Synthesis process of composite piperazine heavy metal chelating agent TDDP

A technology of heavy metal chelating agent and synthesis process, which is applied in water/sludge/sewage treatment, organic chemistry, water/sewage treatment, etc. It can solve the problem of no segmental control of reaction temperature, unreasonable ratio of raw materials, and inability to carry out the reaction, etc. problem, achieve the effect of shortening the reaction time, increasing the temperature and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

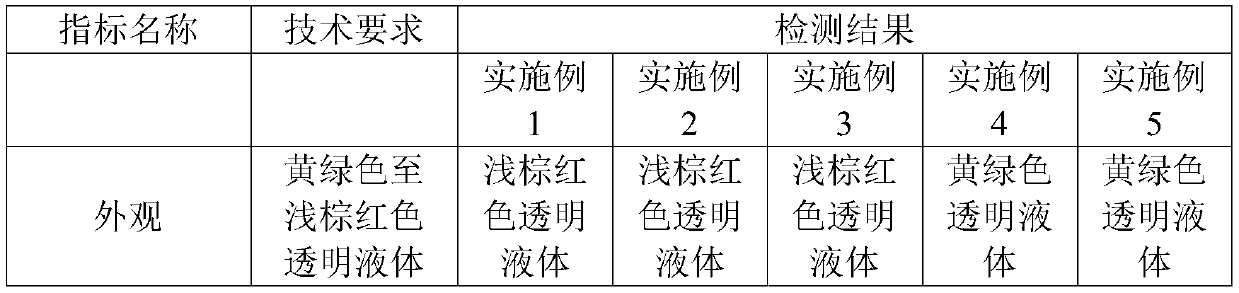

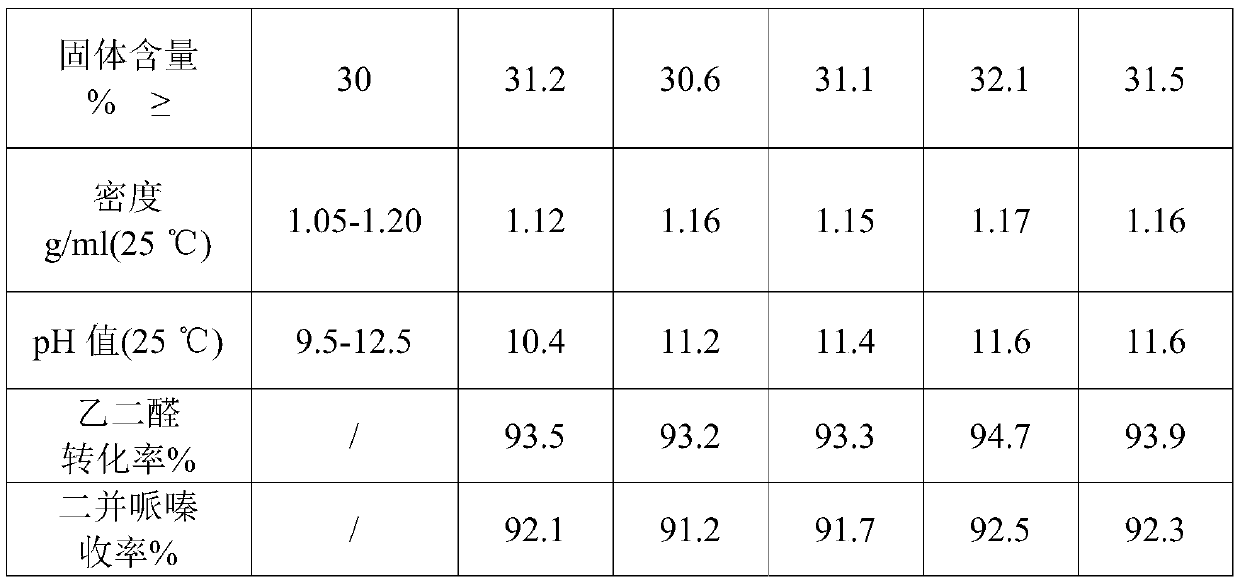

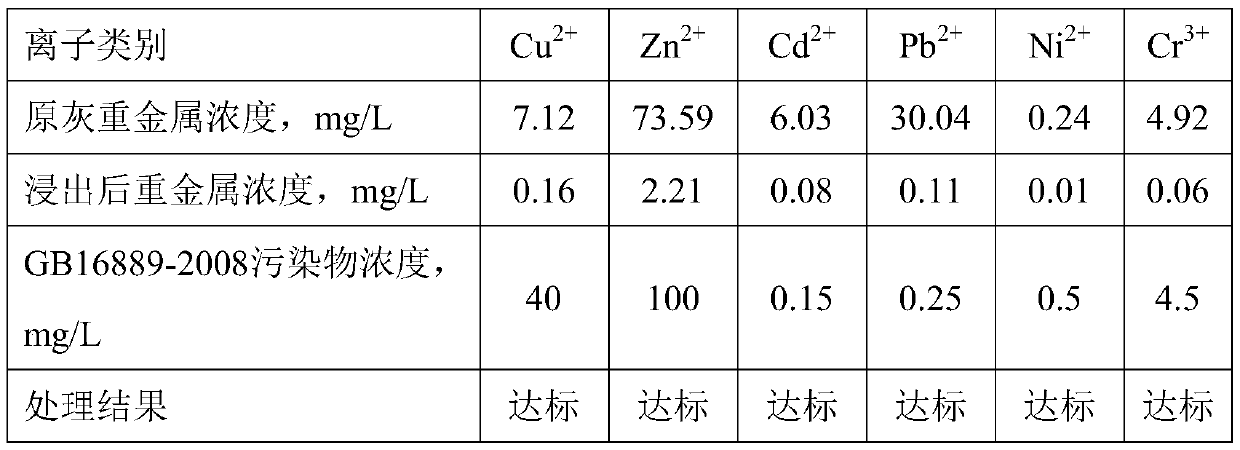

Examples

Embodiment 1

[0070] Embodiment 1: the synthetic technique of compound type piperazine heavy metal chelating agent TDDP

[0071] 1. Raw material preparation: measure 525 kg of ethylenediamine and suck it into the first reaction kettle with vacuum, add 150 g of tetrahydroquinoline, start stirring, and the stirring speed is 83 rpm;

[0072] Measure 315 kg of 40% glyoxal aqueous solution and pump it into the glyoxal high level tank;

[0073] Measure 2760 kg of NaOH solution with a concentration of 30% and put it into the NaOH intermediate tank;

[0074] Use compressed air to press 1335 kg of carbon disulfide from the storage tank into the middle tank of carbon disulfide (the height of the water in the middle tank must be guaranteed not to be lower than 15mm), and press it into the high level tank of carbon disulfide from the middle tank in two times, and press about 700 kg for the first time , the rest is pressed into the carbon disulfide high-level tank for the second time (it must be ensure...

Embodiment 2

[0079] Embodiment 2: the synthetic technique of compound type piperazine heavy metal chelating agent TDDP

