Patents

Literature

293 results about "PHYSICAL FORCES" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

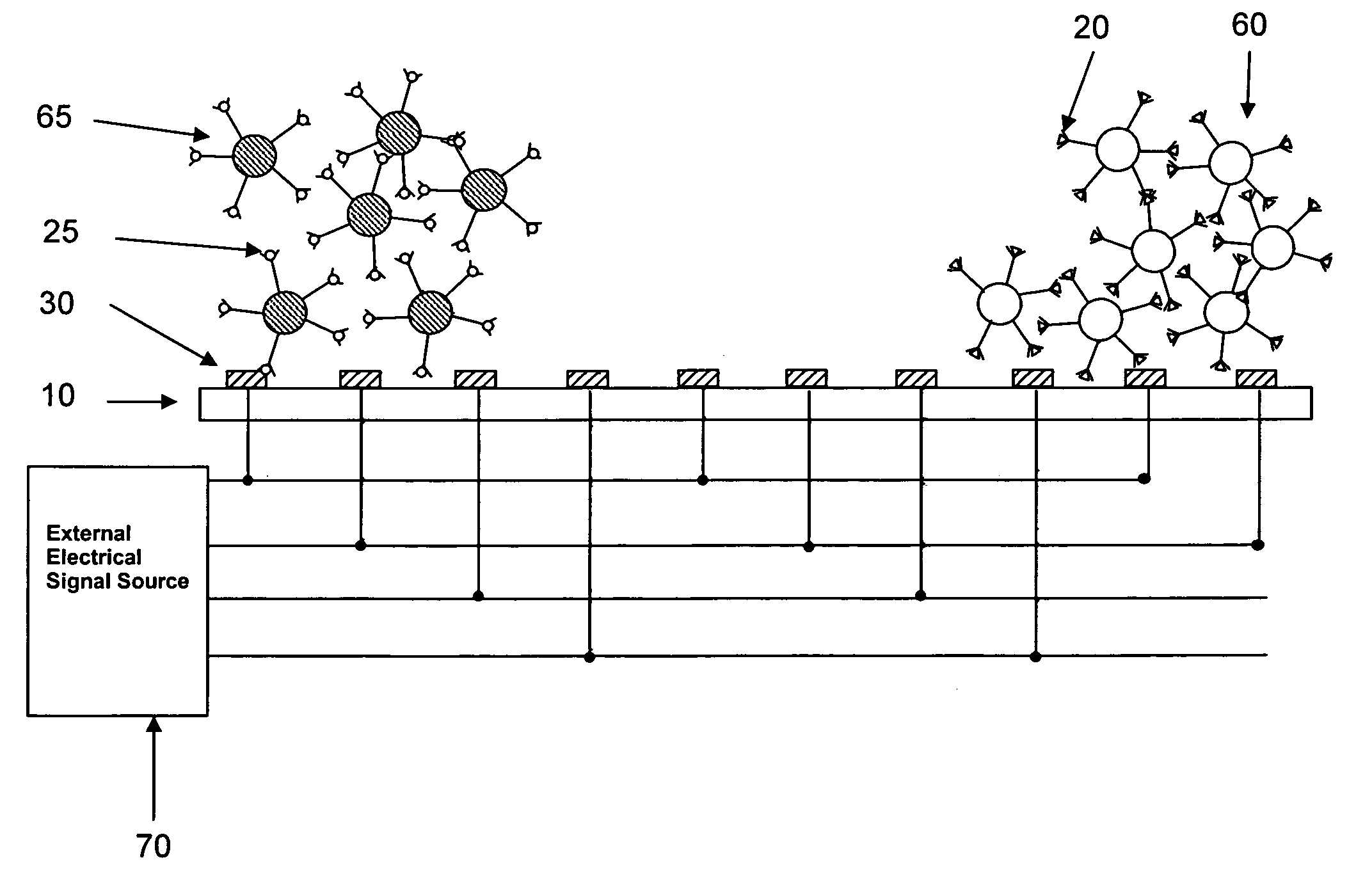

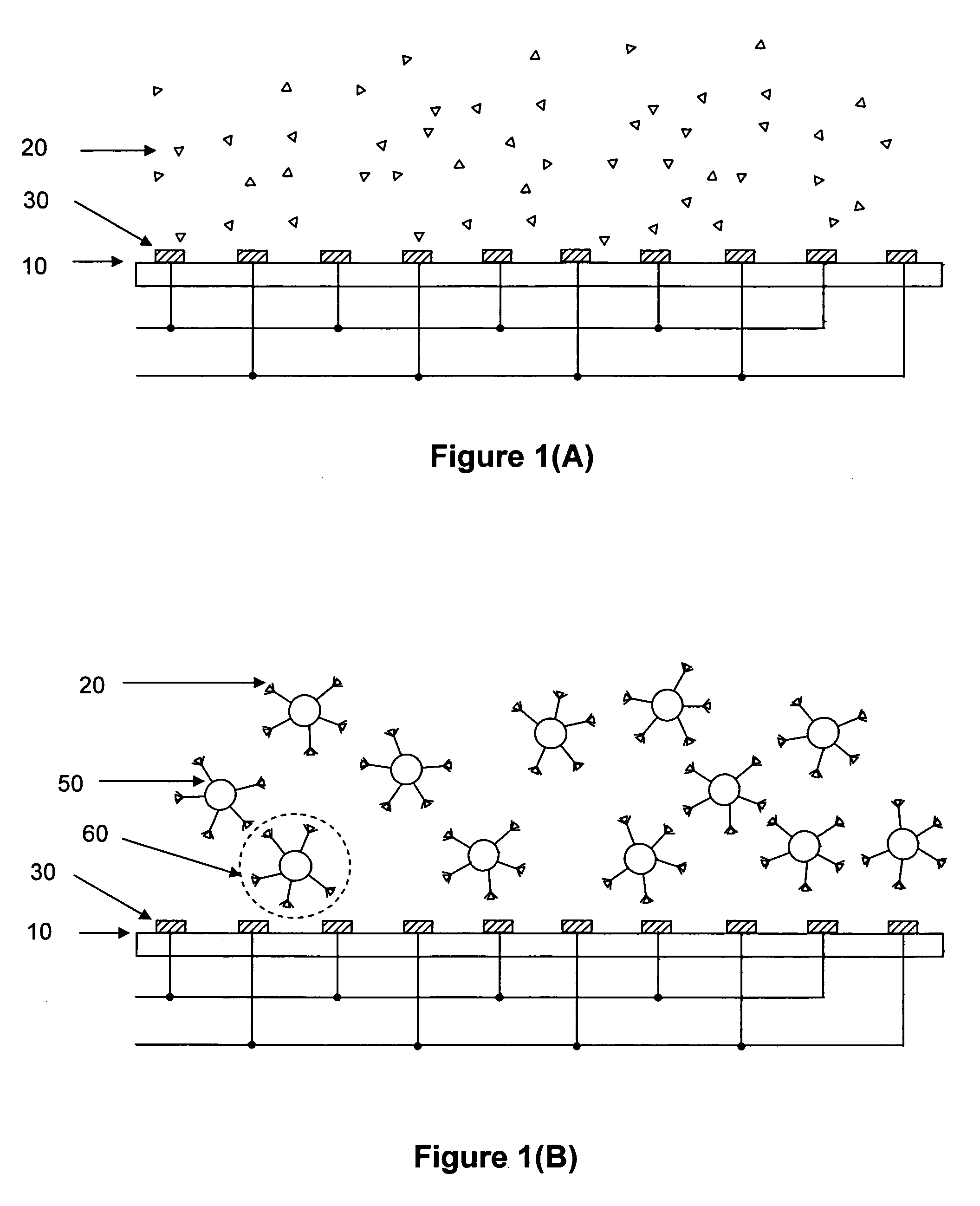

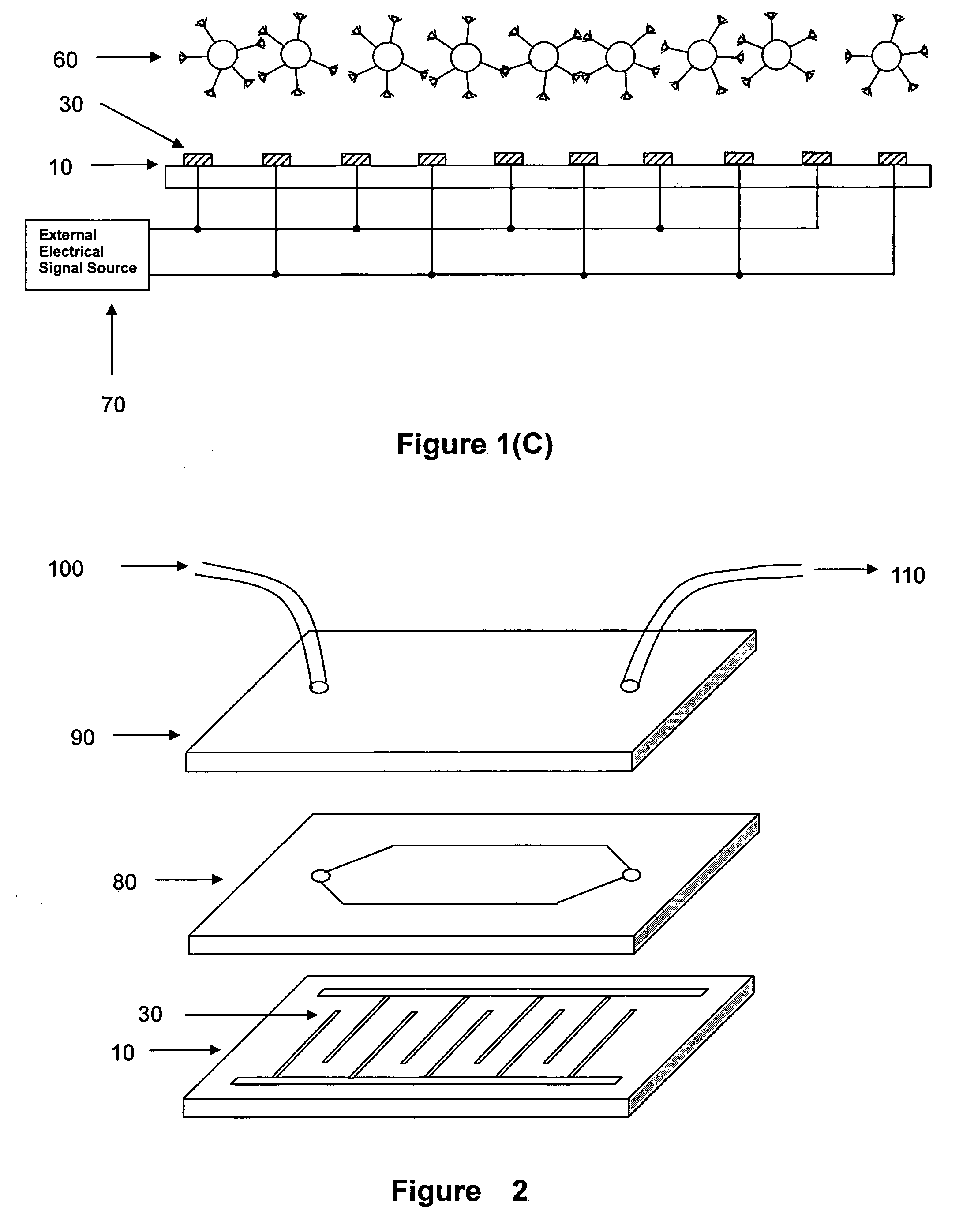

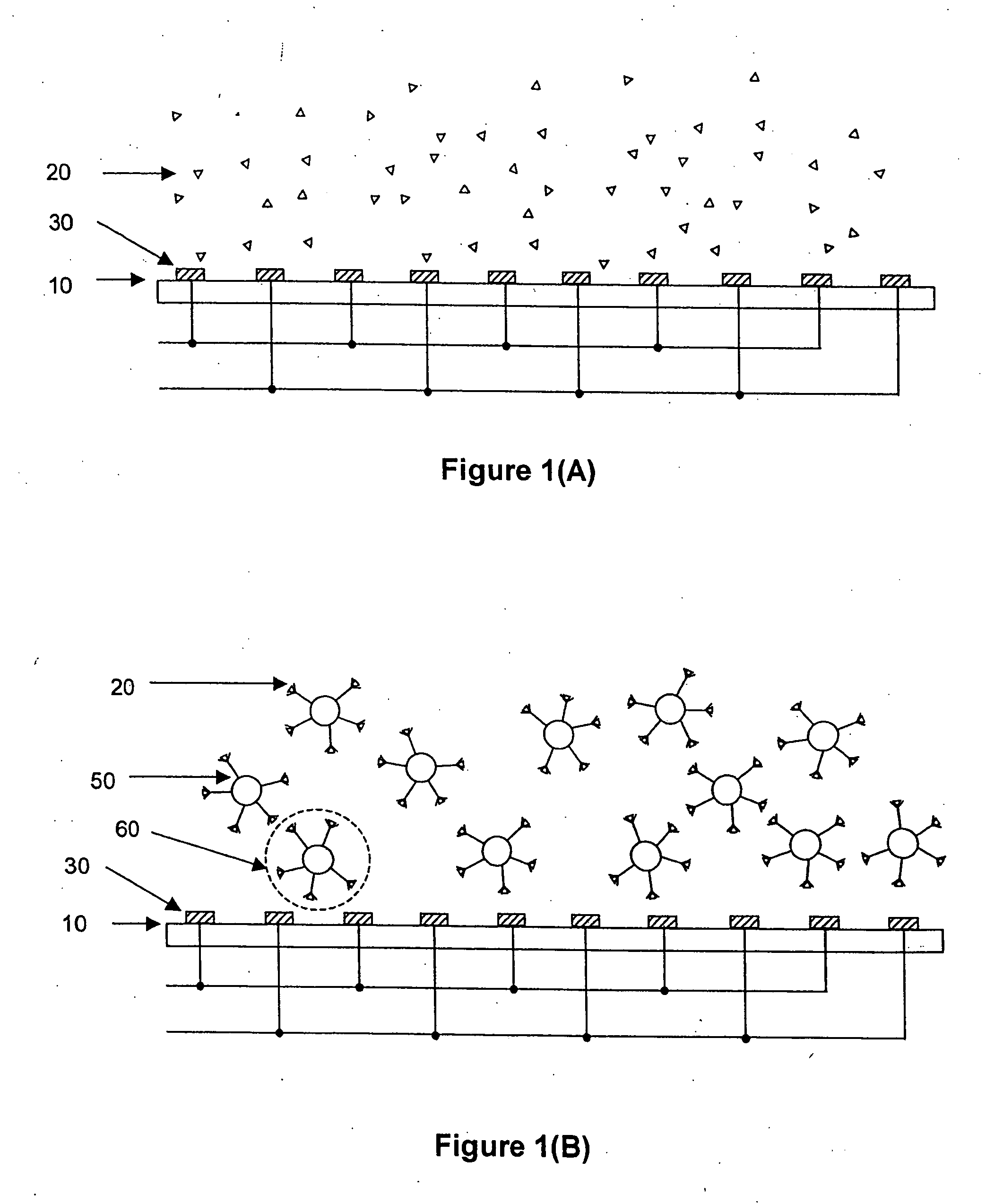

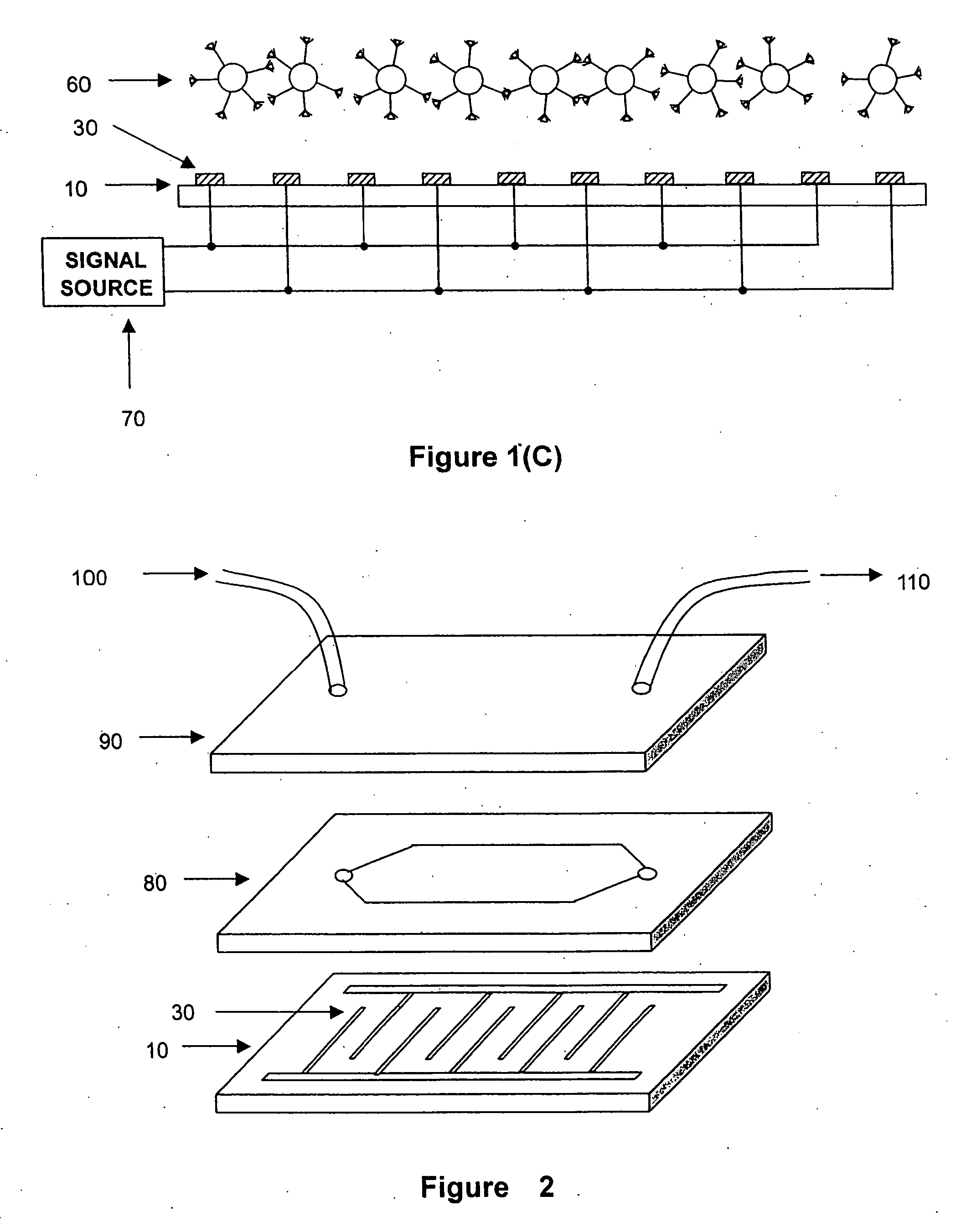

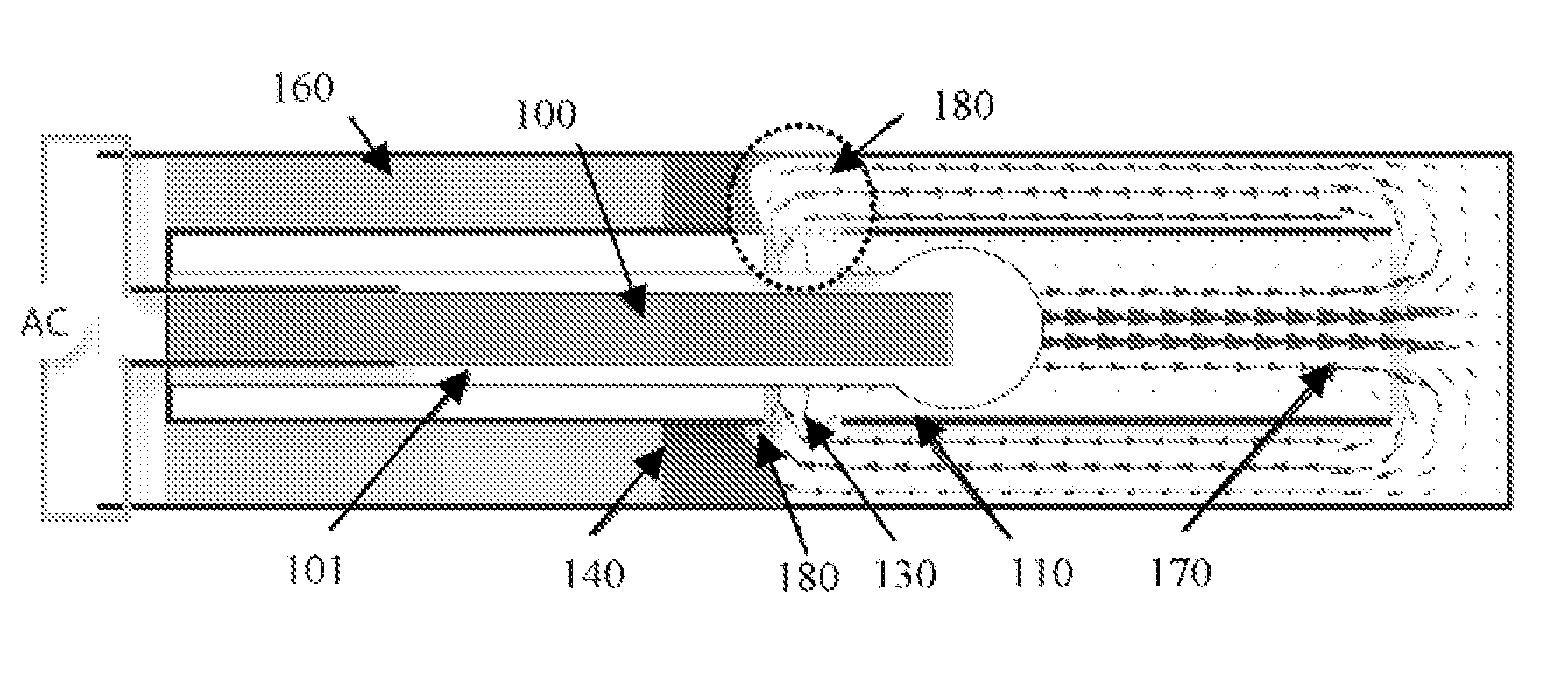

Methods for manipulating moieties in microfluidic systems

InactiveUS7081192B1Simplification and standardization of designExpand and enhance capabilityBioreactor/fermenter combinationsElectrolysis componentsStereochemistryPHYSICAL FORCES

This invention relates generally to the field of moiety or molecule manipulation in a chip format. In particular, the invention provides a method for manipulating a moiety in a microfluidic application, which method comprises: a) coupling a moiety to be manipulated onto surface of a binding partner of said moiety to form a moiety-binding partner complex; and b) manipulating said moiety-binding partner complex with a physical force in a chip format, wherein said manipulation is effected through a combination of a structure that is external to said chip and a structure that is built-in in said chip, thereby said moiety is manipulated.

