Patents

Literature

101results about How to "Reduce polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for treatment of viral diseases

InactiveUS20080161324A1Slow and stop replicationReduce loadBiocideMicrobiological testing/measurementSingle-Stranded RNADisease

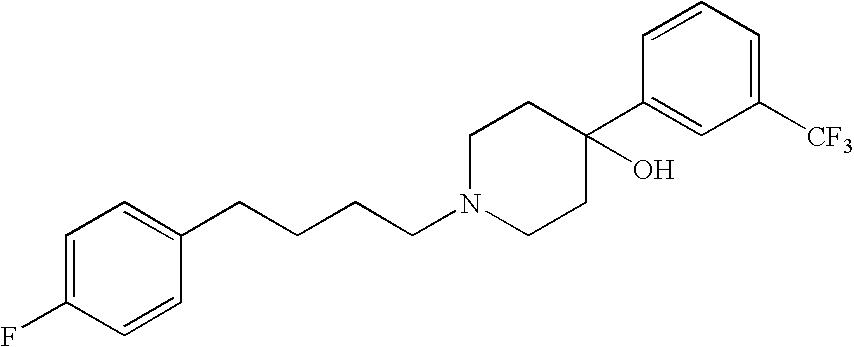

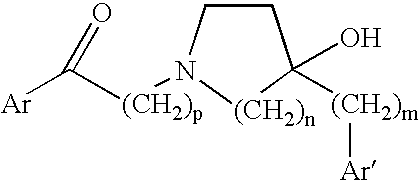

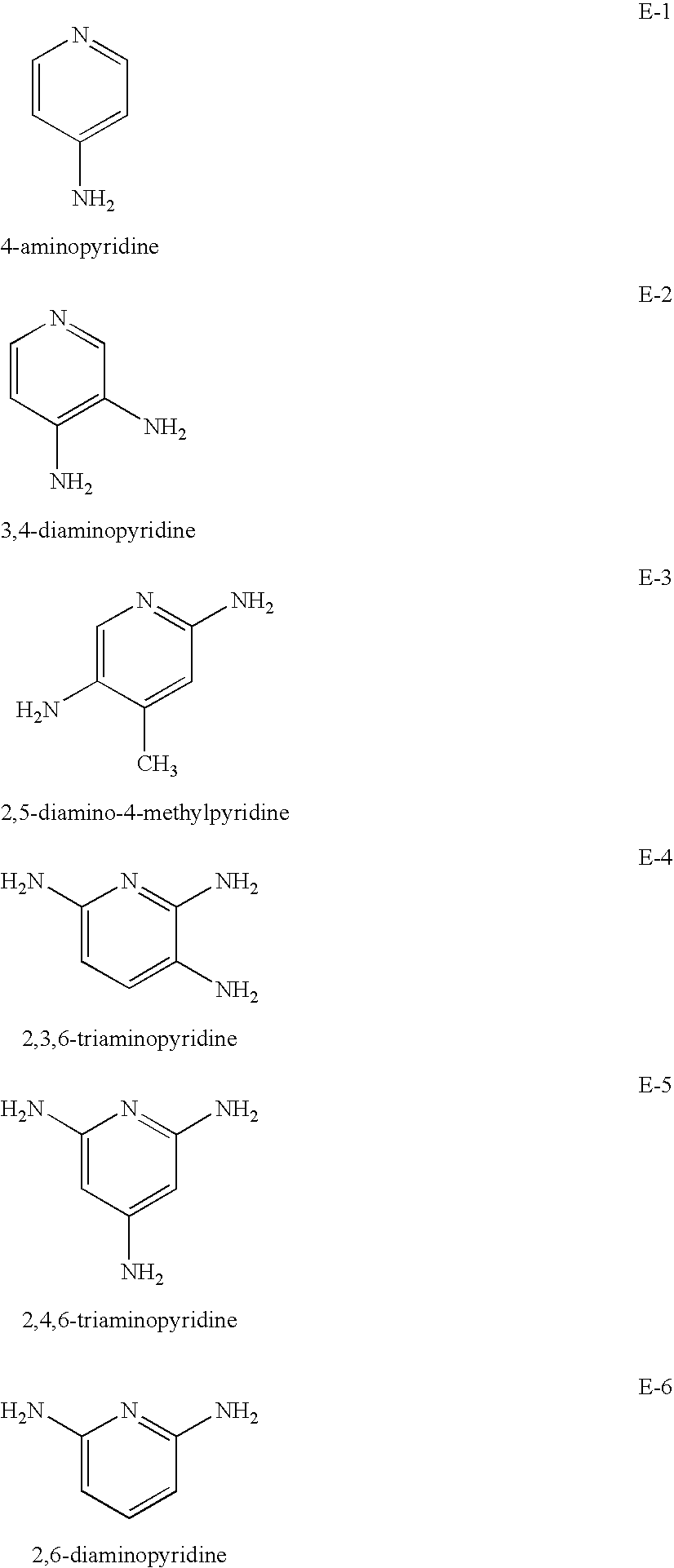

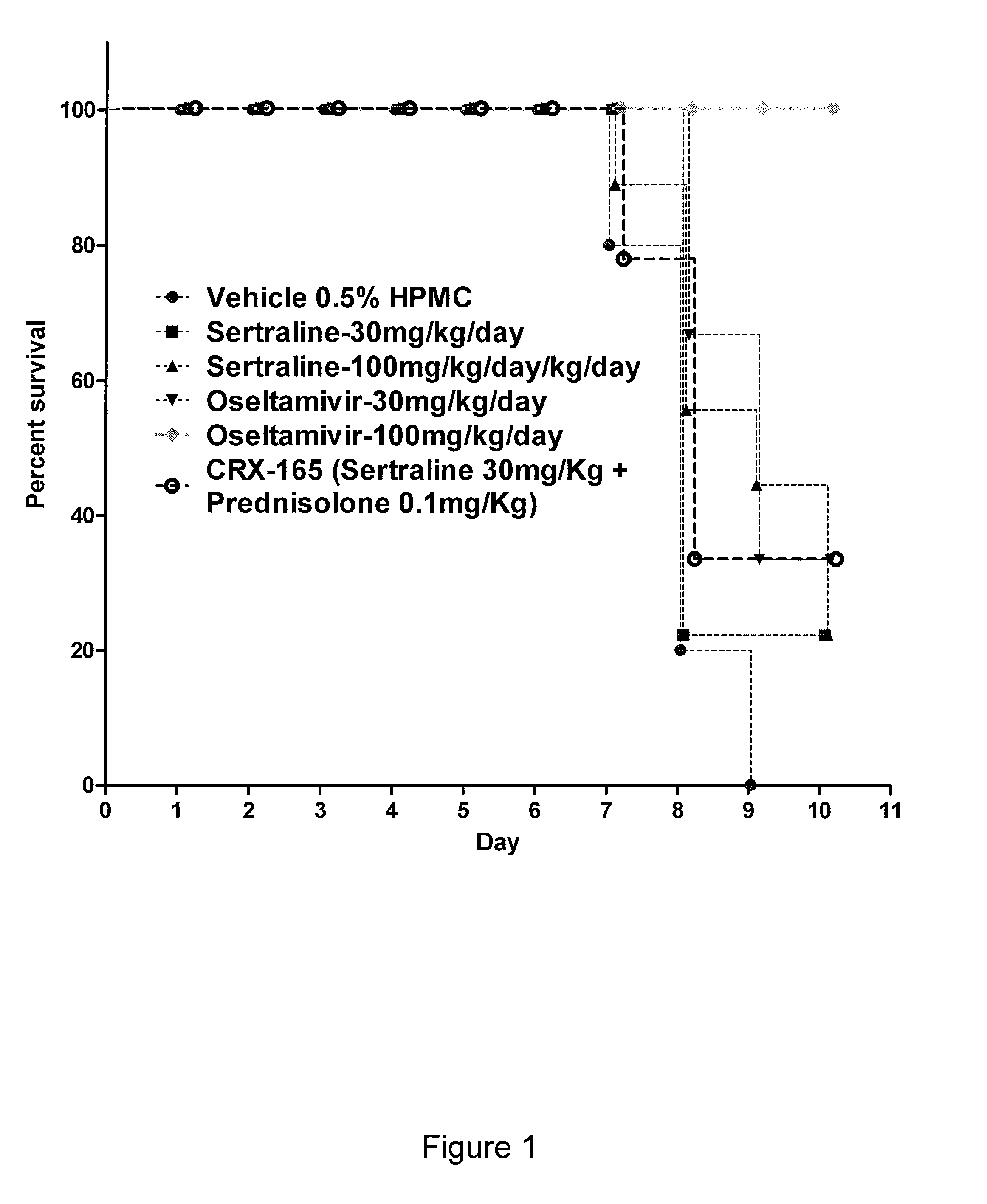

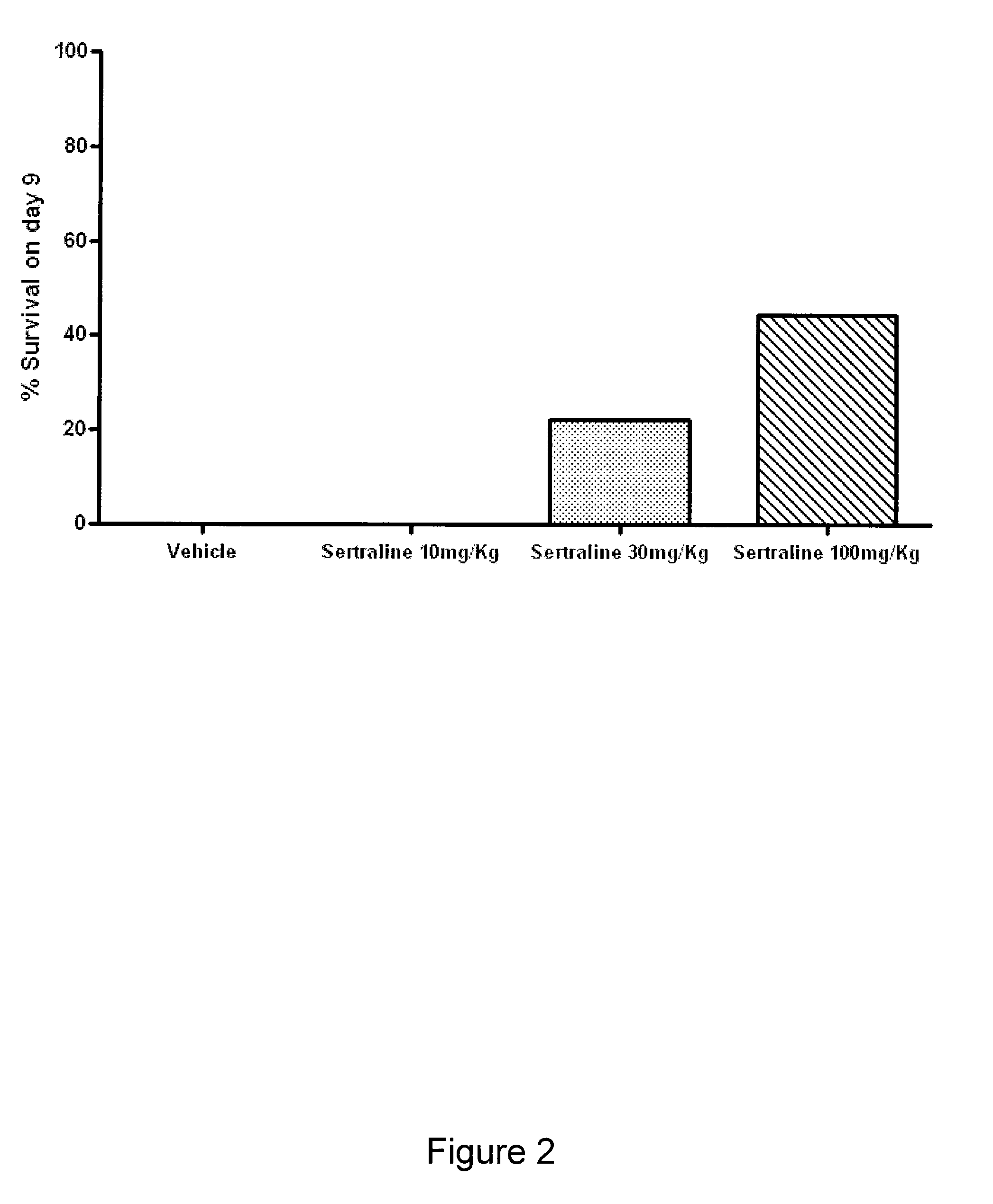

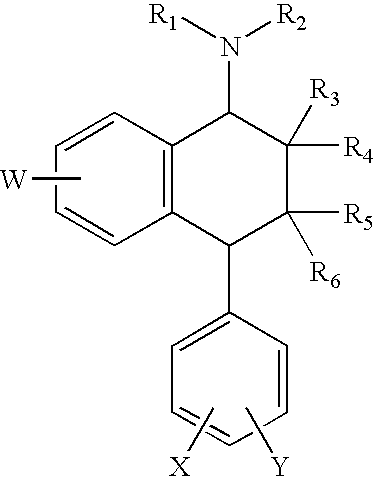

The present invention features compositions, methods, and kits useful in the treatment of viral diseases. In certain embodiments, the viral disease is caused by a single stranded RNA virus, a flaviviridae virus, or a hepatic virus. In particular embodiments, the viral disease is viral hepatitis (e.g., hepatitis A, hepatitis B, hepatitis C, hepatitis D, hepatitis E). Also featured are screening methods for identification of novel compounds that may be used to treat a viral disease.

Owner:EXCRX SINGAPORE PTE +1

Compositions and methods for treatment of viral diseases

InactiveUS20100009970A1Slow and stop replicationReduce loadBiocideNervous disorderSingle-Stranded RNADisease

The present invention features compositions, methods, and kits useful in the treatment of viral diseases. In certain embodiments, the viral disease is caused by a single stranded RNA virus, a flaviviridae virus, or a hepatic virus. In particular embodiments, the viral disease is viral hepatitis (e.g., hepatitis A, hepatitis B, hepatitis C, hepatitis D, hepatitis E) and the agent or combination of agents includes sertraline, a sertraline analog, UK-416244, or a UK-416244 analog. Also featured are screening methods for identification of novel compounds that may be used to treat a viral disease.

Owner:EXCRX SINGAPORE PTE +1

Multi-Solution Bone Cements and Methods of Making the Same

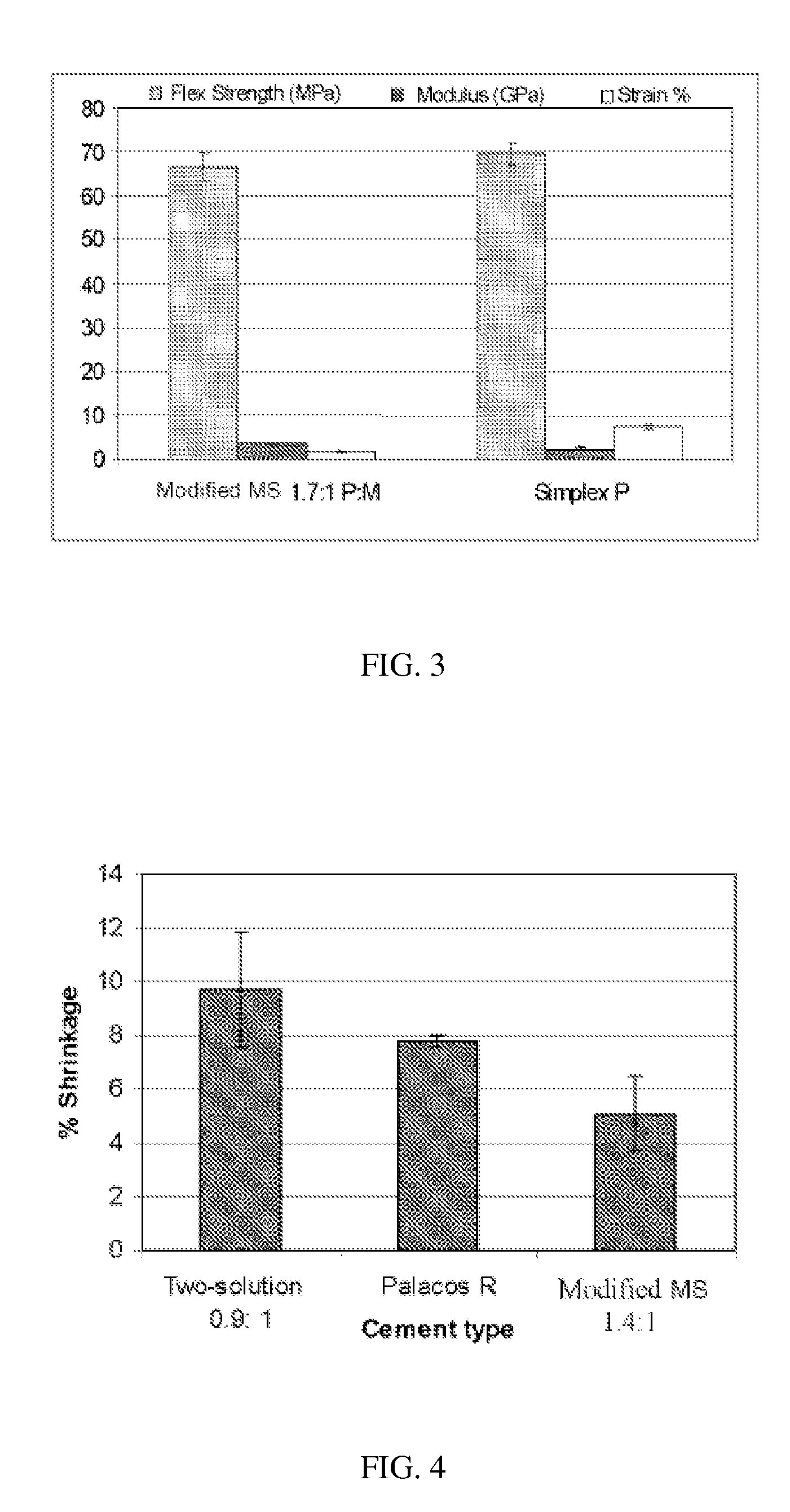

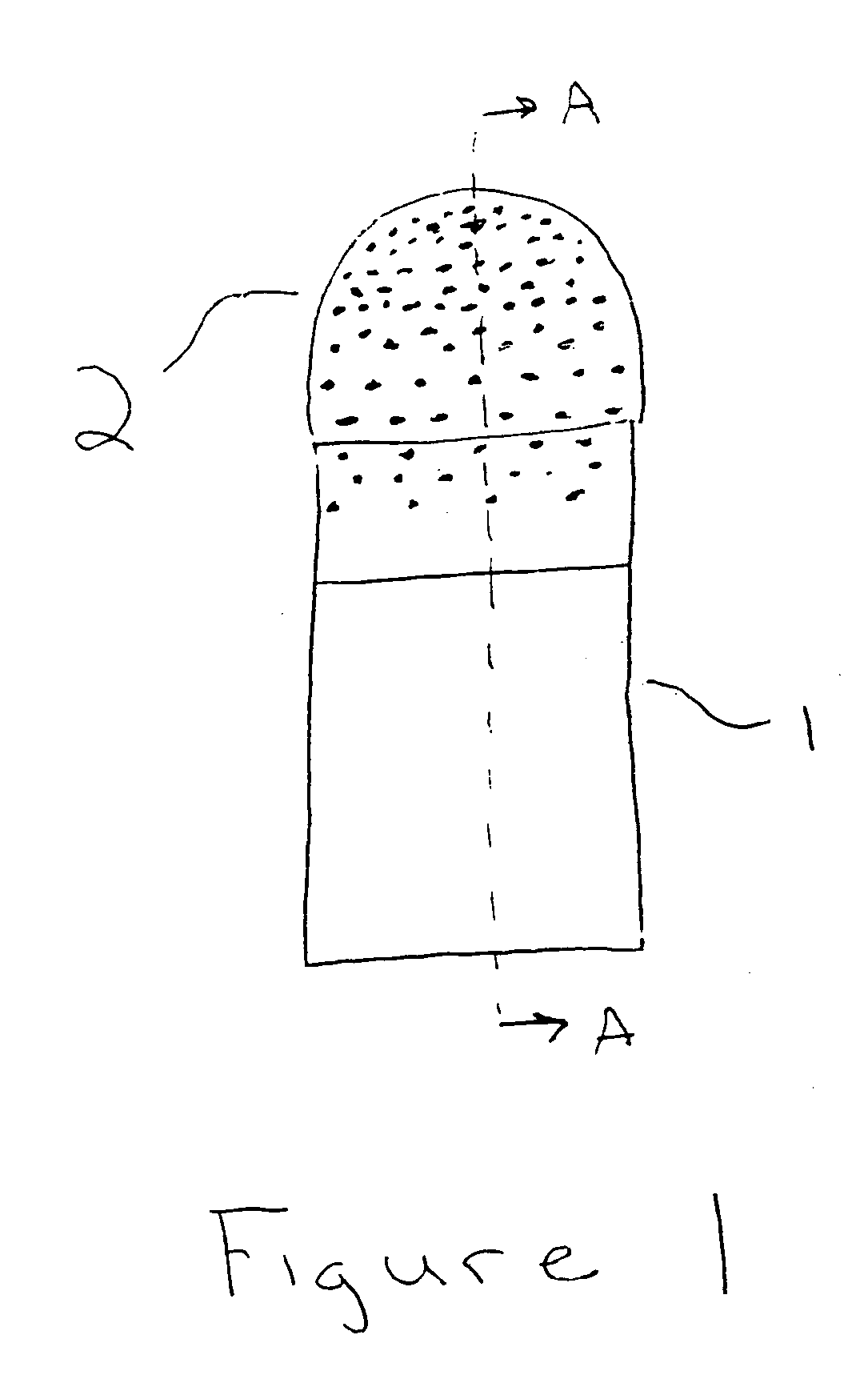

InactiveUS20080039586A1Improve mechanical propertiesAdvantageous for clinical performanceCosmetic preparationsImpression capsDouble bondMonomer

