Patents

Literature

287 results about "Force gauge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A force gauge (also force meter) is a measuring instrument used to measure forces. Applications exist in research and development, laboratory, quality, production and field environment. There are two kinds of force gauges today: mechanical and digital force gauges. Force Gauges usually measure pressure in stress increments and other dependent human factors.

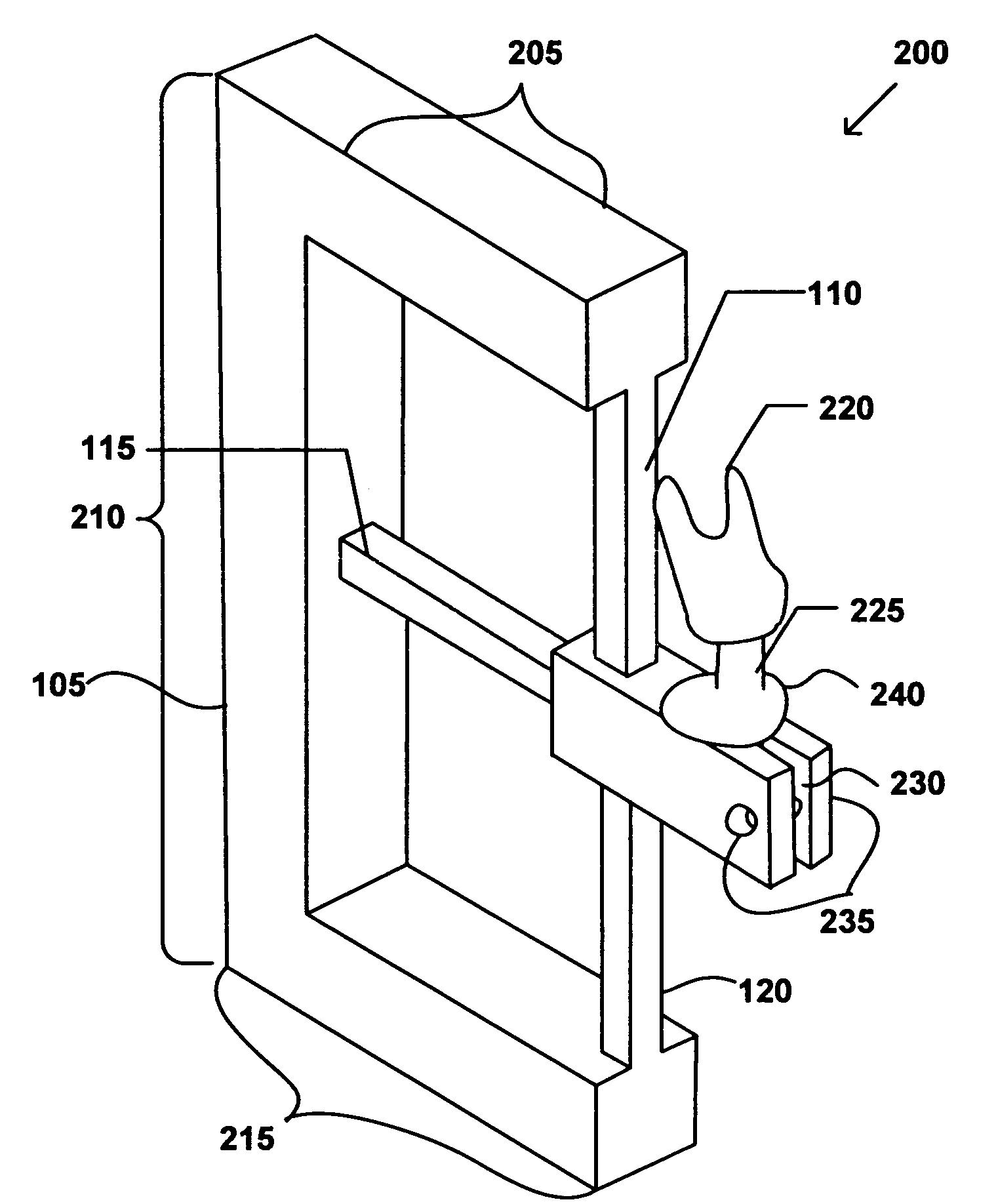

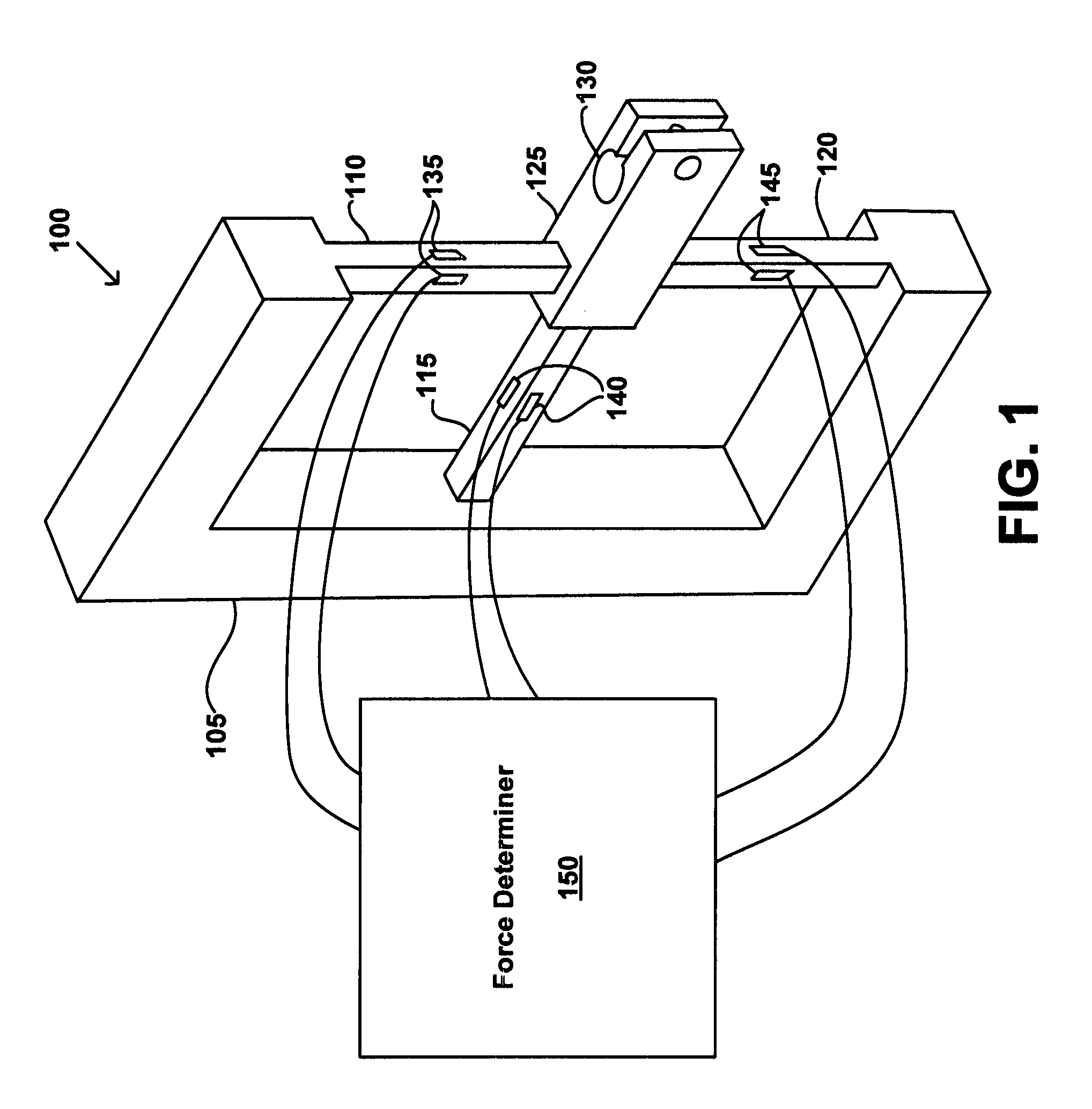

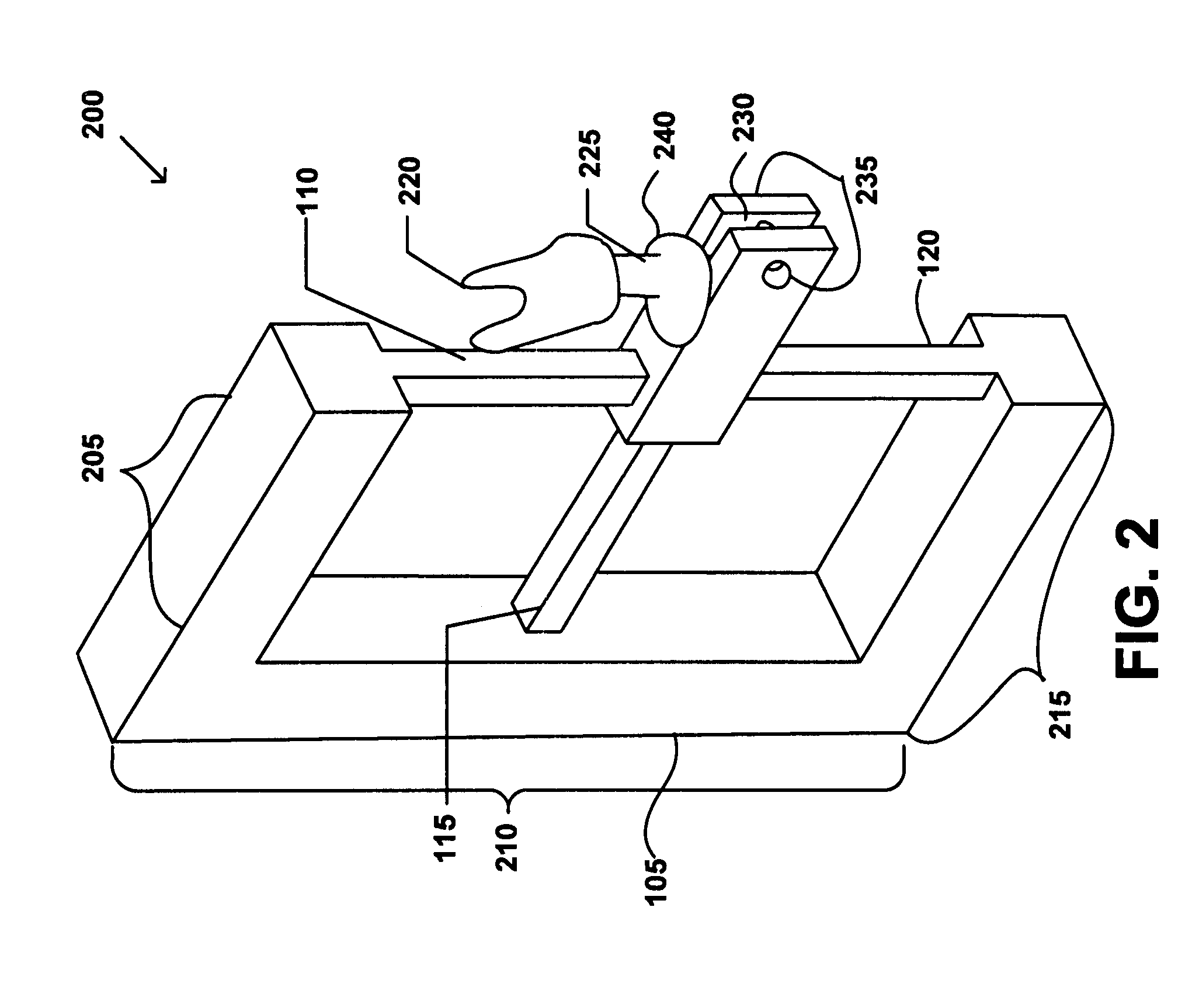

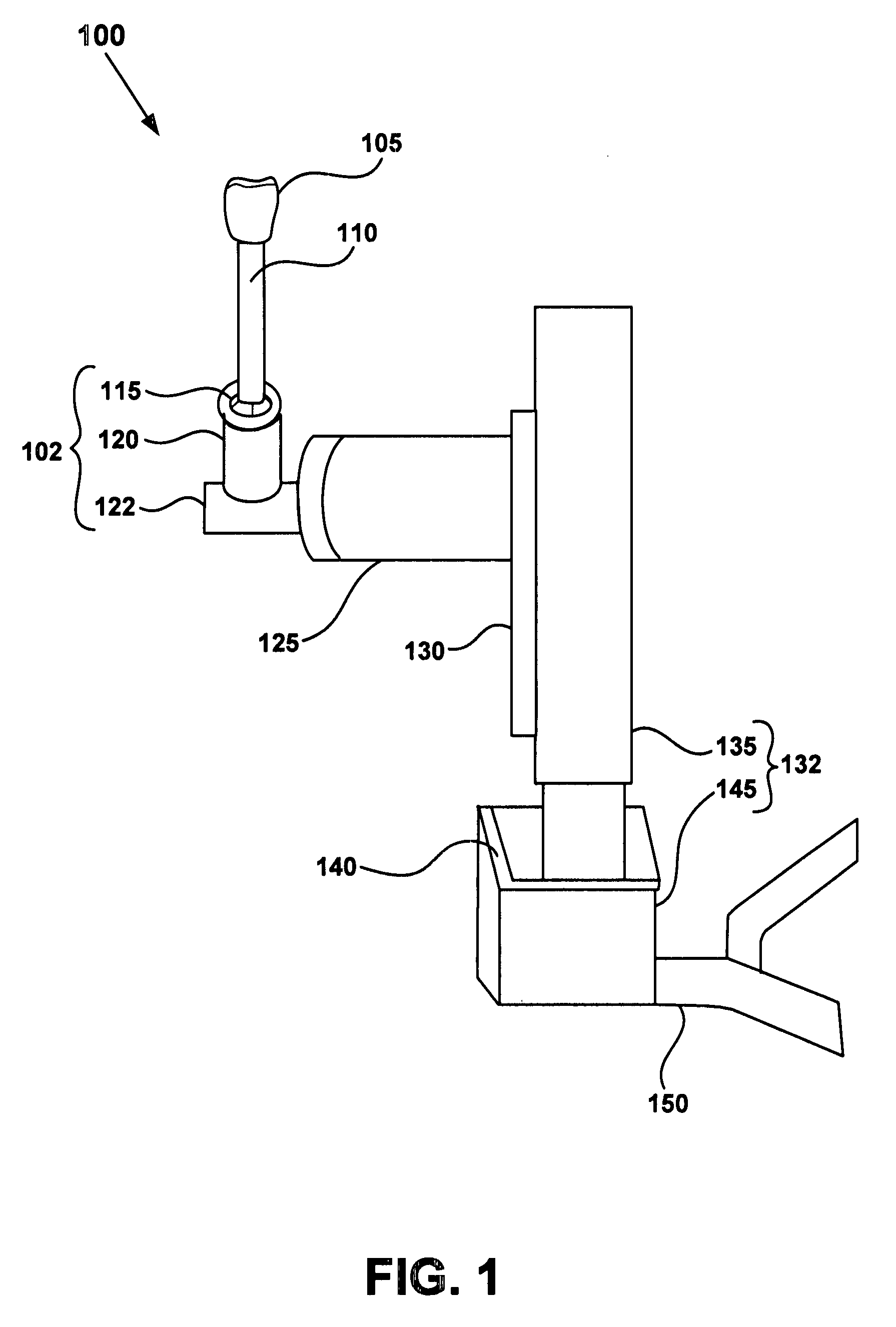

Orthodontic force measurement system

A method for concurrently measuring a force exerted upon each of a plurality of teeth is disclosed. A dentition crown connecting rod associated with a force gauge is positioned such that a dentition crown coupled to the dentition crown connecting rod may be received within a corresponding cavity of a reference aligner. A measurement aligner is then applied to the dentition crown, wherein the dentition crown is positioned to be received within a corresponding cavity of a reference aligner. A force exerted on the dentition crown by the measurement aligner is then calculated.

Owner:ALIGN TECH

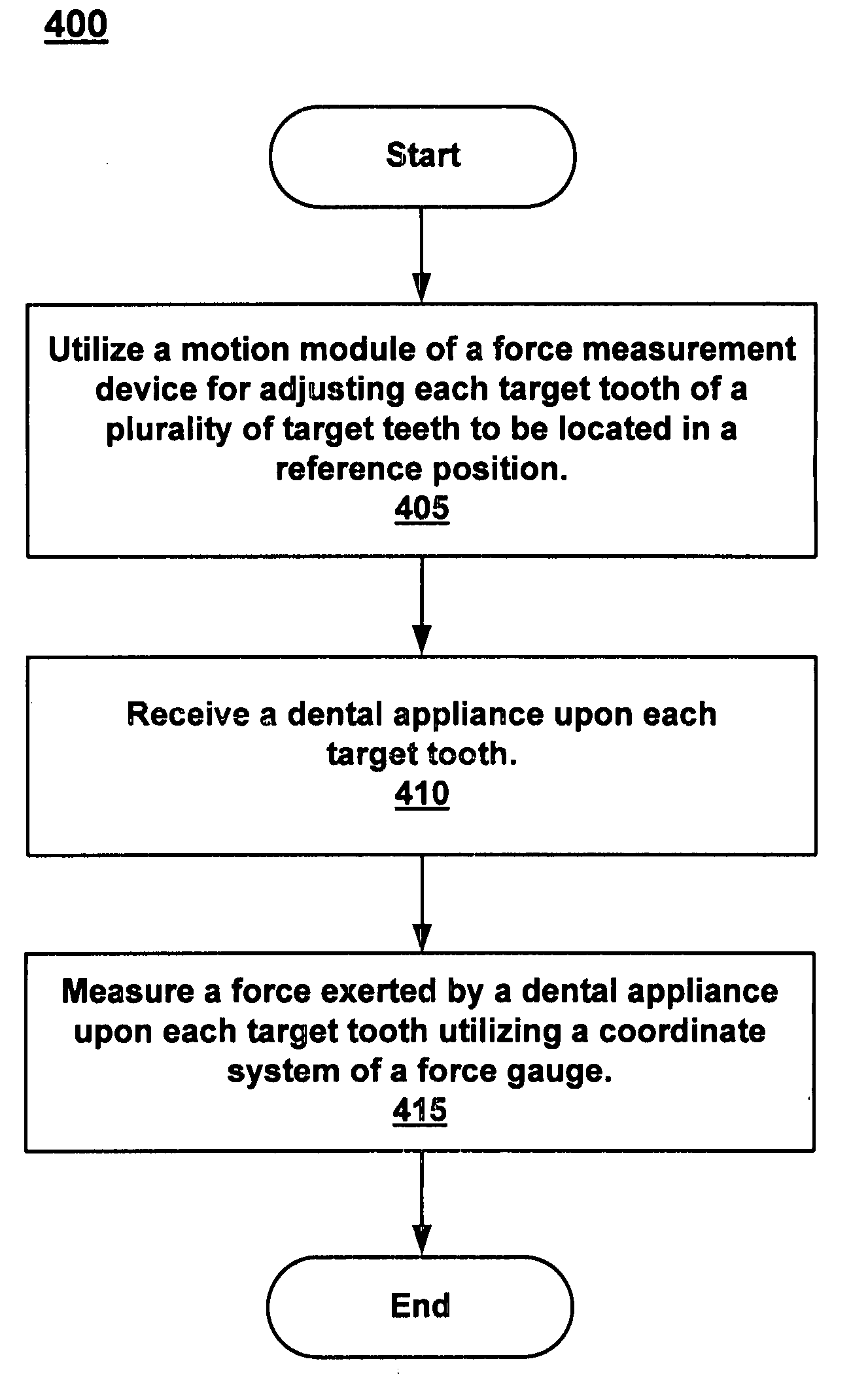

Concurrently measuring a force exerted upon each of a plurality of teeth

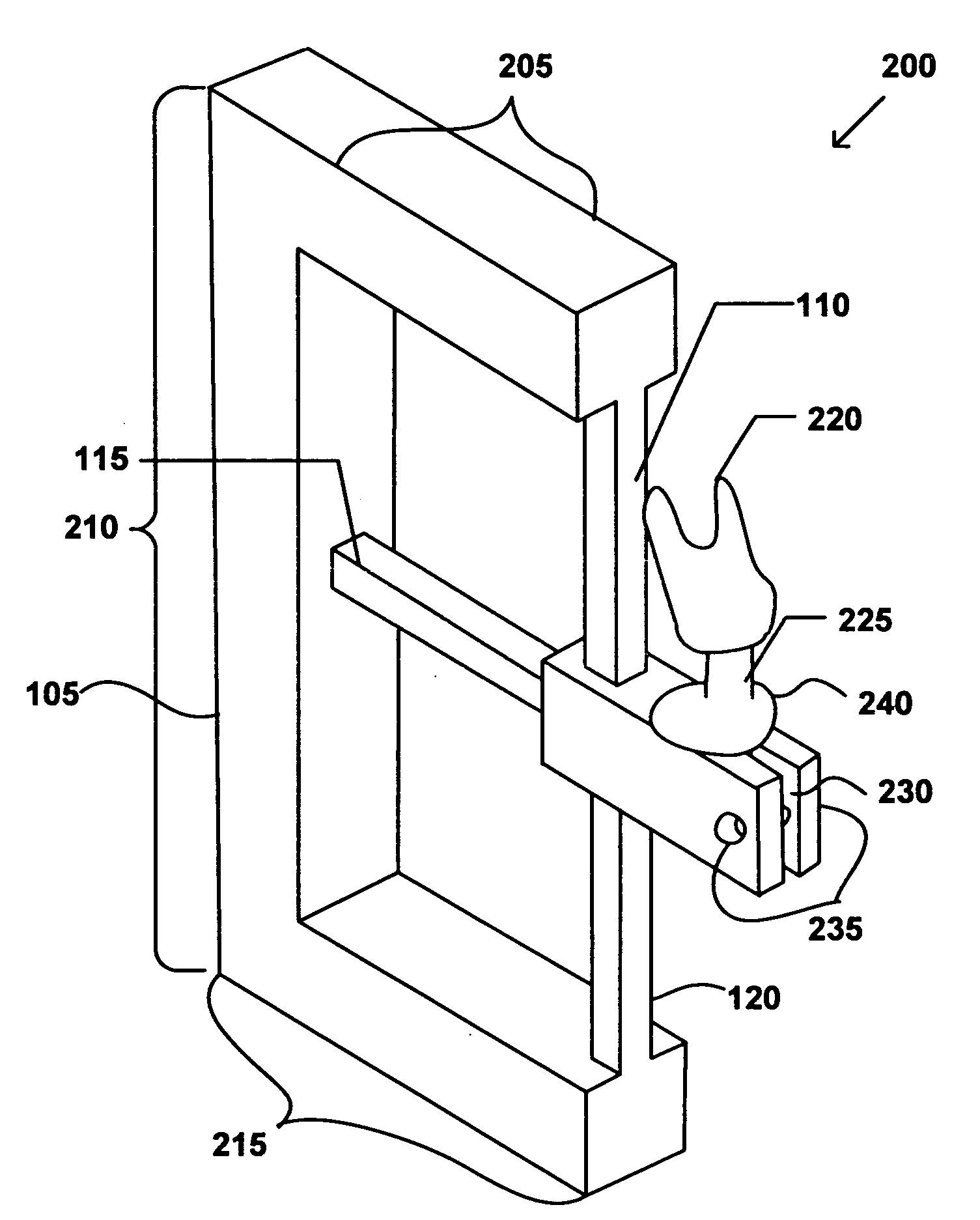

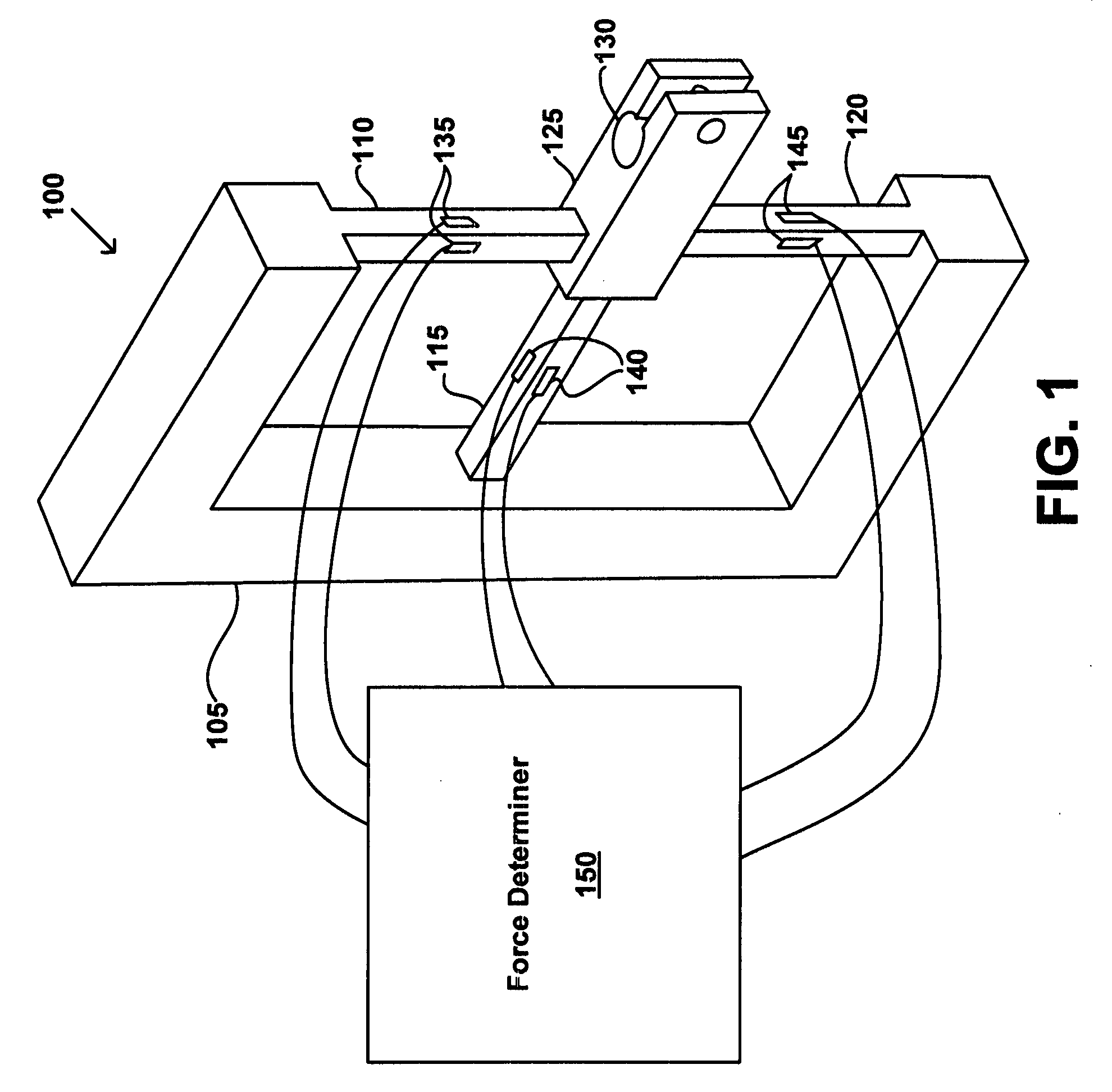

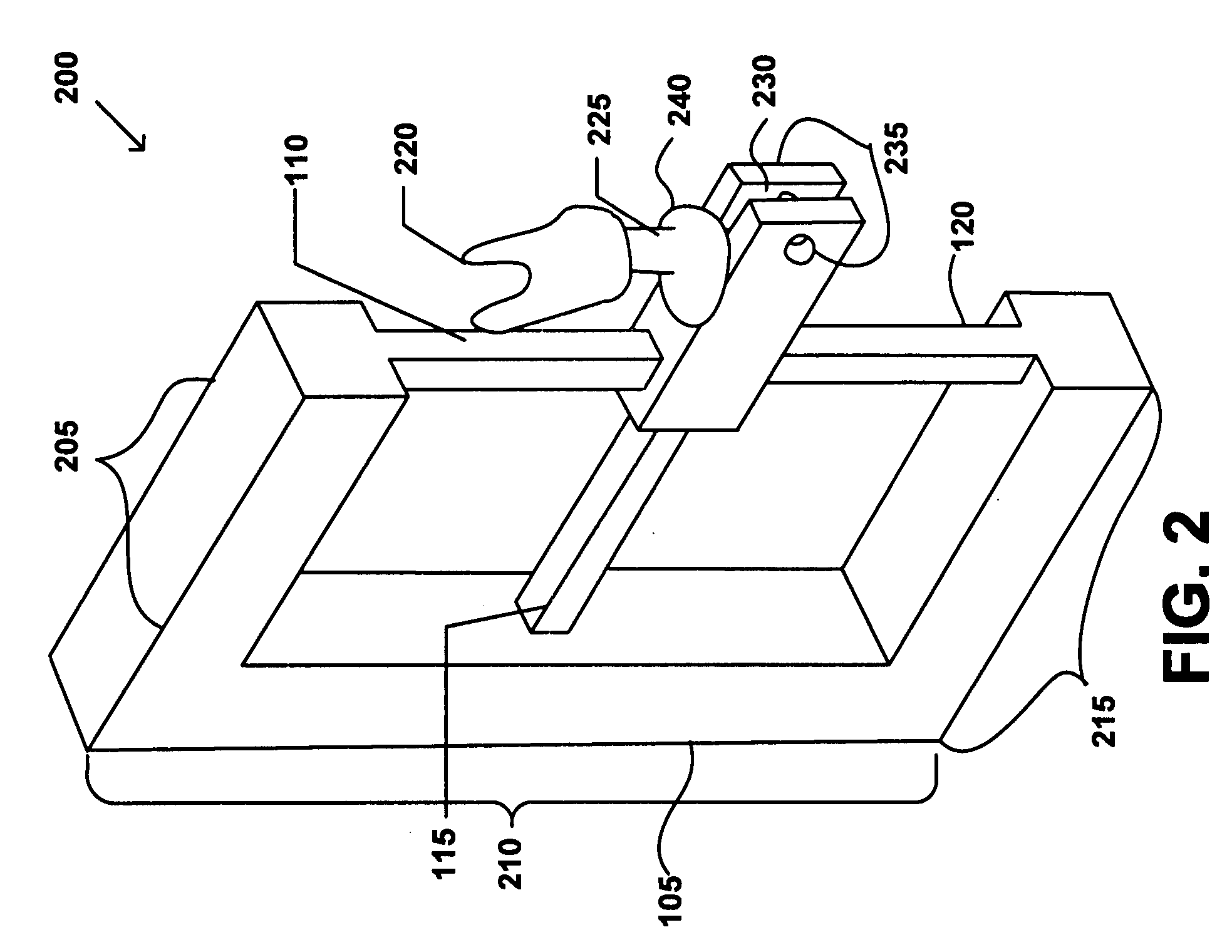

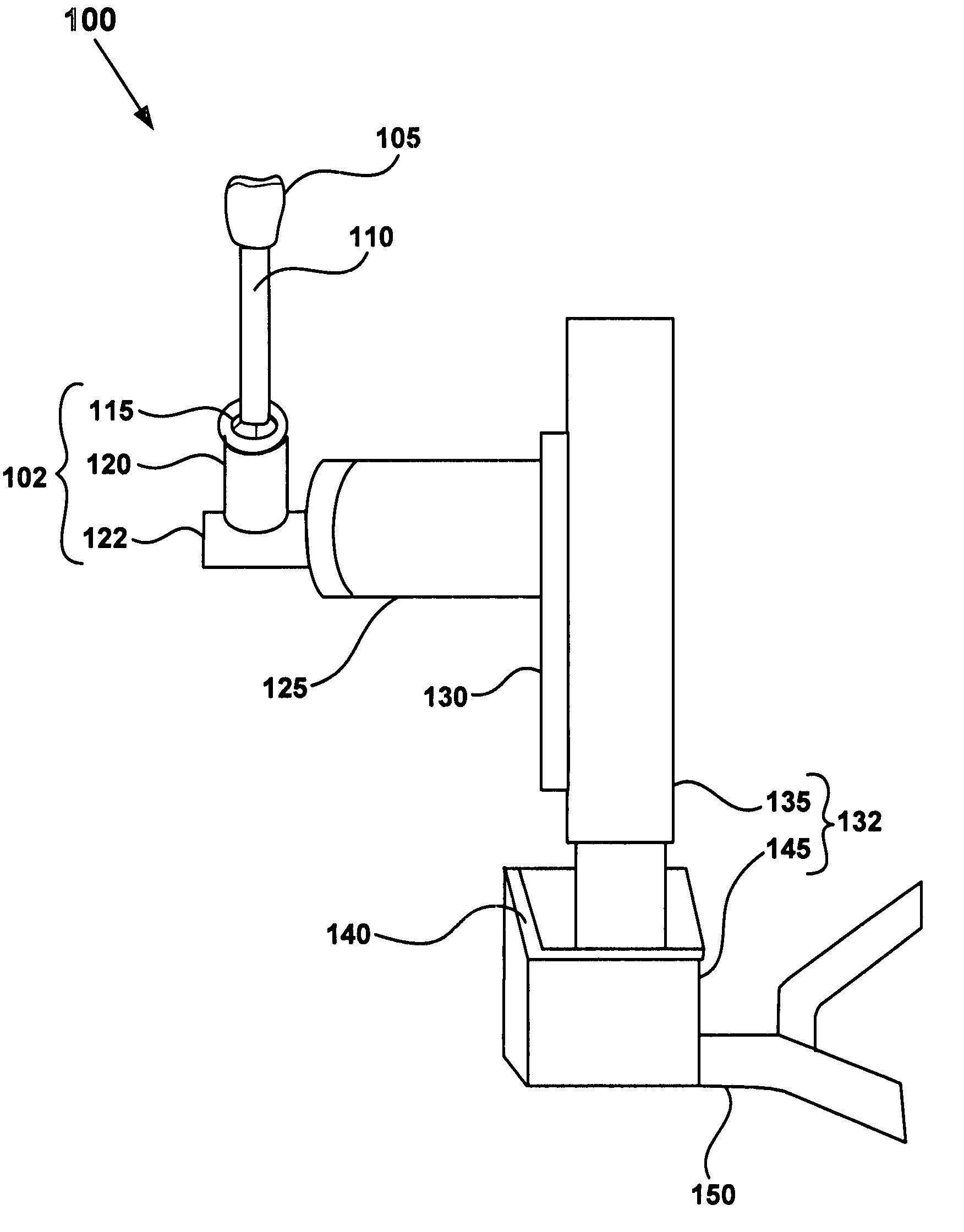

A system and method for concurrently measuring a force exerted upon a tooth is disclosed. In one aspect of the invention, the system includes a target tooth attached to a force gauge which is coupled to a motion module for adjusting the tooth to a reference position. The method includes utilizing a motion module of a force measurement device is utilized to adjust each target tooth of a plurality of target teeth to be located in a reference position. Next, each target tooth receives a dental appliance. Then an exerted force is measured by the dental appliance upon each target tooth utilizing a coordinate system of the force gauge.

