3D printing method for metal material

A 3D printing and metal material technology, applied in the field of metal 3D printing, can solve the problems that affect the forming and tissue performance of metal materials, high equipment prices, and increase costs, so as to improve the effective utilization rate, improve printing efficiency, and reduce equipment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

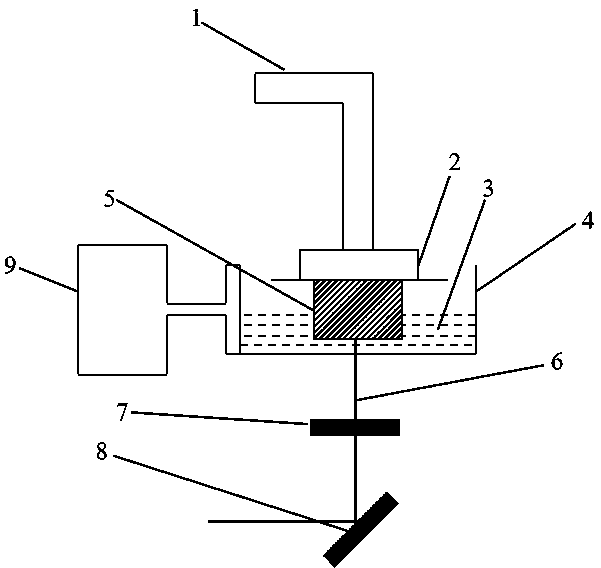

Image

Examples

Embodiment Construction

[0024] 1. In order to make the present invention clearer and easier to understand, the following examples are given for detailed description, and the present invention is not limited to the following examples.

[0025] 2. The present invention relates to a 3D printing method for metal materials, the method comprising the following steps:

[0026] (1) Mix metal powder, organic solvent, binder, dispersant, suspending agent and degasser evenly to prepare a stable and fluid metal powder slurry or suspension, dispersion, complex, colloid, etc. solid-liquid mixture;

[0027] (2) Use 3D software to build a printing model and set laser process parameters;

[0028] (3) Put the prepared metal powder slurry into the storage tank for SLM printing;

[0029] (4) Take out the printed metal product for post-processing.

[0030] 3. Among them, the preparation method of the metal powder slurry is as follows:

[0031] (1) Metal powders are aluminum, cobalt, chromium, iron, nickel, titanium, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com