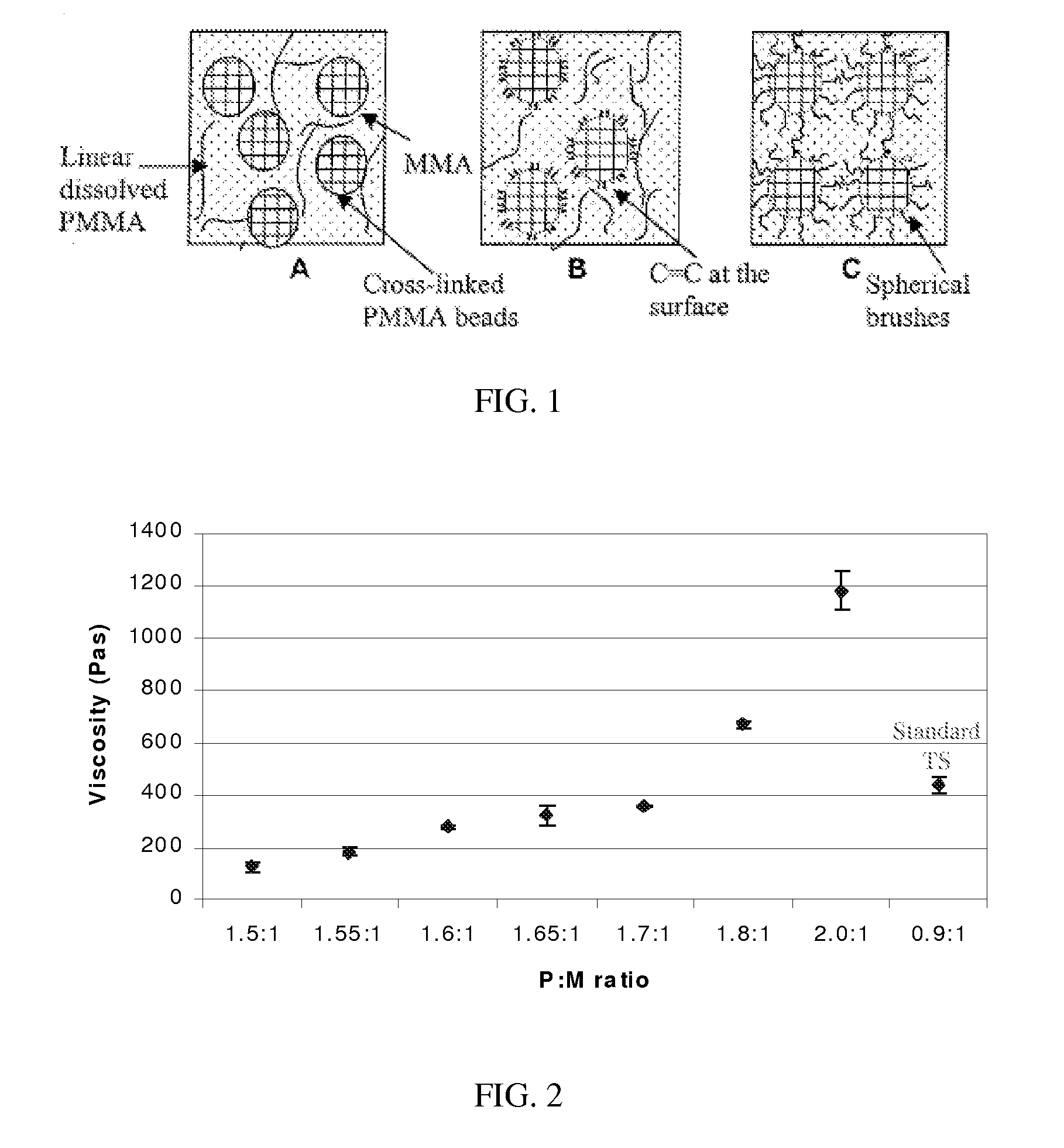

The present invention relates to bone cements and, more particularly, to multi-solution bone cements and methods for making the same. An embodiment of the present invention provides multi-solution bone cements which include cross-linked PMMA beads, thereby providing for a significant increase in the polymer-to-monomer (P:M) ratio. Another embodiment of the present invention provides cross-linked PMMA beads which are surface modified with unsaturated carbon double bonds. A further embodiment of the present invention provides multi-solution bone cements made with PMMA-PMMA spherical brush polymers.

Owner:SYRACUSE UNIVERSITY

Adhesive applicator tip with a polymerization initiator, polymerization rate modifier, and/or bioactive material

InactiveUS20050196431A1Improve distributionReduce polymerization timeSurgical adhesivesMedical applicatorsMonomerPolymerization

An applicator tip for an applicator for applying a polymerizable monomeric adhesive composition can include a bioactive material, a flavorant, a polymerization initiator, and / or a polymerization rate modifier.

Owner:NARANG UPVAN +8

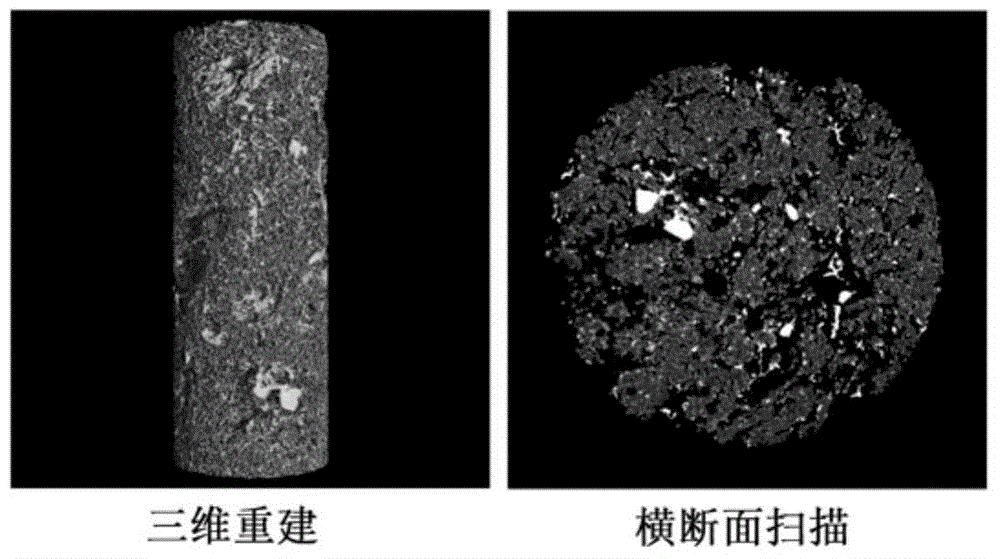

Injectable-porous-drug loaded polymethyl methacrylate-based composite scaffold bone transplant material and preparation method thereof

ActiveCN104906637AEasy to prepareGood biocompatibilityProsthesisReaction temperaturePolymethyl methacrylate

The present invention discloses an injectable-porous-drug loaded polymethyl methacrylate-based composite scaffold bone transplant material and a preparation method thereof, and belongs to the field of organic functional materials preparation. The polymethyl methacrylate-based composite scaffold bone transplant material uses polymethyl methacrylate (PMMA) as a scaffold for providing mechanical supporting, and a chitosan-based thermosensitive hydrogel as a pore forming agent and an osteoconductive material and a drug carrier, and the polymethyl methacrylate (PMMA) and the chitosan-based thermosensitive hydrogel are mixed with each other to form an injectable-porous three-dimensional structural bone cement composite. The scaffold bone transplant material is simple in preparation method, suitable in reaction temperature, and good in biocompatibility, has matched mechanical properties, good biological mineralization and corresponding anti-bacterial, anti-inflammatory or anti-tumor capabilities, and has broad prospects in clinical application of reconstruction of bone tissues in future.

Owner:WUHAN UNIV

Methods for forming amorphous ultra-high molecular weight polyolefins for use as drag reducing agents

InactiveUS6730750B2Low costReduce polymerizationHydrocarbon by isomerisationCatalystsPolyolefinLiquid hydrocarbons

The present invention is directed to improved drag reducing agents and methods of forming improved drag reducing agents comprising the steps of isomerizing olefin monomers to form isomerized olefin monomers, polymerizing the isomerized olefin monomers in the presence of at least one catalyst to form a polyolefin drag reducing agent having unexpectedly superior drag reduction properties when combined with liquid hydrocarbons, such as viscous crude oil. Therefore, the drag reducing agents of the present invention may be introduced into conduits, such as pipelines, to increase the flow of the hydrocarbons through the conduit.

Owner:CMC MATERIALS INC

Selective hydrosilylation method using hydrido (hydrocarbonoxy) silane

InactiveUS6048994AReduce polymerizationStrong position selectivitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrosilylationSilanes

A method for hydrosilylating a vinyl-substituted aromatic compound comprising reacting a hydrido (hydrocarbonoxy)silane compound with the vinyl-substituted aromatic compound in the presence of a platinum or platinum compound catalyst and a carboxylic acid. The presence of the carboxylic acid increases the positional selectivity of addition in the hydrosilylation reaction and reduces the polymerization of vinyl groups even in the case of a high-temperature or long-term hydrosilylation reaction.