Owner:ALIGN TECH

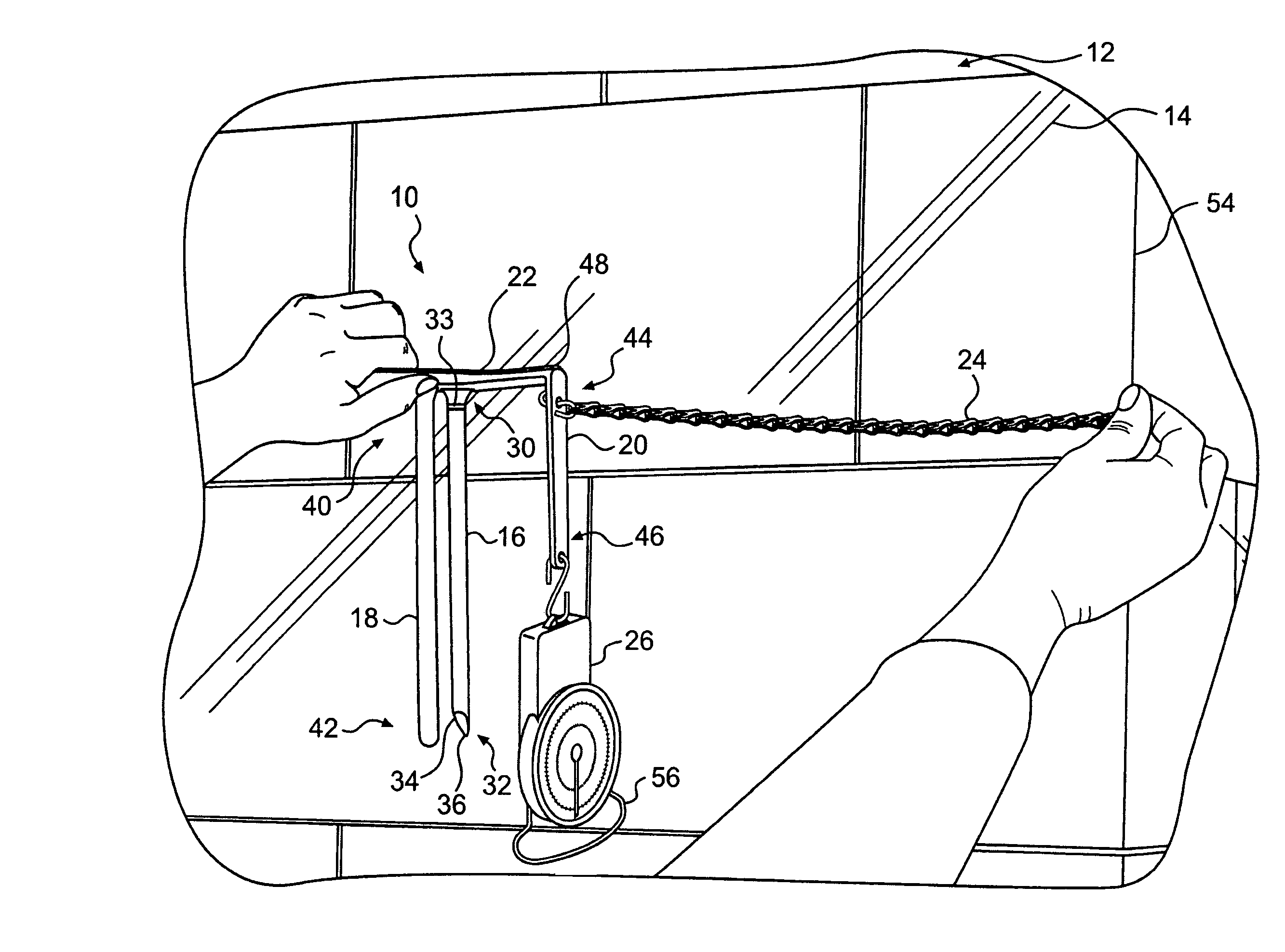

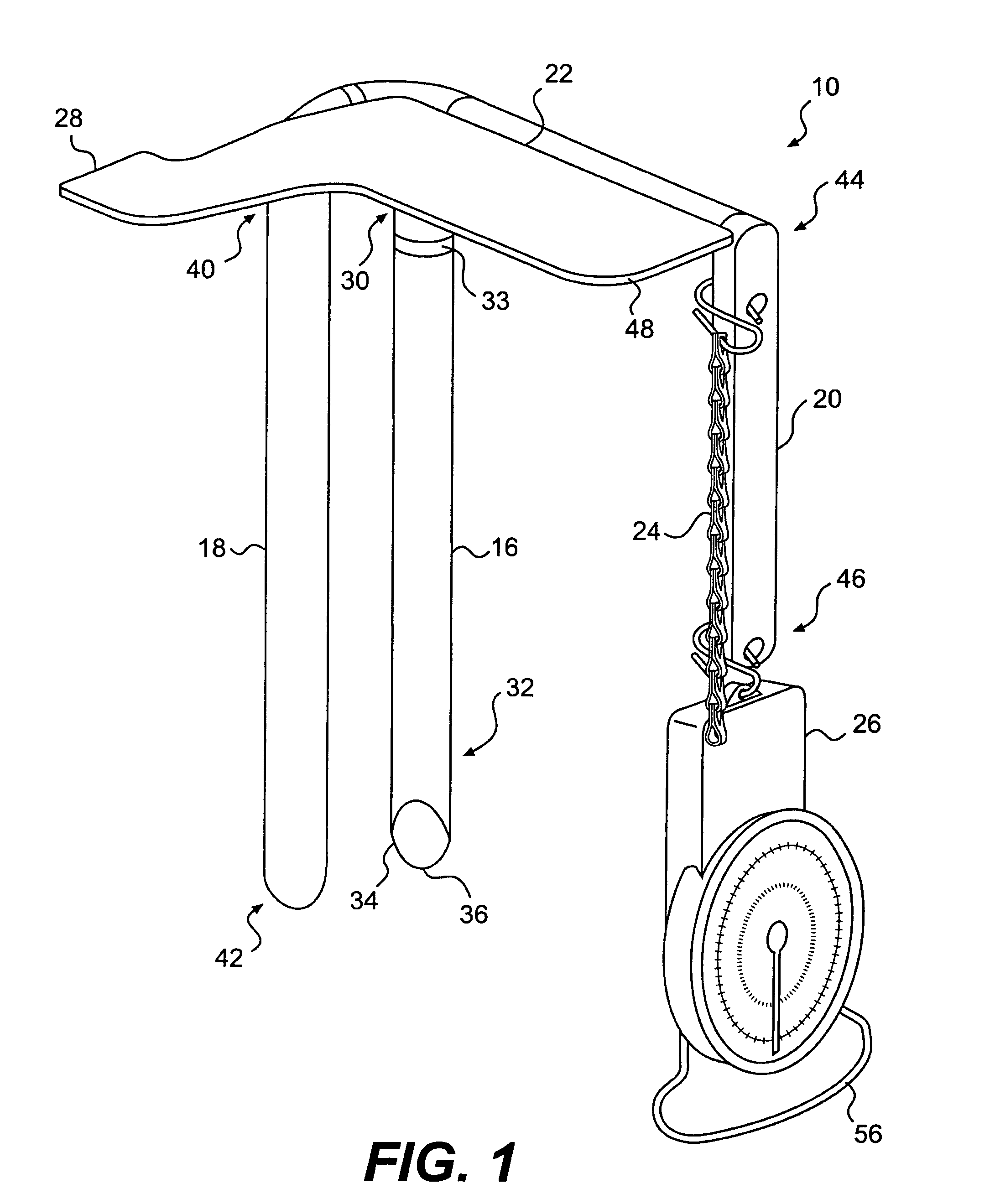

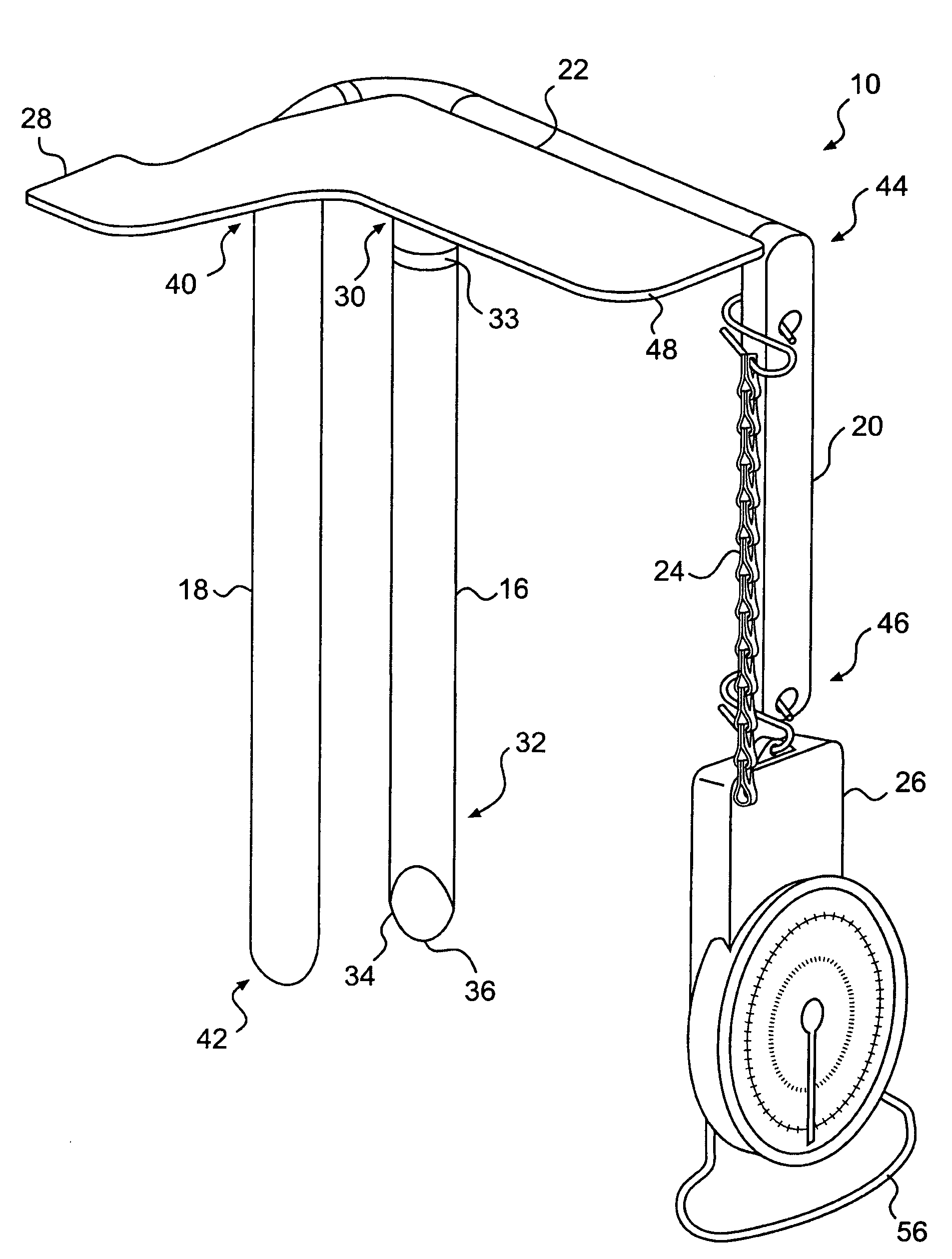

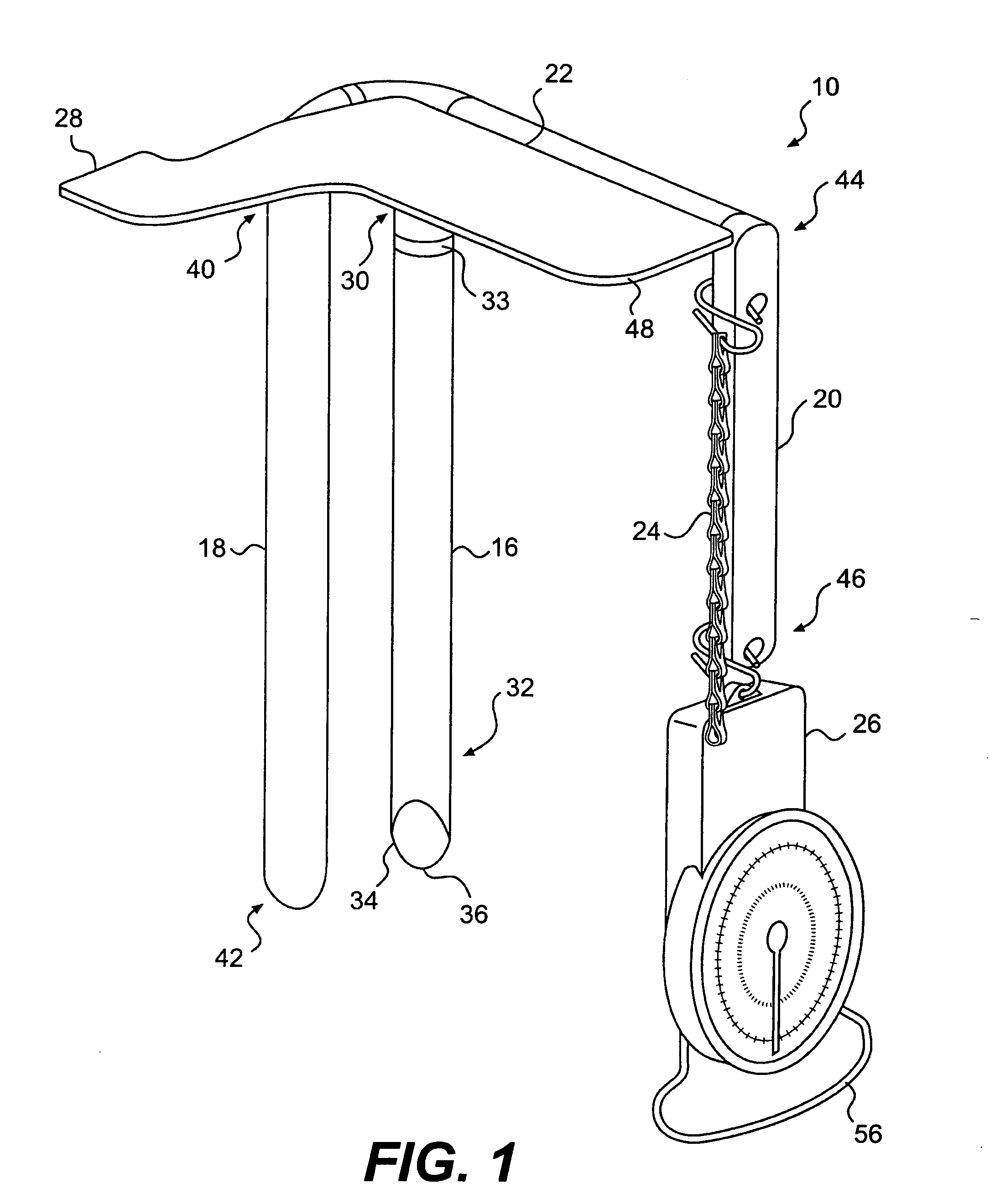

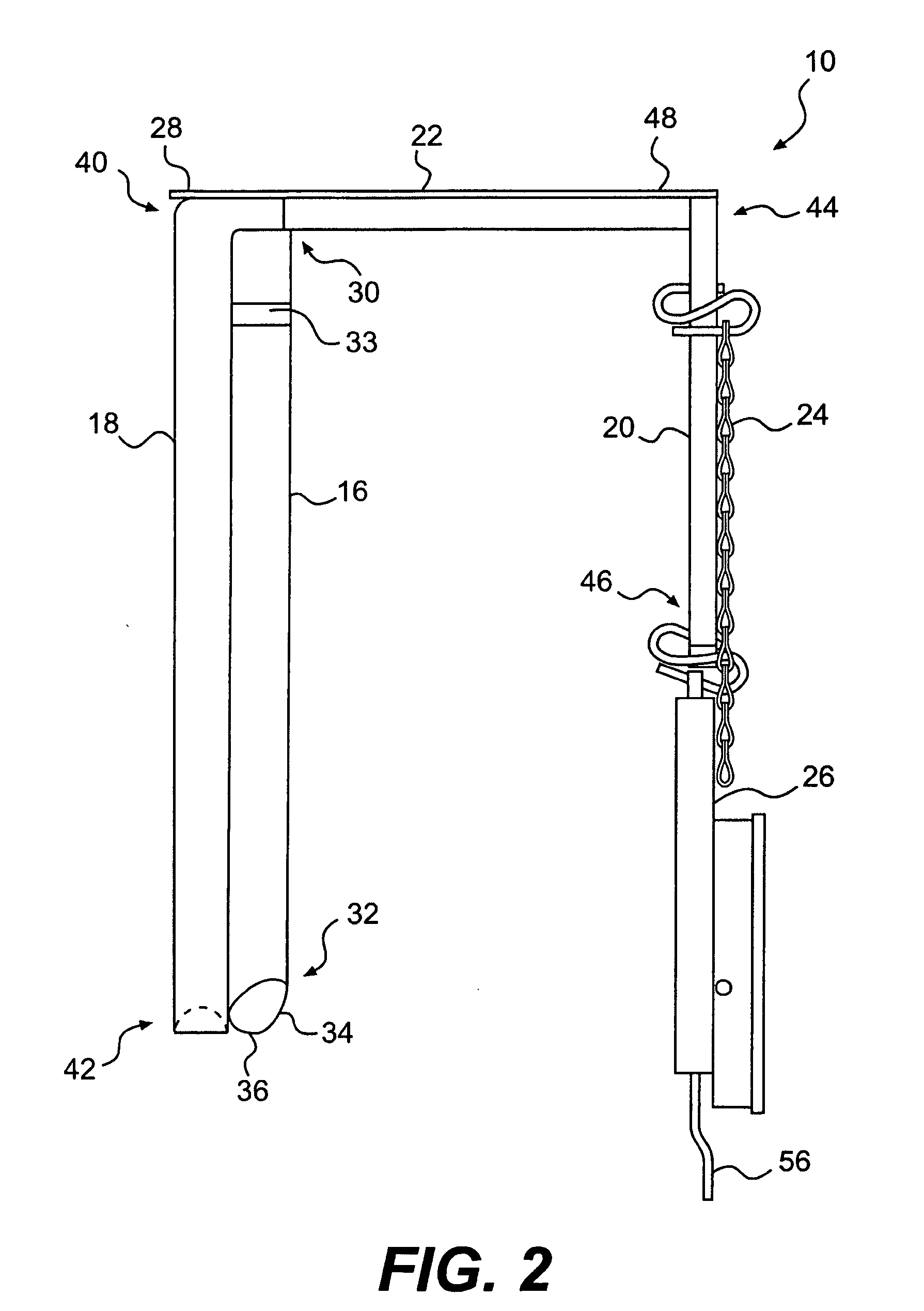

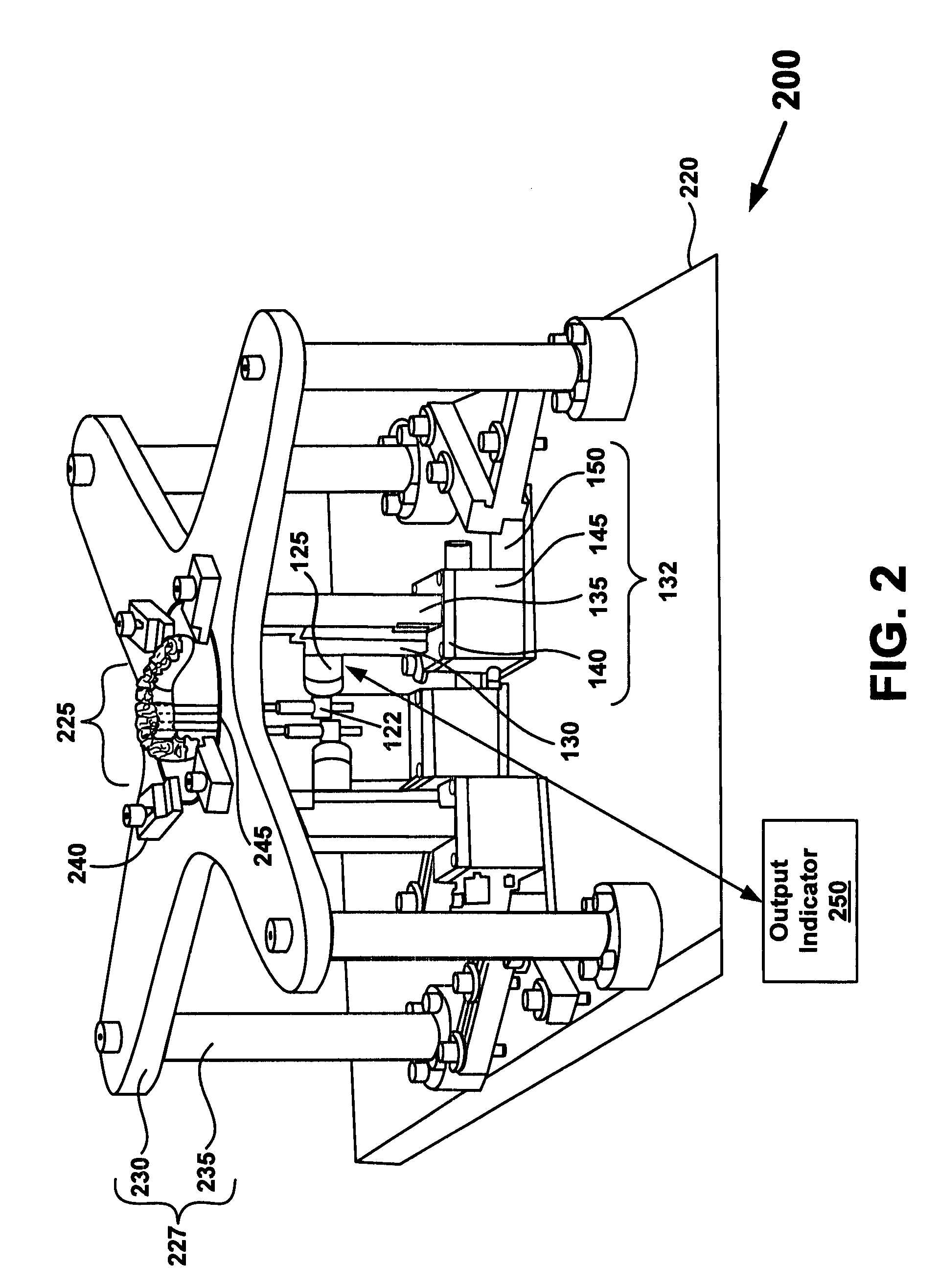

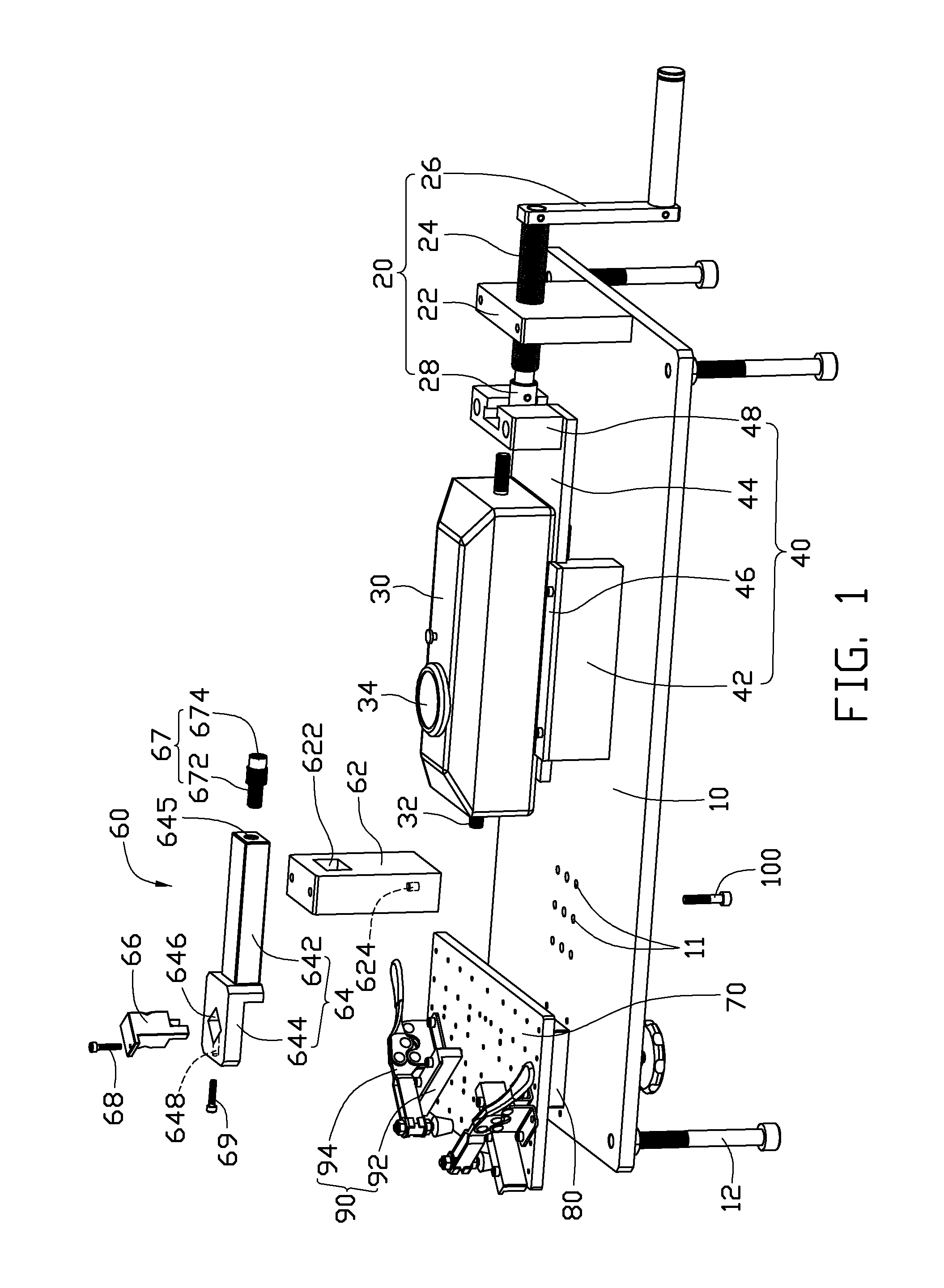

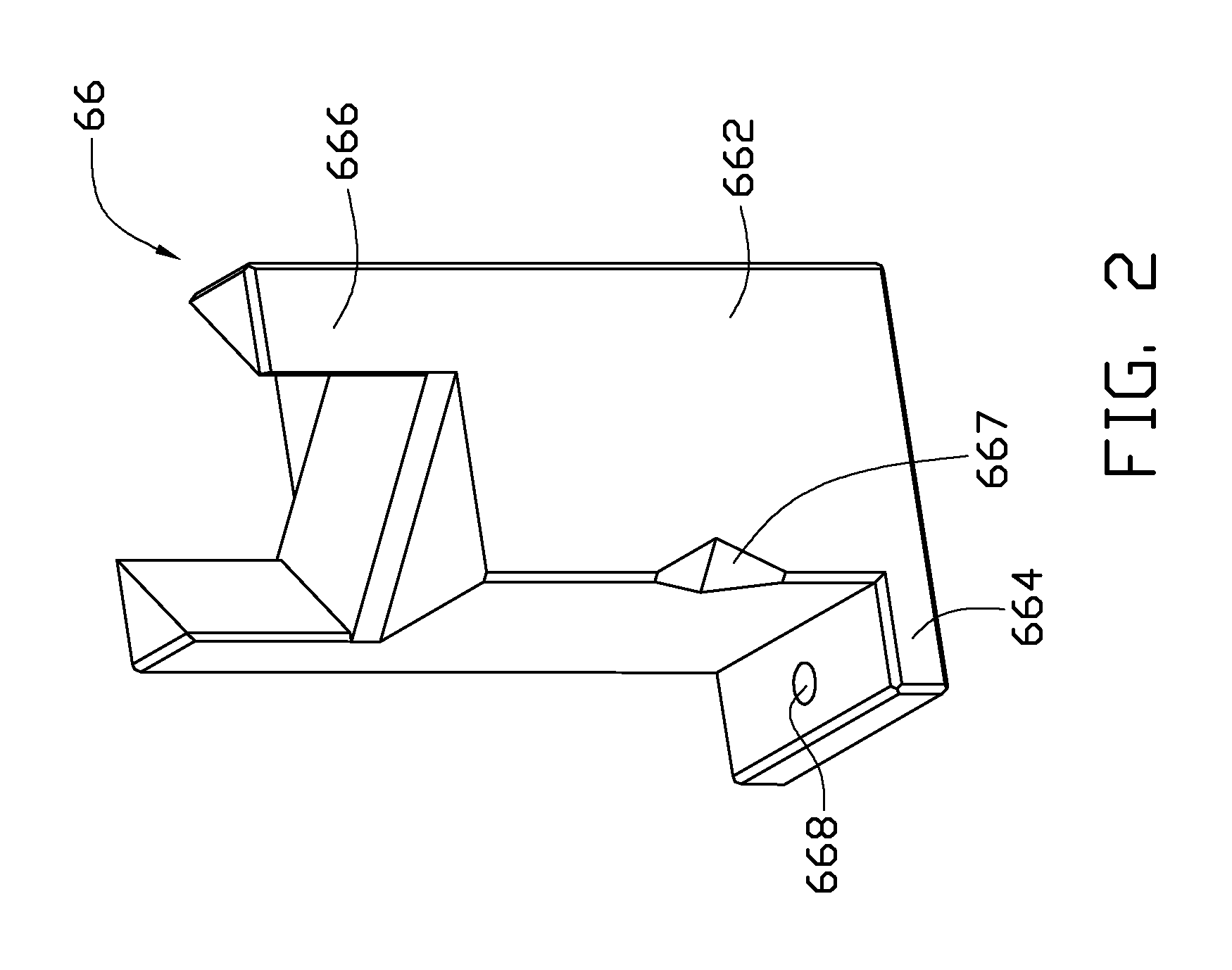

Apparatus and method for measuring containment force in a wrapped load and a control process for establishing and maintaining a predetermined containment force profile

An apparatus and method for measuring containment force on a load is provided. The apparatus may include a first longitudinally extending arm configured to engage a first side of packaging material wrapped around the load. The apparatus may also include a second longitudinally extending arm configured to engage a second side of the packaging material, the second side being opposite the first side. The apparatus may further include an indicator positioned substantially perpendicularly to the first and second arms, a third longitudinally extending arm, and a force gauge configured to measure a force exerted on the third longitudinally extending arm.

Owner:LANTECH COM

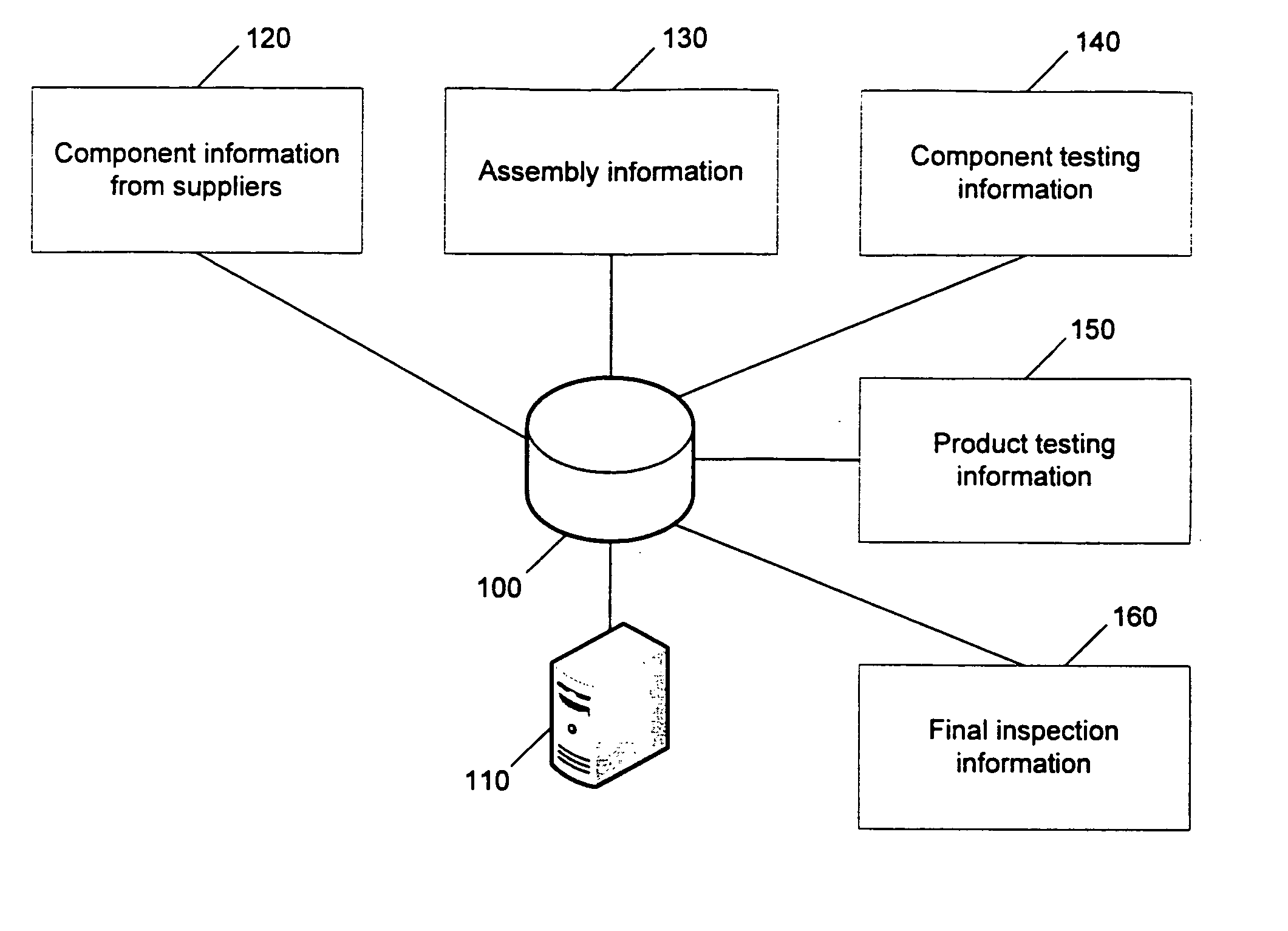

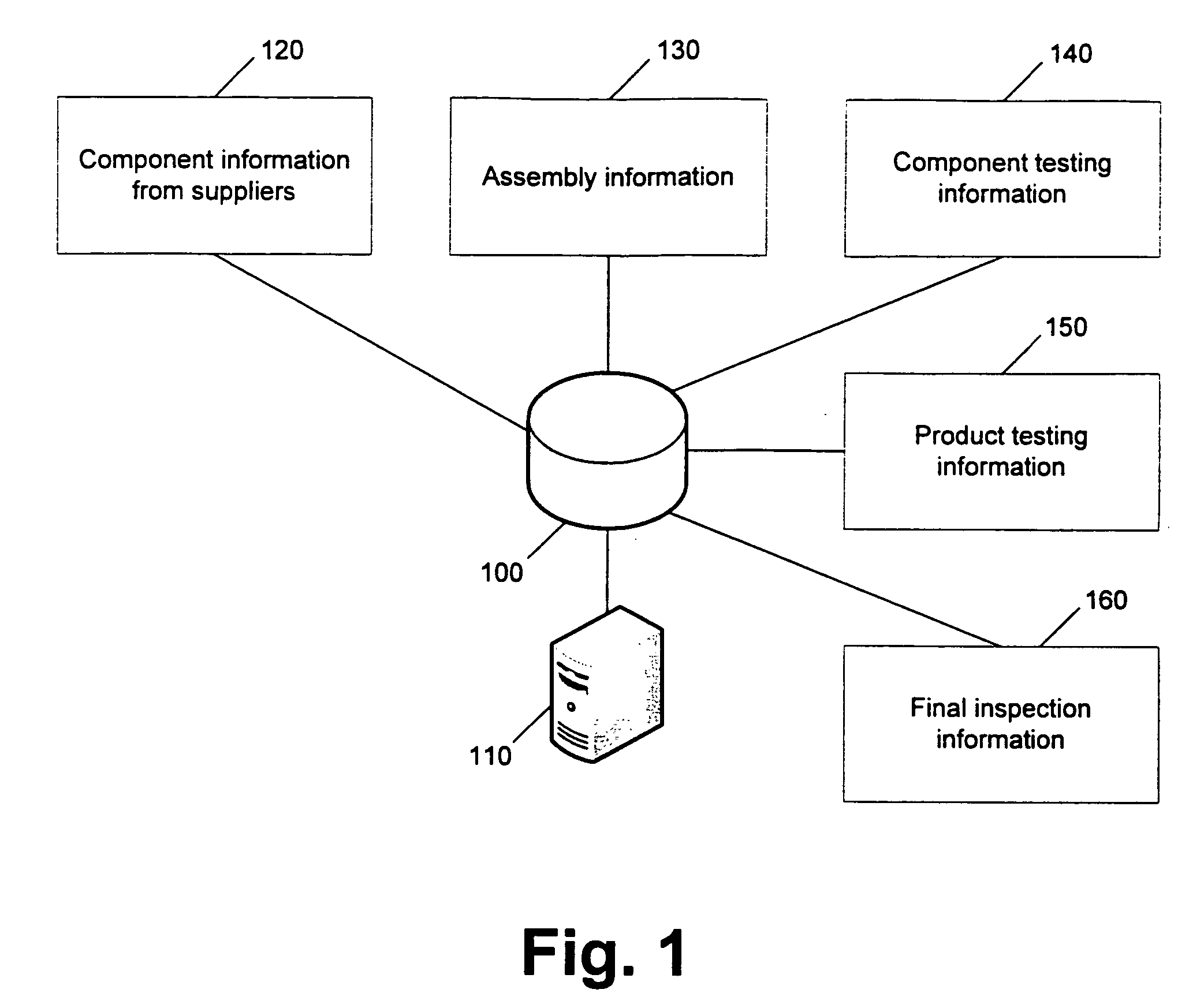

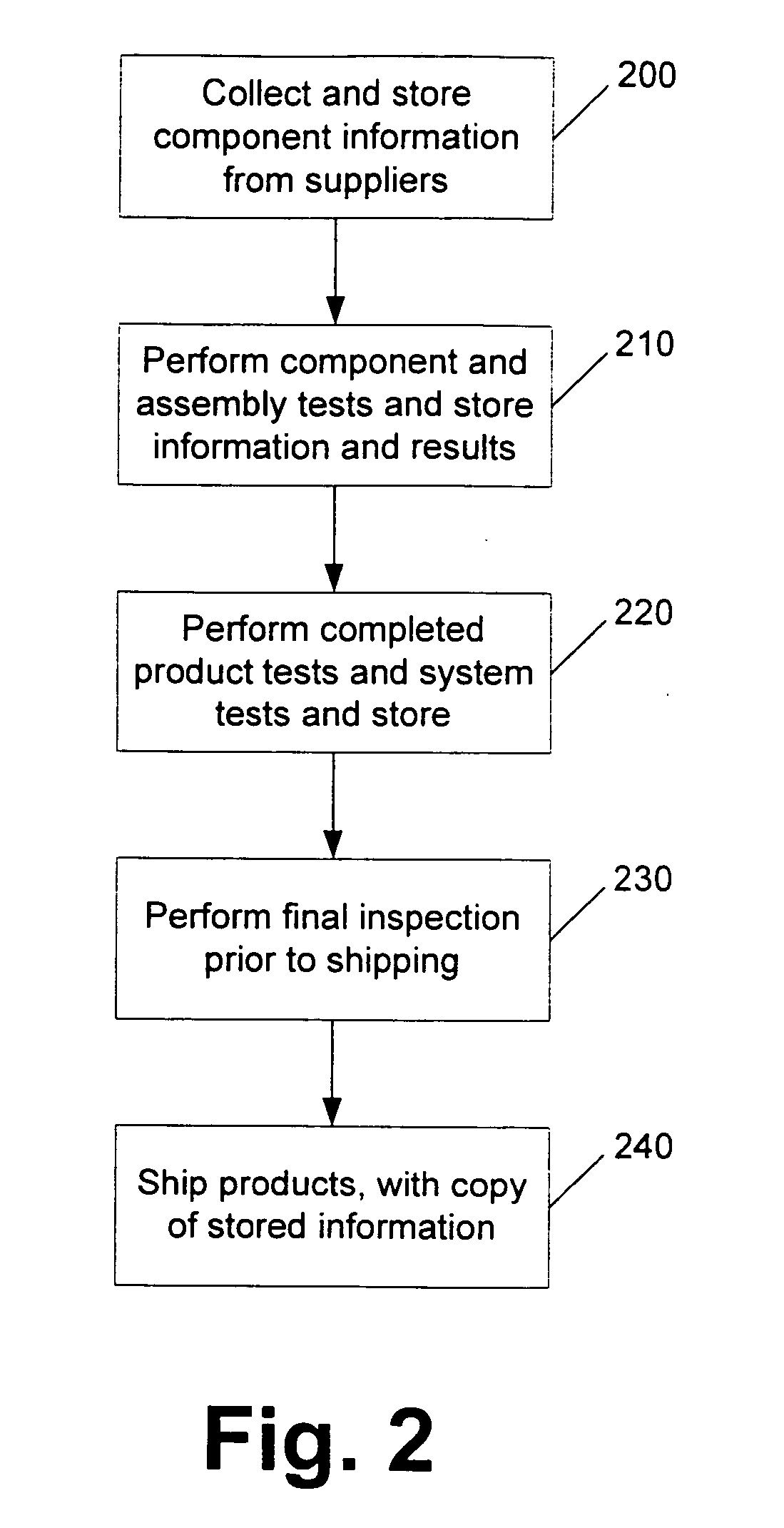

Incrementally accruing product and component quality and tracking data in the manufacturing of devices

InactiveUS20060004475A1Easy to compileDigital data information retrievalSpecial data processing applicationsGraphicsGraphical user interface

The compilation of product and component quality and tracking data for a manufactured device is facilitated. Software modules are provided that collect and transmit data regarding components, products, assembly, and testing to a central database for compilation, storage, and maintenance. A graphical user interface may be provided to assist a user in collecting data. Each module desirably collects one or more pieces of information at various stages during the product manufacturing. Devices such as bar code readers, force gauge meters, etc. can have their “readout” values captured seamlessly and automatically to update the electronic model (stored information) of the product being manufactured. This allows for additional and more accurate quality data to be collected without additional time or effort during manufacturing.

Owner:ABB RES LTD

Apparatus and method for measuring containment force in a wrapped load and a control process for establishing and maintaining a predetermined containment force profile

An apparatus and method for measuring containment force on a load is provided. The apparatus may include a first longitudinally extending arm configured to engage a first side of packaging material wrapped around the load. The apparatus may also include a second longitudinally extending arm configured to engage a second side of the packaging material, the second side being opposite the first side. The apparatus may further include an indicator positioned substantially perpendicularly to the first and second arms, a third longitudinally extending arm, and a force gauge configured to measure a force exerted on the third longitudinally extending arm.

