Watersoluble coating glue containing multiple coating modified poly-ammonium phosphate and uses on textile finishing

A technology of ammonium polyphosphate and water-based coating, which is applied in the fields of fiber treatment, plant fiber, textiles and papermaking, etc., and can solve problems related to the application of water-based flame-retardant coating glue, coatings that are not resistant to long-term blisters and moisture, There are no problems such as chemical or physical forces, and it achieves the effect of hand feeling, twist resistance and flexural resistance, peel strength maintenance, good application value and economic benefits, soft and plump hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 100 grams of melamine-modified Type II APP (product of Changfeng Chemical Co., Ltd., Shifang City, Sichuan, CF-APP202) was added to 250 grams of 95% ethanol, stirred evenly, and 0.75 grams of γ-glycidyl etheroxypropyl trimethyl was added. Oxysilane (KH-560), then add 0.10 g of ammonia water, heat up from room temperature to 78.5°C under uniform stirring, reflux for 1.5 hours, cool down to 70°C, add dropwise 1.2 g of γ-aminopropyltriethoxysilane (KH -550), heated to 78.5°C, refluxed for 1.5 hours, cooled to 70°C, added 2.0 g of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), added 0.10 g of ammonia water, refluxed for 2.5 hours, and then cooled to At 70°C, add 2.5 grams of γ-aminopropyltriethoxysilane (KH-550) dropwise, heat to 80°C, reflux for 3.0 hours, cool down, remove the solvent, dry at 110°C for 0.5 hours, and modify by multiple coatings ammonium polyphosphate.

