Measuring for friction torque of bearing under micro-loading at different rotation rate and measuring apparatus therefor

A friction torque and measuring instrument technology, used in force/torque/work measuring instruments, torque measurement, mechanical bearing testing, etc., can solve the problems of many measurement data and parameters, inability to measure friction torque, and low measurement accuracy, etc. Achieve the effect of small measurement error, few measurement items and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

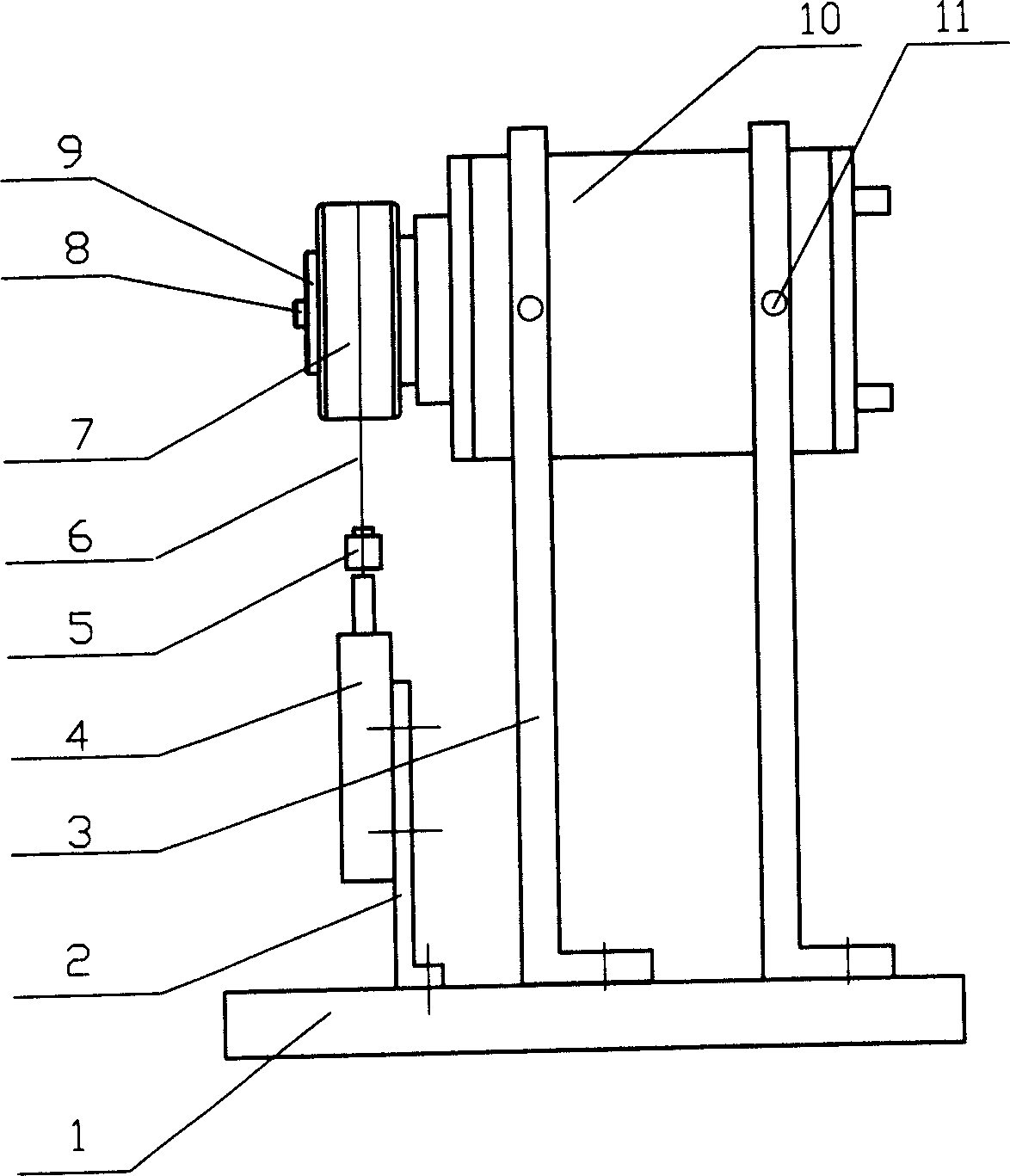

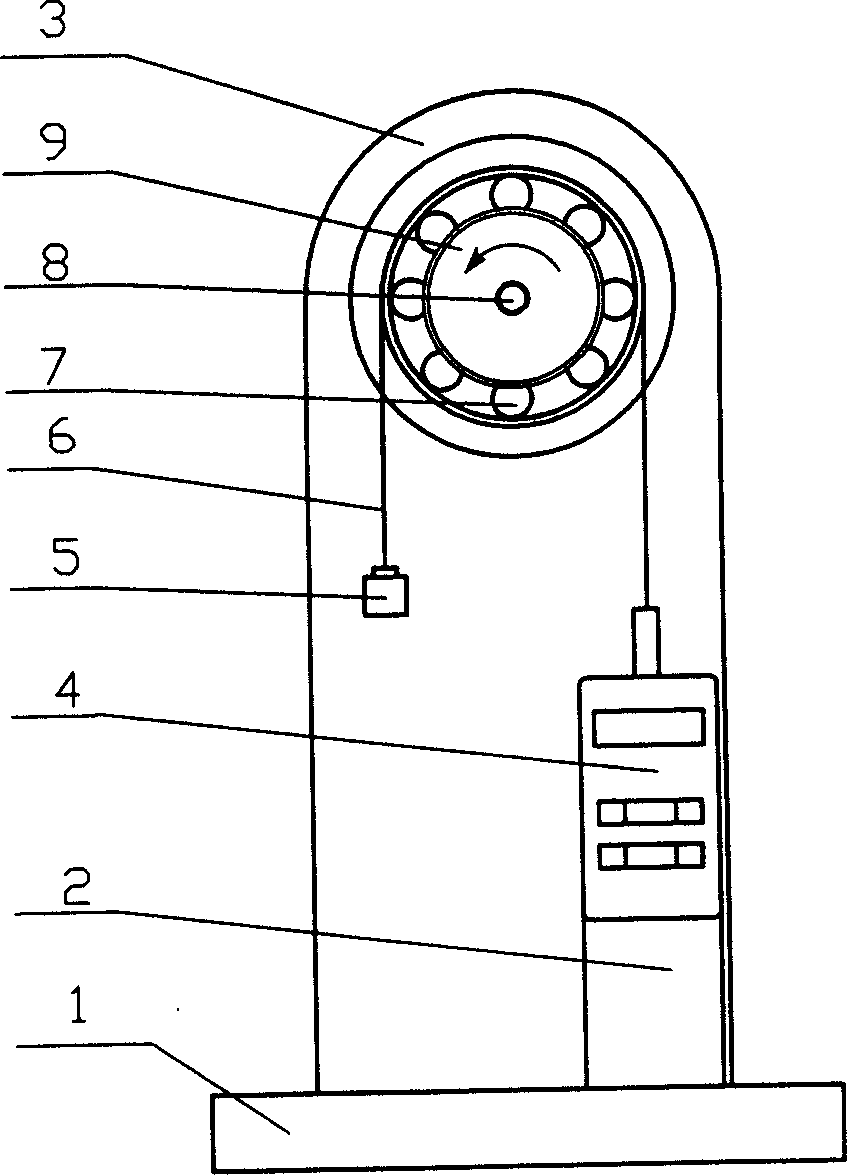

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Friction torque measurement method: a) Select the weight of the French yard when the bearing under test is at rest, hang a very thin nylon filament 6 in the middle of the outer diameter of the bearing, hang a French yard 5 on one end of the nylon filament 6, and hang the French yard 5 on the other end of the nylon filament connected to the force gauge. The weight of the French code 5 is to make the nylon filament 6 and the outer ring of the tested bearing 7 not have relative sliding as the criterion.

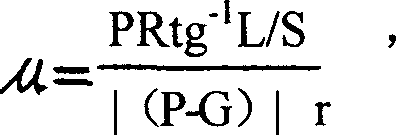

[0020] When the bearing under test is at rest, the tensile force of the French code 5 and the dynamometer 4 is balanced, and the displayed value A on the dynamometer 4 is 1 (Newton N), when the bearing under test rotates counterclockwise with the special mandrel, the inner ring of the bearing rotates at a predetermined speed driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com