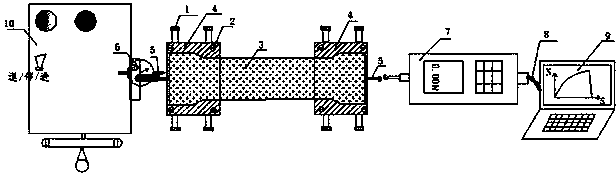

Test method for determining uniaxial tensile strength of soil mass

A technology of uniaxial tensile strength and test method, which is applied in the application of stable tension/compression to test the strength of materials and the preparation of samples for testing, etc. To achieve the effect of simple operation and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] 1. Preparation of samples

[0086] Soil sample:

[0087] A non-dispersed soil is selected, the moisture content of the sample preparation is 18.6%, and the sample preparation density is 1.70g / cm 3 .

[0088] Instruments and auxiliary equipment and materials:

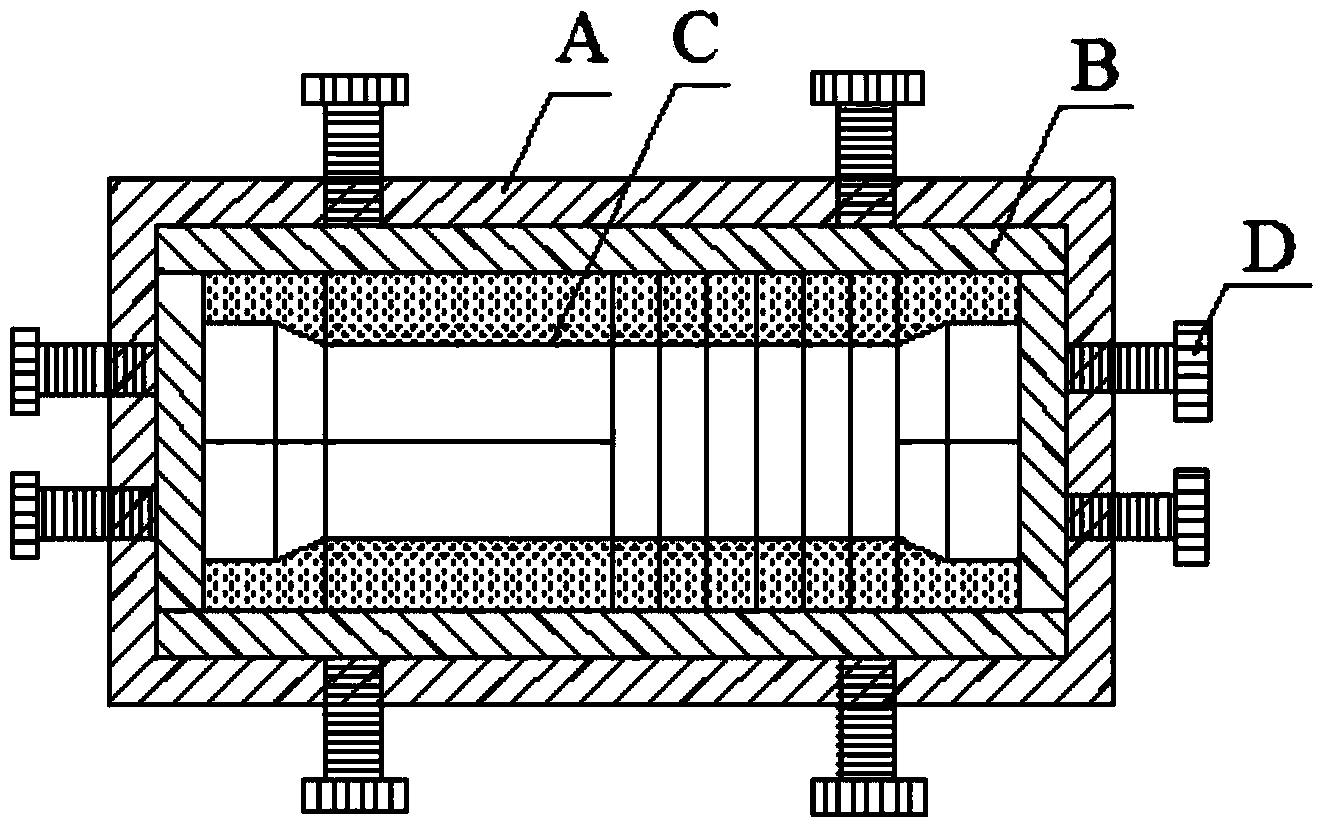

[0089] 1) Sample preparation mold: The sample preparation mold includes four parts: fixed base A, pressure plate B, sample former C, and fixed screw D;

[0090] 2) Live wrench: 1

[0091] 3) Brush: Small model paint brush

[0092] 4) Vaseline: Ordinary white Vaseline

[0093] 5) Jack, reaction frame: lifting capacity 8T

[0094] 6) Balance: precision value 0.01g

[0095] Operation method:

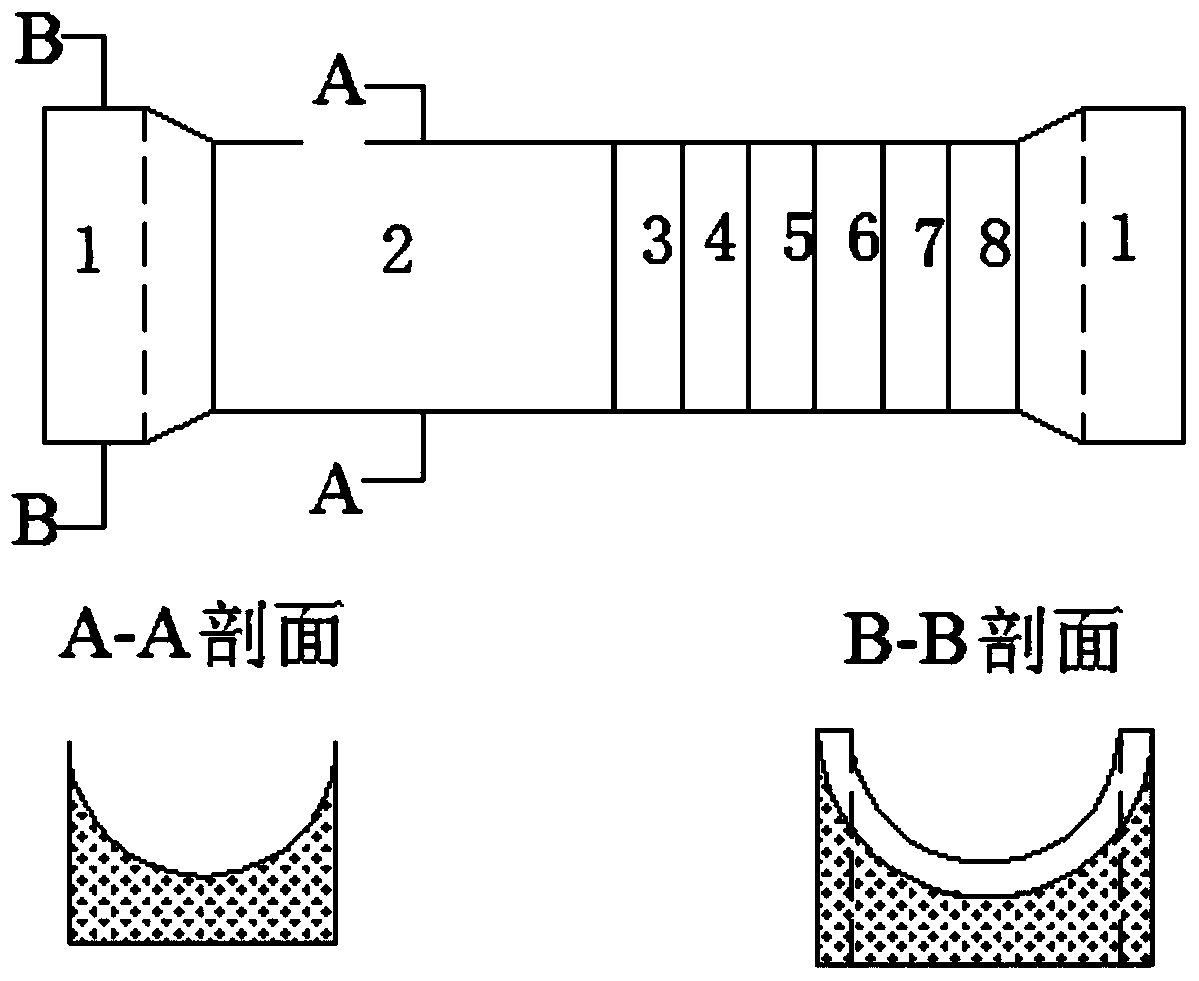

[0096] 1) Select the sample according to the test requirements, the length of the sample is 10cm, that is, one base section with a length of 6cm and four free sections with a length of 1cm are selected. Assemble the base part of the sample maker according to the selected sample length, put it into the bottom groove, pl...

Embodiment 2

[0133] 1. Preparation of samples

[0134] Soil sample:

[0135] A kind of dispersive soil is selected, the moisture content of the sample preparation is 18.6%, and the sample preparation density is 1.70g / cm 3 .

[0136] Instruments and auxiliary equipment and materials:

[0137] 1) Sample preparation mold: The sample preparation mold includes four parts: fixed base A, pressure plate B, sample former C, and fixed screw D;

[0138] 2) Live wrench: 1

[0139] 3) Brush: Small model paint brush

[0140] 4) Vaseline: Ordinary white Vaseline

[0141] 5) Jack, reaction frame: lifting capacity 8T

[0142] 6) Balance: precision value 0.01g

[0143] Operation method:

[0144] 1) Select a sample length of 8cm according to the test requirements, that is, select a base section with a length of 6cm and two free sections with a length of 1cm. Assemble the base part of the sample maker according to the selected sample length, put it into the bottom groove, place the pressure plate aro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com