Owner:LANTECH COM

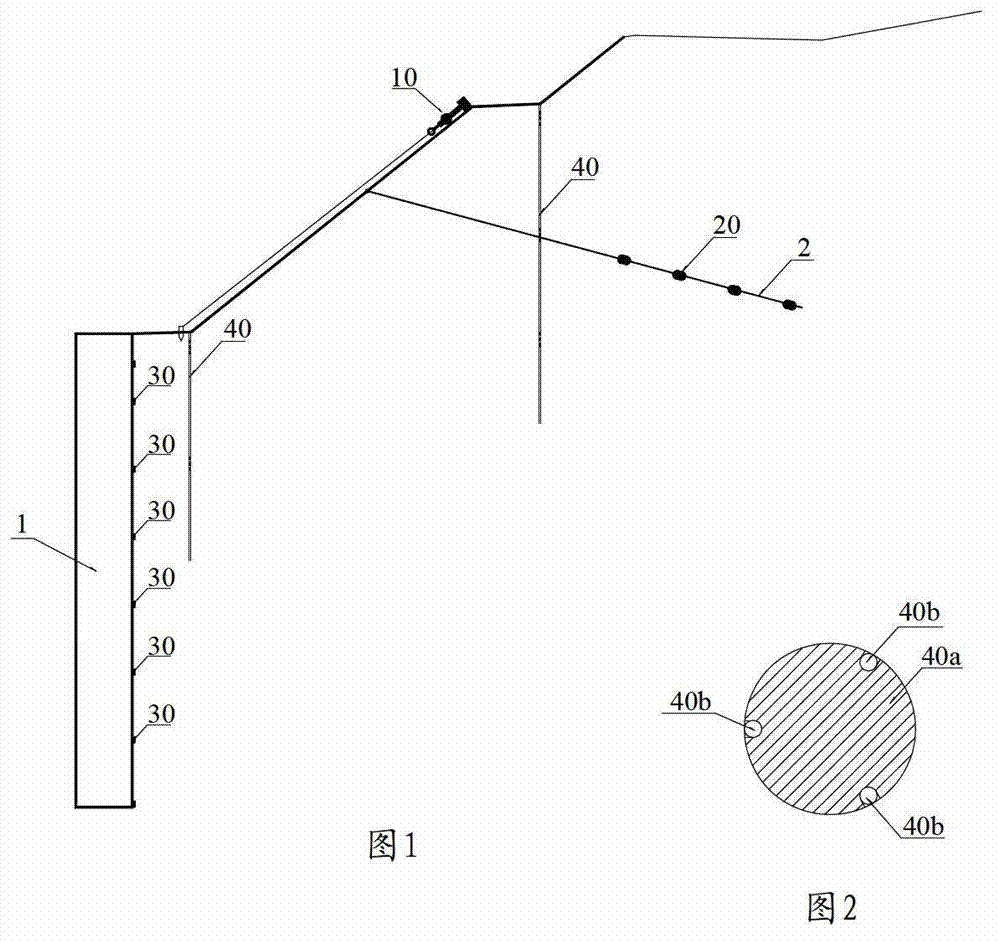

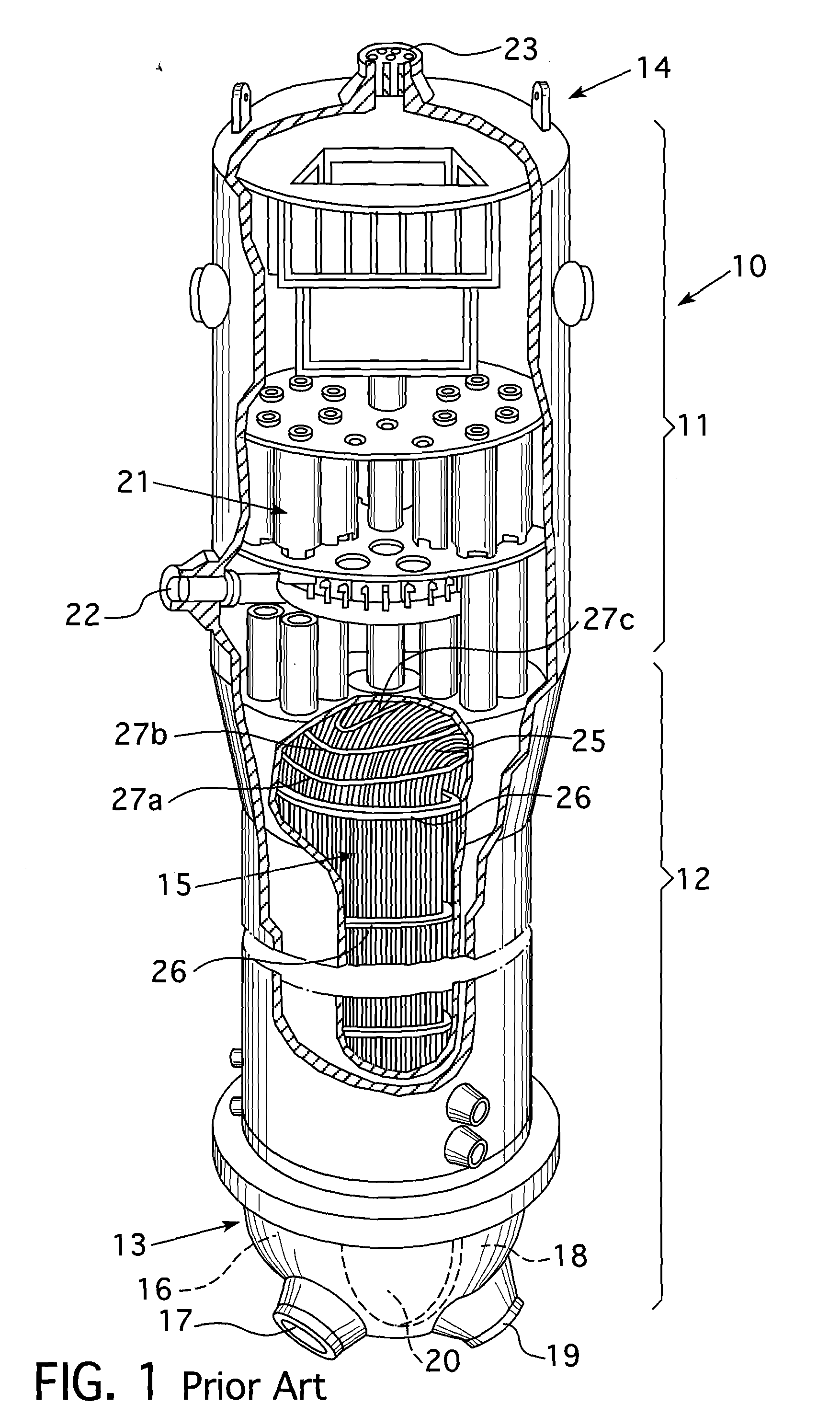

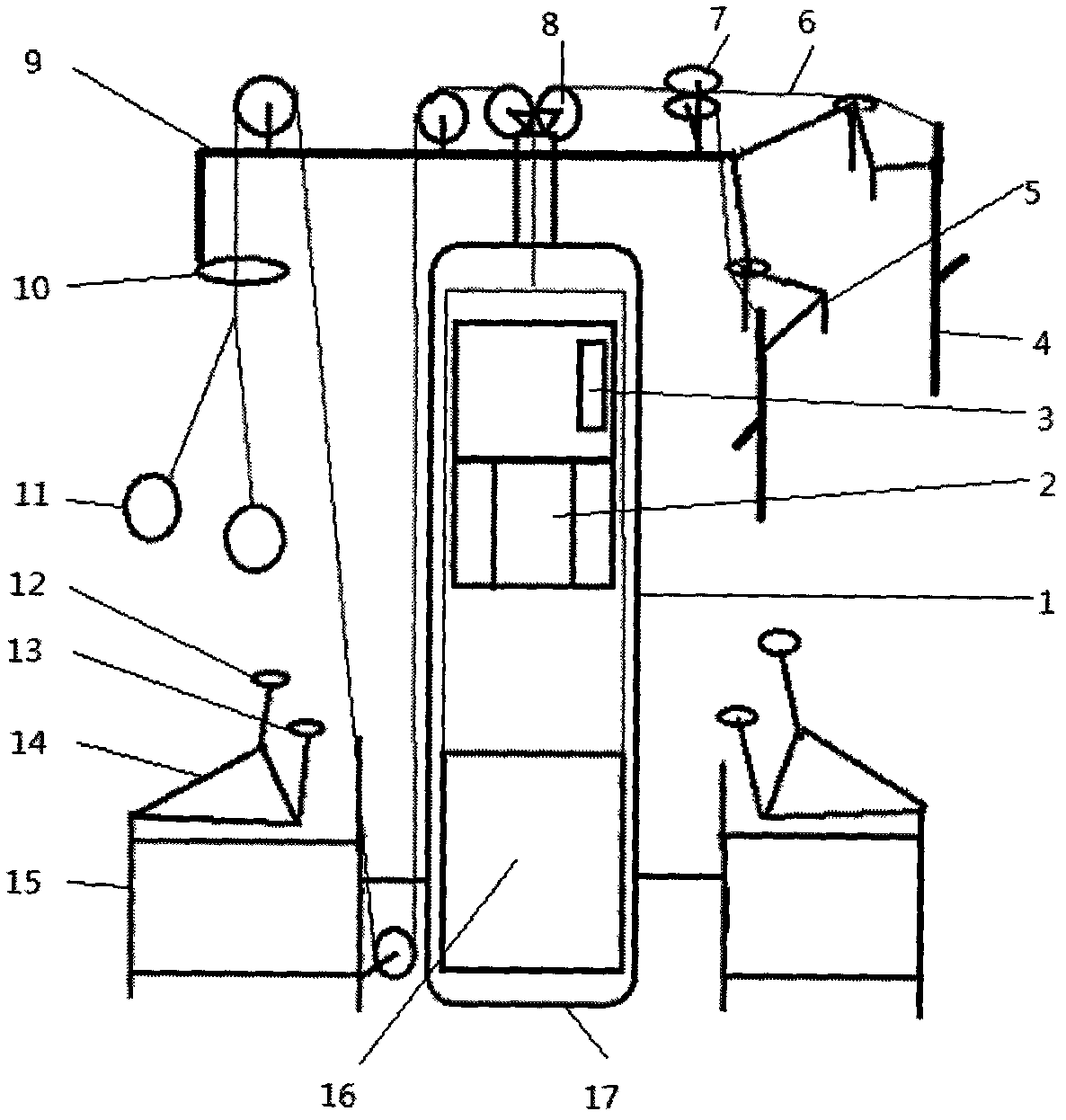

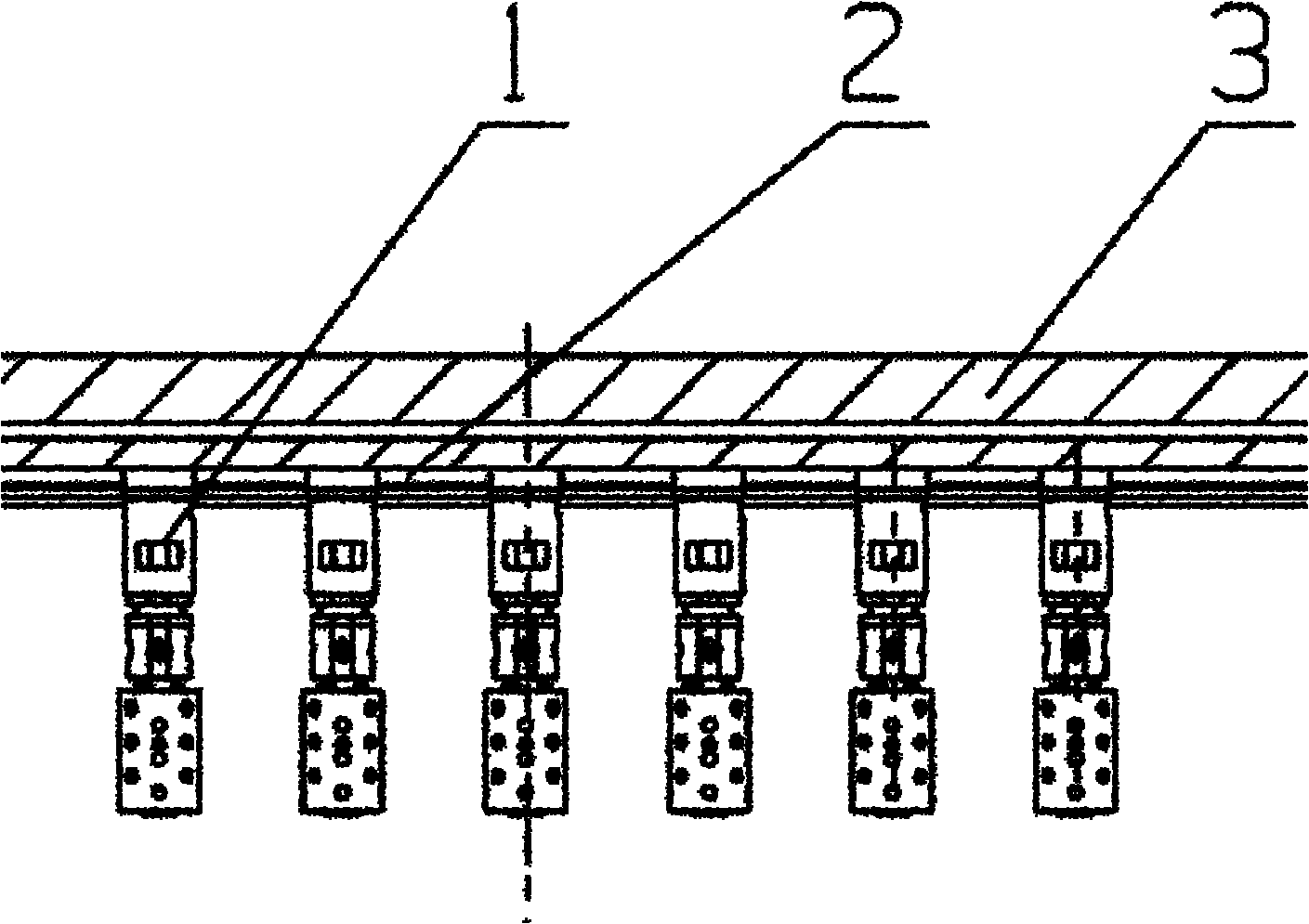

Comprehensive monitoring system for side slope and landslip

InactiveCN102829728AHigh precisionIncreased durabilityForce measurement by measuring optical property variationUsing optical meansFiberGrating

A comprehensive monitoring system for a side slope and a landslip is capable of comprehensively monitoring surface displacement and depth displacement of a slope body, soil pressure of a retaining structure, and internal force of an anchoring structure, and realizing high-efficient acquisition and automation treatment of data. The comprehensive monitoring system for the side slope and the landslip comprises a side slope surface displacement monitoring unit, a side slope supporting structure stress monitoring unit, a side slope interior deformation monitoring unit and a data acquisition and transmission device, wherein the side slope surface displacement monitoring unit is arranged on a side slope surface and adopts a stay cord type fiber bragg grating displacement sensor; and two ends of the side slope surface displacement monitoring unit are respectively fixed on the side slope surface and the top of a slope body retaining structure; the side slope supporting structure stress monitoring unit consists of fiber bragg grating pressure boxes vertically embedded on the back of the slope body retaining structure at intervals, and a fiber bragg grating force gauge arranged on a slope body anchoring component; the side slope interior deformation monitoring unit is a fiber bragg grating intelligent anchoring rod embedded in the slope body by drilling a hole; and the data acquisition and transmission device consists of a multi-channel wavelength demodulator and a monitoring computer.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

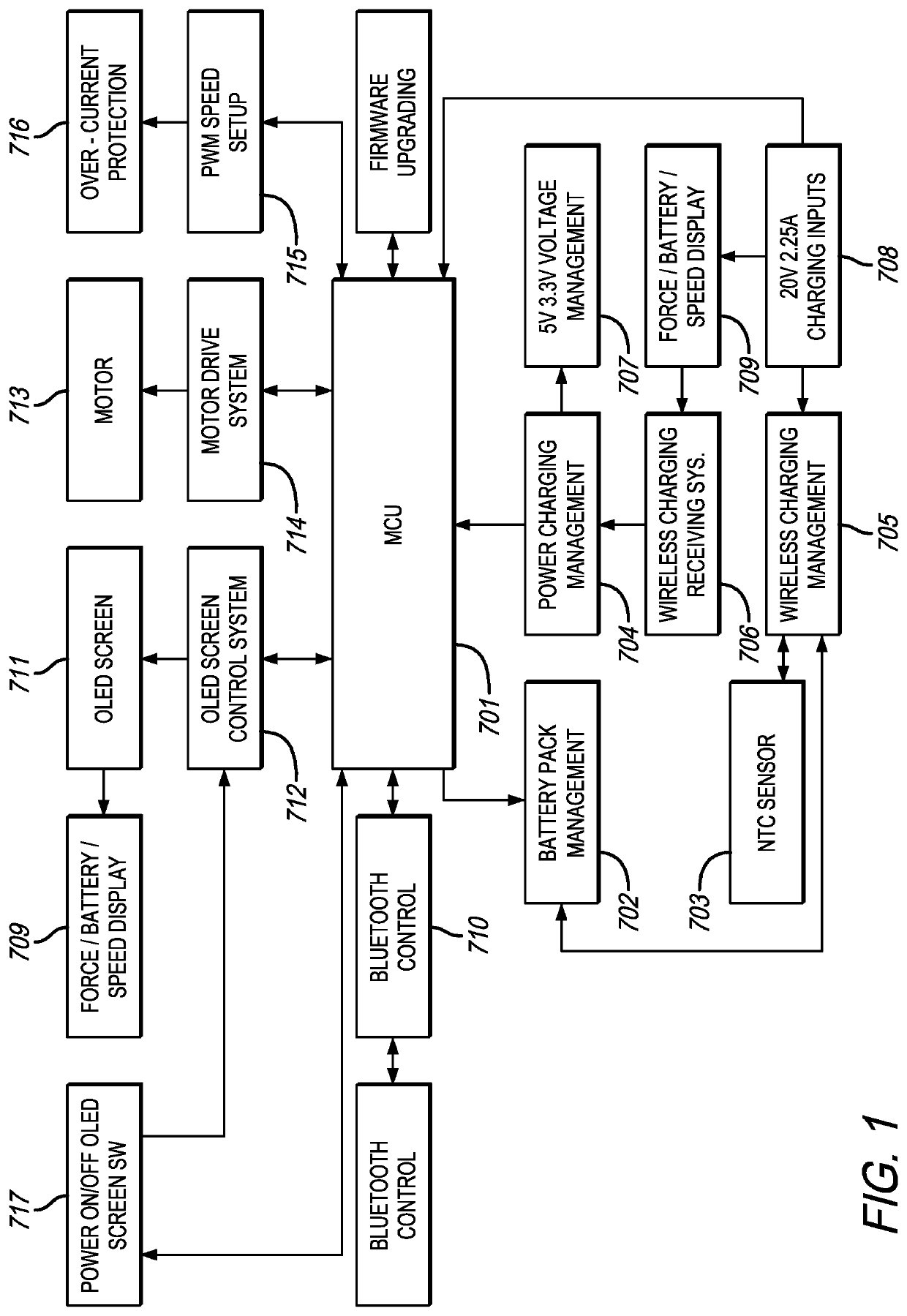

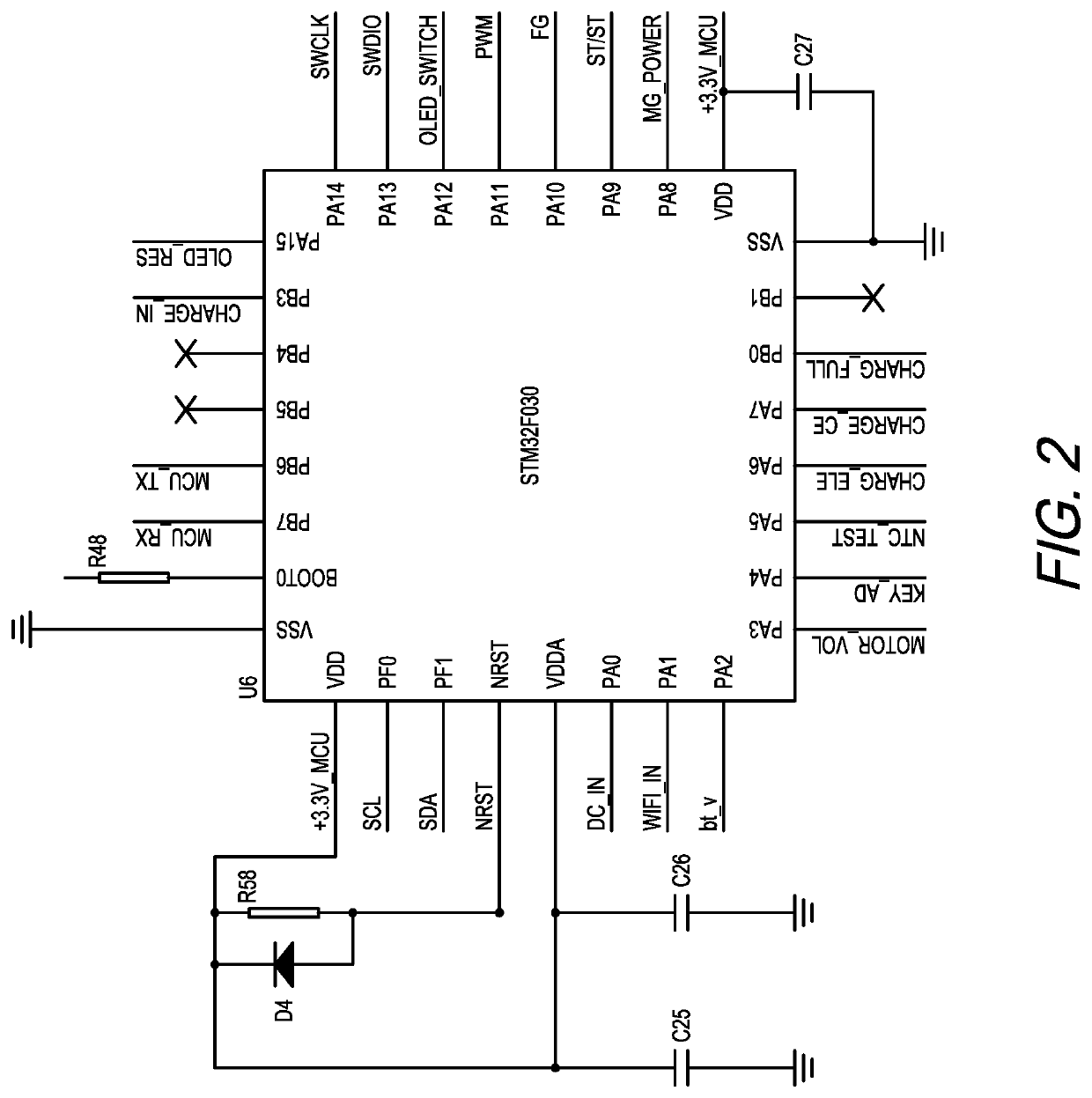

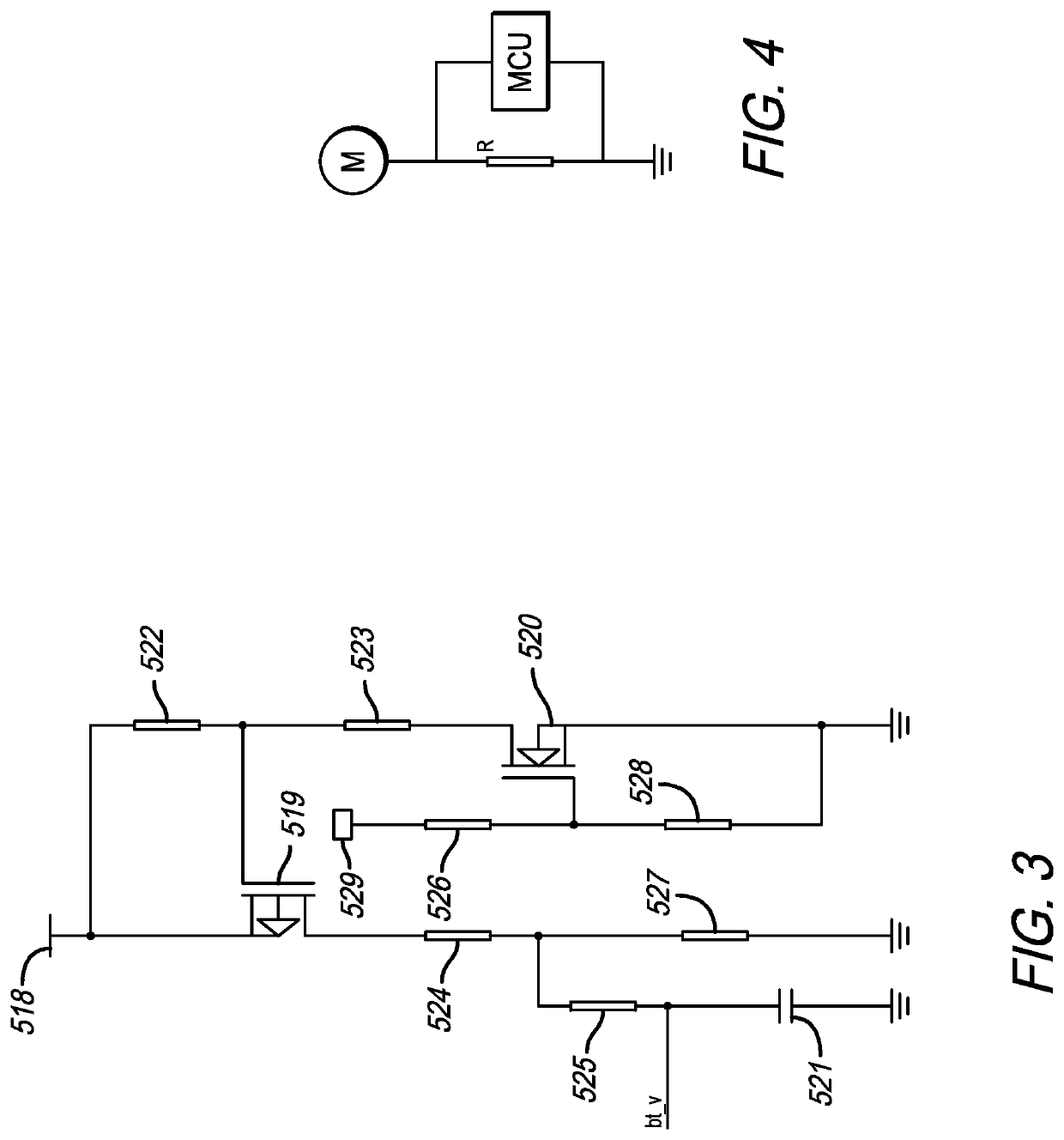

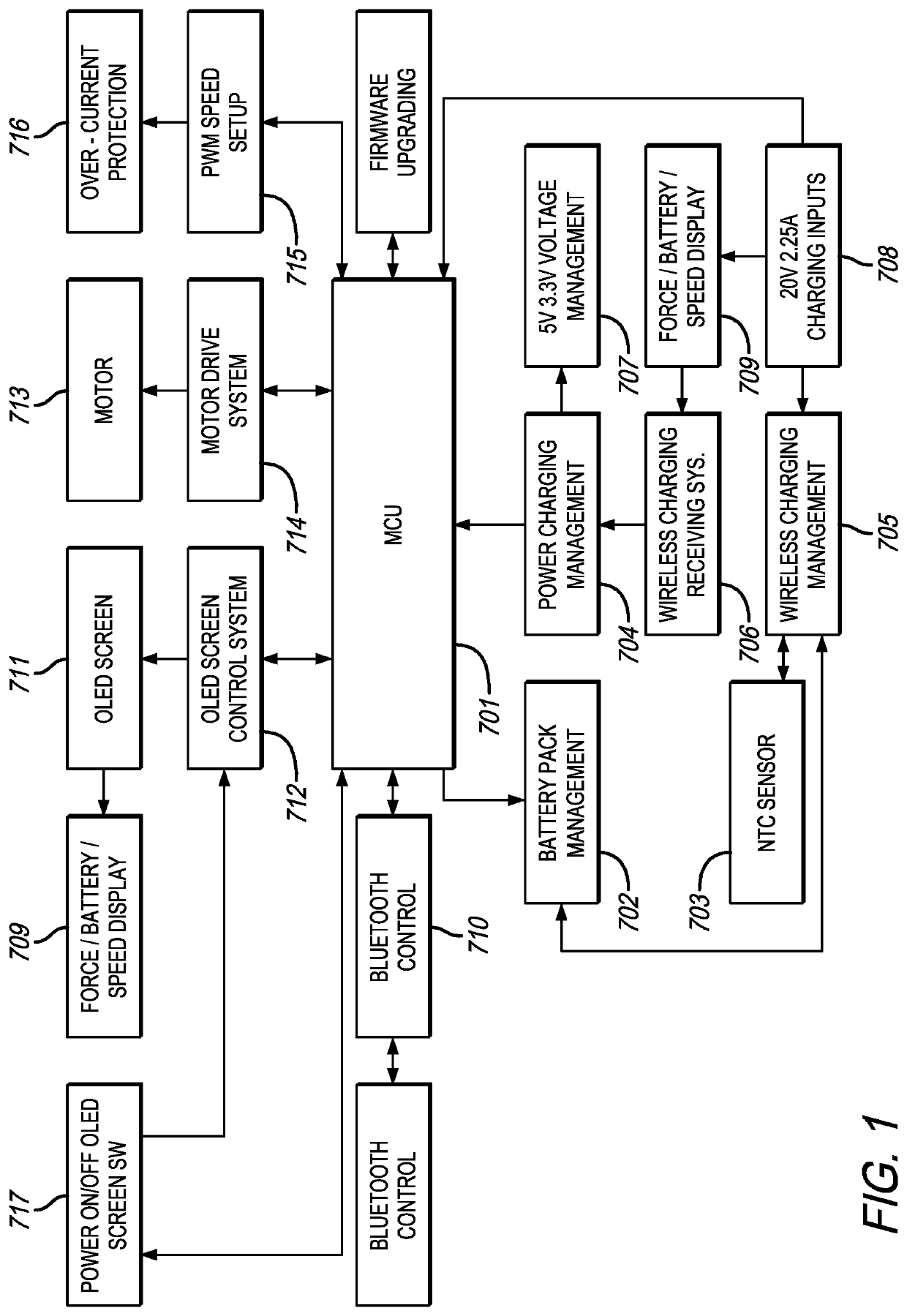

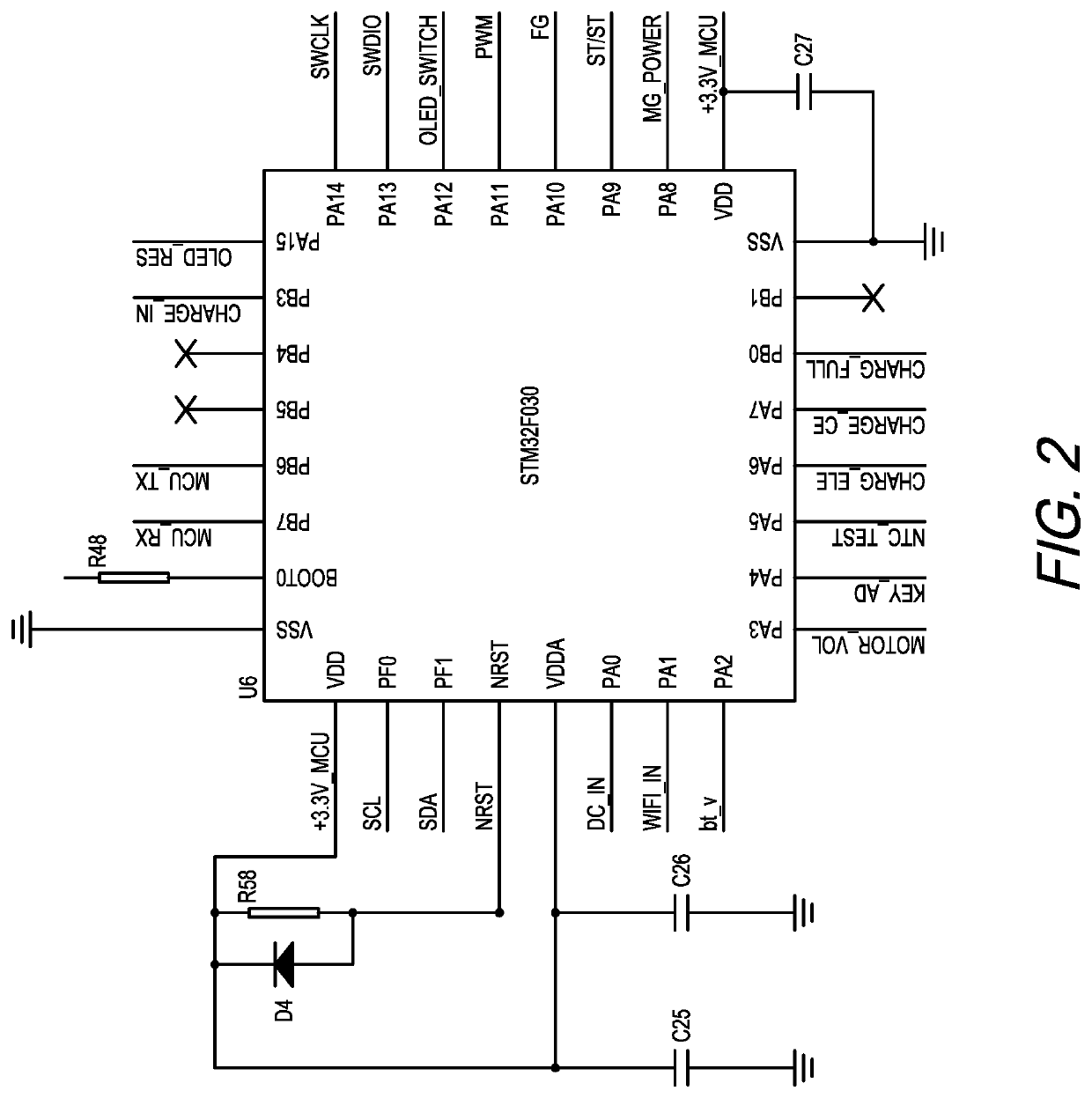

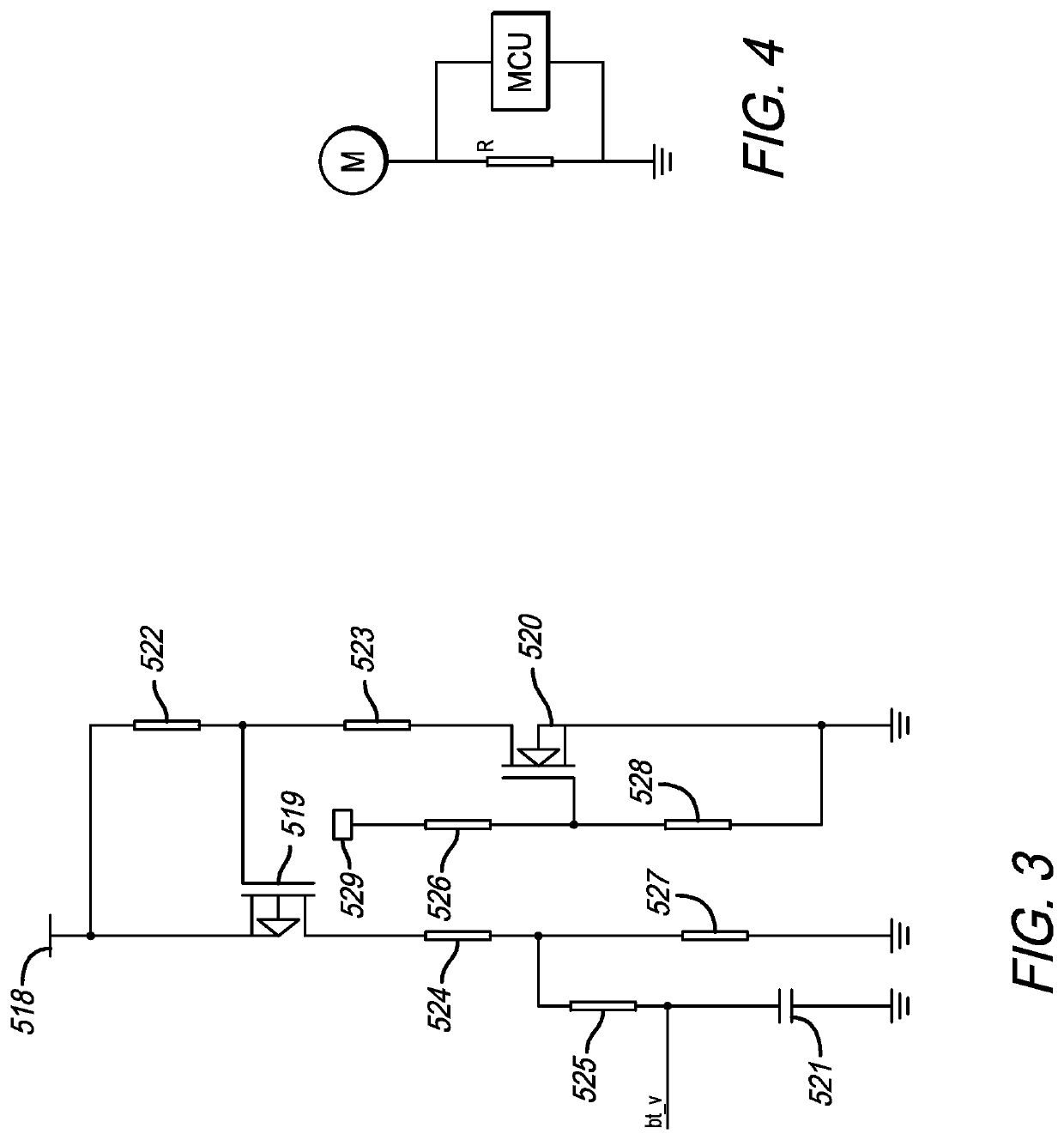

Percussive massage device with force meter

ActiveUS10940081B2Low profilePrecision therapyElectric motor controlSoftware algorithm controlPhysical medicine and rehabilitationElectric machinery

A percussive massage device with a force meter that includes a housing, an electrical source, a motor positioned in the housing, a switch for activating the motor, and a controller configured to obtain a voltage of the motor, generate a lookup table correlating voltage to force applied by the percussive massage device, and display a force magnitude corresponding to the obtained voltage using the lookup table.