Owner:DOW CORNING ASIA

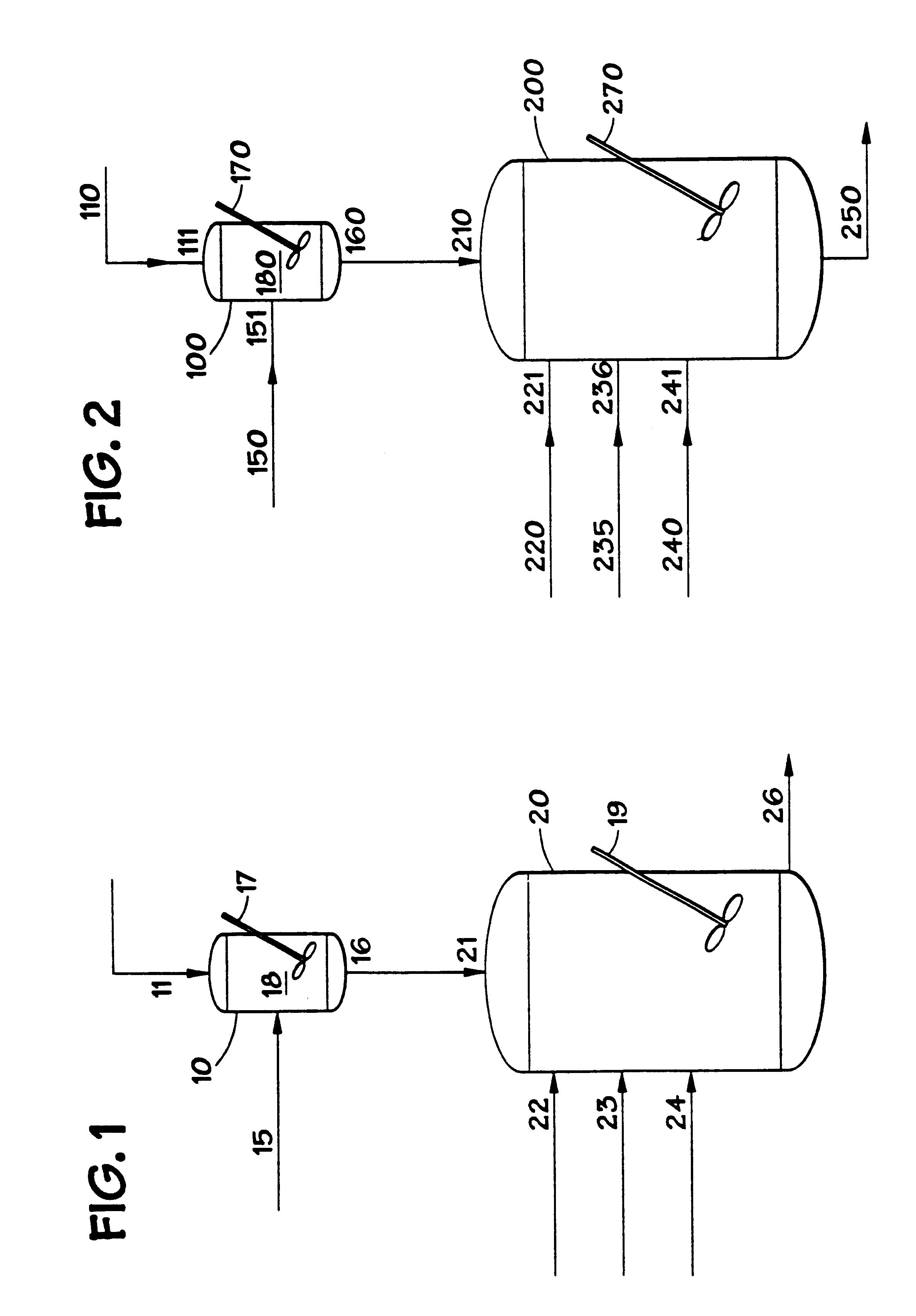

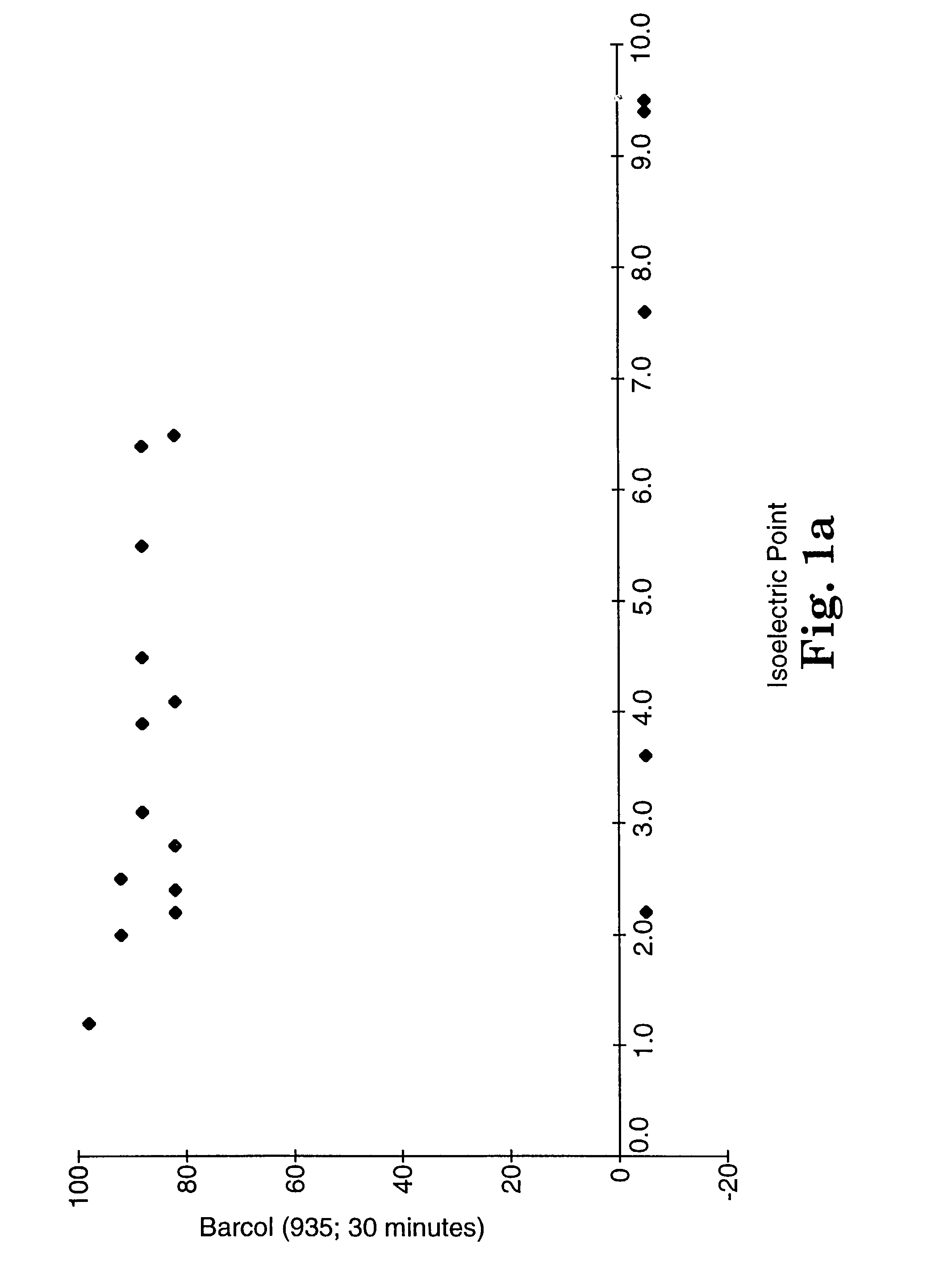

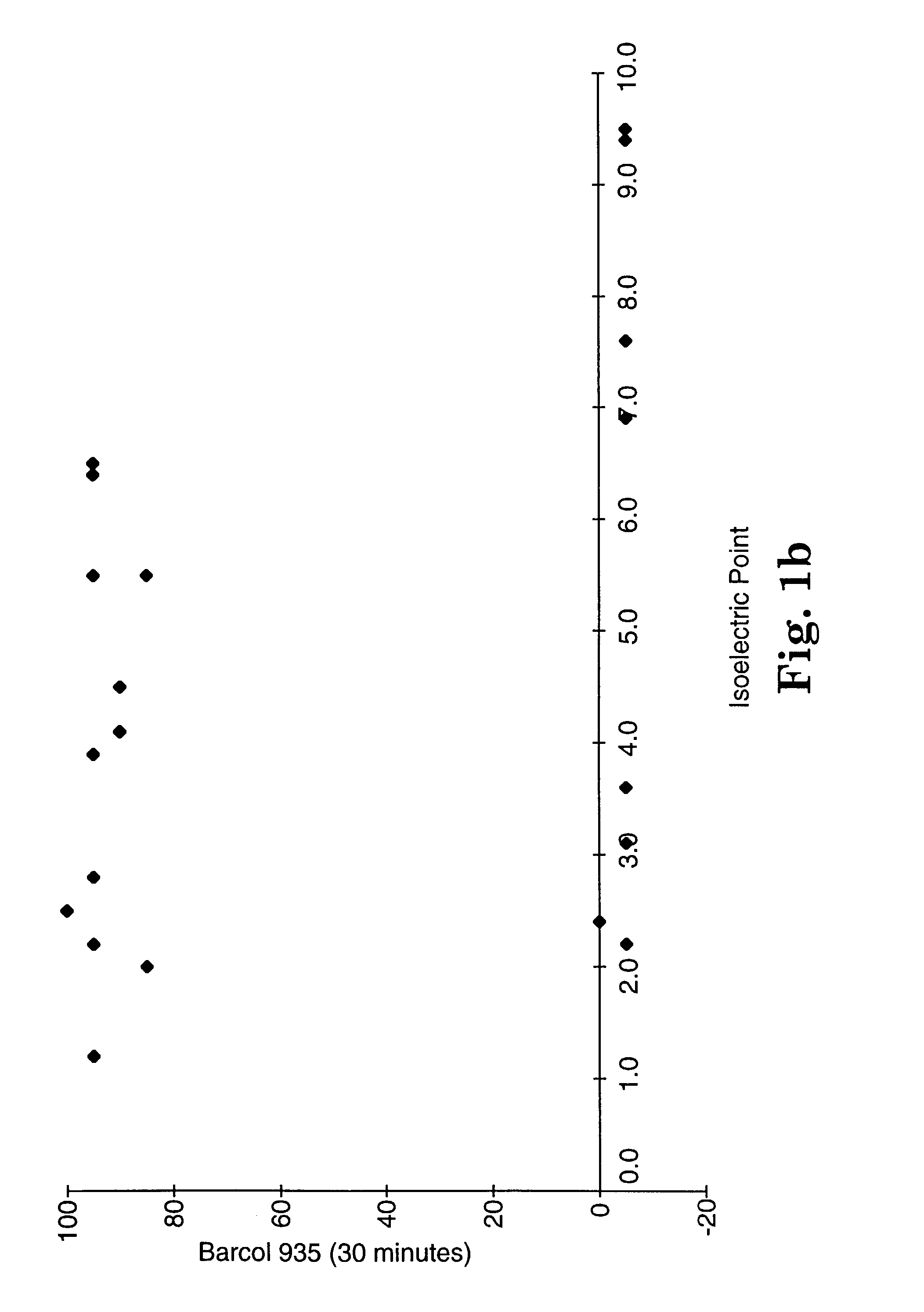

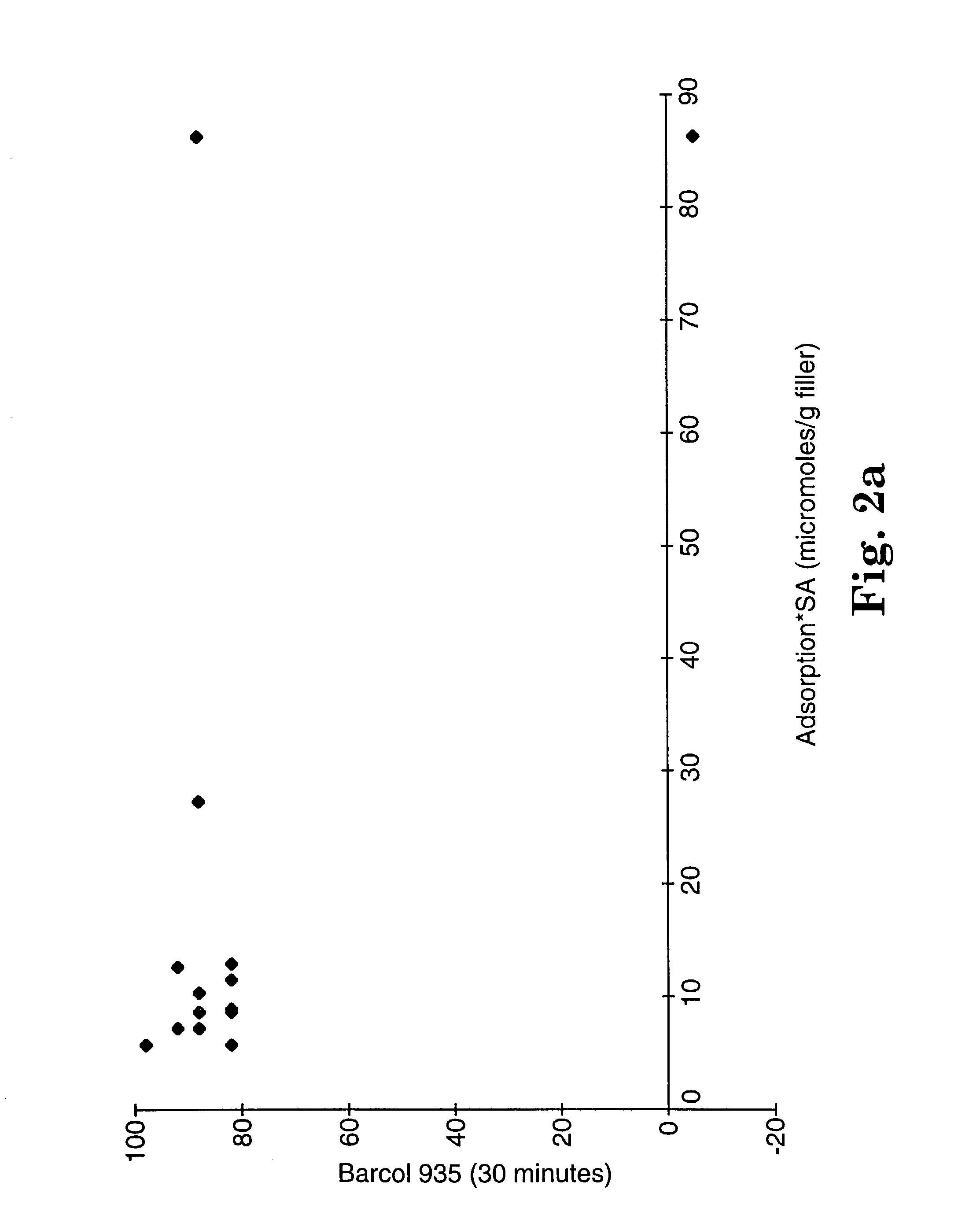

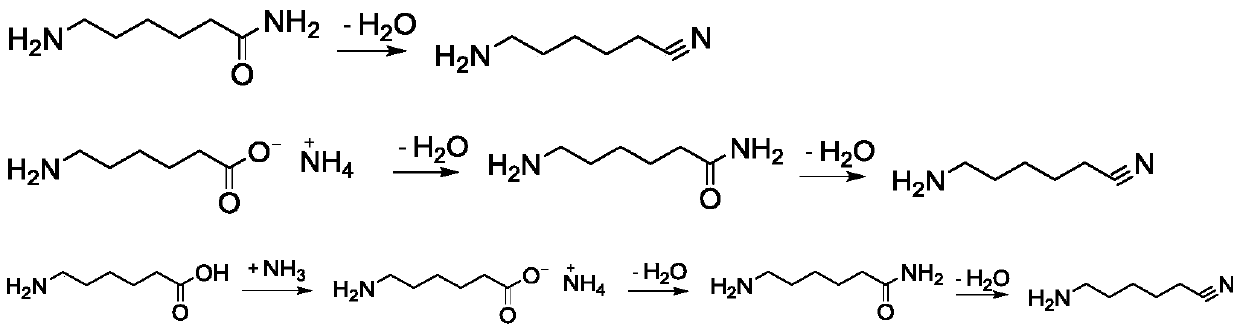

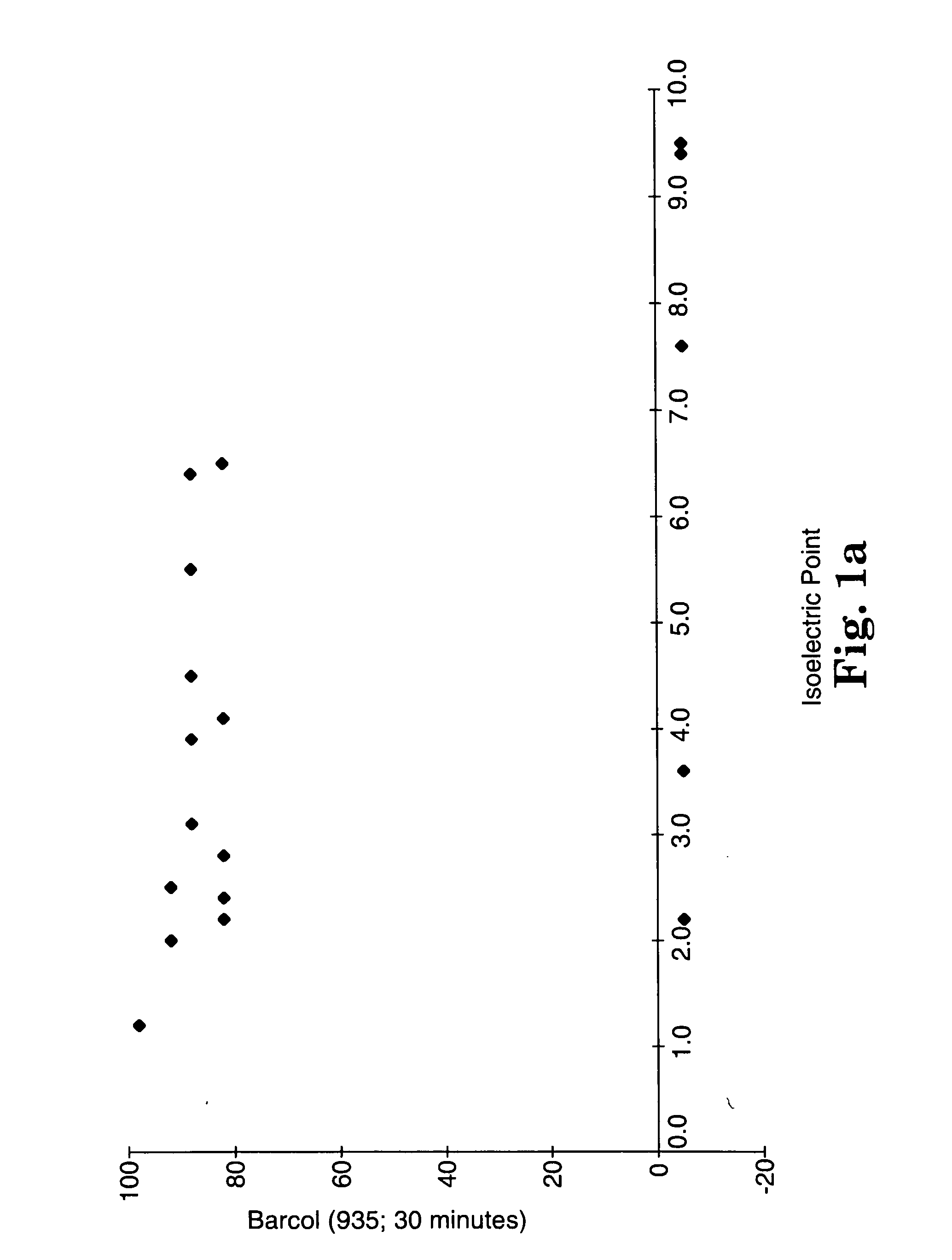

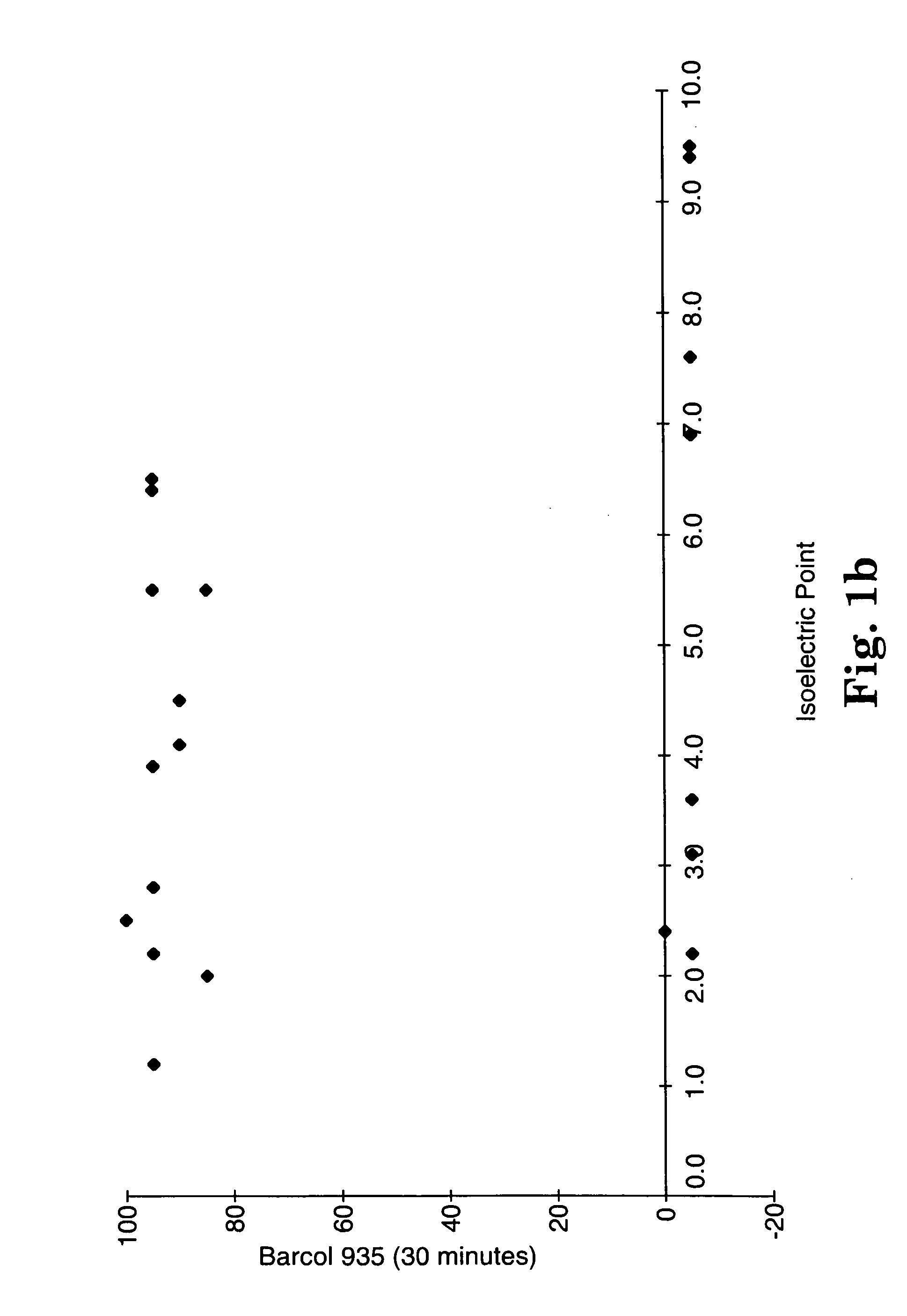

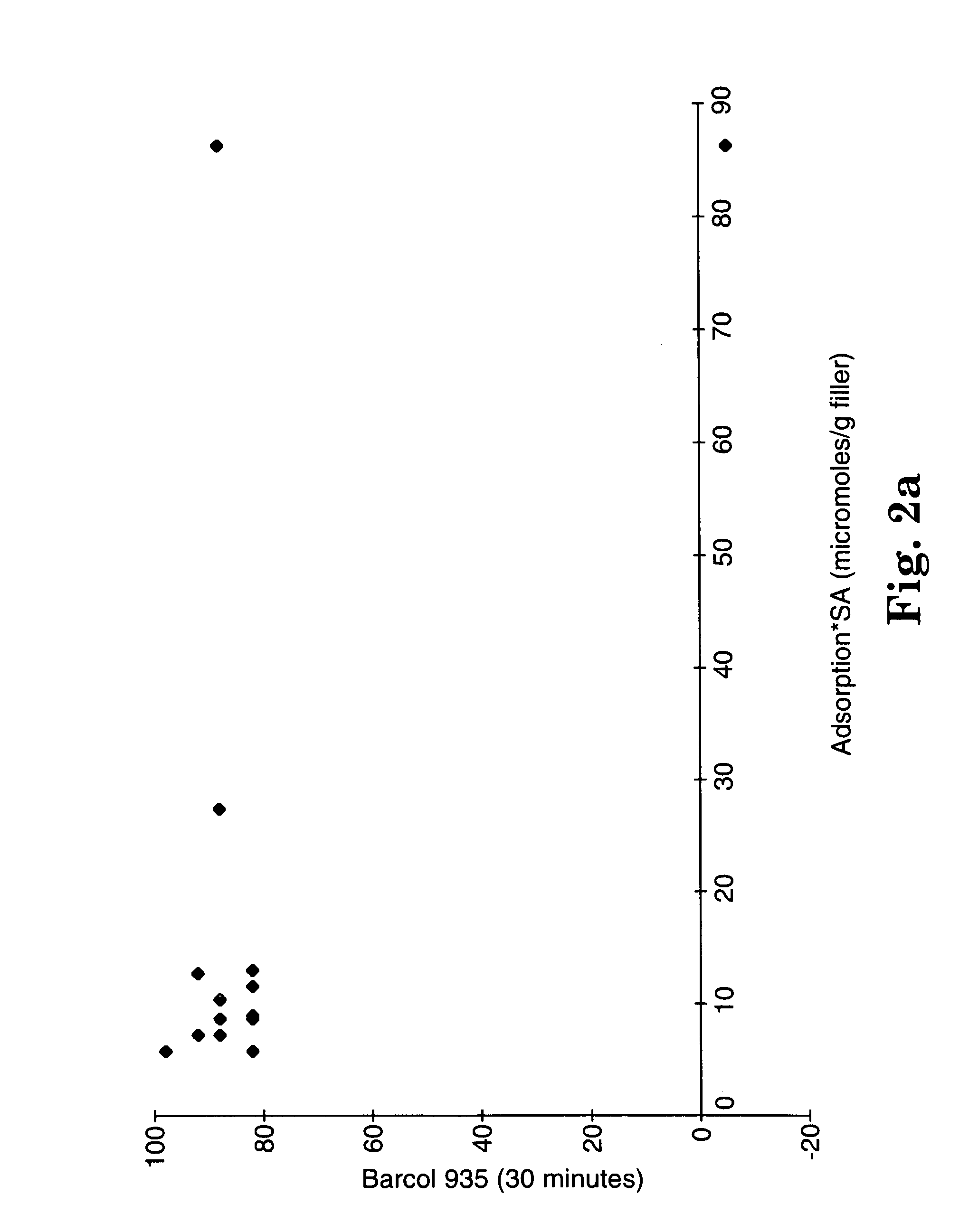

Radiopaque cationically polymerizable compositions comprising a radiopacifying filler, and method for polymerizing same

InactiveUS7030049B2Improve abilitiesReduce opacityCosmetic preparationsPigmenting treatmentCationic polymerizationReaction temperature

Polymerizable compositions that include: (a) a cationically active functional group; (b) an initiation system capable of initiating cationic polymerization of the cationically active functional group; and (c) a filler composition that includes various radiopacifying fillers in an amount sufficient to render the polymerizable composition radiopaque. Components (a), (b), and (c) are selected such that the polymerizable composition polymerizes to form a polymerized composition having a Barcol hardness, measured using a GYZJ-935 meter, of at least 10 within 30 minutes following initiation of the cationically active functional group at a reaction temperature of 25° C.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of nickel-molybdenum clad layer

The invention discloses a preparation method of a nickel-molybdenum clad layer. The method comprises the following steps of: dissolving heteropolymolybdate, fluoride, a complexing agent and chloride into water, and regulating the pH value of a solution with sodium carbonate to obtain a plating solution containing the heteropolymolybdate, fluoride, complexing agent and chloride of the pH value 3-6; and putting a pretreated plating piece to be plated serving as a cathode and a nickel plate serving as an anode into the plating solution containing the heteropolymolybdate, fluoride, complexing agent and chloride of the pH value 3-6 for plating, flushing the plating piece with water, and drying in the air to obtain a plating piece which contains a nickel-molybdenum clad layer on the surface. The hardness of the finally-obtained nickel-molybdenum clad layer is increased remarkably, the thermal expansion coefficient falls, the final hardness is 550-600 HV, and the thermal expansion coefficient is 13*10<-6>-5.2*10<-6> K<-1>.