Owner:AVIVA BIOSCI

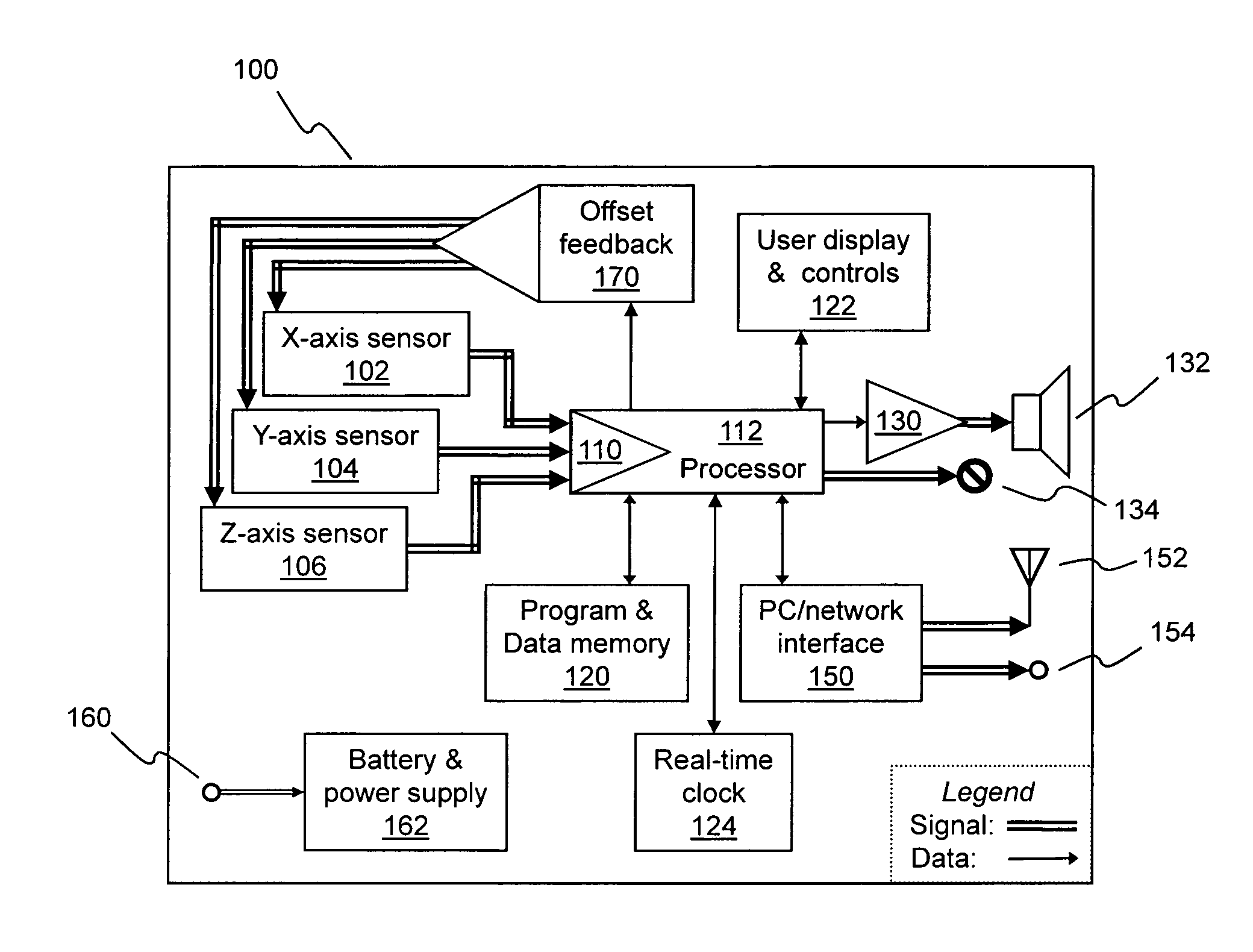

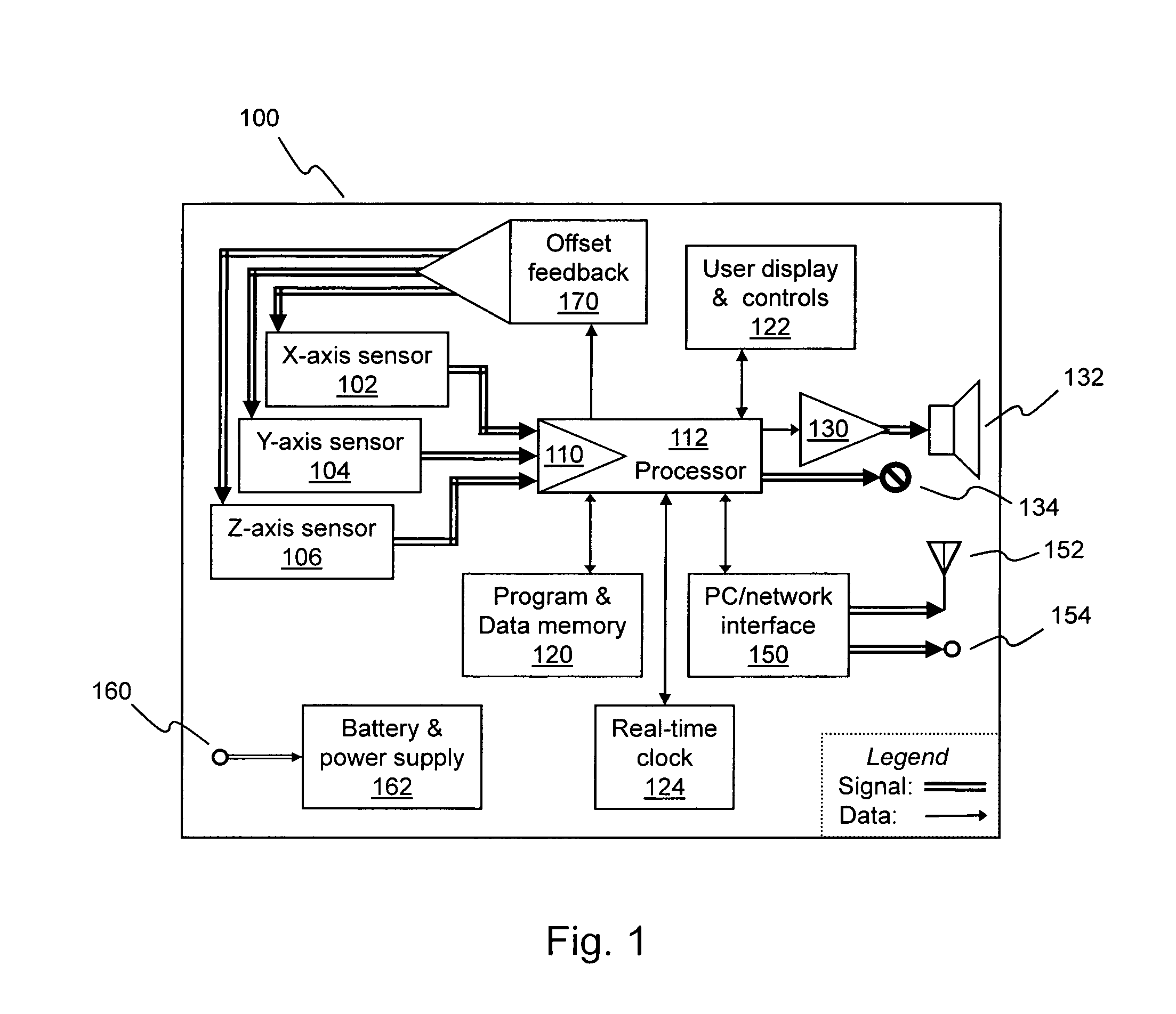

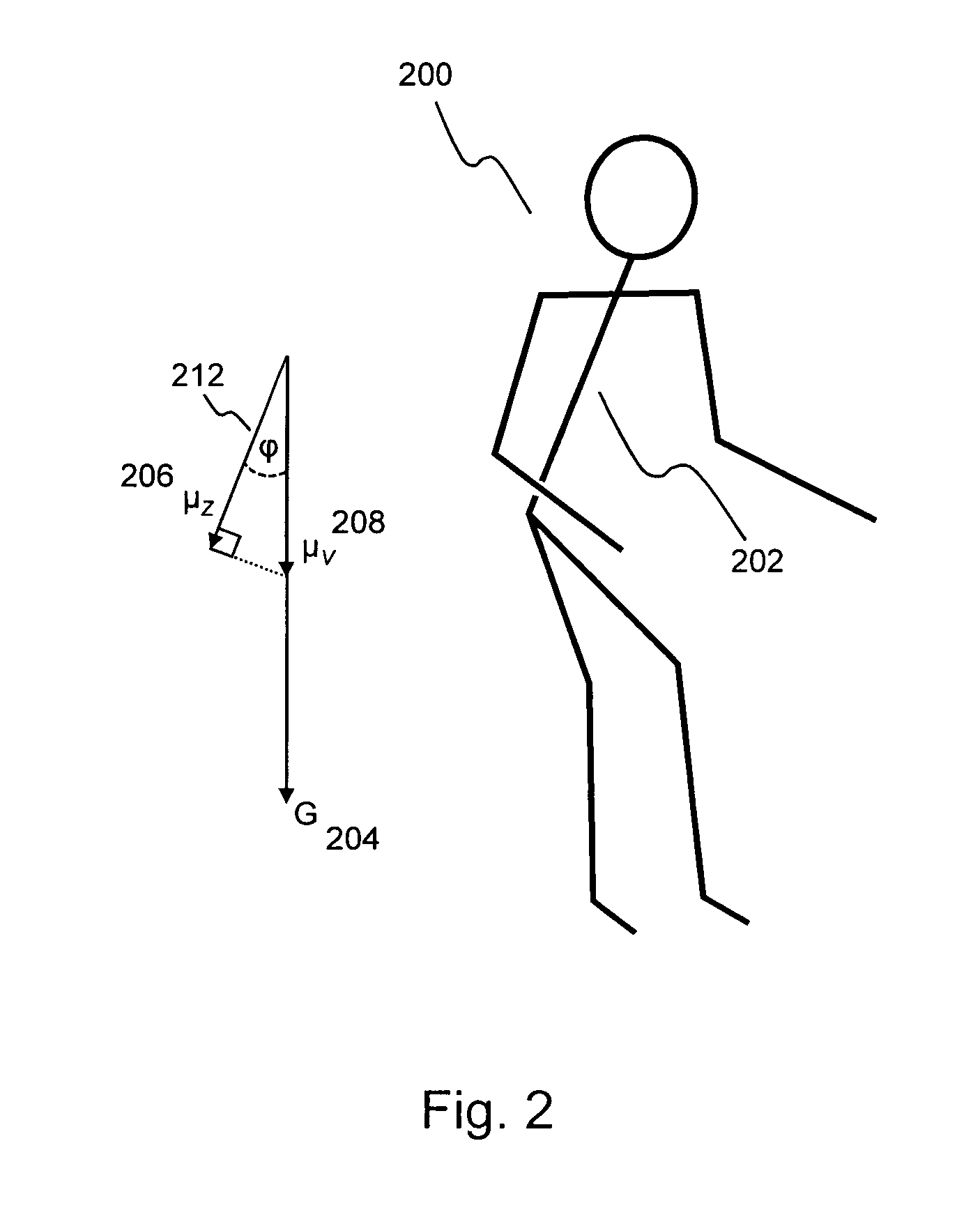

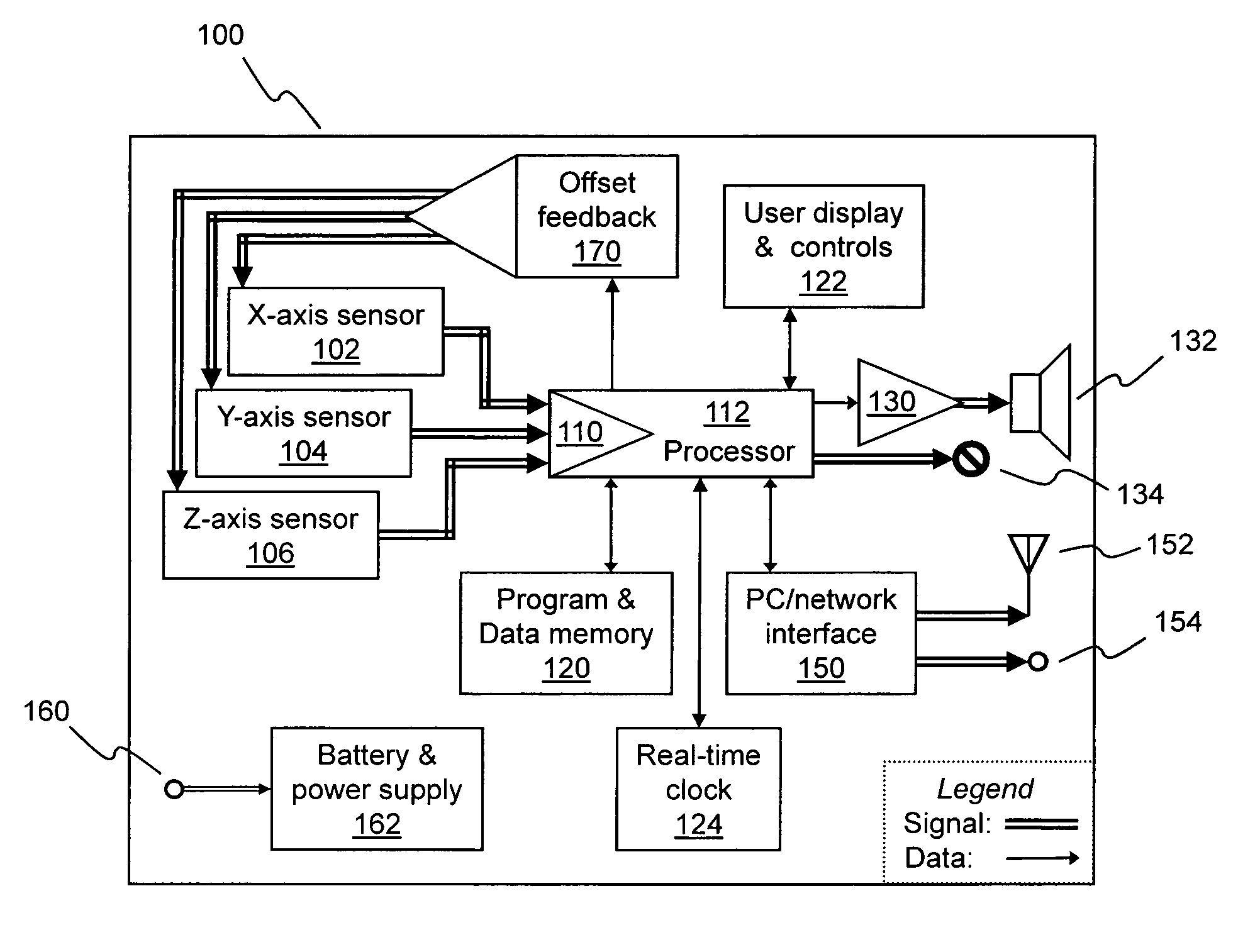

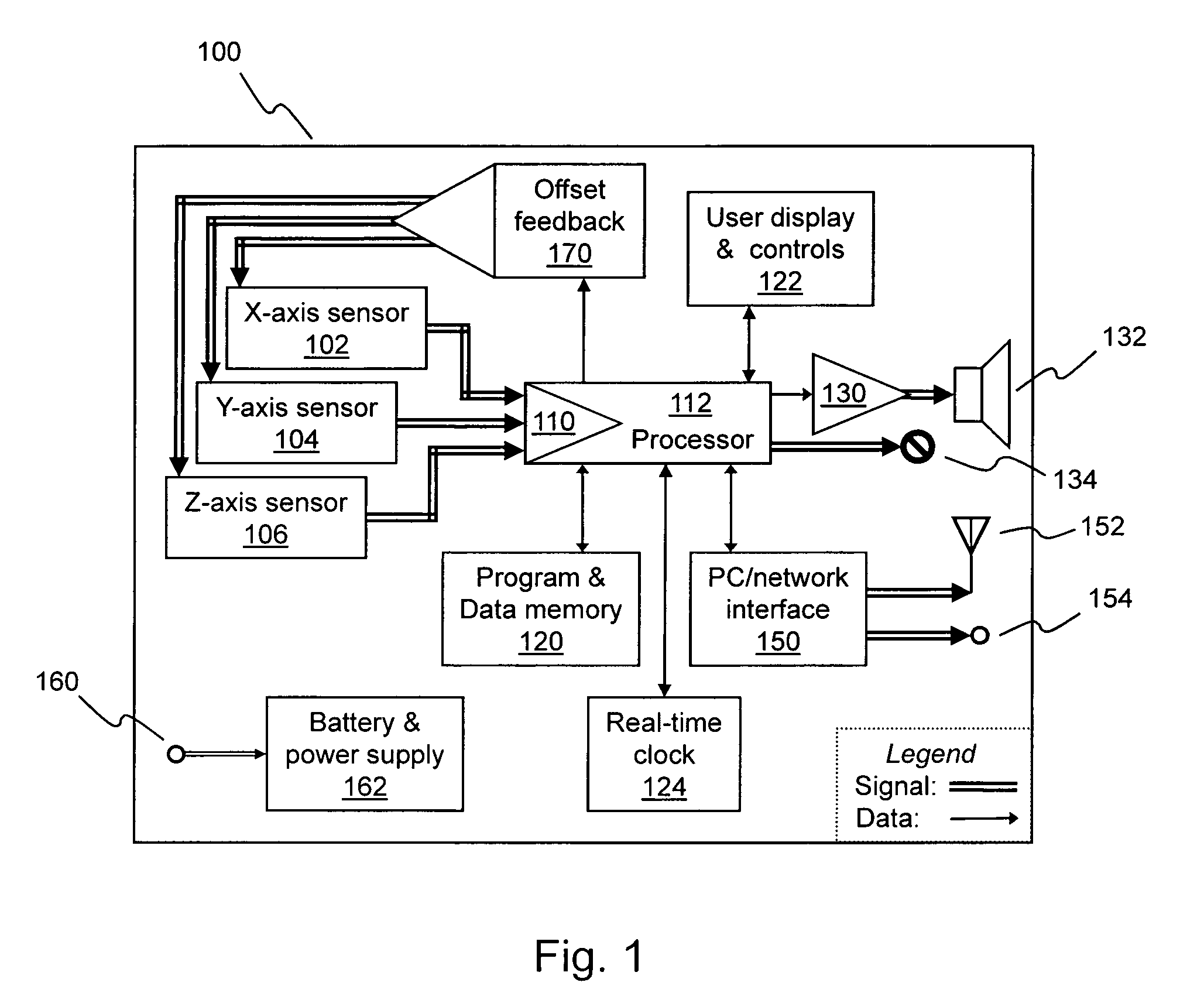

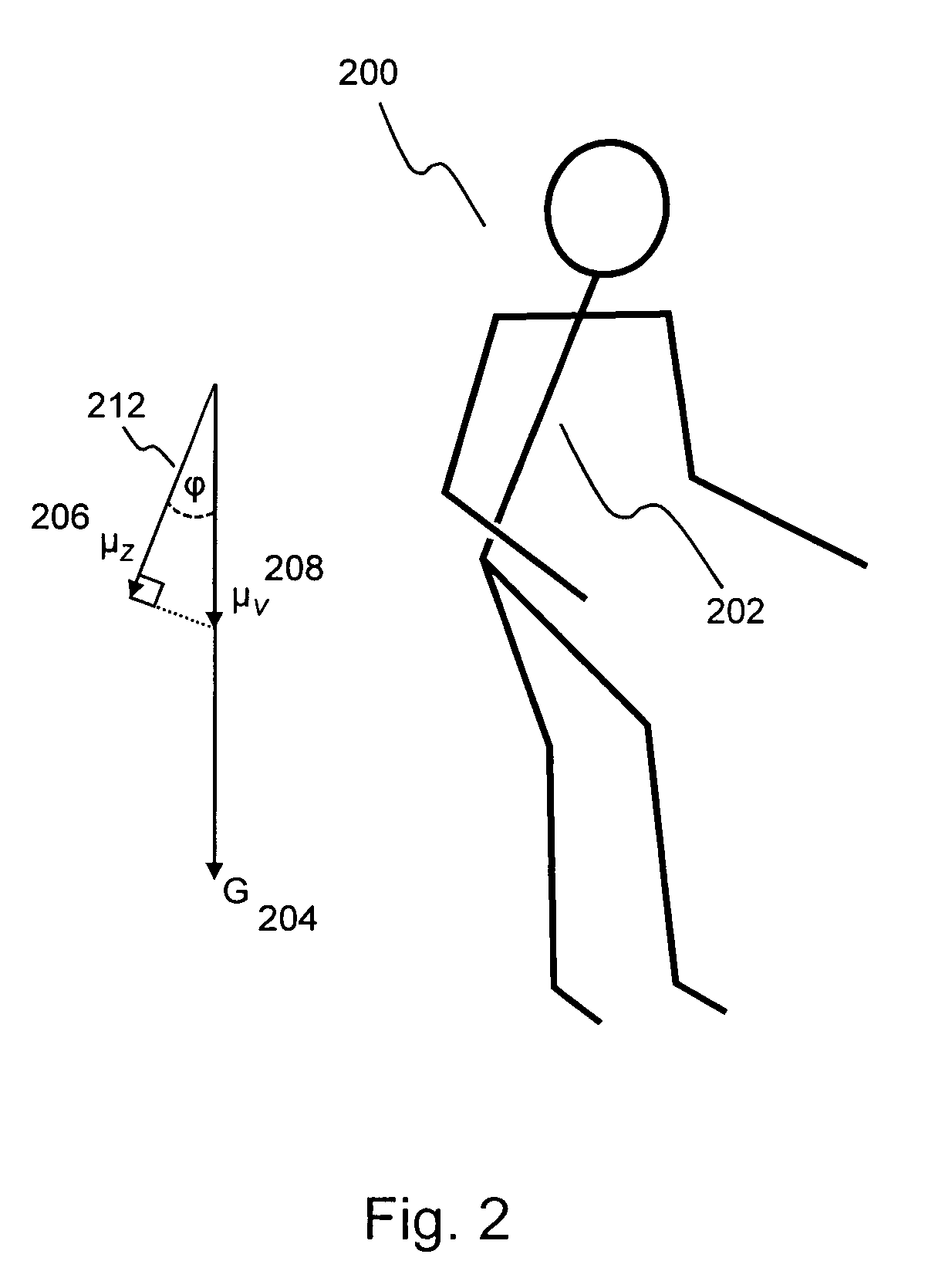

Newtonian physical activity monitor

ActiveUS20080288200A1Accurately determineAccurately determinedGymnastic exercisingInertial sensorsMulti axisEnergy expenditure

An improved apparatus and methods of posture and physical activity monitoring. The apparatus is physically mountable to or associated with an object or person, includes a multi-axis accelerometer, and derives measurements of posture and of acceleration. Methods are disclosed which provide improved estimations of posture, acceleration, energy expenditure, movement characteristics and physical activity, detect the influence of externally-caused motion, and permit automatic calibration of the apparatus in the field.

Owner:NOKIA TECH LTD

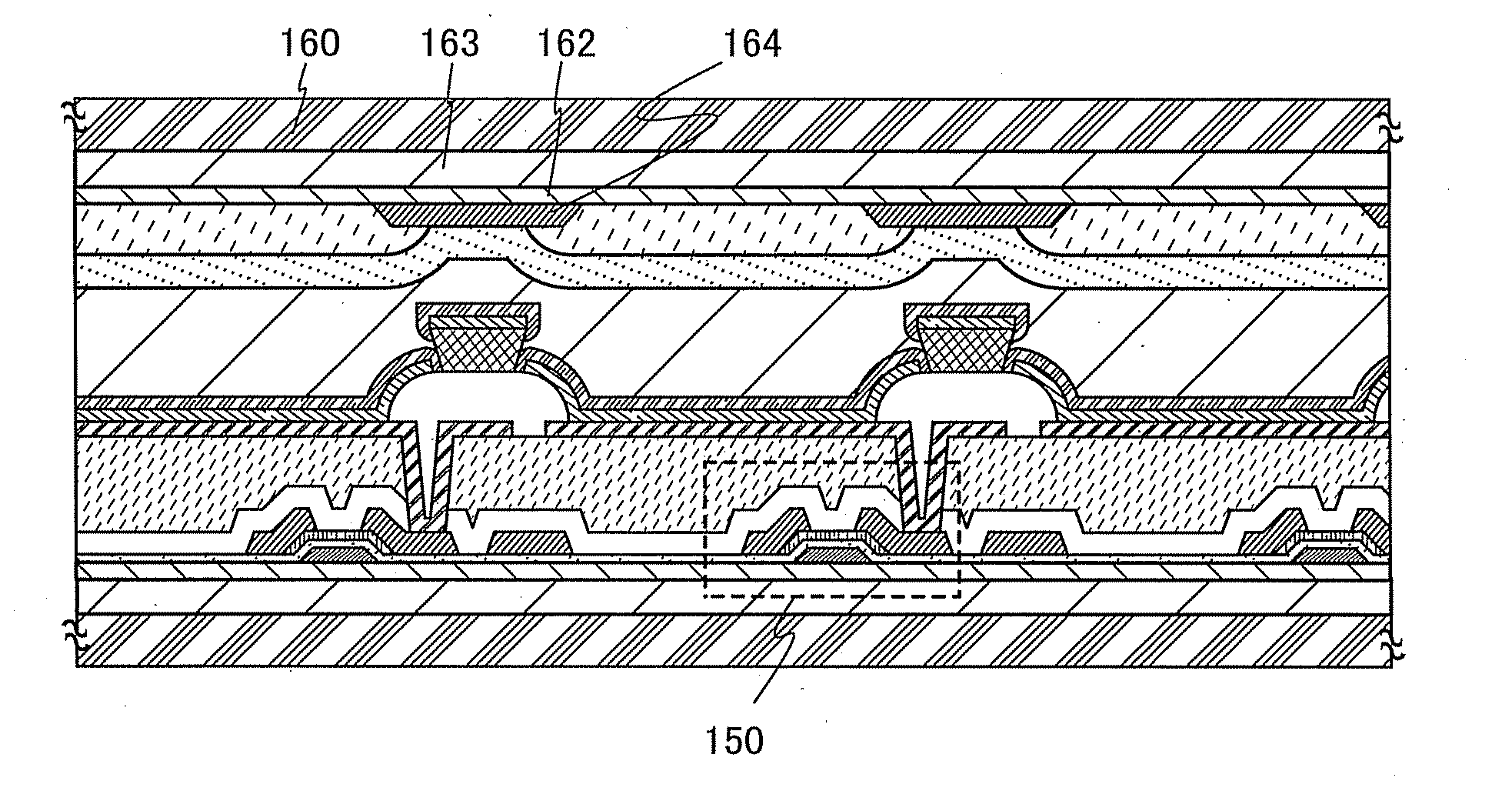

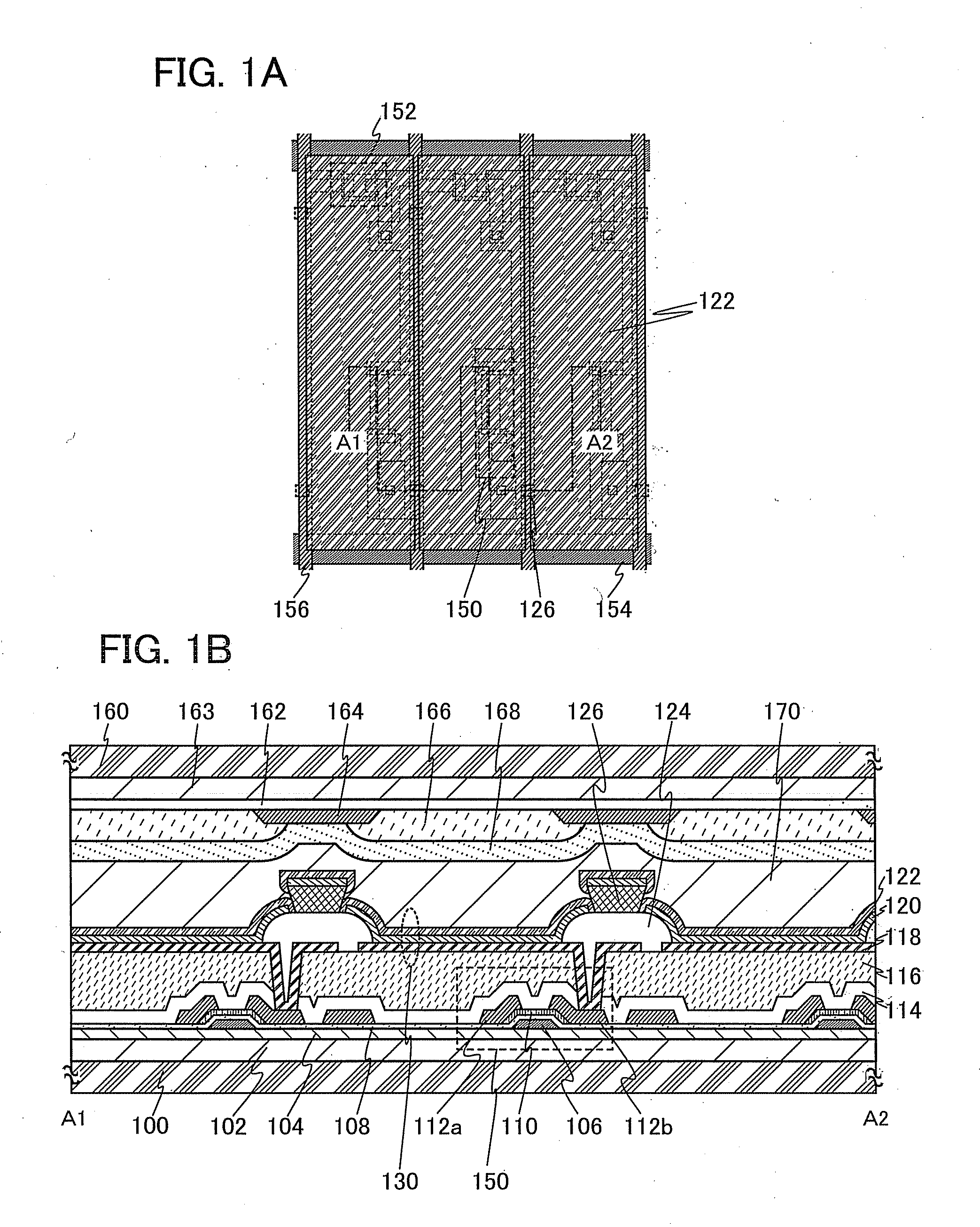

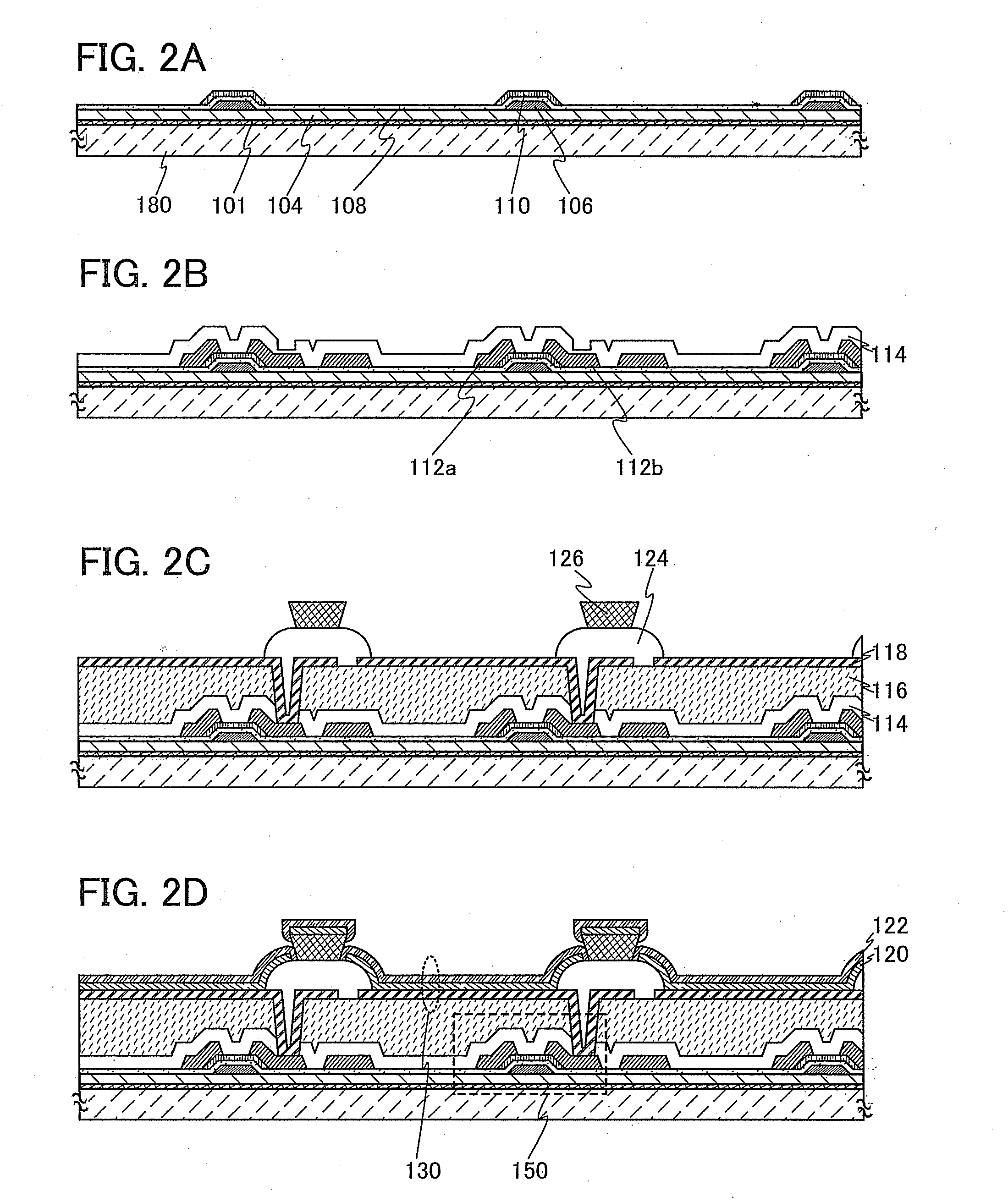

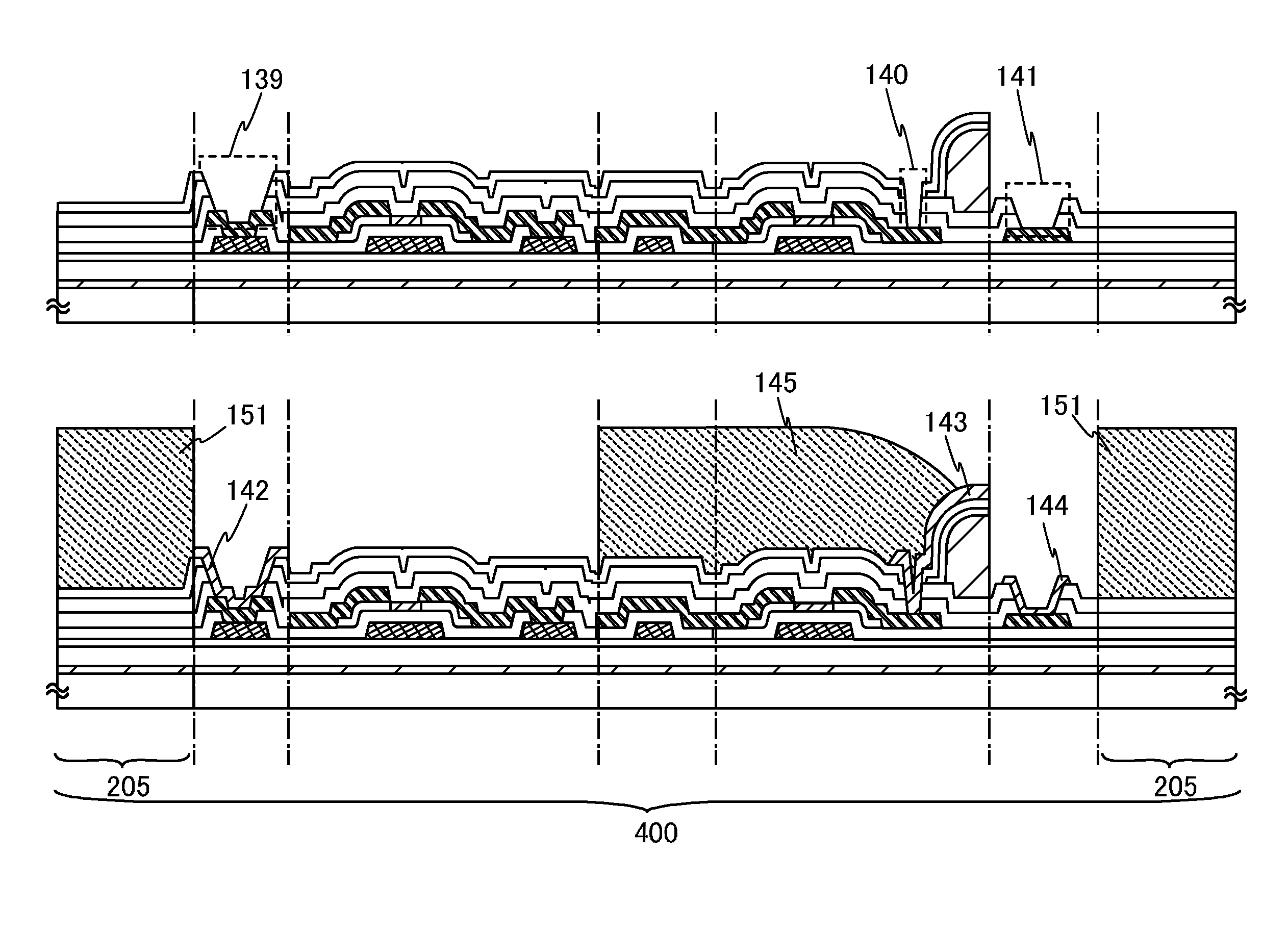

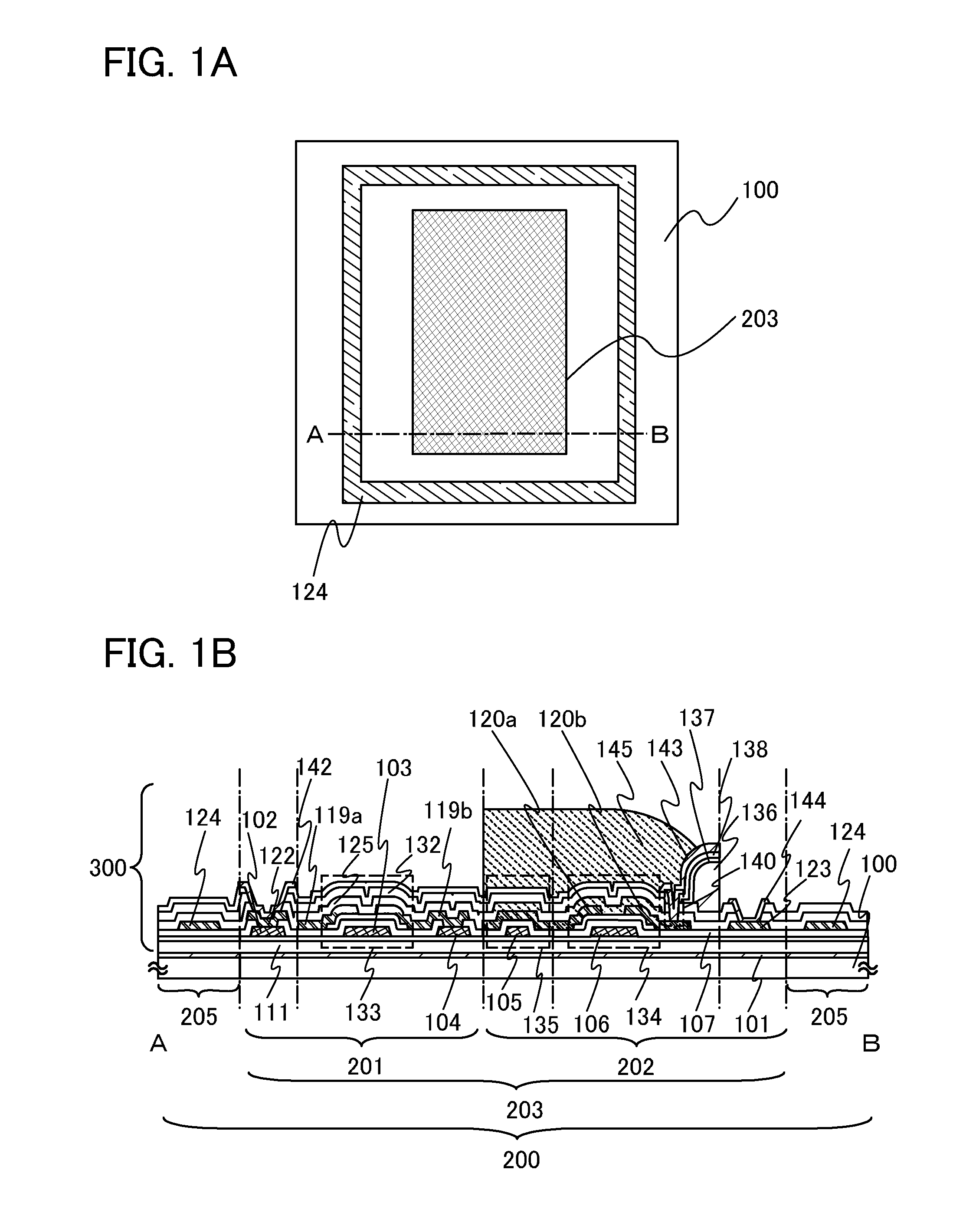

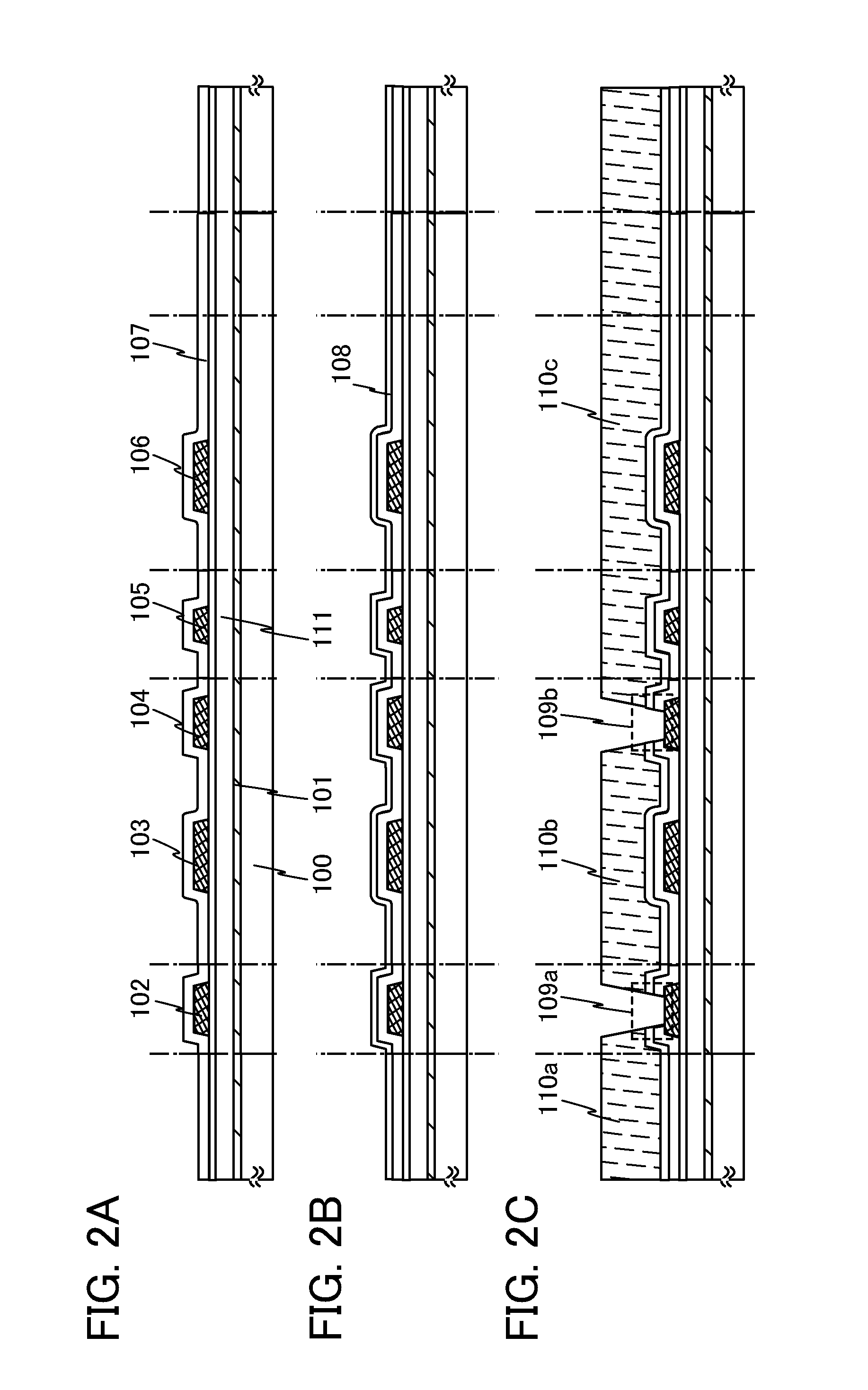

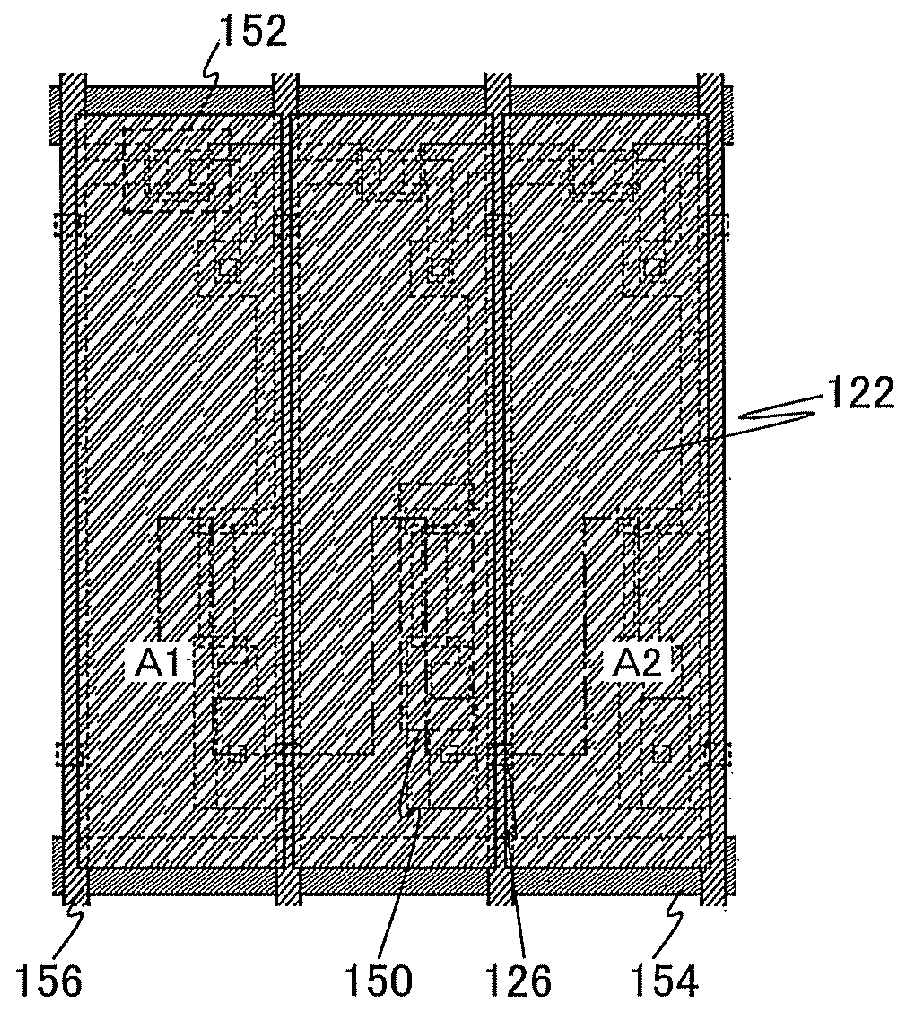

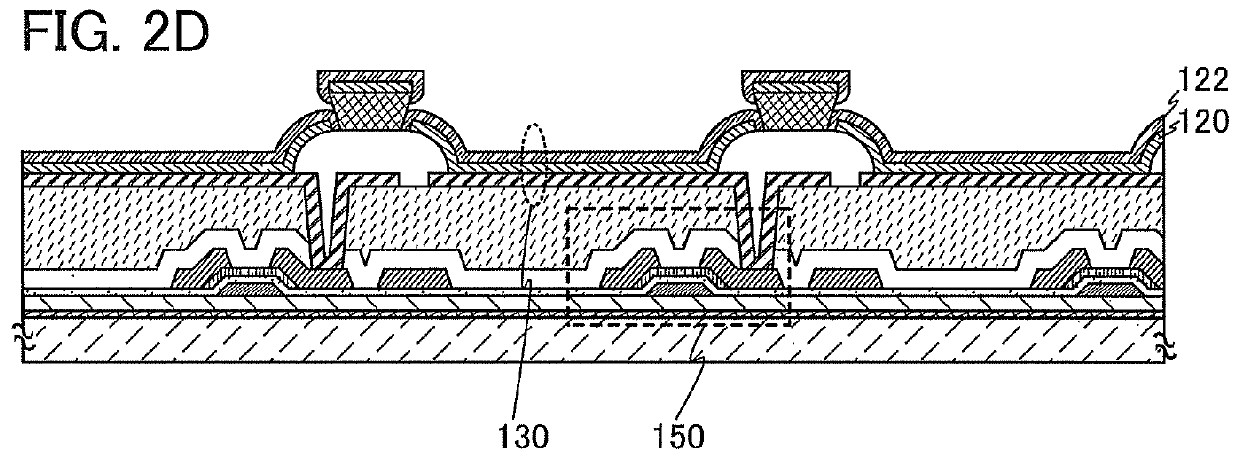

Light-Emitting Device and Electronic Device Using Light-Emitting Device

ActiveUS20120217516A1Avoid damageImprove reliabilityElectroluminescent light sourcesSolid-state devicesEngineeringLight emitting device

Provided is a highly reliable light-emitting device in which a light-emitting element is prevented from being damaged when external physical force is applied. The light-emitting device includes a light-emitting element formed over a first substrate, including a first electrode layer, a light-emitting layer, and a second electrode layer; a structure body formed over the first substrate; a second substrate provided to face the first substrate; and a bonding layer provided between the first substrate and the second substrate. The light-emitting layer is separated by the structure body. By strengthening adhesion between the structure body and the bonding layer, or between the structure body and the second electrode, the highly reliable light-emitting device in which damage of the light-emitting element is prevented can be provided.

Owner:SEMICON ENERGY LAB CO LTD

Newtonian physical activity monitor

ActiveUS7634379B2Accurately determinedImprove estimation accuracyGymnastic exercisingInertial sensorsMulti axisEnergy expenditure

An improved apparatus and methods of posture and physical activity monitoring. The apparatus is physically mountable to or associated with an object or person, includes a multi-axis accelerometer, and derives measurements of posture and of acceleration. Methods are disclosed which provide improved estimations of posture, acceleration, energy expenditure, movement characteristics and physical activity, detect the influence of externally-caused motion, and permit automatic calibration of the apparatus in the field.