Owner:THERABODY INC

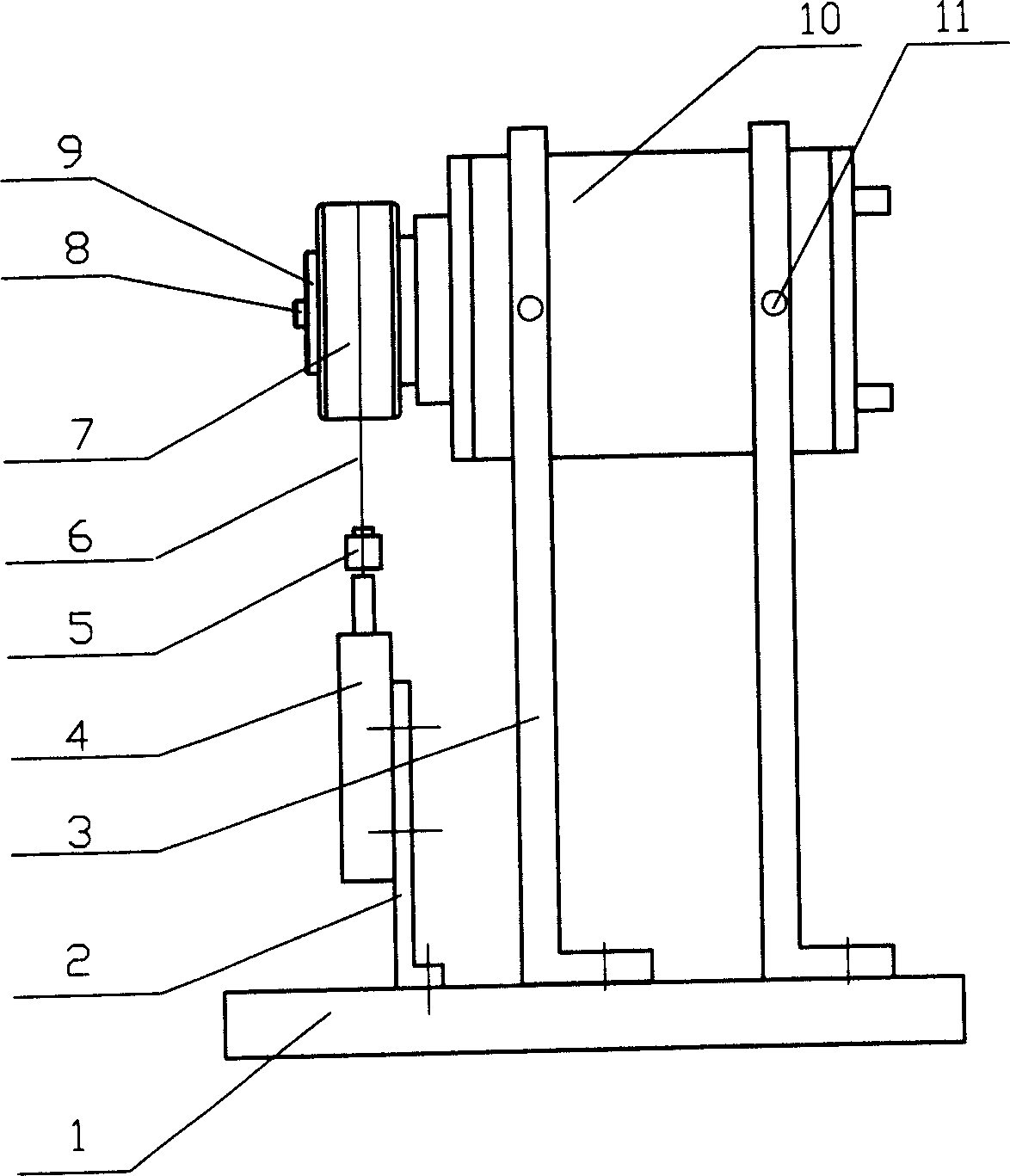

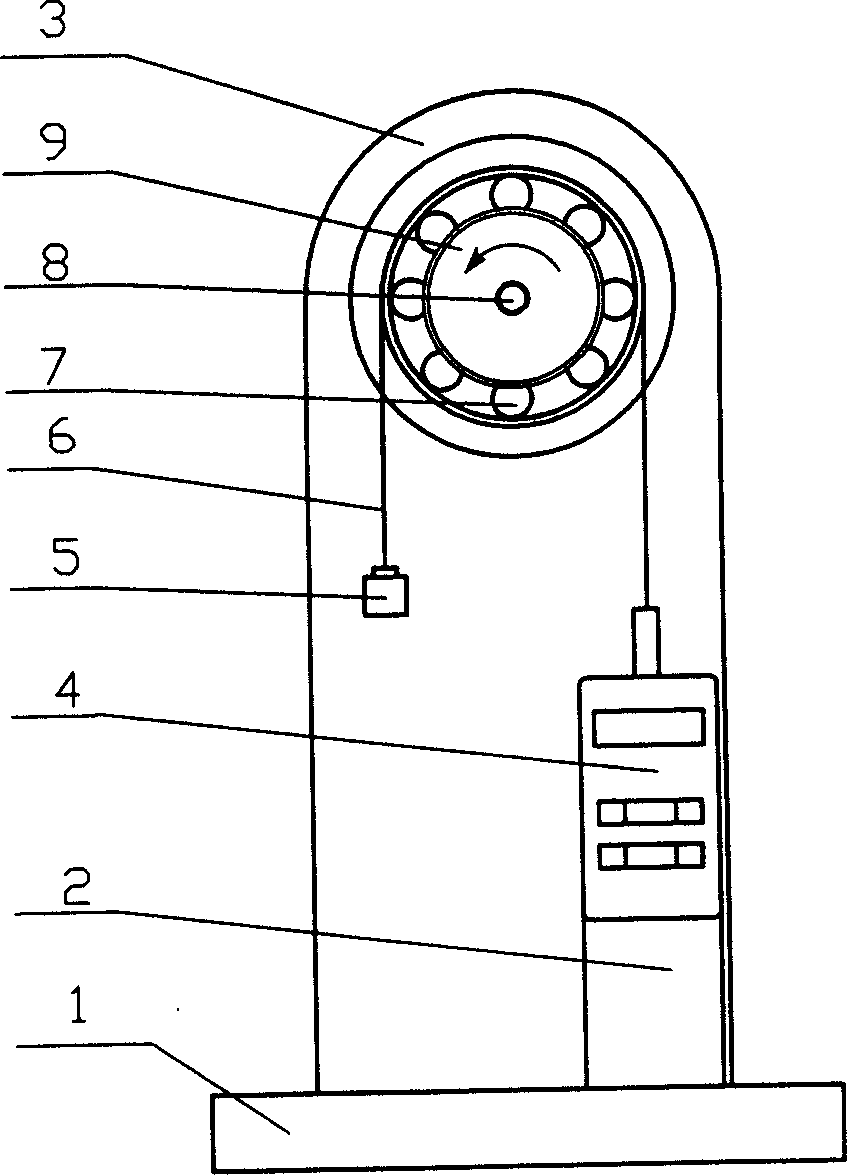

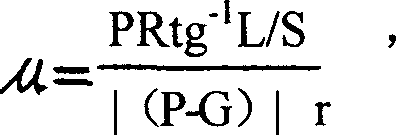

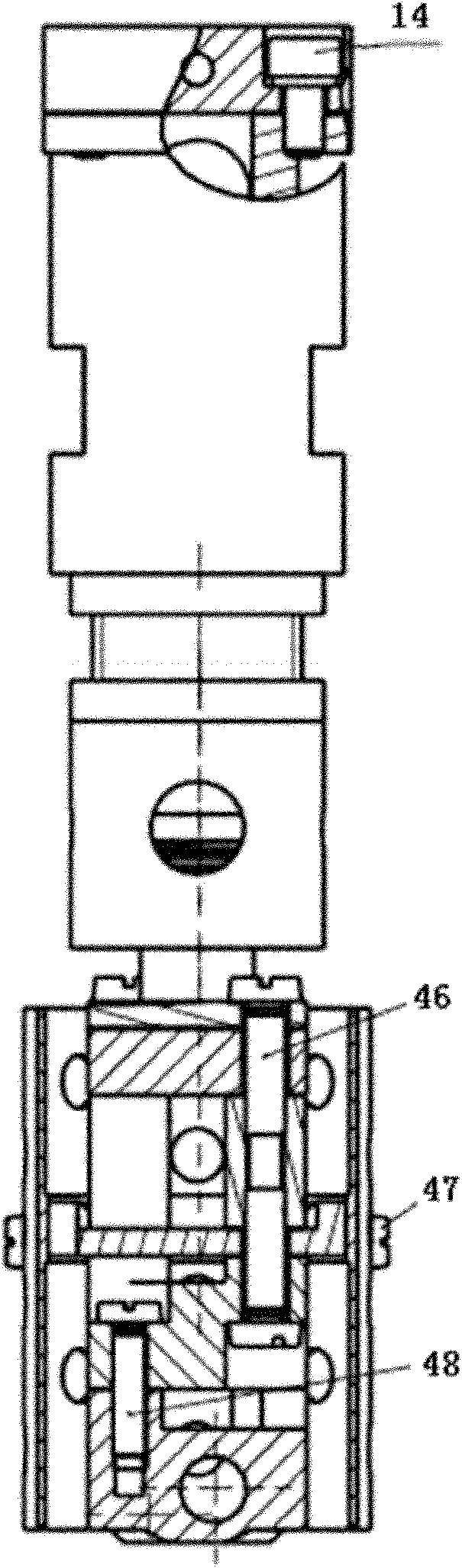

Measuring for friction torque of bearing under micro-loading at different rotation rate and measuring apparatus therefor

ActiveCN1865878AThe principle is simpleSimple structureMachine bearings testingWork measurementObservational errorFriction torque

The disclosed measuring apparatus and method for frictional moment comprise: the target bearing with diameter as D is suspended a segment nylon wire with ends connected to weight and dynamometer respectively, when bearing static, the show value on dynamometer as A1 balances to the weight; if rotating toward one direction by some rate, the show value increases to A2, and the formula M=(A2-A1) .D / 2 can express the corresponding frictional moment. This invention is reliable, simple, and well practical.

Owner:CIXING GROUP

Percussive massage device with force meter

ActiveUS20200352820A1Low profilePrecision therapyElectric motor controlSoftware algorithm controlPhysical medicine and rehabilitationElectric machinery

A percussive massage device with a force meter that includes a housing, an electrical source, a motor positioned in the housing, a switch for activating the motor, and a controller configured to obtain a voltage of the motor, generate a lookup table correlating voltage to force applied by the percussive massage device, and display a force magnitude corresponding to the obtained voltage using the lookup table.

Owner:THERABODY INC

Orthodontic force measurement system

A method for concurrently measuring a force exerted upon each of a plurality of teeth is disclosed. A dentition crown connecting rod associated with a force gauge is positioned such that a dentition crown coupled to the dentition crown connecting rod may be received within a corresponding cavity of a reference aligner. A measurement aligner is then applied to the dentition crown, wherein the dentition crown is positioned to be received within a corresponding cavity of a reference aligner. A force exerted on the dentition crown by the measurement aligner is then calculated.

Owner:ALIGN TECH

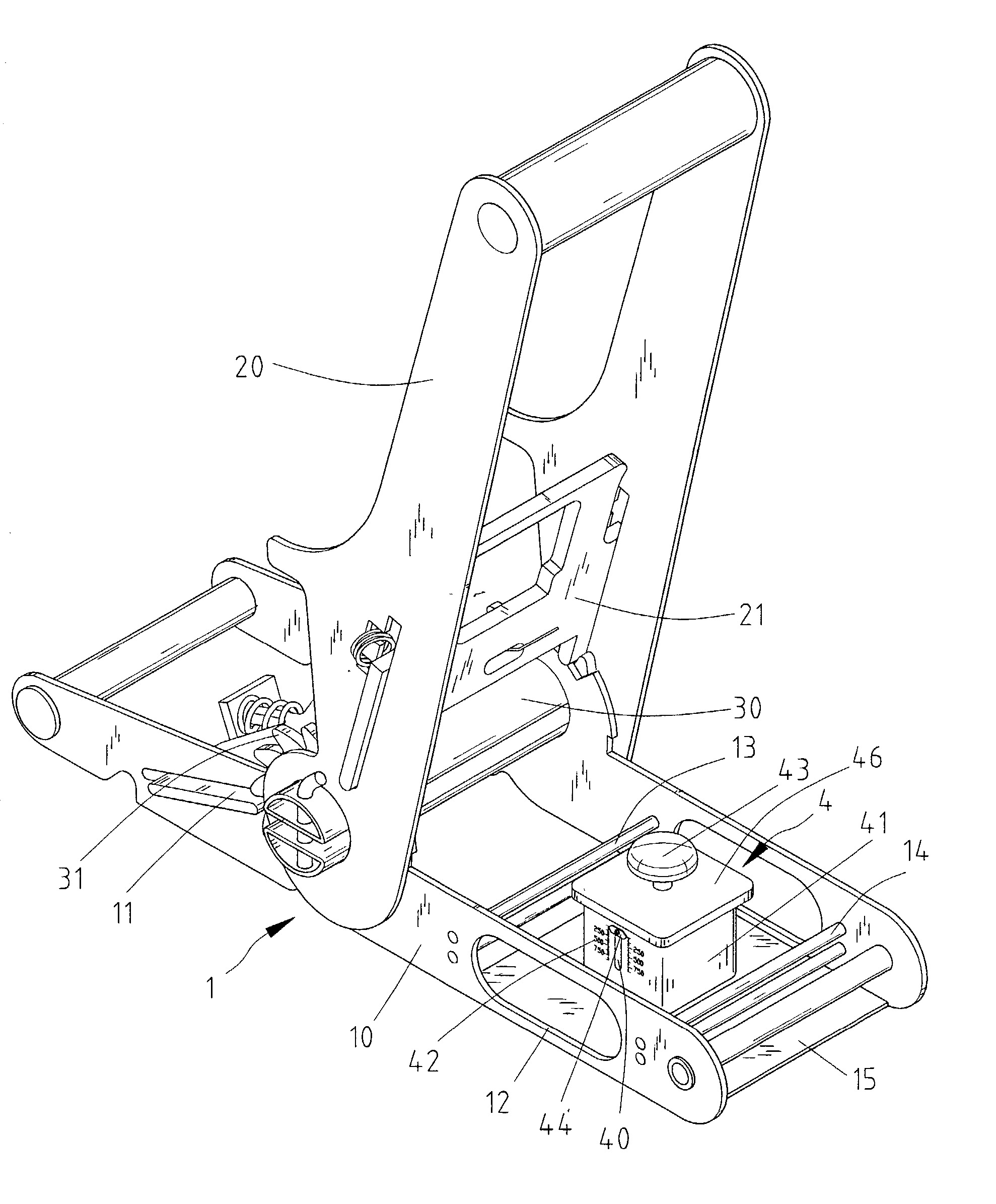

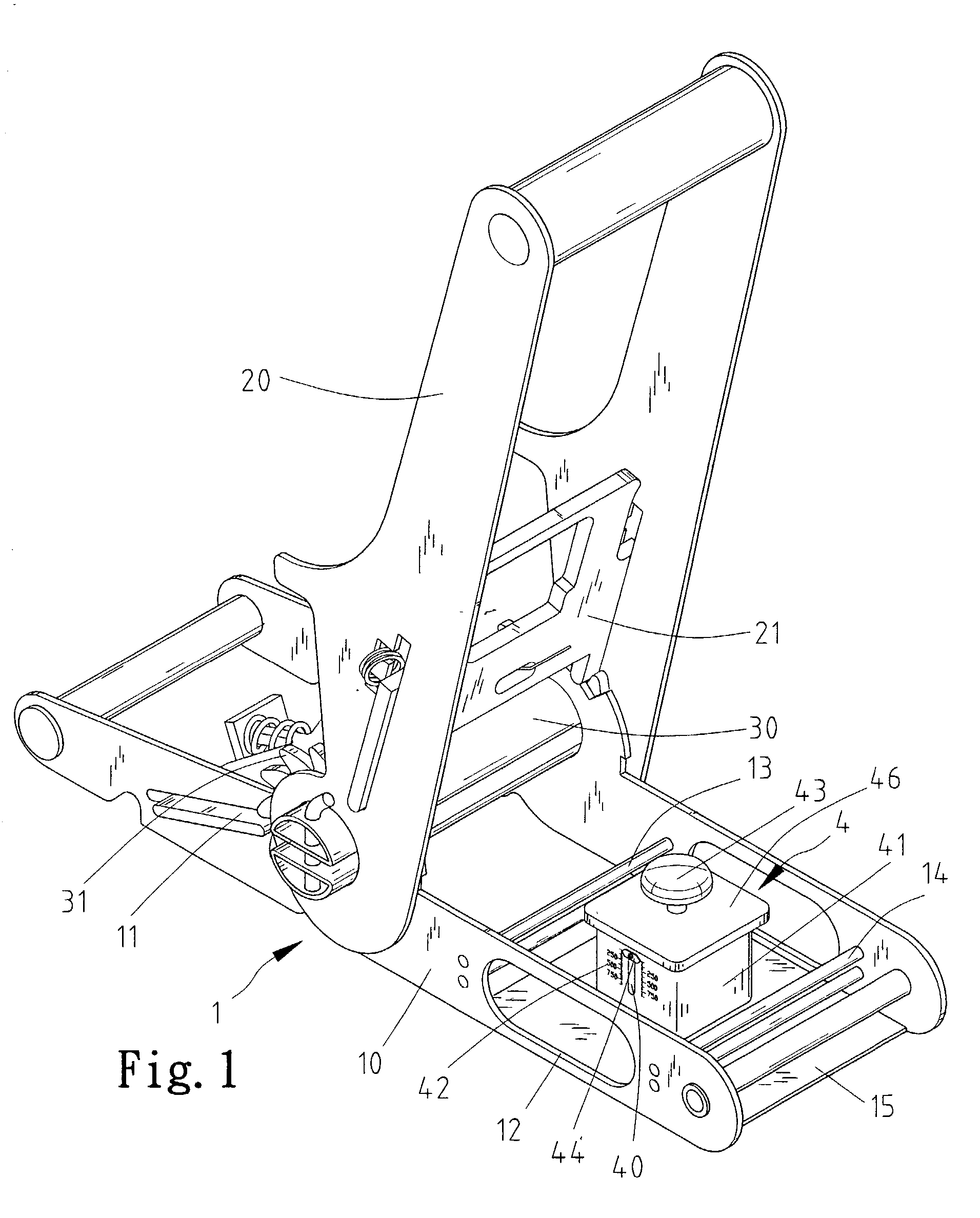

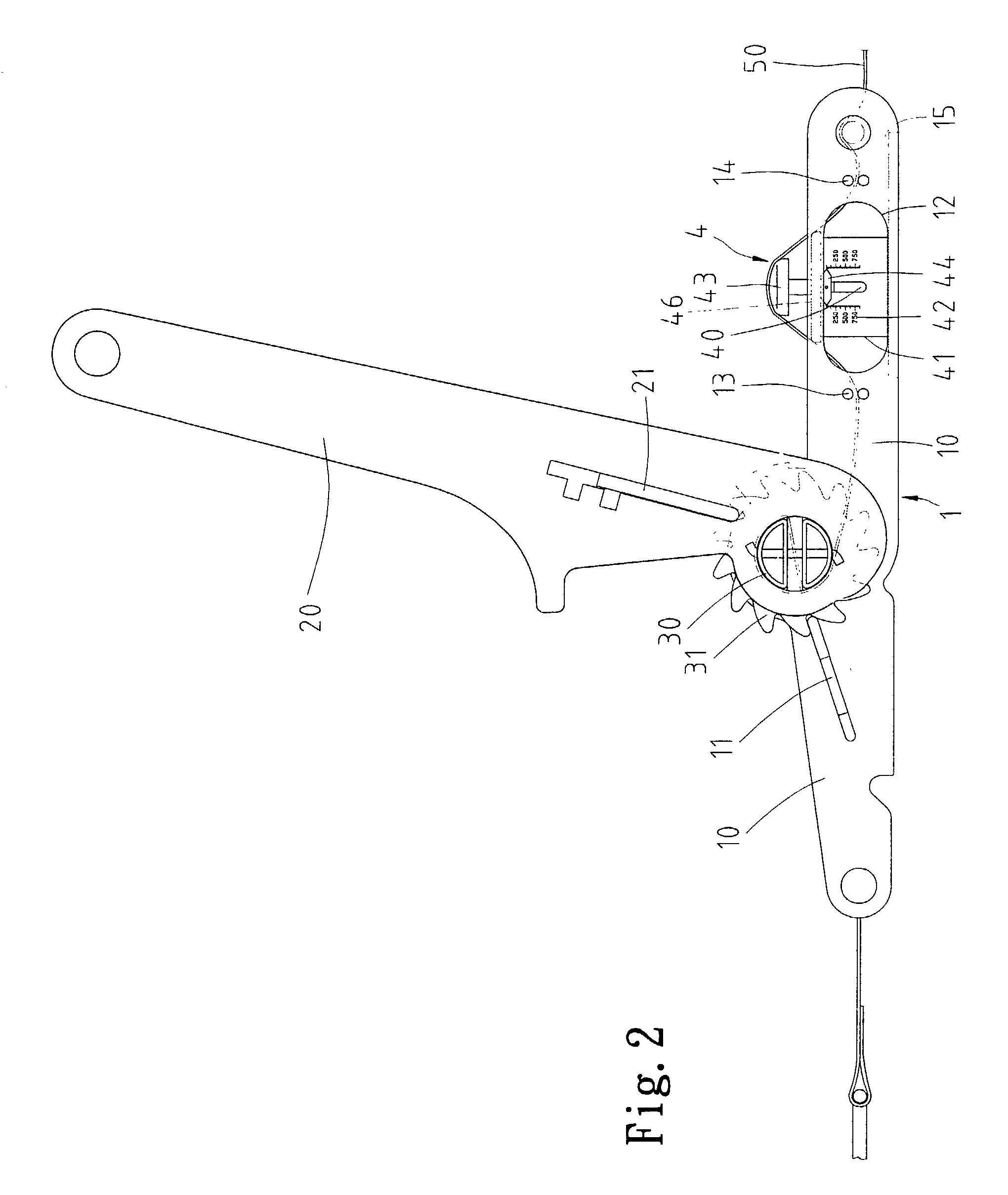

Force-indicating strap fastener

A force-indicating strap fastener includes a base, an axle, a lever, two ratchet wheels, a first detent, a second detent, and a force gauge. The base including a first guiding element formed thereon and a second guiding element formed thereon. The axle is rotationally mounted on the base. The lever is pivotally mounted on the axle. The ratchet wheels are secured to the axle. The first detent is mounted on the base for engagement with the ratchet wheels. Thus, rotation of the axle relative to the base in a first direction is allowed, but rotation of the axle in a second direction opposite to the first direction is avoided. The second detent is mounted on the lever for engagement with the ratchet wheels. Thus, pivoting of the lever in the first direction results in rotation of the axle in the first direction, but pivoting of the lever in the second direction does not entail rotation of the axle in the second direction. The force gauge includes a casing, a spring, an anvil and an indicator. The casing is mounted on the base and formed with a scale. The spring is received in the casing. The anvil includes a first end in contact with the spring and a second end outside the casing. The indicator is connected with the anvil for pointing at a value in the scale depending on the tensile force.

Owner:HUANG HAN CHING

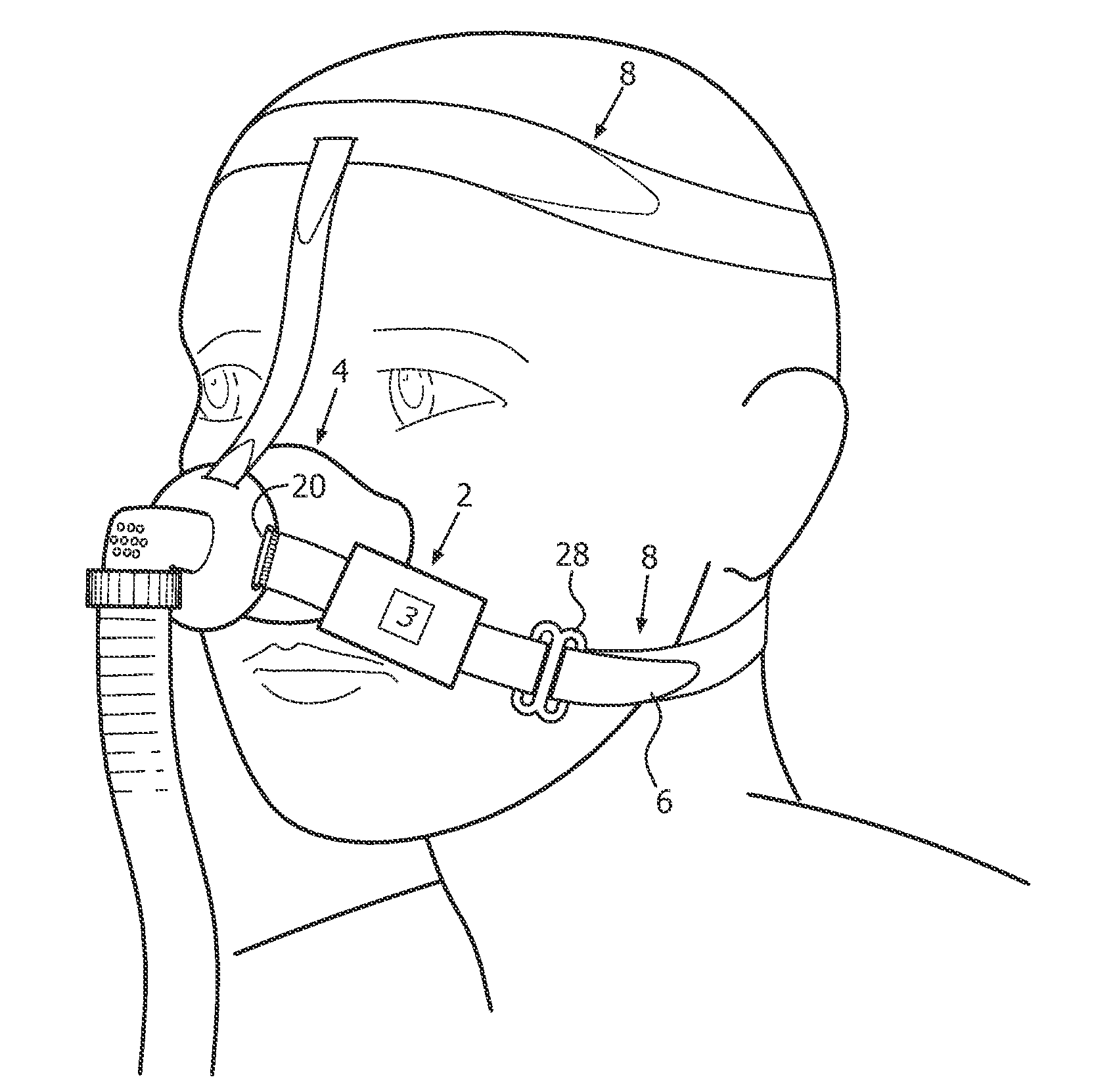

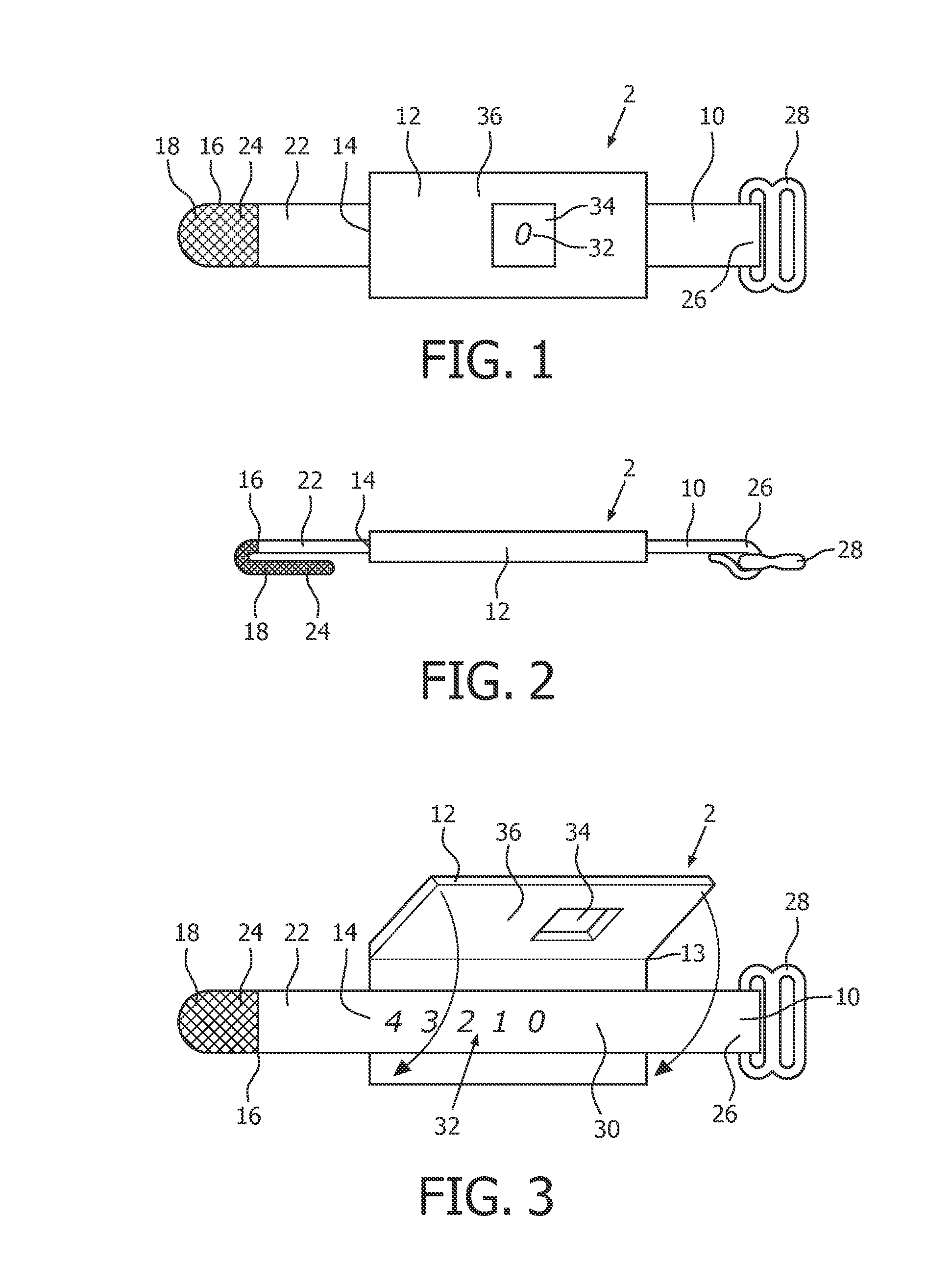

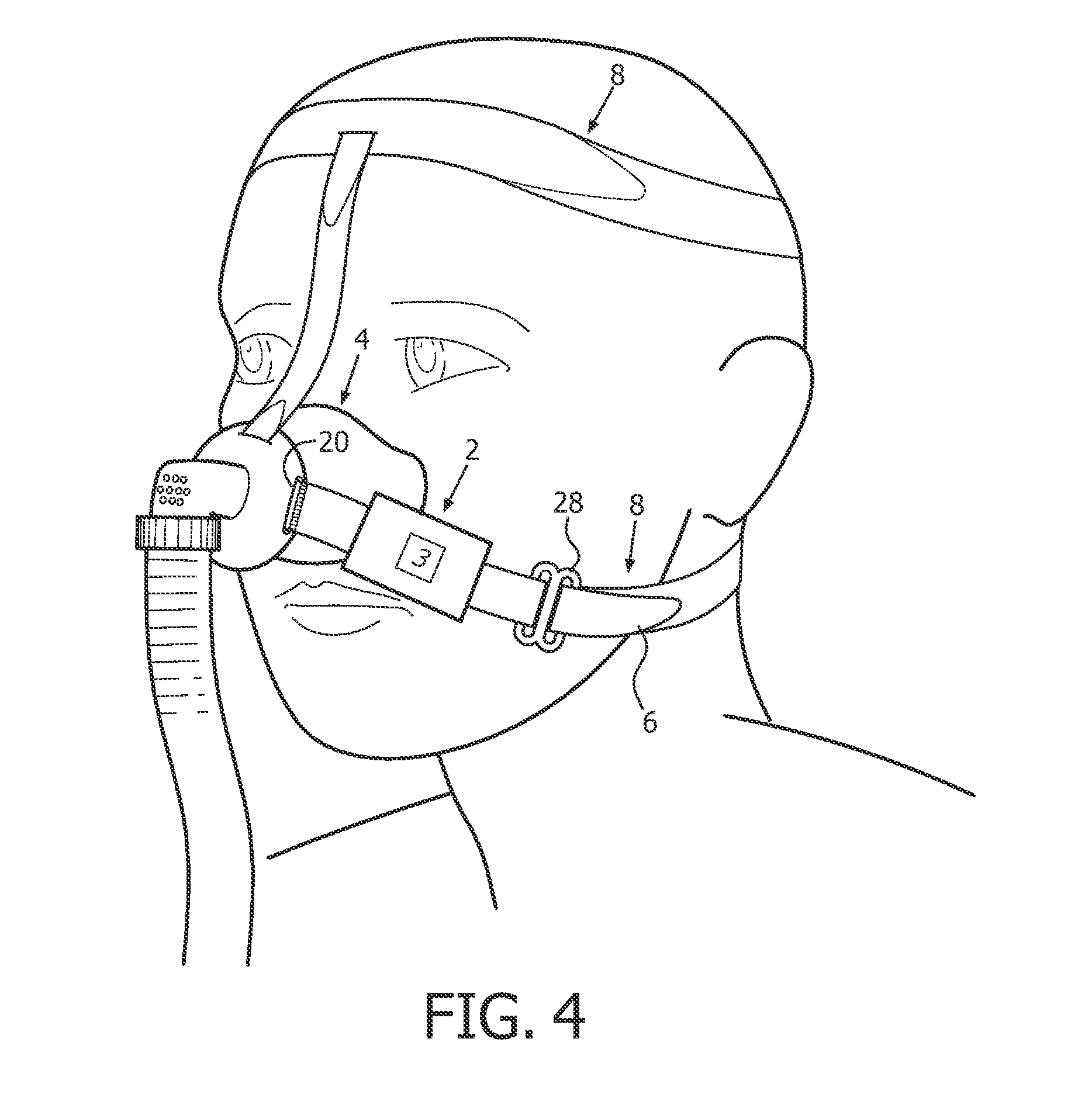

Strapping force indicator accessory

An apparatus for indicating a strapping force applied by a headgear of a patient interface device. The apparatus includes a first portion structured to be selectively connectable to a connecting element of a mask of the patient interface device, a second portion structured to be selectively connectable to a strap of the headgear, and a force gauging mechanism coupled to the first portion and the second portion. The force gauging mechanism is structured to gauge and indicate a force being applied by the headgear in response to the second strap portion being pulled by the strap of the headgear.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

