Organic metal film preparation enhancing ultraviolet response of silicon based image device

An imaging device and organometallic technology, which is applied in the field of vacuum evaporation preparation of organometallic complex Alq3 powder as coating material, can solve the problems of attenuation and aging of organic frequency conversion films, and achieve the goal of overcoming attenuation and aging with time and improving ultraviolet response Ability, Enhanced Sensitivity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for preparing an organometallic thin film that enhances the ultraviolet response of silicon-based imaging devices. First, the selected organometallic complex Alq 3 The powder is used as the coating material, the baking time is 6-12 hours, preferably 8 hours, and the temperature is 300°C.

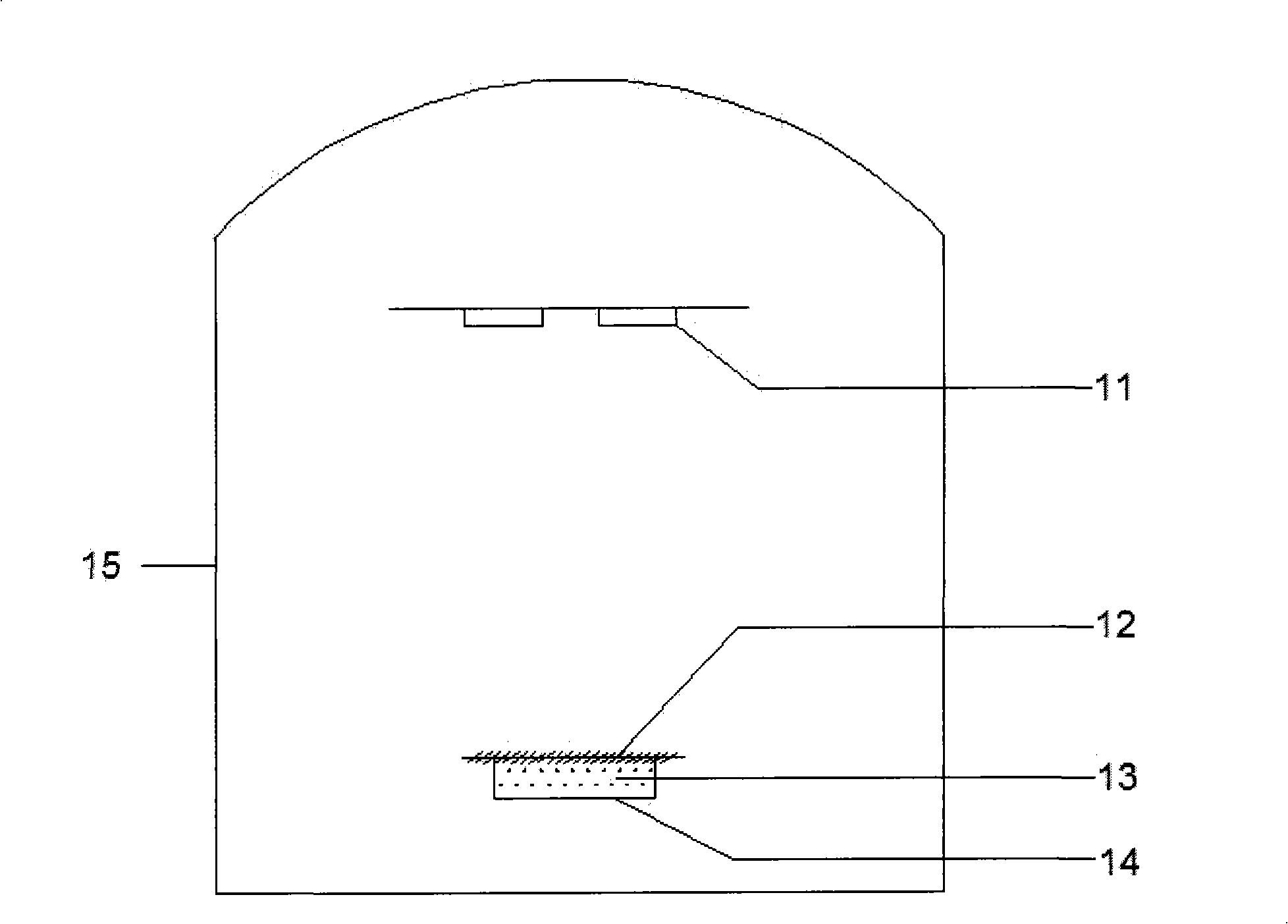

[0016] The vacuum coating device used in the present invention is as figure 1 shown. The prebaked Alq 3 The coating material 13 is placed on the evaporation boat 14 connected with the evaporation electrode, and the processed photosensitive element 11 is placed on the substrate frame. Evacuate the high vacuum chamber, vacuum degree: 2×10 -3 Pa; after the pressure in the bell jar 15 reaches the required value, the evaporation boat 14 can be heated for evaporation, evaporation current: 20A; baking temperature: 200°C; optical monitoring wavelength: 500nm; film thickness: optical thickness 125nm ; After the evaporation is completed, close the high vacuum valve, deflate the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com