Owner:NOKIA TECH LTD

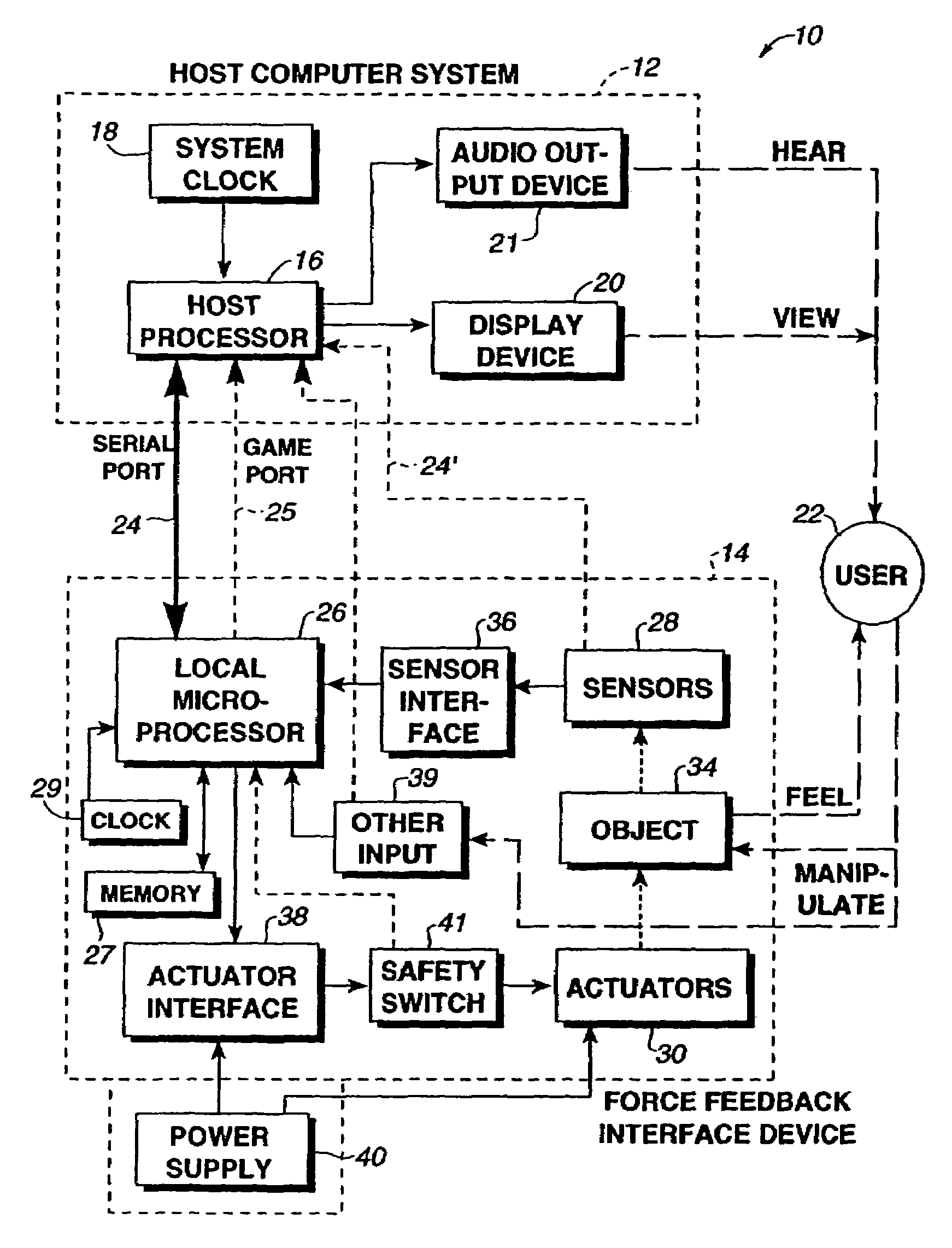

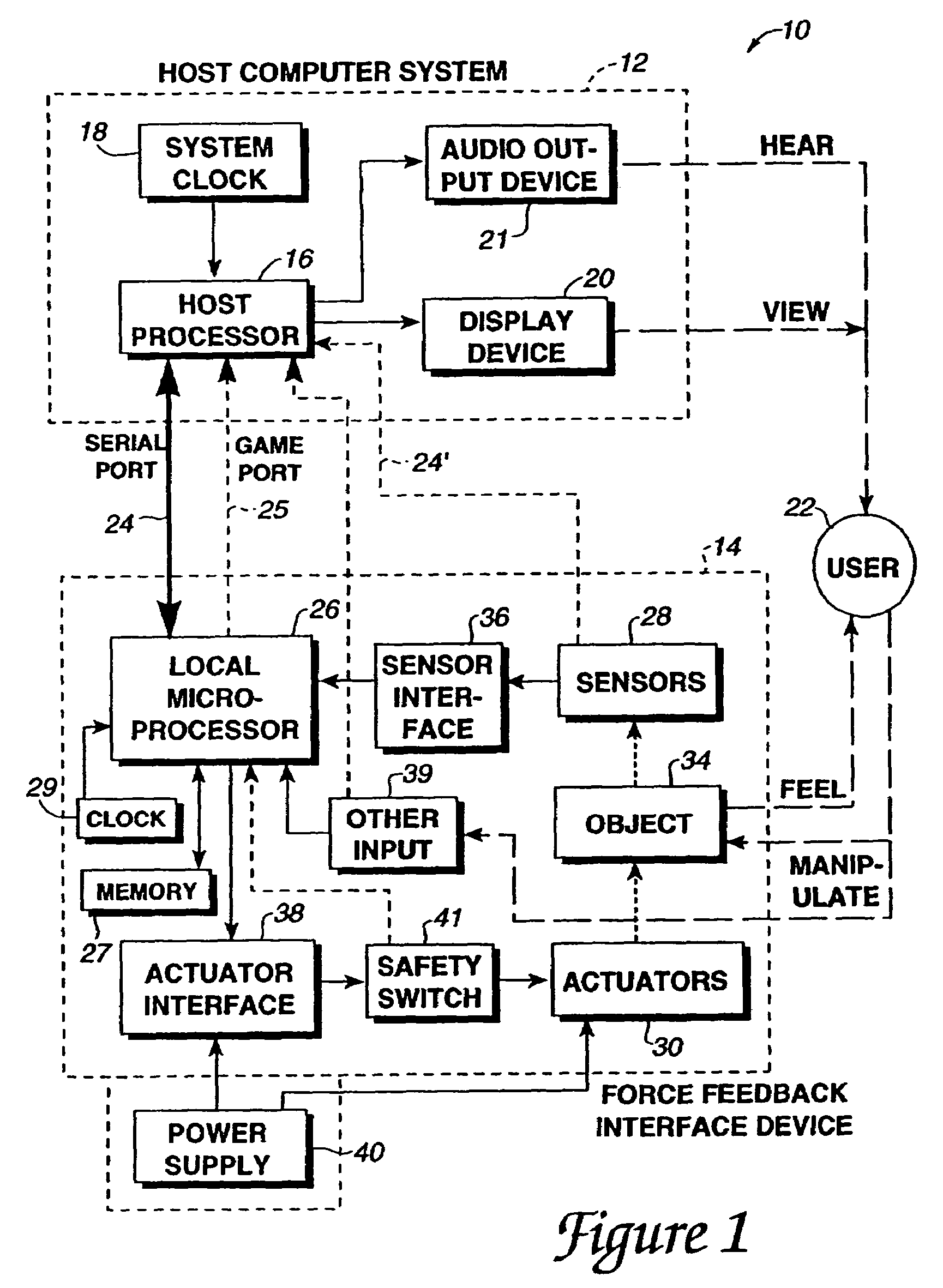

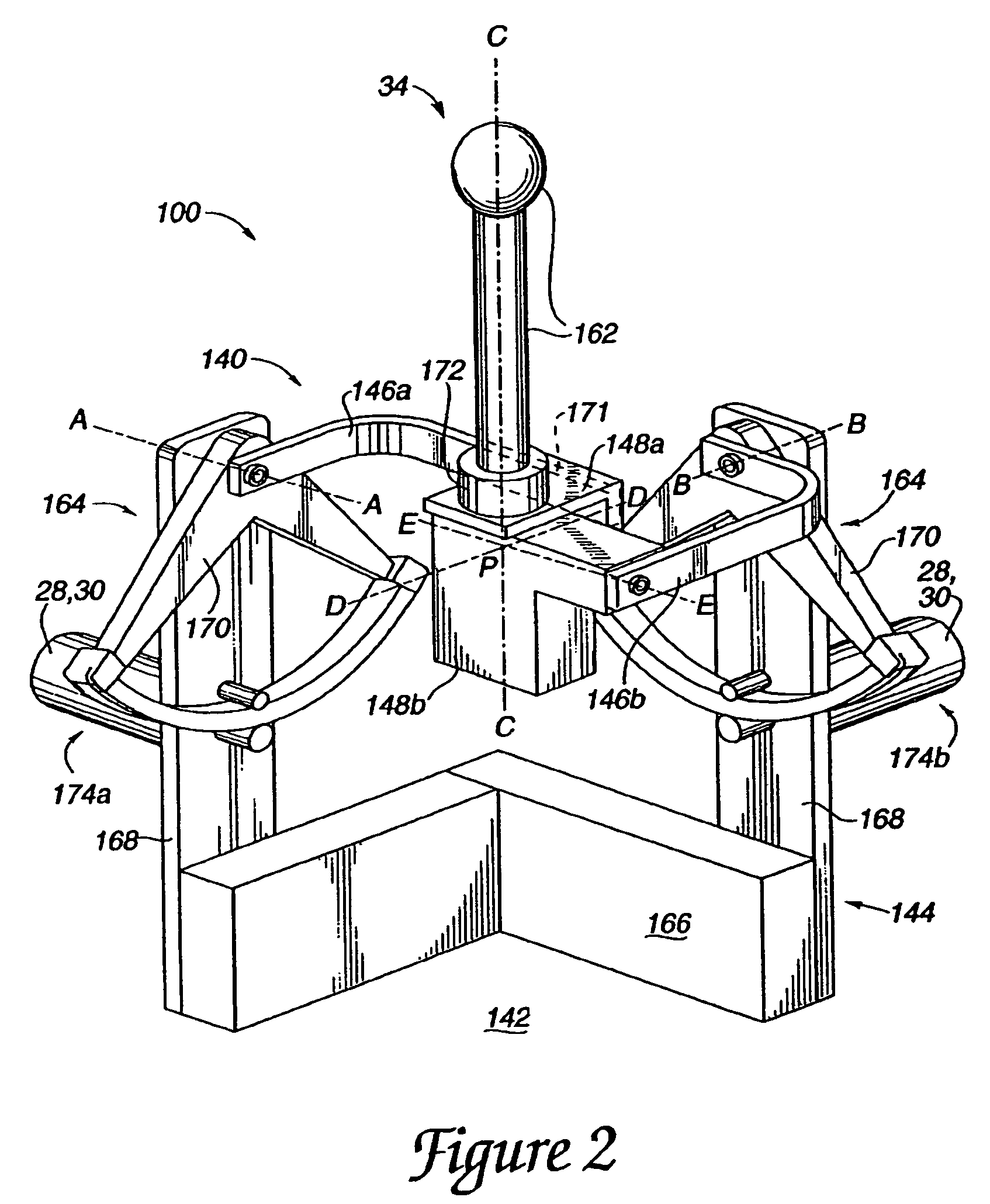

Method and apparatus for streaming force values to a force feedback device

InactiveUS7209117B2Minimal reduction in realismLess forceInput/output for user-computer interactionManual control with multiple controlled membersPulse parameterEngineering

A method and apparatus for shaping force signals for a force feedback device. A source wave is provided and is defined by a set of control parameters (including a steady state magnitude, a frequency value and a duration value) and modified by a set of impulse parameters (including an impulse magnitude, and a settle time representing a time required for the impulse magnitude to change to the steady-state magnitude). Optionally, application parameters specifying a direction of force signal and trigger parameters specifying activating buttons can also be provided for the source wave. Using a host processor or a local processor, the force signal is formed from the source wave and the sets of control parameters and impulse parameters, where the force signal includes an impulse signal followed by a continual steady-state signal after an expiration of the settle time. A feel sensation is generated to a user of the force feedback device as physical forces produced by actuators on the force feedback device in response to the force signal. The steady-state magnitude value is lower than a magnitude value of a non-impulse-shaped force signal required to create a corresponding feel sensation having a similar apparent sensation to the user.

Owner:IMMERSION CORPORATION

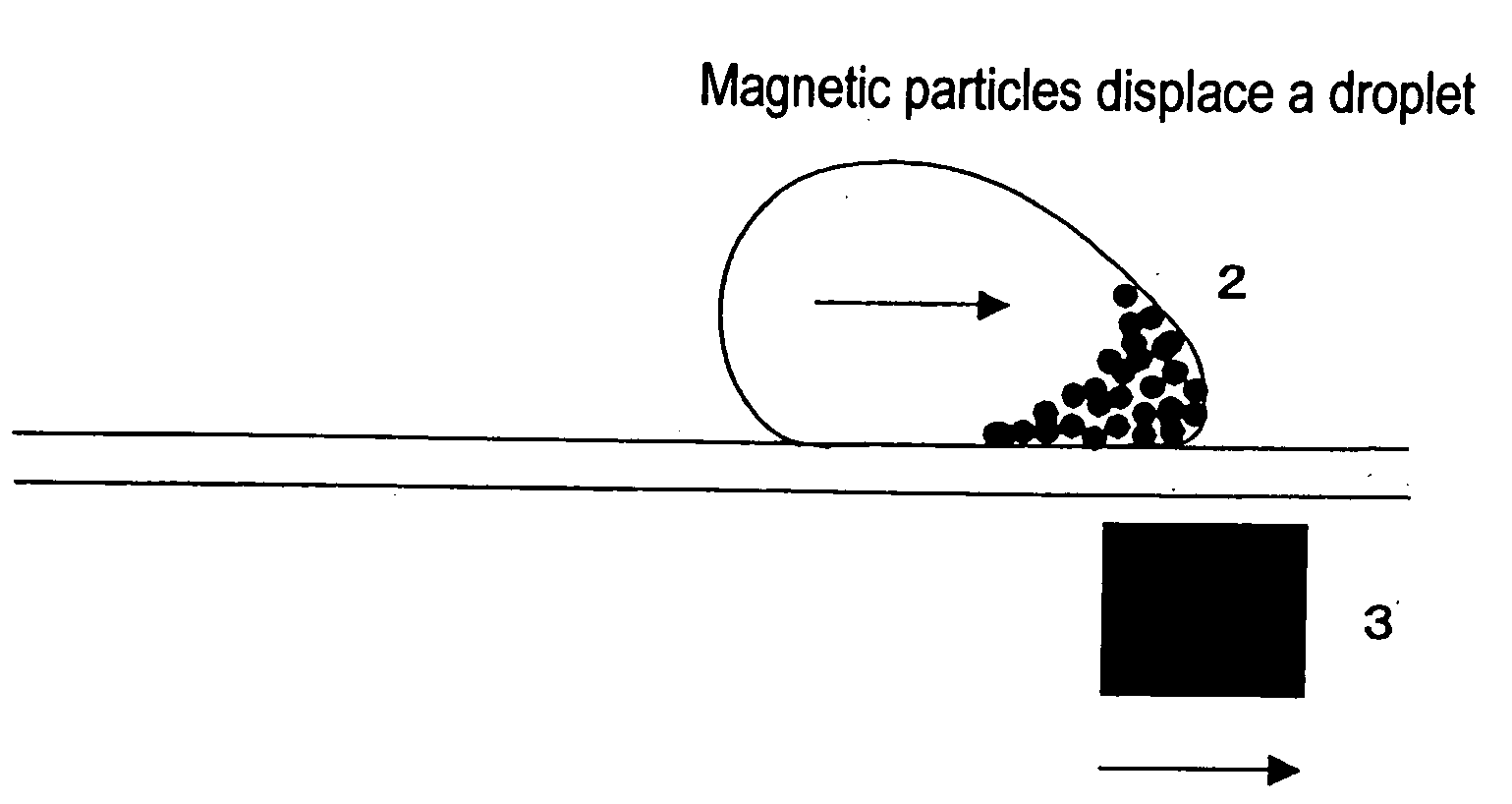

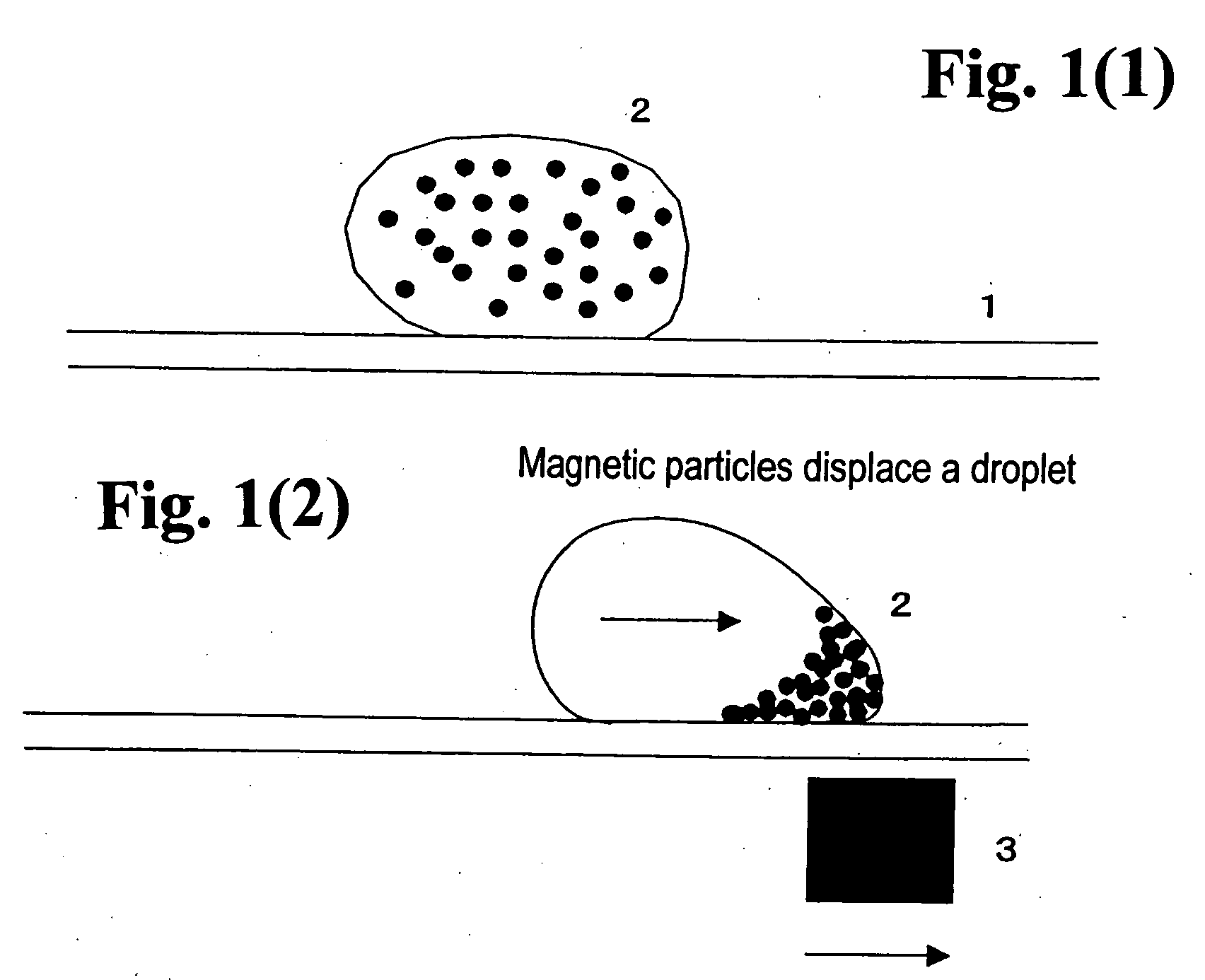

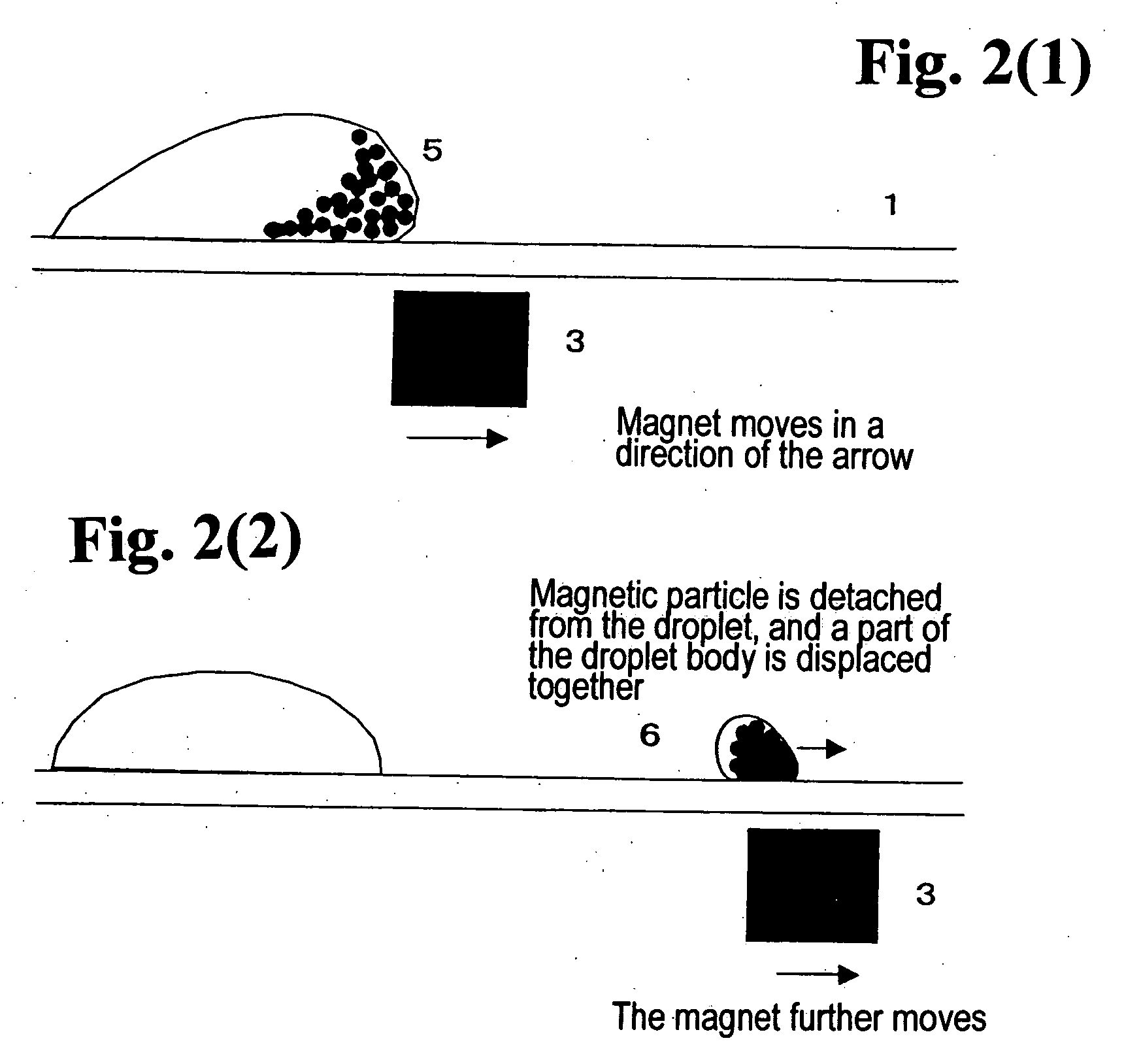

Microchemistry reaction method and device

A chemical reaction is conducted in a fluid of a droplet inside a reaction receptacle or on a surface of a reaction substrate. Fluctuations of a magnetic field are applied to the droplet including an aqueous solution having magnetic body particles with a hydrophilic surface, and a physical force is transmitted to the surrounding aqueous solution through the magnetic body particles. The droplet is thus moved by the physical force to conduct an operation necessary for a chemical reaction.

Owner:SHIMADZU CORP

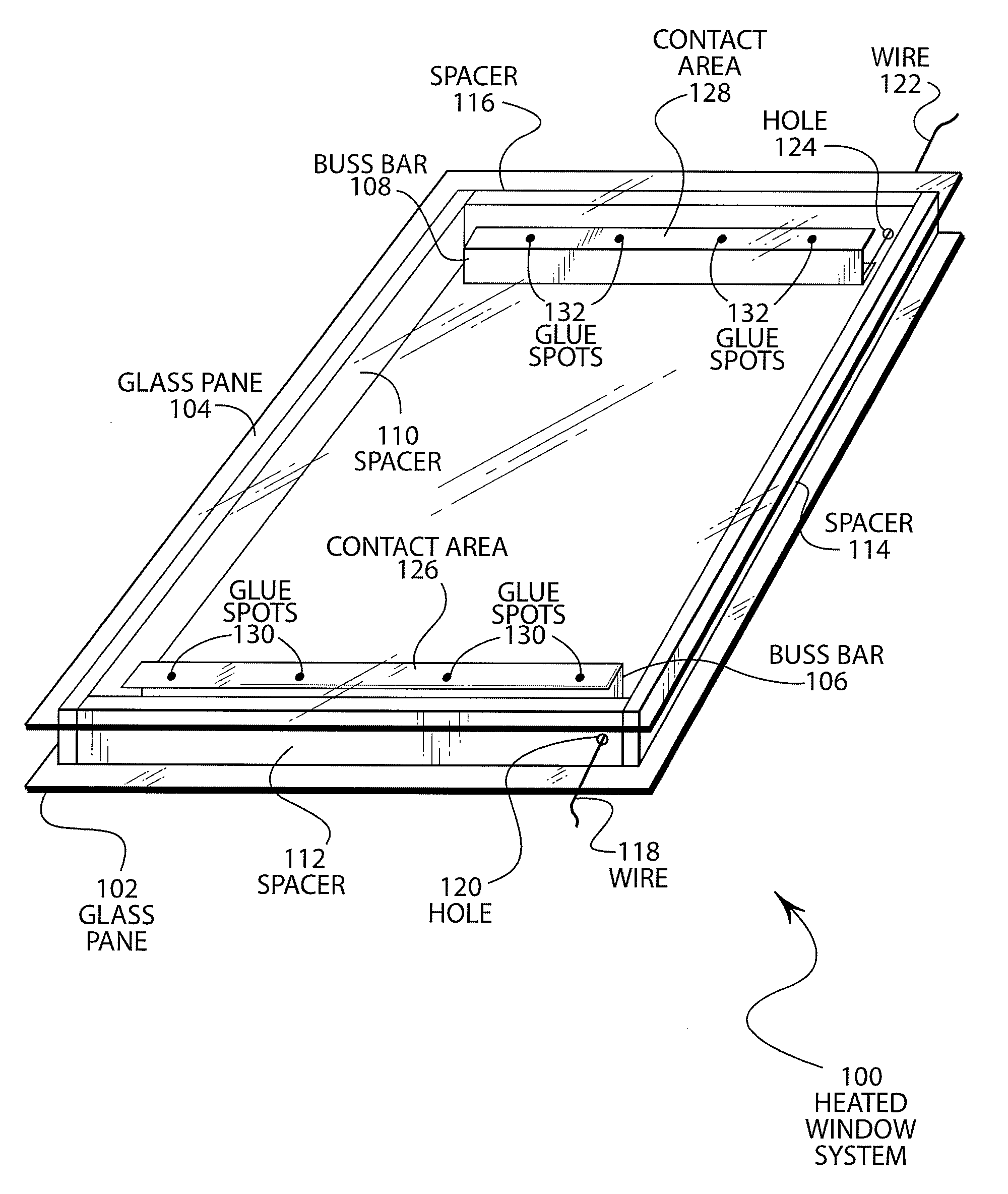

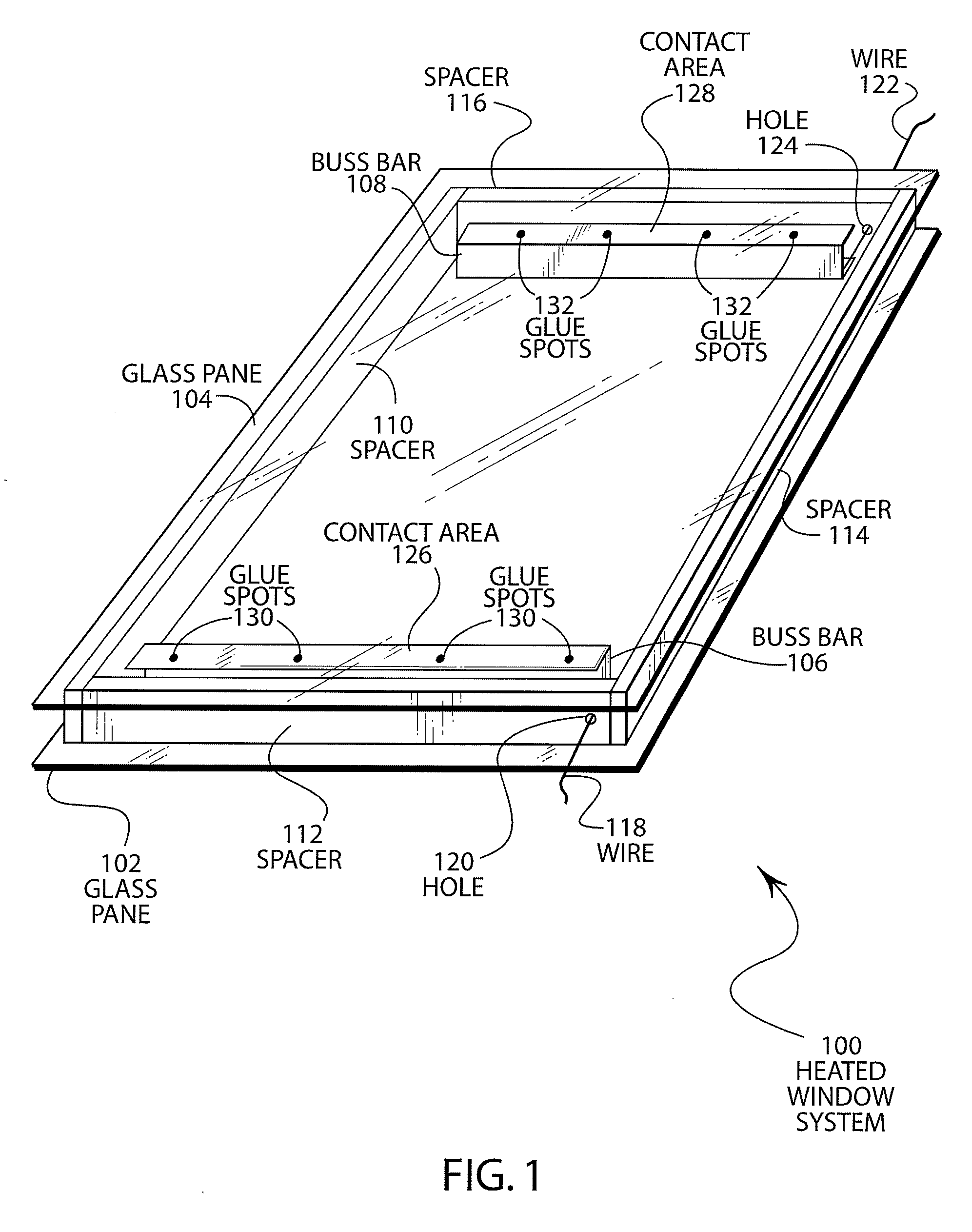

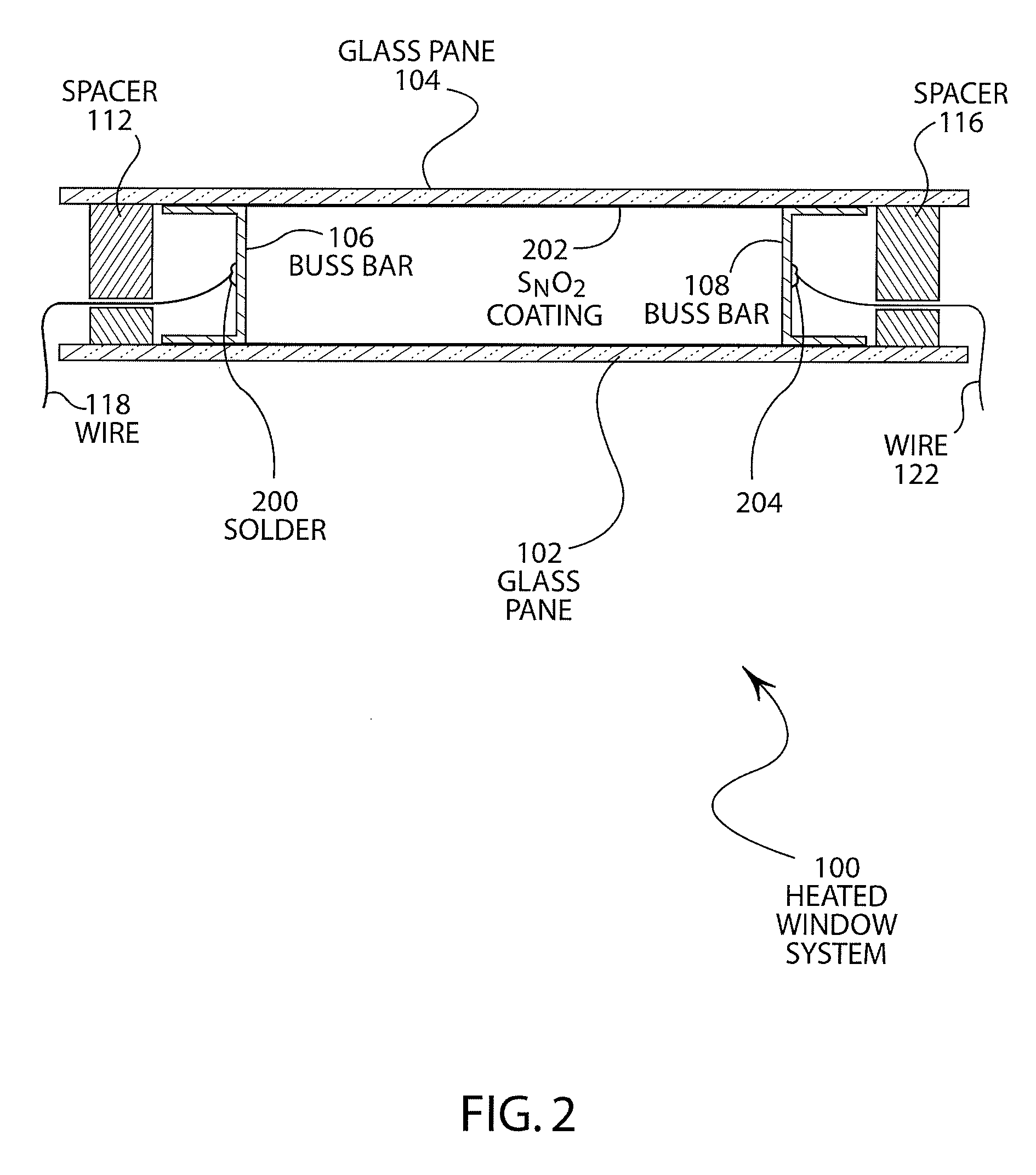

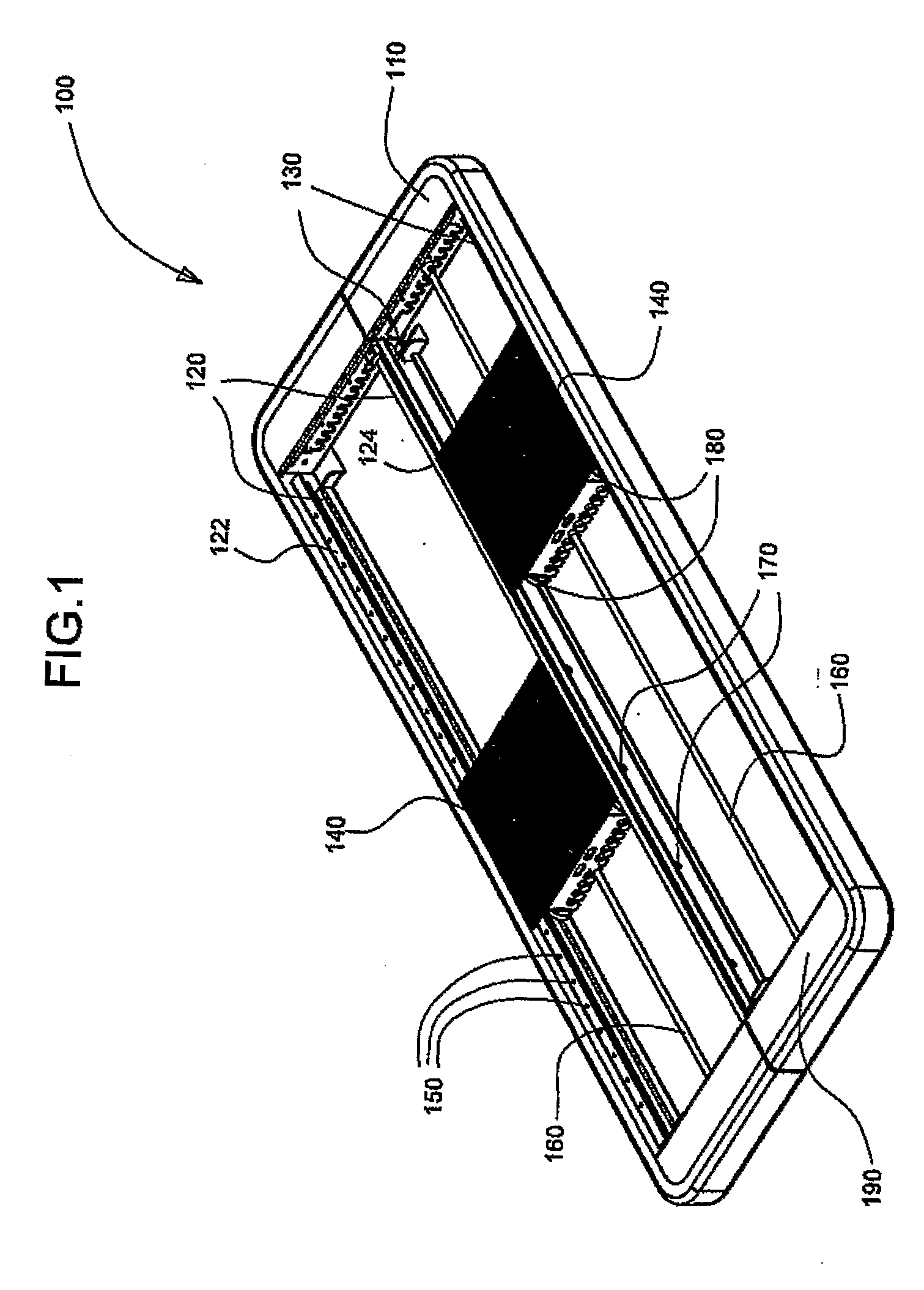

Warm Window System

InactiveUS20060283084A1Sufficient currentOhmic-resistance electrodesLighting and heating apparatusElectricityMetal strips

Disclosed is a warm window system that utilizes individual buss bars that are placed within the space between an inside window pane and an outside window pane and creates sufficient physical force to create an electrical contact on the tin oxide layer on the inside surface of the inside pane of glass. An insulating nonconductive layer can also be used in conjunction with the buss bars. That include metal strips, braided wires, spring loaded indentations, etc. The buss bars have a modulus of elasticity to ensure sufficient electrical contact with the tin oxide layer. The buss bars can be used with either hard coat or soft coat tin oxide coatings on tempered glass or annealed glass. Electrical connections and wires are hidden from the viewing area of the warm window system to enhance the aesthetic value of the warm window system. Retrofit systems allow use of the warm window system in conjunction with an existing installed window system.