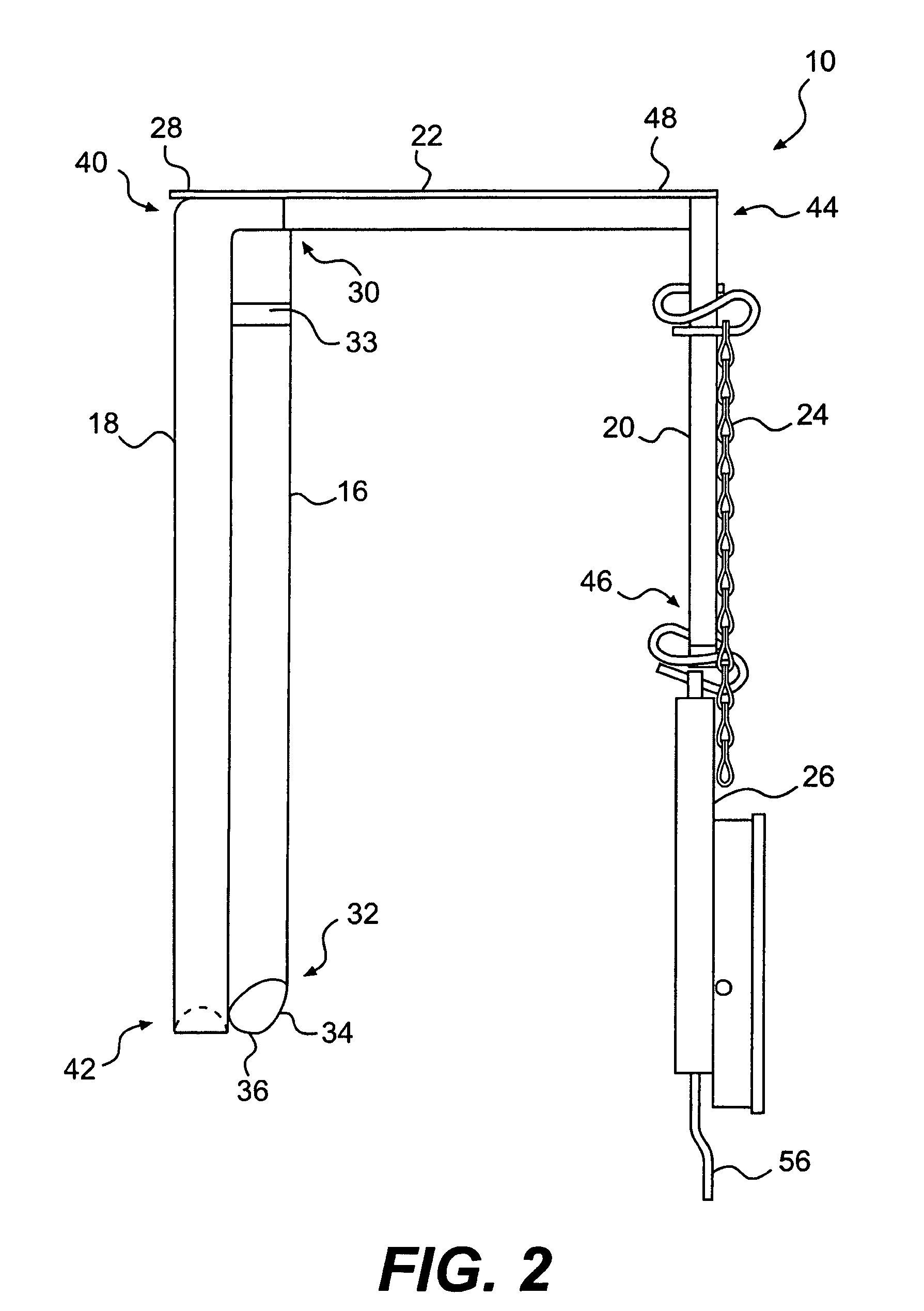

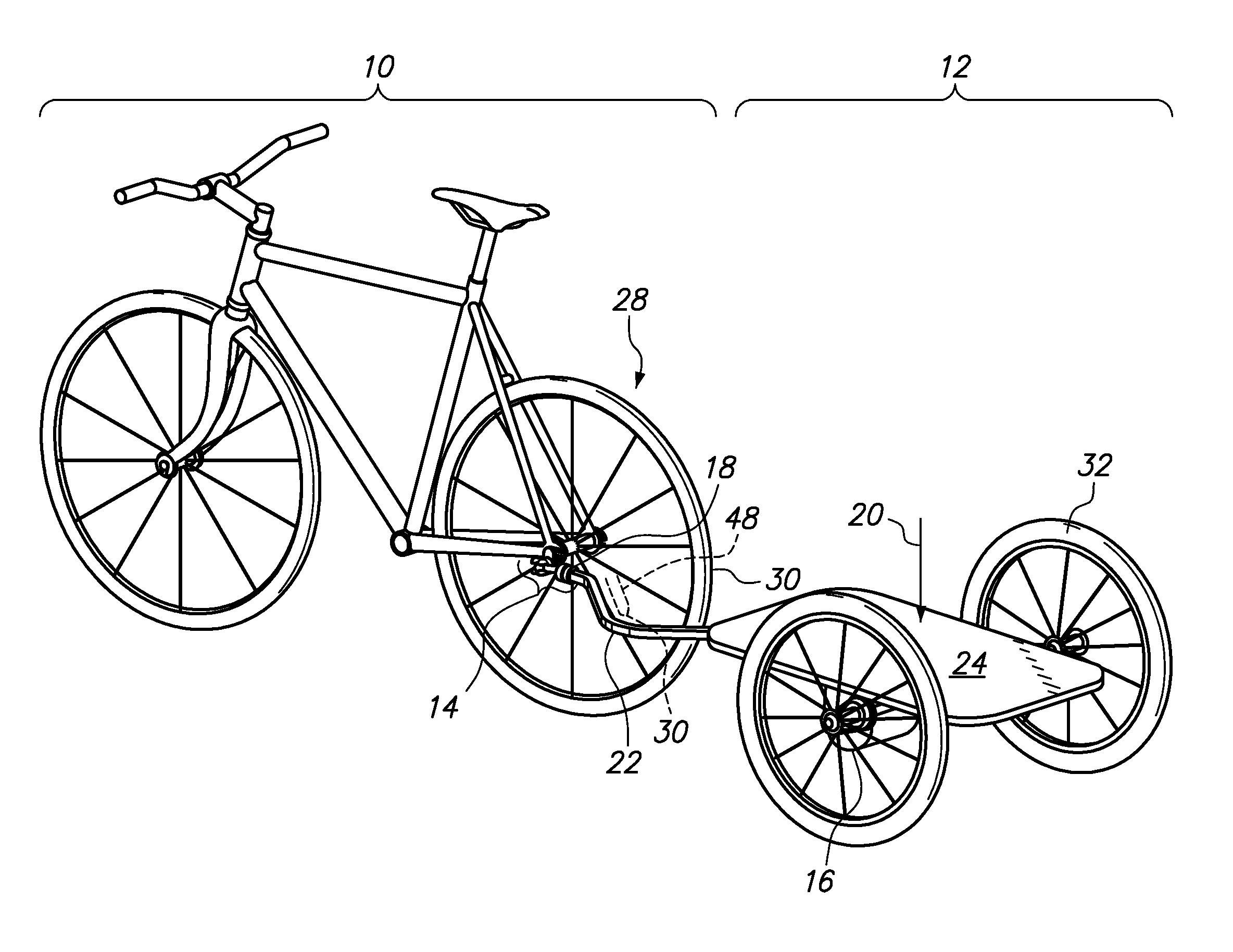

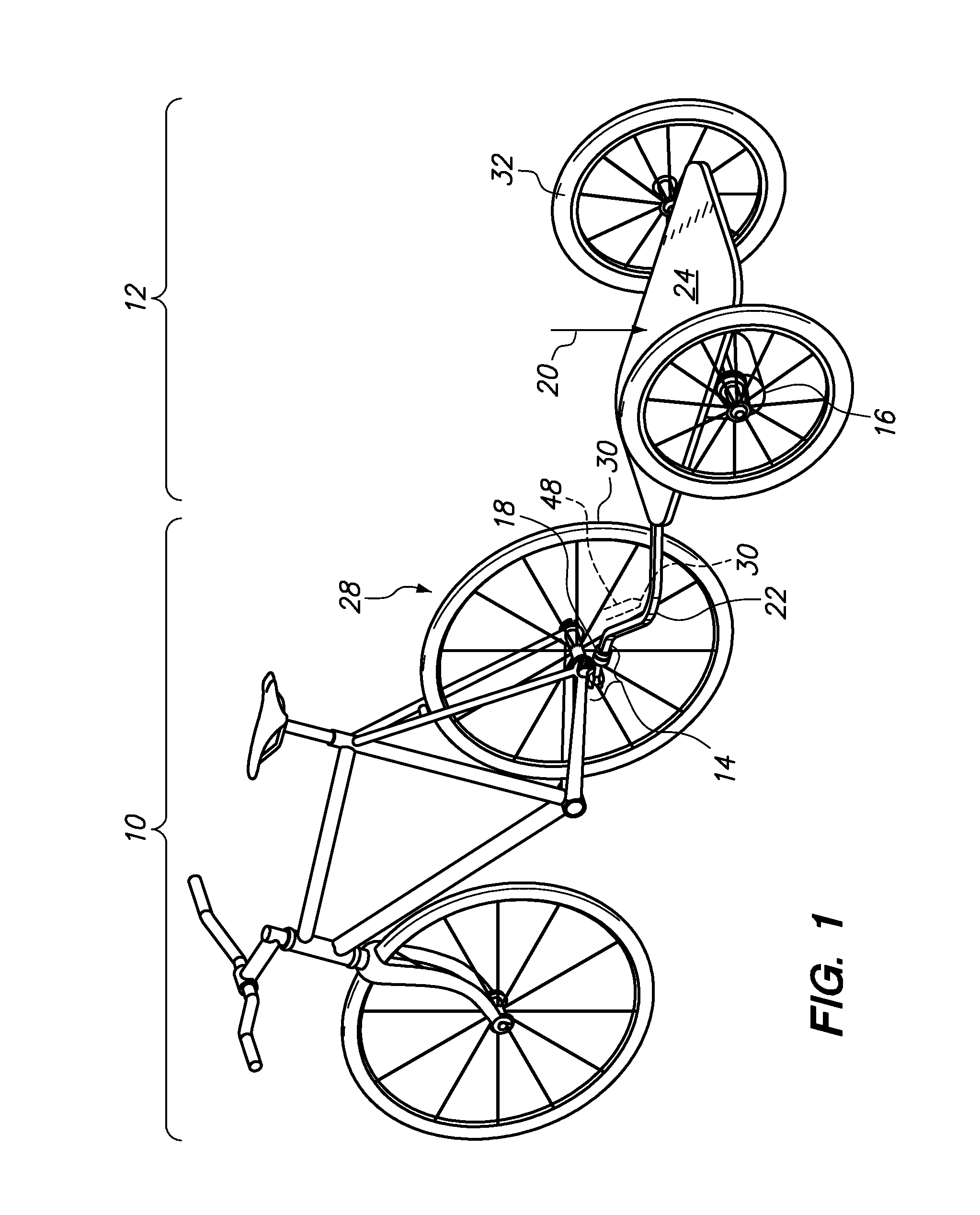

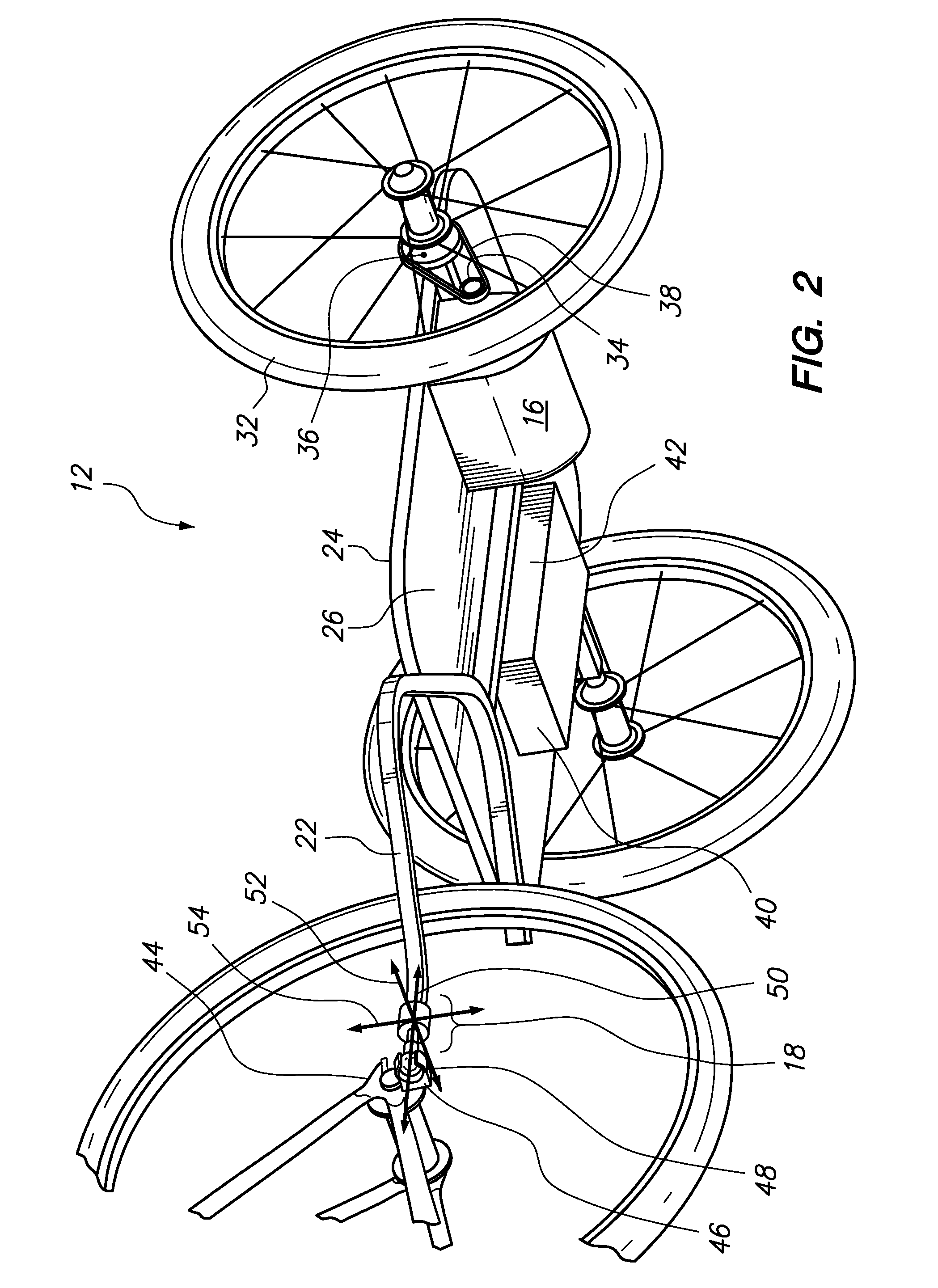

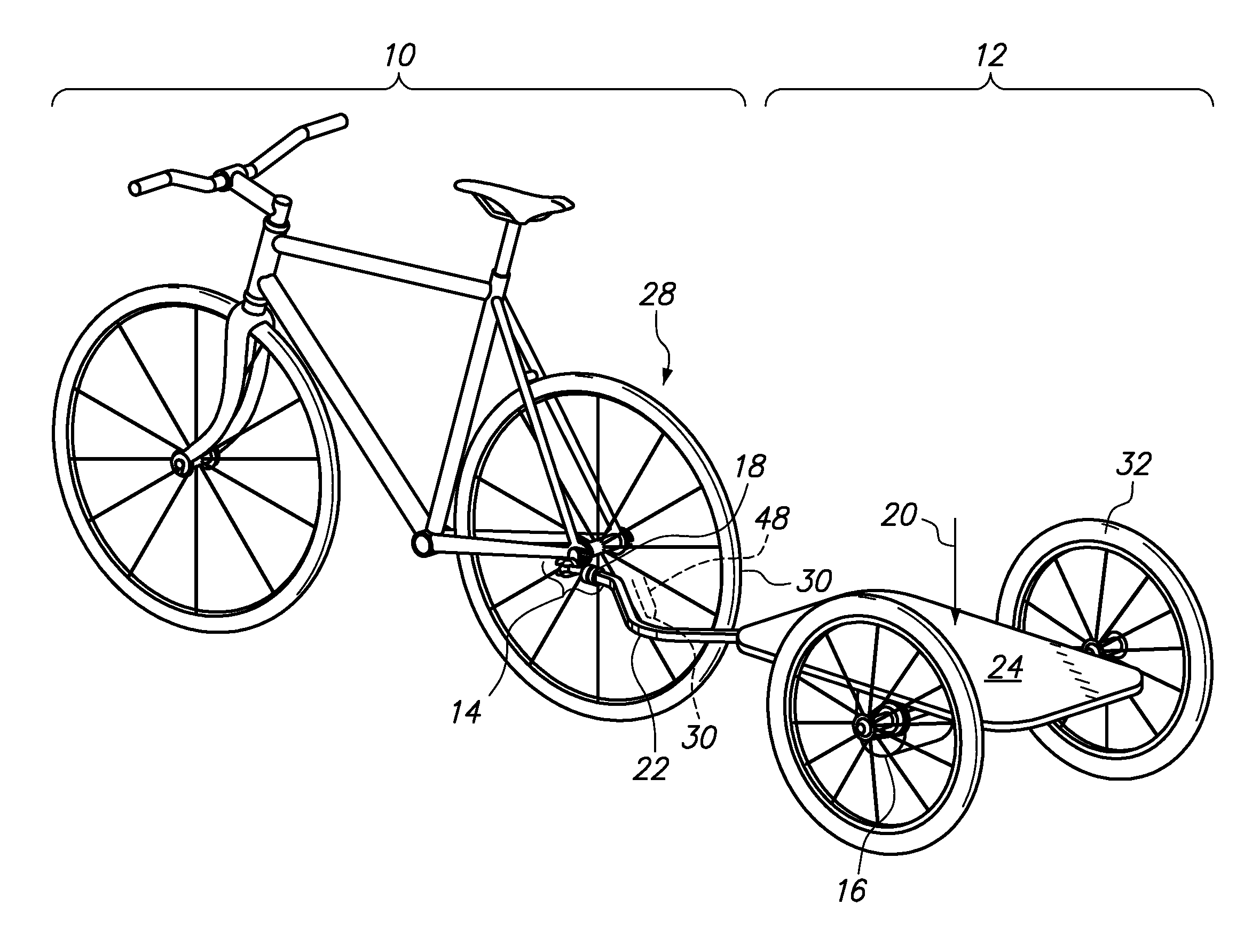

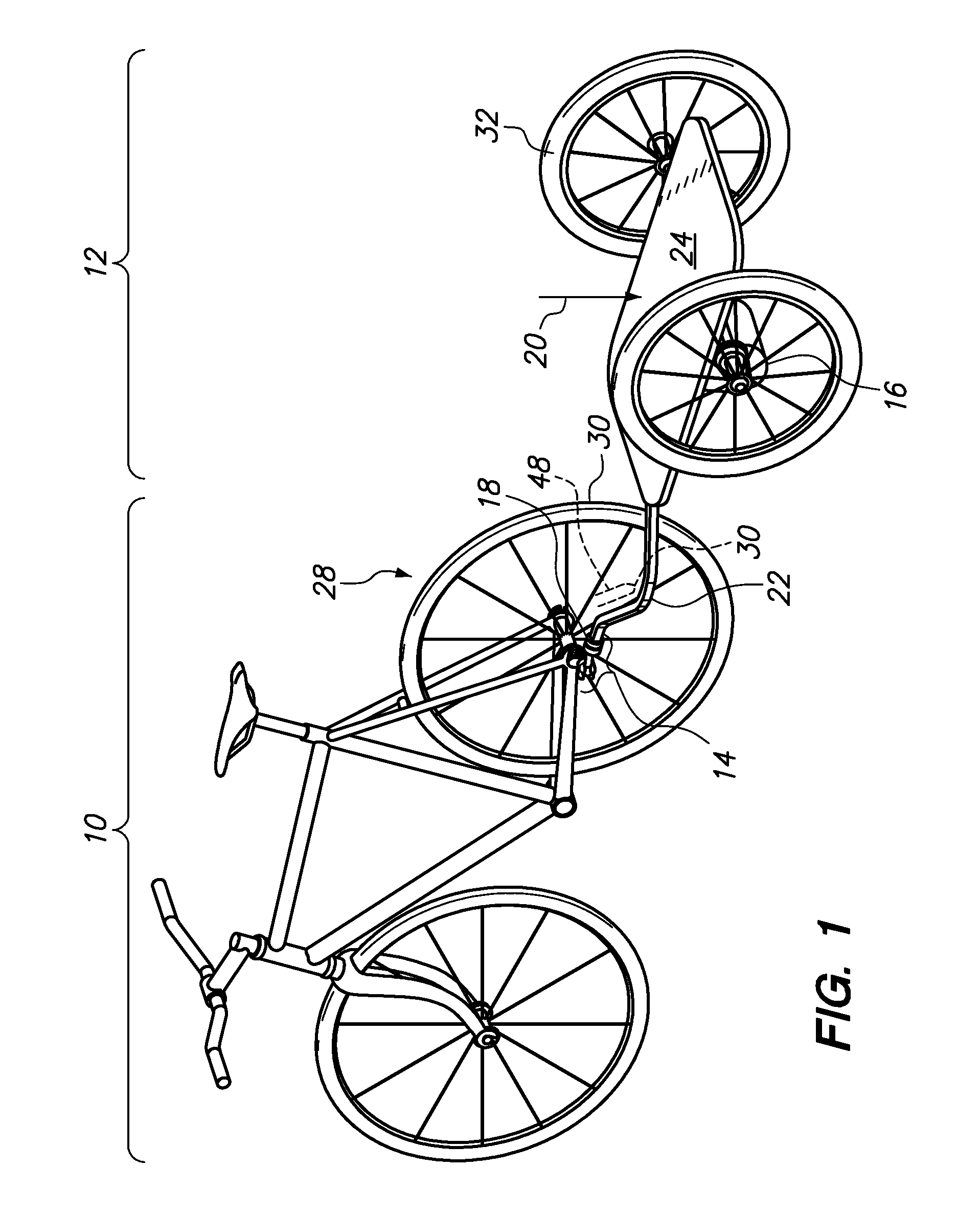

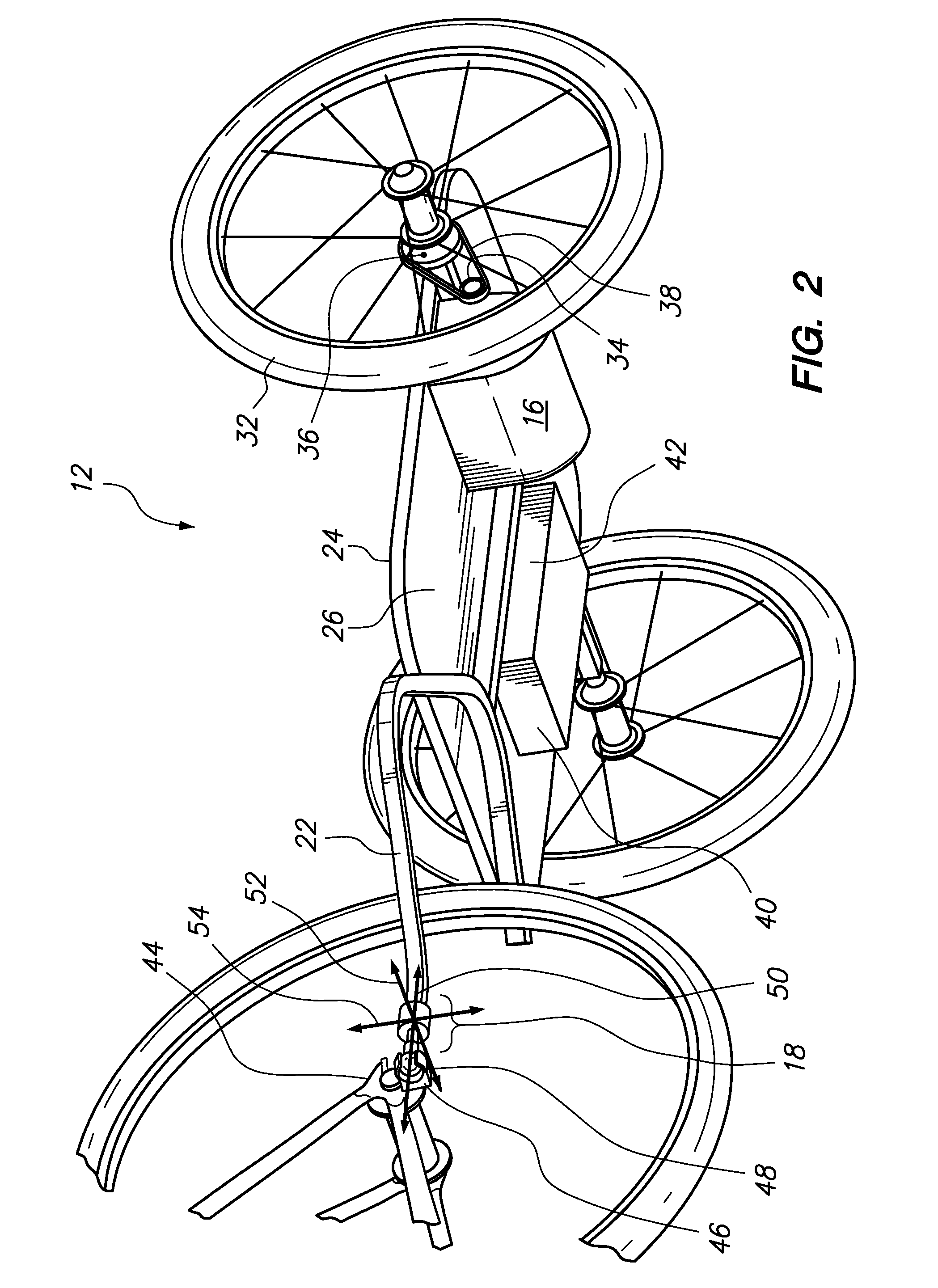

Motor Powered Bicycle Trailer with Integral Hitch Force Metering

A self-propelled trailer may be attached to a bicycle. The speed of the trailer is adjusted based on a signal from a force gauge which indicates whether the bicycle is pulling the trailer or the trailer is pushing the bicycle. In the former situation, the force gauge indicates a tensile load, and in the latter situation, the force gauge indicates a compressive load. Based on the feedback from the force gauge, the speed of the motor attached to the self-propelled trailer is adjusted so that the trailer and bicycle are moving at the same speed or the bicycle is pulling the trailer.

Owner:FELT RACING

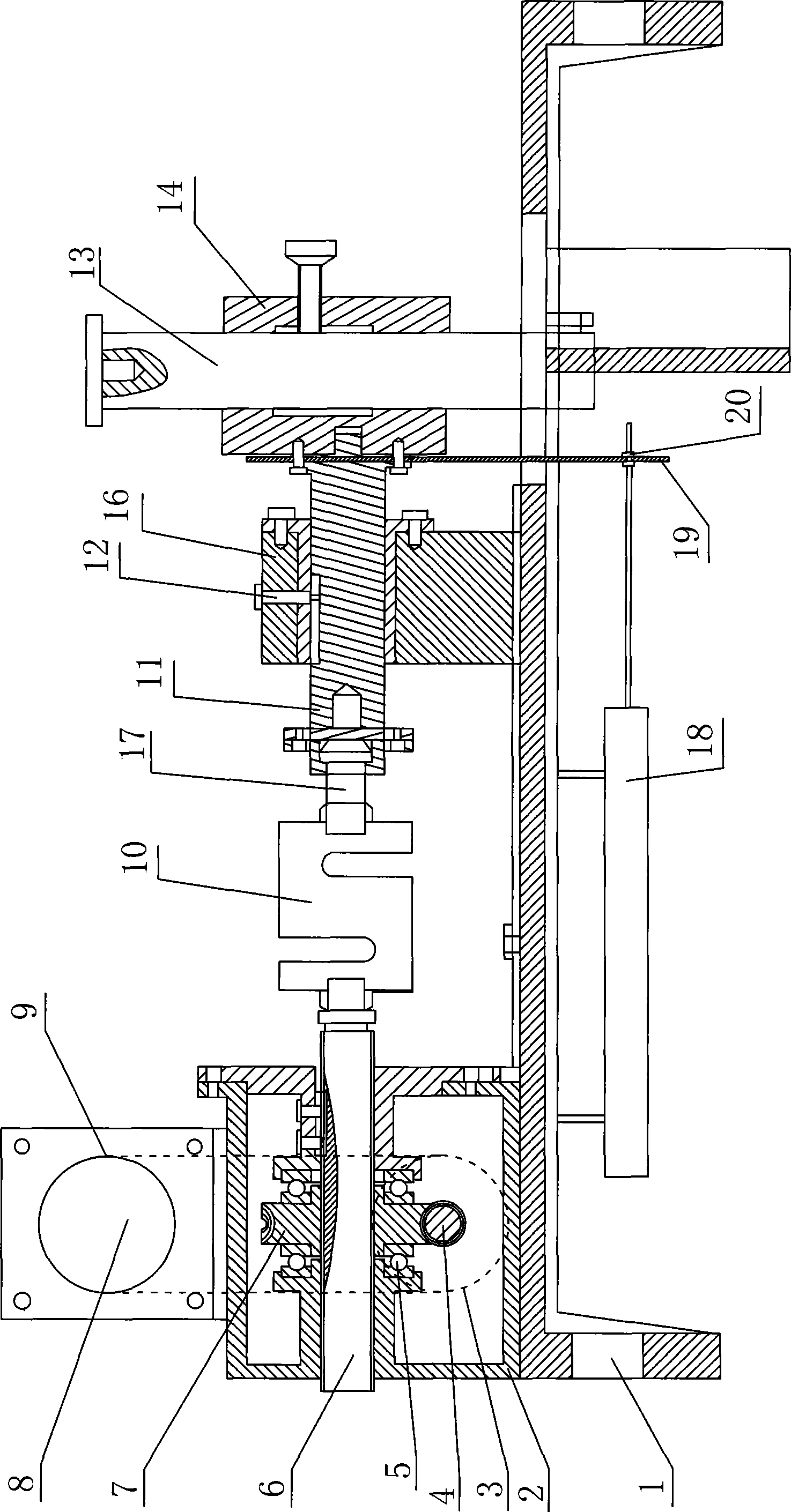

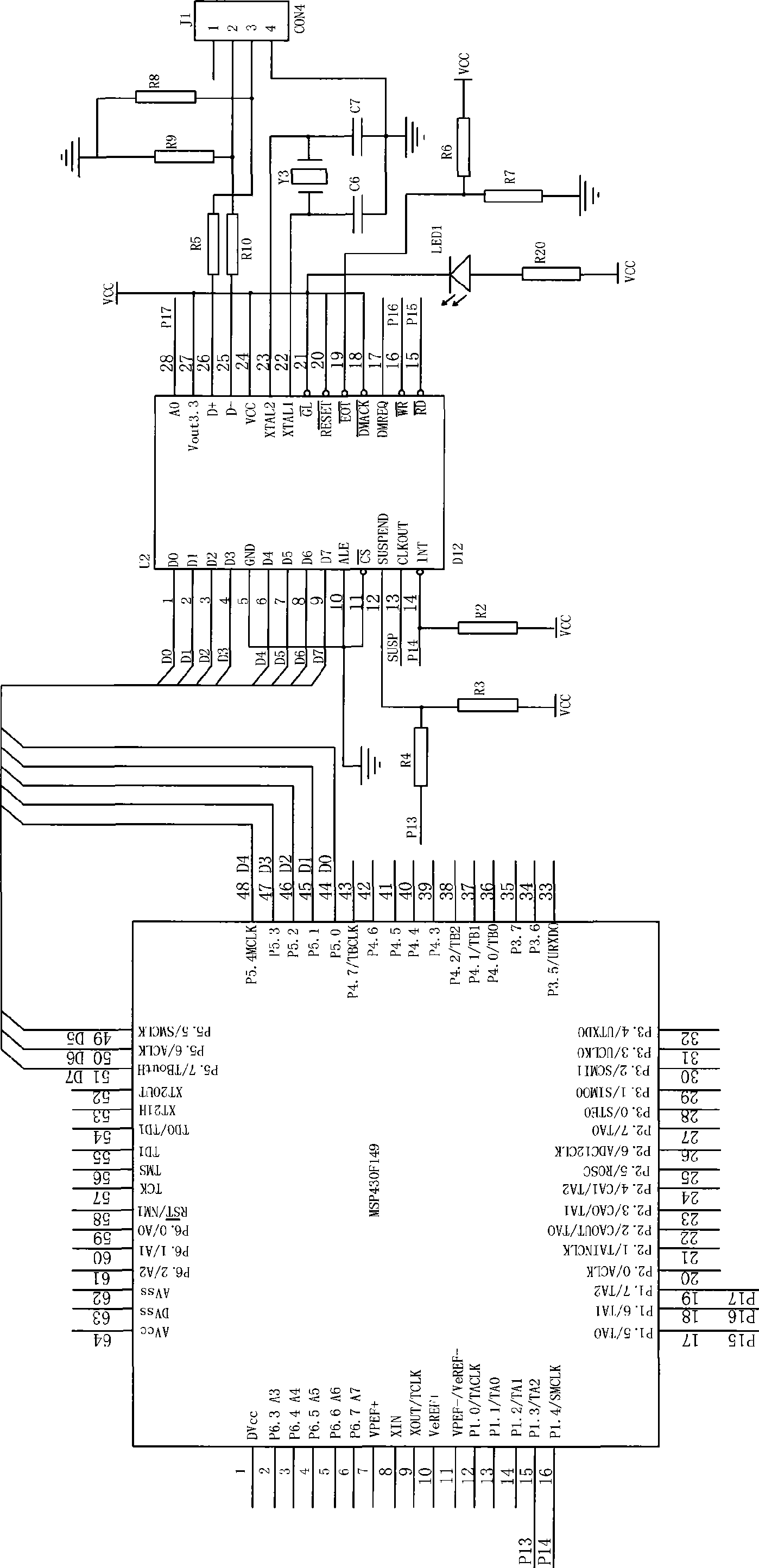

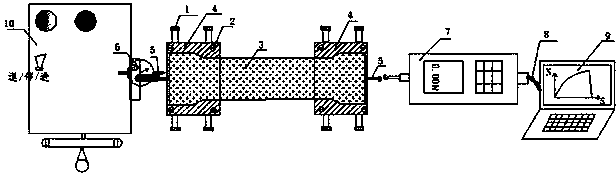

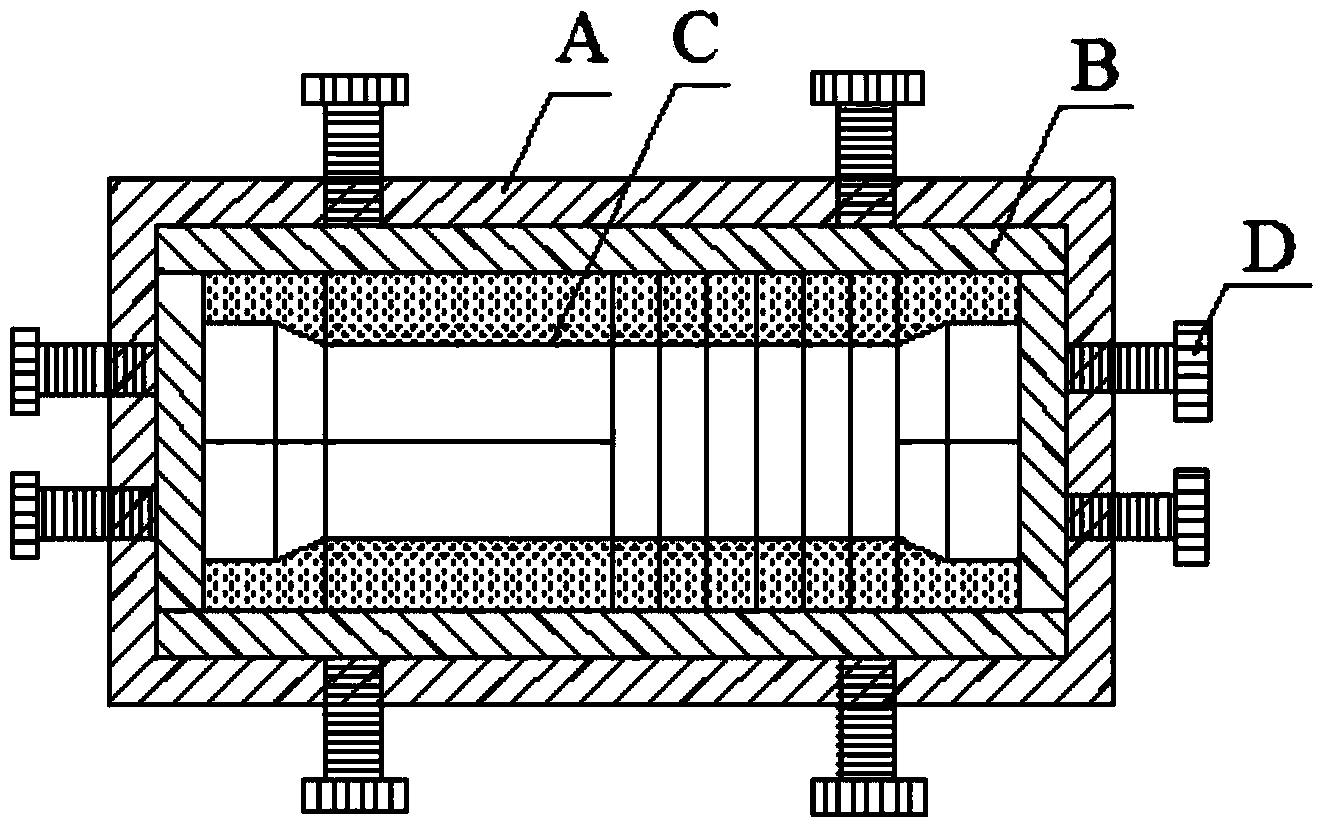

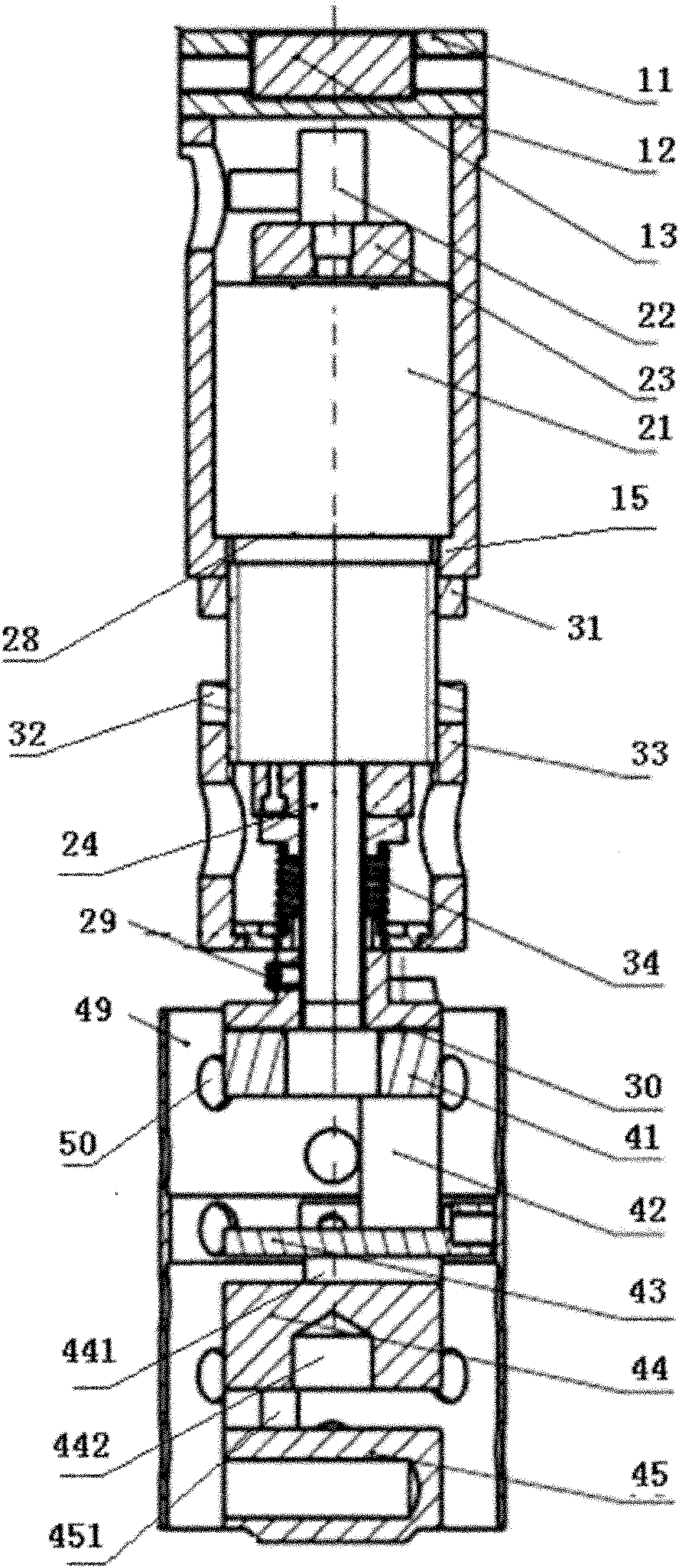

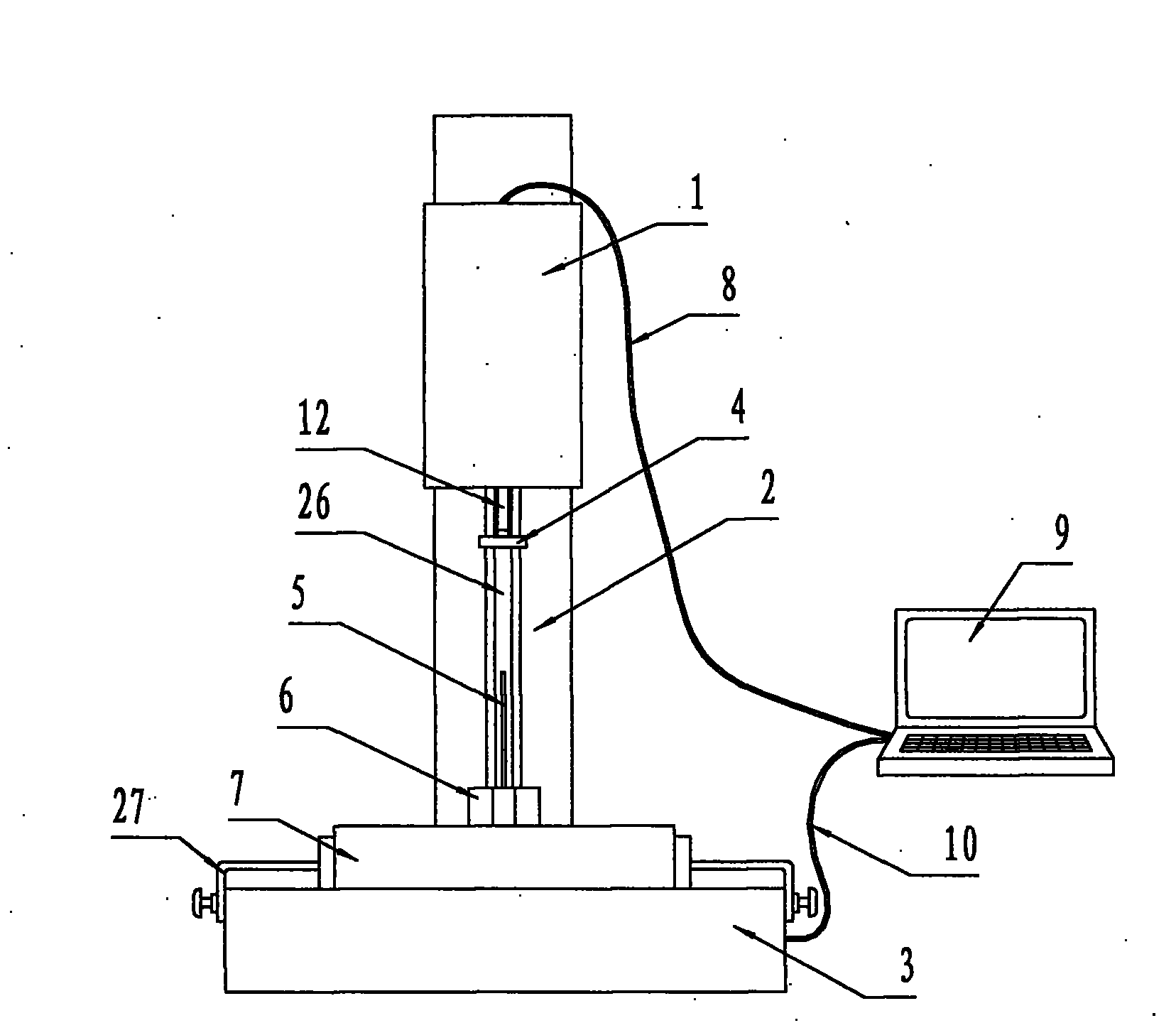

Interlayer shear strength detecting instrument for asphalt pavement

InactiveCN101464239ASimple structureAchieving Horizontal ShearingMaterial strength using steady shearing forcesMaterial testing goodsMicrocontrollerData acquisition

The invention discloses an instrument for detecting the shearing strength of the interlayer of an asphalt pavement. The instrument comprises a base, a driving motor, a pushing piece which ensures that the driving motor drives a shearing piece to shear a sample through a transmission piece, and a force gauge for real-time detection of shearing force; the transmission piece is mounted on the base; a data acquisition and control system which analyzes and processes signal detected by the force gauge and accordingly controls the driving motor according to the processing results, and a host computer connected with the data acquisition and control system are further included; the driving motor is a stepping motor; and the data acquisition and control system adopts an MSP430 singlechip, and is engaged in two way communication with the host computer through a USB interface. The invention has the advantages of reasonable mechanical structure, small size, light weight, high degree of automation and convenient use and operation, and can effectively monitor and control the shearing piece to be tested in a real-time manner and greatly improve the measuring accuracy.

