Construction method of interlocking pile for soft soil and soil layer with obstacle

A construction method and obstacle technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of affecting the quality of the project, difficult to implement, economic loss, etc., to ensure the quality of the pile, save time and cost, and expand the application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

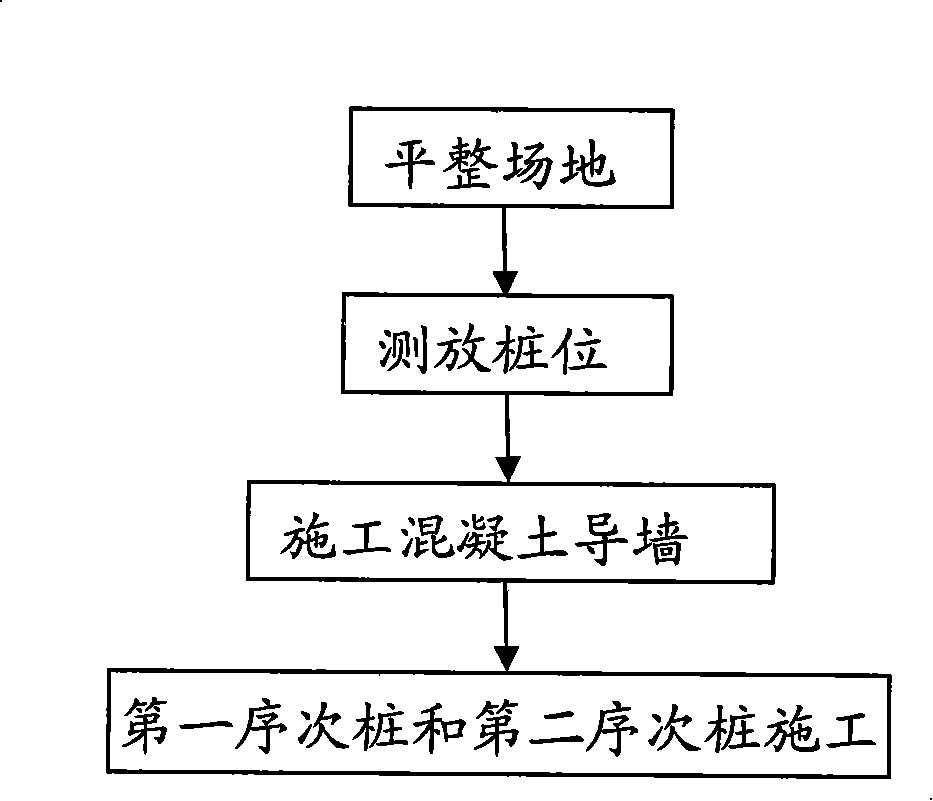

[0032] Below in conjunction with accompanying drawing, the present invention is described clearly and completely:

[0033] Such as figure 1 Shown: A construction method for occlusal piles suitable for soft soil and soil layers with obstacles, including the following steps:

[0034] 1) Leveling the site: ensure that the base site of the rotary drilling rig should be leveled and compacted.

[0035] 2) Pile position measurement: it is convenient for subsequent pile-forming mechanical work.

[0036] 3) Constructing the concrete guide wall: The construction of the concrete guide wall should meet three requirements: first, it can provide a working platform for the pile-forming machinery and withstand the huge force of the pile-forming machinery when pressing, pulling, and twisting the casing; It can play the role of positioning and guiding the casing; the third is that the installation of the concrete guide wall can meet the measurement requirements and have sufficient friction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com