Owner:ENERGIZED GLASS

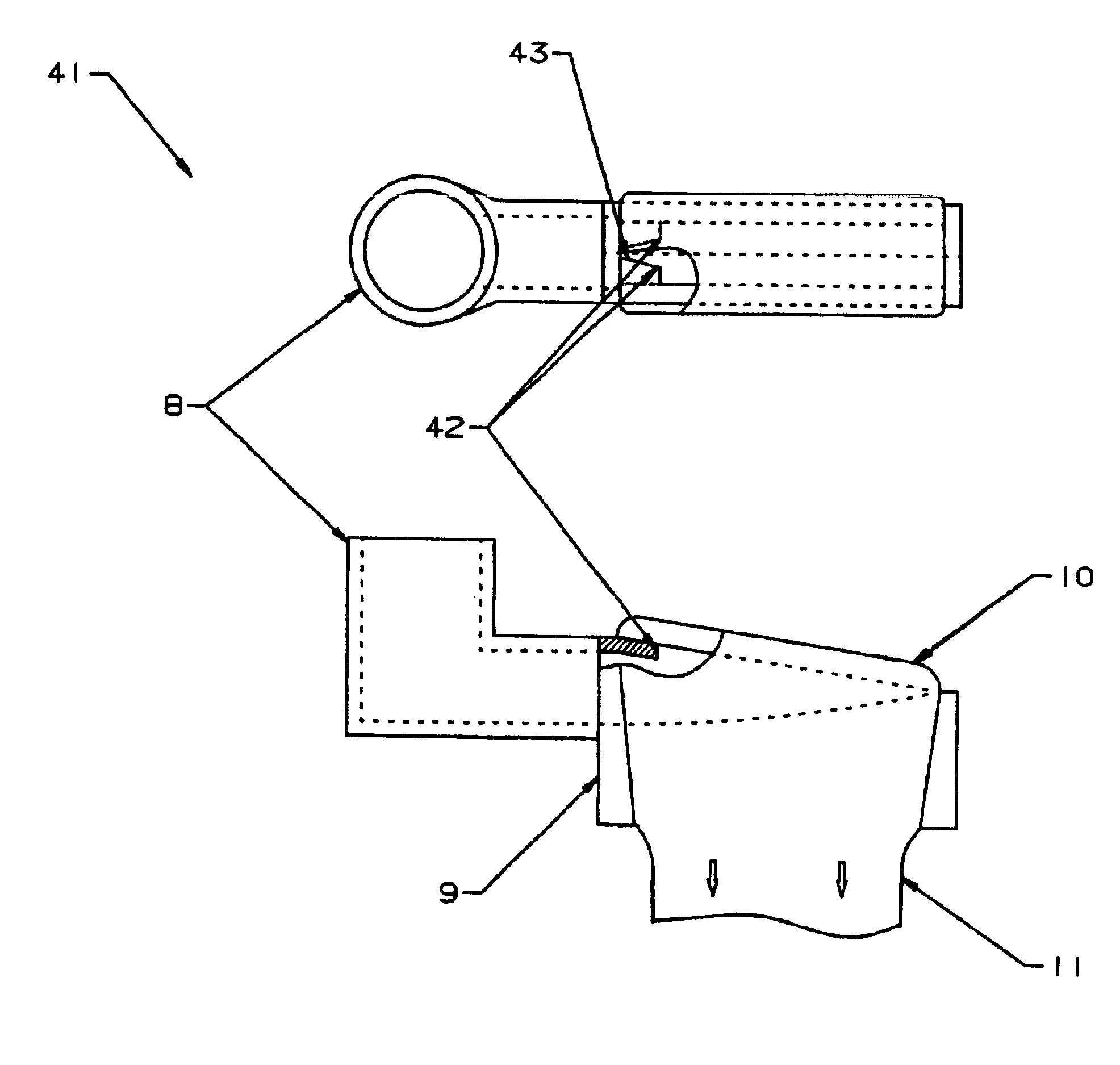

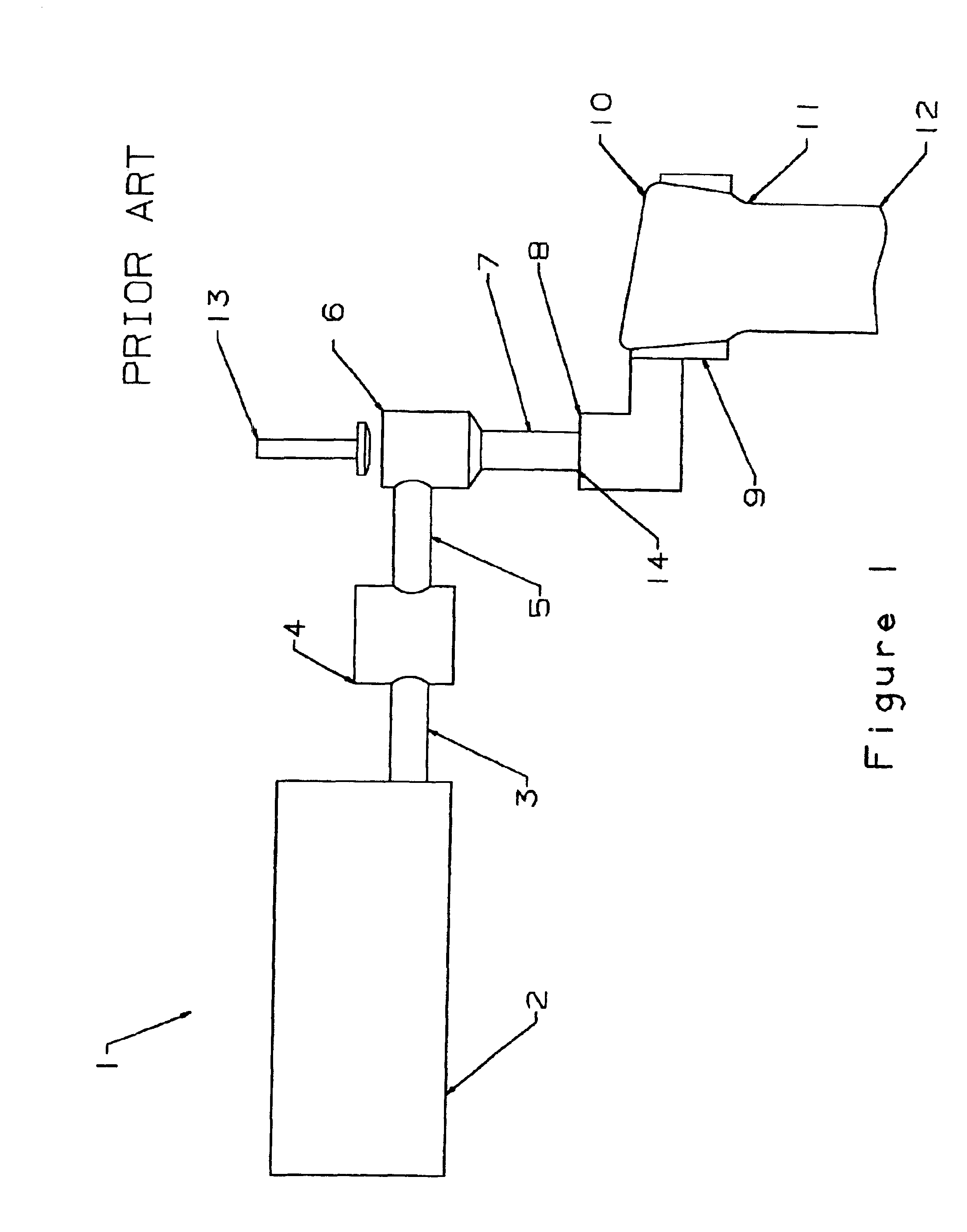

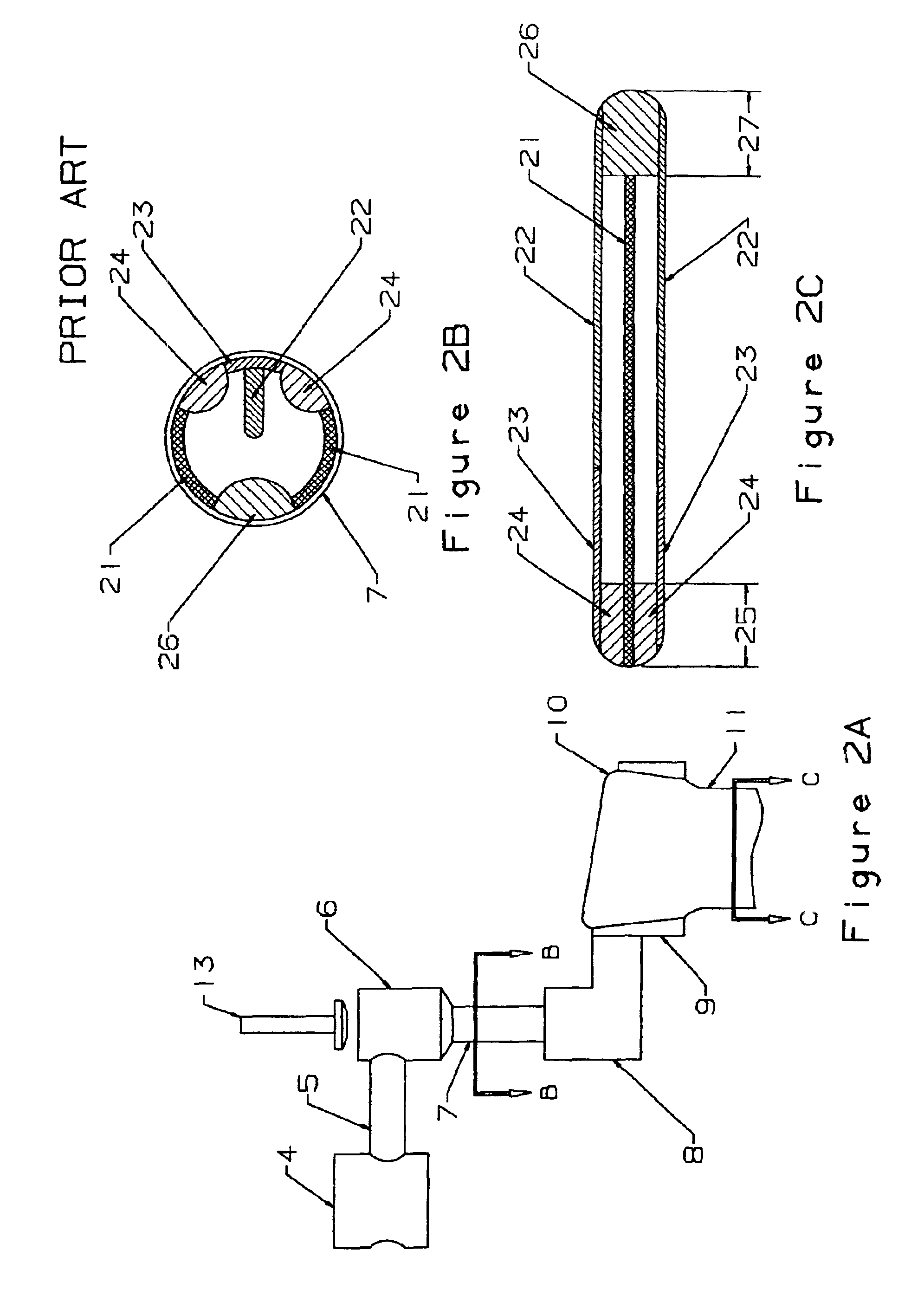

Overflow downdrawn glass forming method and apparatus

InactiveUS6889526B2Reduce unevennessEfficient degradationGlass furnace apparatusGlass drawing apparatusThermal creepEngineering

Owner:CORNING INC

Method for manufacturing semiconductor device

ActiveUS20110318889A1Crack suppressionHigh yield manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

An object is to provide a manufacturing method of a semiconductor device in which a defect in characteristics due to a crack occurring in a semiconductor device is reduced. Provision of a crack suppression layer formed of a metal film in the periphery of a semiconductor element makes it possible to suppress a crack occurring from the outer periphery of a substrate and reduce damage to the semiconductor element. In addition, even if the semiconductor device is subjected to physical forces from the outer periphery in separation and transposition steps, progression (growth) of a crack to the semiconductor device can be suppressed by the crack suppression layer.

Owner:SEMICON ENERGY LAB CO LTD

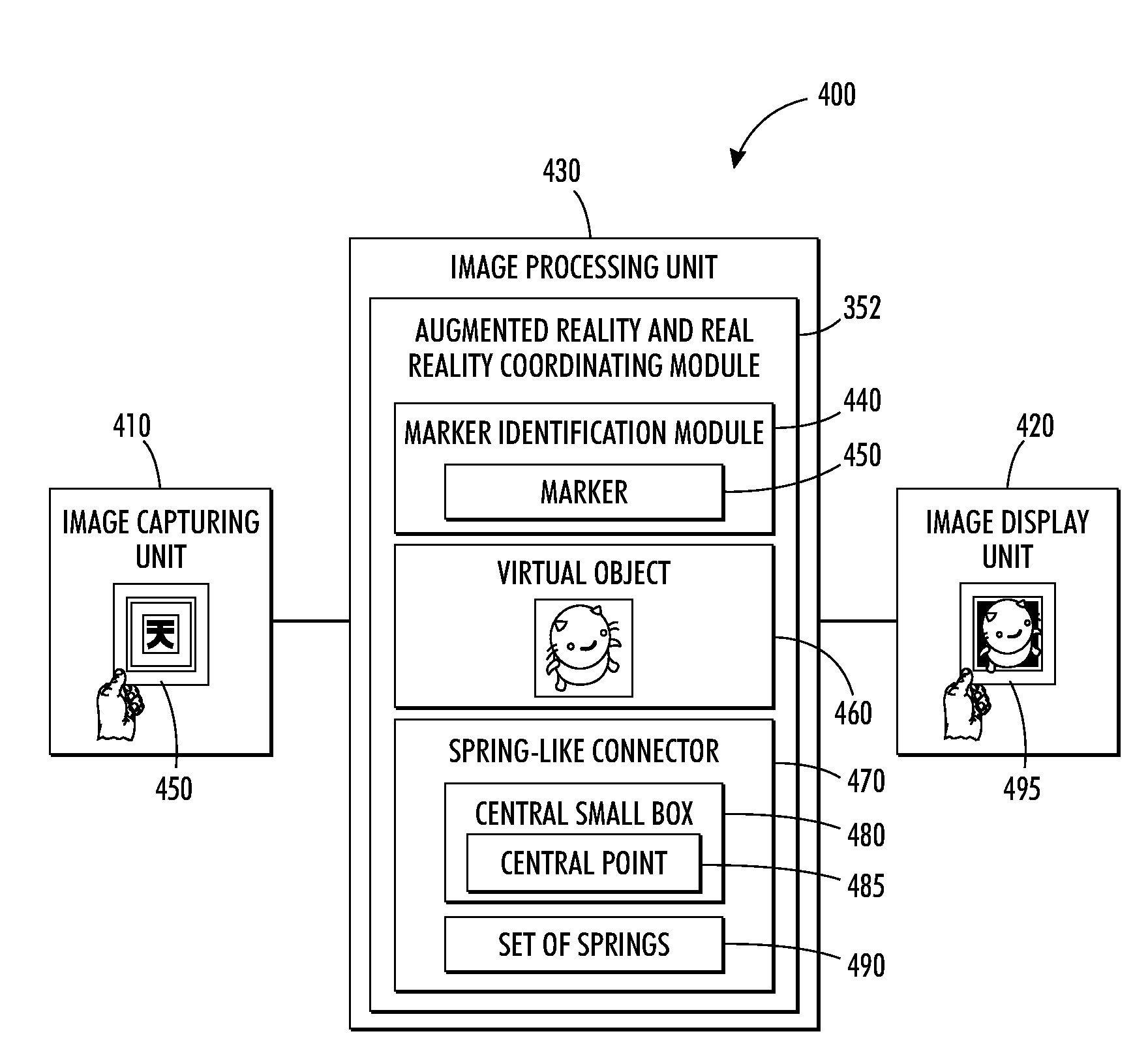

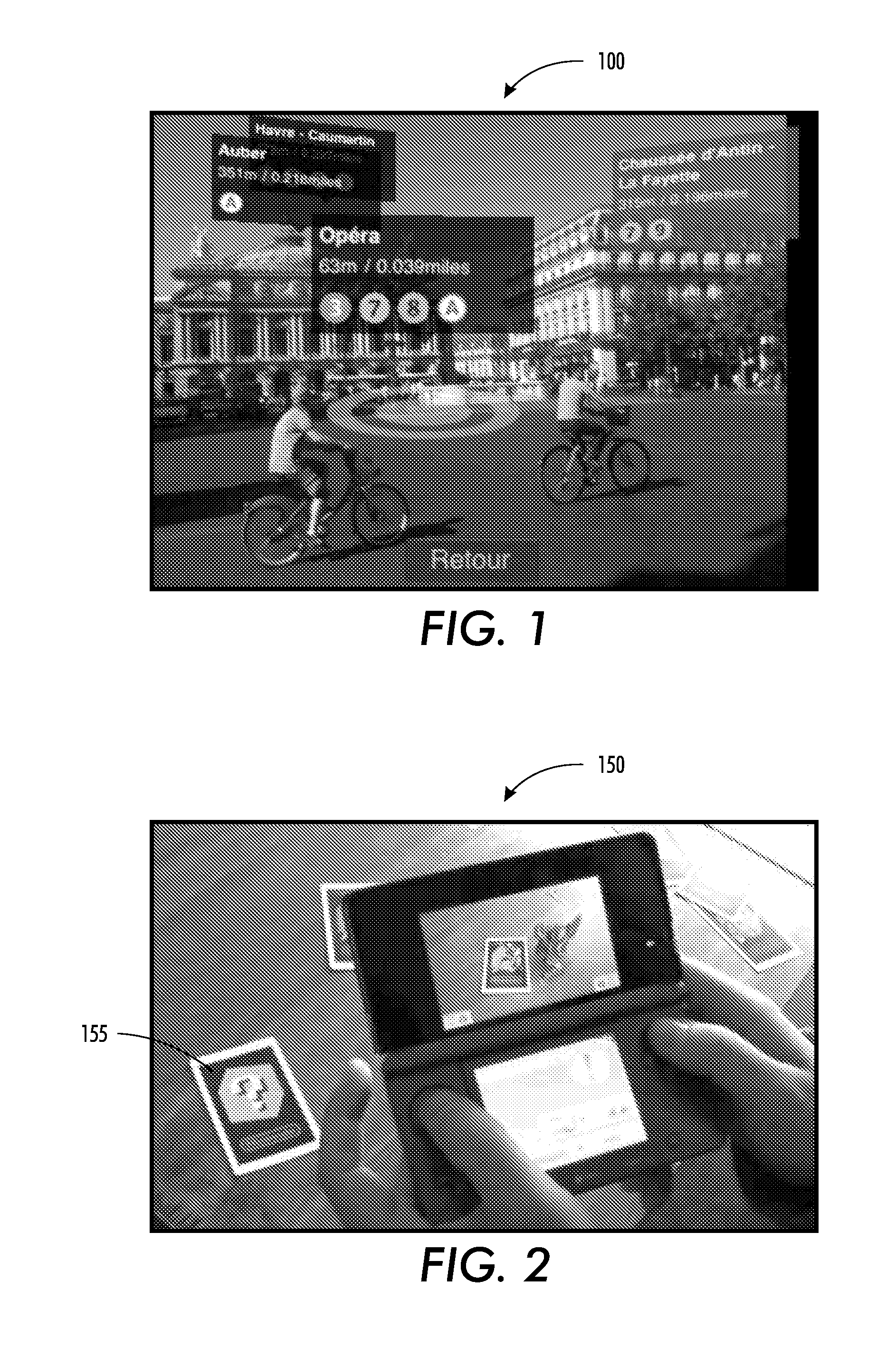

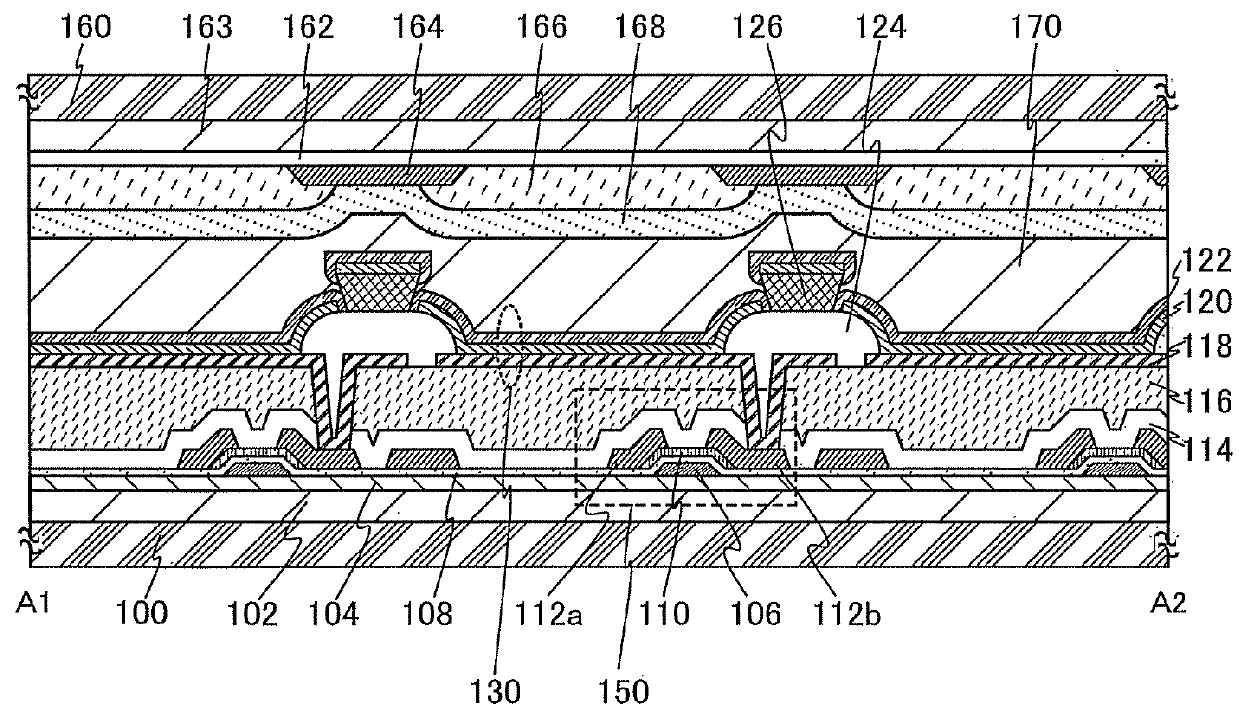

Method and system for coordinating collisions between augmented reality and real reality

InactiveUS20130155106A1Smoother and intuitive connectionCathode-ray tube indicatorsImage generationVirtual worldComputer science

A method and system for coordinating placement of an augmented reality / virtual world object(s) into a scene relative to position and orientation. The object(s) can be connected to an anchor point having an absolute location relative to the marker via a connector (e.g., spring-like connector) in such a way that the behavior of the object responds to a physical force and a collision which exists in the augmented reality scene. The connection between the virtual object and location of the marker permits the object to exactly track the marker when there are no real world collisions between the markers. The virtual objects can be displaced so the objects do not pass through one another when the real world markers come into a close spatial proximity and the corresponding virtual objects begin to collide.

Owner:XEROX CORP

Light-emitting device and electronic device using light-emitting device

ActiveUS9337244B2Improve reliabilityImprove adhesionElectroluminescent light sourcesSolid-state devicesEngineeringLight emitting device

Provided is a highly reliable light-emitting device in which a light-emitting element is prevented from being damaged when external physical force is applied. The light-emitting device includes a light-emitting element formed over a first substrate, including a first electrode layer, a light-emitting layer, and a second electrode layer; a structure body formed over the first substrate; a second substrate provided to face the first substrate; and a bonding layer provided between the first substrate and the second substrate. The light-emitting layer is separated by the structure body. By strengthening adhesion between the structure body and the bonding layer, or between the structure body and the second electrode, the highly reliable light-emitting device in which damage of the light-emitting element is prevented can be provided.

Owner:SEMICON ENERGY LAB CO LTD

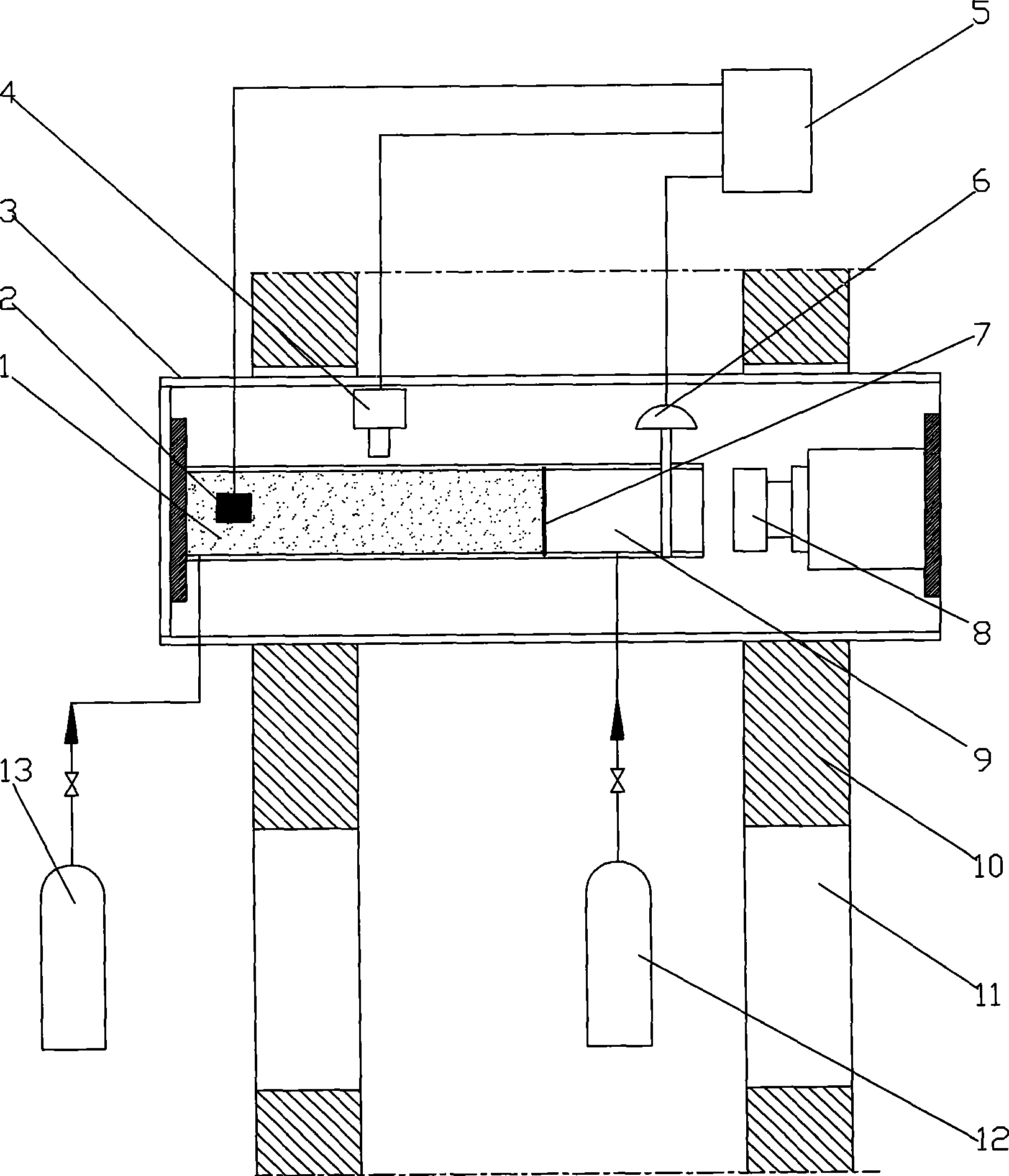

Test apparatus for coal and gas burst

InactiveCN101487835AQuick releaseFlexible useGeological measurementsMaterial analysisEngineeringAtmospheric pressure

The invention discloses an experimental device for the coal and gas burst, comprising a coal sample chamber and an atmospheric pressure loading device, wherein the coal sample chamber is provided with coal and gas exhaust nozzles having control valves, the atmospheric pressure loading device is provided with an atmospheric pressure loading channel that communicates with the inside of the coal sample chamber having a diaphragm in front of the control valves, and a cavity between the diaphragm and the control valves is a balancing cavity connected with a balanced atmospheric pressure loading device; the device also comprises a pressure acquisition device in the coal sample chamber and a camera arranged outside the coal sample chamber and the part of the coal sample chamber opposite to the camera is transparent. The invention is capable of simulating the pressure of gas and physical force of coal, achieving the instant fast pressure release to be closer to the actual coal and gas burst and the damage process of coal, and observing and recording the simulation to provide the theoretical foundation of forecasting and preventing the coal and gas burst; during the use, the grain diameterof powdered coal, pressure while the formation and charging pressure can be regulated to observe the grain diameter parameters of different powdered coals and the experimental result under different pressures, and the device is flexible in use.

Owner:CHONGQING INST OF COAL SCI RES INST +1

Methods for manipulating moieties in microfluidic systems

InactiveUS20060228749A1Increase flexibilityRaise the possibilityPeptide librariesElectrostatic separatorsStereochemistryPHYSICAL FORCES

This invention relates generally to the field of moiety or molecule manipulation in a chip format. In particular, the invention provides a method for manipulating a moiety in a microfluidic application, which method comprises: a) coupling a moiety to be manipulated onto surface of a binding partner of said moiety to form a moiety-binding partner complex; and b) manipulating said moiety-binding partner complex with a physical force in a chip format, wherein said manipulation is effected through a combination of a structure that is external to said chip and a structure that is built-in in said chip, thereby said moiety is manipulated.