Owner:CHANGAN UNIV

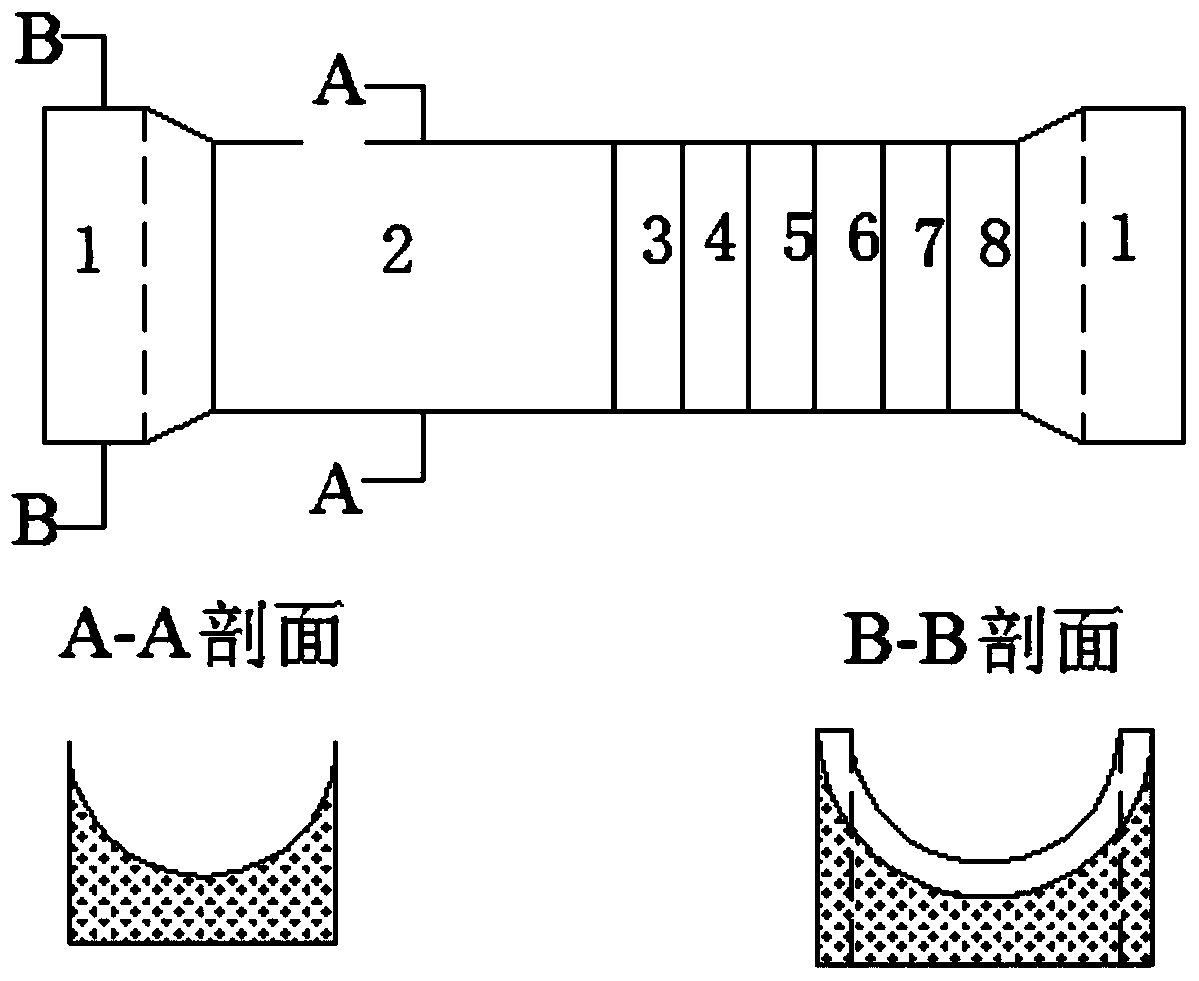

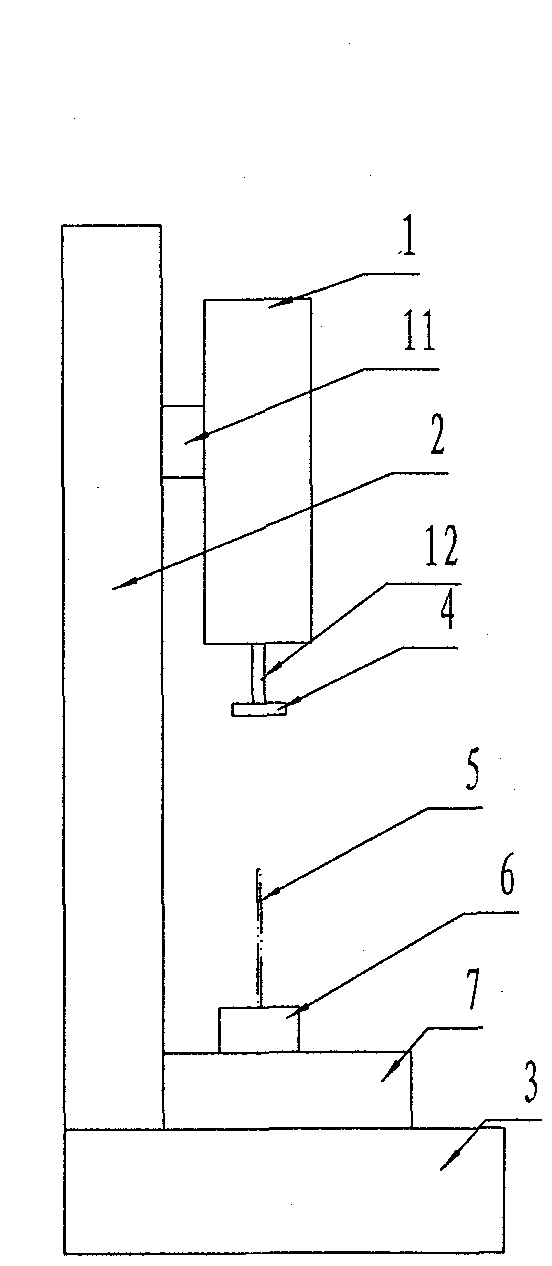

Test method for determining uniaxial tensile strength of soil mass

InactiveCN103674723AAvoid weak pointsEasy to operatePreparing sample for investigationMaterial strength using tensile/compressive forcesStress concentrationPull force

The present invention discloses a test method for determining uniaxial tensile strength of soil mass. According to the method, test equipment comprising a sample preparation system, a tension system and a data acquisition system is adopted, wherein the sample preparation system comprises a fixation base, a pressing plate, a sample forming device and a fixation screw, the tension system comprises a three-speed electric scissors instrument and a sample clamper, and the data acquisition system comprises a digital display push-pull force gauge, a dial indicator and a computer. According to the method, the one-time static pressure molding technology is adopted to prepare the sample, such that the weak surface caused by layering compaction sample preparation can be avoided; the sample presents the dumbbell shape, and both ends are adopted as the fixation end, such that the operation is simple, and the connection is firm; the fixation end of the sample and the middle part of the sample are connected through the transition section, such that the influence of stress concentration due to sudden diameter change on the test is avoided; and the digital display push-pull force gauge is connected with the computer, such that the pull force can be real-timely recorded, and the maximum pull force value during sample breaking can be accurately recorded.

Owner:NORTHWEST A & F UNIV

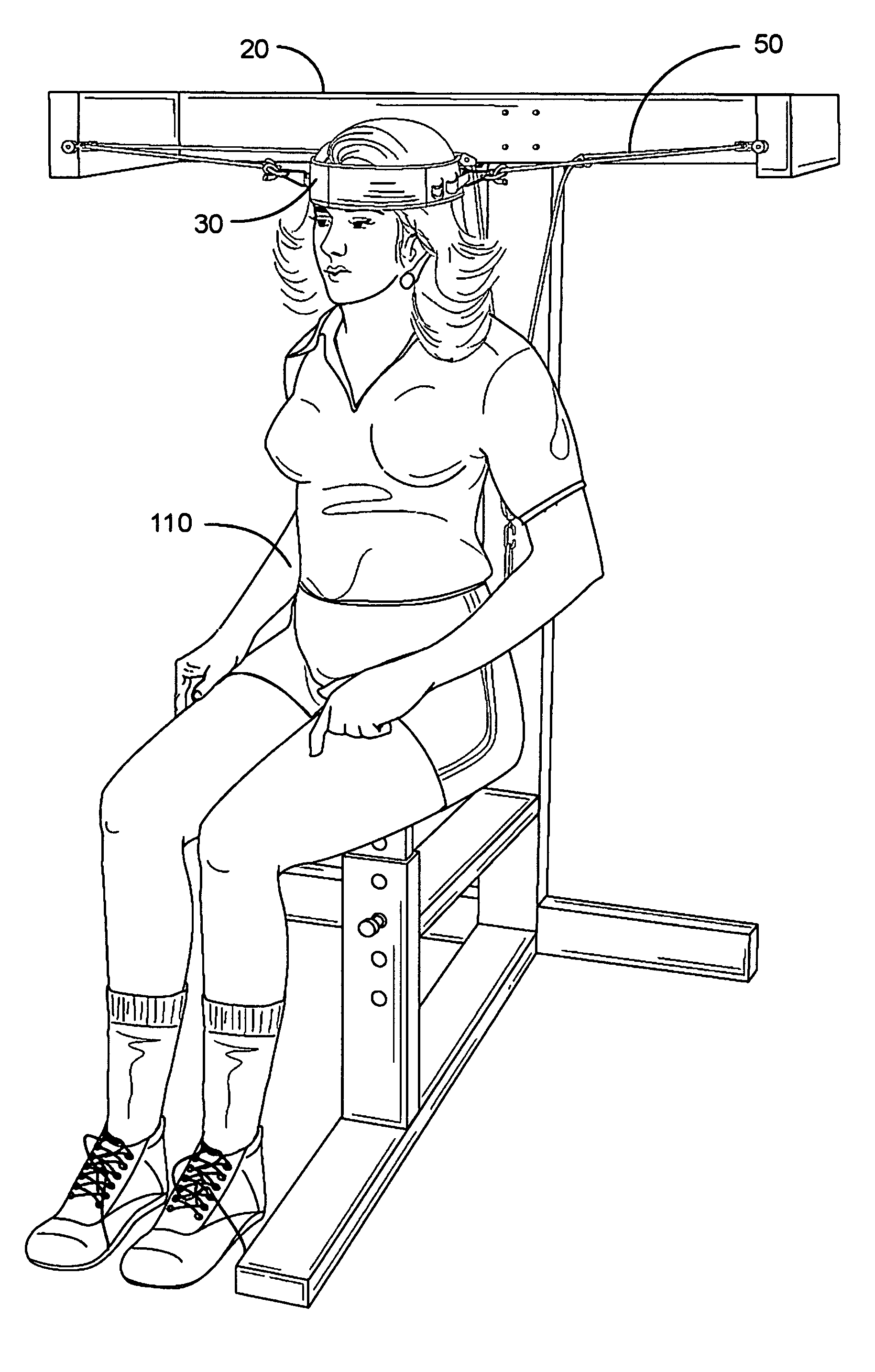

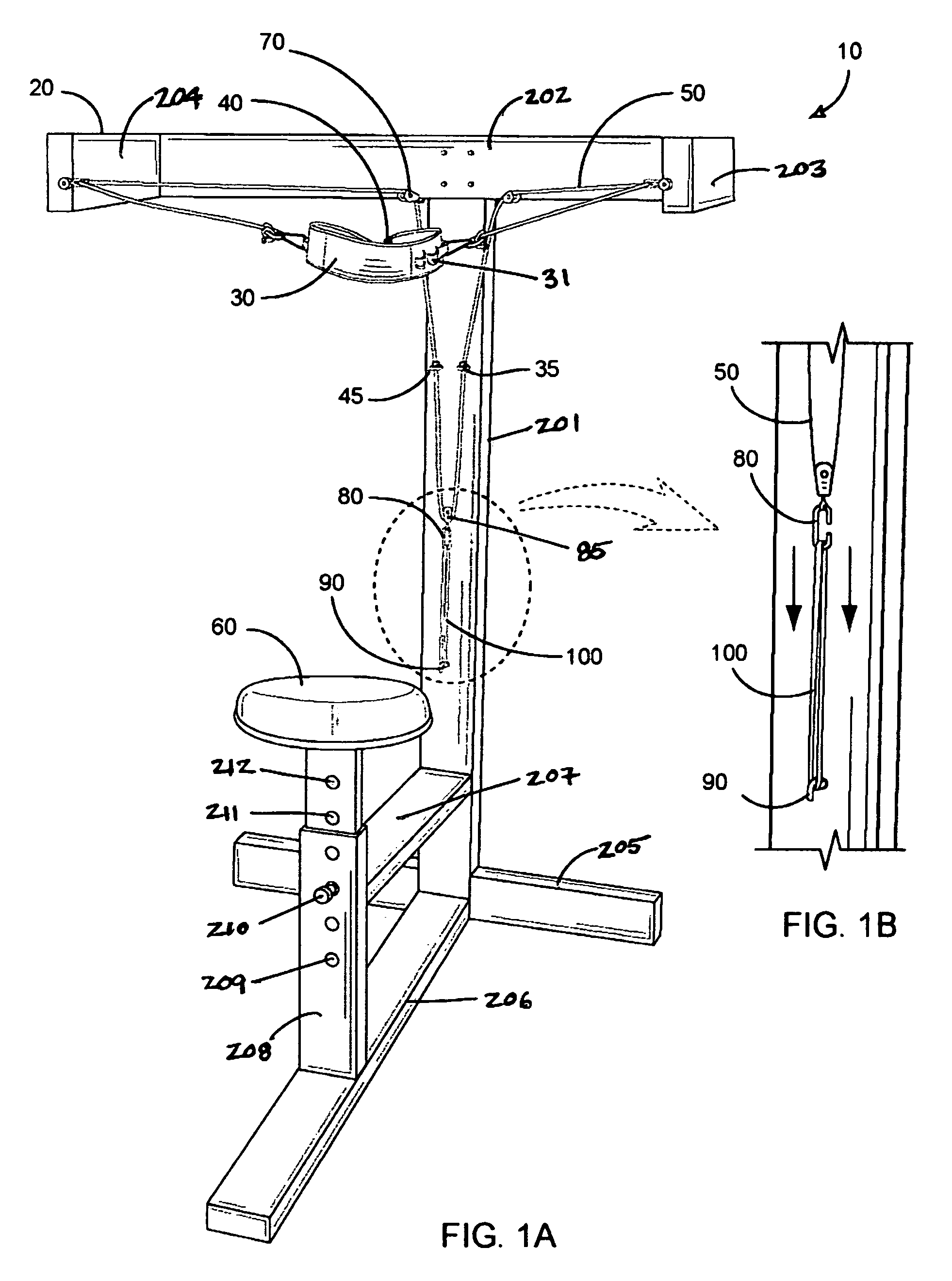

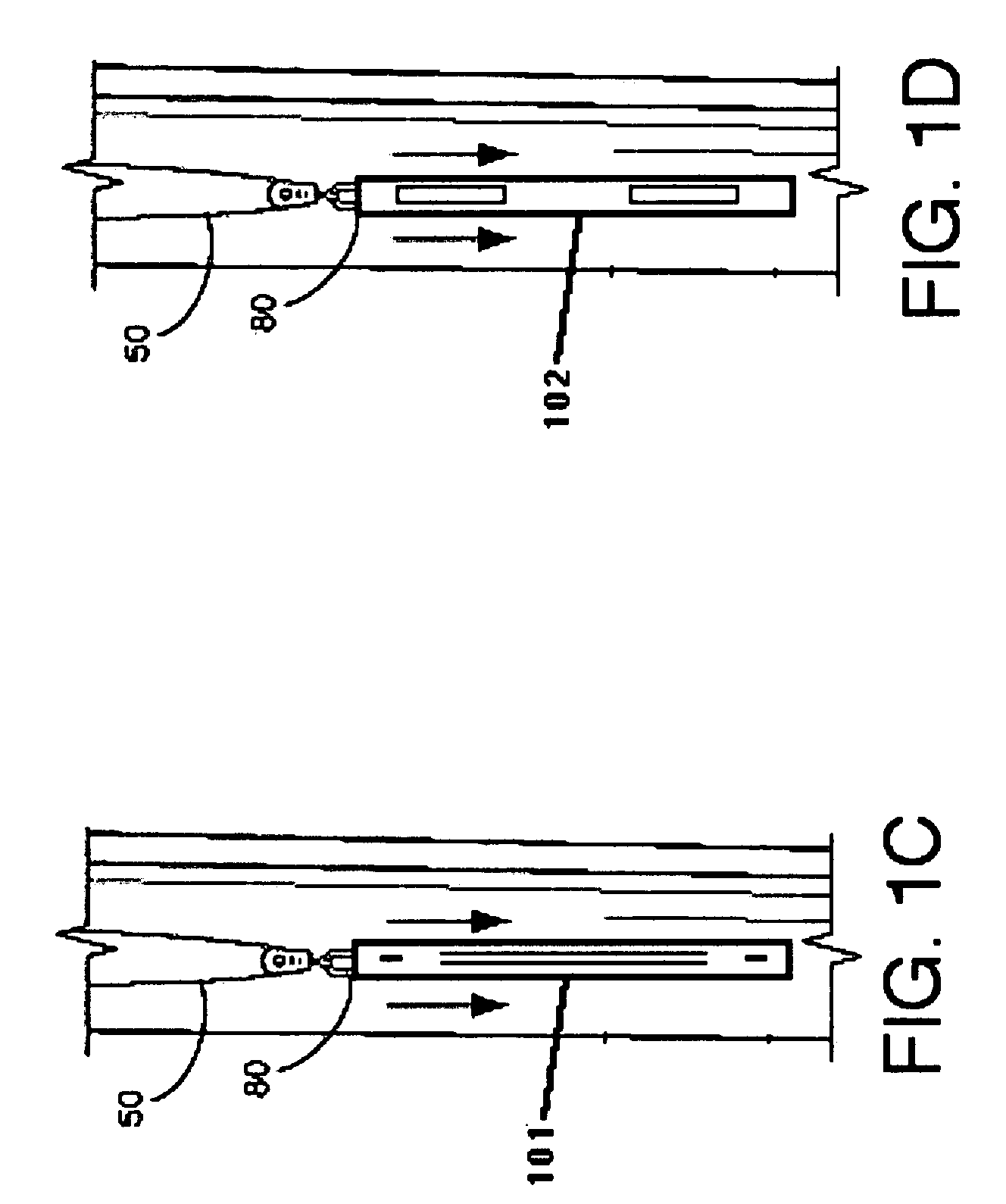

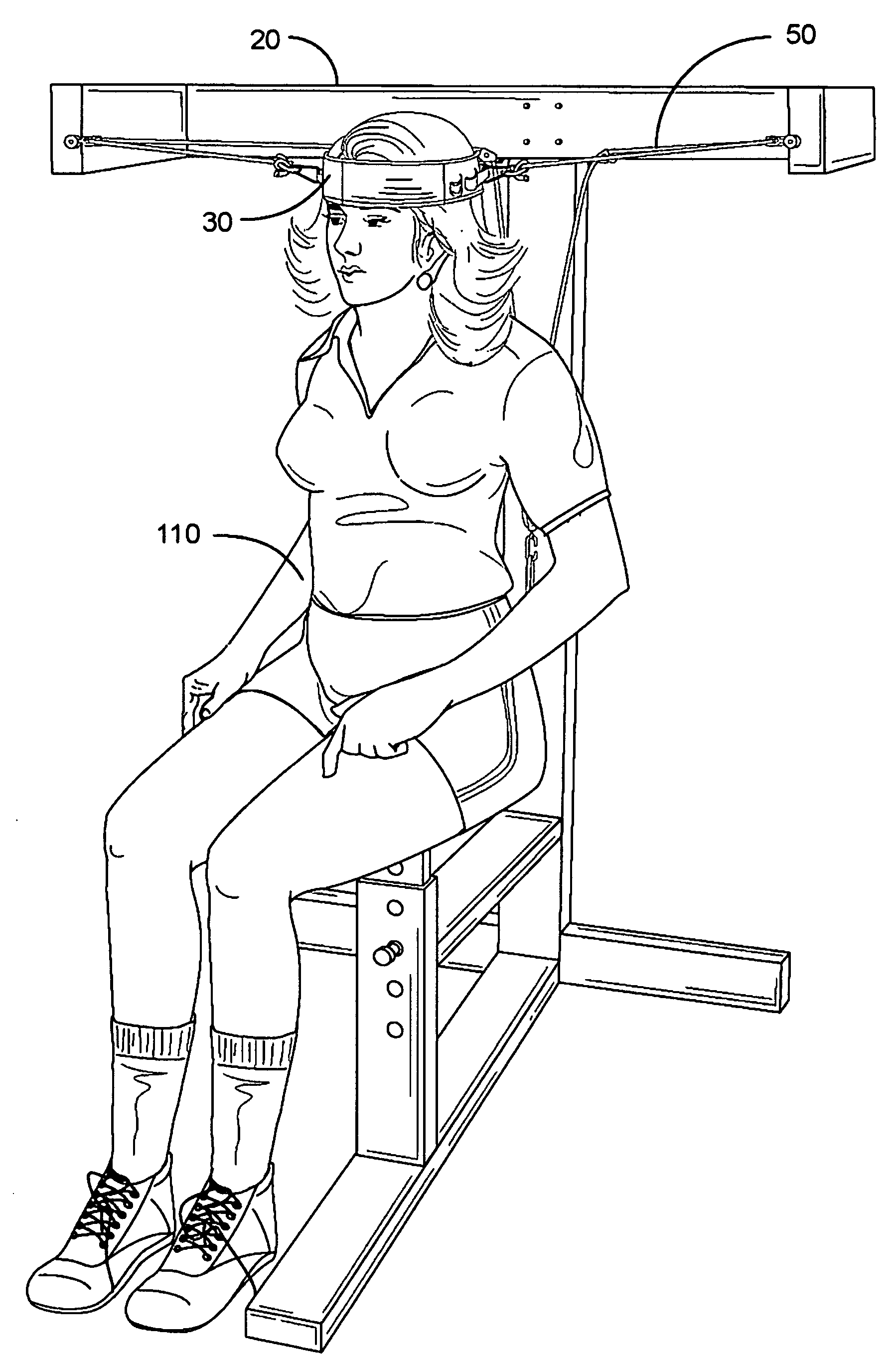

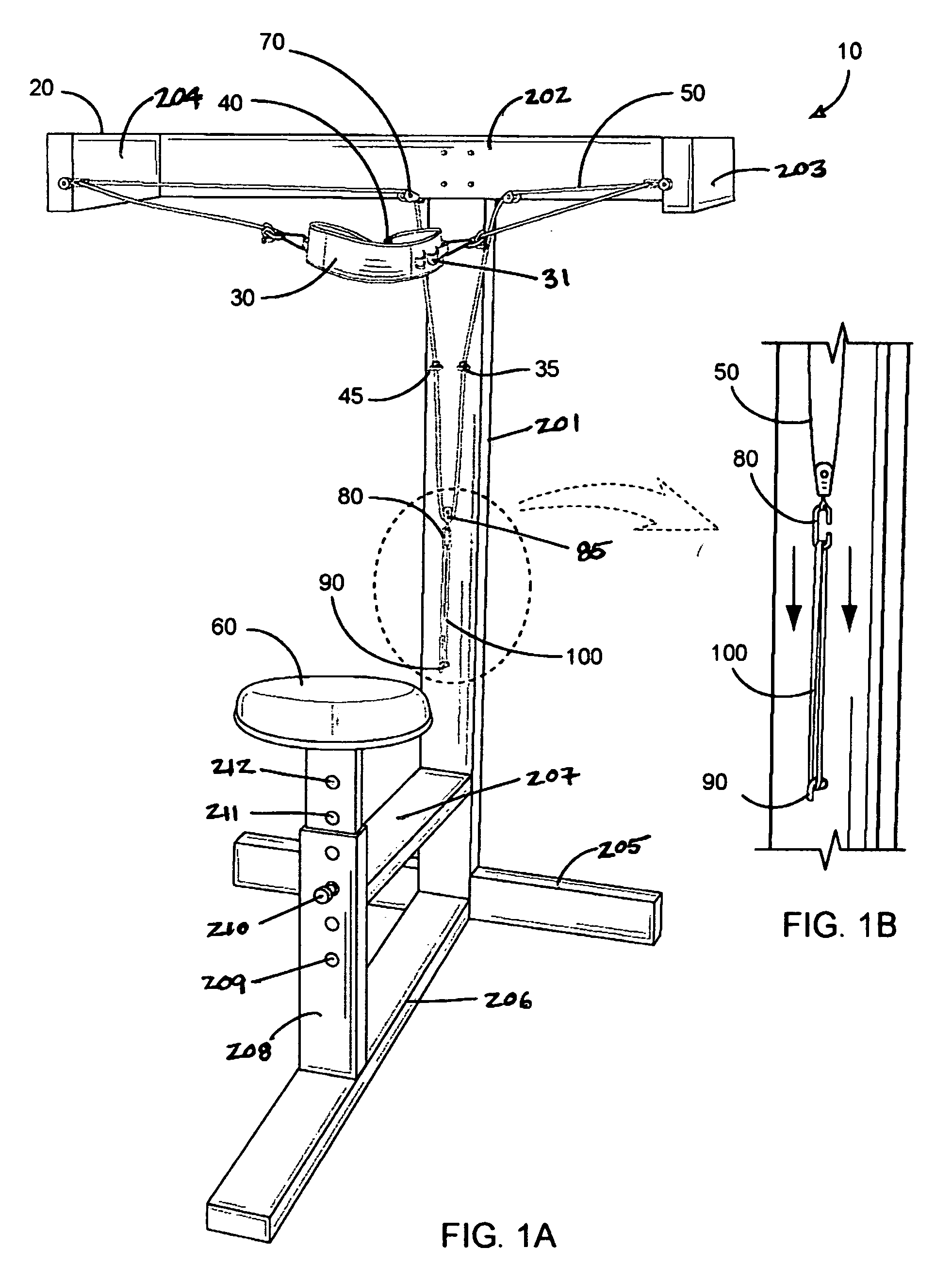

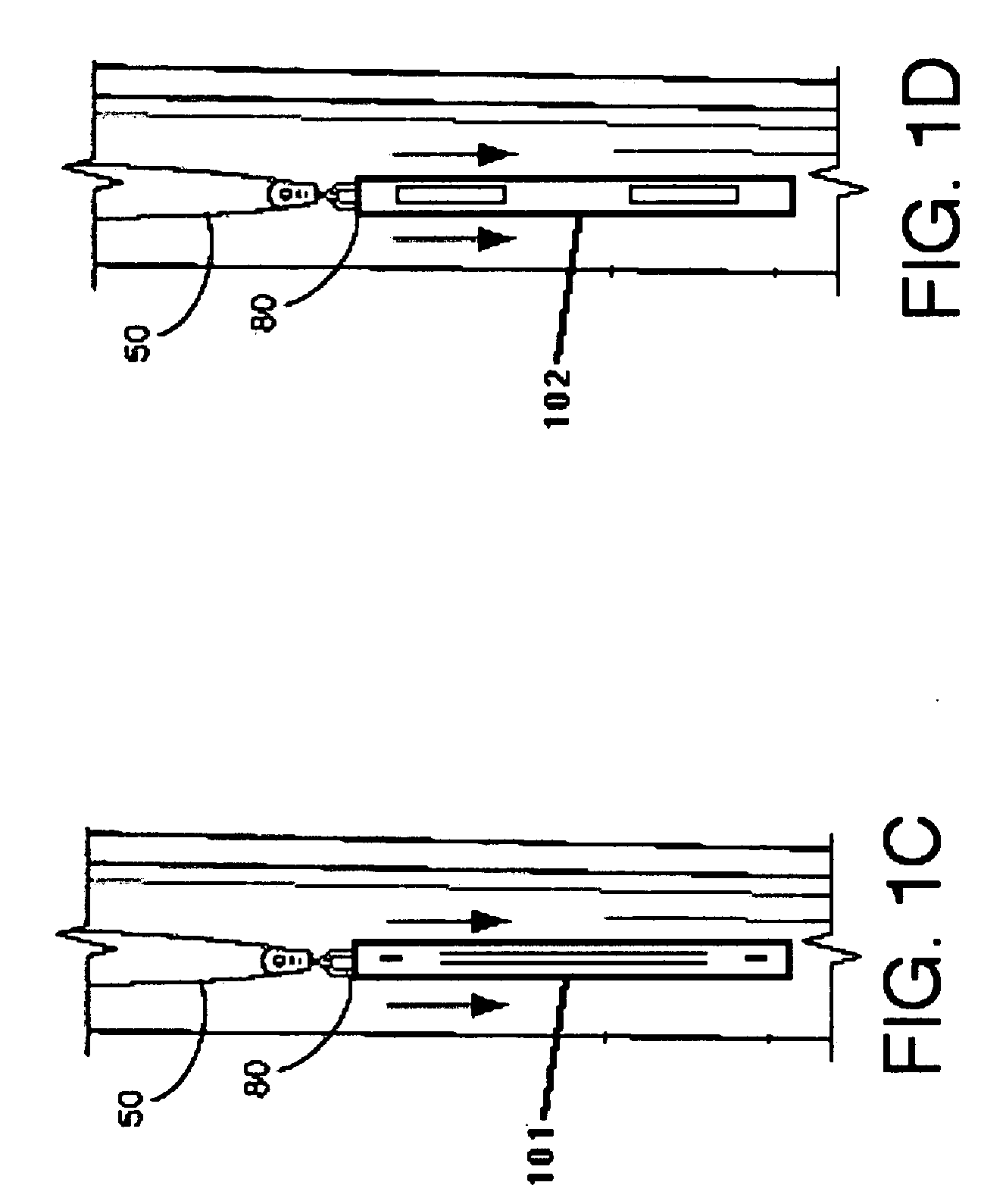

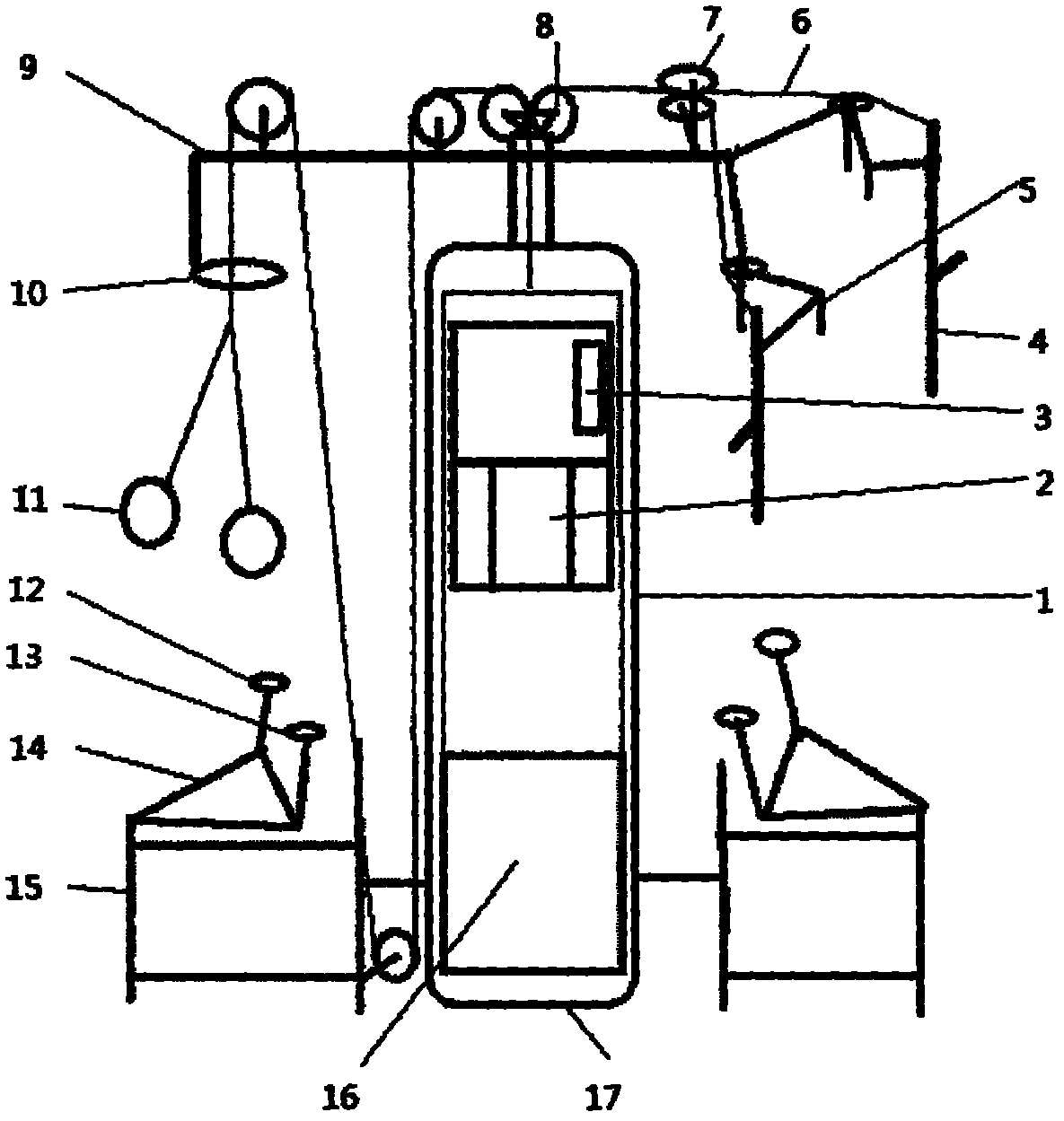

Neck exercise machine

InactiveUS7468019B2Easily disassembled and transported and reassembledResilient force resistorsSpace saving gamesHydraulic cylinderNeck muscle

Owner:ZYLSTRA DIRK

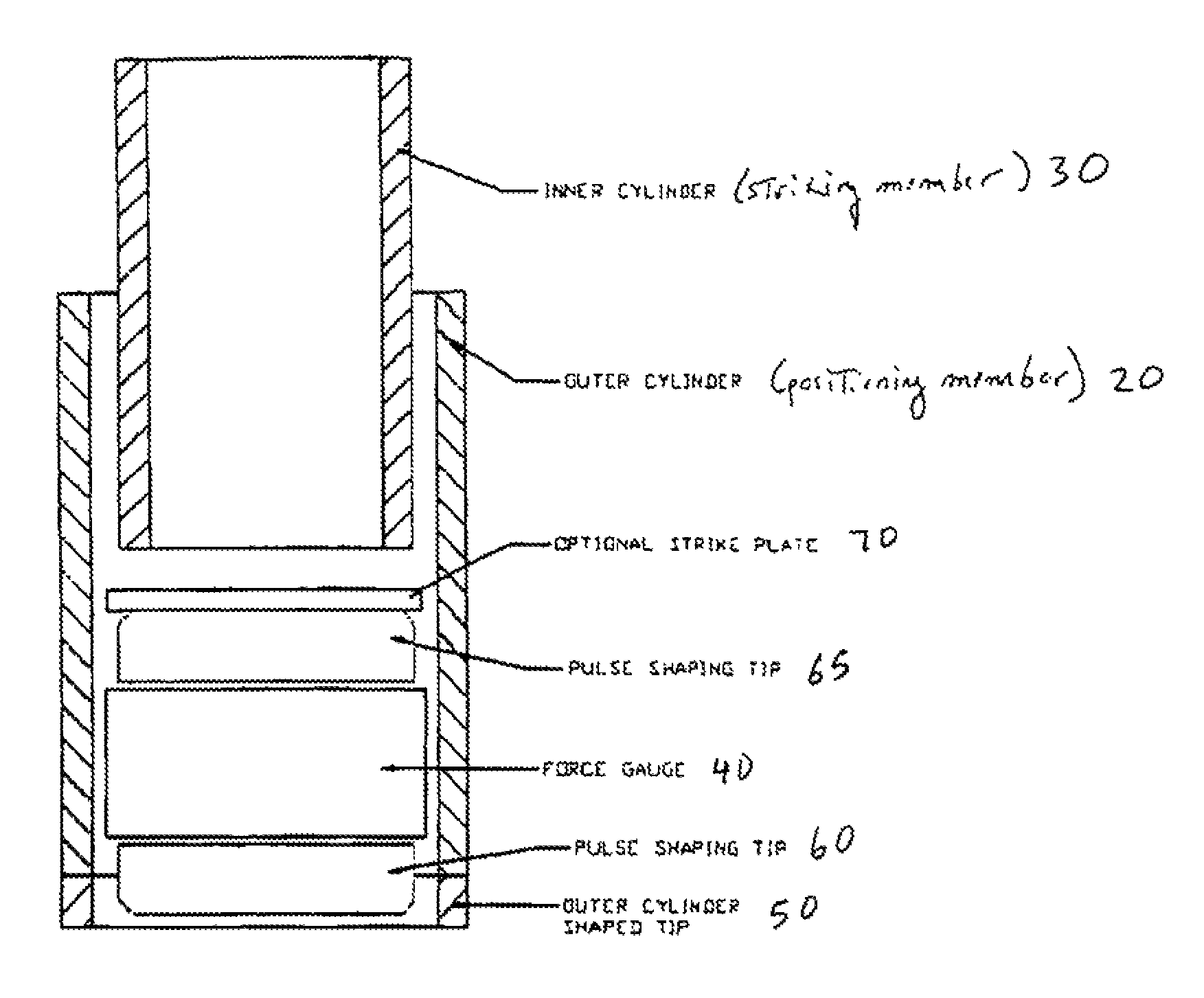

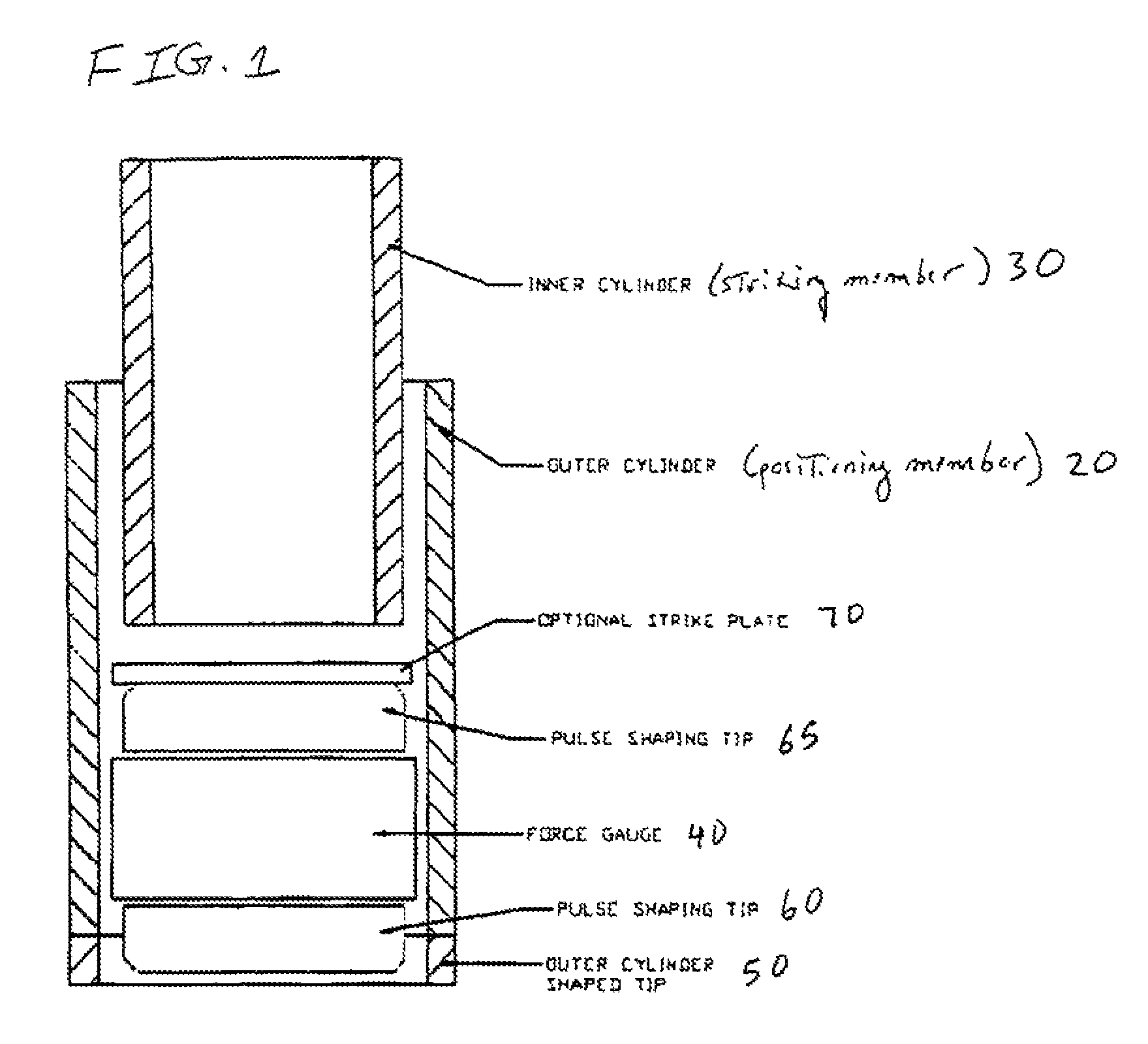

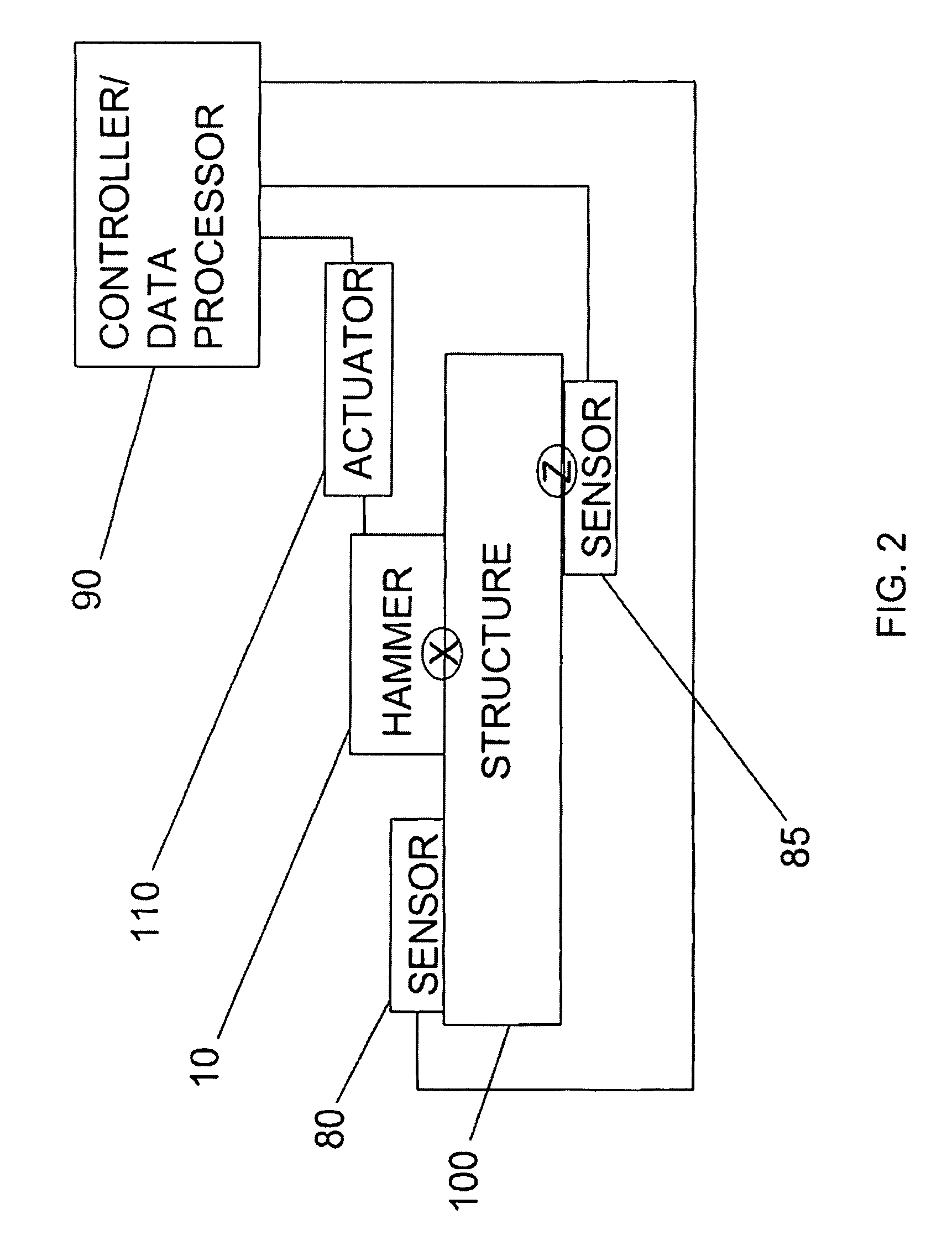

Calibrated impact hammer

InactiveUS7900498B1Easy to useMinimal effortAcceleration measurement using interia forcesAnalysing solids using sonic/ultrasonic/infrasonic wavesDetentEngineering