Owner:SHANGHAI INST OF TECH

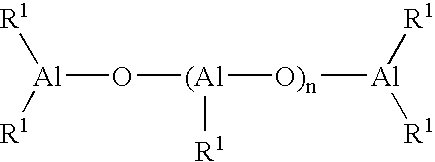

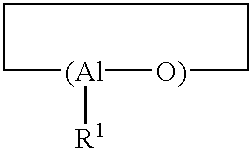

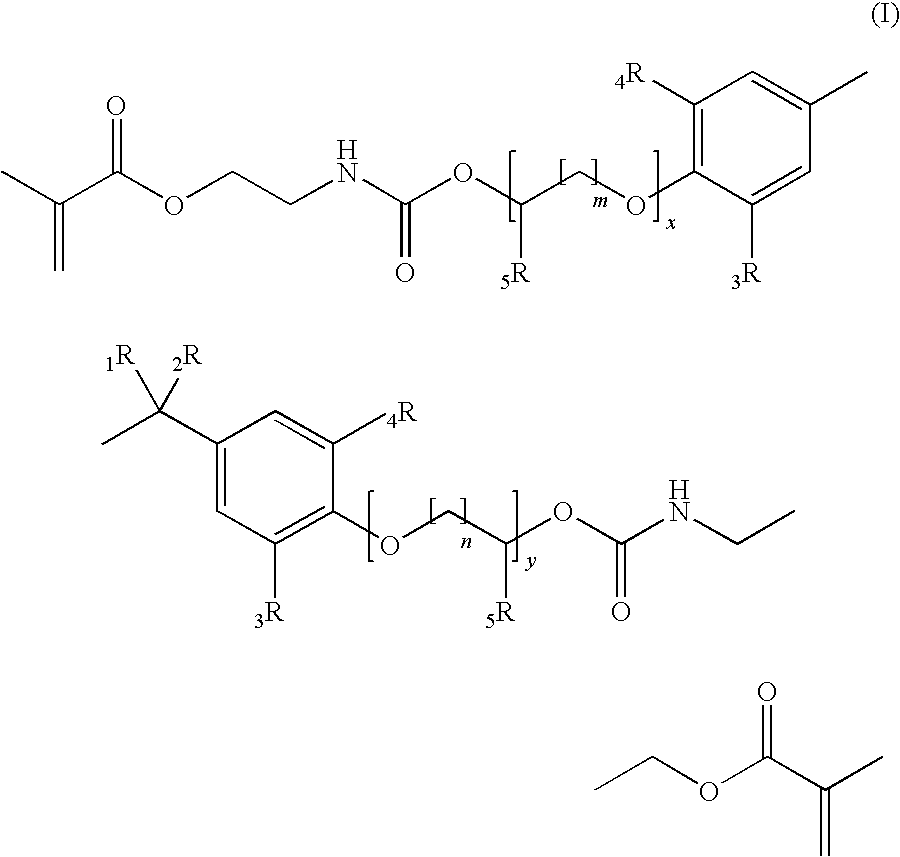

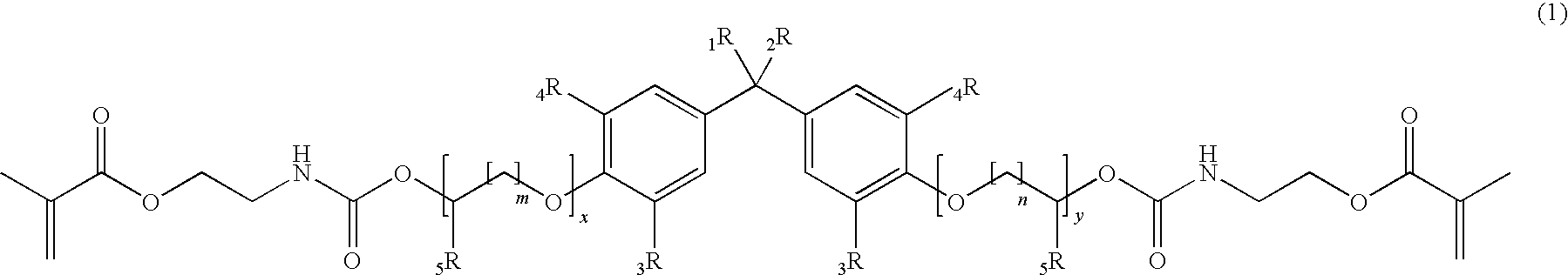

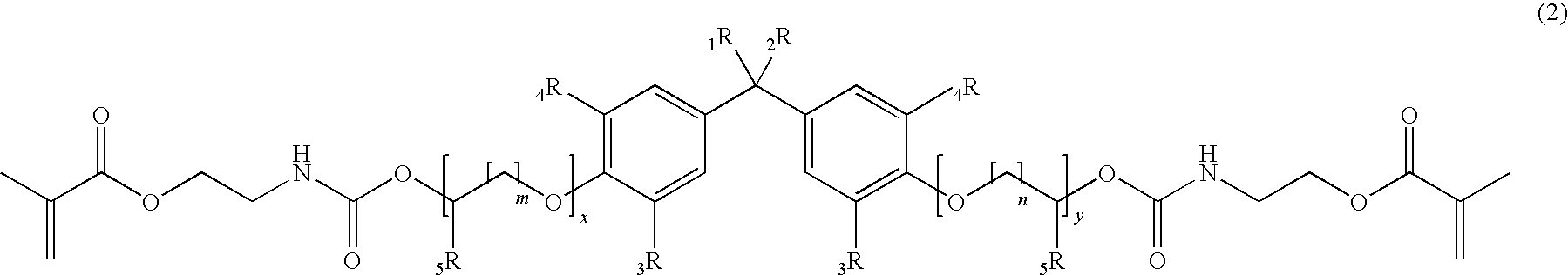

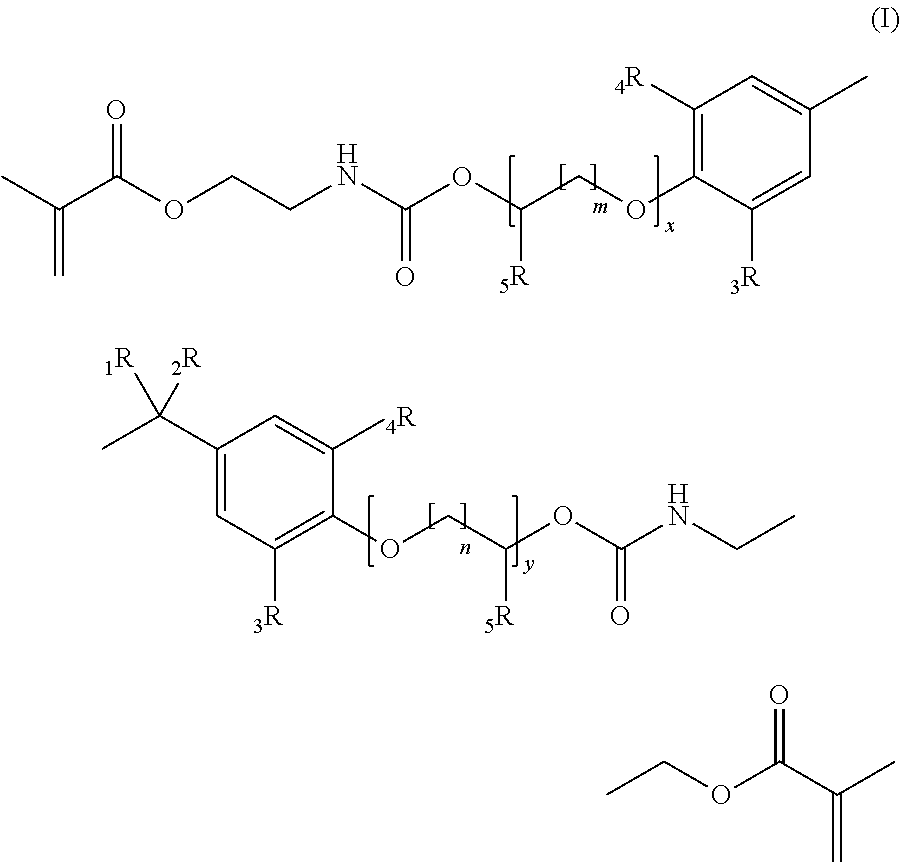

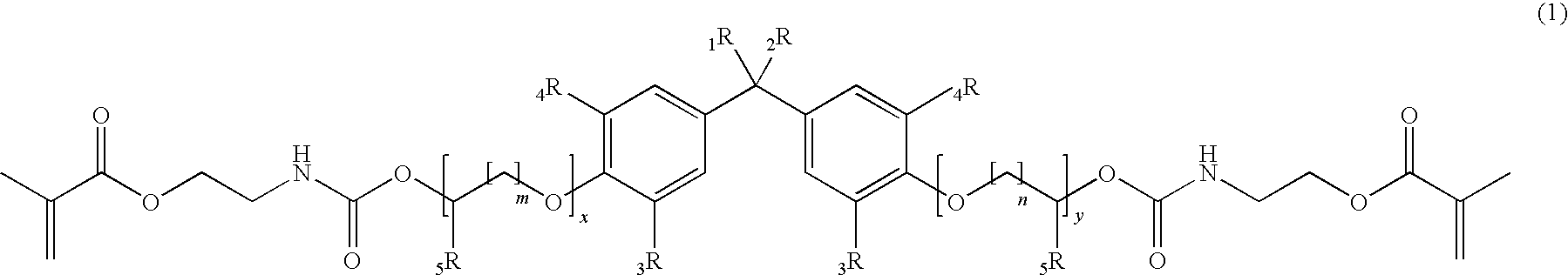

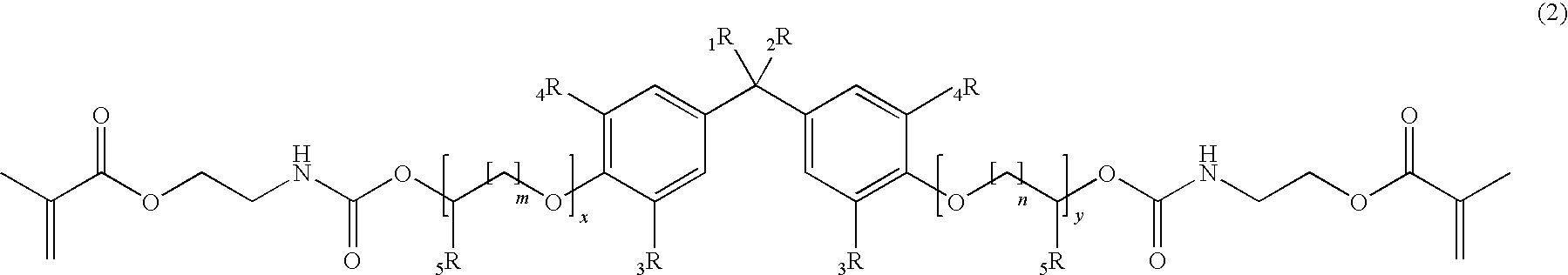

Methacrylate based monomers containing a urethane linkage, process for production and use thereof

ActiveUS20100197824A1Well-balanced propertyReduce polymerizationCosmetic preparationsImpression capsMethacrylatePhenyl group

The invention relates to a dental composition comprising a monomer or mixture of monomers represented by the following structure(1) with 1,2R independently selected from H, alkyl (e.g. CH3C2H5), and Phenyl, 3,4R independently selected from H, alkyl (e.g. CH3), and halogen (Cl, Br, F), 5R independently selected from H, alkyl (e.g. CH3), m, n=1, 2 and x+y=2 to 10, with the proviso that if m=n=2, than x+y=2 and if m=n=1, than x+y=4 to 10. The invention also relates to a process for producing the monomer or mixture of monomers and the use thereof especially as dental composition.

Owner:3M INNOVATIVE PROPERTIES CO

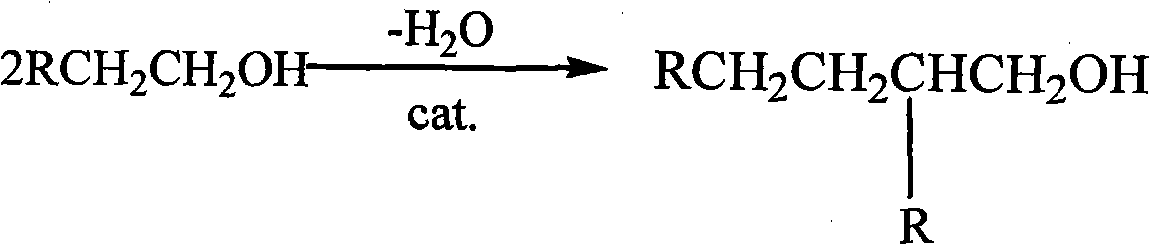

Preparation method of guerbet alcohol

ActiveCN102020533AHigh yieldReduce PolymerizationOrganic compound preparationHydroxy compound preparationMetalloleAlcohol

The invention discloses a preparation method of guerbet alcohol. In this method, nano-scale metal oxides are taken as catalysts, strong alkaline substances are taken as cocatalysts, and fatty alcohol is catalyzed and condensed with one water molecule removed at nitrogen atmosphere to obtain the guerbet alcohol. The invention is characterized in that the reaction time is short, the highest yield is up to 92%, the product purity is greater than 96%, and the product selectivity is high (the content of trimers in product is less than 2.5%).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