Owner:AVIVA BIOSCI

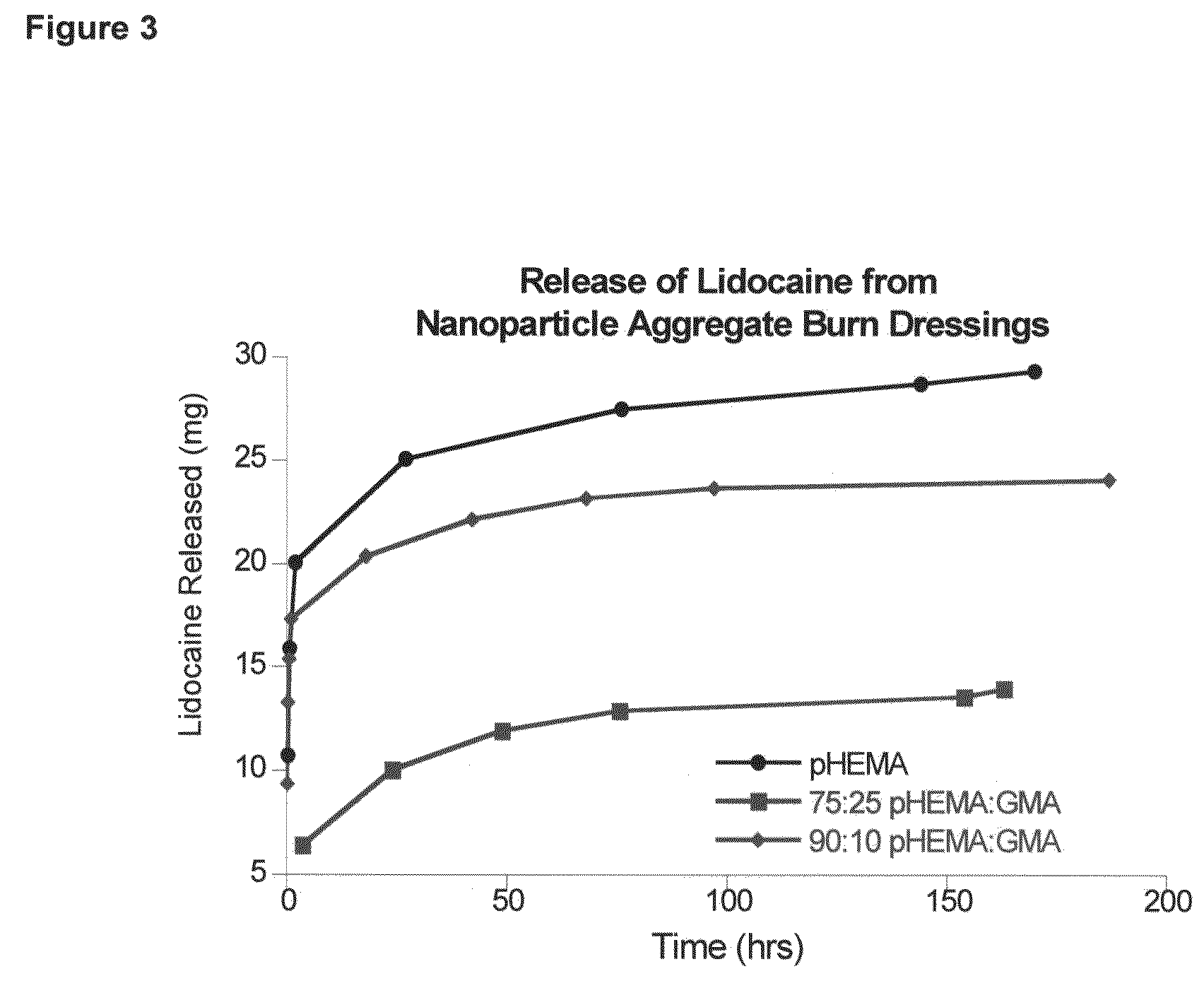

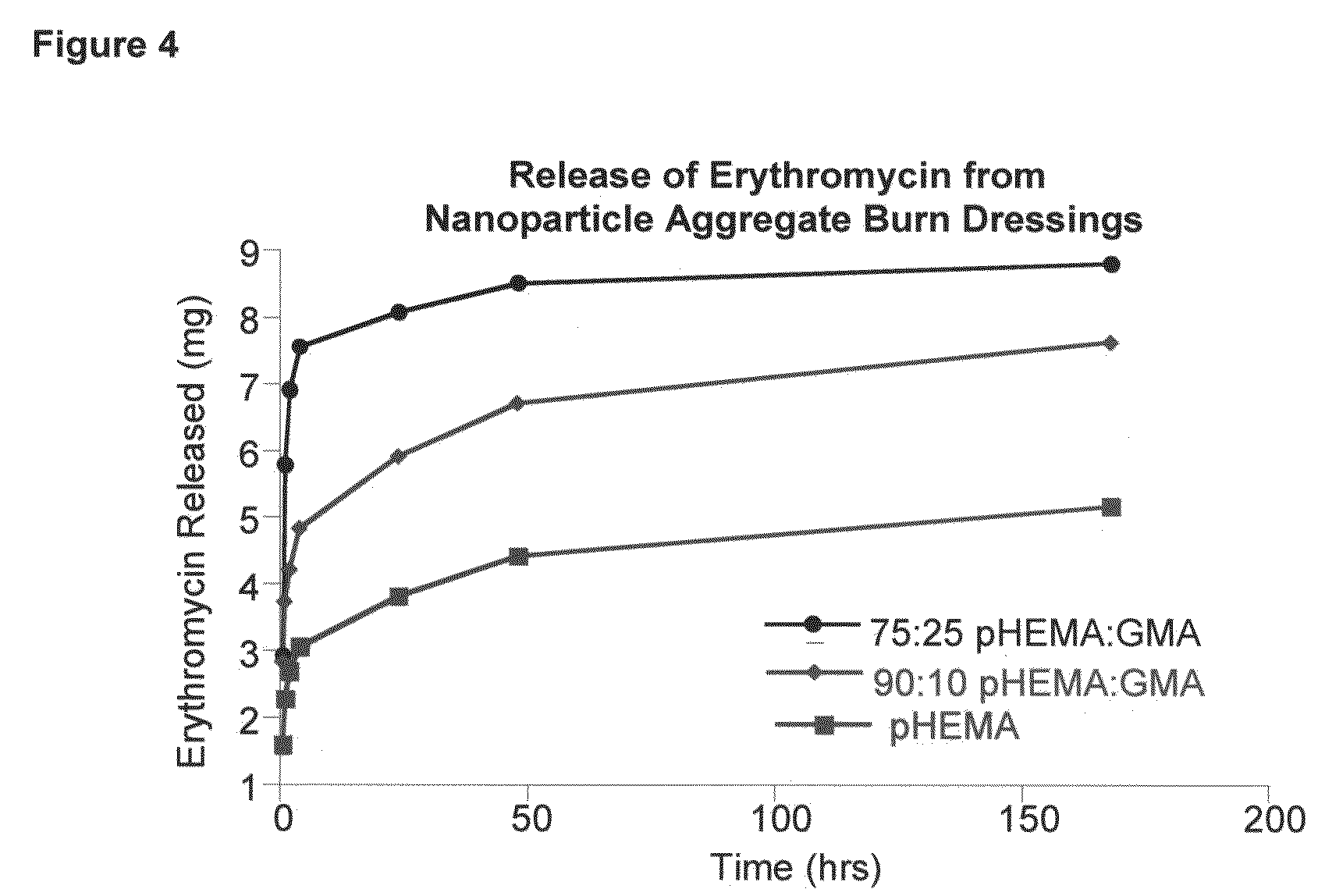

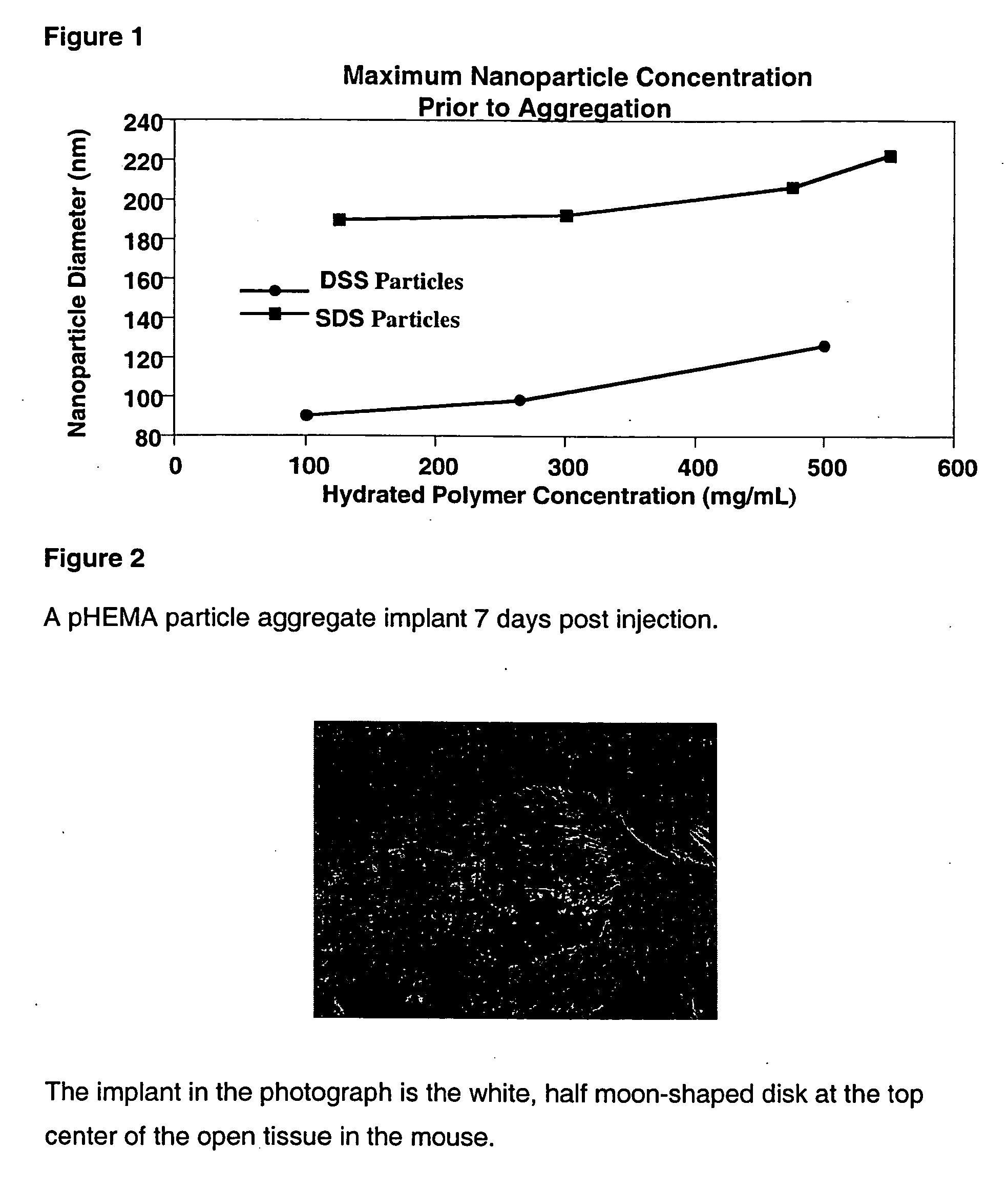

Hydrogel wound dressing and biomaterials formed in situ and their uses

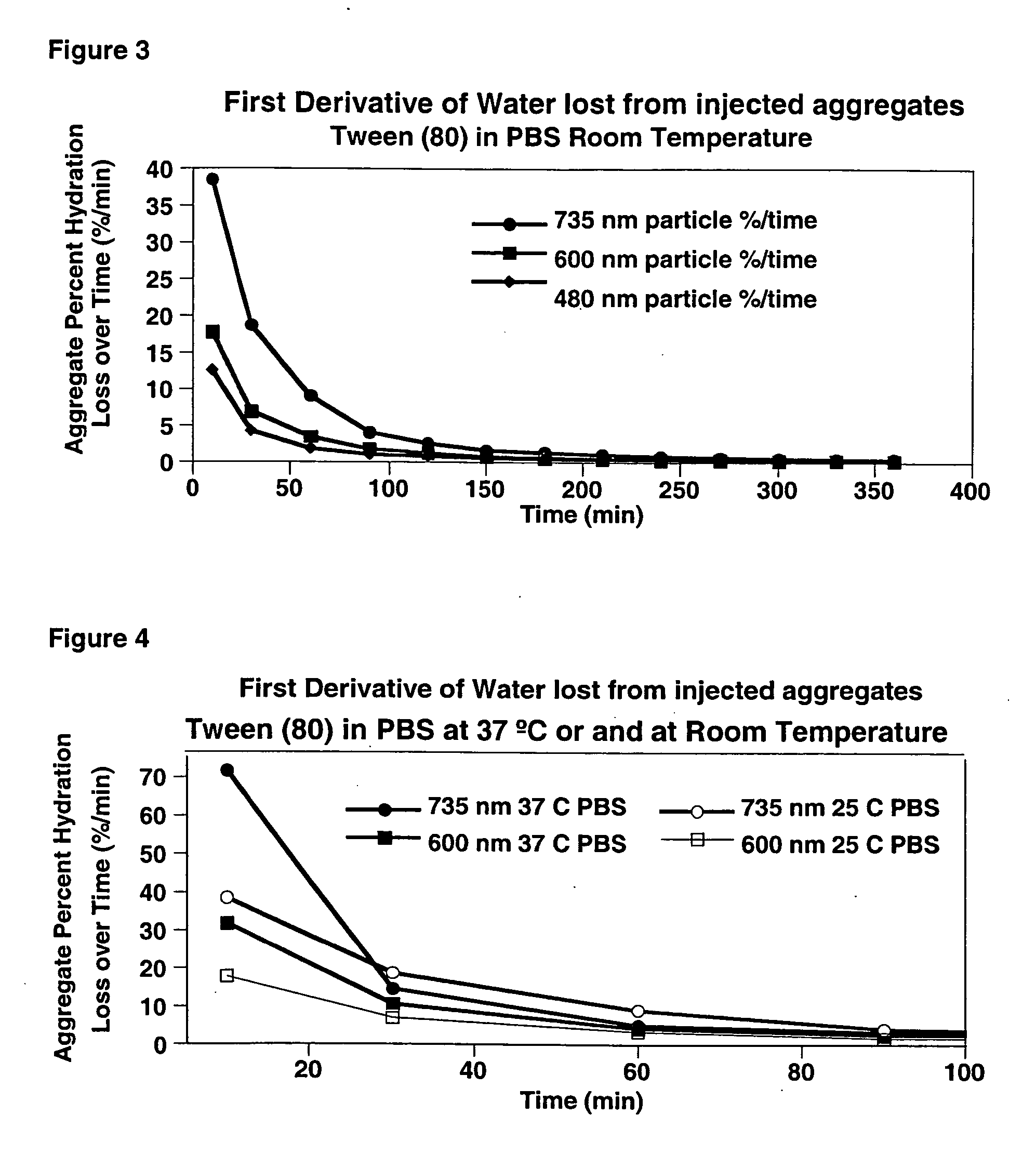

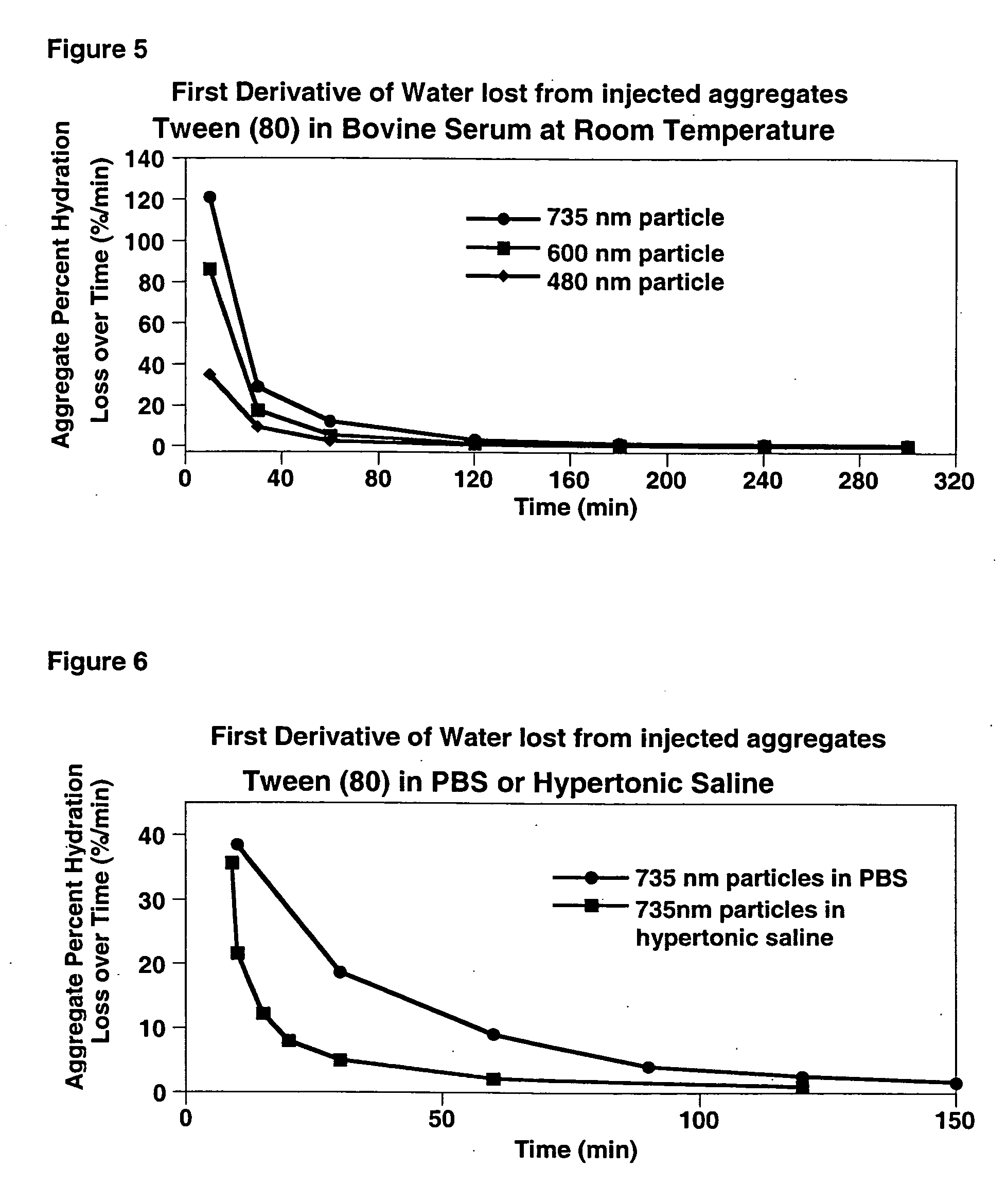

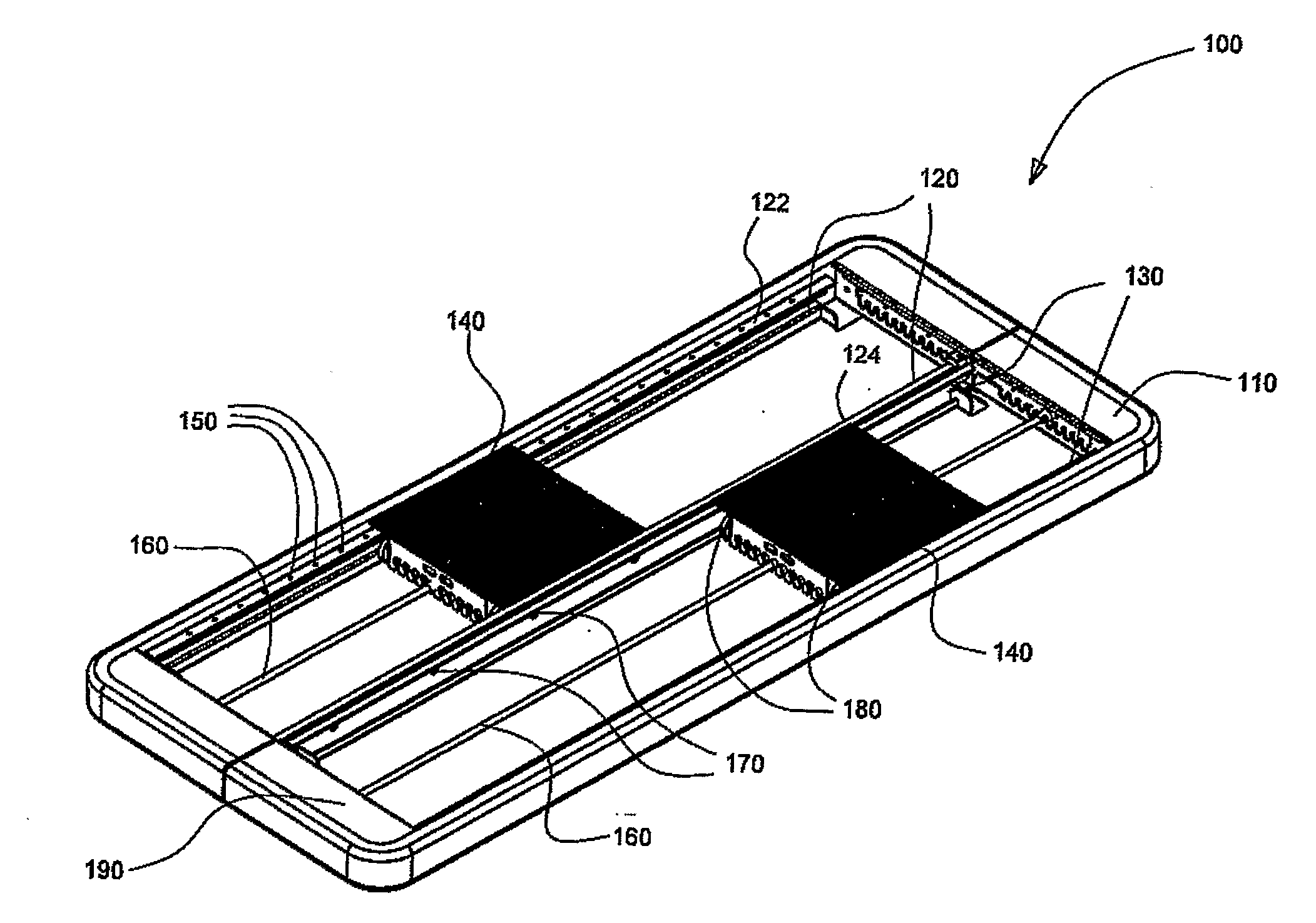

The present invention relates to a method of forming shape-retentive and shape-conforming aggregate wound dressings and biomaterials composed of gel nanoparticles and wound or bodily fluid in which the aggregates are held together by non-covalent bond physical forces such as, without limitation, hydrophobic-hydrophilic interactions and hydrogen bonds. The method comprises introducing a dry powder of gel nanoparticles to a wound site in which the nanoparticles absorb some of the blood or wound exudate and coalesce in situ into the claimed shape-retentive aggregate dressing. The method also comprises introducing the dry nanoparticle powder in or on a wet bodily tissue in vivo to form the claimed shape-retentive biomaterial. In addition, the method also comprises incorporating biomedical agents to produce medicated aggregate dressings or biomaterials for a variety of medical applications. This invention also relates to uses of the method of formation of the shape-retentive aggregates of gel nanoparticles.

Owner:ULURU INC

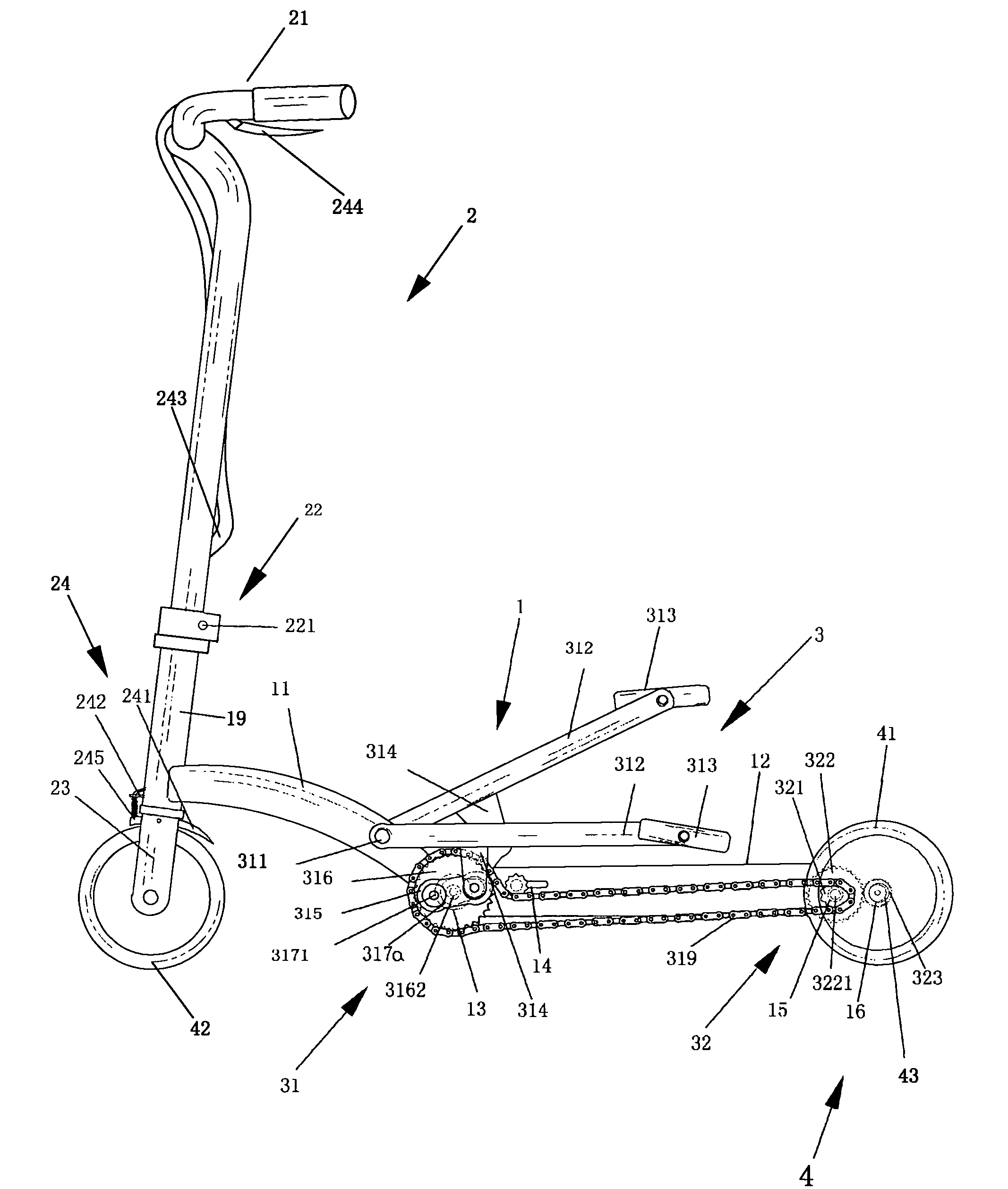

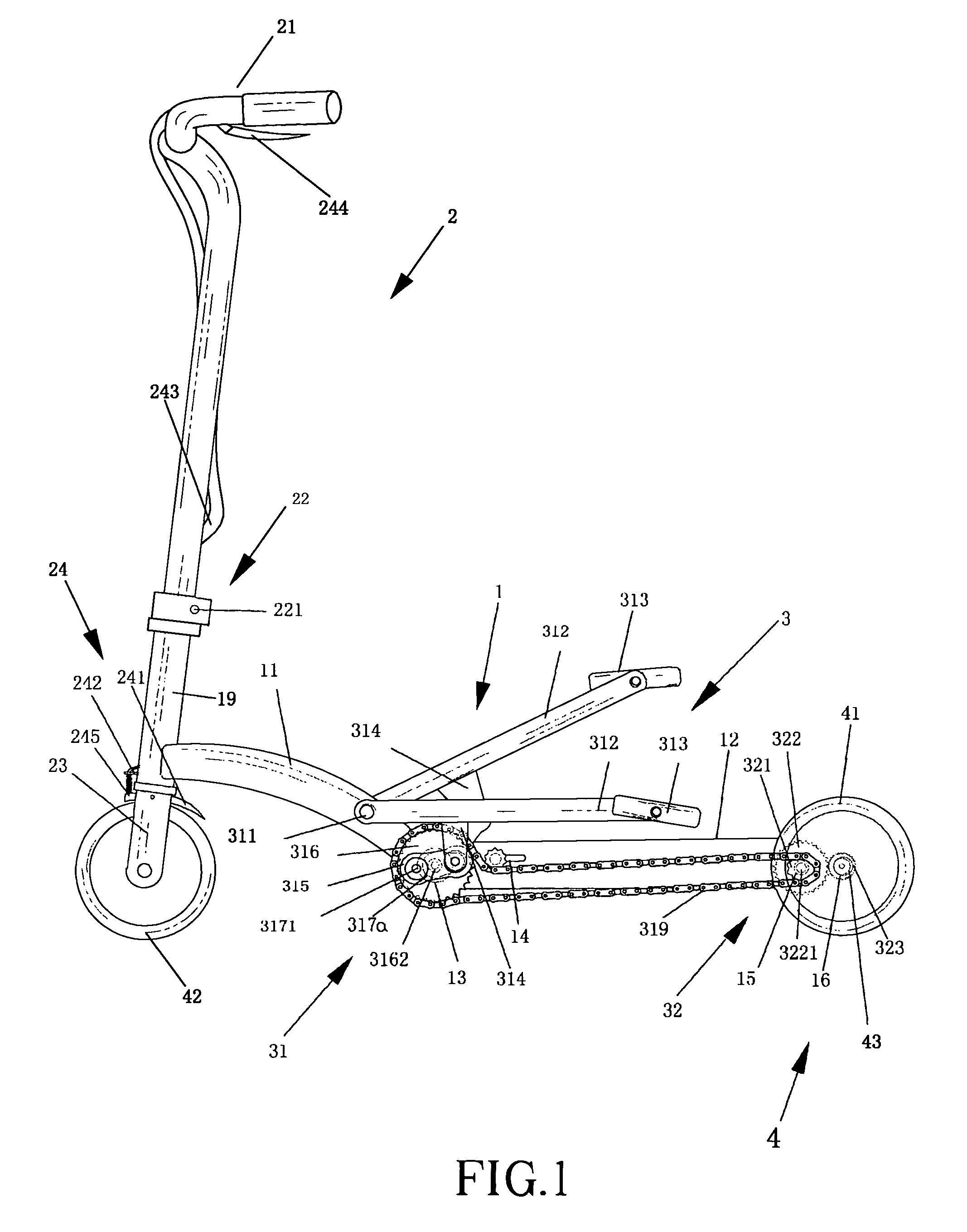

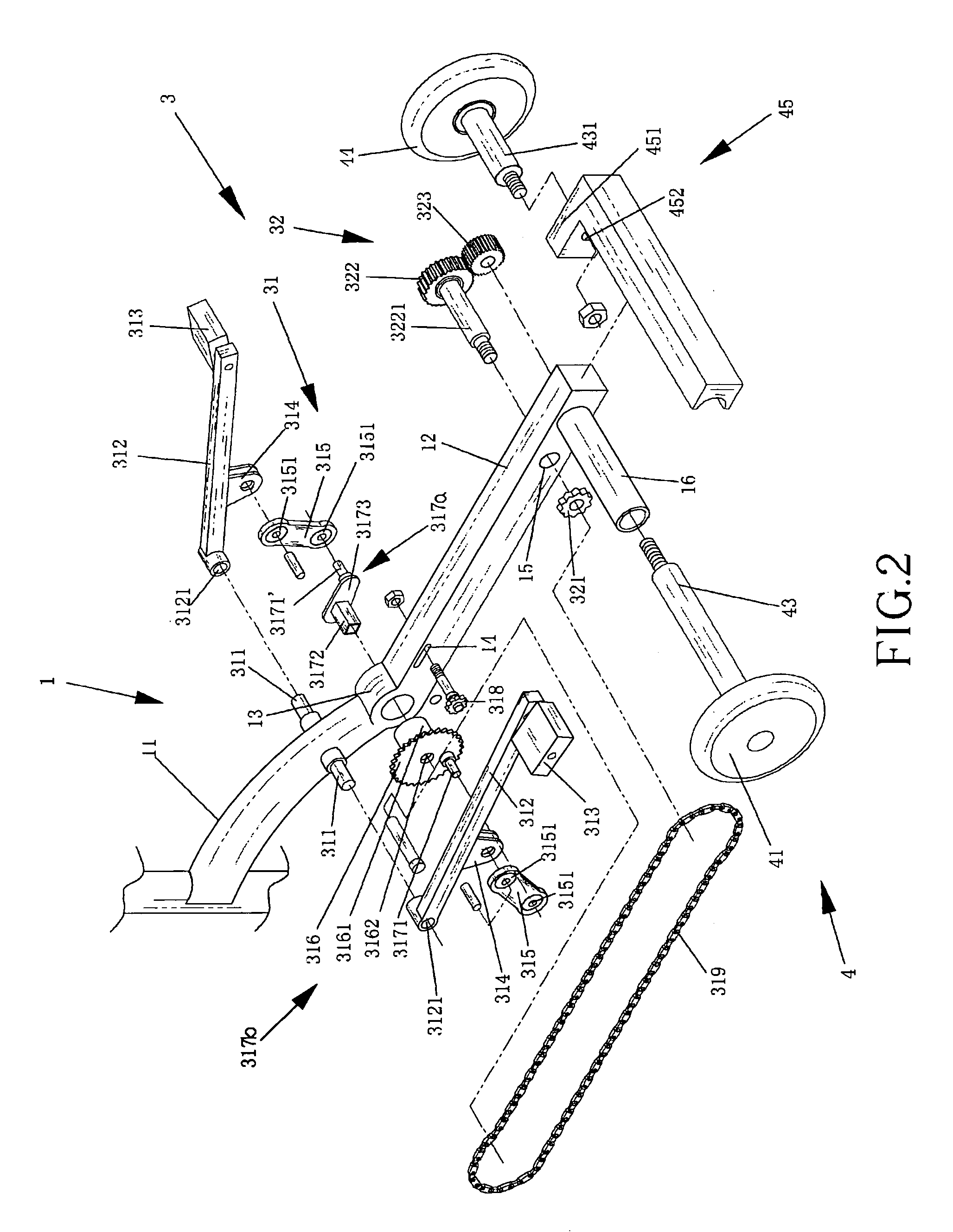

Stepping Scooter

InactiveUS20100001487A1Driving safetyValid conversionFoot-driven leversChain/belt transmissionDrive wheelHuman power

A stepping scooter includes a scooter body for supporting a rider, a moving system, a driving system and a steering lever. The moving system includes a driving wheel rotatable connected with the scooter body, a driven wheel coaxially aligned with the driving wheel and rotatable connected with the scooter body. The driving system includes a driving arrangement pivotally connected to the scooter body, and a transmission and speeding up arrangement engaged with the driving arrangement to convert a human power applied on the driving arrangement into a rotation power to drive the moving system. When the human power is applied on the driving arrangement, the driving wheel is rotated so as to drive the driven wheel to move forward. On the other hand, the transmission and speeding up arrangement is capable of increasing a transmission velocity twice to save a physical force for the rider at the same time.

Owner:PANG MINGFANG

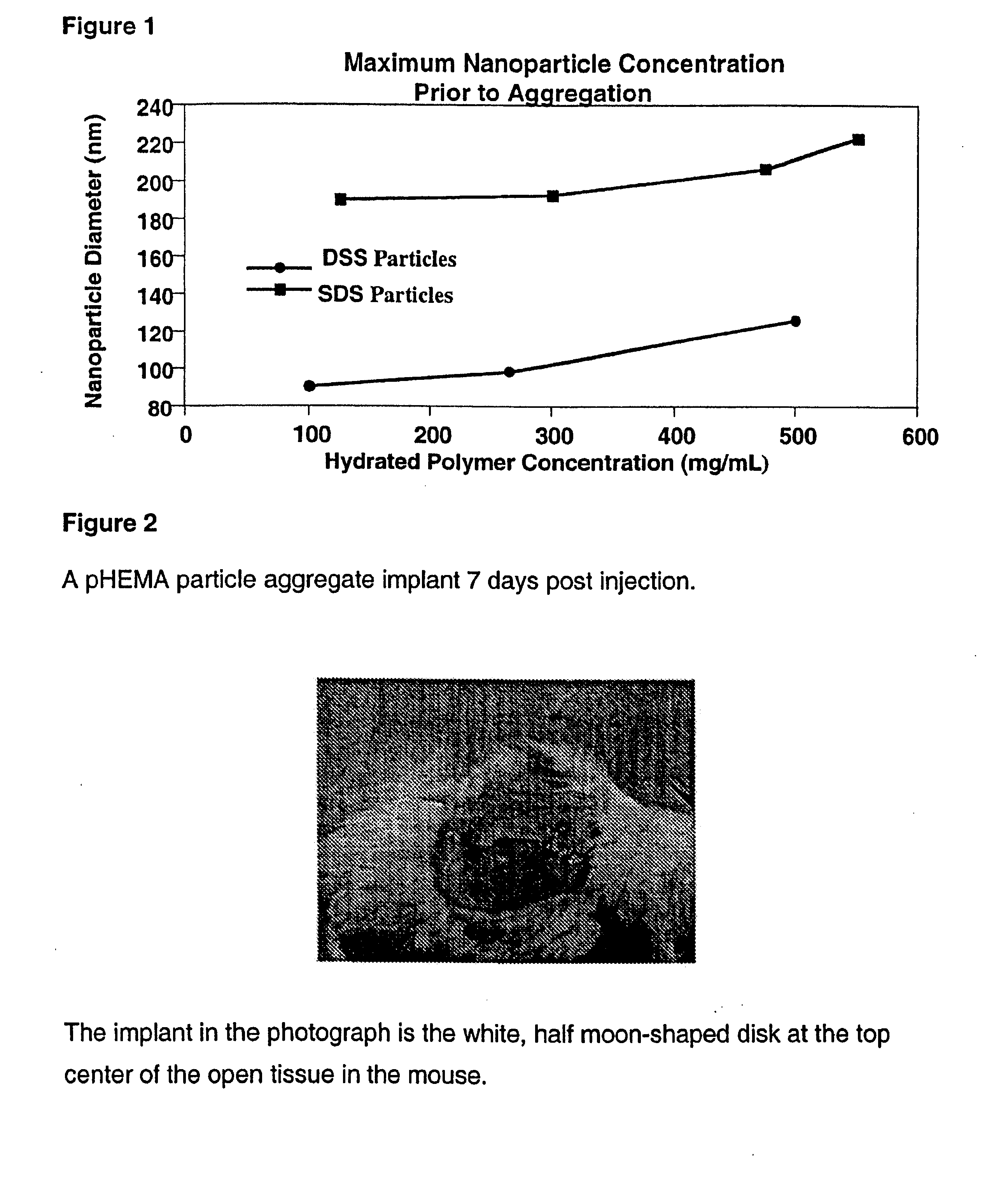

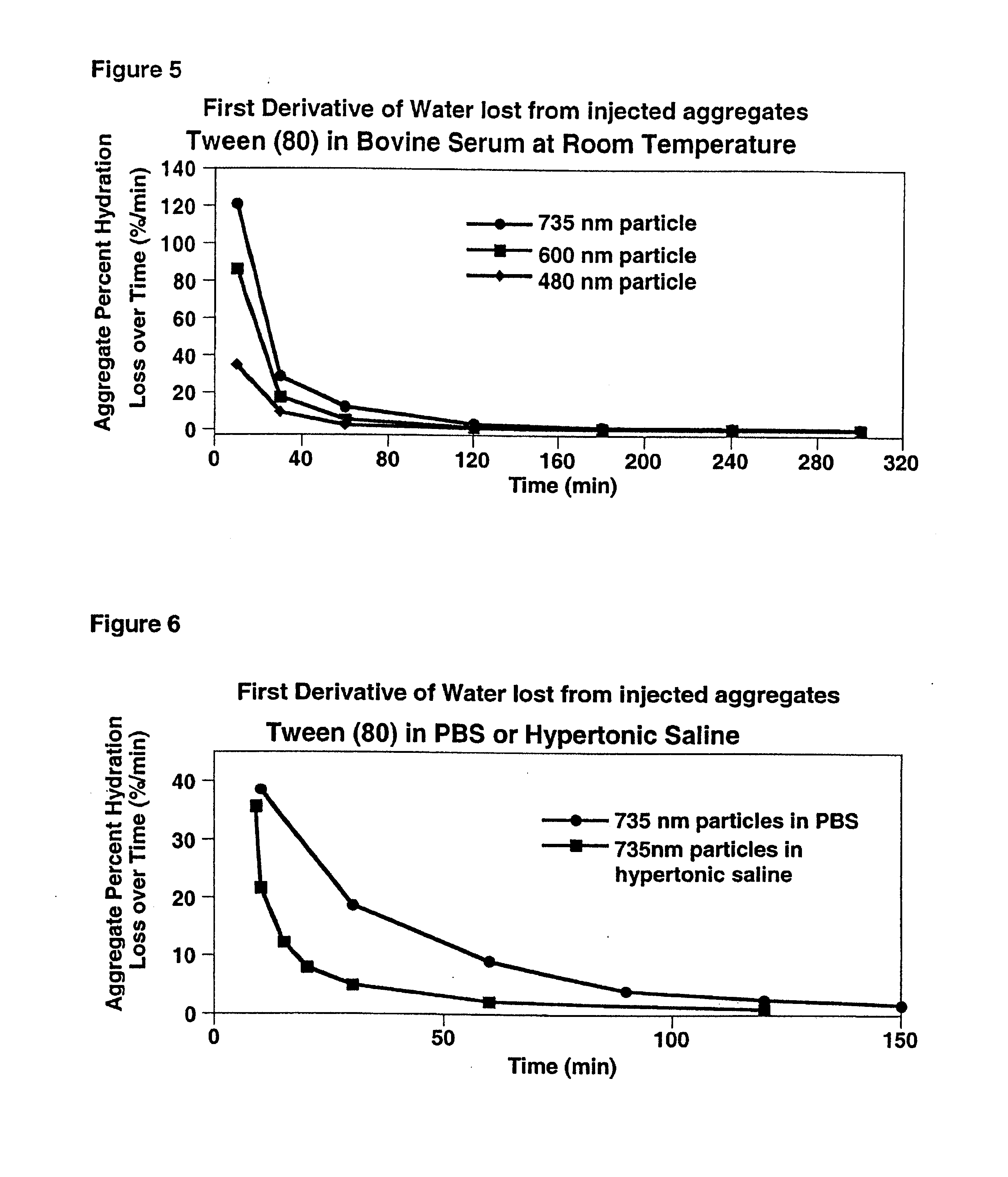

Method of formation of shape-retentive aggregates of gel particles and their uses

The present invention relates to a method of forming shape-retentive aggregates of gel particles in which the aggregates are held together by non-covalent bond physical forces such as, without limitation, hydrophobic-hydrophilic interactions and hydrogen bonds. The method comprises introducing a suspension of gel particles in a polar liquid at a selected concentration, wherein the gel particles have an absolute zeta potential, into a medium in which the absolute zeta potential of the gel particles is decreased, resulting in the gel particles coalescing into the claimed shape-retentive aggregate. This invention also relates to uses of the method of formation of the shape-retentive aggregates of gel particles.

Owner:ULURU INC

Chemical industrial gypsum building materials and method for manufacturing same

InactiveCN101139198AImprove protectionSimple production processSolid waste managementSlurryQuenching

The present invention relates to a chemical gesso building material, which consists of the following components according to weight ratio: 30-60 percent of waste gesso, 15-25 percent of powder coal; 20-30 percent of scoria and 5-20 percent of cement material. The chemical waste stone includes titanium gesso and phosphor gesso. The scoria includes titanium scoria, steel residue, water quenching residue and silicon powder stone. The chemical gesso also includes an assistant agent with the weight ratio of 0-5 percent. The preparation method for the chemical gesso building material includes the following steps: the raw materials are to be prepared according to the corresponding weight ratio for each component; the components are mixed and grinded to prepare the material slurry, and then is to be pressed into a mould; the mould is kept for more than 7 days. The present invention uses the chemical waste residue as the main materials and adopts simple process and equipments; without any calcining, the chemical gesso building products with much better physical force performance can be manufactured. The present invention is with much greater economical benefit and social benefit.

