Spheroidizing method

A technology of spheroidizing treatment and spheroidizing agent, which is applied in the field of spheroidizing treatment of the flushing-in-bag method, can solve the problems of low absorption rate of effective elements and violent reaction, and achieves the solution of molten iron splashing, production cost reduction, loss prevention and other problems. escape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

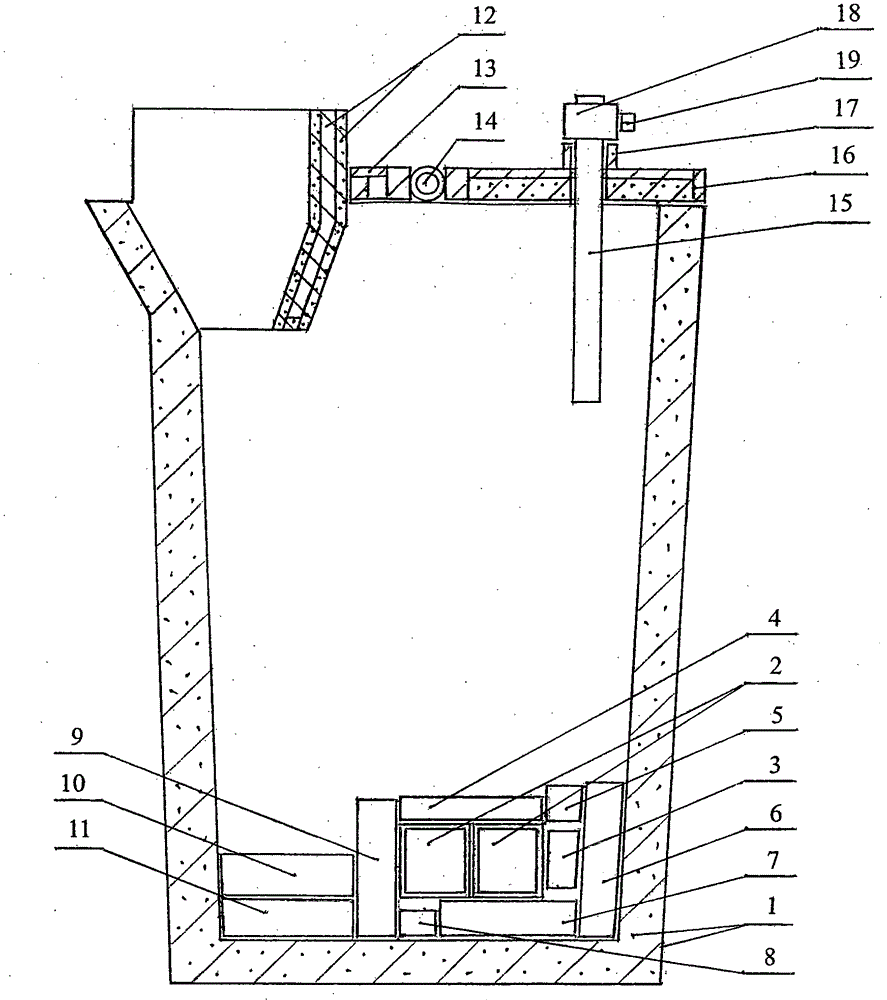

[0031] Embodiment 1: Carry out under cold air cupola smelting conditions, melting rate is 2 tons / hour, adopts attached figure 1 The overall rare earth magnesium silicon ferrosilicon nodulizer 2 with the outer lined square steel pipe is stably fixed on the bottom of the molten iron ladle by wedge-shaped plugs for nodulization treatment. The weight of molten iron per ladle is 1000kg, and the red hot ladle is used for continuous operation. , the temperature of the molten iron in the tap trough is 1485°C, and the sulfur content of the original molten iron is 0.063%, excluding the overall rare earth magnesium ferrosilicon nodularizer containing Mg15%, RE2% and Si58% for the outer lining square steel pipe, and its input includes the outer lining The overall weight of rare earth magnesium silicon iron nodulizer 2 of the square steel pipe accounts for 1.15% of the weight of the molten iron to be processed, and 0.4% is added to the 72SiFe inoculant bag, so that ferrite and perlite are n...

Embodiment 2

[0032] Embodiment 2: Carry out under the smelting condition of intermediate frequency electric furnace, adopt the attached figure 1 The overall rare earth magnesium silicon ferrosilicon nodulizer 2 with the outer lined square steel pipe is stably fixed on the bottom of the molten iron ladle by a wedge-shaped plug to carry out the nodularization treatment. The weight of molten iron per ladle is 1000kg, and the temperature of the molten iron from the electric furnace is 1568 ℃, the sulfur content of the original molten iron is 0.025%, excluding the overall rare earth magnesium ferrosilicon nodulizers containing Mg12.5%, RE1% and Si58% for the outer lining of the square steel pipe, and its input includes the overall rare earth magnesium of the outer lining of the square steel pipe The weight of ferrosilicon nodulizer 2 accounts for 0.75% of the weight of the molten iron to be processed, and 0.35% is added to the 72SiFe inoculant bag. After the spheroidization reaction is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com