On-machine calibration method for grinding dynamometer and horizontal force loader

A calibration method and the technology of a dynamometer, applied in the field of sensor testing, to achieve good measurement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

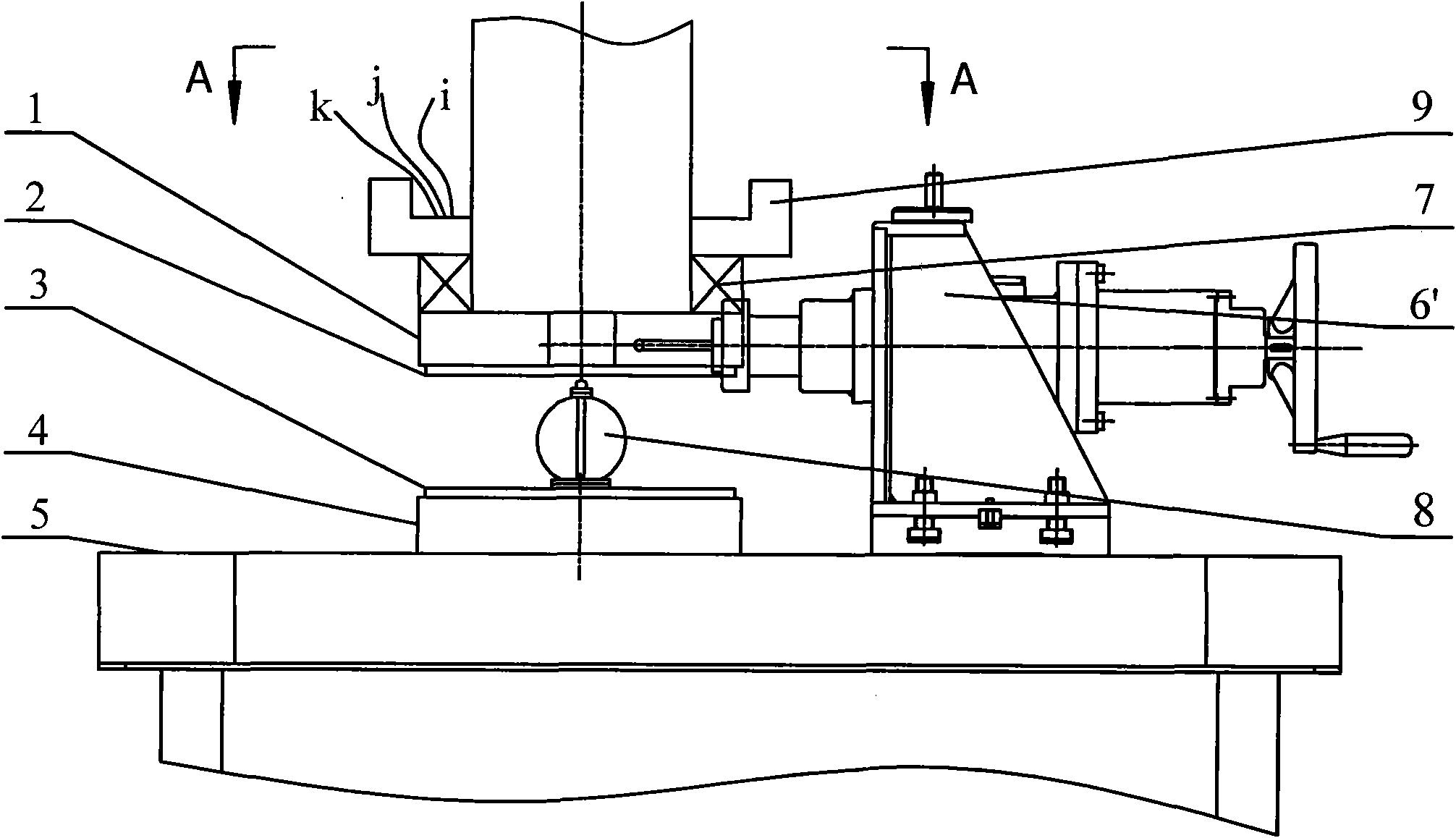

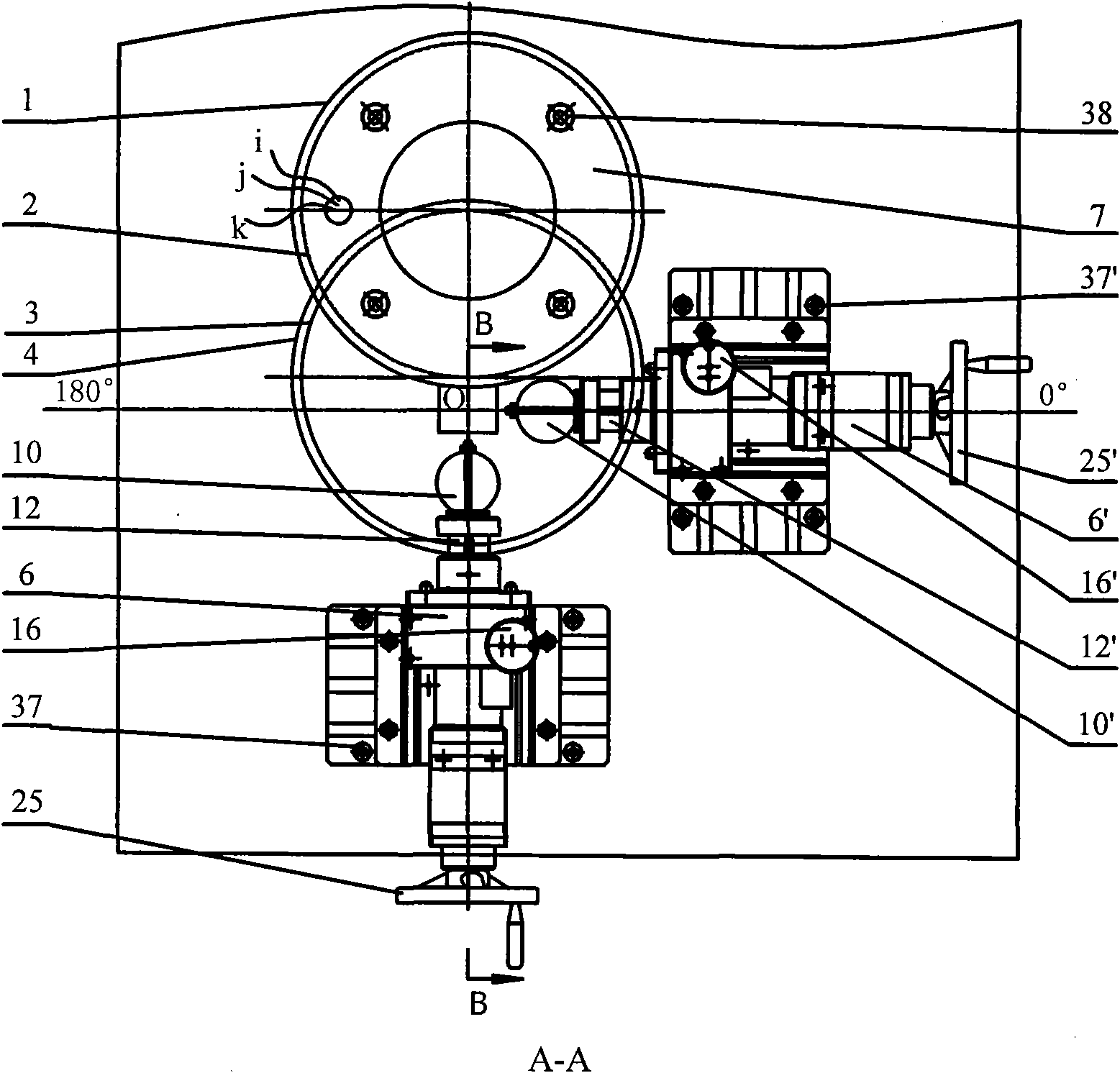

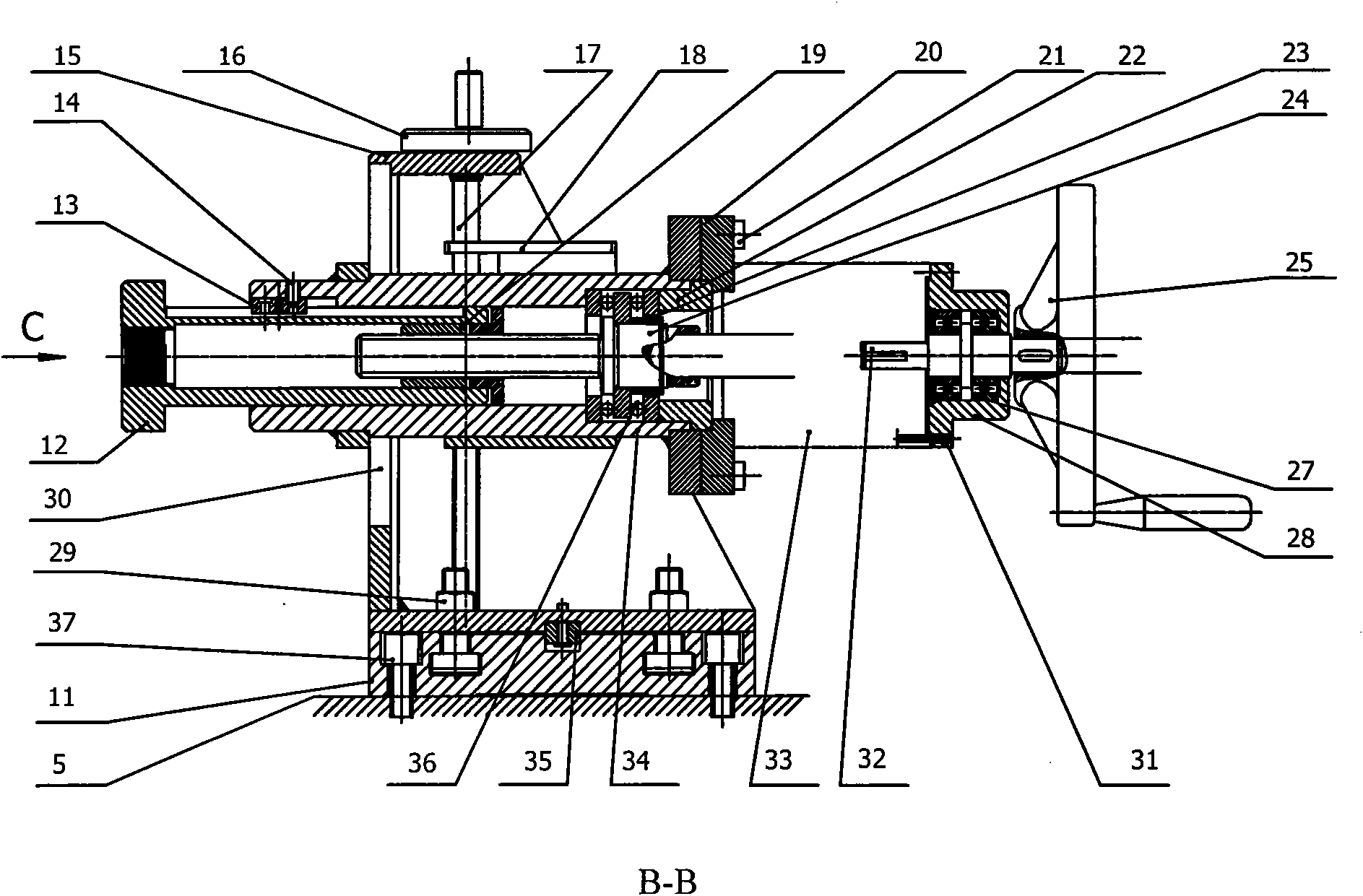

[0015] The specific implementation of the present invention is described in detail in combination with the accompanying drawings and technical solutions. The present invention takes the grinding dynamometer as an example of on-machine calibration. Before the dynamometer is formally connected, each component link must be checked one by one to prevent it from being Short circuit, open circuit, especially excessive zero drift. Check whether the low-noise cable connected between the dynamometer and the charge amplifier is short-circuited, open-circuited, and whether the insulation resistance between electrodes is ≥10 13 Ω, otherwise it needs to be cleaned and dried; after the charge amplifier is warmed up for 30 minutes, connect it to the monitoring software to check its no-load zero drift situation. If it exceeds the specified index (3mv / min) of the dynamometer, the input End sockets should be cleaned and dried. The above instruments and wires can be connected and debugged only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com