Owner:深圳清研创业投资有限公司

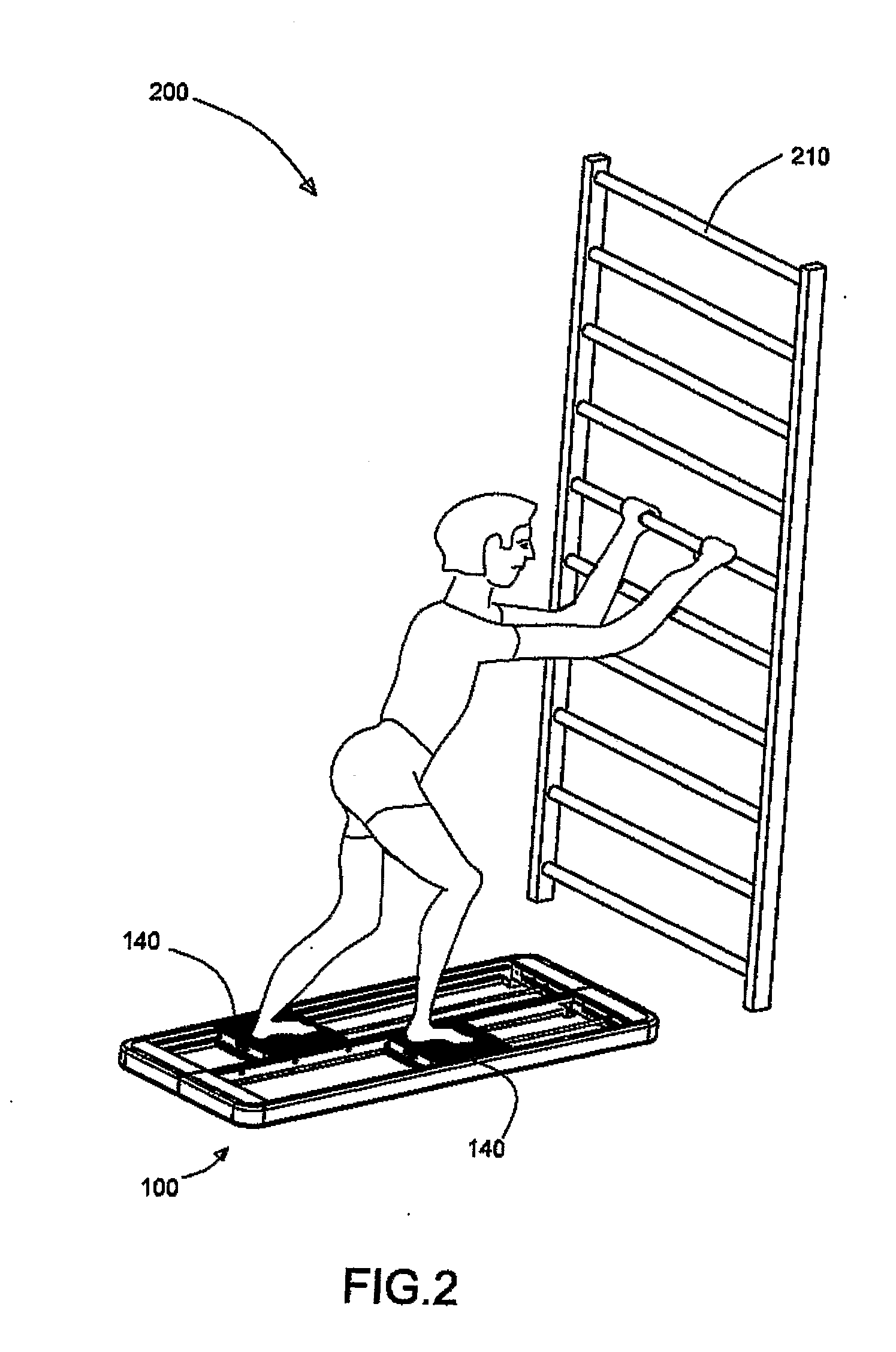

Dual track exercise device

ActiveUS20090098983A1Prevent slippingResilient force resistorsMovement coordination devicesEngineeringPHYSICAL FORCES

Owner:BALANCED BODY INC

Method and apparatus for stimulating nerve regeneration

A method is provided for stimulating nerve growth, especially for nerve regeneration after damage to the nerve. The method comprises: applying thermal energy to one or more nerve segments adjacent a damaged region of the nerve, such that nerve fibers from the treated adjacent segment are stimulated to grow and extend toward the damaged region. The method may be used to enhance mechanical stimulative effect at a terminus of a severed nerve or a region of nerve injured by crush or other physical forces. The method may also be used to treat nerve segments retrograde up the nerve fiber and to increase the response of the injured nerve to regrowth and extension rapidly. An apparatus for delivery of thermal energy to the distal terminus of the severed nerve or region is disclosed. Thermal conductive or electromagnetic energy is delivered through a probe having a handle and a shaft. An energy delivery portion of the probe is configured to apply thermal energy to the distal segments of the severed nerve to promote rapid and more extensive growth of the nerve cells.

Owner:HUGH R SHARKEY

Method of formation of shape-retentive aggregates of gel particles and their uses

The present invention relates to a method of forming shape-retentive aggregates of gel particles in which the aggregates are held together by non-covalent bond physical forces such as, without limitation, hydrophobic-hydrophilic interactions and hydrogen bonds. The method comprises introducing a suspension of gel particles in a polar liquid at a selected concentration, wherein the gel particles have an absolute zeta potential, into a medium in which the absolute zeta potential of the gel particles is decreased, resulting in the gel particles coalescing into the claimed shape-retentive aggregate. This invention also relates to uses of the method of formation of the shape-retentive aggregates of gel particles.

Owner:ULURU INC

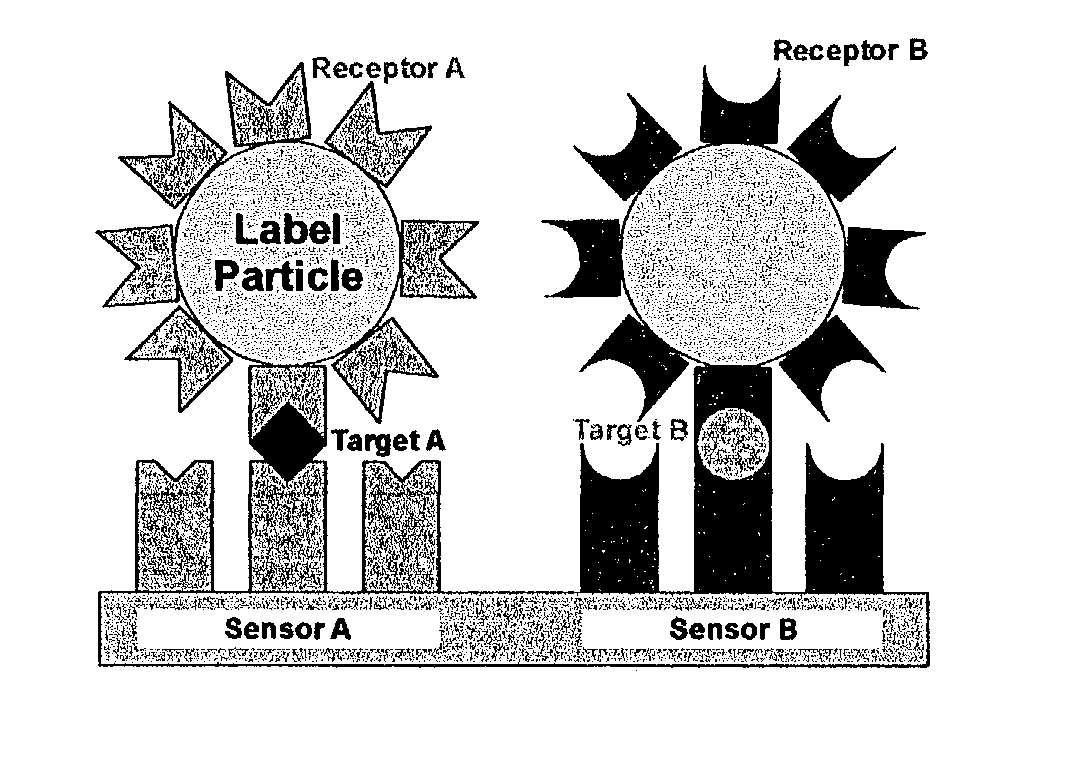

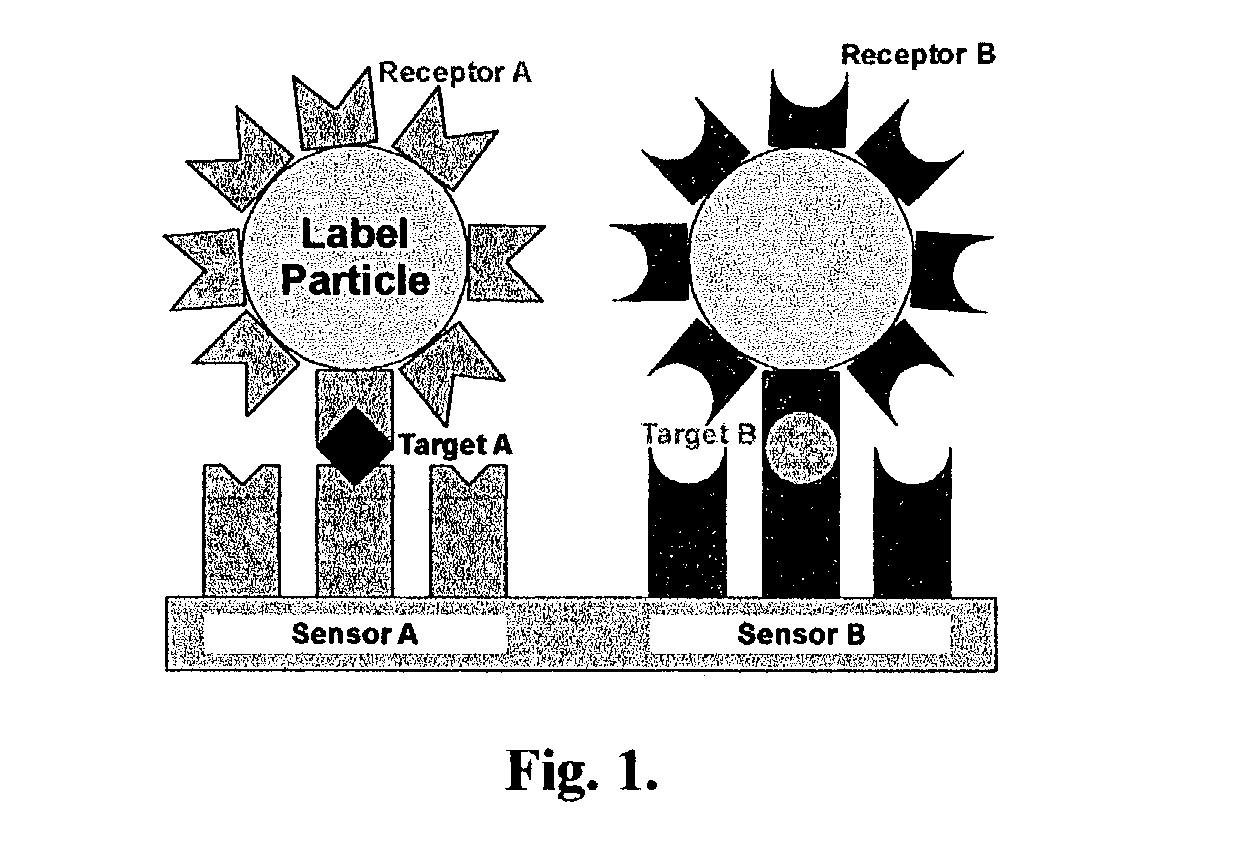

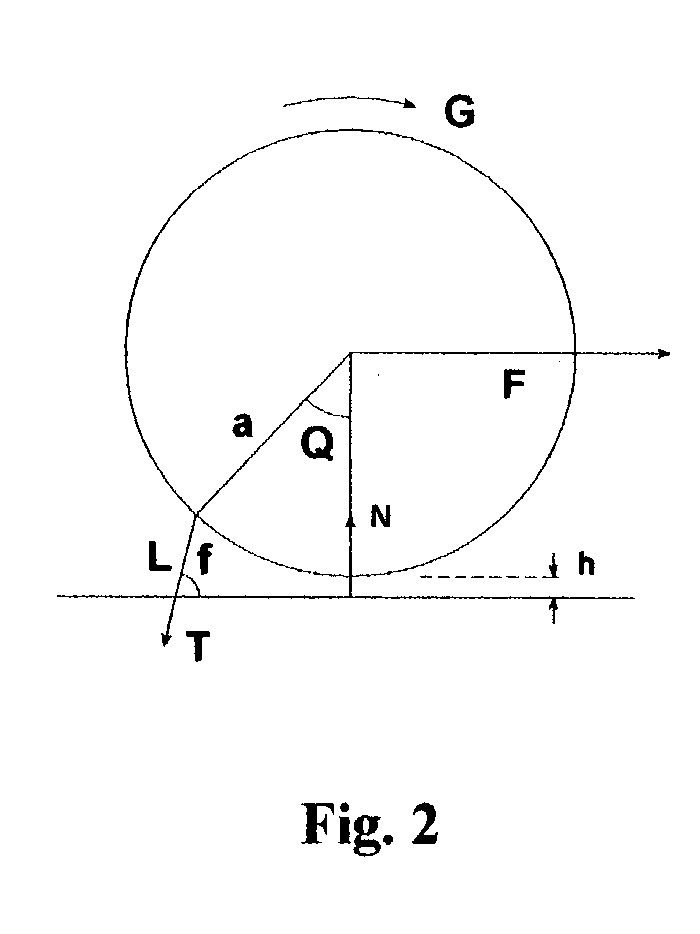

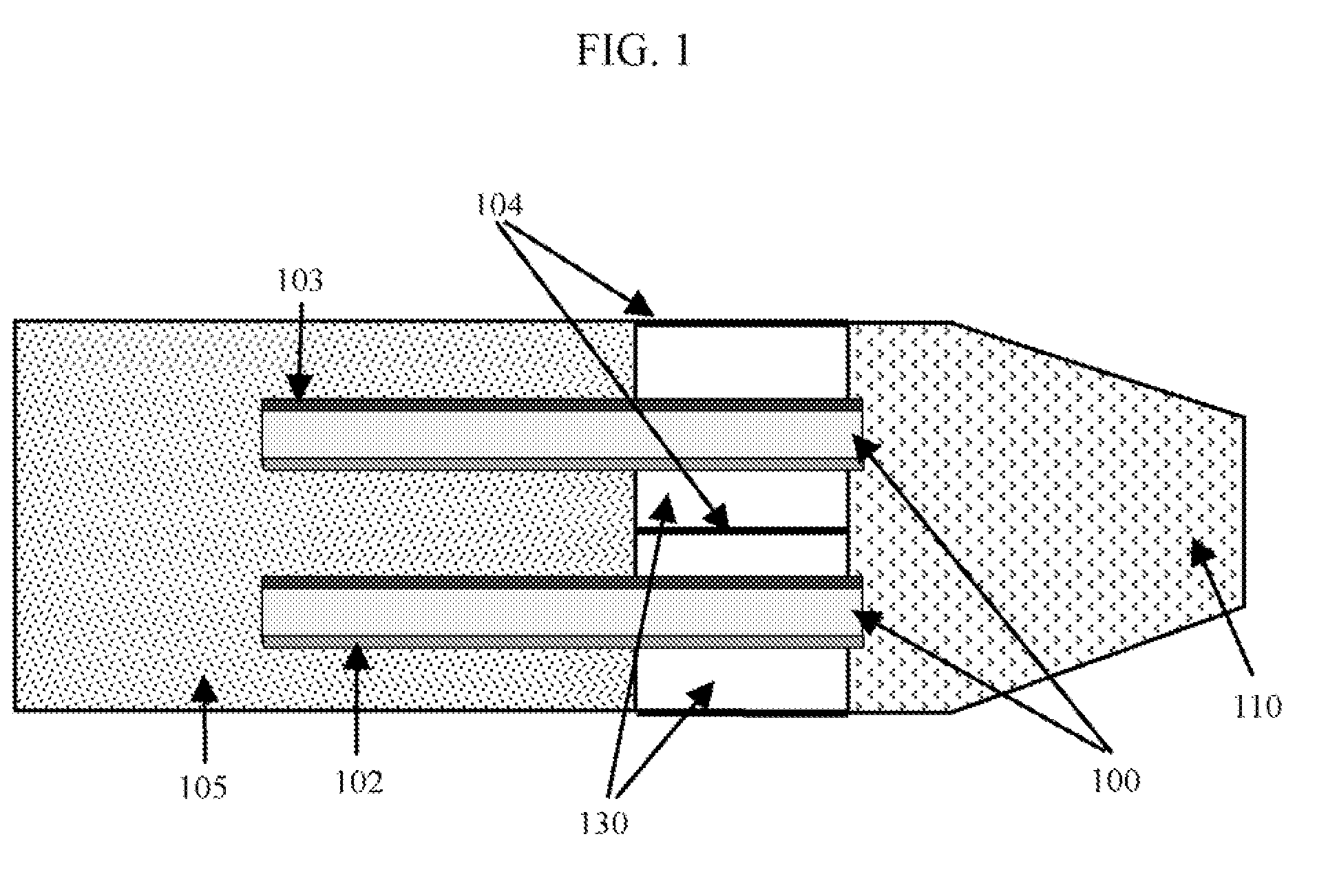

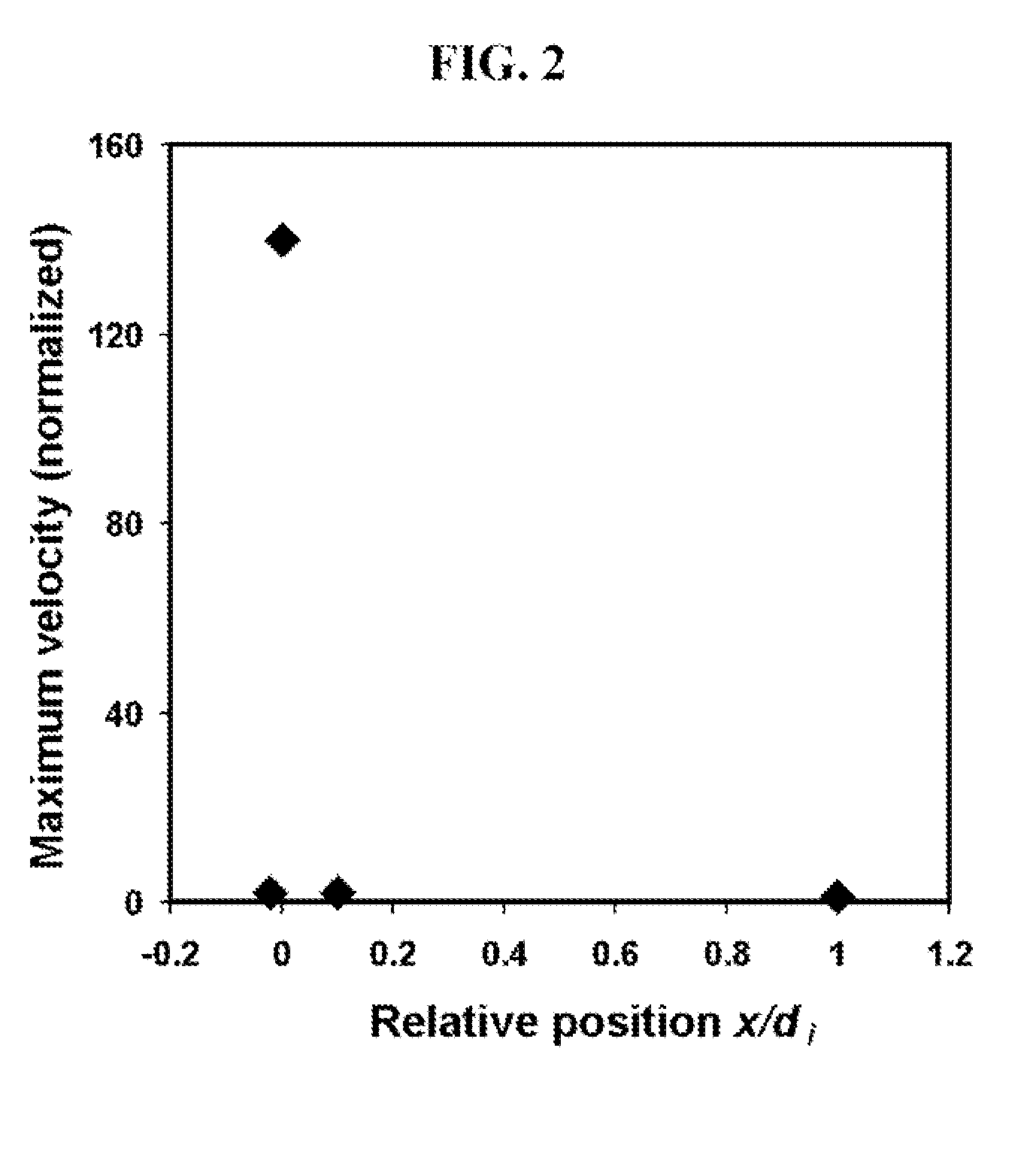

Fluidic force discrimination

InactiveUS20040253744A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicrometer scaleUltimate tensile strength

This invention describes a method of using controlled fluidic forces to improve the performance of a biochemical binding assay where a target molecule is captured by specific molecular recognition onto a substrate surface with an affinity coating, and then labeled with a detectable micrometer-scale particle using a second specific molecular recognition reaction with the target. By using specific ranges of label sizes and laminar flow conditions, controlled fluidic forces can be applied to the label particles in order to selectively remove molecules bound to a surface according to their binding strength, and thereby increase the ratio of specifically bound labels to more weakly attached non-specifically bound labels. This method can be used with a wide variety of label types and associated detection methods, improving the sensitivity and selectivity of a broad range of binding assays.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

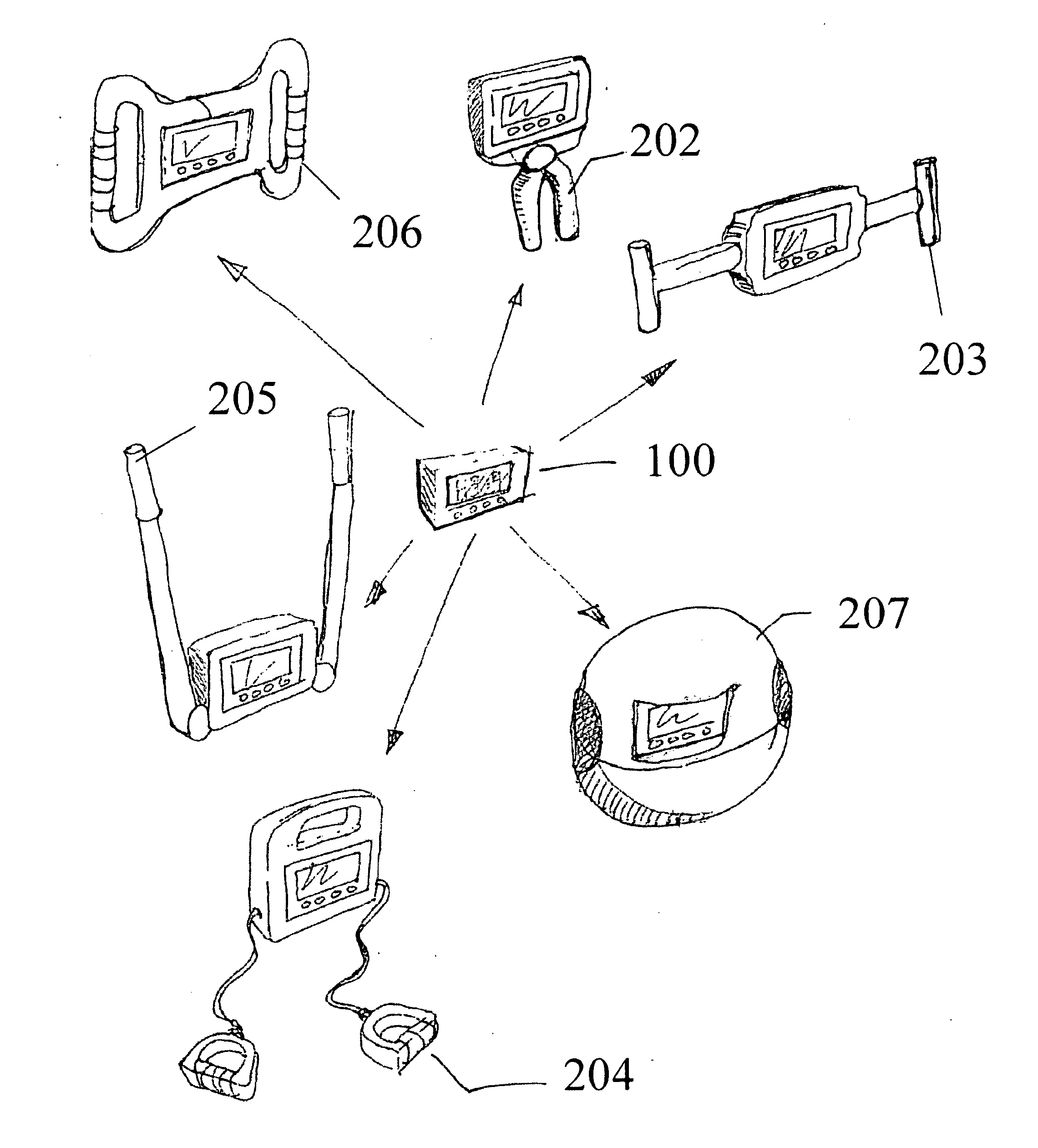

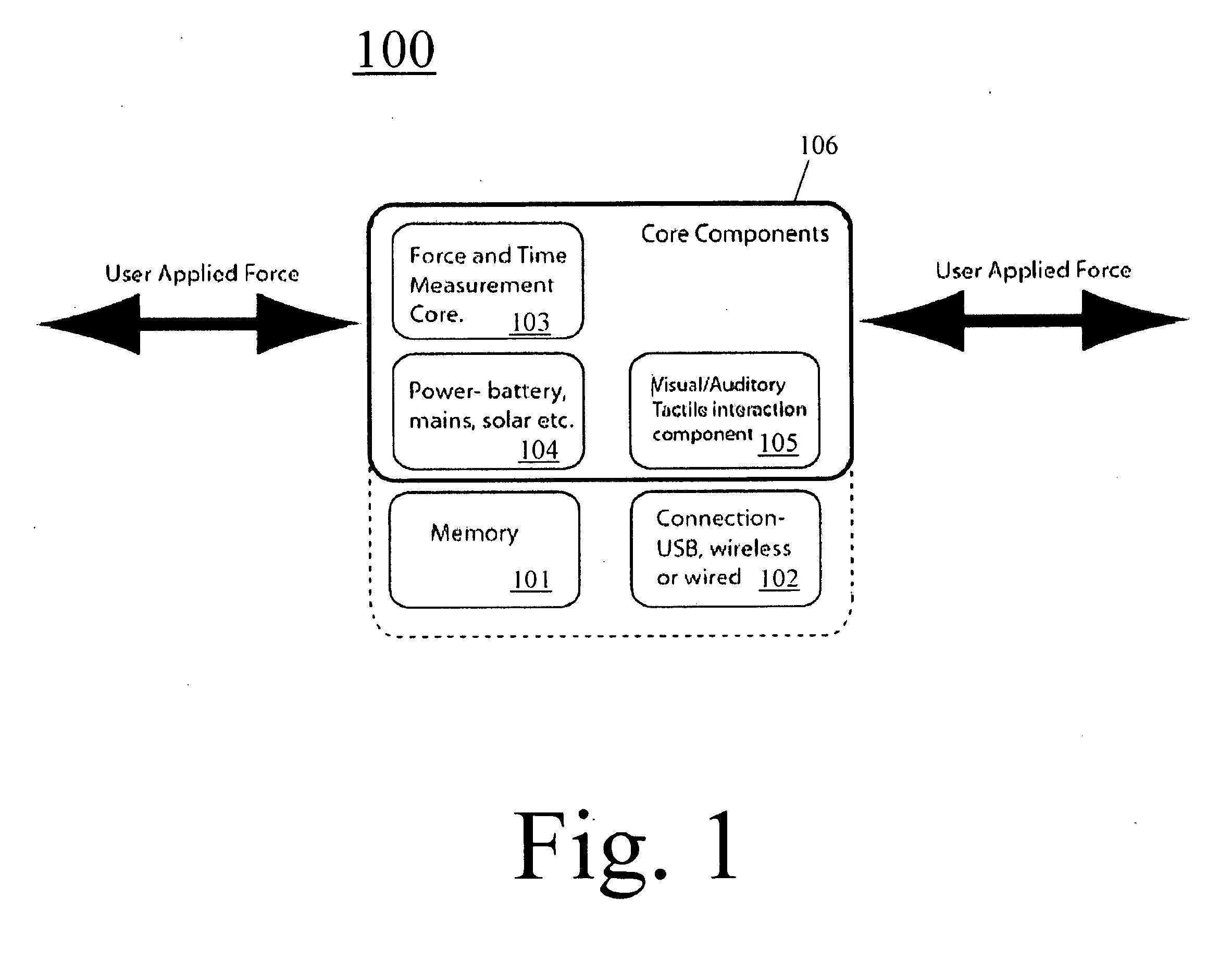

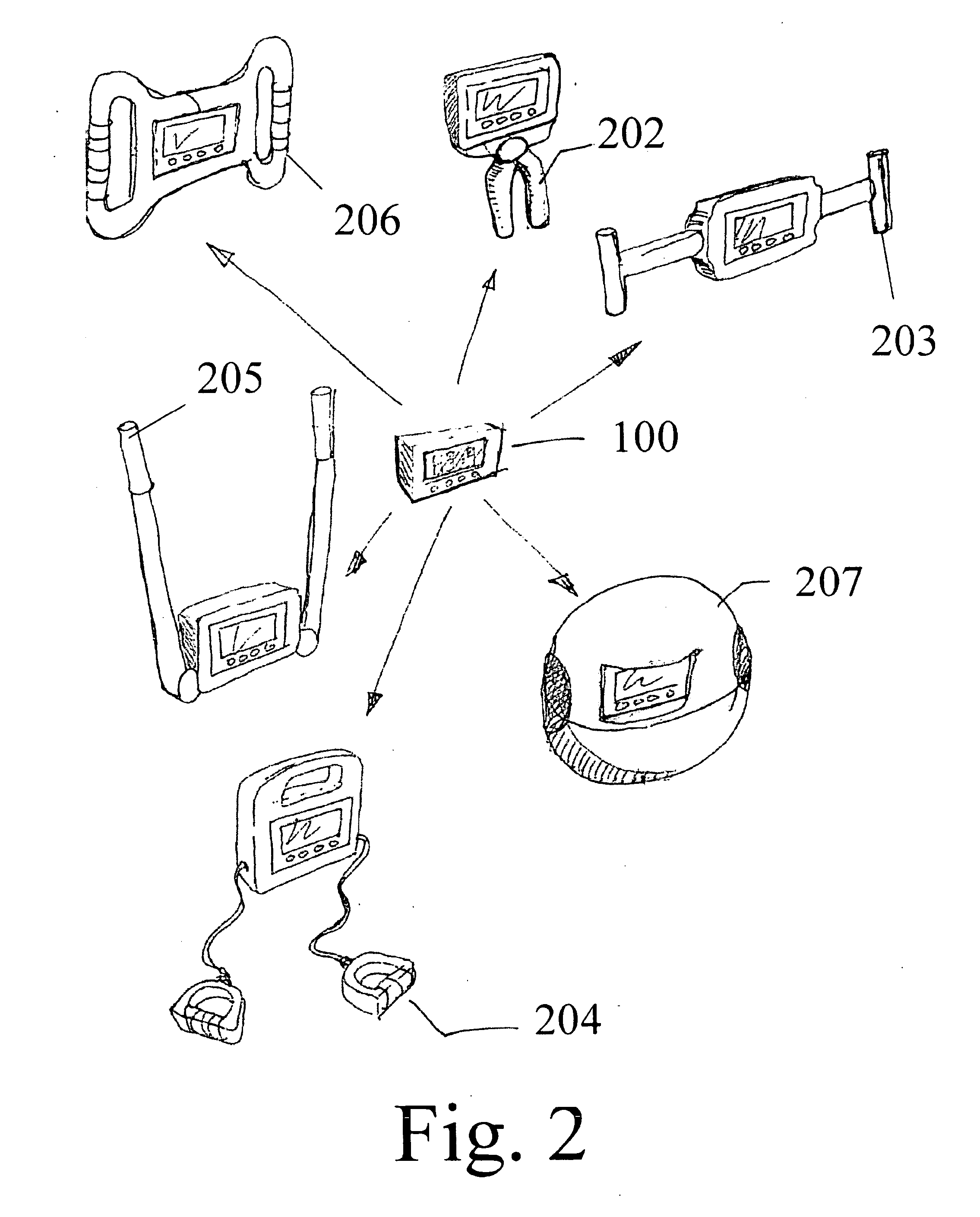

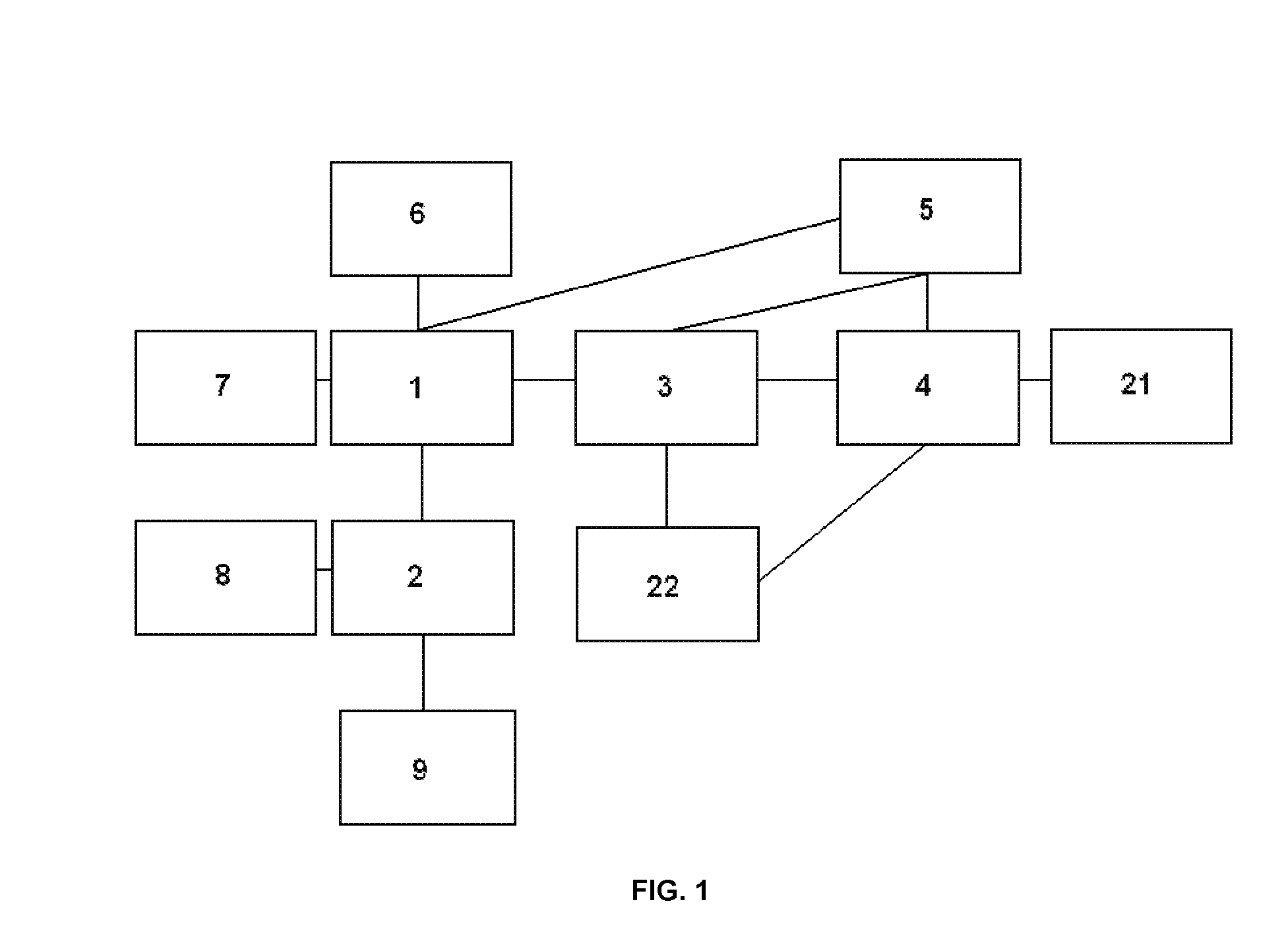

Modular Isometric and Speed Training Device

InactiveUS20100240495A1Little movementFlexible movementClubsMuscle exercising devicesTouch PerceptionModularity

A modular exercise device that provides isometric and speed training in a plurality of embodiments by providing a single sensing core that can be encased in multiple housings. A force measurement smart core is an electronic piece although a pressure indicator or physical force gauge could be used also. A feedback interface providing visual / auditory tactile interaction could be visual using an LCD or LEDS, audible, or tactile (vibration feedback) Means to setup the device include buttons or dials to set the goal force or change the exercise program. A memory allows the device to be programmed to walk the user through a routine or to allow the user to see previous workouts. A connection means to connect to a computer, the network or other electronic device using standard known architecture would be utilized. This could be wireless, wired or through memory cards.