An apparatus includes a positioner. The apparatus includes a striker axially movable in the positioner. The striker includes a striker inner end. The apparatus includes a force gauge axially movable in the positioner. The force gauge includes a force gauge inner end. The force gauge inner end is in communication with the striker inner end. Optionally, the striker defines at least one fluid passage axially therethrough.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

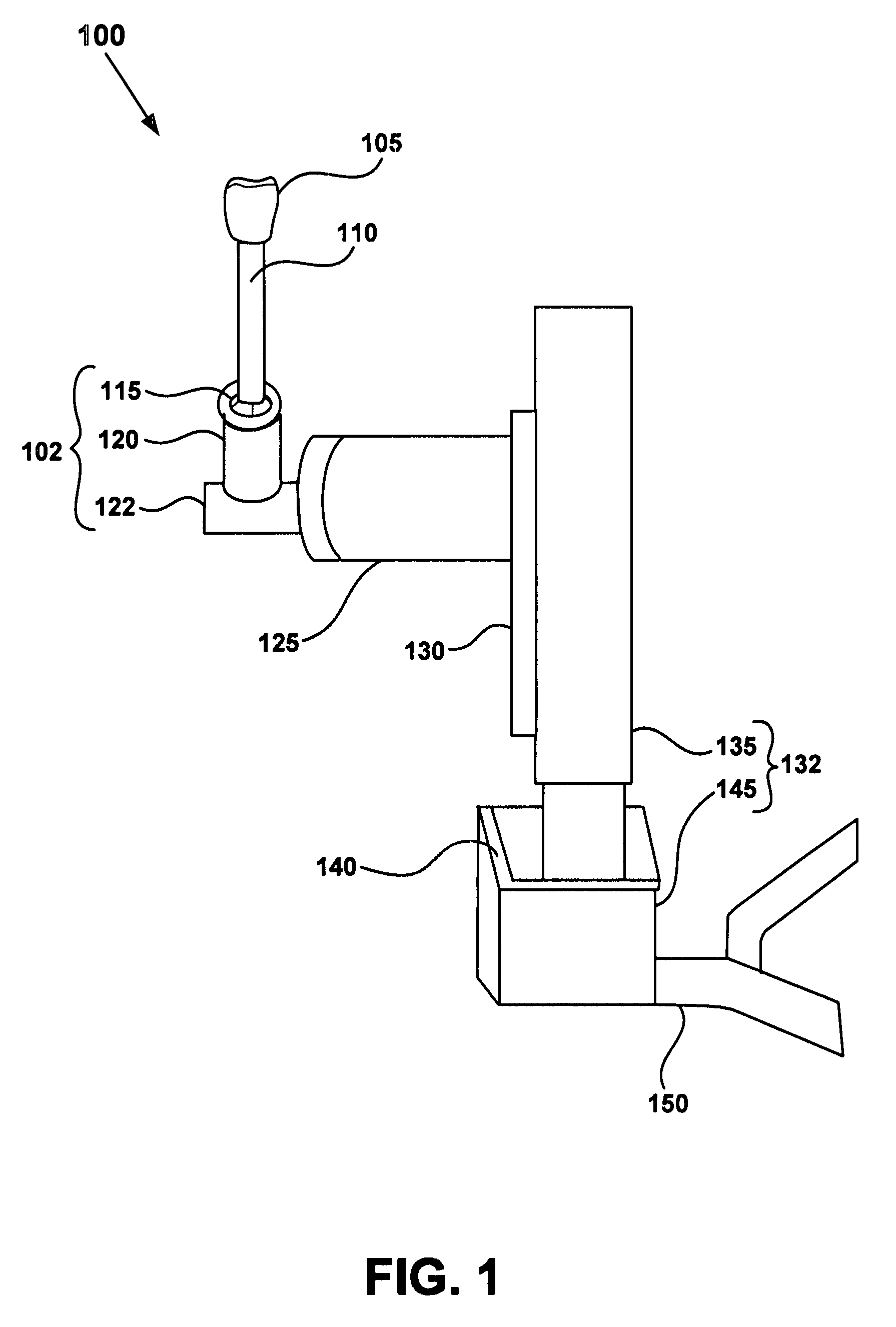

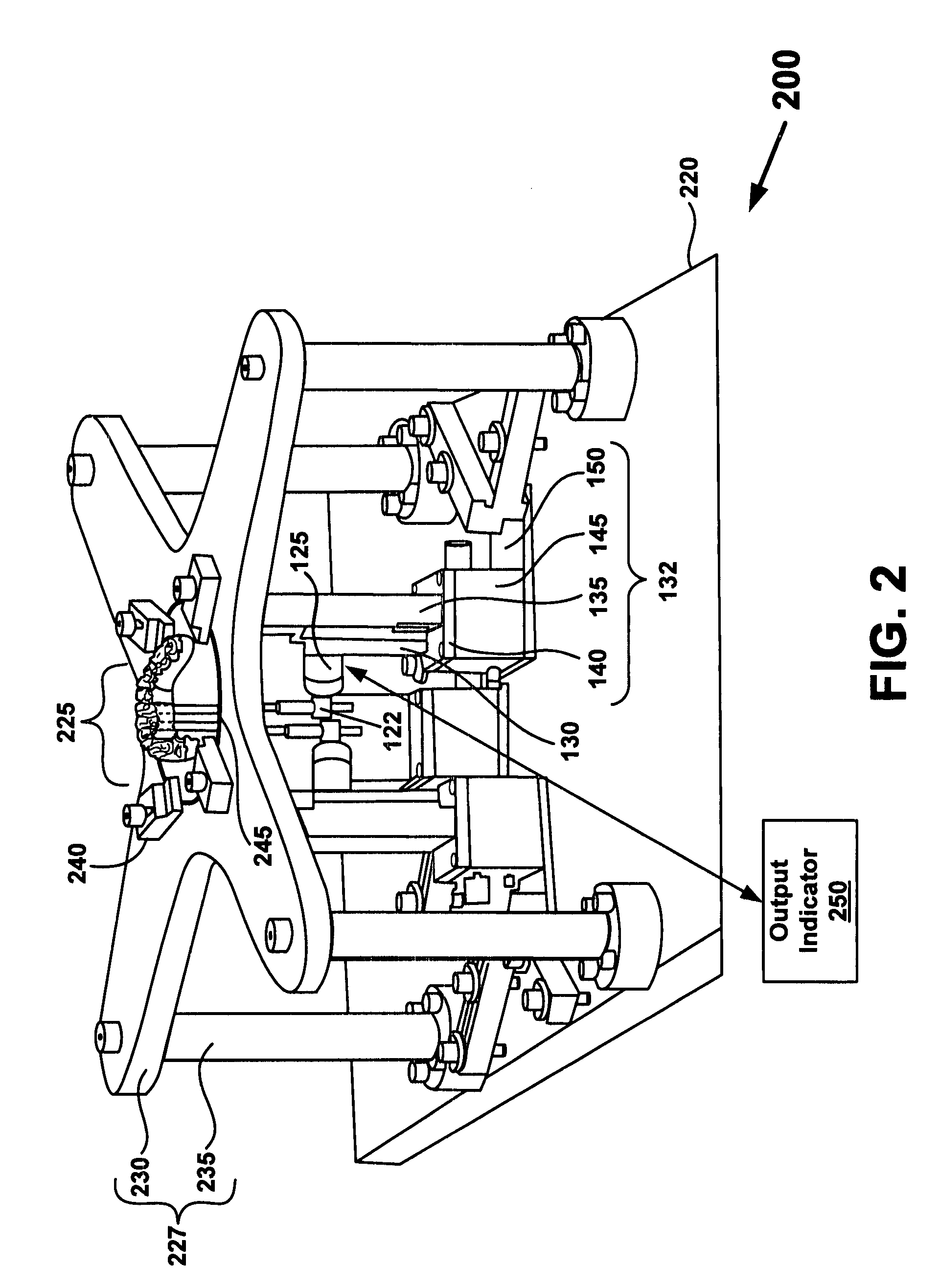

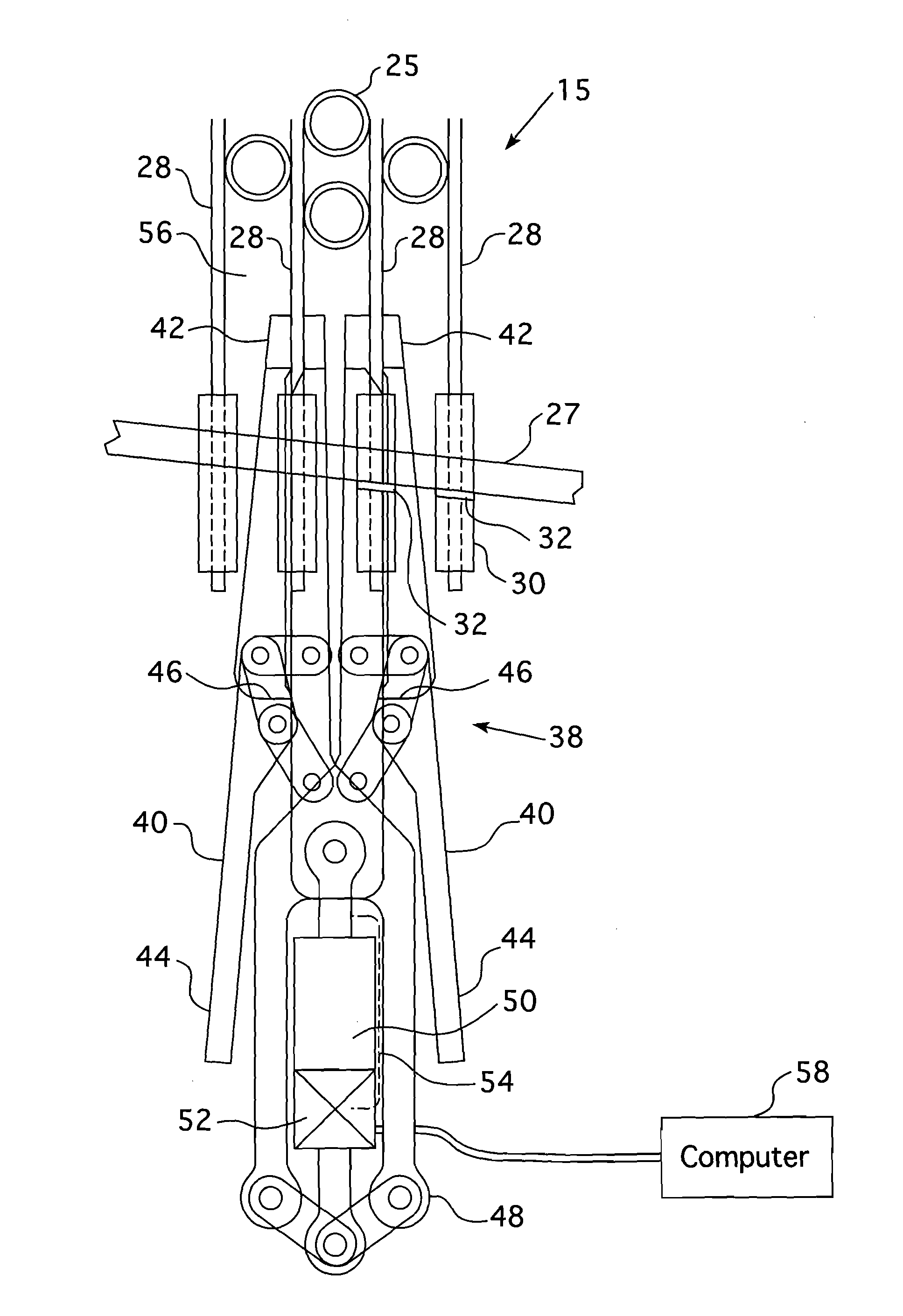

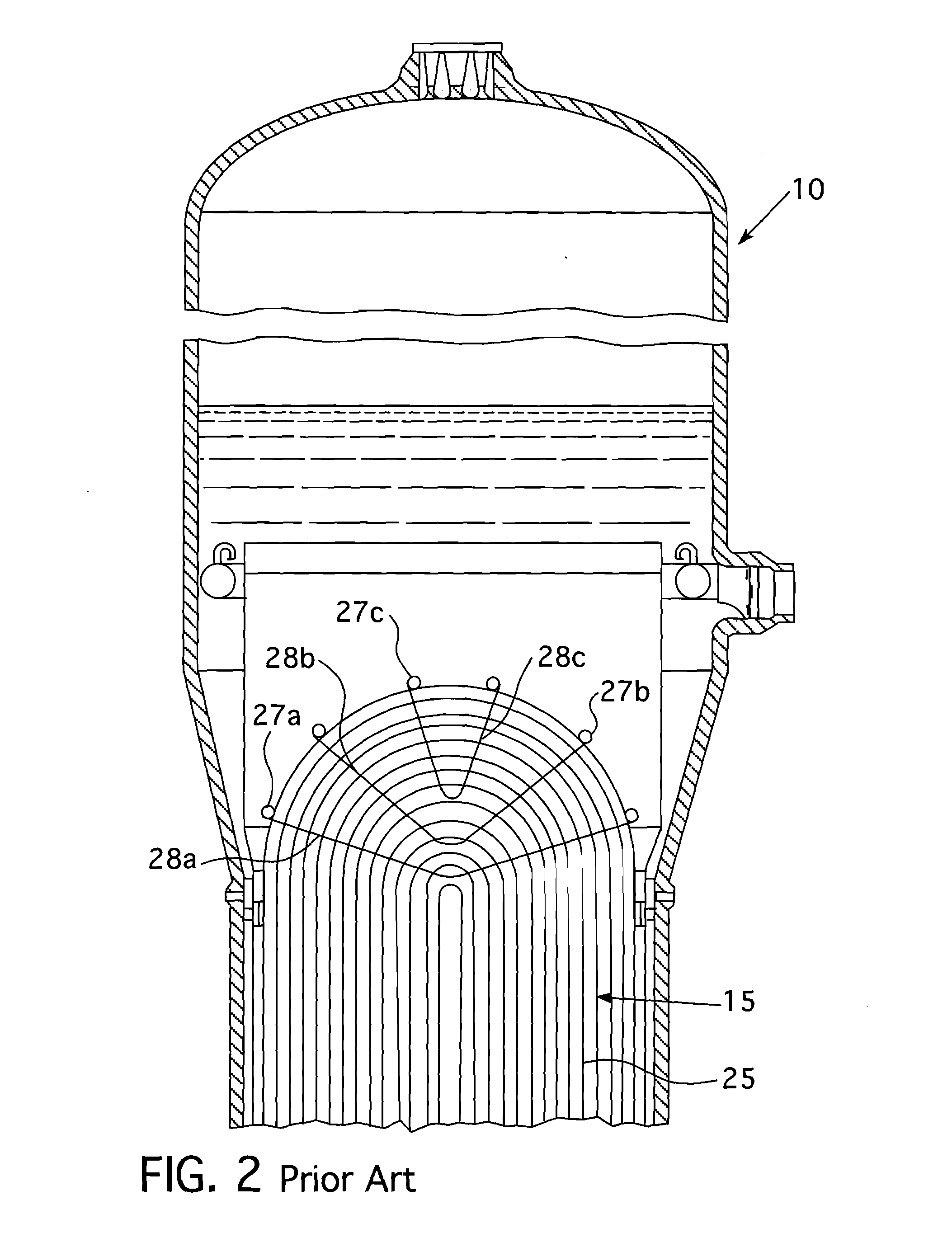

Anti-vibration bar clamping tool

An automated tool and method for spacing a gap between the anti-vibration bars and the flow tubing in the bend region of a tube bundle of a U-tube steam generator, prior to welding, during manufacture. The tool comprises two toggle clamp elements attached to a scissors assembly, which are actuated by a linear drive motor in line with a force gauge, and coupled to a distance measuring device. The tool is operated by first attaching the toggle clamps respectively to two adjacent anti-vibration bars. A linear drive motor on the tool is then cycled and readouts of force and distance are plotted on a curve to determine the point of contact between the anti-vibration bar and the tube. The computer then automatically cycles the drive motor to adjust the gap to a desired range of position coordinates adjacent the point at which the curve markedly changes slope.

Owner:WESTINGHOUSE ELECTRIC CORP

Neck exercise machine

InactiveUS20080119331A1Easy to disassembleEasy to transportResilient force resistorsSpace saving gamesHydraulic cylinderNeck muscle

A neck exercise machine including a frame, a seat, a set of pulleys, a head band, an adjustable tensioner, and a cable adjustably attached to the head band, threaded through the pulleys, and removably connected to the adjustable tensioner, such that when a user sits in the seat and attaches the head band, they can exercise their neck muscles in a variety of different angles, rotations, and tensions. Elastic bands, an analog / digital force gauge, or hydraulic cylinder may be used as the adjustable tensioner and incorporate processor, memory, and data output mechanisms for performance analyses. The machine can also be broken down into numerous parts for easy transport and reassembly.

Owner:ZYLSTRA DIRK

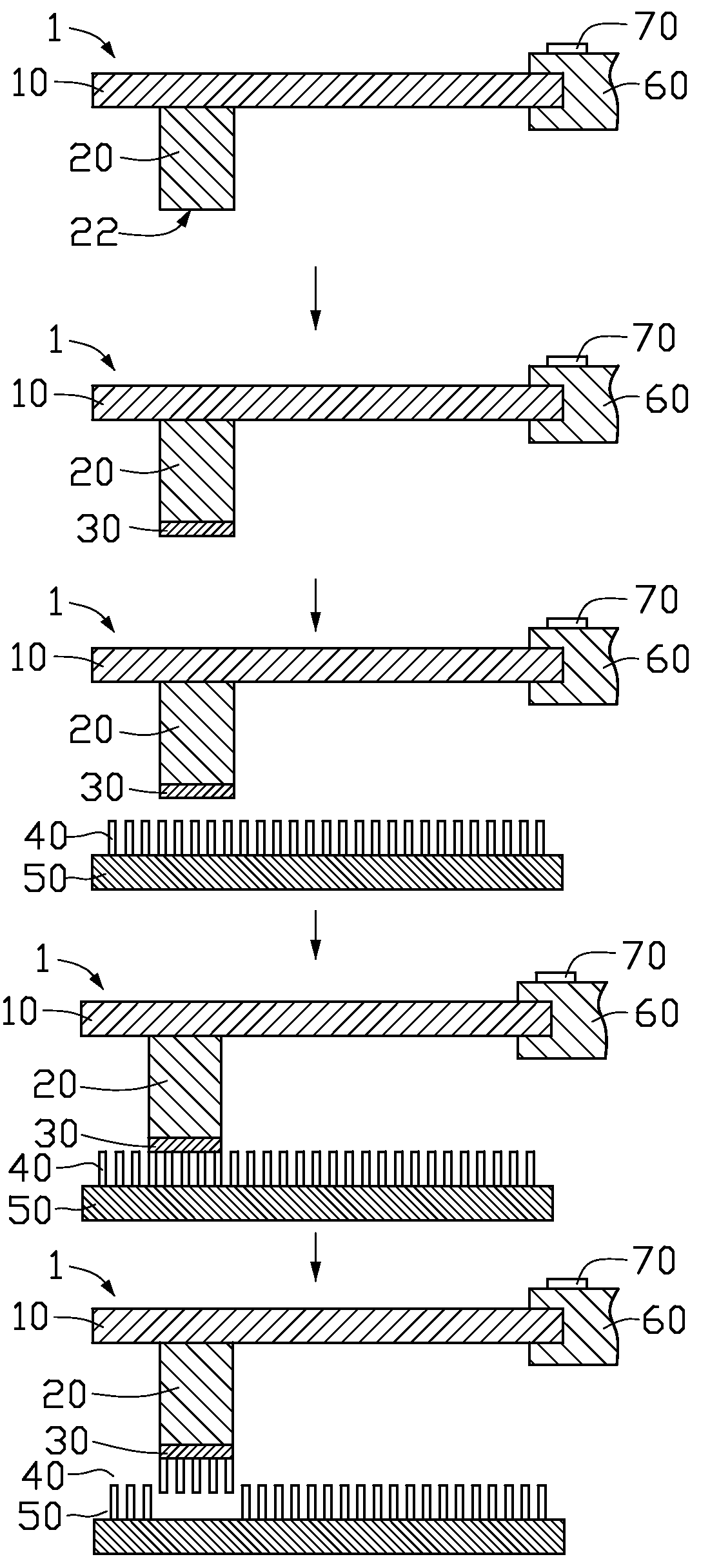

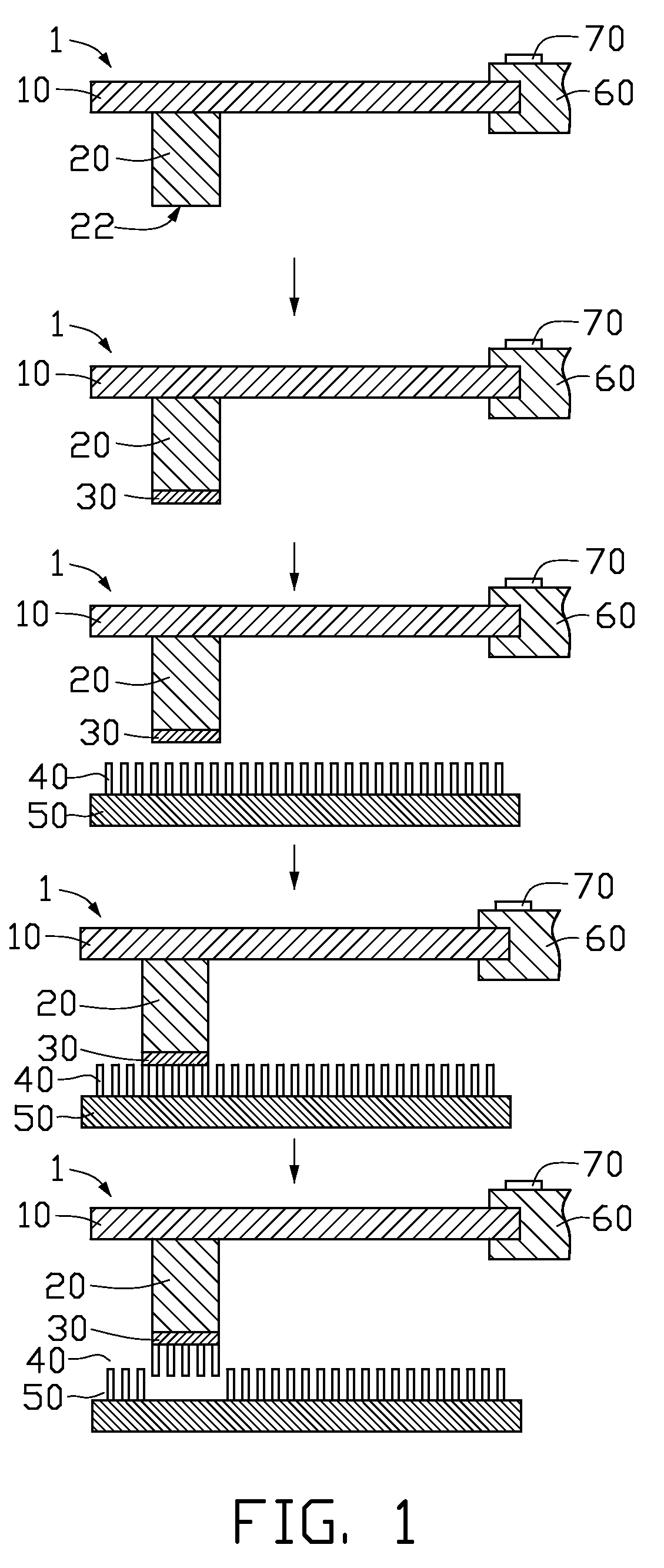

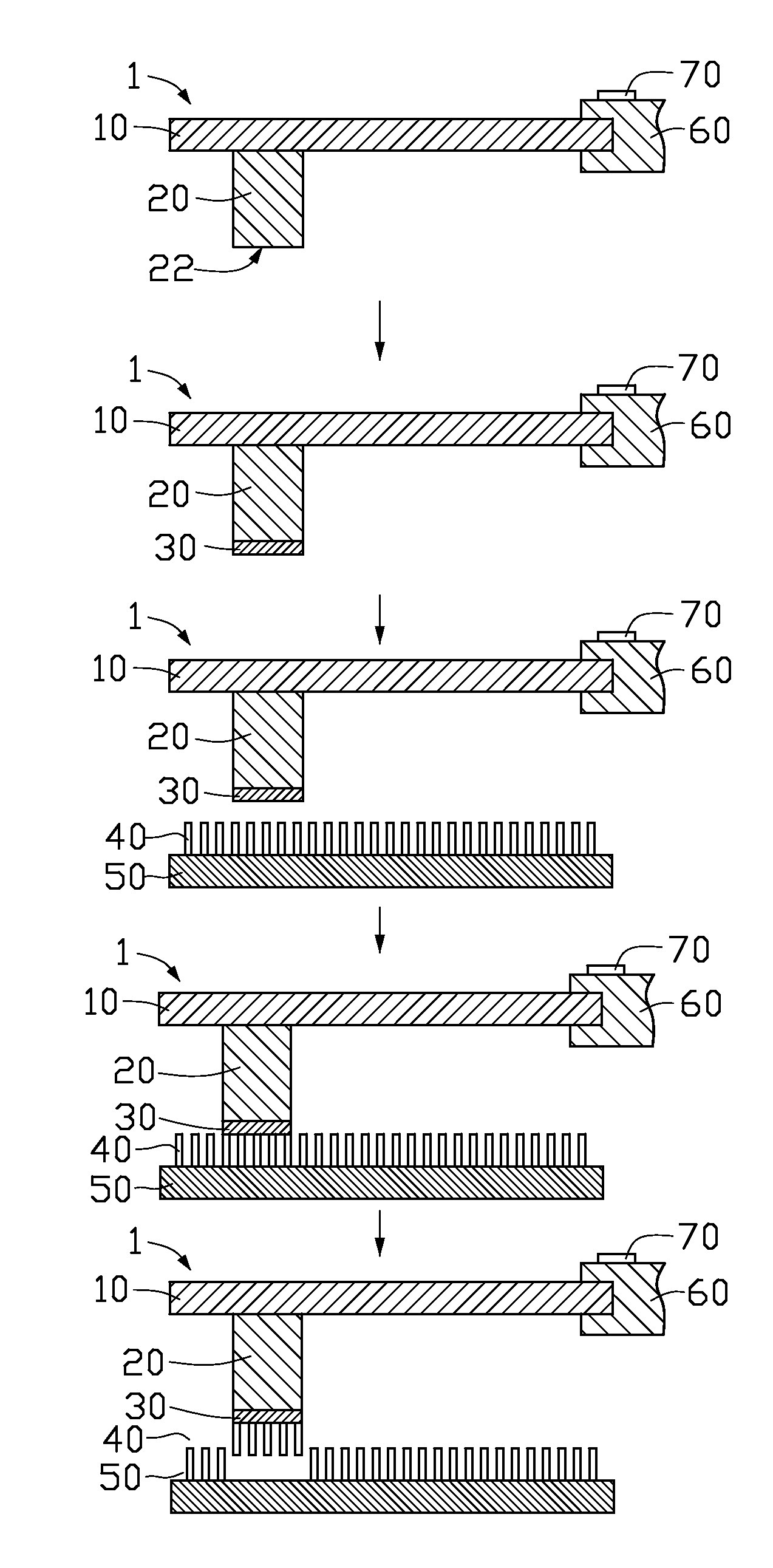

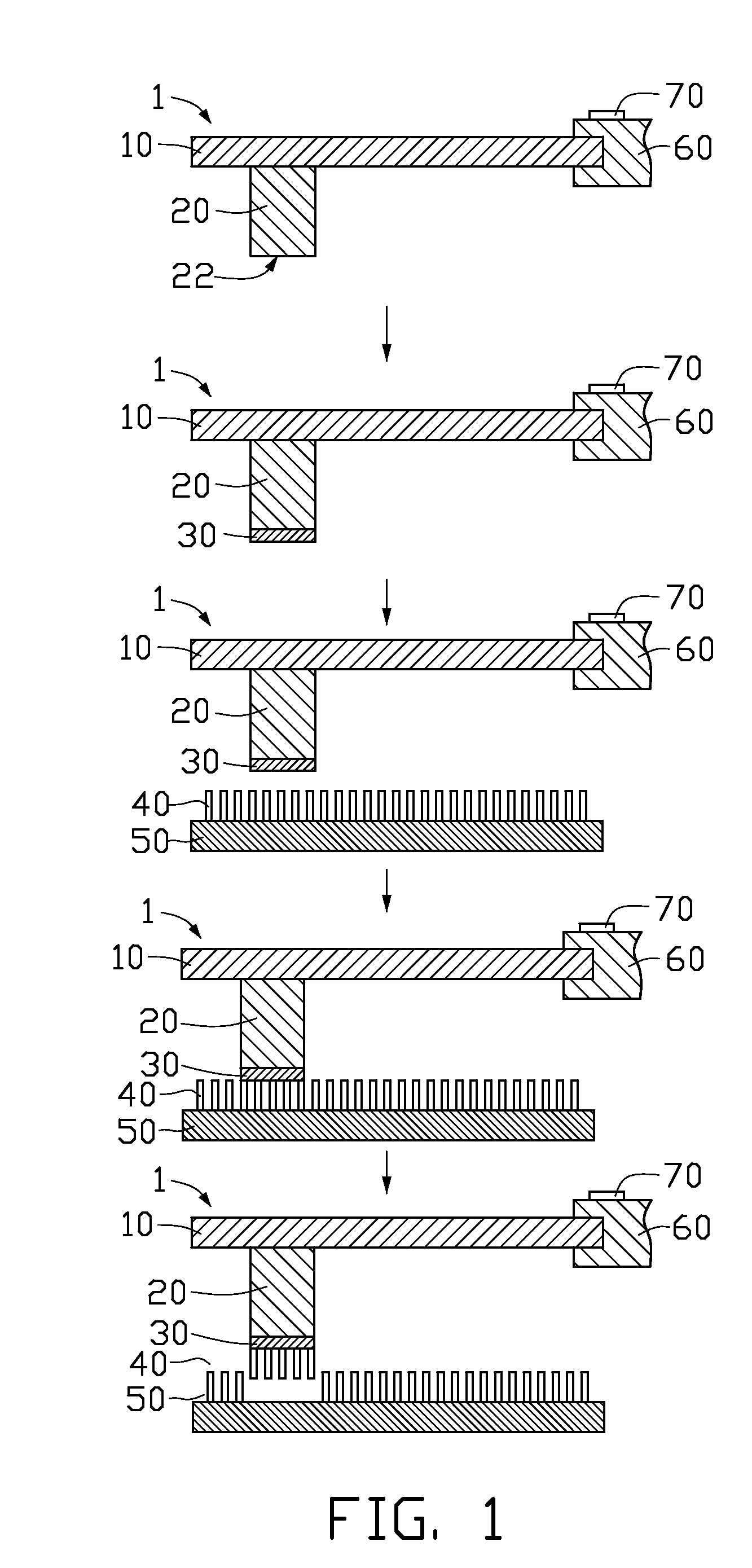

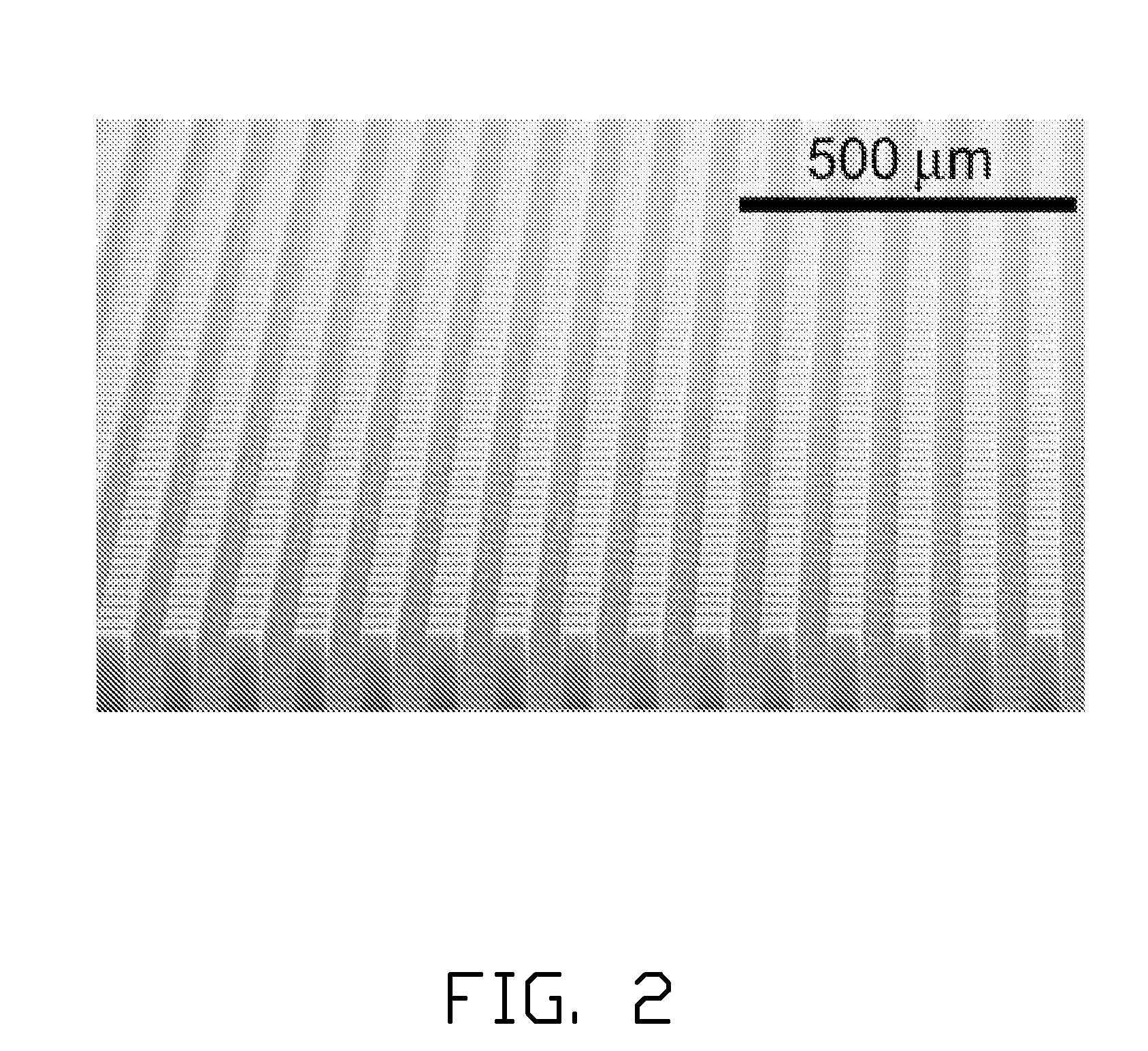

Method for measuring bonding force between substrate and carbon nanotube array formed thereon

ActiveUS7559253B2Improve signal-to-noise ratioPrevent and minimize Van der Waals forceMaterial strength using tensile/compressive forcesUsing mechanical meansUltimate tensile strengthCantilever

A method for measuring a bonding force between a substrate (50) and a carbon nanotube array (40) formed thereon, wherein the carbon nanotube array includes a plurality of carbon nanotubes. A force gauge (1) including a cantilever (10), a flat-surface probe (20), a movement mechanism (60), and a force sensor (70) is provided. The probe is secured at one end of the cantilever. An adhesive layer (30) is formed on the flat surface of the probe. The probe is moved toward the substrate and is brought into bonding contact with the carbon nanotube array by the movement mechanism. The probe is pulled away from the substrate by the movement mechanism, causing the carbon nanotubes adhered thereto to separate from the substrate. The force at separation is detected by the force sensor, and that force can be converted into an average nanotube / substrate bonding force / strength.

Owner:TSINGHUA UNIV +1

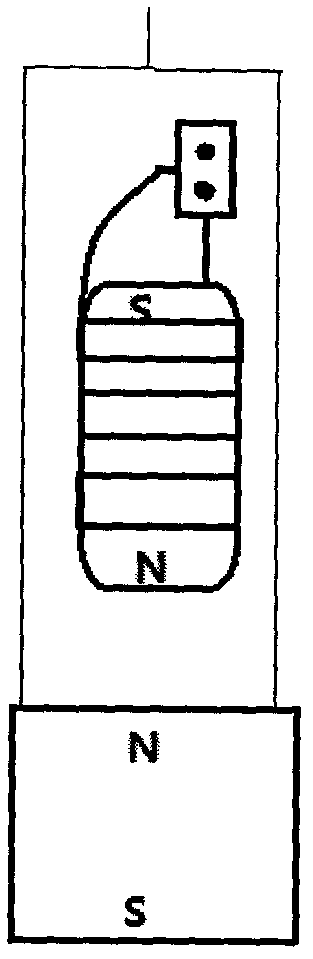

Multi-functional electromagnetic combined fitness equipment

InactiveCN102397664ARally displayThe size of the pulling force is displayedMuscle exercising devicesMicrocontrollerMagnetic tension force

The invention provides a multi-functional electromagnetic combined training stand. The multi-functional electromagnetic combined training stand mainly comprises a main shell, an electromagnet, a singlechip, chest-expanding arms, a rotating shaft, a steel wire, a universal wheel, a small rotating wheel, a supporting frame, a fixed ring, lantern rings, a force gauge, a frequency gauge, a training bench, a base frame, a permanent magnet, a base and the like. The multi-functional electromagnetic combined training stand is characterized in that: the gravity of an iron block which is required to be used is replaced by the magnetic force of the magnet, the electromagnet is fixed at the upper end of the main shell, and the permanent magnet is arranged at the lower end of the main shell. The electromagnet is controlled by the singlechip and can produce large magnetic force when being electrified; and the magnitude of current can be adjusted by using the singlechip, the magnitude of tension can be adjusted so as to save the trouble of adding heavy objects, and the effect of stepless tension regulation can also be achieved. In addition, the force gauge and the frequency gauge are also fixed at both ends of the training bench, and a user can read the force applied by arms during training through the force gauge and read the times of the training through the frequency gauge so as to fulfill the aim of higher humanization. The invention has the advantages that: the multi-functional electromagnetic combined training stand can perform stepless tension regulation, is designed in a more reasonable and humanized way, has high applicability, and is very convenient to use.

Owner:HENAN POLYTECHNIC UNIV

Concurrently measuring a force exerted upon each of a plurality of teeth

A system and method for concurrently measuring a force exerted upon a tooth is disclosed. In one aspect of the invention, the system includes a target tooth attached to a force gauge which is coupled to a motion module for adjusting the tooth to a reference position. The method includes utilizing a motion module of a force measurement device is utilized to adjust each target tooth of a plurality of target teeth to be located in a reference position. Next, each target tooth receives a dental appliance. Then an exerted force is measured by the dental appliance upon each target tooth utilizing a coordinate system of the force gauge.

