Device for testing axial compressibility of fiber material

A technology of axial compression and testing equipment, which is applied in the direction of measuring equipment, analyzing materials, and testing the strength of materials by applying stable tension/pressure, which can solve the lack of comparability of test results, small radial size of fiber samples, and constraints Differences and other issues, to achieve reliable and reasonable test results, eliminate reproducibility, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

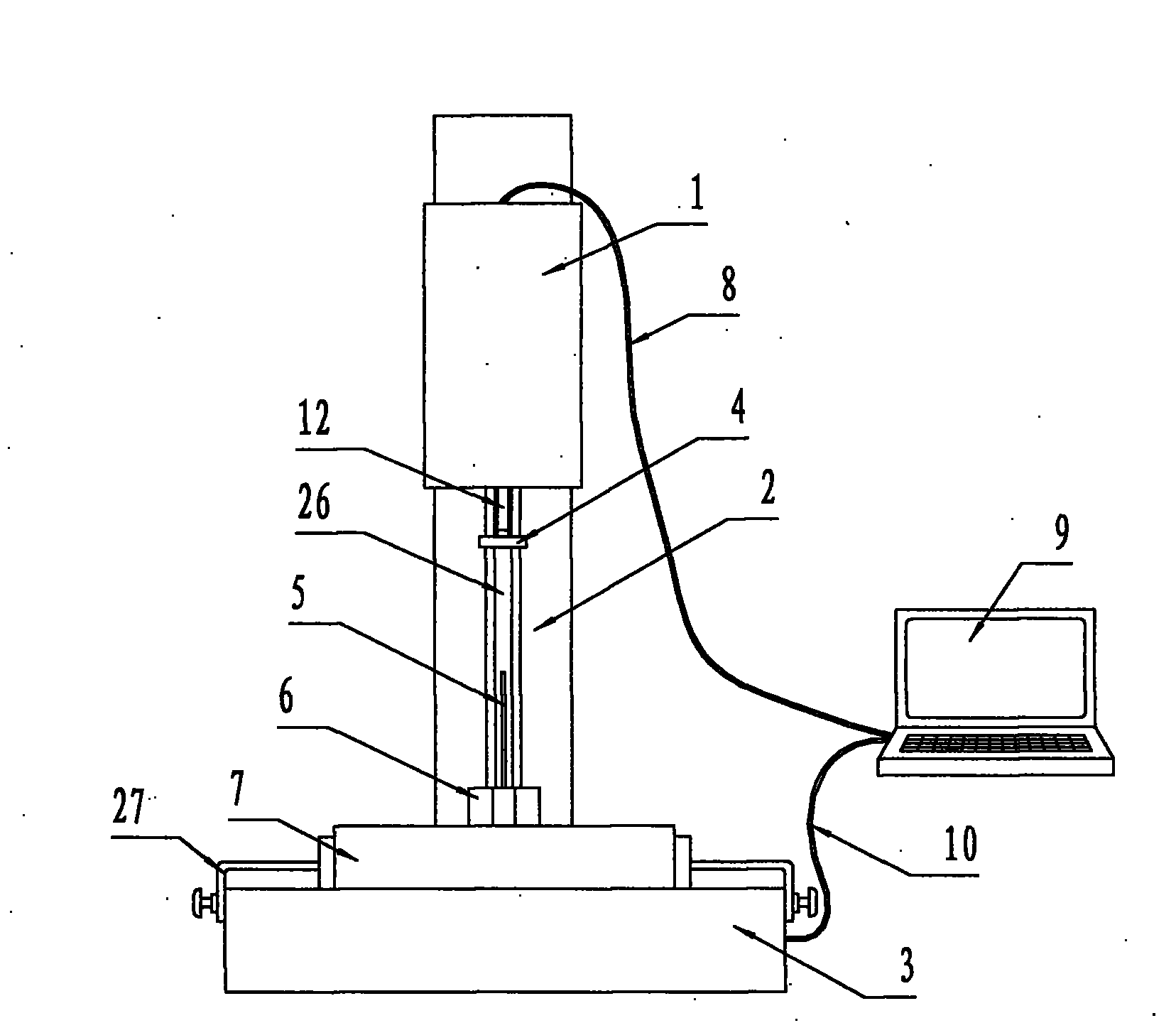

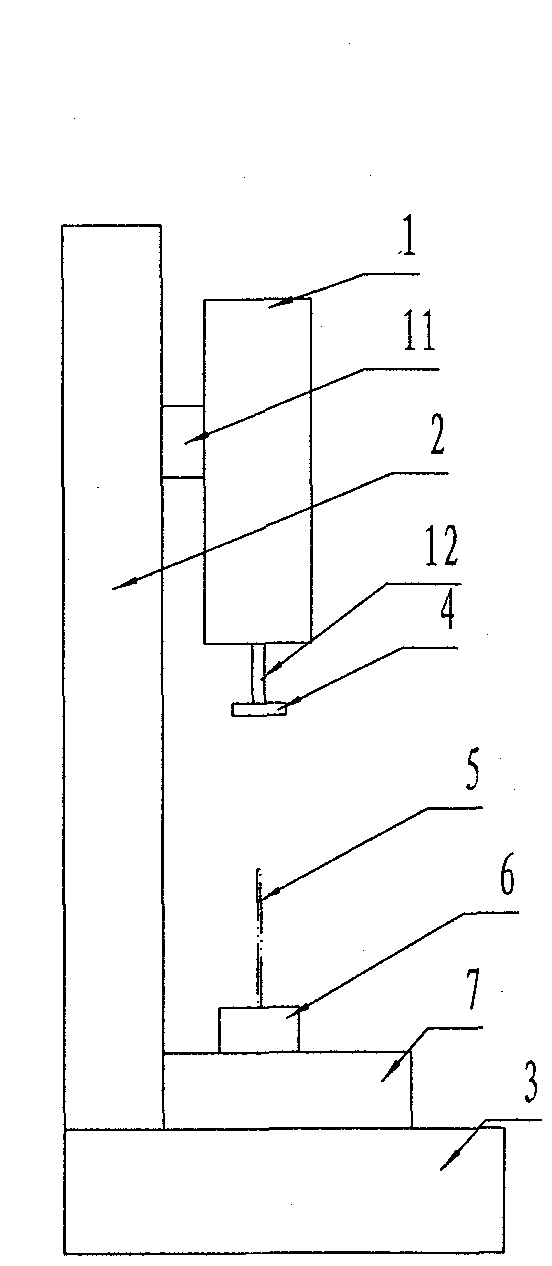

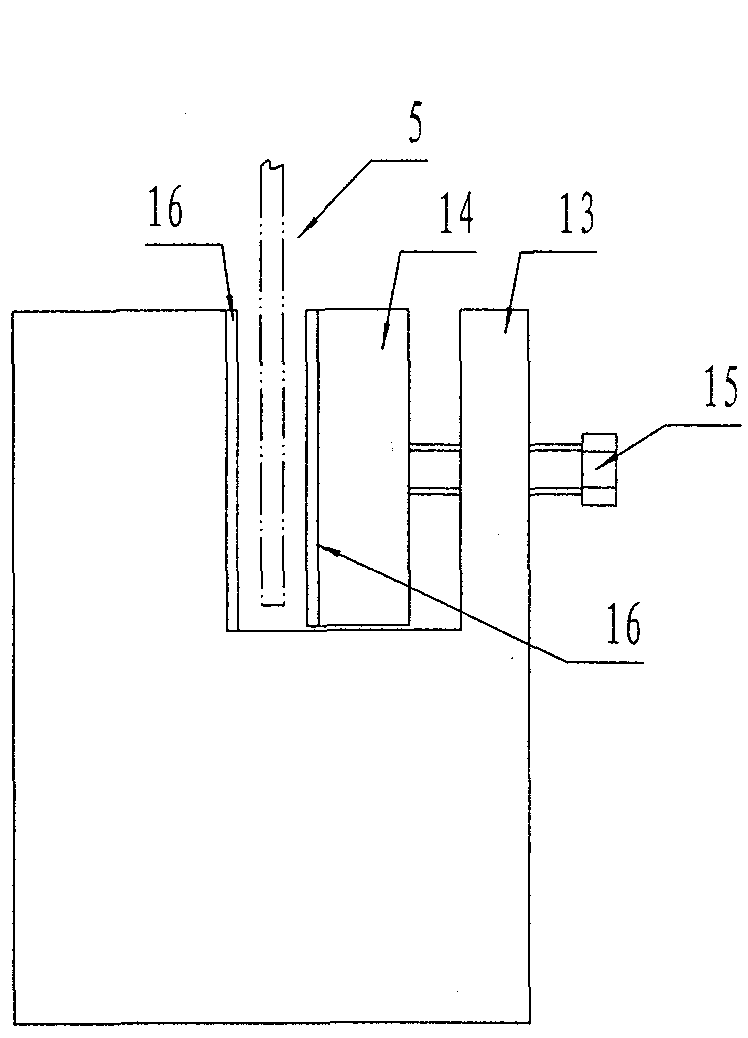

[0026] see figure 1 , figure 2 , one end of the fiber sample 5 is clamped on the lower holder 6, the lower holder is fixed on the test bench 7, the upper test head is installed on the test rod 12 of the electronic push-pull gauge 1 through the screw hole, and the upper test head It includes an upper holder or a disc-type test head 4. During the test, one end is clamped and the other end is a free end or both ends are clamping constraints according to the test method, and the upper test head is selected. The electronic push-pull force gauge 1 is installed on the slide block 11 on the column 2 of the supporting test bench, and moves up and down at a set speed along with the slide block 11 . When the electronic push-pull force gauge moves down with the slider 11 to the set compression stroke at the set speed, the axial compression test process of the fiber sample can be realized. The speed and the compression stroke of the electronic push-pull dynamometer can be set by the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com