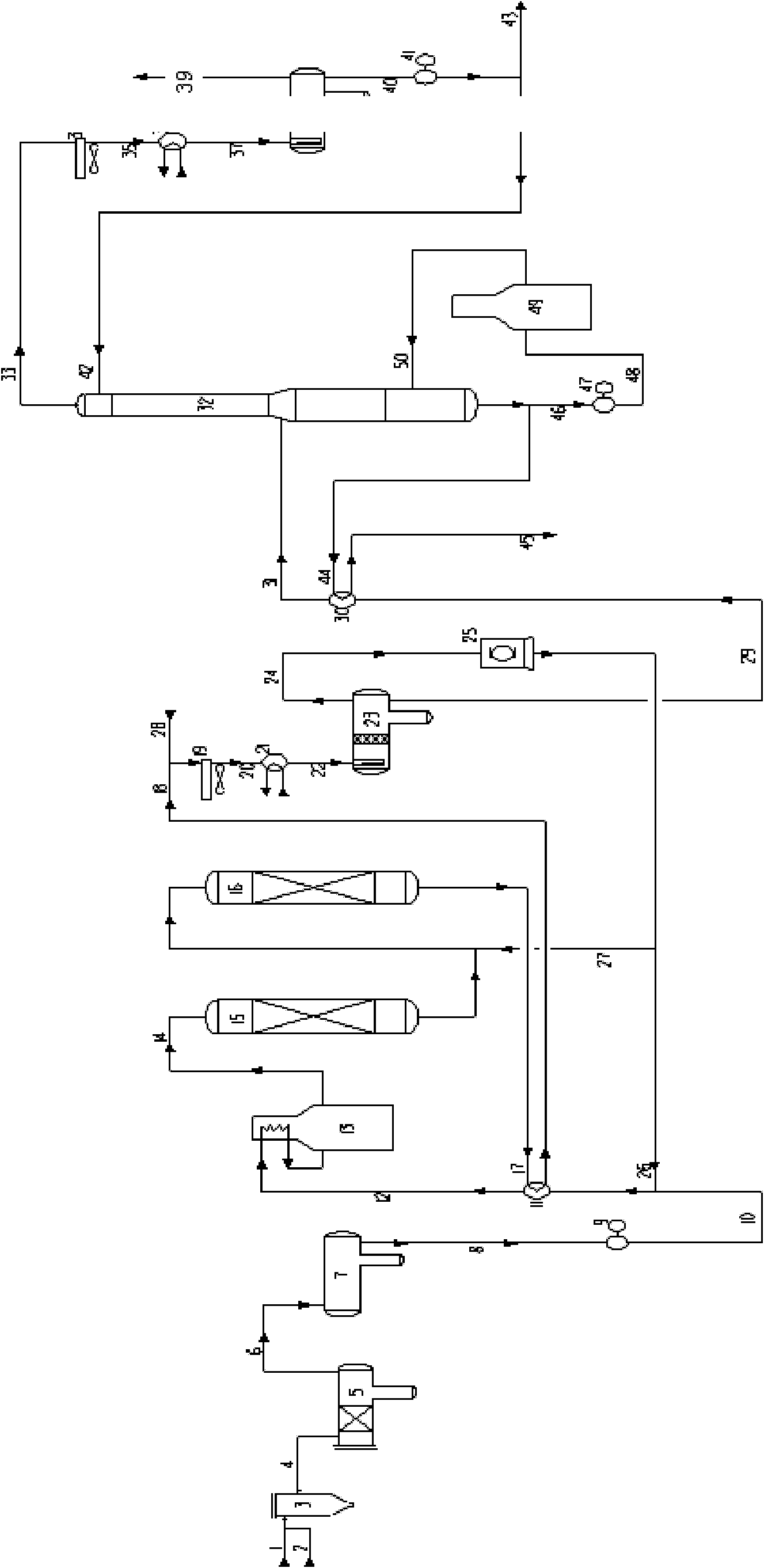

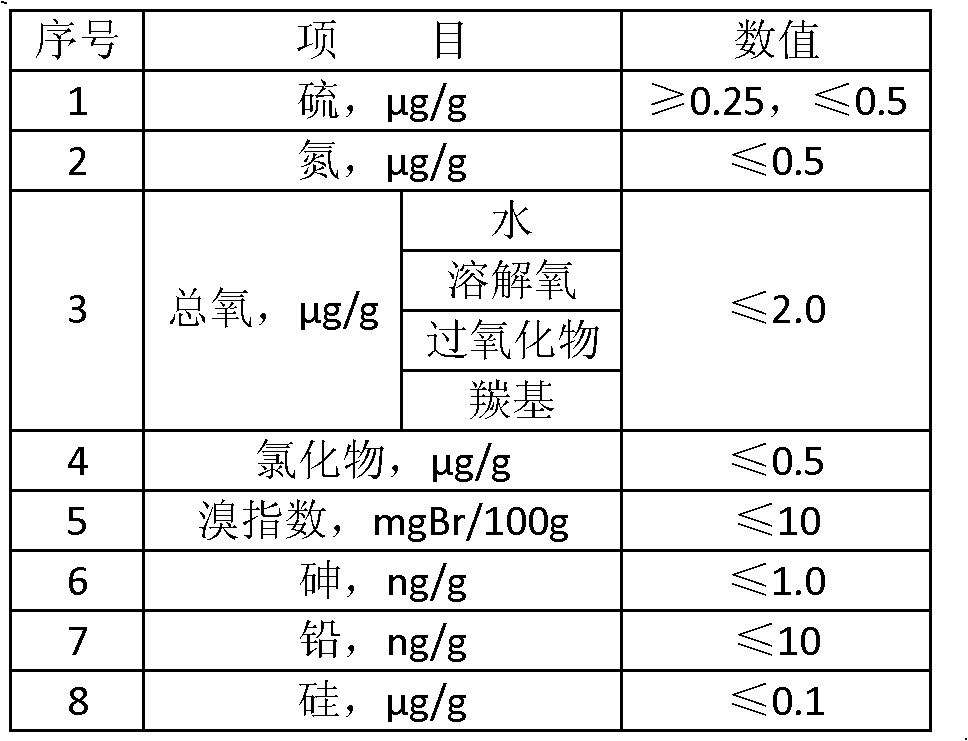

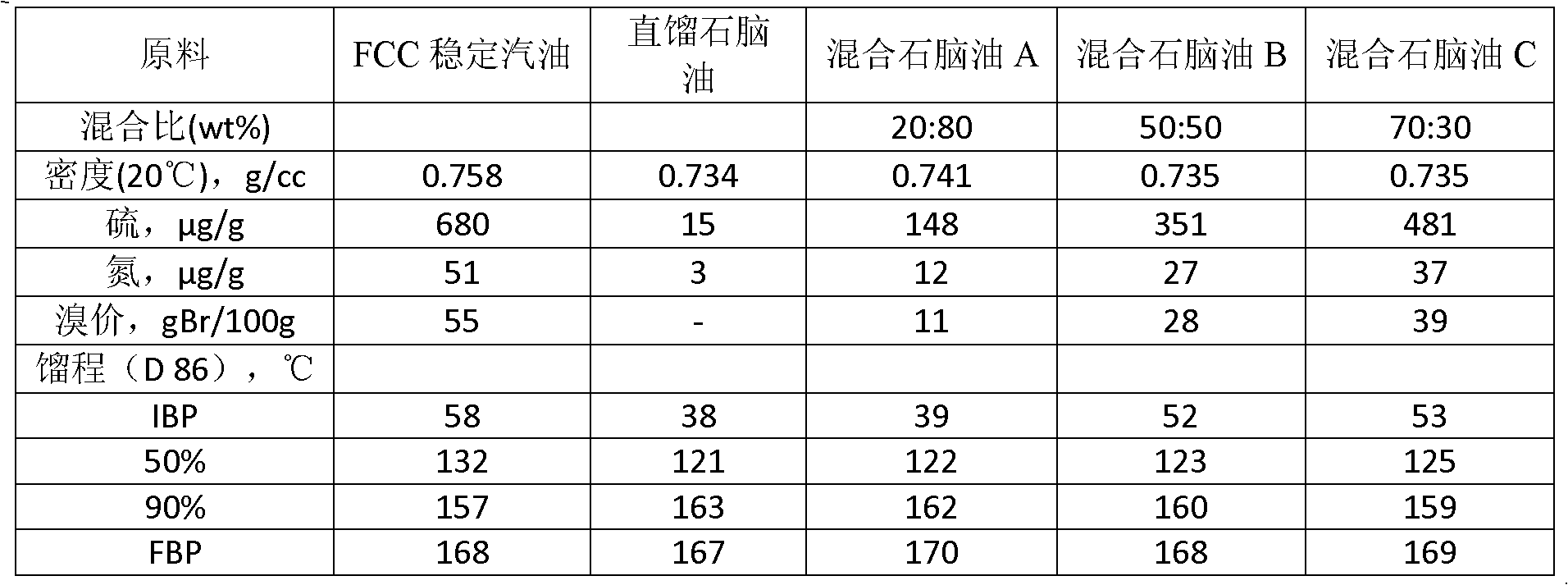

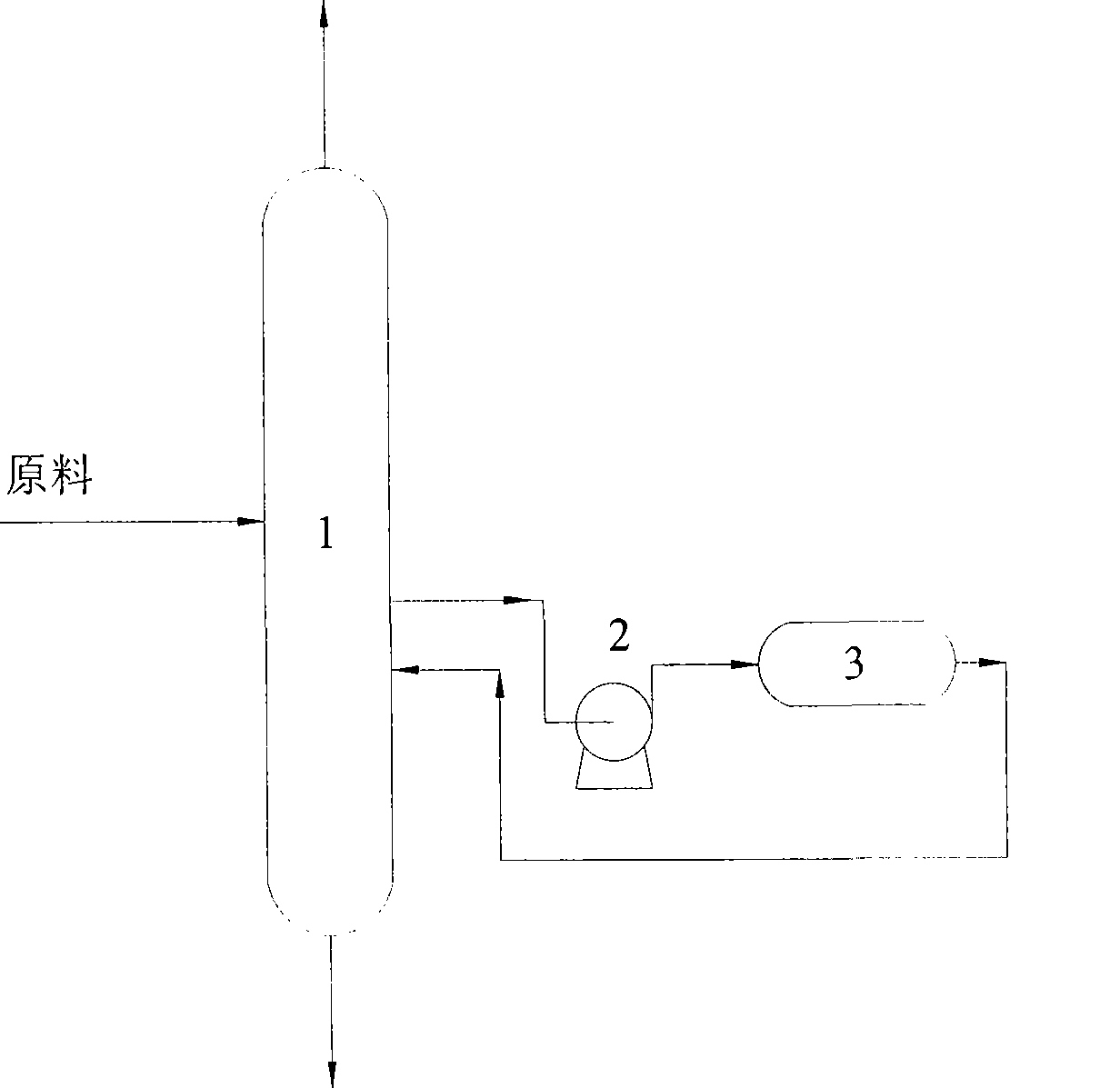

Method for widening catalytic reforming feedstock

ActiveCN102041092AExpand sourceSlow down olefin polymerizationTreatment with hydrotreatment processesChemistryNaphtha

The invention relates to method for widening catalytic reforming feedstock. The comprises the following steps: mixing FCC (fluid catalytic cracking) stabilized gasoline and straight-run naphtha in a ratio of (50:50) to (70:30), filtering the obtained mixture by a feedstock filter so as to remove impurities in the mixture, and then removing the water carried in the mixed naphtha by a coalescer; mixing the mixed naphtha with hydrogen, and heating the obtained mixture to a reaction temperature by a heating furnace, then feeding the obtained mixture into a hydrogenation reactor to contact with a hydrogenation catalyst so as to be subject to olefin saturation, desulphurization and denitrification reactions; and condensating and cooling the obtained hydrogenation effluent, then separating the obtained product so as to obtain hydrogen-rich gas and hydrogenated gasoline, recycling the hydrogen-rich gas, and feeding the hydrogenated gasoline into an evaporation tower to be subject to strippingfractionation, thereby obtaining a refined naphtha meeting the reforming feeding requirements. By utilizing the method provided by the invention, the mixed naphtha containing more than 50 percent of the FCC stabilized gasoline can be subject to hydroprocessing so as to obtain the refined naphtha, wherein the content of the impurities in the refined naphtha satisfies the reforming feeding requirements, thereby solving the shortage problem of the reforming feedstock, and widening the source of the reforming feedstock.

Owner:PETROCHINA CO LTD +1

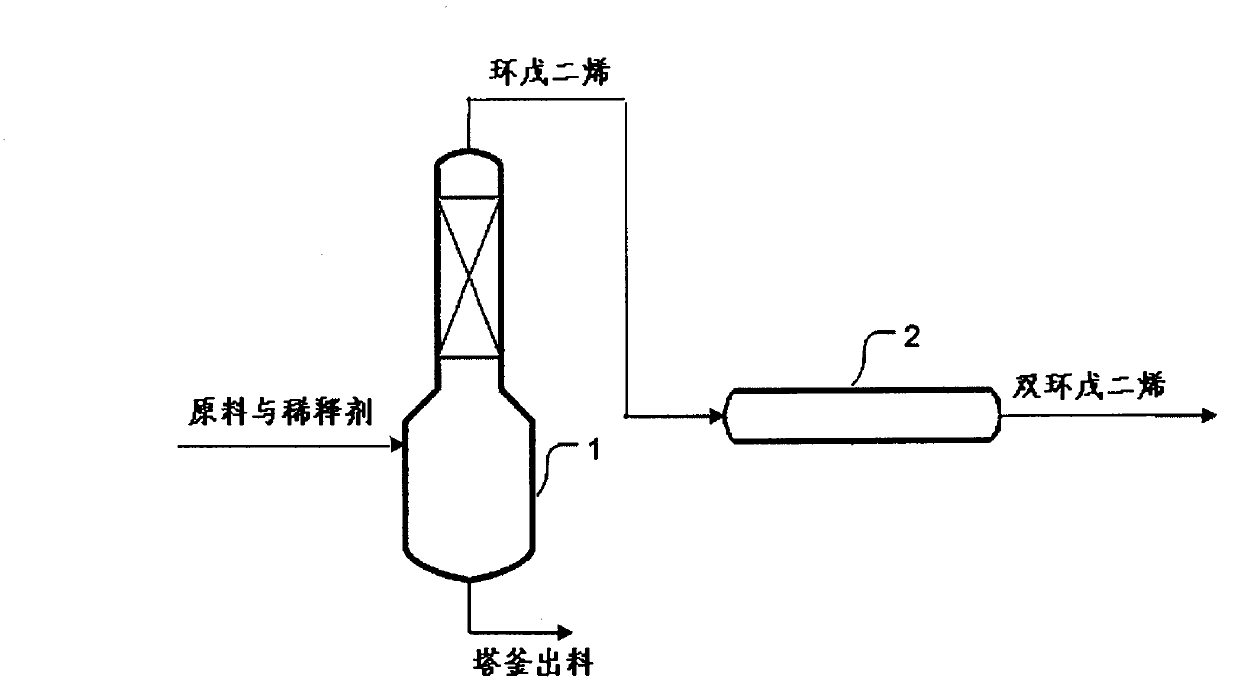

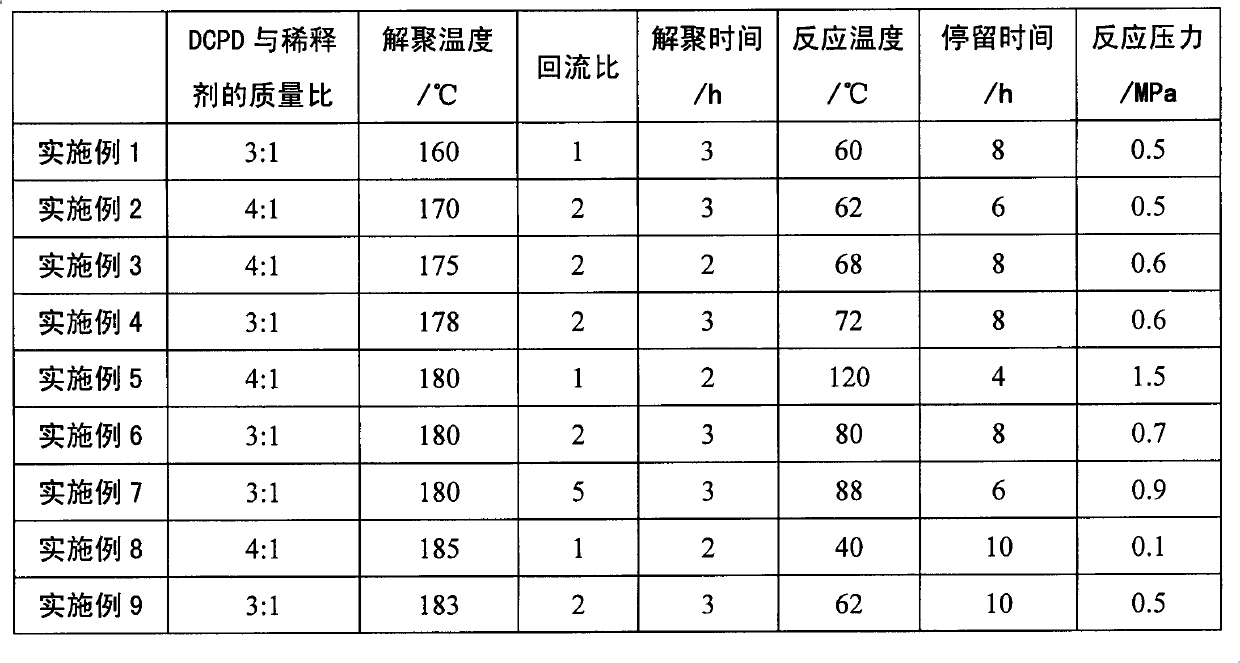

Method for preparing high-purity dicyclopentadiene

InactiveCN103664472AIncreased degree of disaggregationReduce PolymerizationHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationNorbornenePyrolysis

The invention discloses a method for preparing high-purity dicyclopentadiene (DCPD). The method comprises the steps of adding a diluting agent into crude dicyclopentadiene serving as a raw material during depolymerization, mixing dicyclopentadiene with the diluting agent in a ratio of 0.5-5, and then putting the mixture into a depolymerization rectifying tower, wherein at a normal pressure, the depolymerization temperature is 160-200 DEG C, the reflux ratio is 0.5-5, and the depolymerization time is 1-3 hours; obtaining high-purity cyclopentadiene (CPD) from the top of the tower, putting the cyclopentadiene into a tubular reactor to finally obtain dicyclopentadiene of which the purity is more than 99%, wherein the reaction temperature is 40-120 DEG C, the reaction pressure is 0.1-1.5MPa, and the residence time is 4-10 hours. The method disclosed by the invention has obvious beneficial effects, can reduce polymerization reaction of the crude dicyclopentadiene during depolymerization, and can improve the yield of the dicyclopentadiene; meanwhile, the diluting agent can ensure that impurities including isopropenyl norbornene and the like can be depolymerized, and the purity of dicyclopentadiene is improved, so that the method is particularly suitable for preparing high-purity dicyclopentadiene from the raw material of crude dicyclopentadiene which is obtained through pyrolysis C5 thermal dimerization separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating and purifying nonane diacid

ActiveCN101250101AReduce lossesGuaranteed yieldCarboxylic preparation by ozone oxidationCarboxylic compound separation/purificationPurification methodsDecomposition

The invention discloses a separation purification method of azelaic acid, belonging to the separation purification technical field of organic compound, which comprises depressurizing and distilling the oxidation solution obtained by treating ozonation-oxidation decomposition on unsaturated fatty acid to remove solvent and pelargonic acid, transferring left oxidation solution to a film evaporator to be distilled to obtain crude azelaic acid, extracting and recrystallizing the crude azelaic acid to obtain azelaic acid crystal. In the recrystallization of azelaic acid, the low-carbon dibasic acid of C<4>-C<8> in azelaic acid is dissolved in cold water, to be discharged along with crystallization mother liquor, and the left azelaic acid in the recrystallization mother liquor is recovered by the film separator. The obtained azelaic acid is transferred to a rising film evaporator to be dried and dehydrated and the dehydrated azelaic acid is evaporated by film to obtain the azelaic acid. The whole process can confirm the yield of azelaic aicd and obtain high-quality azelaic acid, while the whole system is sealed and the process has better environmental compatibility.

