Method for preparing fine-grain low silica/alumina ratio X zeolite

A technology of zeolite and grain size, which is applied in the field of preparation of small-grain X zeolite, can solve the problems that are not conducive to improving the adsorption efficiency and reducing the effective cage structure, so as to reduce the subsequent processing steps, reduce the synthesis cost, and simplify the operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

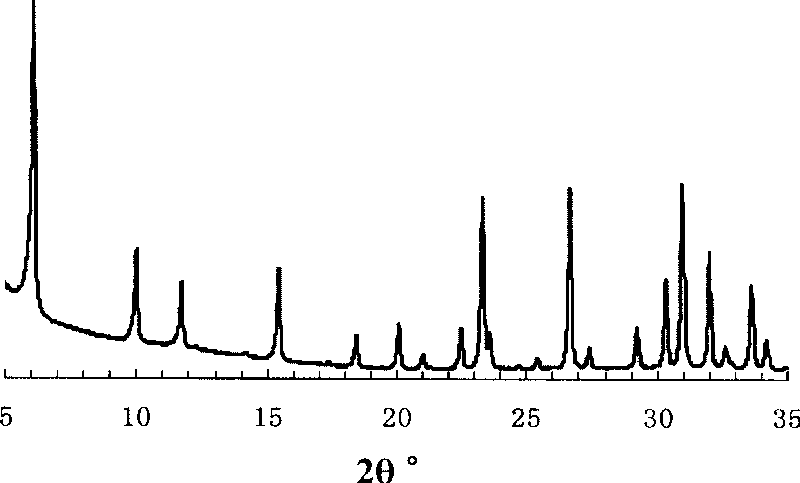

Image

Examples

example 1

[0031] Small crystal X zeolites are prepared according to the process of the present invention.

[0032] (1) Preparation of directing agent

[0033] Add 10.3 grams of sodium metaaluminate solution (which contains Al 2 o 3 17.3% by mass, Na 2 (21.0 mass%), 55.9 gram deionized water and 13.3 gram sodium hydroxide, stir to make solid alkali dissolve completely, then add 55.3 gram sodium silicate solution (wherein contain SiO 2 28.3% by mass, Na 2 (08.8% by mass), stirred until uniformly mixed, 25 ℃ static aging 20 hours made the directing agent, and its molar composition was 16Na 2 O: Al 2 o 3 : 14.93SiO2 2 :318H 2 O.

[0034] (2) Preparation of X zeolite

[0035] At 25°C, add 214.2 grams of sodium silicate solution, 526 grams of deionized water, 42 grams of sodium hydroxide and 210 milliliters of sulfuric acid solution with a concentration of 2.5 mol / liter into a 2-liter stainless steel synthesis kettle, stir to make it fully mixed, and Add 213.2 grams of sodium metaa...

example 2

[0037] In the synthesis kettle, add 214.2 grams of sodium silicate solution, 715.4 grams of deionized water, 30 grams of sodium hydroxide and 33 grams of anhydrous sodium sulfate at 25 ° C, stir to dissolve them fully and mix them evenly, then add 206 grams of gram of sodium metaaluminate solution, then add the directing agent prepared by 24 gram examples 1, continue to stir until mixing evenly, the molar composition of the mixture that obtains is 4.7Na 2 O: Al 2 o 3 : 3.0 SiO 2 : 0.65SO 4 2- : 157.9H 2 O, and then heated to 98 ° C, static crystallization for 2 hours. The product was washed with water until the pH value of the washing solution was less than 10, filtered, and dried at 80°C for 12 hours to obtain the X zeolite product. The property data are shown in Table 1.

example 3

[0039] Get 102 grams of aluminum sulfate octadecahydrate and add it to 407 grams of deionized water, and stir until completely dissolved to make an aluminum sulfate solution. Add 214.2 grams of sodium silicate solution, 323 grams of deionized water and 62 grams of sodium hydroxide in the synthesis kettle, mix well, add 115 grams of sodium metaaluminate solution and the above-mentioned aluminum sulfate solution successively under stirring, and then add 24 grams of For the directing agent prepared in Example 1, continue stirring at 25°C until it is evenly mixed, and the molar composition of the obtained mixture is 4.32Na 2 O: Al 2 o 3 : 3.0 SiO 2 : 1.3SO 4 2- : 161H 2 O, and then heated up to 102°C for static crystallization for 2 hours. The product was washed with water until the pH value of the washing solution was less than 10, filtered, and dried at 80°C for 12 hours to obtain the X zeolite product. The property data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com