[0080] 1. Raw material preparation: measure 536 kg of ethylenediamine and suck it into the first synthesis kettle with vacuum, add 170 g of tetrahydroquinoline, start stirring, and the stirring speed is 83 rpm;

[0081] Measure 320 kg of 40% glyoxal aqueous solution and pump it into the glyoxal high level tank;

[0082] Measure 2850 kg of NaOH solution with a concentration of 30% and put it into the middle tank;

[0083] Use compressed air to press 1355 kg of carbon disulfide from the storage tank into the middle tank of carbon disulfide (the height of the water in the middle tank must not be lower than 15mm), and press it into the high level tank of carbon disulfide from the middle tank in two times, and press about 700 kg for the first time , the rest is pressed into the carbon disulfide high-level tank for the second time (it must be ensured that the height of the wa...

Embodiment 3

[0088] Embodiment 3: the synthetic technique of compound type piperazine heavy metal chelating agent TDDP

[0089] 1. Raw material preparation: measure 538 kg of ethylenediamine, suck it into the first synthesis kettle with vacuum, add 180 g of tetrahydroquinoline, start stirring, and the stirring speed is 83 rpm;

[0090] Pump 322 kg of 40% glyoxal aqueous solution into the glyoxal high level tank after metering;

[0091] Measure 2980 kg of NaOH solution with a concentration of 30% and put it into the middle tank;

[0092] Use compressed air to press 1365 kg of carbon disulfide from the storage tank into the middle tank of carbon disulfide (the height of the water in the middle tank must be guaranteed not to be lower than 15mm), and press it into the high level tank of carbon disulfide from the middle tank in two times, and press about 750 kg for the first time , the rest is pressed into the carbon disulfide high-level tank for the second time (it must be ensured that the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com