, 0.4 mol of oxalic acid and 3 mol of sodium dihydrogen phosphate into a mixed solvent composed of 3L of ethanol and 18L of water, seal and heat at 160°C for 36 hours, cool to room temperature, and put the cotton cloth treated in step 1) Immerse in it, adopt the process of two immersion and two dehydration, each immersion for 10 minutes; each dehydration control liquid retention rate is 80%, and dry at 60°C for 3 hours;

[0030] 3) Mix FG-410 water-repellent and oil-repellent treatment agent with water at a concentration of 30g / L. Immerse the cotton cloth treated in step 2) into it, and adopt a two-immersion and two-dehydr...

Embodiment 2

[0032] A method for finishing anti-pollution textiles, comprising the following steps:

[0033] 1) Corona treatment is performed on the cotton cloth: it is carried out under the condition of a mixed gas with a volume ratio of oxygen and nitrogen of 2:8, and the treatment is carried out under the condition of 8kV for 6s.

[0034] 2) Add 1 mol of butyl titanate, 0.3 mol of oxalic acid and 2 mol of sodium dihydrogen phosphate into a mixed solvent composed of 2L of ethanol and 14L of water, seal and heat at 140°C for 30 hours, cool to room temperature, and put the cotton cloth treated in step 1) Immerse in it, adopt the process of two immersion and two dehydration, each immersion for 12 minutes; each dehydration control liquid retention rate is 100%, and dry at 60°C for 3 hours;

[0035] 3) FG-410 water-repellent and oil-repellent treatment agent is mixed with water, the concentration is 40g / L, and the cotton cloth treated in step 2) is immersed in it, and the process of two immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com