Owner:LAW DAVID +1

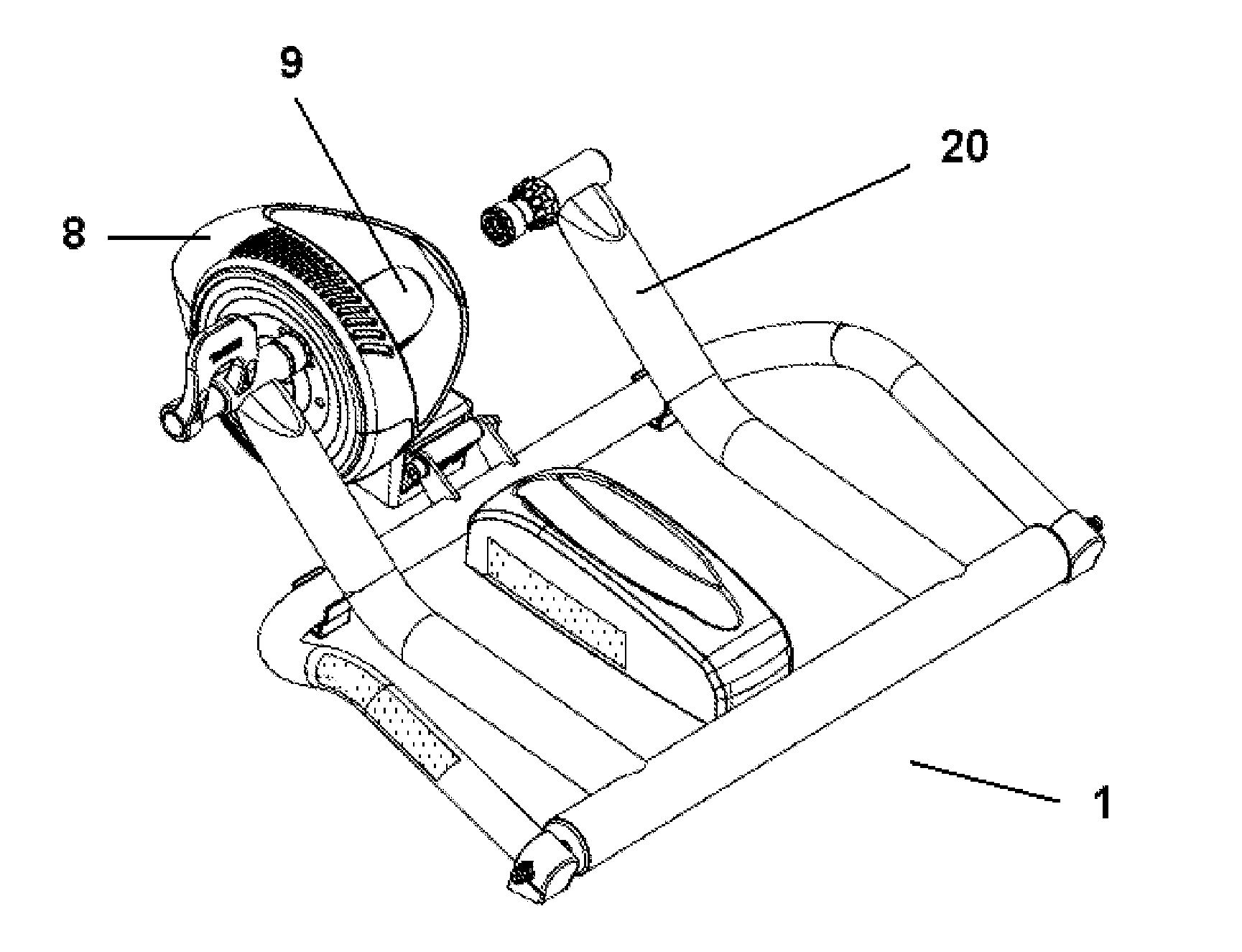

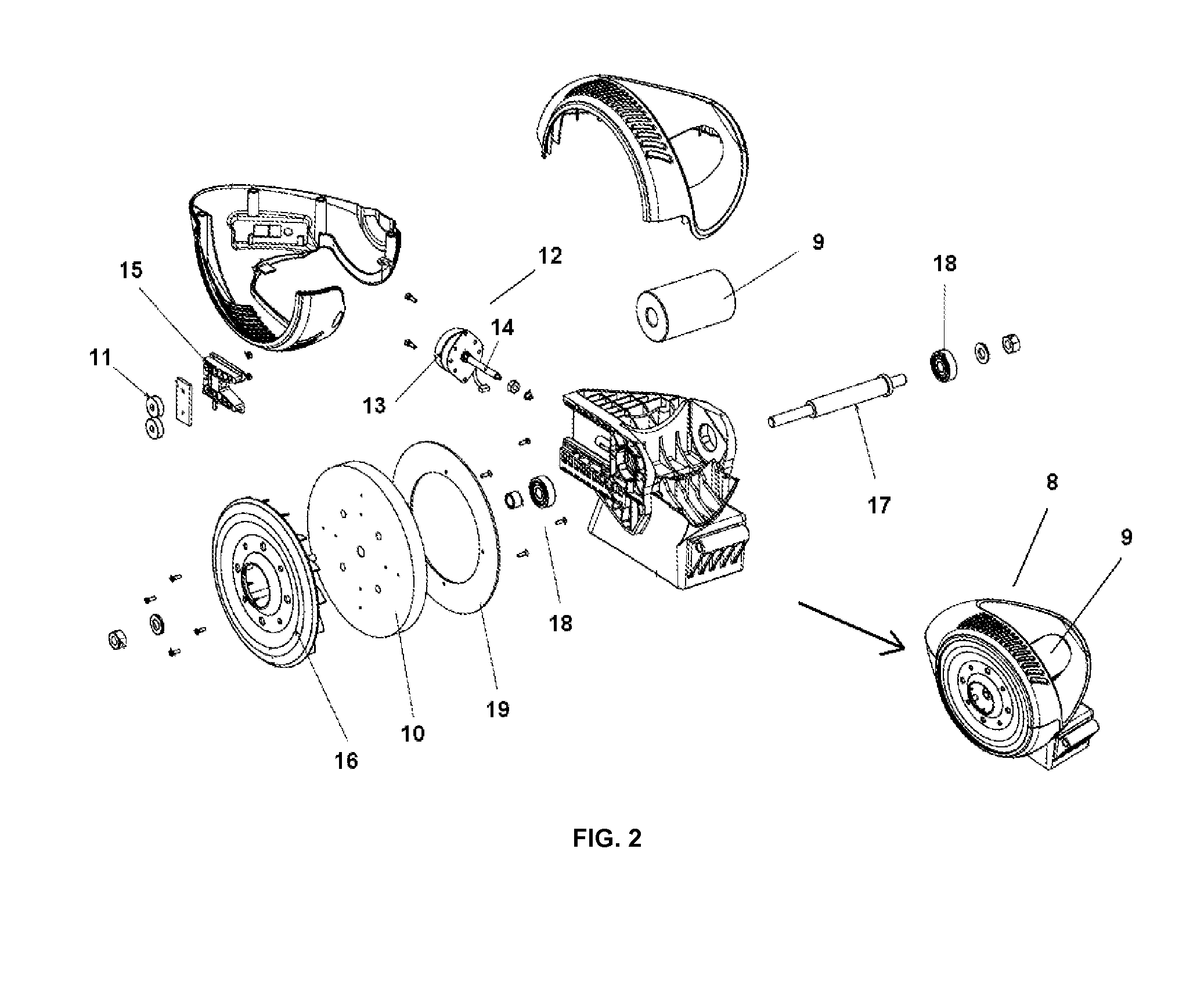

Sports training device

ActiveUS20130210582A1Asynchronous induction clutches/brakesSpace saving gamesCommunication unitEngineering

The present invention relates to a training device usable in both indoor and outdoor training sessions, linked to a communication network capable of connecting multiple remote users during shared training sessions. Said device comprises, among other elements, a training means which presents a variable resistance against a physical force applied by a user; a monitoring and communication unit of data regarding the physical condition of the user and the mechanical conditions of the training means; a simulation and control unit; and a plurality of sensors for acquiring information on the physical condition of the user, on the mechanical conditions of the training means and on the user's environment.

Owner:BKOOL

Enhanced pollenizer and method for increasing seedless watermelon yield

InactiveUS20060168701A1Increase productionEasy to destroyClimate change adaptationPlant genotype modificationPollenizerOpen pollination

Owner:SYNGENTA PARTICIPATIONS AG

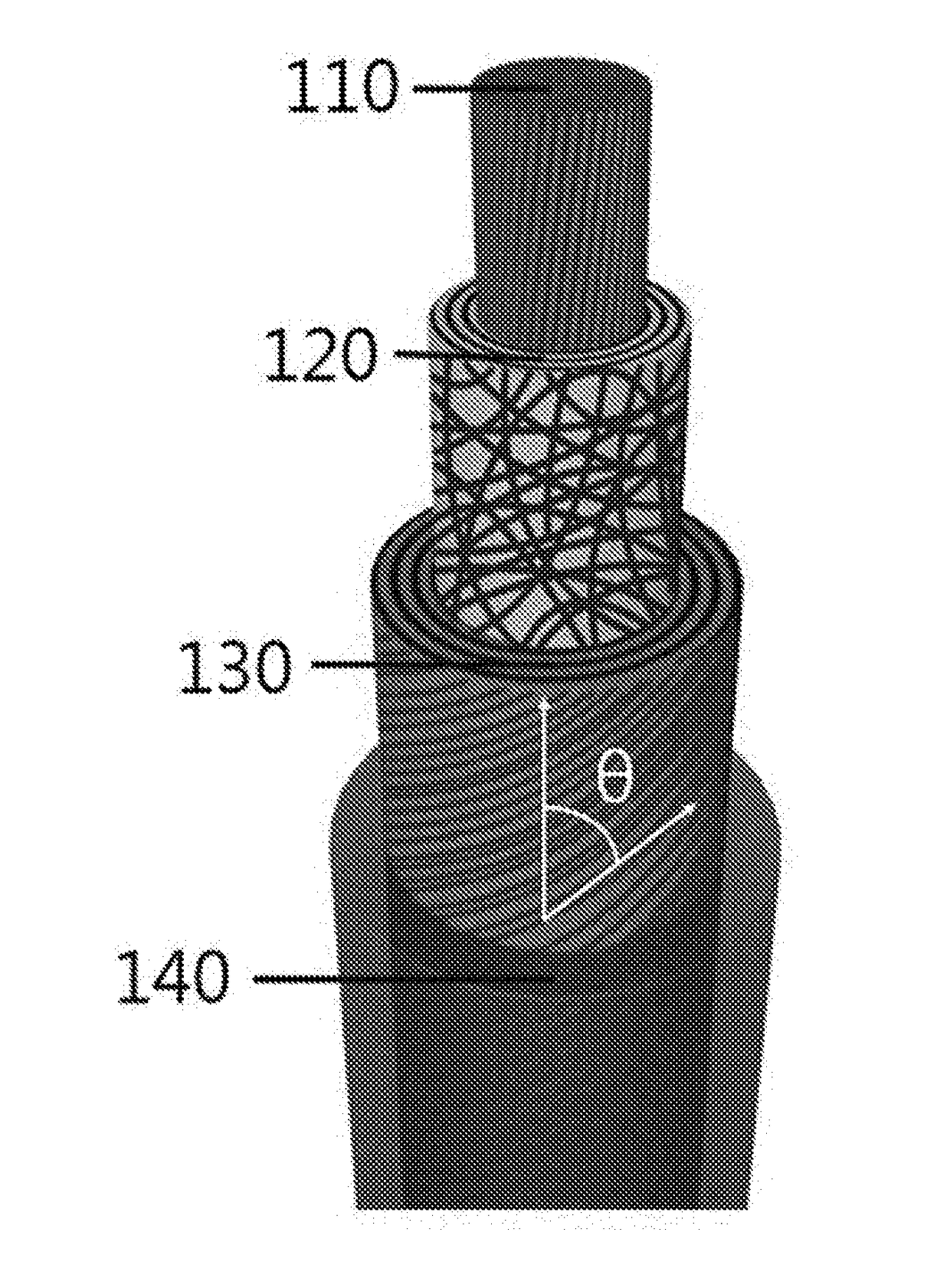

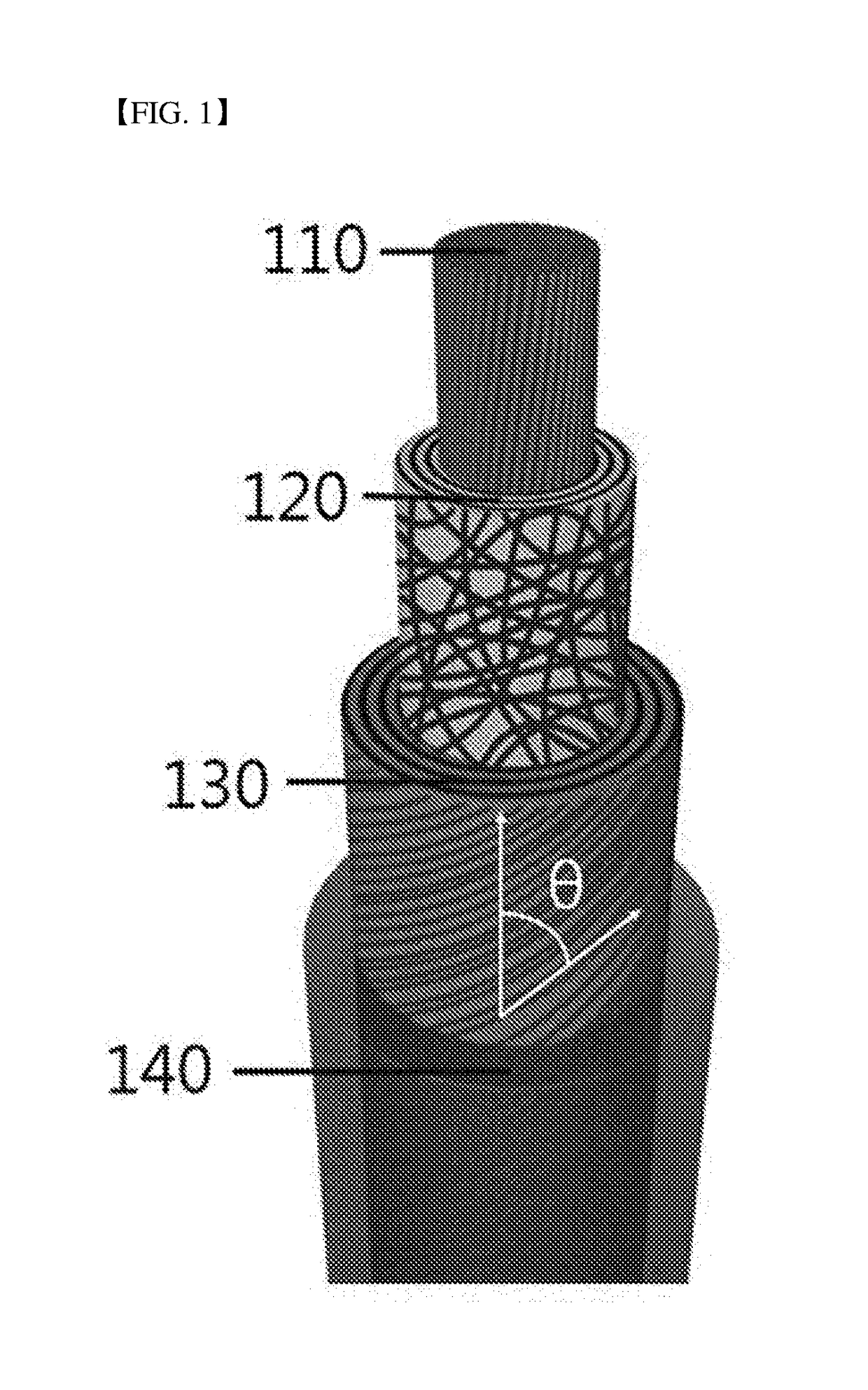

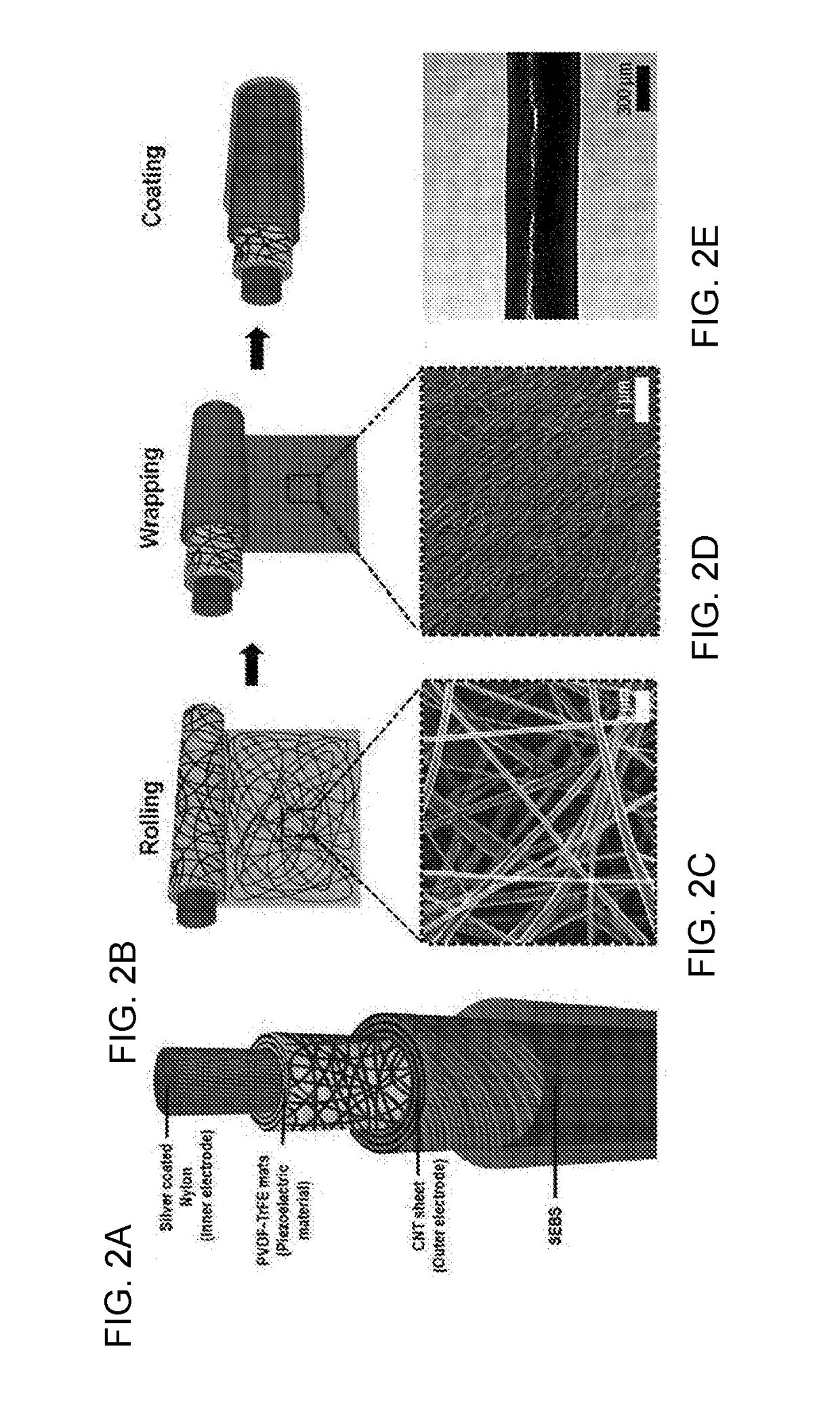

Piezoelectric fiber having excellent flexibility and elasticity, and method for manufacturing the same

ActiveUS20170331027A1Good flexibilitySolving the Insufficiency of ElasticityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesFiberPliability

The present invention relates to a piezoelectric fiber having excellent flexibility, the piezoelectric fiber employs a conductive fiber member as an inner electrode, on which a piezoelectric polymer layer, an outer electrode and a coating layer are sequentially formed, thereby having excellent flexibility and sufficient elasticity to be sewed, woven, knotted or braided. Therefore, the piezoelectric fiber can be applied in power supplies for a variety of sizes and types of wearable electronic devices, portable devices, clothing, etc. In addition, since the piezoelectric fiber has excellent piezoelectricity and durability because of the above-described structure, it can effectively convert deformation or vibration caused by external physical force into electric energy, and thus can replace existing ceramic-based and polymer piezoelectric bodies, etc. Furthermore, an economical and simple method of manufacturing a piezoelectric fiber having excellent piezoelectricity is provided.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

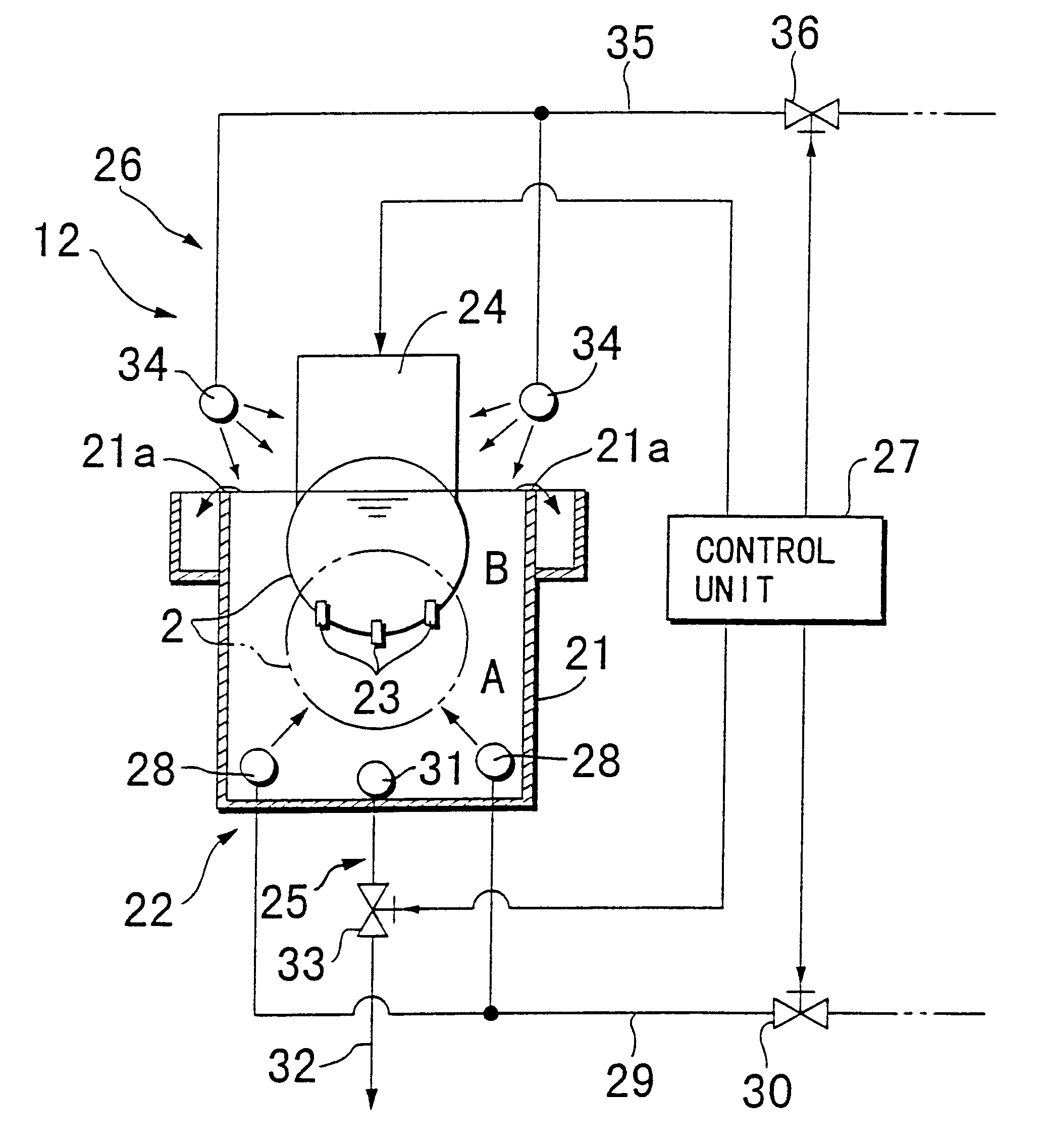

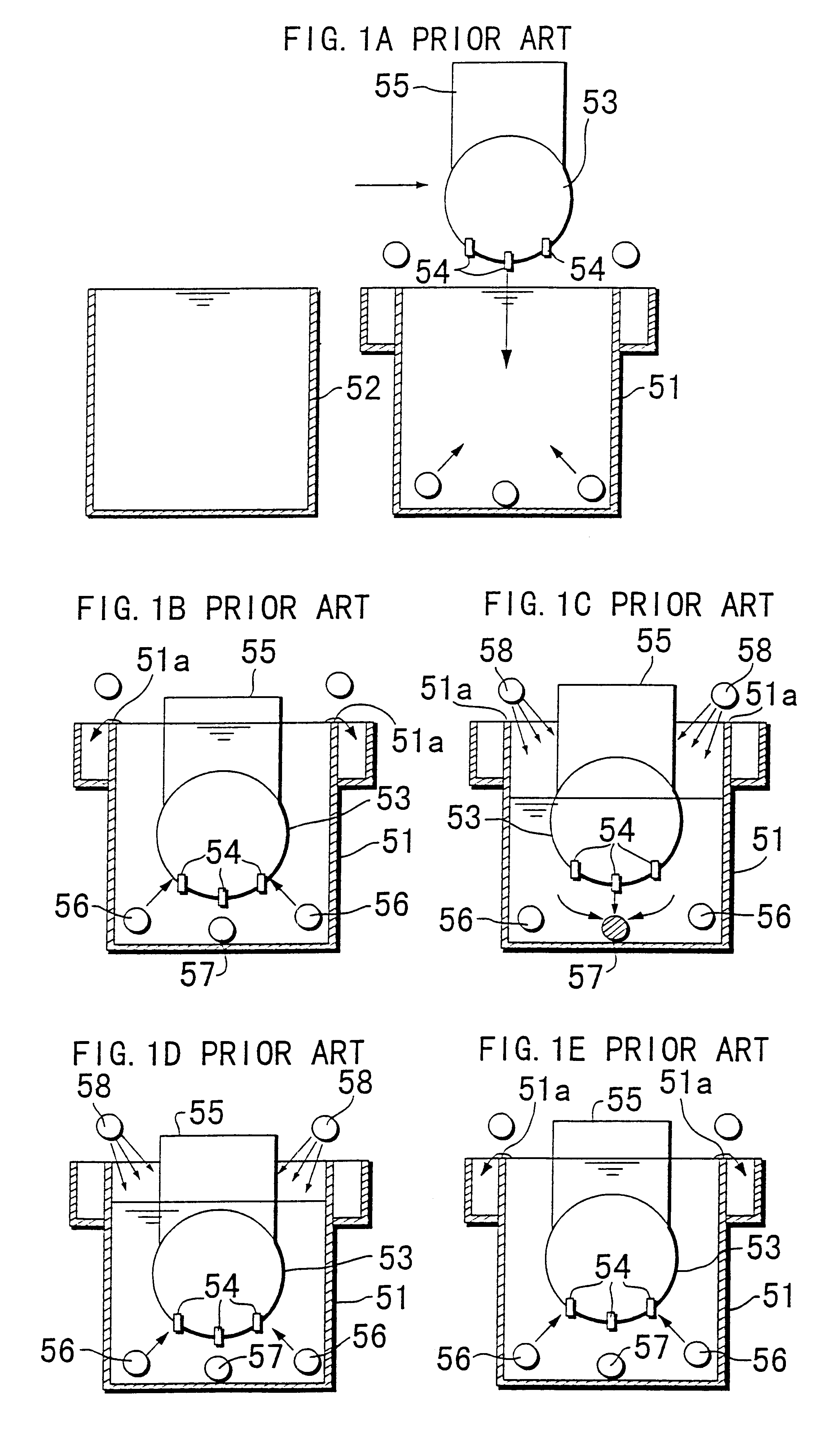

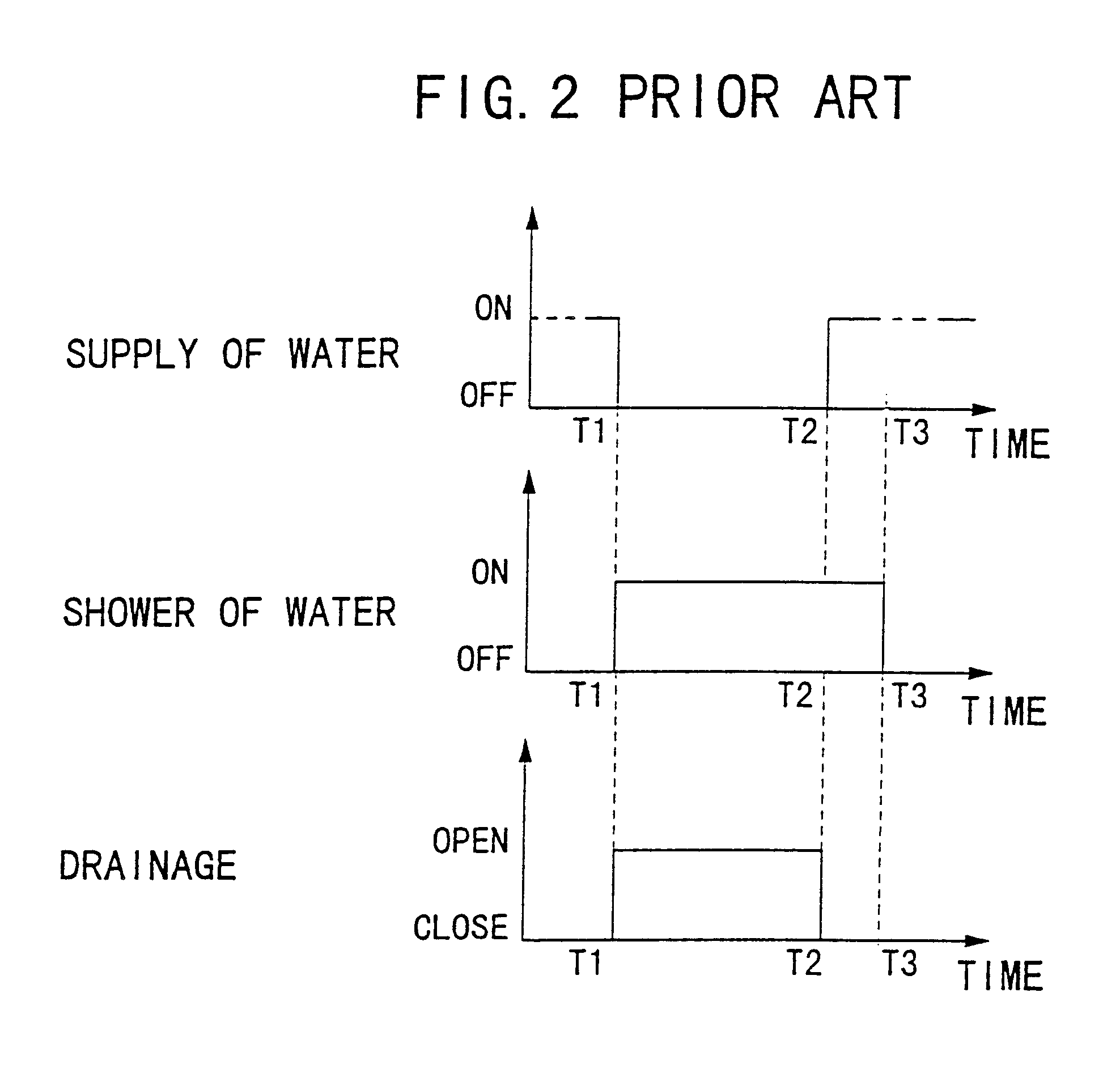

Substrate treating apparatus and substrate treating method

InactiveUS6352083B1Avoid tiltingPrevent adhesionSemiconductor/solid-state device manufacturingCleaning using liquidsMedicineControl cell

A control unit controls a lifter to raise at least part of each of a group of substrates above the liquid level of a treating liquid in a treating bath. Thereafter, a valve is opened to drain the treating liquid from the treating bath at a high speed. As a result, a physical force to tilt and adhere an upper portion of the adjacent substrates accompanied by lowering of the liquid level of the treating liquid due to the high speed drainage acts upon a lower portion of the substrates near the lowered liquid level of the treating liquid, thereby reducing the physical force exerted on the substrates. This arrangement, even if a holding interval between the substrates is narrowed at a half of a normal pitch, eliminates a contact of the adjacent substrates and prevents damage of the substrates due to the contact without providing an additional member such as a substrate support guide in the treating bath.

Owner:DAINIPPON SCREEN MTG CO LTD

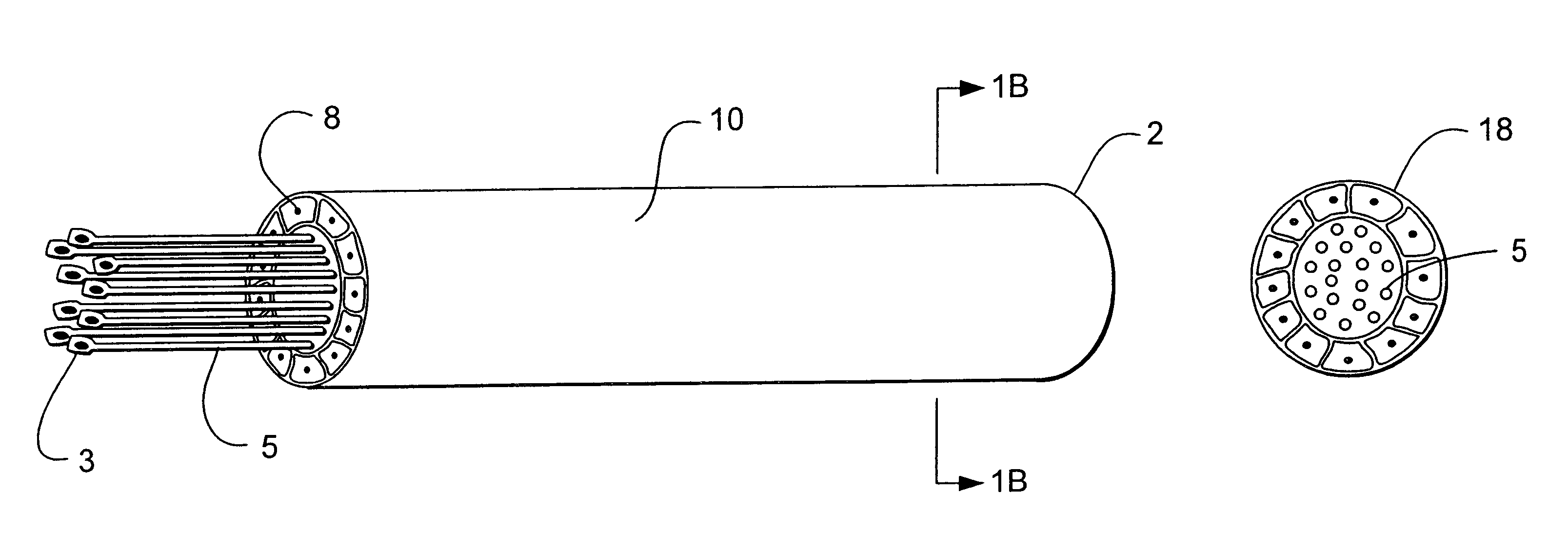

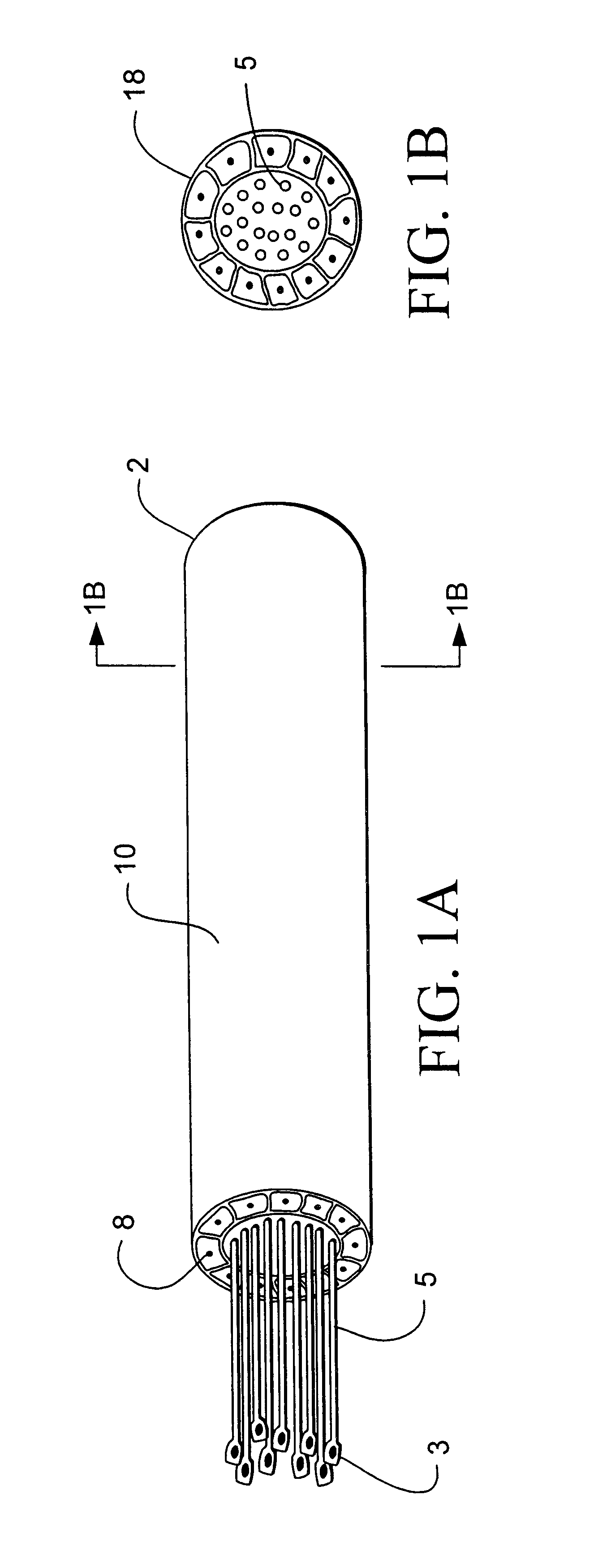

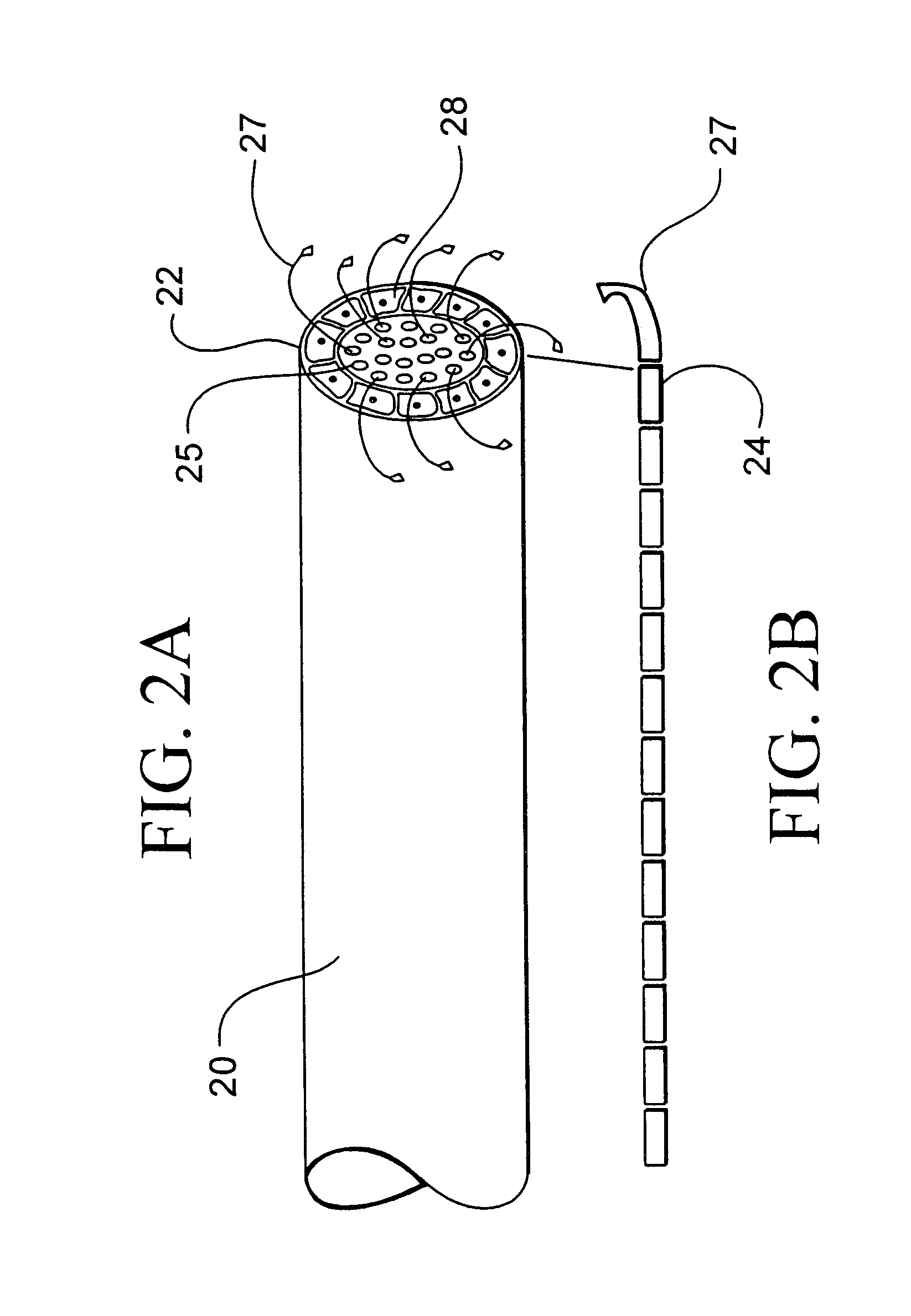

Thrombectomy microcatheter

The present invention is an ultrasonic thrombectomy catheter that produces physical forces (shear rates) strong enough to emulsify obstructions such as thrombi and emboli without causing damage to arterial walls. This is accomplished by properly arranging piezoelectric transducers within a catheter and a tubular catheter head separated by a gap to generate acoustic streaming that simultaneously emulsifies the obstruction and sweeps resulting debris into a catheter lumen for removal. The open gap may be formed by supporting struts that connect the catheter to the catheter head. The design of the catheter tip allows the fabrication of catheters capable of removing partial or complete blockages from arteries and other vessels having diameters as small as 2 mm.