Owner:SICHUAN SIPO CHEMICAL CO LTD

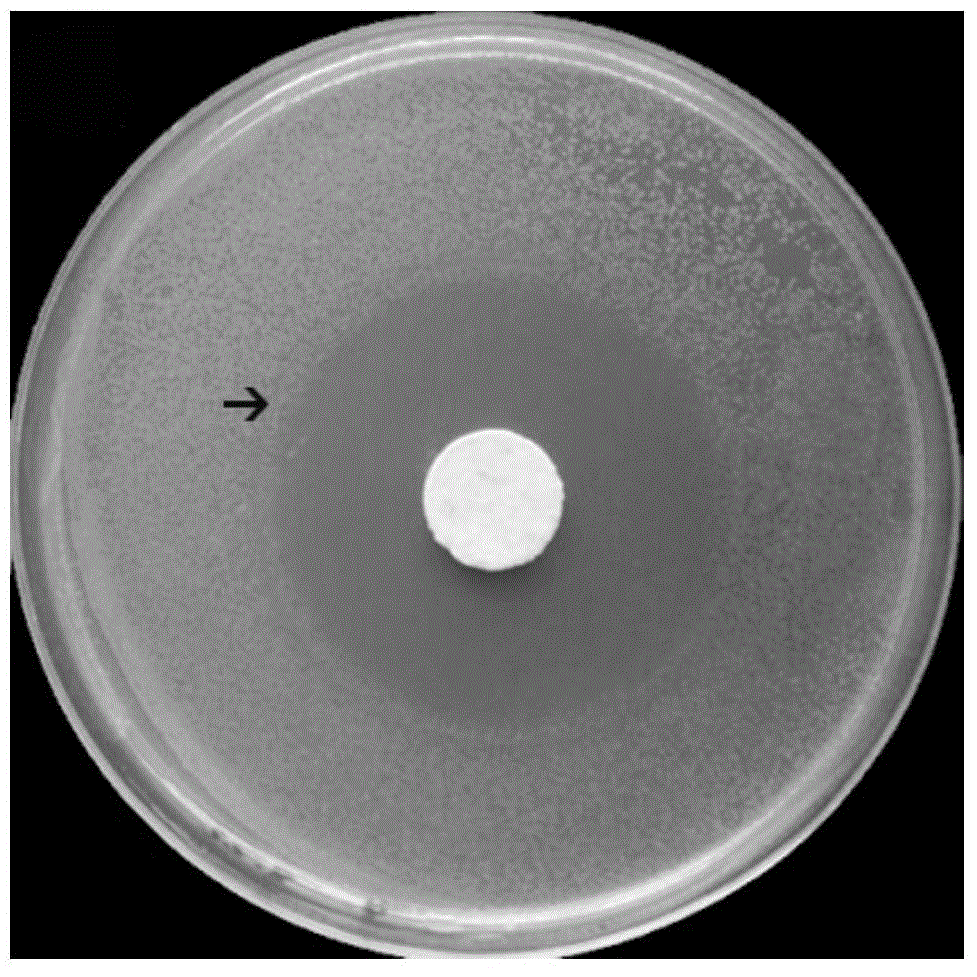

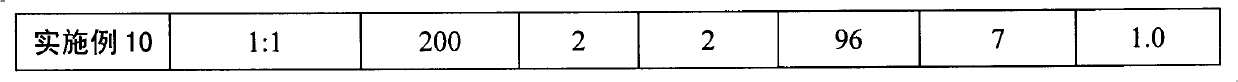

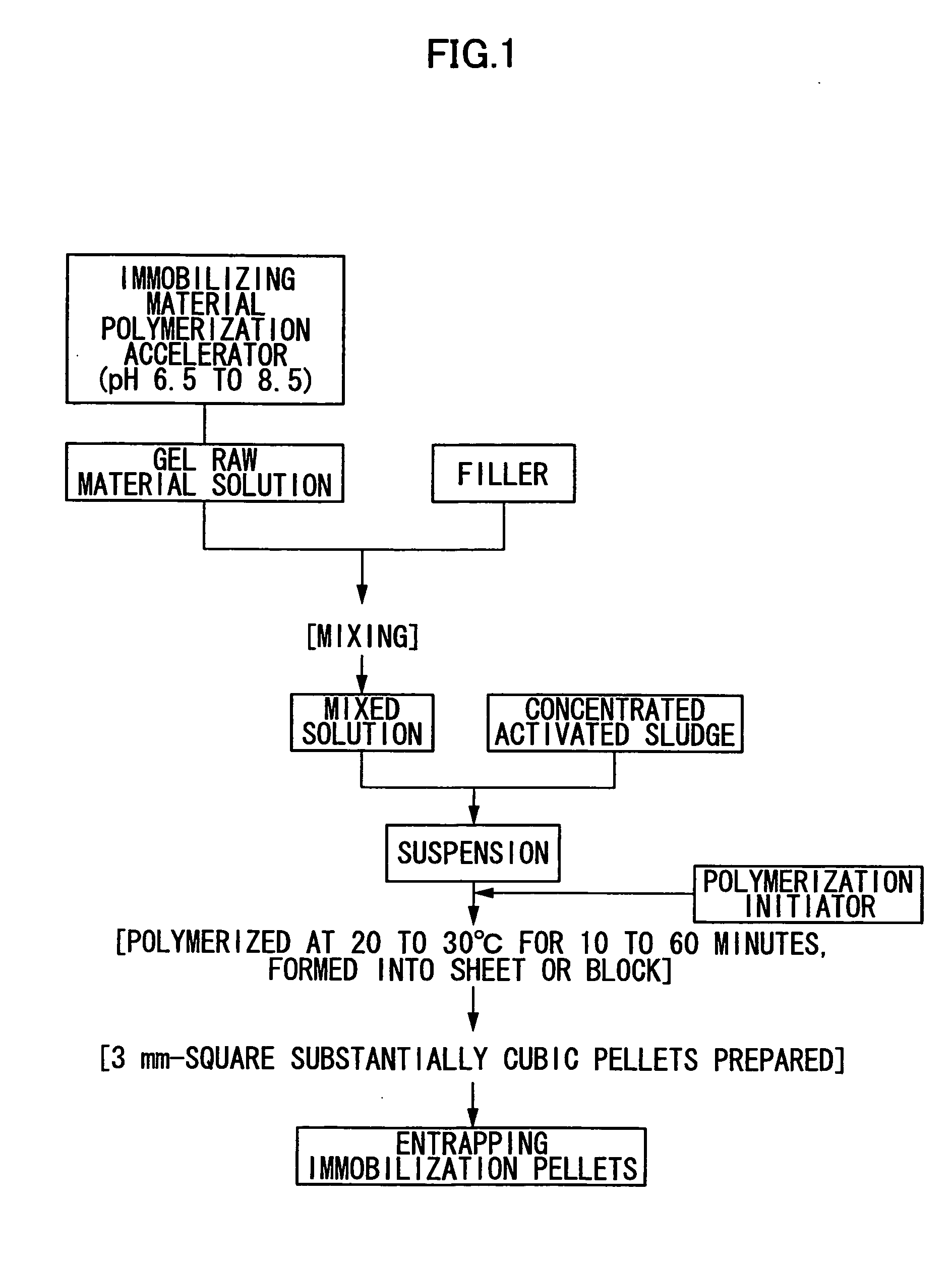

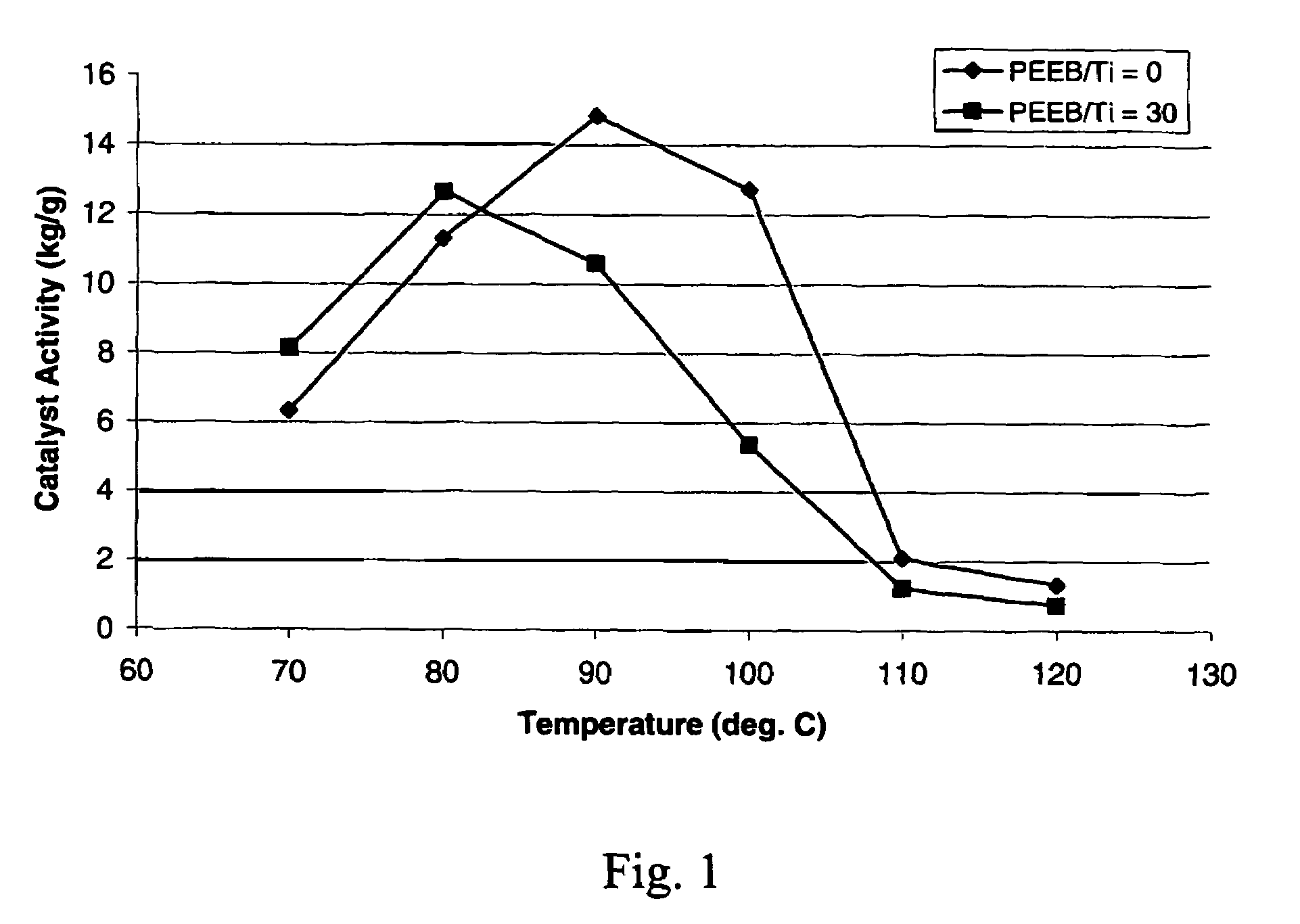

Entrapping immobilization pellets and process for producing the same

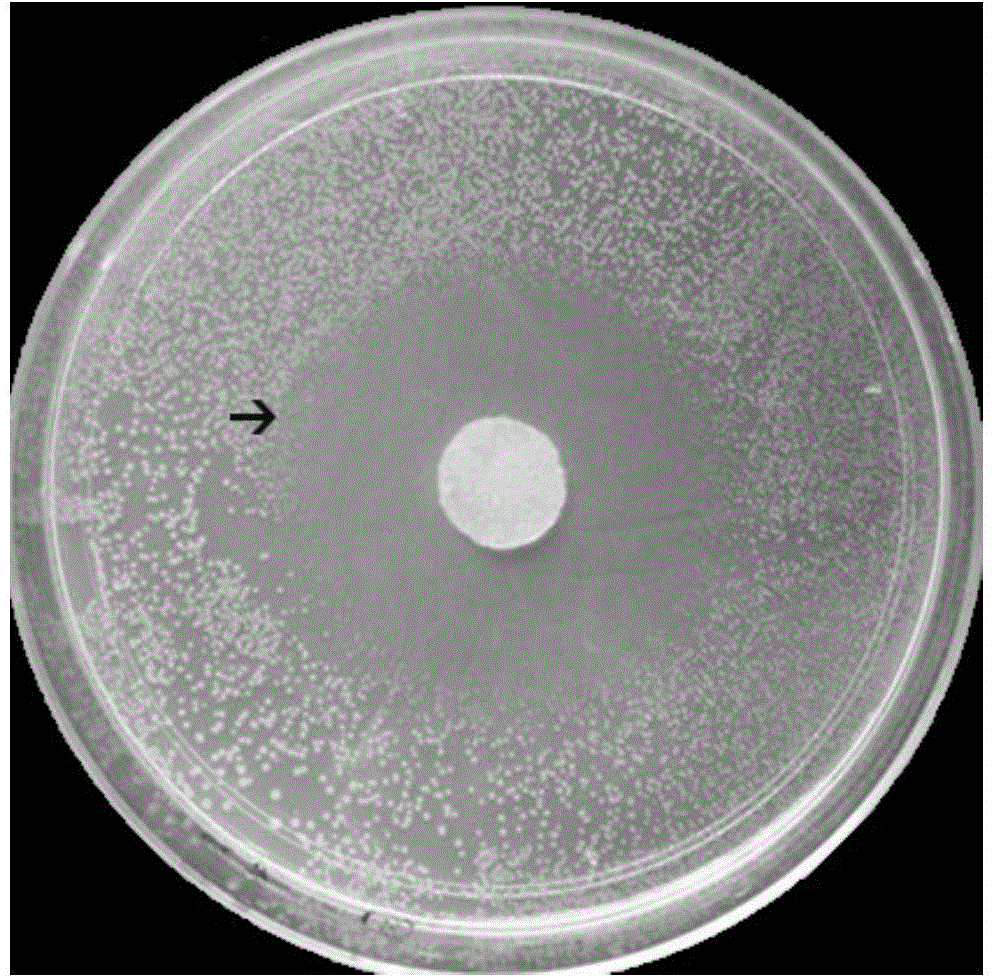

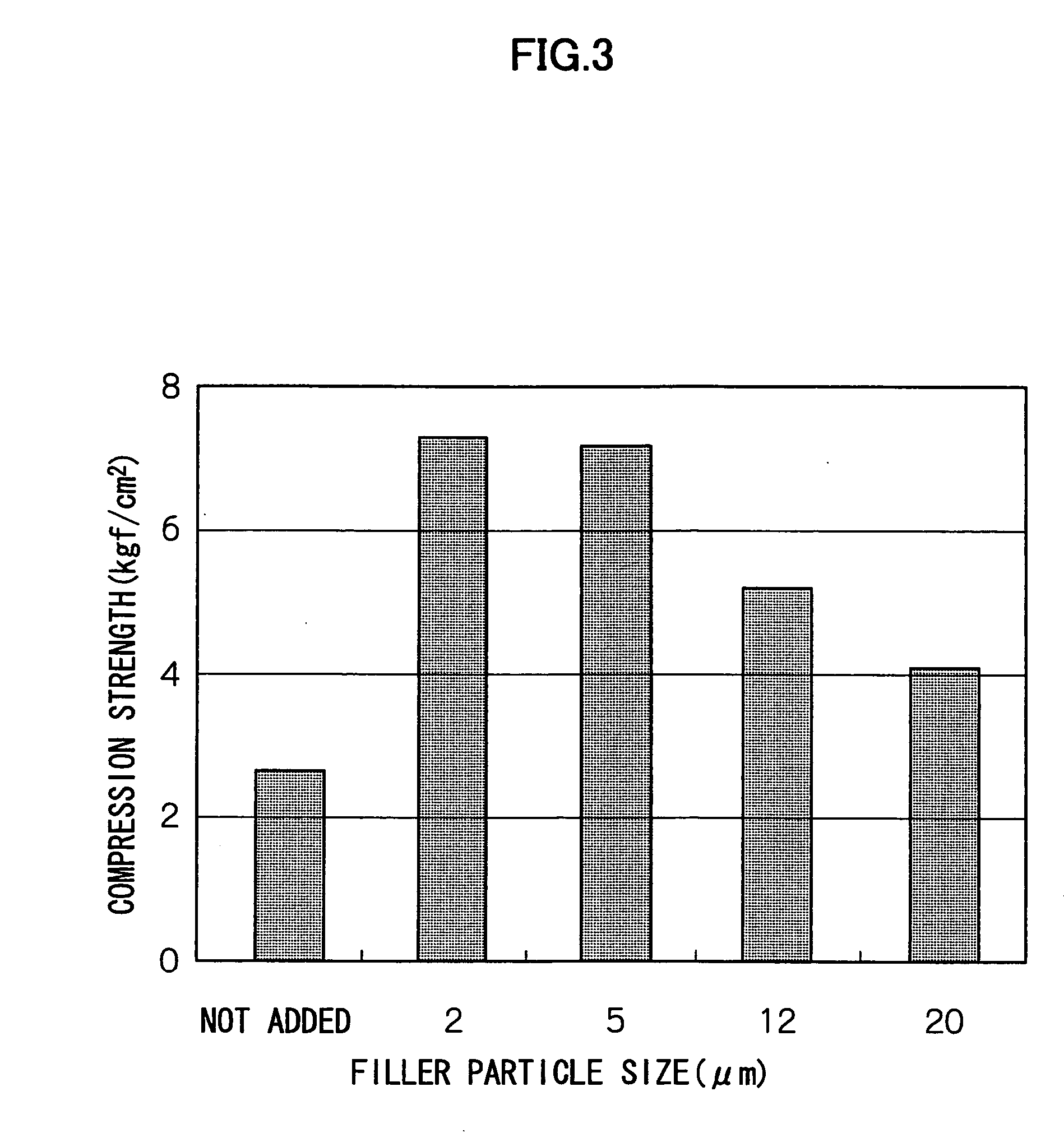

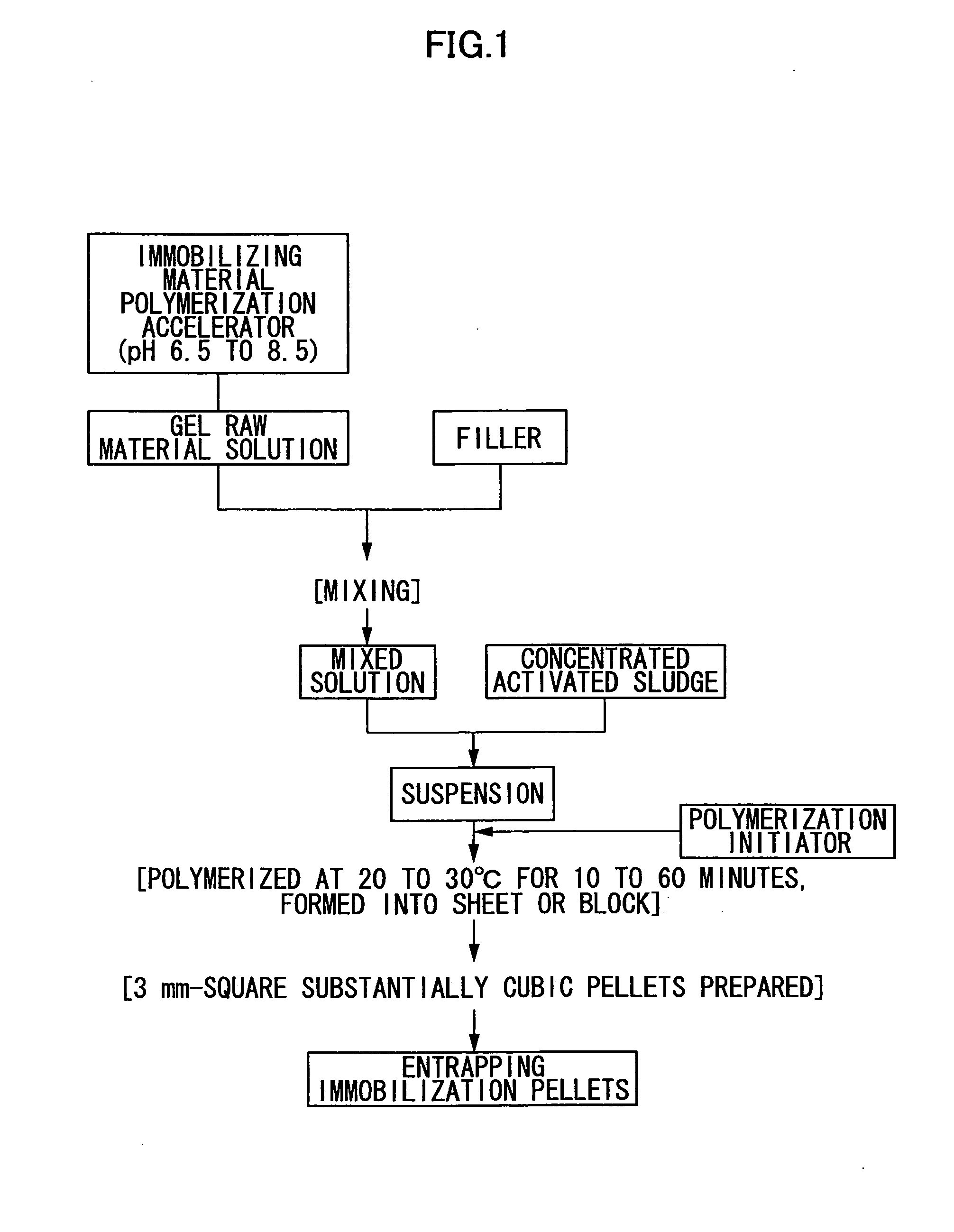

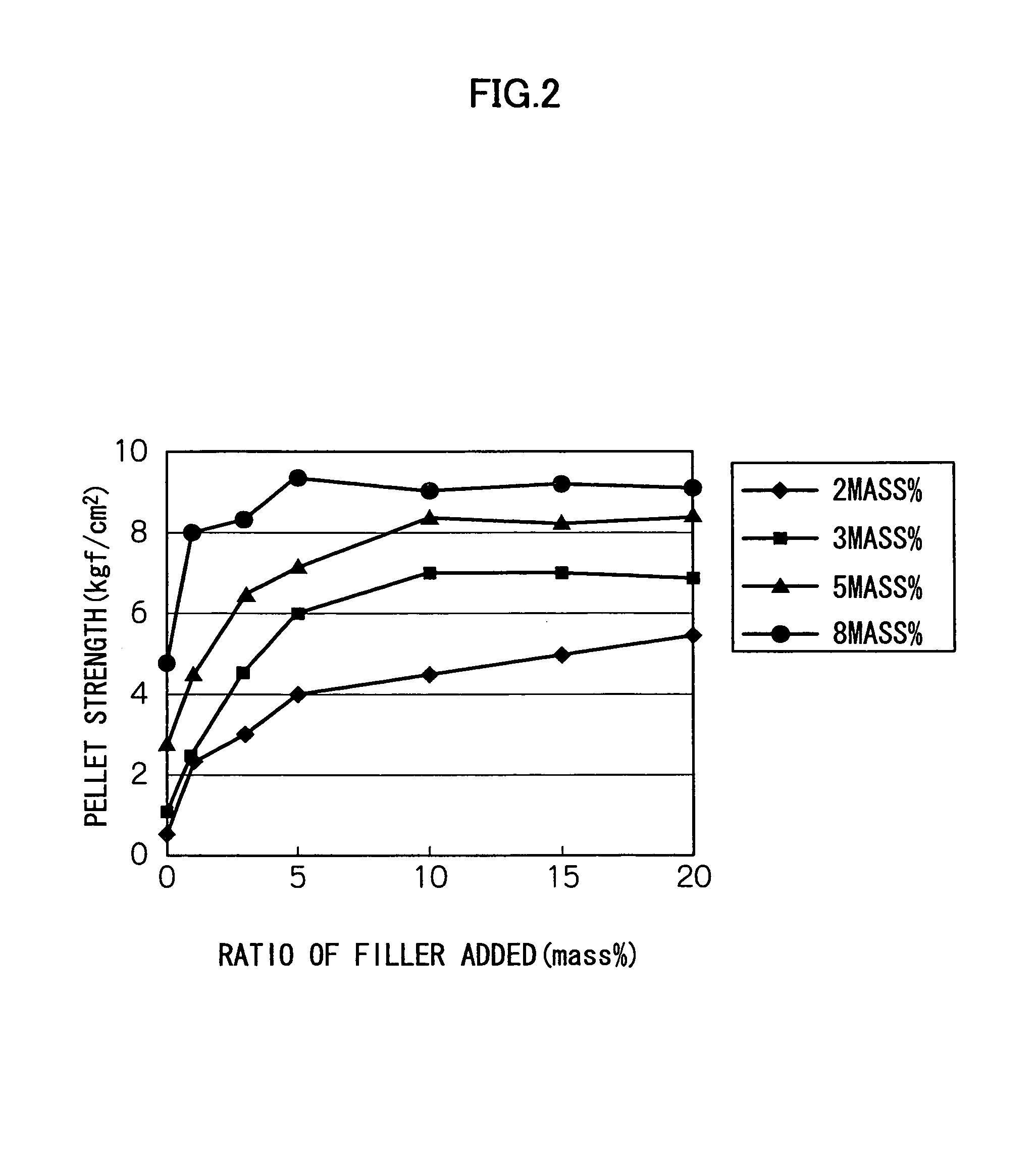

InactiveUS20070015268A1Reduced activityHigh shape accuracyBacteriaUnicellular algaeCrystal structureUltimate tensile strength

The present invention produces entrapping immobilization pellets which have high pellet strength and retain high and stable microbial activity (nitrification activity) even if a low concentration of a material involved in immobilization (such as an immobilizing material or polymerization initiator) used. The entrapping immobilization pellets in which microorganisms are entrapped and immobilized in an immobilizing material comprise a filler having a plate-like and / or needle-like crystal structure in the immobilizing material.

Owner:HITACHI PLANT TECH LTD

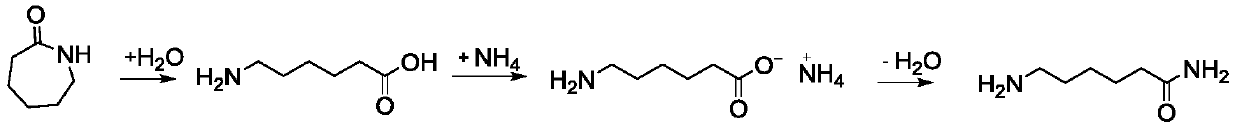

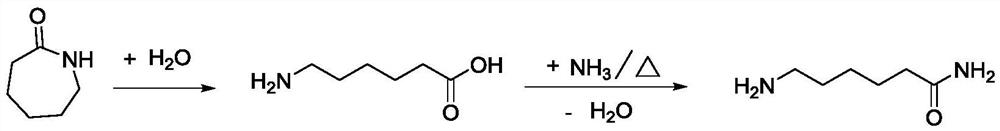

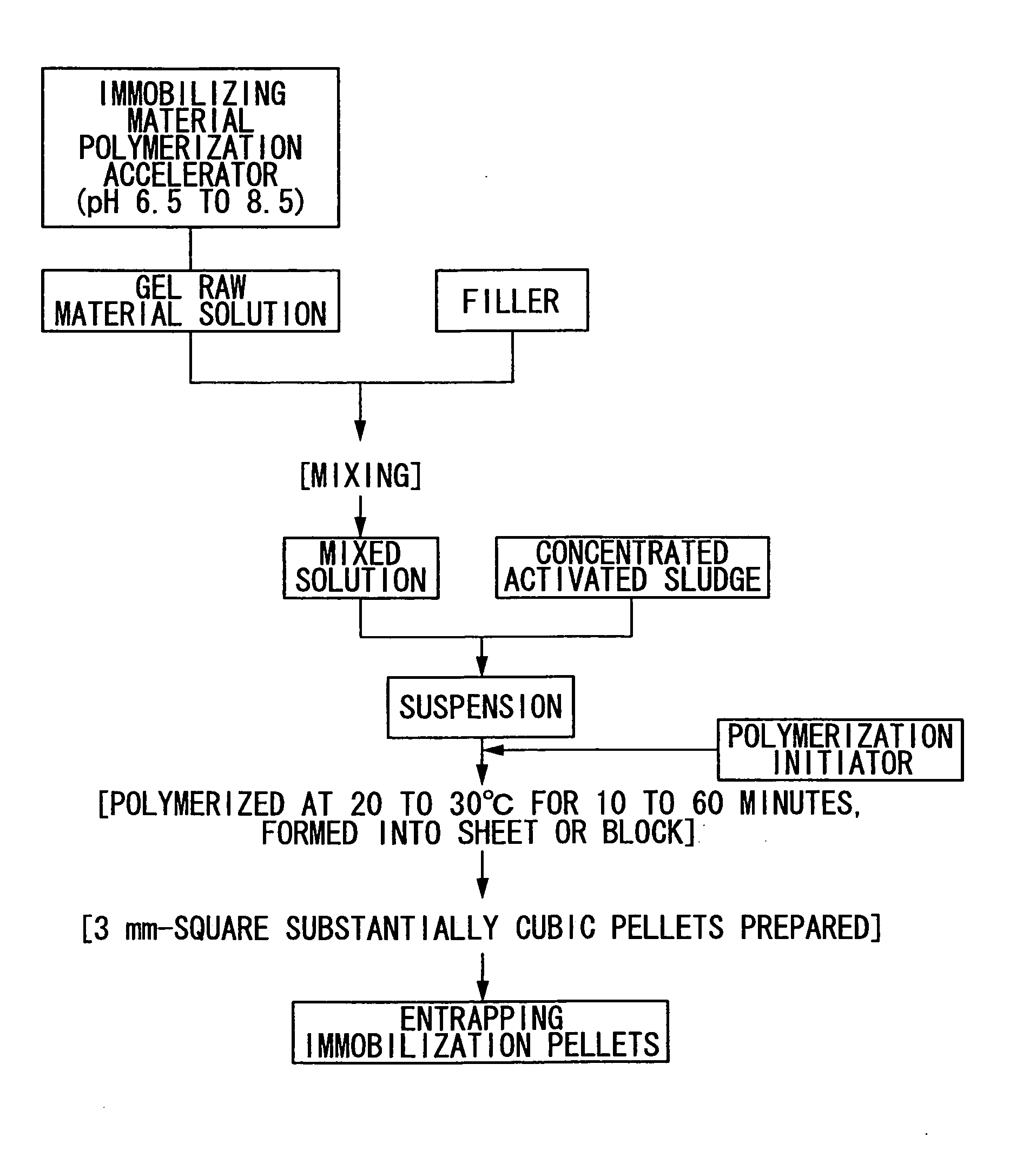

Method for producing hexamethylenediamine key intermediate 6-aminocapronitrile by continuous gas-phase two-step method

ActiveCN111574401AReduced Catalytic PolymerizationReduce polymerizationOrganic compound preparationCarboxylic acid amides preparationAminocapronsäurePtru catalyst

The invention provides a method for producing a hexamethylenediamine key intermediate 6-aminocapronitrile by a continuous gas-phase two-step method. The method comprises the following steps: S1, mixing caprolactam and water in a gas phase state to carry out continuous hydrolysis or mixing caprolactam and ammonia water in a gas phase state to carry out continuous hydrolysis ammoniation reaction toobtain a first