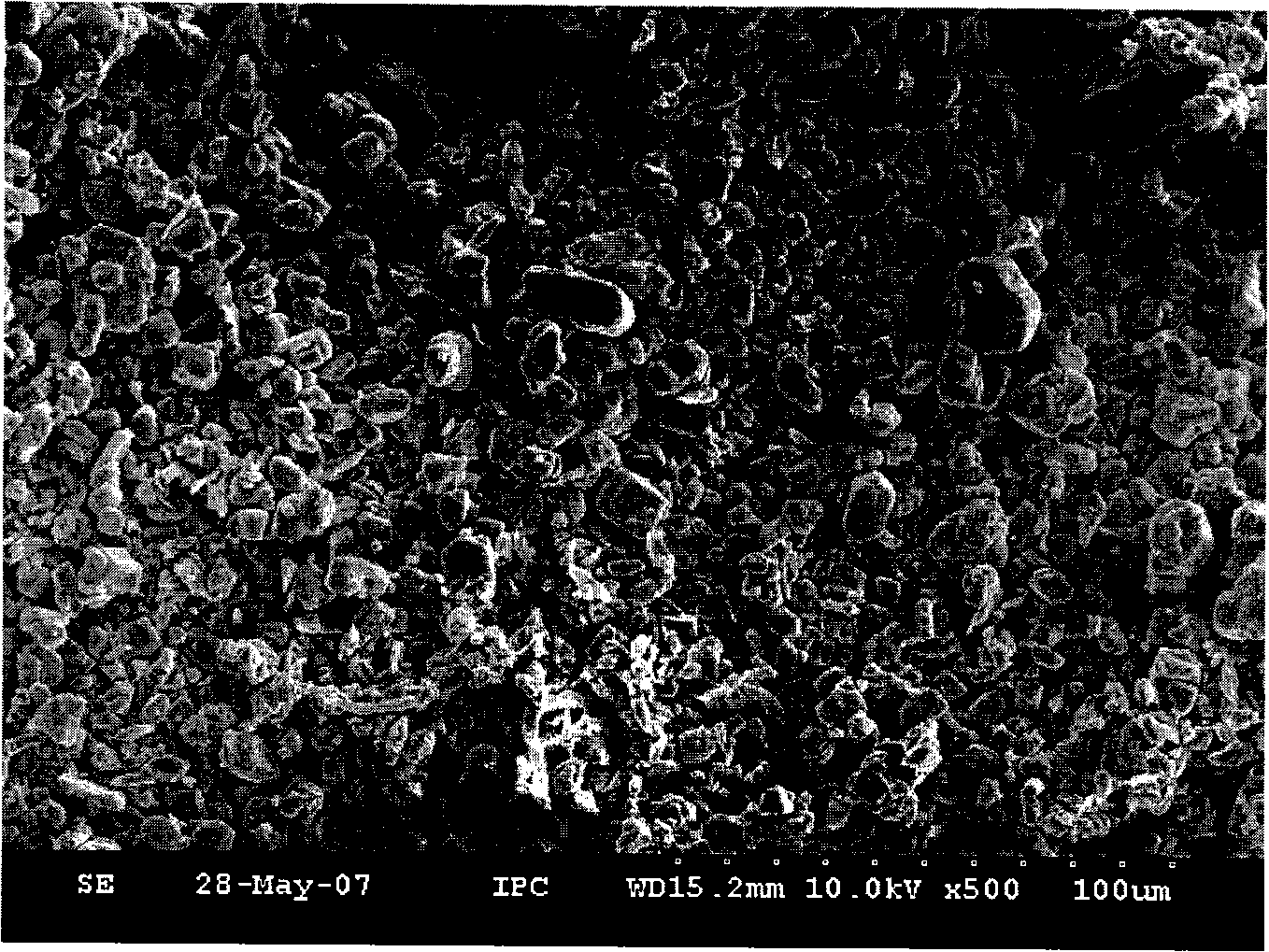

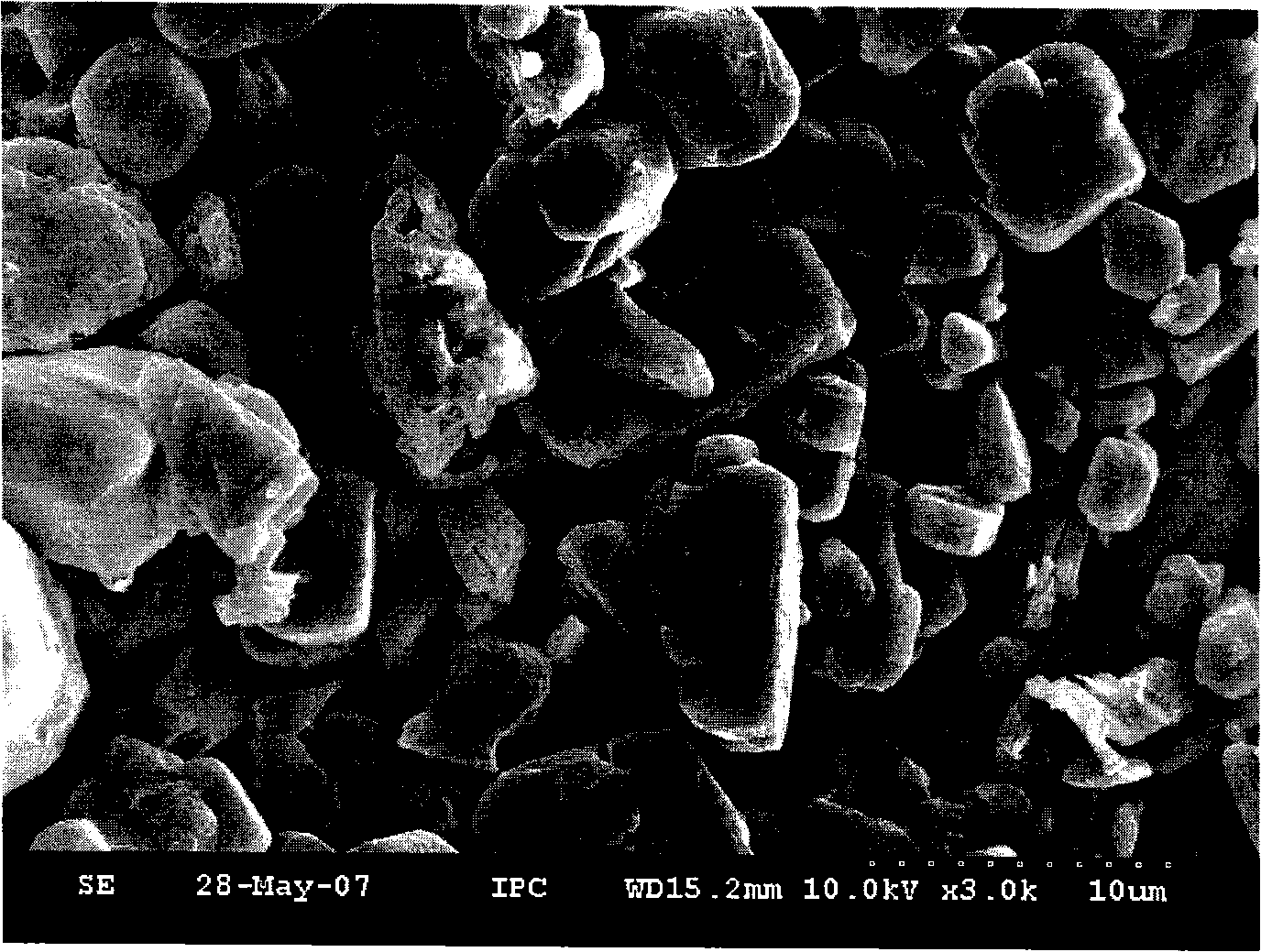

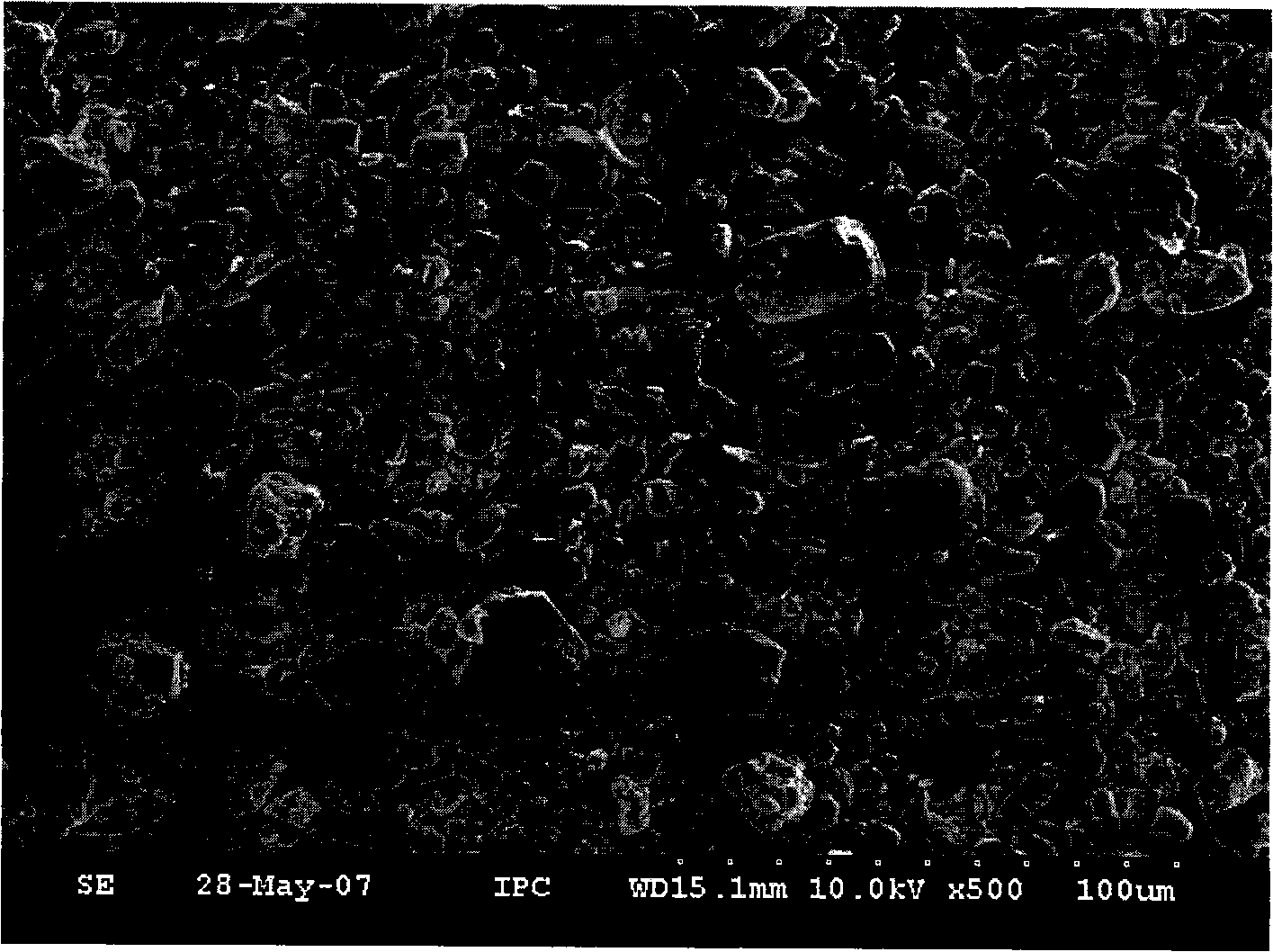

[0028] Figure 1-4 It is the surface morphology of ammonium polyphosphate before and after modi...

Embodiment 2

[0033] 150 grams of melamine-modified Type II APP (product of Changfeng Chemical Co., Ltd., Shifang City, Sichuan, CF-APP202), was added to 300 grams of isopropanol, stirred evenly, and 1.0 grams of γ-glycidyl etheroxypropyl trimethyl Oxysilane (KH-560), 2.0 grams of deionized water, 0.1 grams of ammonia water, heated from room temperature to 82.5°C under uniform stirring, refluxed for 0.5 hours, cooled to 75°C, added dropwise 1.5 grams of γ-aminopropyl triethoxy base silane (KH-550), heated to the boiling point, refluxed