Owner:ALIGN TECH

Crystal curing press head applied to electronic tag back-off encapsulation equipment

InactiveCN101973011AGuarantee the quality of thermocompression bondingEffectively fixedSemiconductor/solid-state device manufacturingMetal-working hand toolsPull forcePush pull

The invention relates to a crystal curing press head applied to electronic tag back-off encapsulation equipment, which comprises a low-friction cylinder, a connection assembly, a spring, an adjusting ring and a heating block, wherein a cylinder body of the low-friction cylinder is connected with an upper hot-press head template through the connection assembly; the spring is arranged on the adjusting ring; the adjusting ring and the spring are sleeved on a piston rod, and the upper end of the adjusting ring is in threaded connection with the lower end of the cylinder body; and the heating block is connected with the lower end of the piston rod. In the crystal curing press head, the spring thrust is changed by rotating the adjusting ring to perform fine adjustment according the required pressure, and the fine adjustment pressure is detected by a high-precision push-pull force gauge, so that the pressure of a plurality of press heads is uniform, good hot-press crystal curing effect is achieved, and chips can be fixed effectively.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

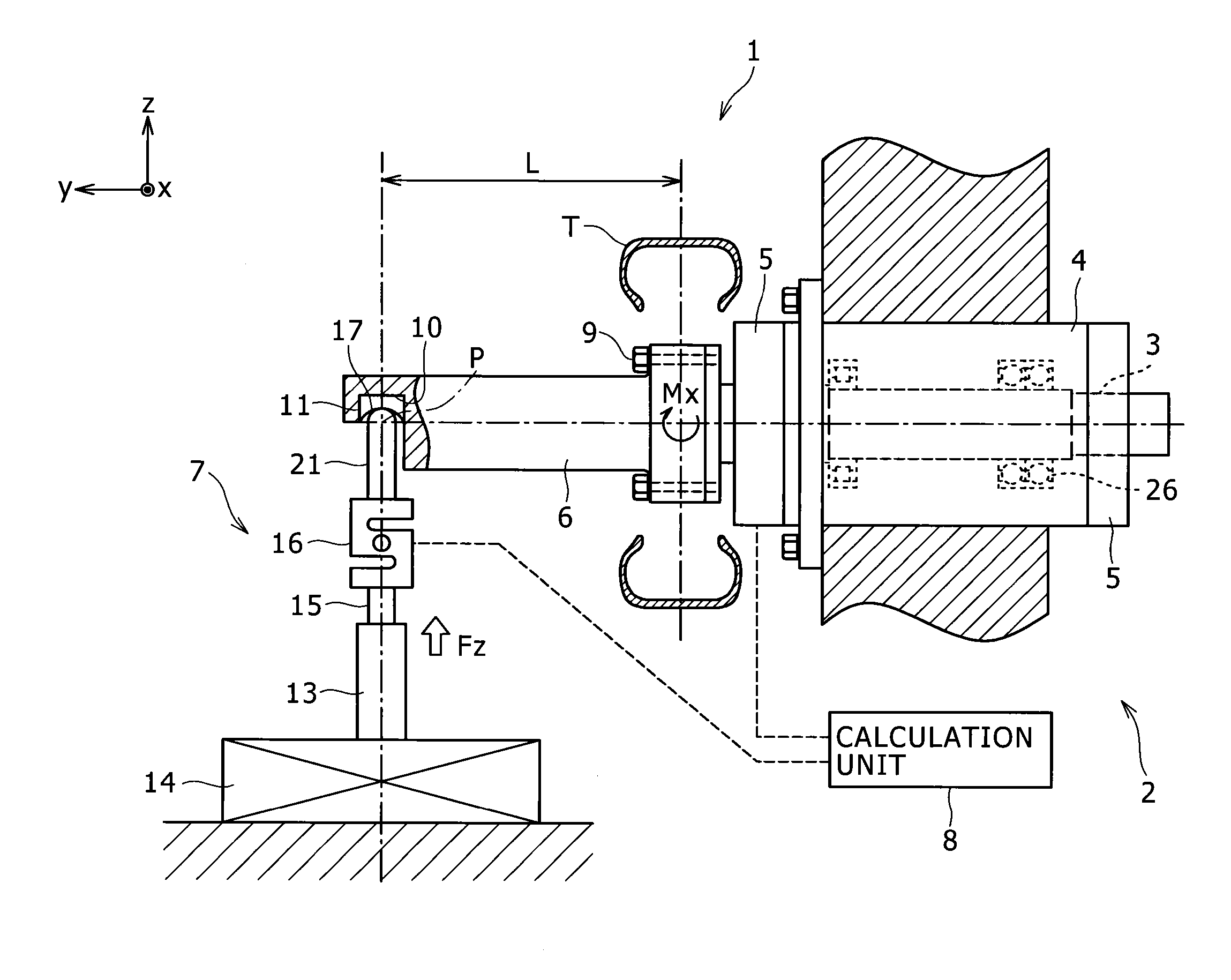

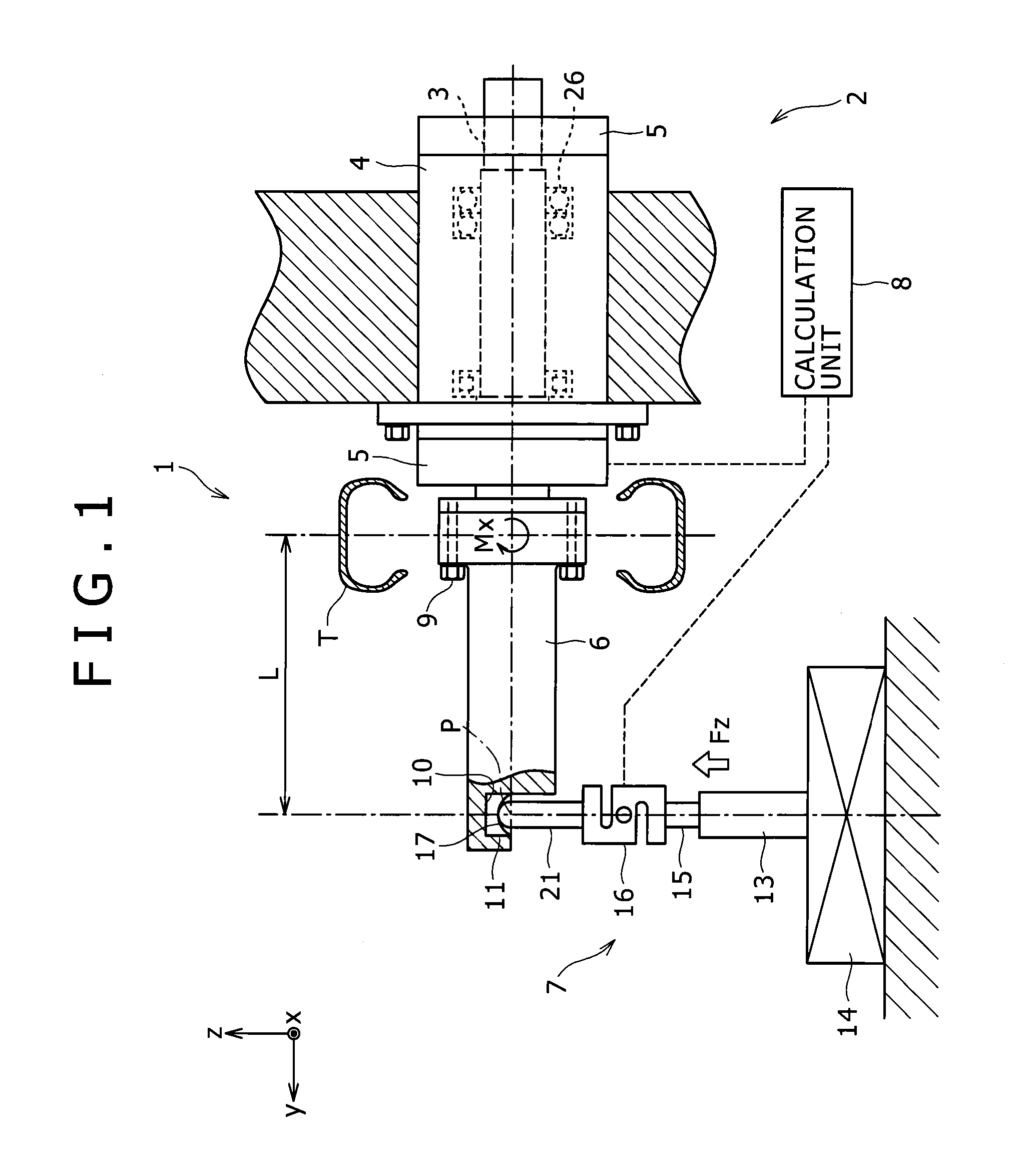

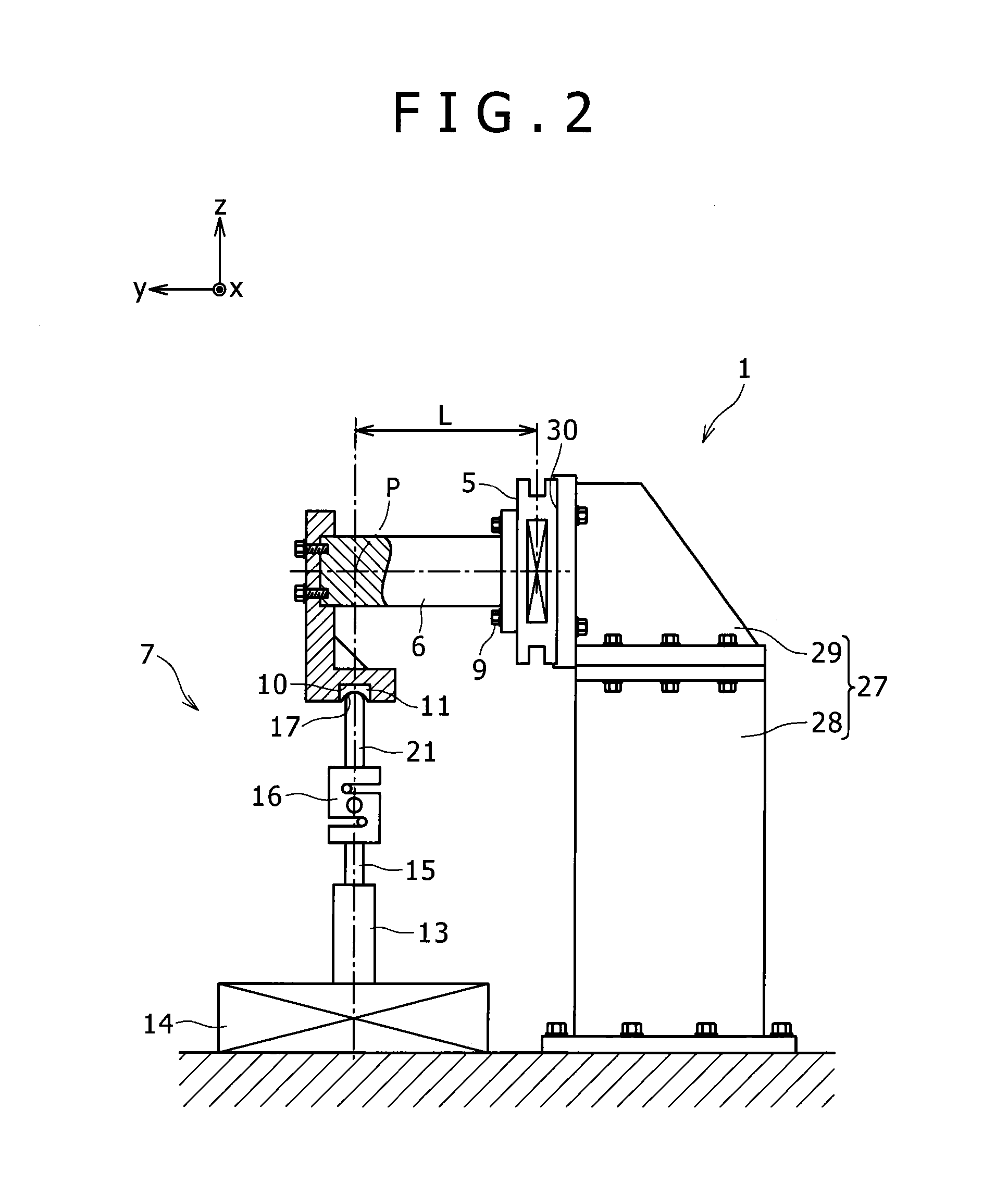

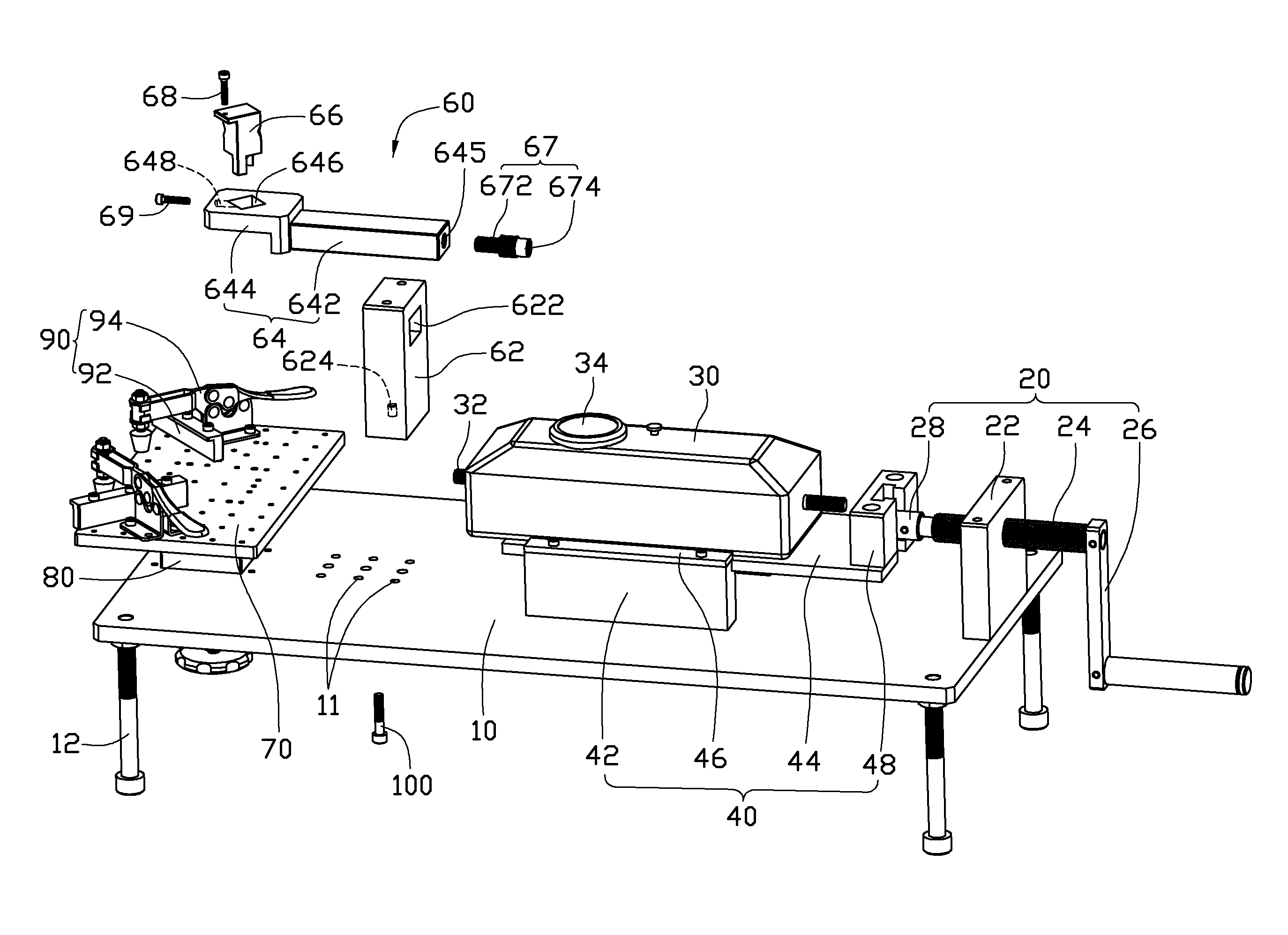

Moment calibrating apparatus for multi-component force gauge and method of moment calibration

InactiveUS20120297858A1Accurate and effectiveEffective and accurate calibrationStatic/dynamic balance measurementWeighing apparatus testing/calibrationEngineeringPerpendicular direction

A moment calibrating apparatus (1) is provided with an elongated force transmitting member (6) for transmitting a force applied to the end portion thereof to a multi-component force gauge (5), a load applying mechanism (7) for applying a load without changing the direction of the force along a direction perpendicular to said end portion, and a calculation unit (8) for calculating a true moment free from the effect of a perpendicular load on the basis of the moment value around the axis in the direction orthogonal to the perpendicular direction, measured by the multi-component force gauge (5) under the condition that said perpendicular load along the direction perpendicular to said end portion is applied by the load applying mechanism (7), wherein a moment calibration of the multi-component force gauge (5) is performed using said true moment calculated by the calculation unit (8).

Owner:KOBE STEEL LTD

Method for measuring bonding force between substrate and carbon nanotube array formed thereon

ActiveUS20080173098A1Improve signal-to-noise ratioPrevent and minimize Van der Waals forceMaterial strength using tensile/compressive forcesUsing mechanical meansUltimate tensile strengthCantilever

A method for measuring a bonding force between a substrate (50) and a carbon nanotube array (40) formed thereon, wherein the carbon nanotube array includes a plurality of carbon nanotubes. A force gauge (1) including a cantilever (10), a flat-surface probe (20), a movement mechanism (60), and a force sensor (70) is provided. The probe is secured at one end of the cantilever. An adhesive layer (30) is formed on the flat surface of the probe. The probe is moved toward the substrate and is brought into bonding contact with the carbon nanotube array by the movement mechanism. The probe is pulled away from the substrate by the movement mechanism, causing the carbon nanotubes adhered thereto to separate from the substrate. The force at separation is detected by the force sensor, and that force can be converted into an average nanotube / substrate bonding force / strength.

Owner:TSINGHUA UNIV +1

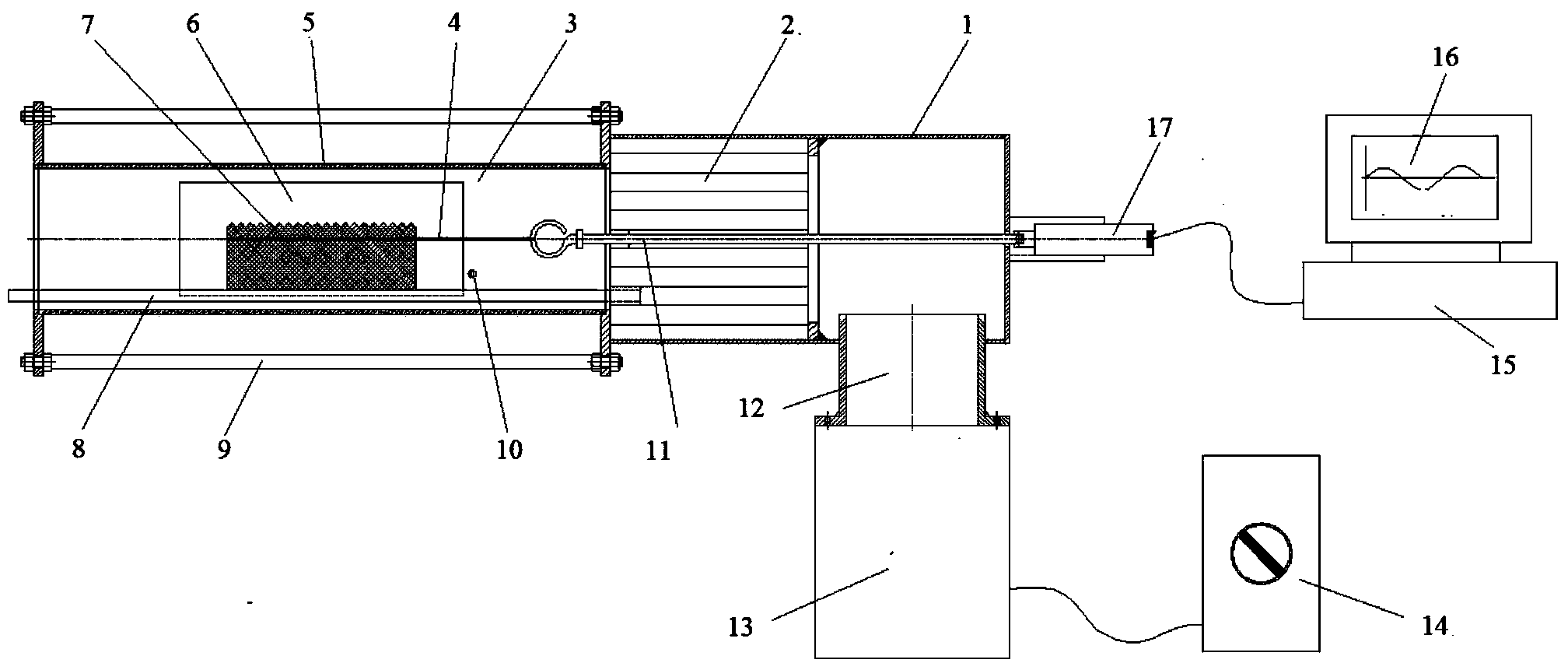

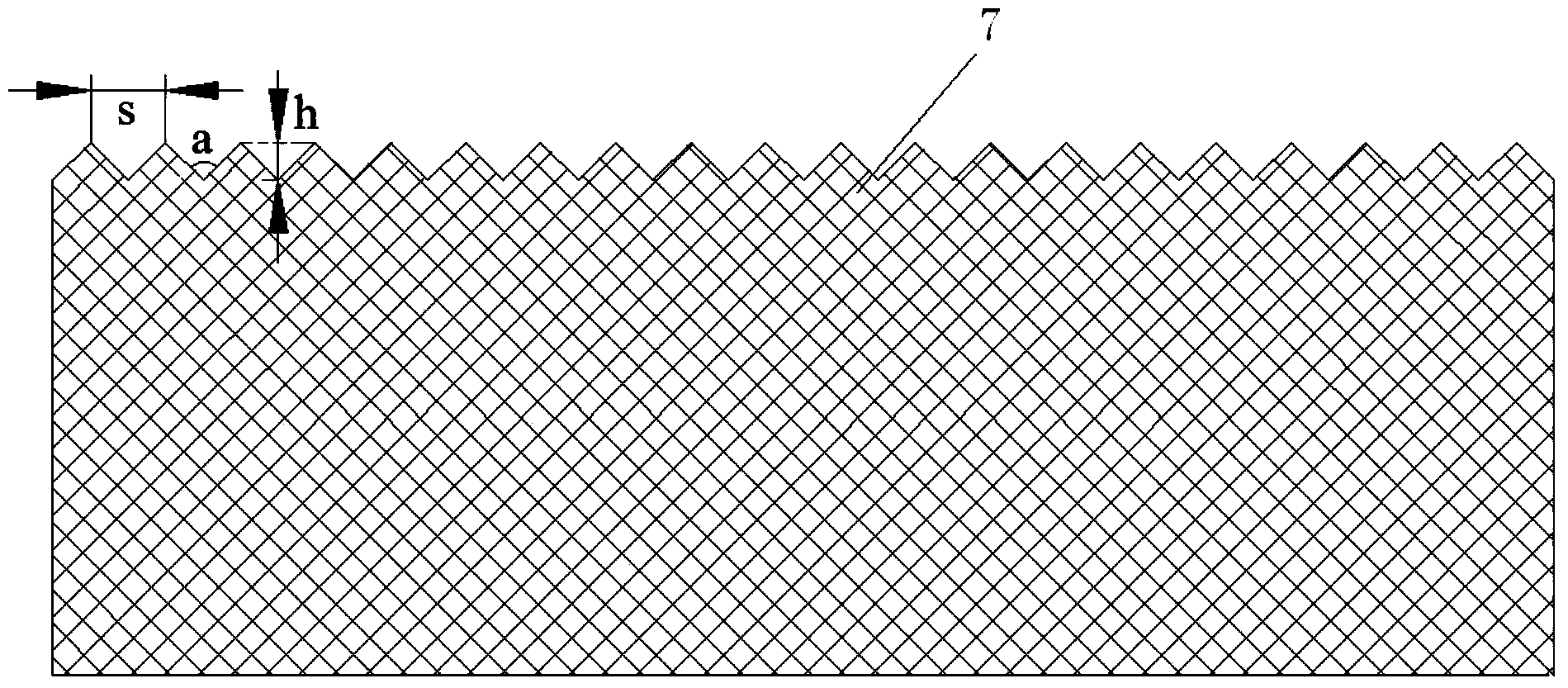

Resistance measuring device and method for measuring wind resistance factor of non-smooth surface object

The invention discloses a resistance measuring device and method for measuring the wind resistance factor of a non-smooth surface object. The device comprises a dynamometer connecting shaft, a wind inlet section, a wind meter, a fan, a test observation section and a flow guide wind grid arranged between the wind inlet section and the test observation section; the test observation section is provided with two guide rails; the dynamometer connecting shaft penetrates through the wind inlet section and the test observation section; during the test, the non-smooth surface object is placed on the dual guide rails firstly, and one end of a stay wire is tied and suspended on a hook of the dynamometer connecting shaft; then the fan is electrified to suck external air, the air is shunted by the flow guide wind grid and is exhausted after passing by the non-smooth surface object; meanwhile, the non-smooth surface object moves on the dual guide rails along the horizontal direction, when the dynamometer connecting shaft horizontally moves as the non-smooth surface object is subjected to the resistance of the air flow, the dynamometer connecting shaft can pulls a digital dynamometer to test the magnitude of the wind resistance applied to the non-smooth surface object. The resistance measuring device is simple in structure, the test means is simple, convenient and fast and the errors are smaller.

Owner:SOUTH CHINA UNIV OF TECH

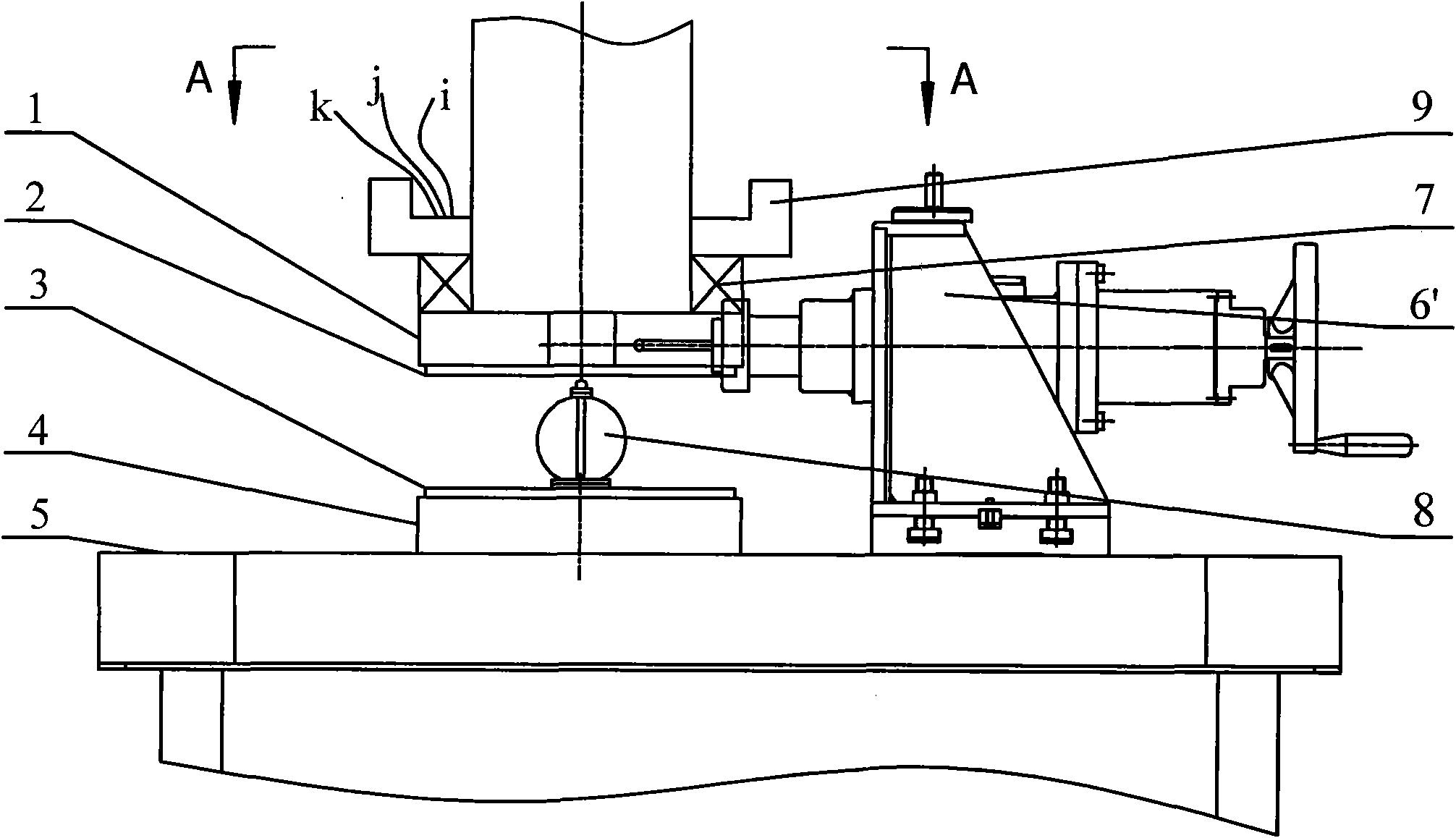

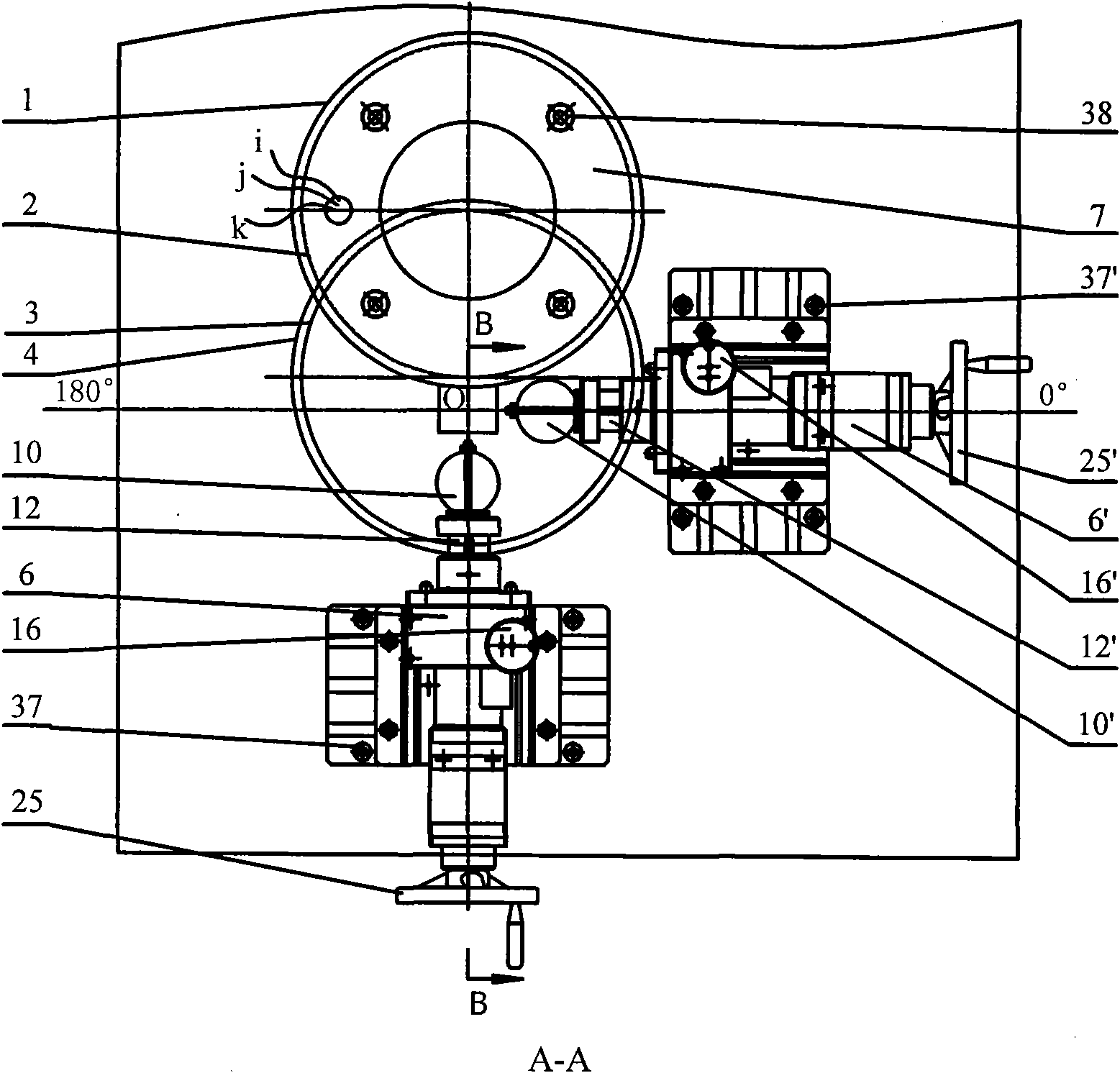

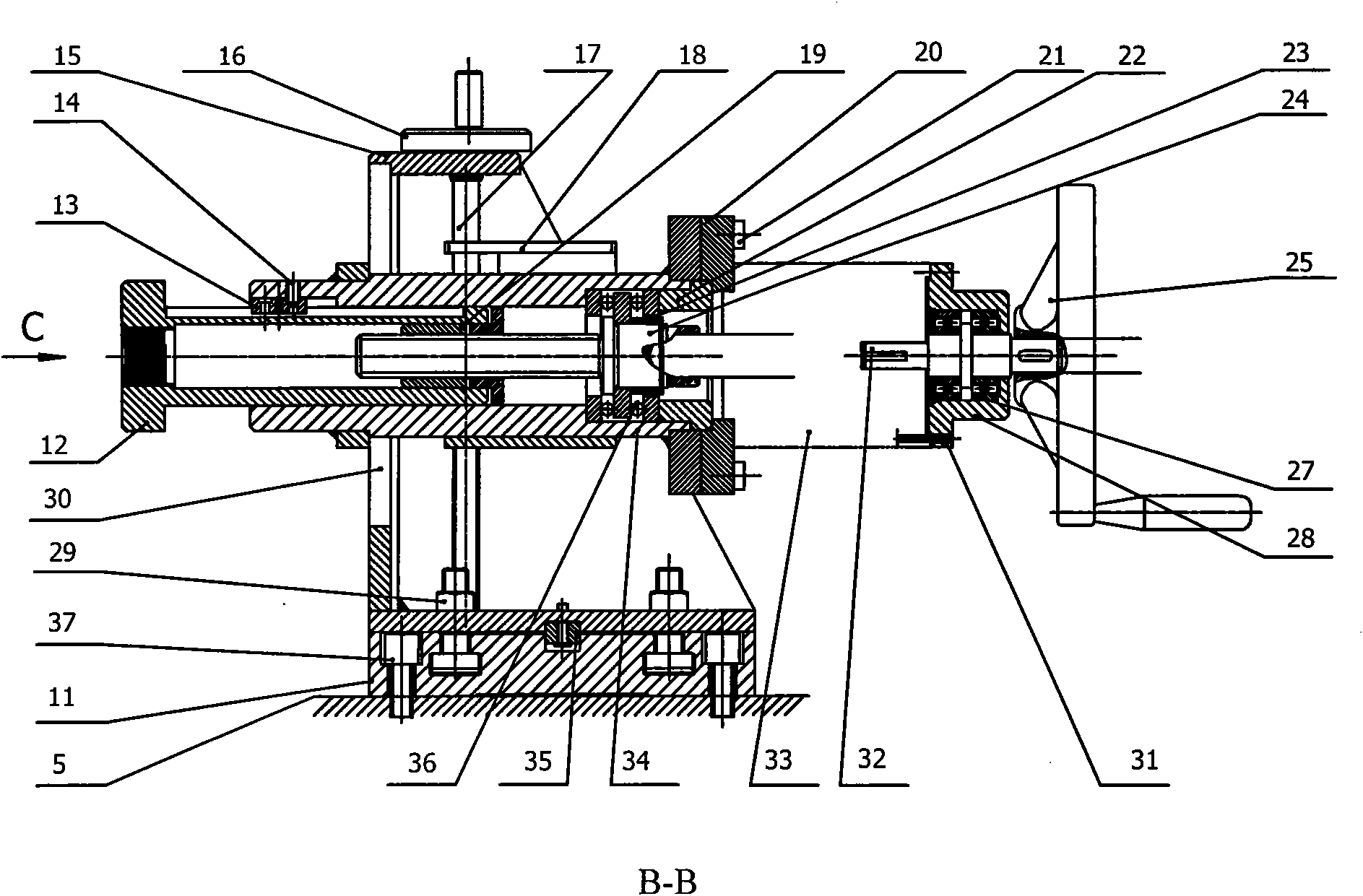

On-machine calibration method for grinding dynamometer and horizontal force loader

InactiveCN102039557AReduce duplicationReduce distractionsGrinding feed controlDynamometerTangential force

The invention discloses an on-machine calibration method for a grinding dynamometer and a horizontal force loader, and belongs to the technical field of sensing test. In the method, the grinding dynamometer is connected with a charge amplifier, a data acquisition card and an industrial personal computer in turn to form a measurement and control system. After the grinding dynamometer is arranged on a grinding machine, a standard load is applied to the grinding dynamometer, the grinding dynamometer is subjected to normalized regulation, and the normalized sensitivity of the grinding dynamometer in each direction is determined; and after the monitoring software installed in the industrial personal computer process the data, a 'force value-indicating value' on-machine calibration curve of the grinding dynamometer is established, and then each performance index is solved. Two horizontal force loaders with totally same structures and the standard dynamometer are adopted in the on-machine calibration method to measure an axial force Fz, a radial force Fr and a tangential force Ft generated when a silicon wafer is ground; and each horizontal force loader consists of a mobile sleeve, a lifting screw, an end connecting plate, a screw, a connecting shaft, a speed reducer, a horizontal guide sleeve and the like. The method is simple and convenient, has low interference, and can achieve good measurement performance.

Owner:DALIAN UNIV OF TECH

Apparatus for testing object strength

An apparatus for testing strength of a corner portion of an object includes a support platform, an installation mechanism having a slidable plate mounted on the platform, a force gauge fixed to the slidable plate, a drive mechanism connected to the slidable plate to move the slidable plate, and a push-pull mechanism. The push-pull mechanism is connected to the force gauge to be pushed or pulled by the force gauge and exerts push or pull force on the corner portion of the object.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Device for testing axial compressibility of fiber material

InactiveCN101788426AReliable clampingAccurate clampingMaterial strength using tensile/compressive forcesFiberTest efficiency

The invention relates to a device for testing axial compressibility of a fiber material, which can broaden the testing scope and improve the testing efficiency and accuracy. In the technical scheme, the device comprises a testing table, a digital type electronic push-pull force gauge and a measuring and controlling computer, wherein an upright column with a vertical slide rod is arranged on a base of the testing table, the electronic push-pull force gauge is connected with the slide rod in a sliding way through a slide block, the end of a testing rod on the lower end of the electronic push-pull force gauge is provided with an upper testing head, and the upper testing head is a disc type testing head or an upper clamp; and a lower clamp corresponding to the upper testing head is arranged on the testing table. The invention not only simplifies the testing device and the operating method, but also eliminates the factors affecting the reproducibility in the testing process. Moreover, the invention broadens the application scope of the device, can reliably, accurately and simply clamp the sample, and has high reproducibility and maneuverability.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Motor powered bicycle trailer with integral hitch force metering

A self-propelled trailer may be attached to a bicycle. The speed of the trailer is adjusted based on a signal from a force gauge which indicates whether the bicycle is pulling the trailer or the trailer is pushing the bicycle. In the former situation, the force gauge indicates a tensile load, and in the latter situation, the force gauge indicates a compressive load. Based on the feedback from the force gauge, the speed of the motor attached to the self-propelled trailer is adjusted so that the trailer and bicycle are moving at the same speed or the bicycle is pulling the trailer.

Owner:FELT RACING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com