Injection device and method for uniformly lubricating roll gap of rolling mill

A technology of spraying device and spraying method, which is applied in the direction of rolling, metal rolling, metal rolling, etc., and can solve the problems of easy dripping and splashing of emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

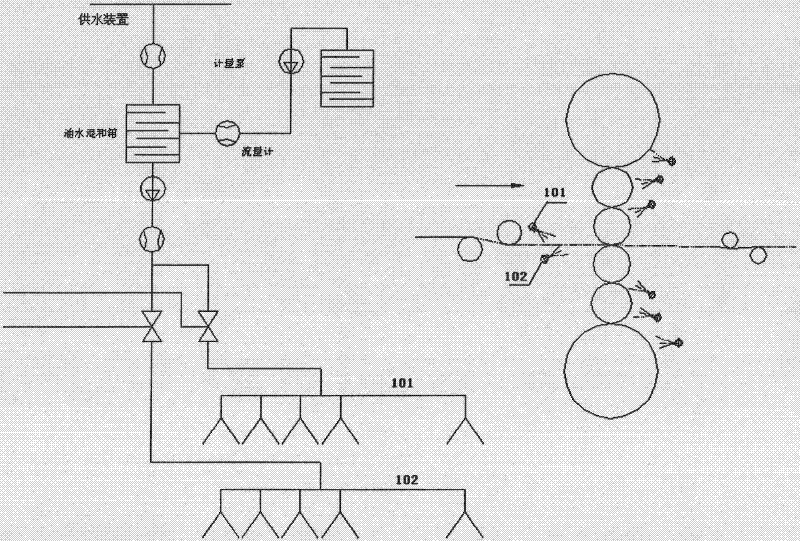

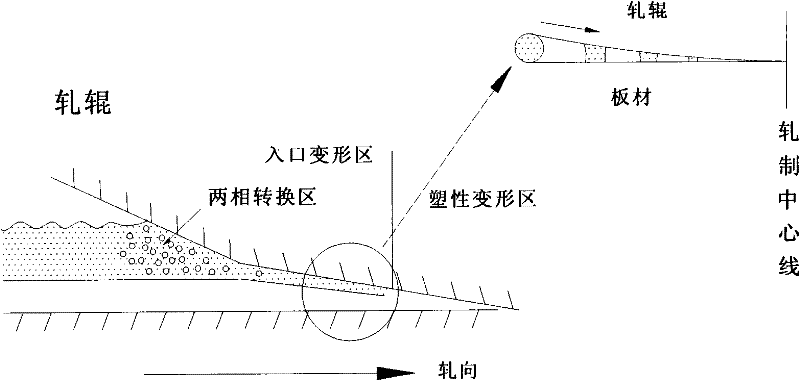

[0052] Such as Figure 4 As shown, the second spray device 103 is arranged on the lower surface of the steel strip 104, and this part of the emulsion is directly sprayed on the surface of the rotating work roll through the spray rack 103, and this part of the emulsion is brought to the surface by the rotation of the work roll. The emulsion that enters the lower roll gap and the spray frame 102 directly sprays on the surface of the steel strip merges to form a certain lubricating oil film thickness. In this way, the problem that the emulsion flow rate of the lower spray frame 102 is too small, the oil film thickness is too small, and the emulsion flow rate is too large, which is easy to drip and splash, is solved.

[0053] The injection method of injection device of the present invention is specifically:

[0054] In the first step, the equipment is transformed, and the second spray rack 103 is arranged on the lower surface of the steel strip, and the spray rack 103 sprays the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com