Efficient manufacturing technology of DTY elasticity enhancement addition agent composite material

A preparation process and composite material technology are applied in the field of high-efficiency preparation technology of DTY texturing aid composite materials, which can solve the problems of uneven oiling, poor smoothness, and no disclosure of the preparation process, so as to improve production efficiency and solve the Environmental pollution problems, beneficial effects of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

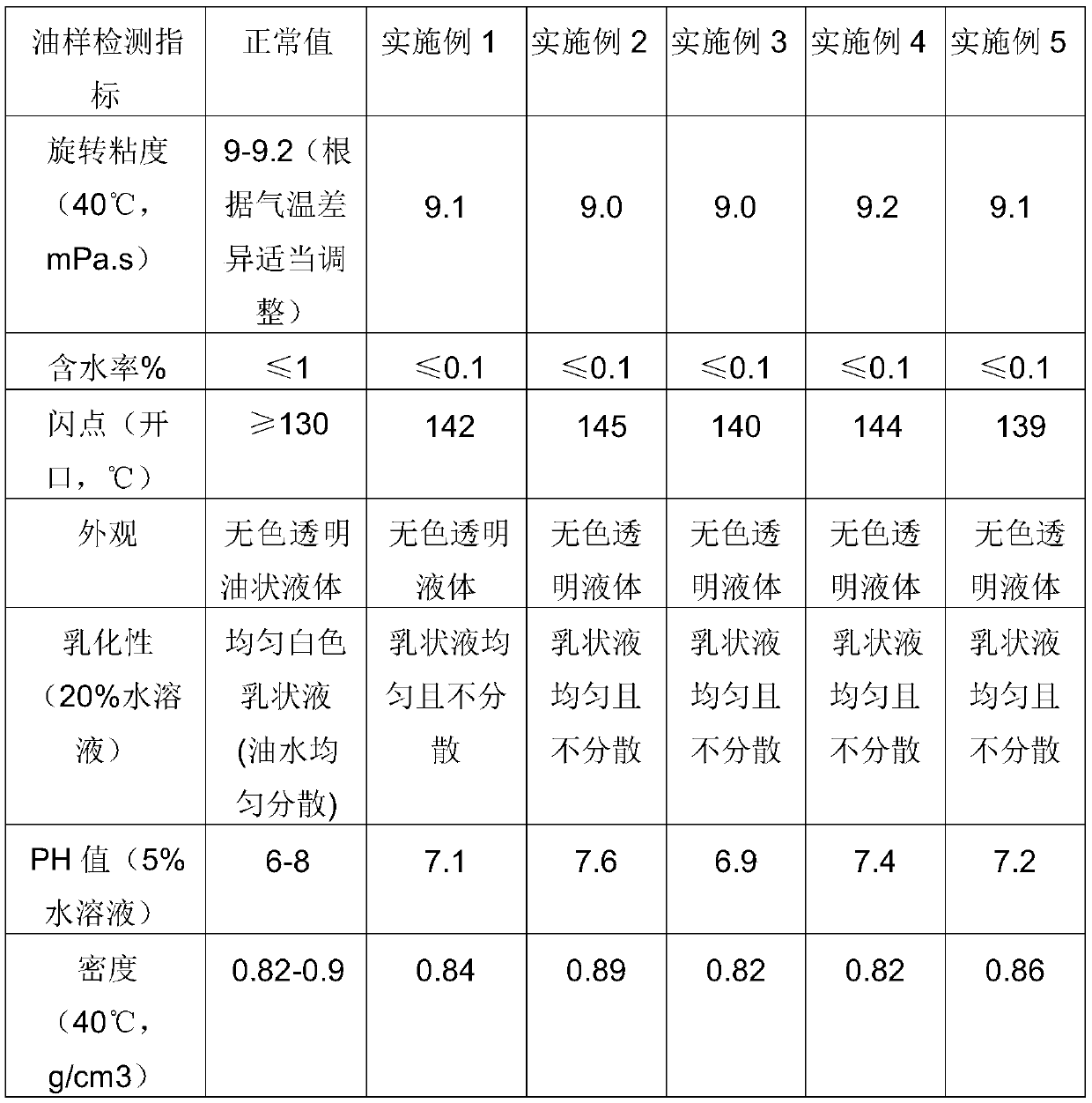

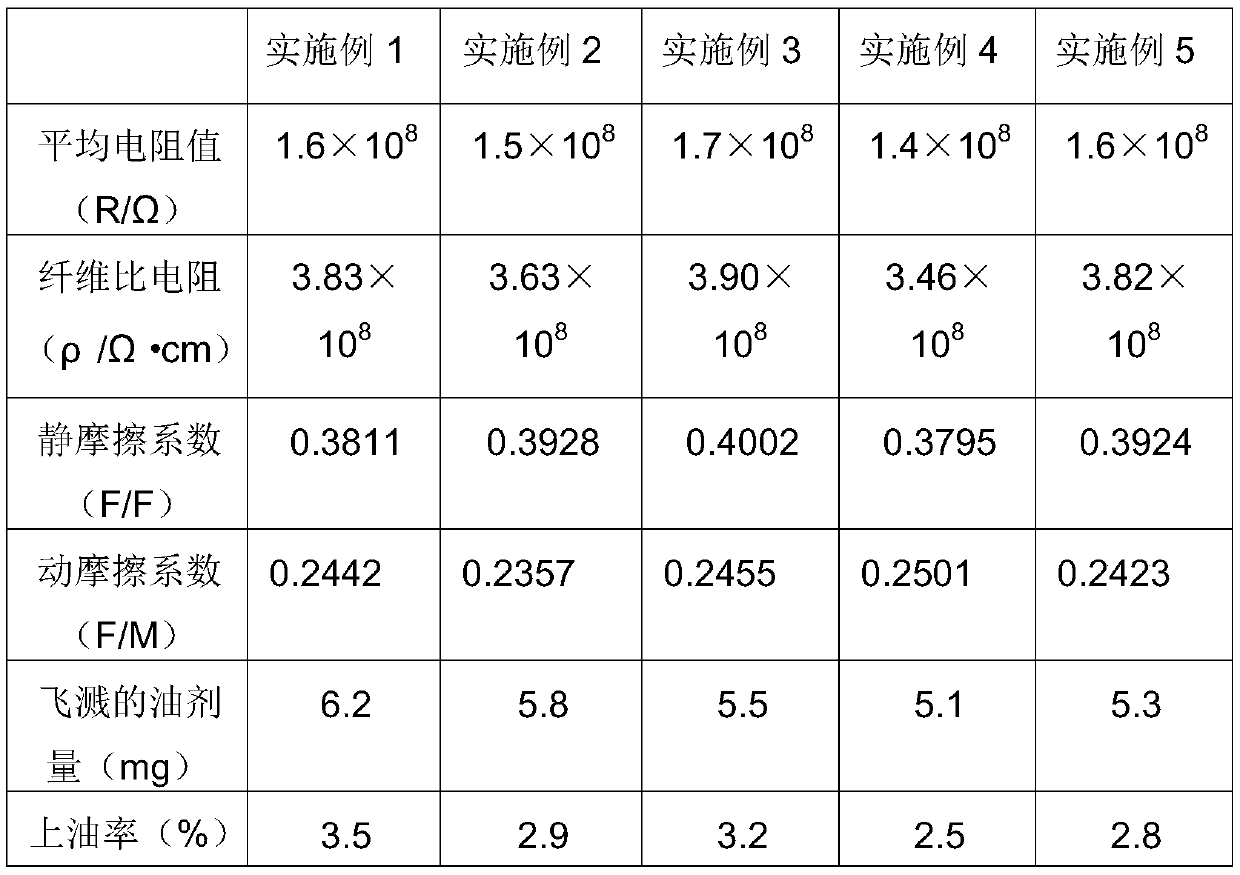

Examples

Embodiment 1

[0026] The preparation of described DTY elastic aid compound comprises the steps:

[0027] (1) add mineral oil A, mineral oil B, allocate in proportion to obtain the mixed mineral oil that viscosity is 20Pa·s, then stir at normal temperature and pressure for 30 minutes; described mineral oil A and mineral oil B are industrial white oil and The viscosity of the mineral oil A and mineral oil B is between 5-46Pa·s;

[0028] (2) Add anti-splash agent, penetrating agent, composite material successively in the mixed mineral oil after above-mentioned stirring, allotment, stir, stir at normal temperature and pressure for 30 minutes, obtain mixed oil agent; The injection ratio of described anti-splash agent is 1.0% of the quality of the mixed mineral oil, the injection ratio of the penetrant is 0.5% of the quality of the mixed mineral oil;

[0029] The anti-splash agent is composed of the following components in parts by mass: 25 parts of ethylene-propylene copolymer, 25 parts of poly...

Embodiment 2

[0036] The preparation of described DTY elastic aid compound comprises the steps:

[0037] (1) add mineral oil A, mineral oil B, allocate in proportion to obtain the mixed mineral oil that viscosity is 20Pa·s, then stir at normal temperature and pressure for 30 minutes; described mineral oil A and mineral oil B are industrial white oil and The viscosity of the mineral oil A and mineral oil B is between 5-46Pa·s;

[0038](2) Add anti-splash agent, penetrating agent, composite material successively in the mixed mineral oil after above-mentioned stirring, allotment, stir, stir at normal temperature and pressure for 30 minutes, obtain mixed oil agent; The injection ratio of described anti-splash agent is 1.5% of the quality of the mixed mineral oil, the input ratio of the penetrant is 0.5% of the quality of the mixed mineral oil;

[0039] The anti-splash agent is composed of the following components in parts by mass: 25 parts of ethylene-propylene copolymer, 20 parts of polyisobu...

Embodiment 3

[0046] The preparation of described DTY elastic aid compound comprises the steps:

[0047] (1) add mineral oil A, mineral oil B, allocate in proportion to obtain the mixed mineral oil that viscosity is 20Pa·s, then stir at normal temperature and pressure for 30 minutes; described mineral oil A and mineral oil B are industrial white oil and The viscosity of the mineral oil A and mineral oil B is between 5-46Pa·s;

[0048] (2) Add anti-splash agent, penetrating agent, composite material successively in the mixed mineral oil after above-mentioned stirring, allotment, stir, stir at normal temperature and pressure for 30 minutes, obtain mixed oil agent; The injection ratio of described anti-splash agent is 1.2% of the quality of the mixed mineral oil, the input ratio of the penetrant is 0.8% of the quality of the mixed mineral oil;

[0049] The anti-splash agent, in parts by mass, consists of the following components: 24 parts of ethylene-propylene copolymer, 22 parts of polyisobu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com