for 1.0 hours, cooled to 75°C, added 1.8 grams of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), added 0.10 grams of ammonia water, refluxed at 82.5°C for 1.5 hour, then lower the temperature to 75°C, add dropwise 2.0 g of γ-aminopropyltriethoxysilane (KH-550), heat to 84°C, reflux for 2.5 hours, lower the temperature, remove the solvent, and dry at 110°C for 0.5 hour to obtain Multiple coating modified ammonium polyphosphate products.

[0034] Take by...

Embodiment 3

[0036] 1 50 grams of melamine-modified Type II APP (product of Changfeng Chemical Co., Ltd., Shifang, Sichuan, CF-APP202), was added to 300 grams of isopropanol, stirred evenly, and 1.0 grams of γ-glycidyl etheroxypropyl was added Trimethoxysilane (KH-560), 0.1 g of ammonia water, 2.0 g of deionized water, heated from room temperature to 82.5 °C under uniform stirring, refluxed for 1 hour, cooled to 75 °C, and added dropwise 1.5 g of γ-aminopropyl triethyl Oxysilane (KH-550), heated to the boiling point of alcohol, refluxed for 1 hour, cooled to 75°C, added 1.8 grams of methacryloxypropyltrimethoxysilane (KH-570)) and 0.15 grams of ammonia water, 82.5 Reflux at ℃ for 1.5 hours, then lower the temperature to 75℃, add 2.0 g of γ-aminopropyltriethoxysilane (KH-550) dropwise, heat to 84℃, reflux for 2 hours, lower the temperature, remove the solvent, and dry at 110℃ for 0.5 Hours, multi-coated modified ammonium polyphosphate products.

[0037] Take by weighing 150 grams of multip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com