product system containing 6-aminocaproic acid, 6-aminocaproic acid ammonium salt and / or 6-aminocaproamide; and S2, carrying out continuous gas-phase catalytic ammoniation and dehydration reaction on the first product system and ammonia gas to obtain a second product system containing 6-aminocapronitrile. According to the patent of the invention, the problem that water generated by reaction in a one-step process promotes polymerization reaction of the raw material caprolactam is reduced from the source, and the selectivity of aminocapronitrile is improved; and the problems of catalyst deactivation and pressure drop rise caused by polymerization and coking of caprolactam in the reactor are effectively reduced, the stability of the device is improved, and the service life of the catalyst is prolonged.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Composite paste for dental prostheses

InactiveUS20070065780A1Optimize working timeReduce the amount requiredTeeth fillingDentistry preparationsSingle plateMaterials science

In general, the invention comprises a composite paste (“try-in paste”) made with the same or similar components in similar proportions as a veneer cement except part or all of the initiation system is removed or reduced to cause it to have an extended working time under the type of ambient light conditions expected during the trial placement of the veneer. Preferably, the imitator is decreased by not eliminated from the try-in paste. The invention can be presented in the form of a kit containing one or more shades of veneer cement with corresponding shades of try-in paste.

Owner:DANVILLE MATERIALS

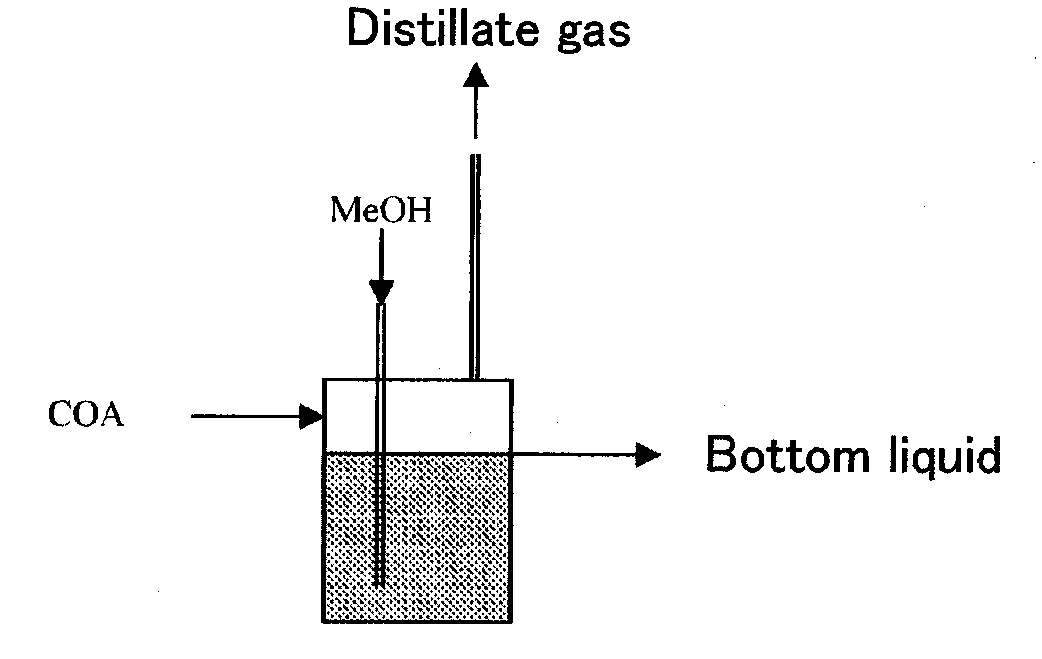

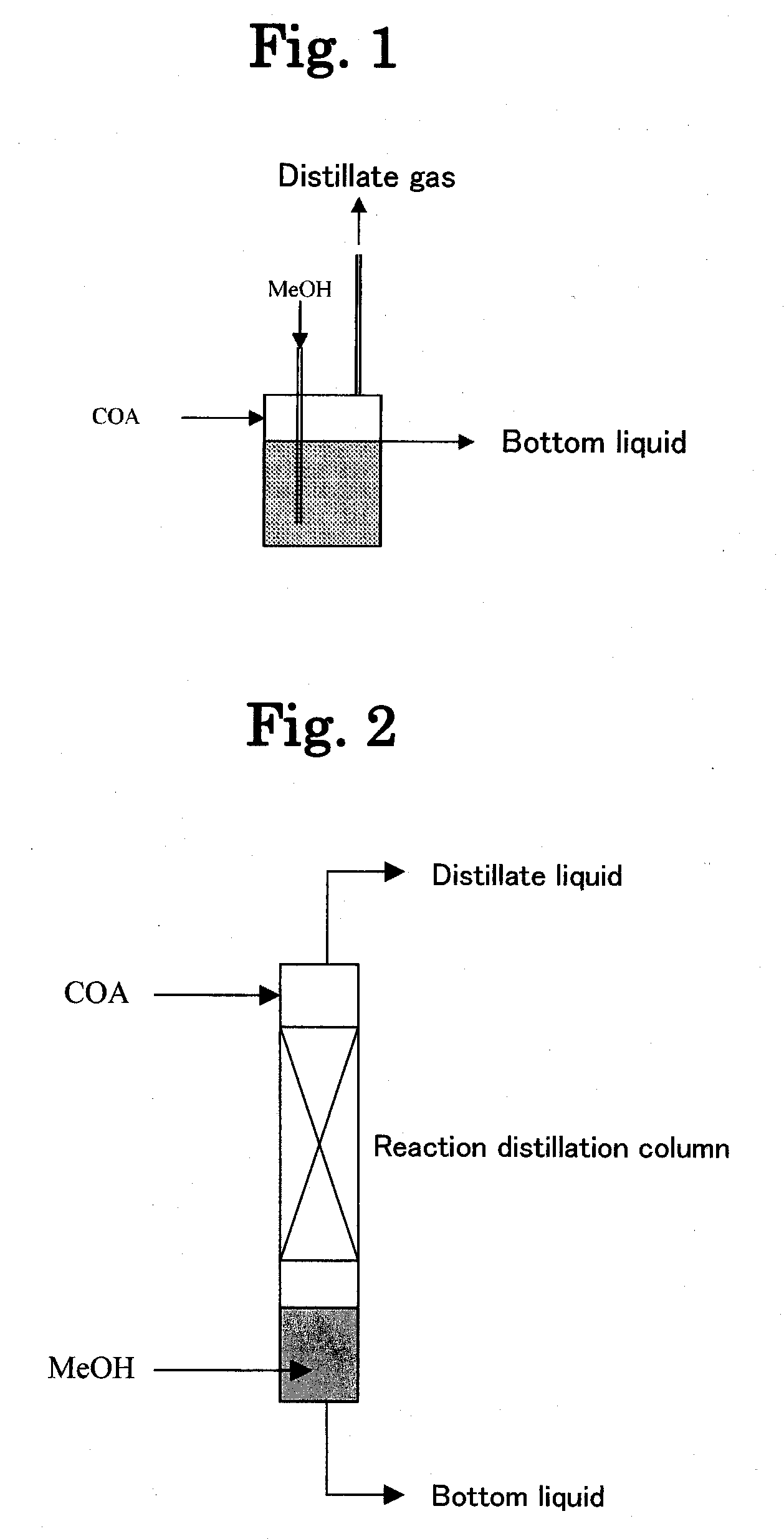

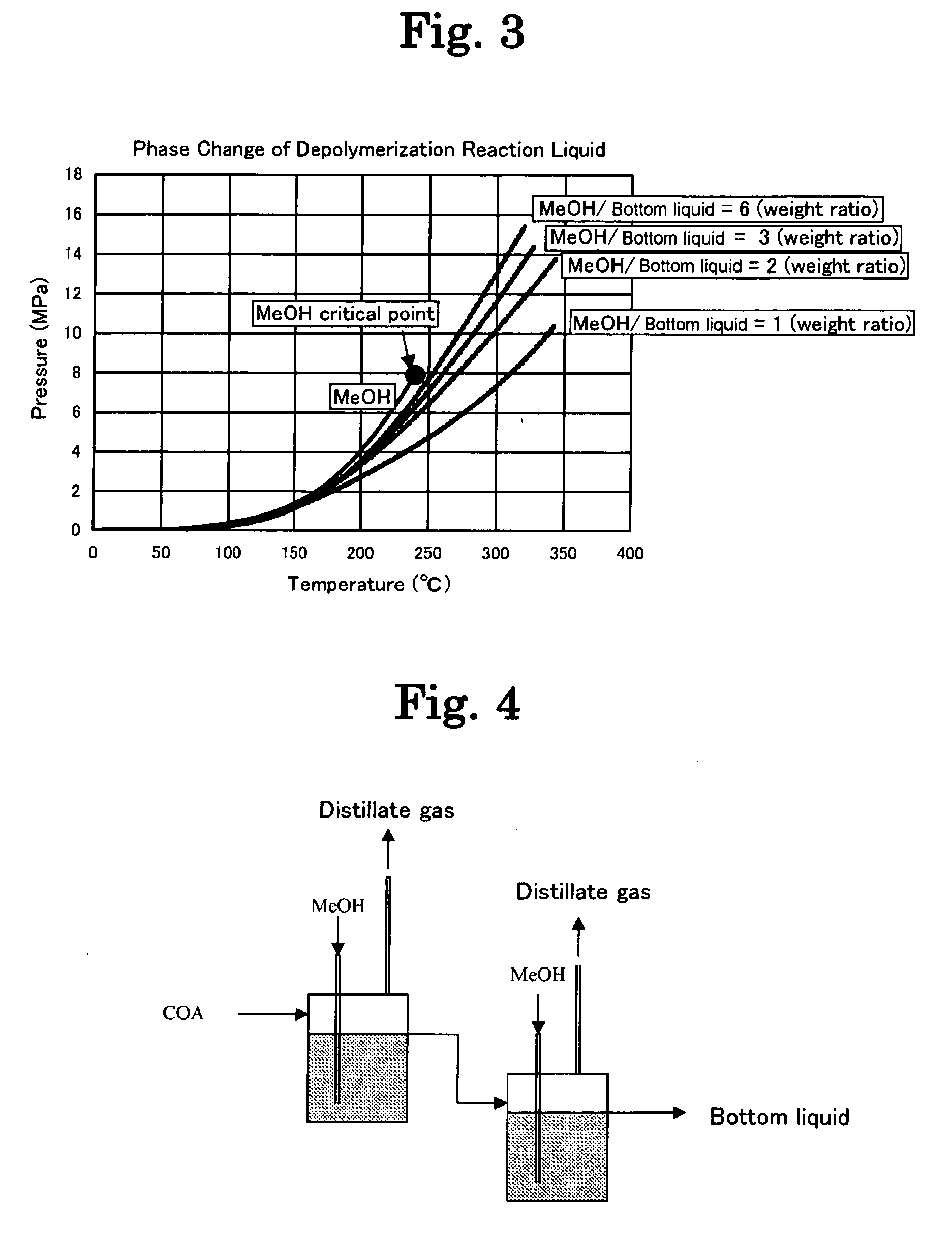

Production Process of 1,6-Hexanediol

ActiveUS20090048471A1Avoid corrosionEfficient executionPreparation by oxidation reactionsPreparation by ester-hydroxy reactionDistillationHigh pressure