Owner:CFD RES CORP

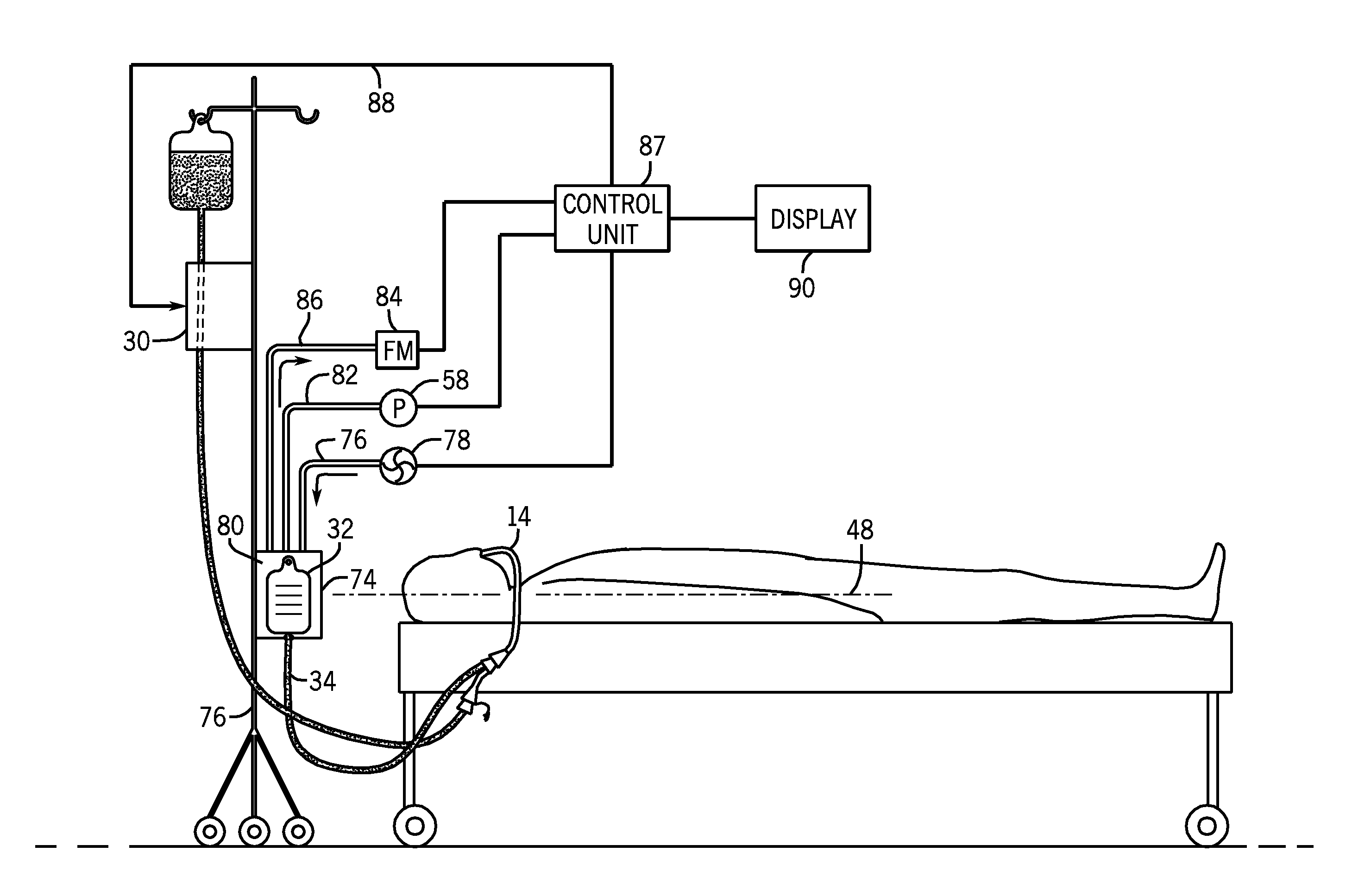

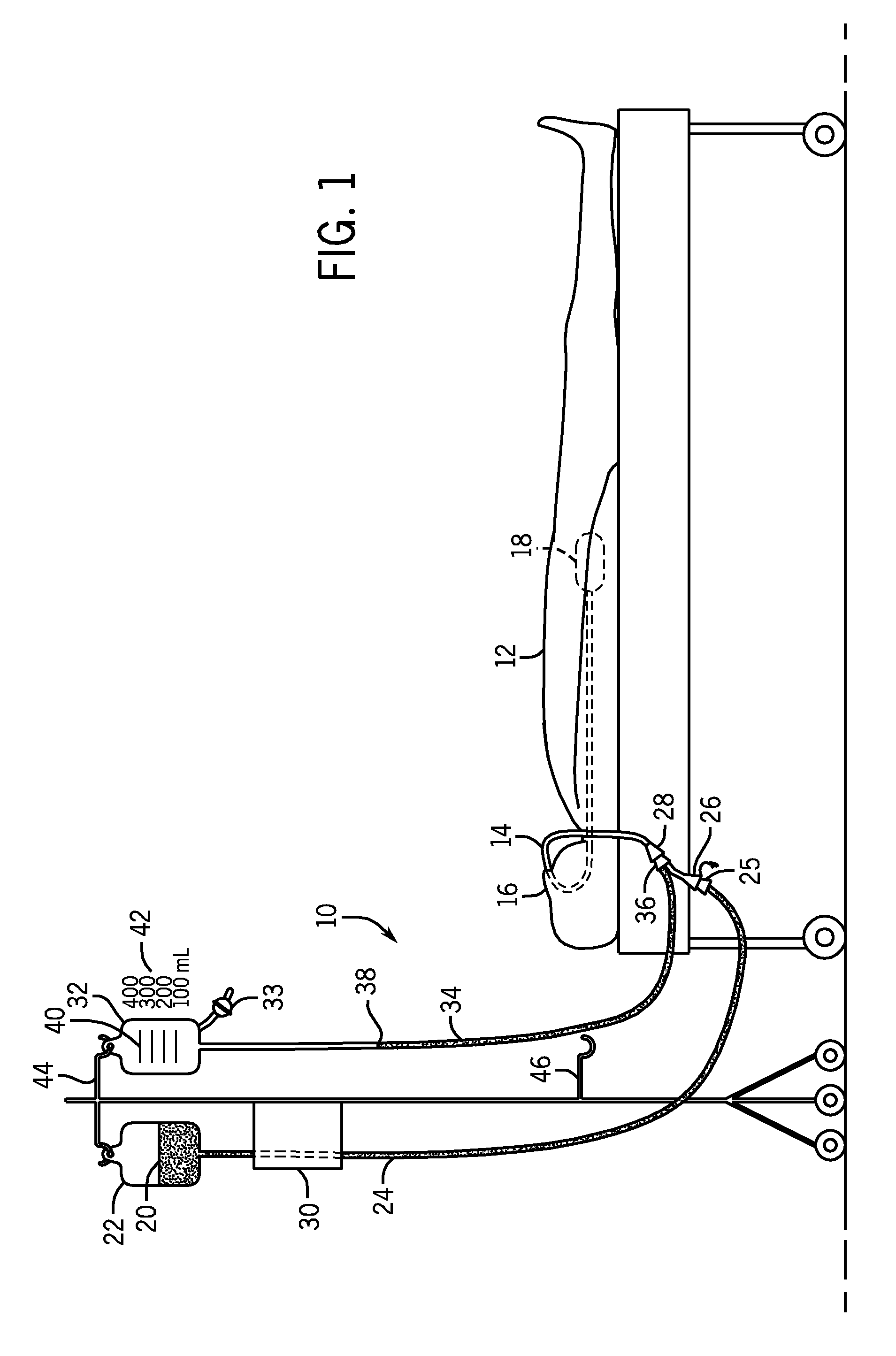

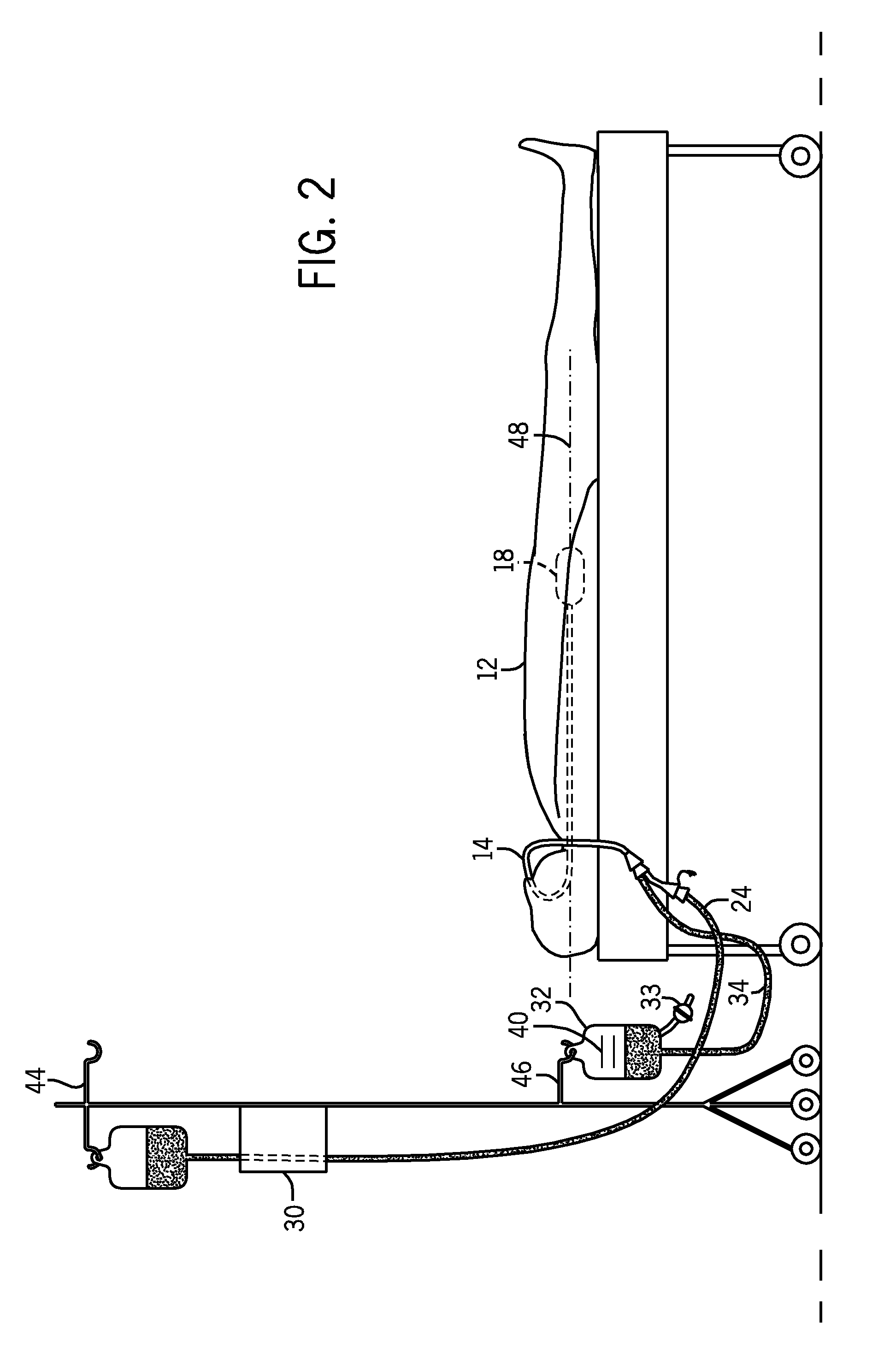

Method and system for the determination of residual volume in patients having an enteral feeding tube

InactiveUS20100137746A1Avoid flowMedical devicesDiagnostic recording/measuringEnteral feedingsMedicine

A method and system for determining the residual volume within a patient having a naso-enteral feeding tube. A collection container is coupled to the naso-enteral feeding tube and a physical force is applied to the collection container to prevent stomach fluid from flowing into the collection container. The physical force is removed from the collection container and the stomach fluid is allowed to flow into the collection container. The volume of fluid within the collection container is determined, which represents the gastric residual volume of the patient. At least a portion of the collected volume of stomach fluid is returned to the patient from the collection container.

Owner:HOLTECH MEDICAL

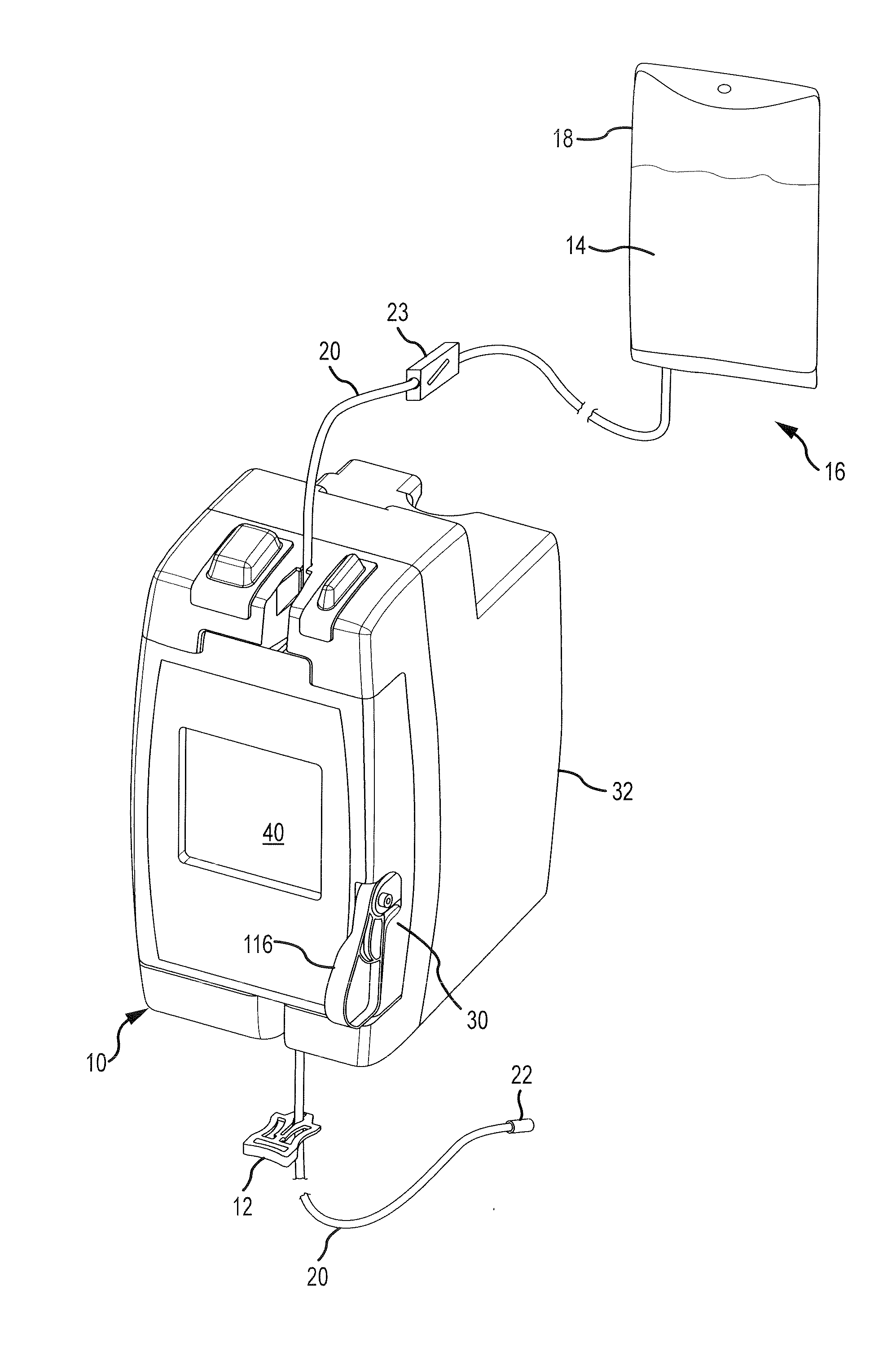

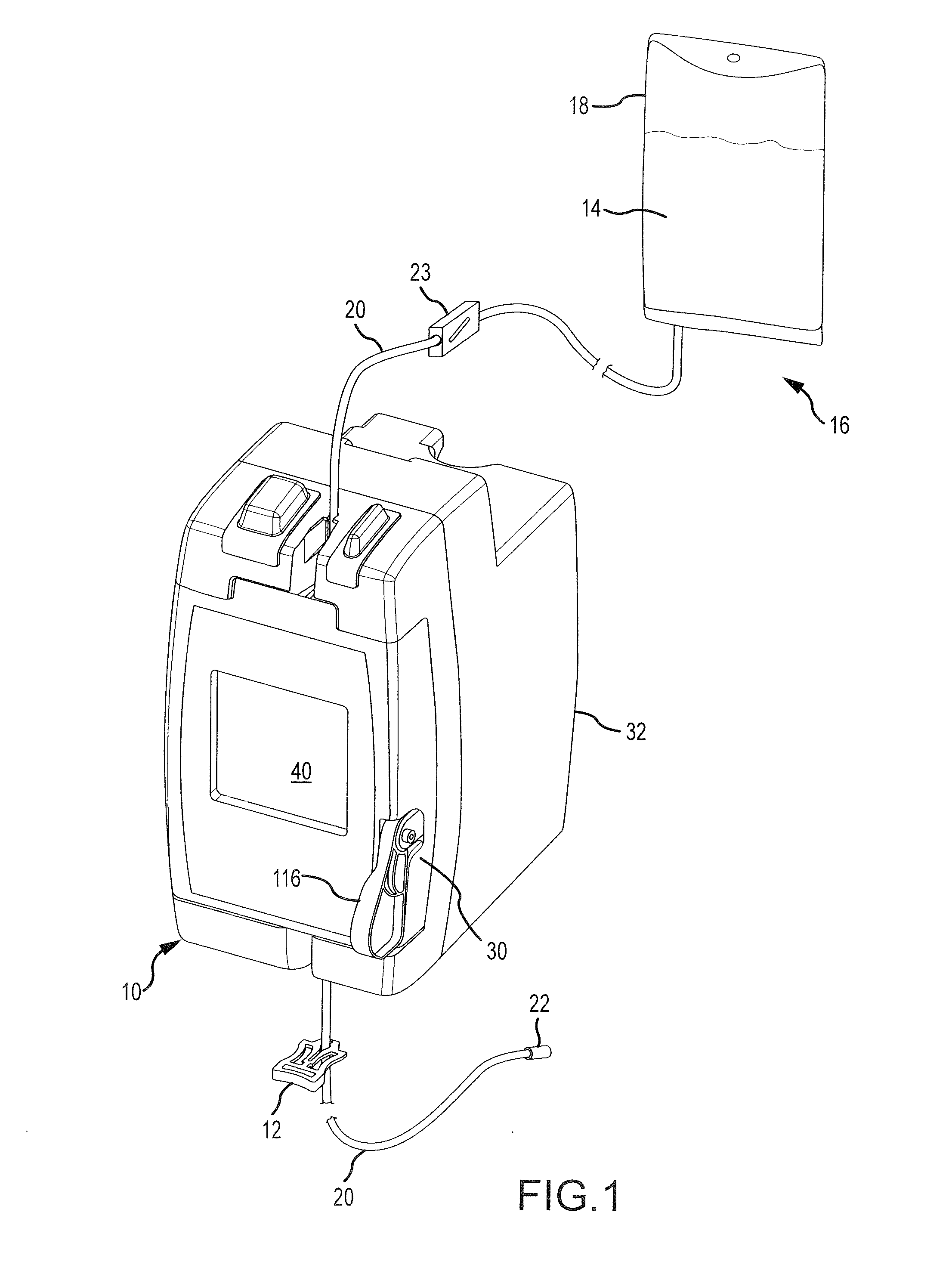

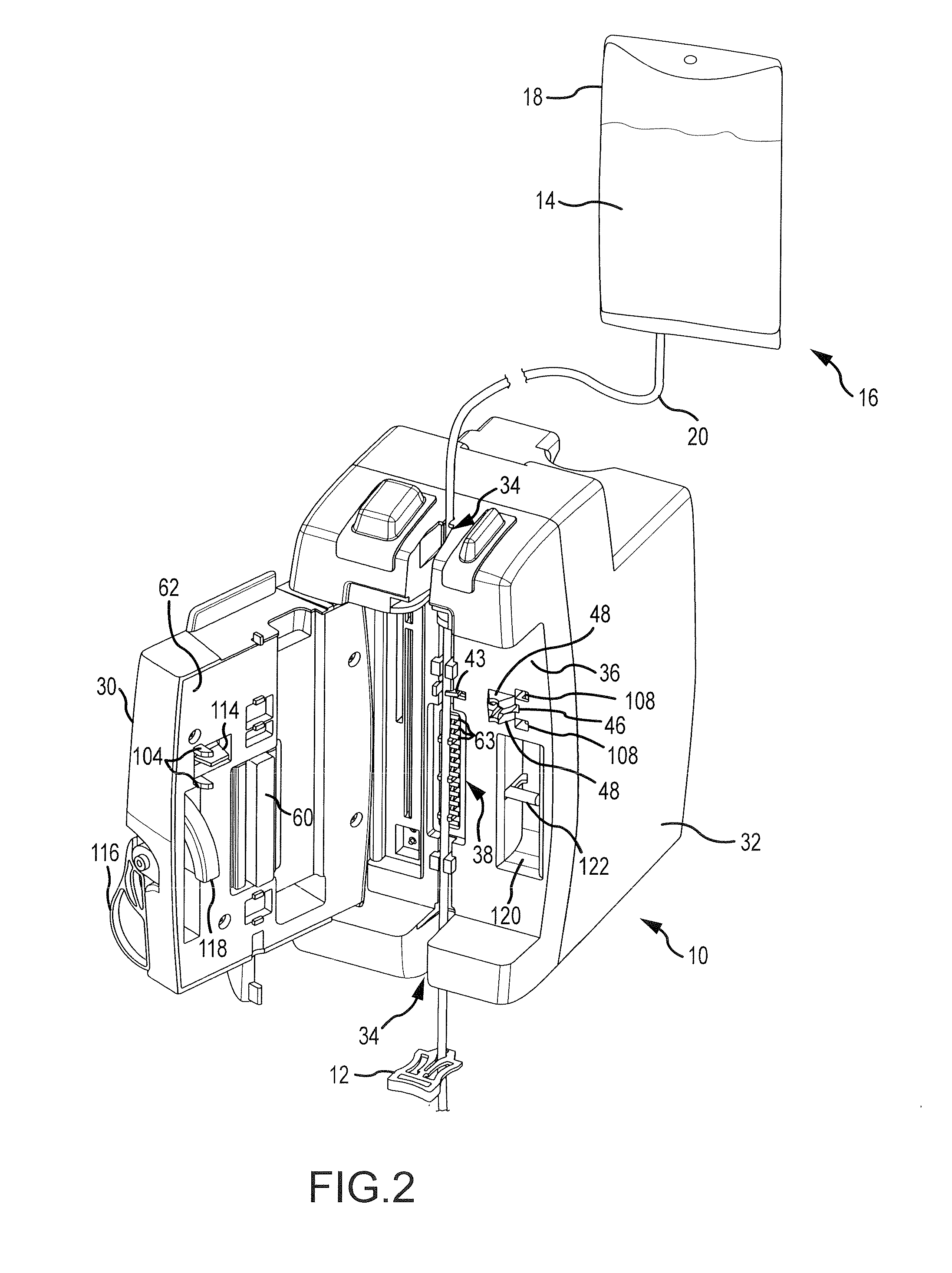

Infusion Pump and Method Which Inhibits Unintended Tubing Withdrawal

InactiveUS20130138074A1Avoid free flowBlock deliveryMedical devicesIntravenous devicesMedicineInfusion pump

A delivery tube is inhibited from unintended withdrawal from an infusion pump which has an internal occlusion clamp that clamps the delivery tube to prevent the free flow of fluid through the tube, by overlapping a blocking lip from a compression edge of the occlusion clamp with a restraint surface of an anvil against which the tubing is compressed and by overlapping a blocking projection from the restraint surface with the compression edge. Inhibition is also achieved by positioning an obstruction protrusion adjacent to the compression edge and the blocking lip to resist the application of exterior physical force to force the occlusion clamp from an occluding position to a non-occluding position.

Owner:WALKMED INFUSION

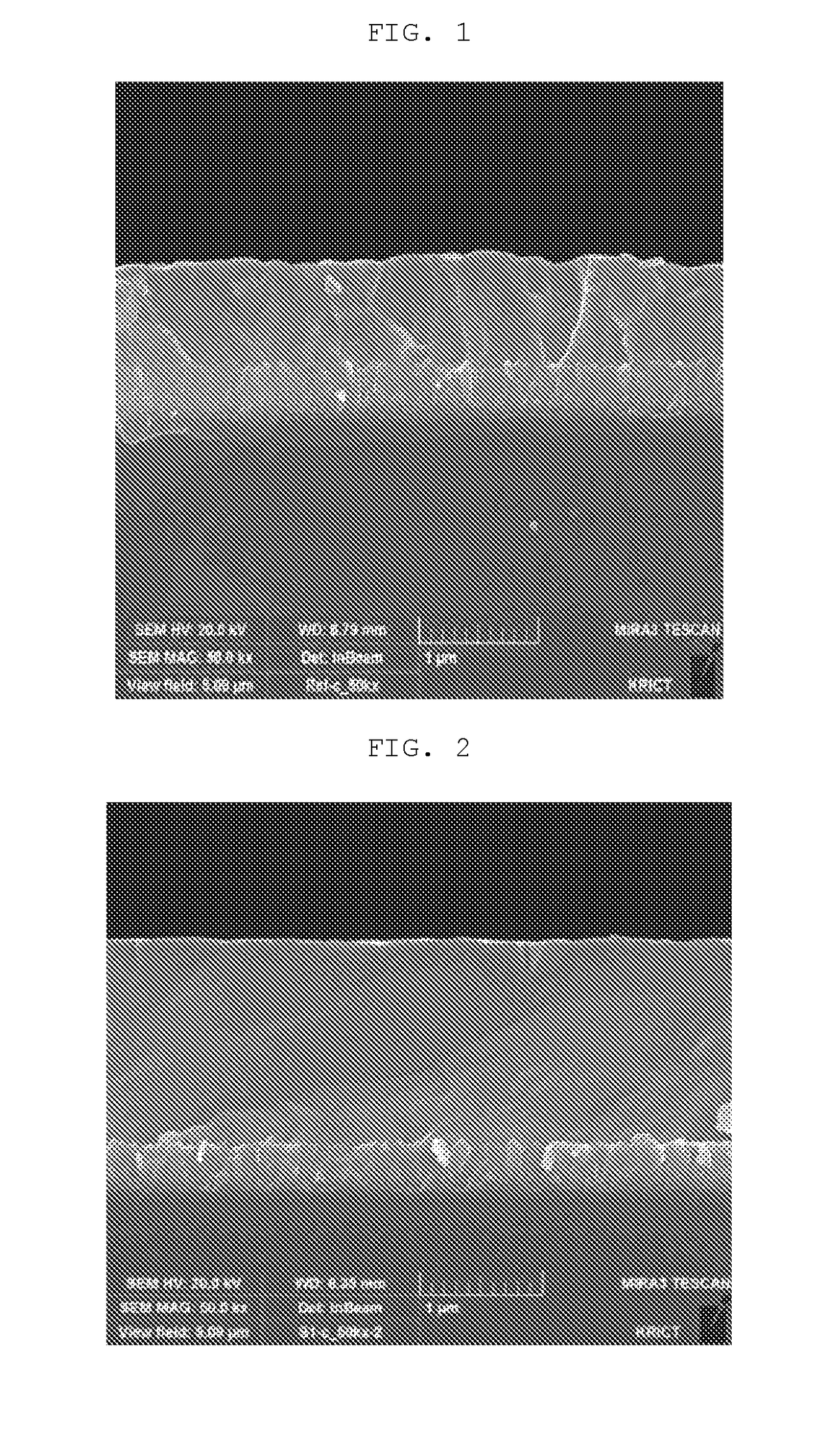

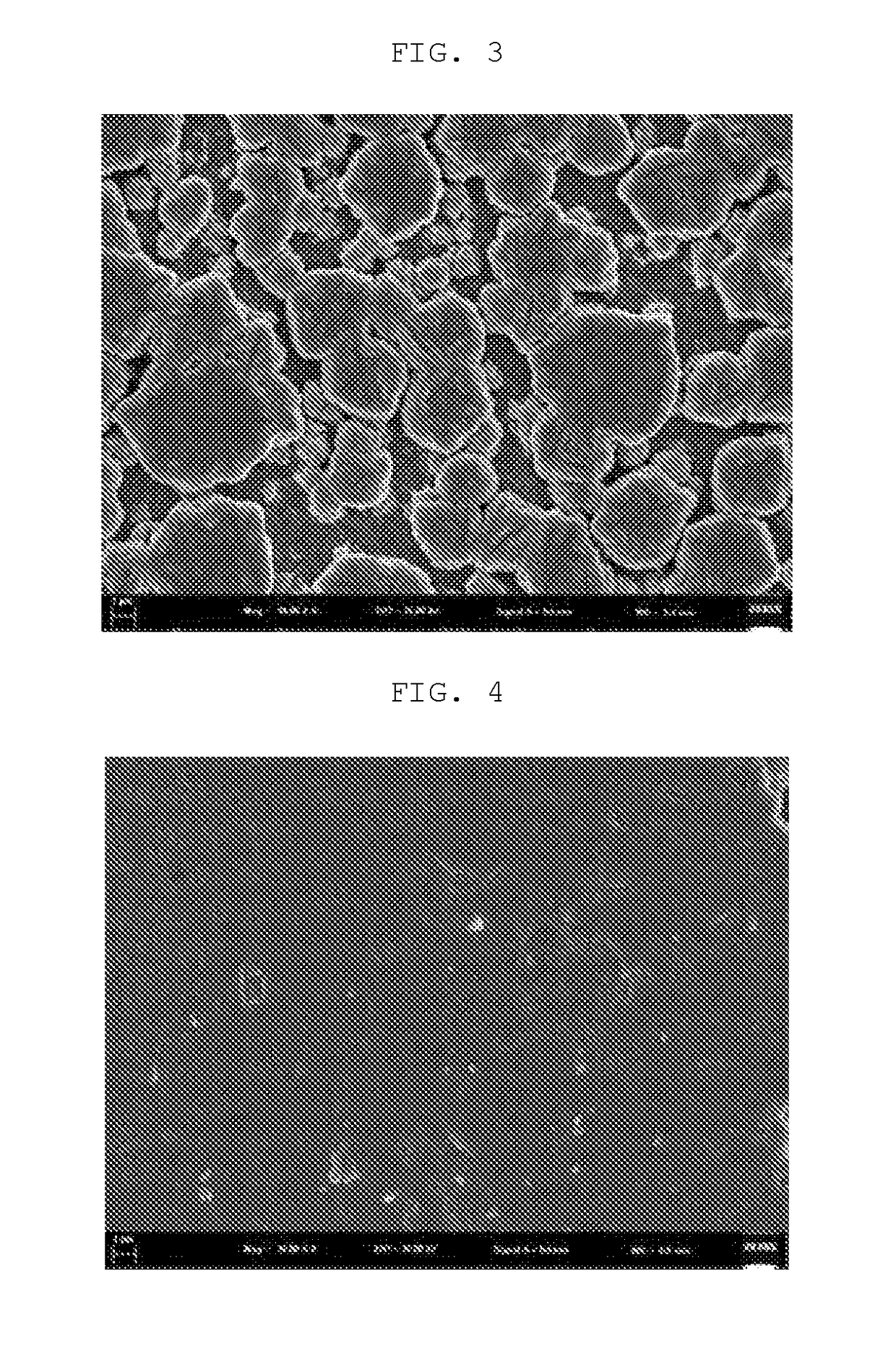

Method for manufacturing device comprising inorganic/organic hybrid perovskite compound film and device comprising inorganic/organic hybrid perovskite compound film

ActiveUS20180248052A1High crystallinityCoarse crystal grain sizeAdjustable jointsCouplingsSurface layerEngineering

A method for manufacturing a device comprising an inorganic / organic hybrid perovskite compound film, according to the present invention, comprises the steps of: a) laminating a first structure and a second structure to allow the first surface layer and the second surface layer to be in contact with each other, the first structure comprising a first surface layer containing at least one of materials i) to v) below, the second structure comprising a second surface layer containing, independently from the first surface layer, at least one of materials i) to v) below; and b) applying heat and physical force to the laminate in which the first structure and the second structure are laminated: i) an inorganic / organic hybrid perovskite compound, ii) an organic halide, iii) a metal halide, iv) an inorganic / organic hybrid perovskite compound precursor, and v) a metal halide precursor.

Owner:KOREA RES INST OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com