Fibrilia grafting amination modifying process

A technology of hemp fiber and grafted amine, which is applied in the field of textile printing and dyeing auxiliaries, can solve the problems of environmental pollution, inability to degrade and recycle, and negative impact on water quality and soil, etc., to achieve improved softness and hygroscopicity, remarkable dyeing performance, The effect of improving dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of oxidized flax fabric: the preparation mass percentage is 0.4% NaIO 4 Add a certain amount of linen fabric to the aqueous solution, control the bath ratio to 1:30, react at a temperature of 40° C. for 15 minutes, and rinse the linen fabric with water several times.

[0030] Amino-terminated hyperbranched compound grafted flax fabric process: put the oxidized flax fabric in a solution of 1% amino-terminated hyperbranched compound by mass percentage, react at a temperature of 60°C for 5 minutes, take it out, wash it with water, and dry it to obtain a surface-grafted flax fabric. Aminated modified linen fabric.

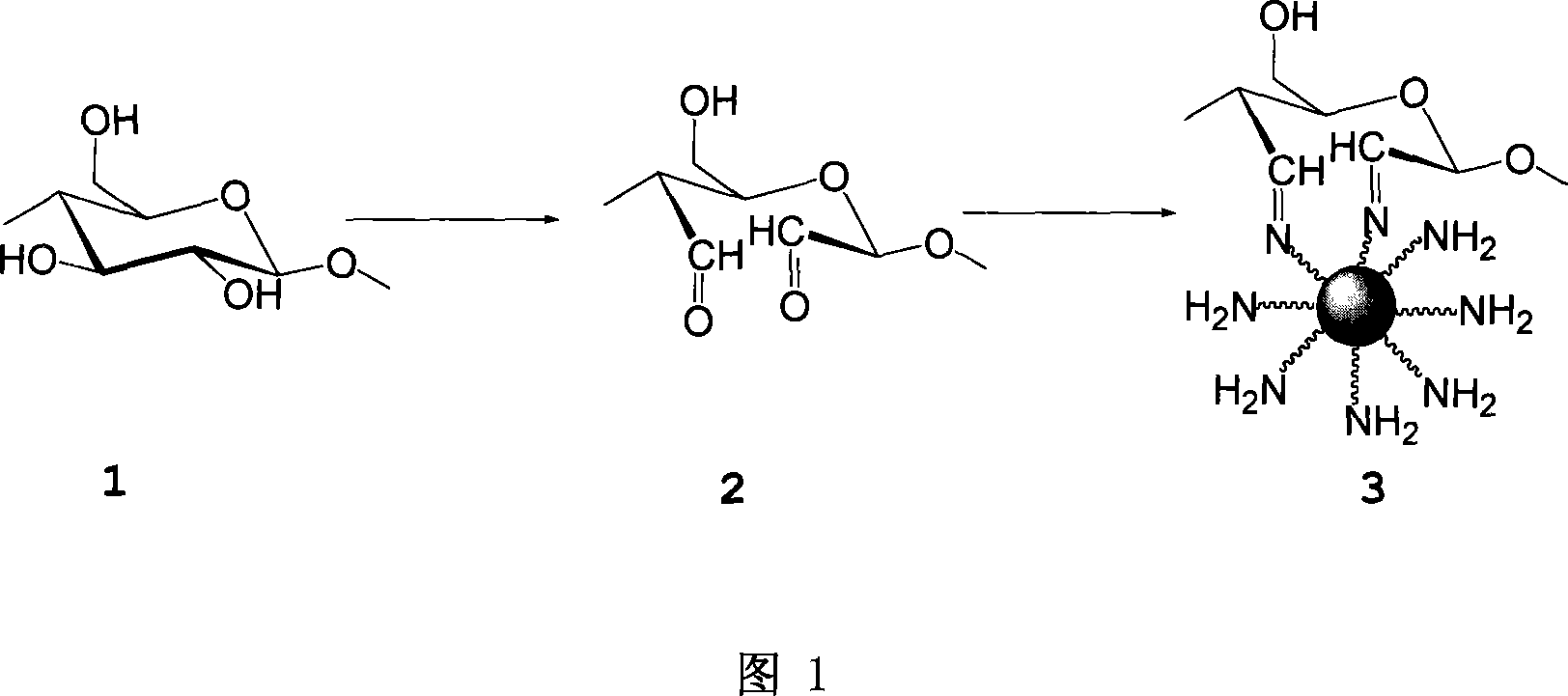

[0031] The principle of the technical solution of the present invention is shown in Figure 1, referring to accompanying drawing 1, hemp fiber 1 can be selectively oxidized under the effect of oxidizing agent such as sodium periodate, and C-2 and C-3 form aldehyde groups, endow oxidation The reactivity of the hemp fiber 2; the oxidized hemp fiber und...

Embodiment 2

[0036] Preparation of oxidized ramie fabric: Prepare a 0.4% aqueous solution by mass, add a certain amount of ramie fabric, control the bath ratio 1:30, take it out after reacting at 40°C for 30 minutes, and rinse the ramie fabric several times with deionized water.

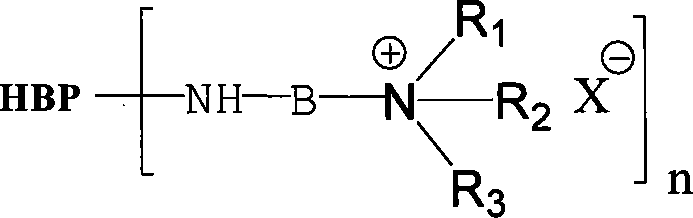

[0037] Preparation of amino-terminated hyperbranched compounds with amino quaternization:

[0038] Place 52ml of polyamino compound divinyltriamine in a 250ml three-necked flask, cool in an ice-water bath, and place in N 2 Under protection, use a constant pressure funnel to slowly add a mixed solution of 43ml methyl acrylate and 100ml methanol dropwise, and react at room temperature for 4 hours after the dropwise addition to obtain light yellow transparent AB 2 type monomer. Then it was transferred to a rotary evaporator eggplant-shaped flask, methanol was removed under reduced pressure, the temperature was raised to 150°C to continue the reduced-pressure reaction for 4 hours, and the reaction was stopped to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com