Self-expanding protection disc

A technology of self-expanding and fixing discs, which is applied in the direction of injection devices, etc., and can solve the problems of cumbersome disc protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing:

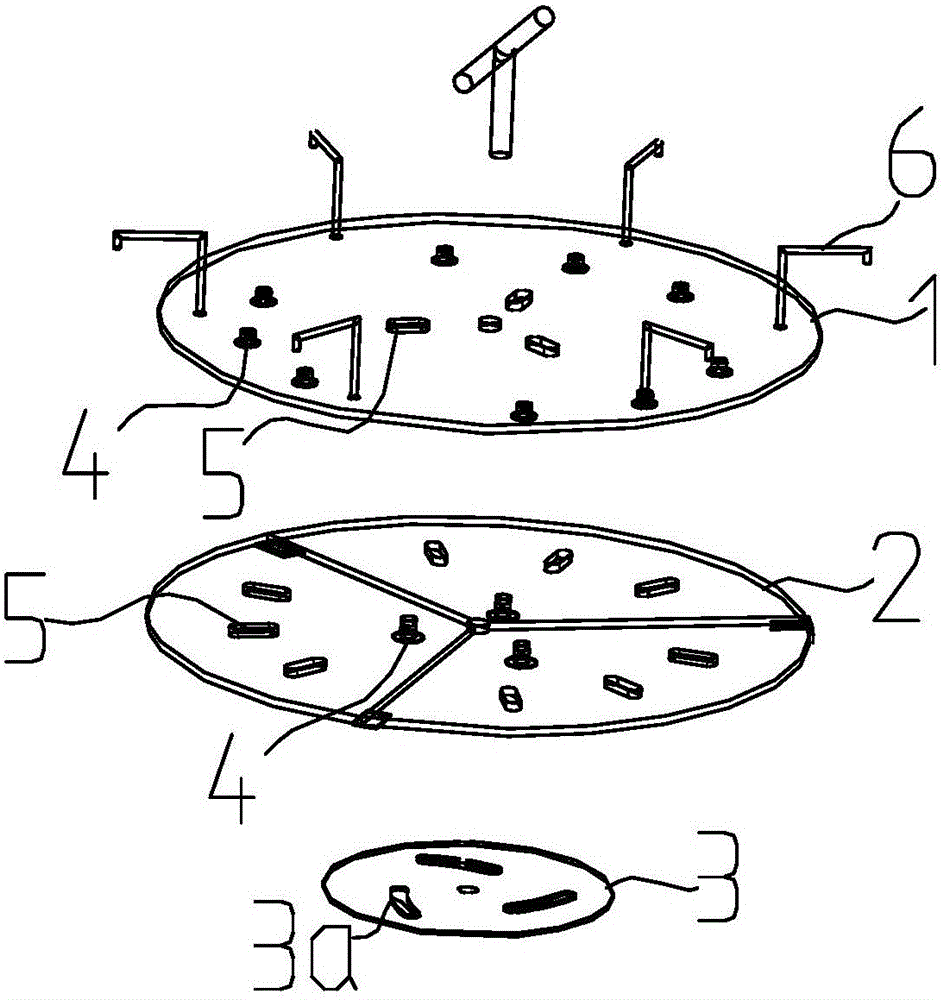

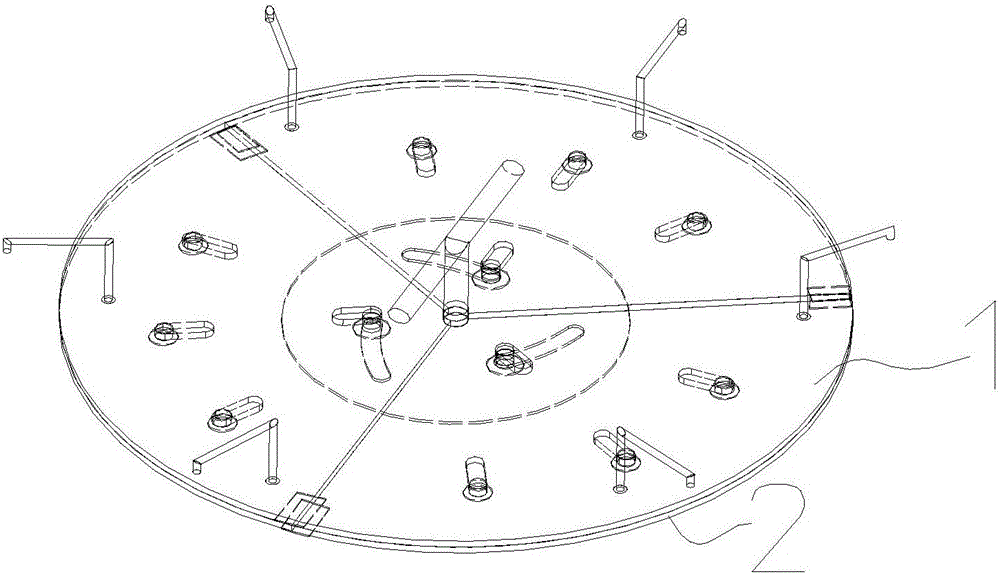

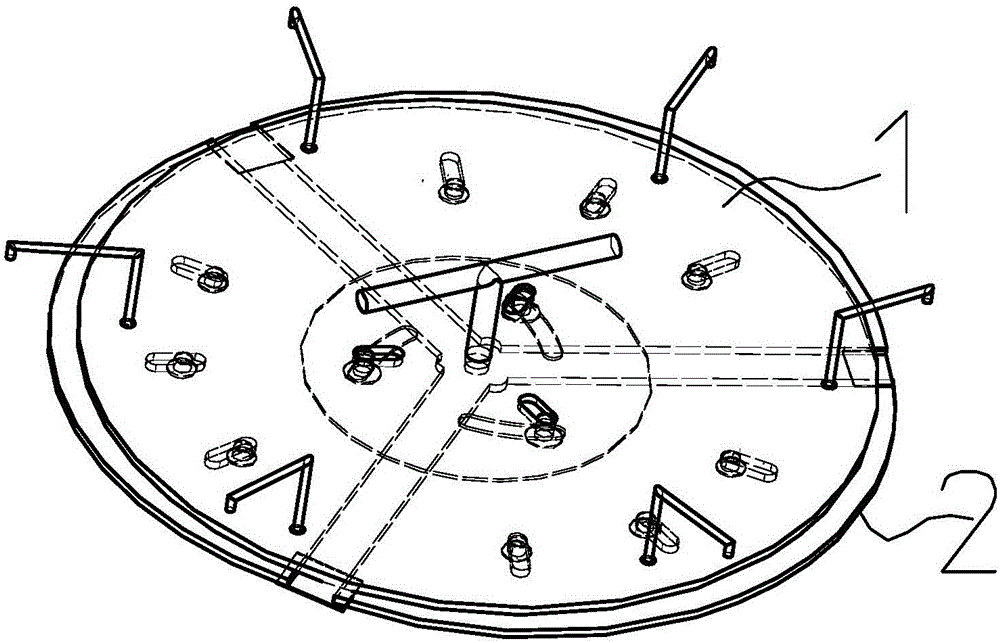

[0032] Such as figure 1 , 2 As shown, a self-expanding diameter protection plate, which includes an upper fixed plate 11, a middle layer diameter expansion plate, and a lower layer cam plate 33, which are stacked sequentially from top to bottom, and the middle layer diameter expansion plate is formed by splicing three fan-shaped plates 22, The angle of each fan-shaped disk is 120°, and the opposite sides of the apex of the fan-shaped plate 2 are joined together to form a disk-shaped middle-level expansion disk. A screw 4 as a slider is perforated on each fan-shaped plate 2 , the screw 4 is located on the symmetry axis of the corresponding fan-shaped plate 2, the position of the screw 4 is close to the apex of the corresponding fan-shaped plate 2, and the screw 4 on the upper fixed disk 1 corresponds to the screw 4 on the middle expansion disk. There are a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com