A method is provided for obtaining highly pure 1,6-hexanediol in which the contents of impurities such as 1,4-cyclohexanediol, 1,5-hexanediol, 1,2-cyclohexanediol, 1,7-pentanediol, 1,5-pentanediol and high boiling point components are significantly reduced.This process for producing 1,6-hexanediol from cyclohexane comprises the steps of:(1) treating an aqueous extraction concentrate of a reaction mixture obtained by oxidation of cyclohexane with a lower alcohol to esterify monocarboxylic acids and dicarboxylic acids contained in the extract, and simultaneously remove and separate by distillation water, excess lower alcohols and carboxylic acid esters; (2) converting oligomer esters contained in the bottom liquid to carboxylic acid esters by depolymerizing the oligomer esters at a high temperature and high pressure in the presence of a lower alcohol and a catalyst; and (3) hydrogenating the carboxylic acid esters distilled off in the step (1) and the carboxylic acid esters obtained in the step (2) either respectively or collectively to convert to 1,6-hexanediol.

Owner:UBE CORP

Methacrylate based monomers containing a urethane linkage, process for production and use thereof

ActiveUS8426490B2Well-balanced propertyReduce polymerizationCosmetic preparationsImpression capsMethacrylateHalogen

The invention relates to a dental composition comprising a monomer or mixture of monomers represented by the following structure(1) with 1,2R independently selected from H, alkyl (e.g. CH3C2H5), and Phenyl, 3,4R independently selected from H, alkyl (e.g. CH3), and halogen (Cl, Br, F), 5R independently selected from H, alkyl (e.g. CH3), m, n=1, 2 and x+y=2 to 10, with the proviso that if m=n=2, than x+y=2 and if m=n=1, than x+y=4 to 10. The invention also relates to a process for producing the monomer or mixture of monomers and the use thereof especially as dental composition.

Owner:3M INNOVATIVE PROPERTIES CO

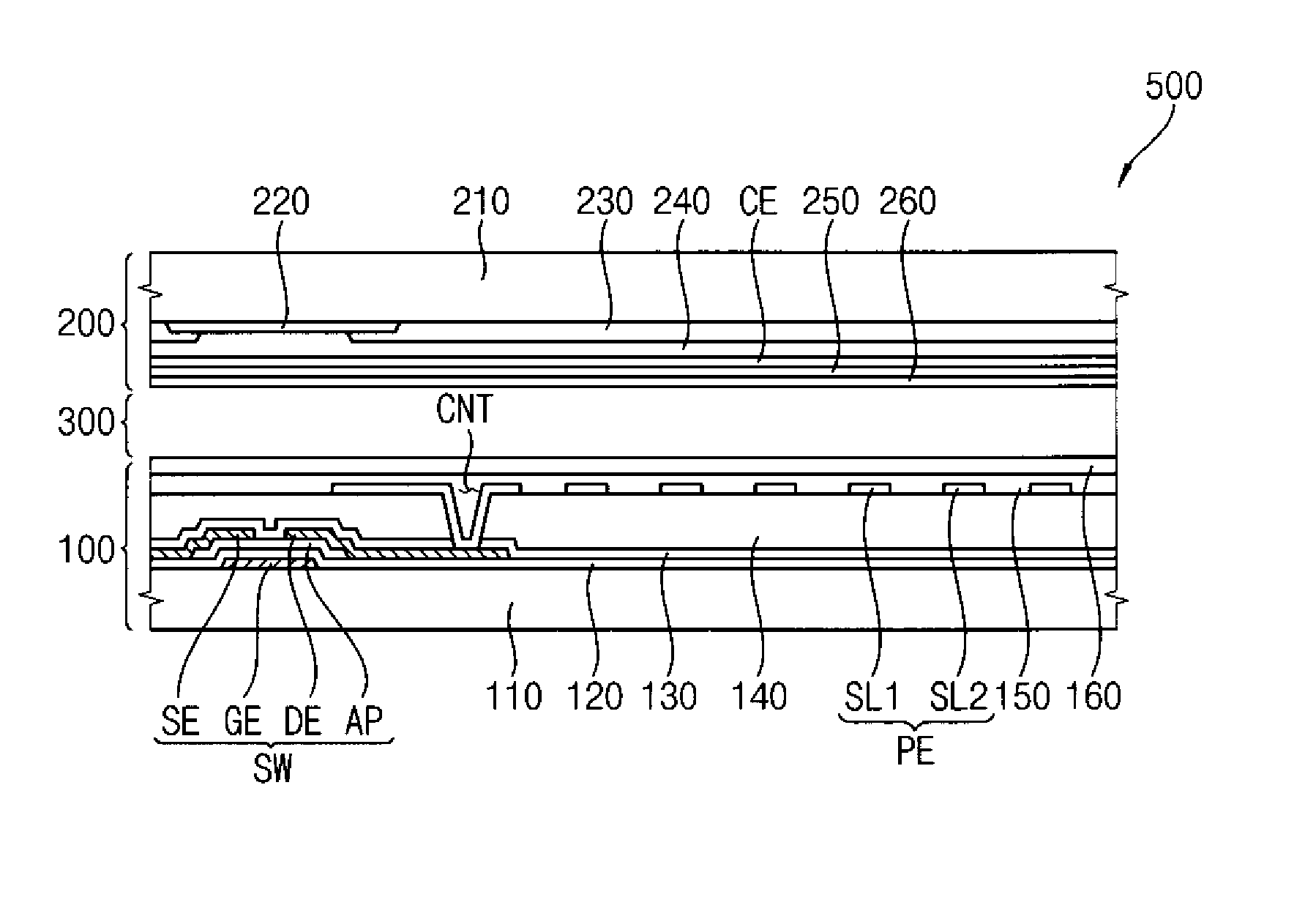

Reactive mesogen compound, liquid crystal composition including the same, method of manufacturing a display panel, and display panel

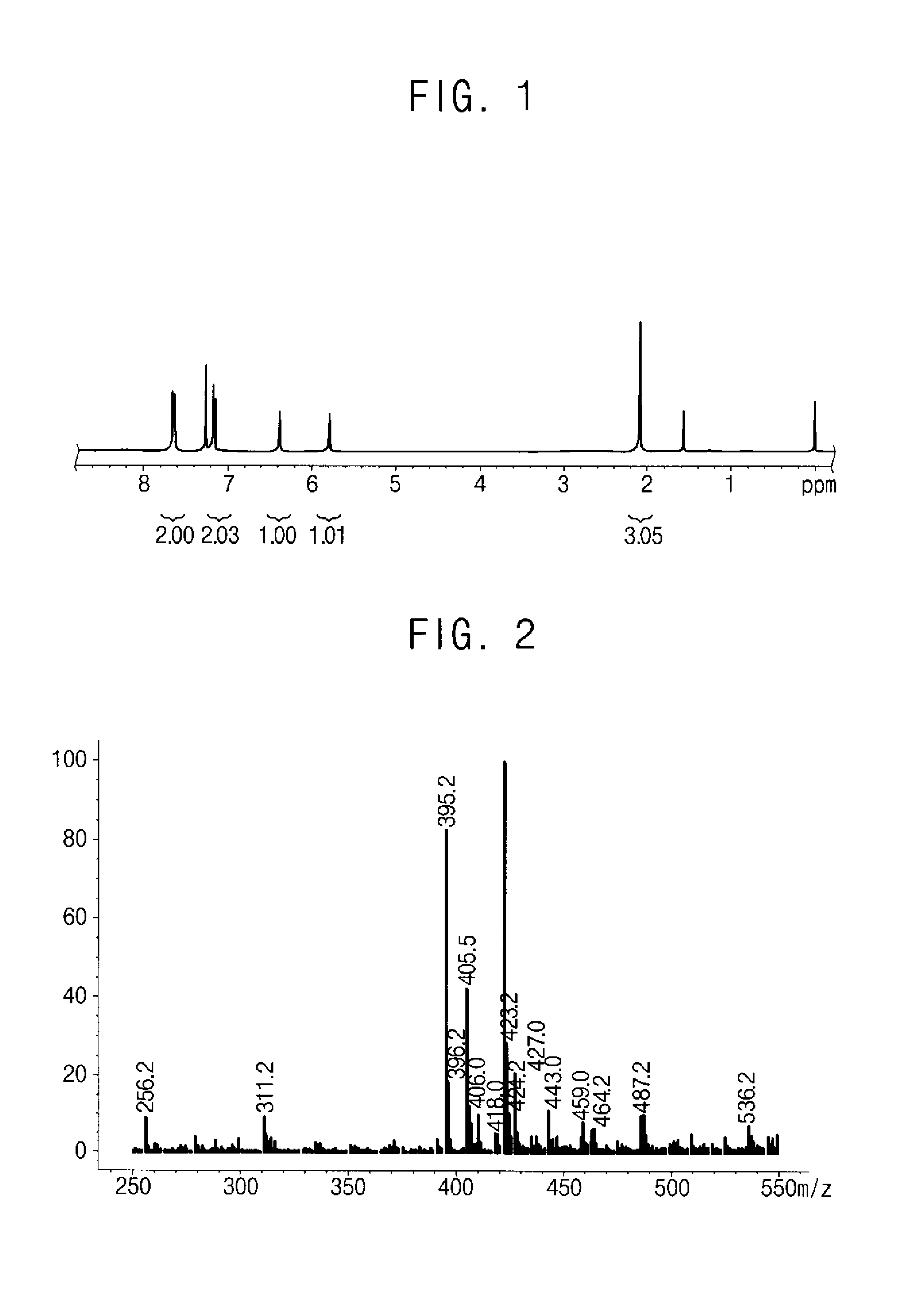

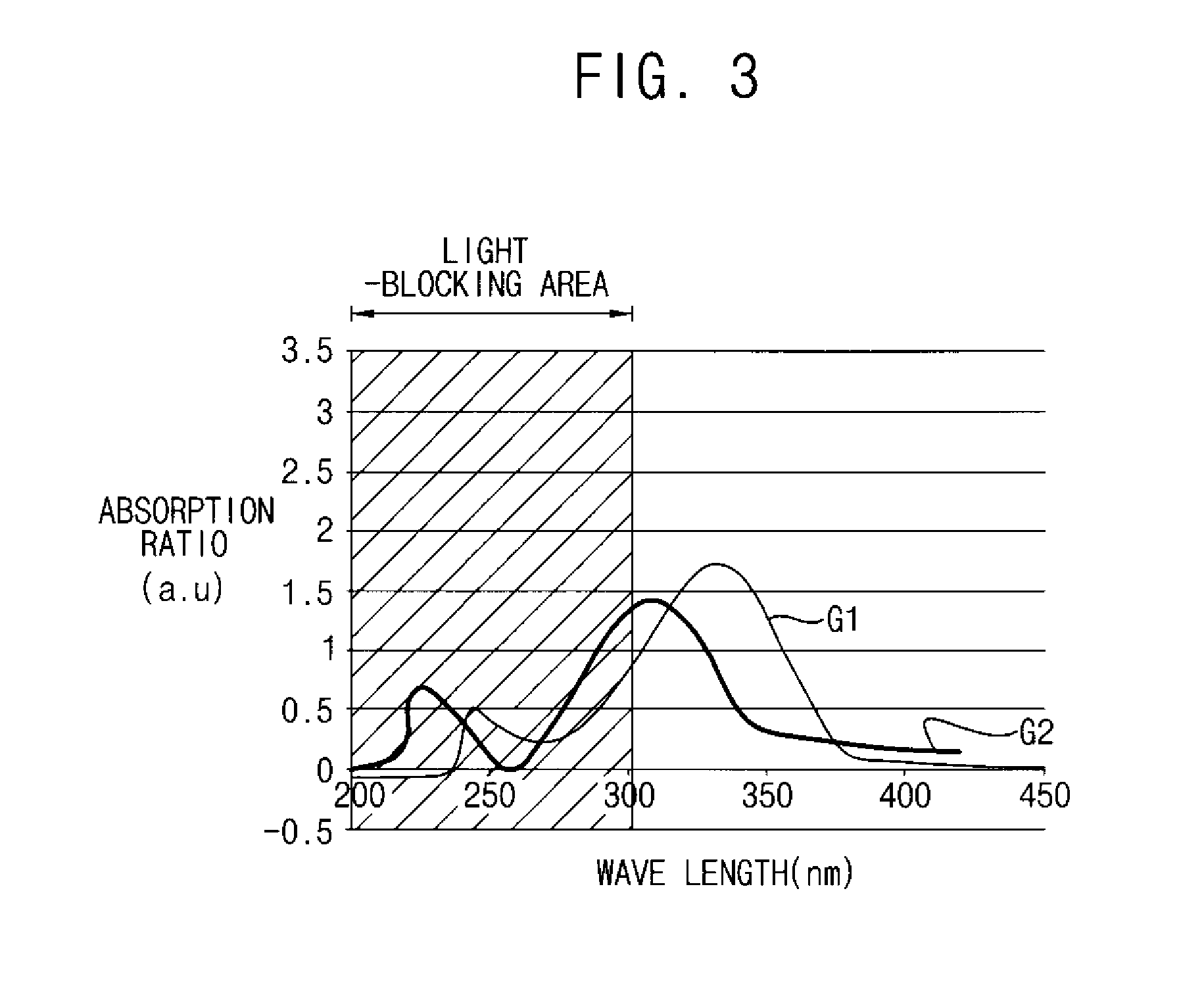

InactiveUS20130208222A1Effective compoundReduce polymerization timeLiquid crystal compositionsOrganic chemistryLength waveMesogen

A reactive mesogen compound, a liquid crystal composition including the reactive mesogen compound, a method of manufacturing a display panel, and a display panel are disclosed. The reactive mesogen compound may be activated by light having a wavelength between about 300 nm and about 700 nm.

Owner:SAMSUNG DISPLAY CO LTD

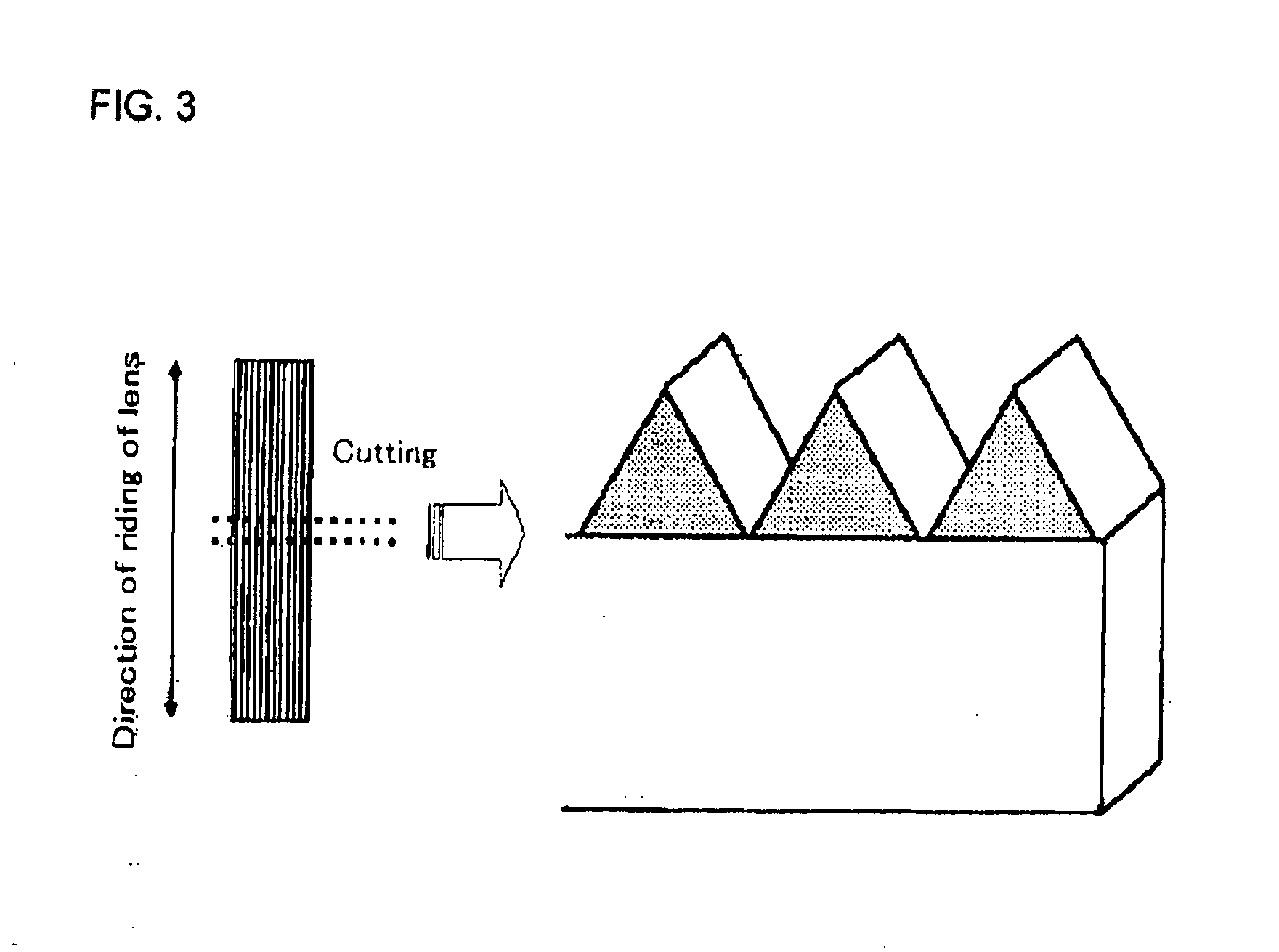

Active energy ray curable resin composition and sheet-like optical article

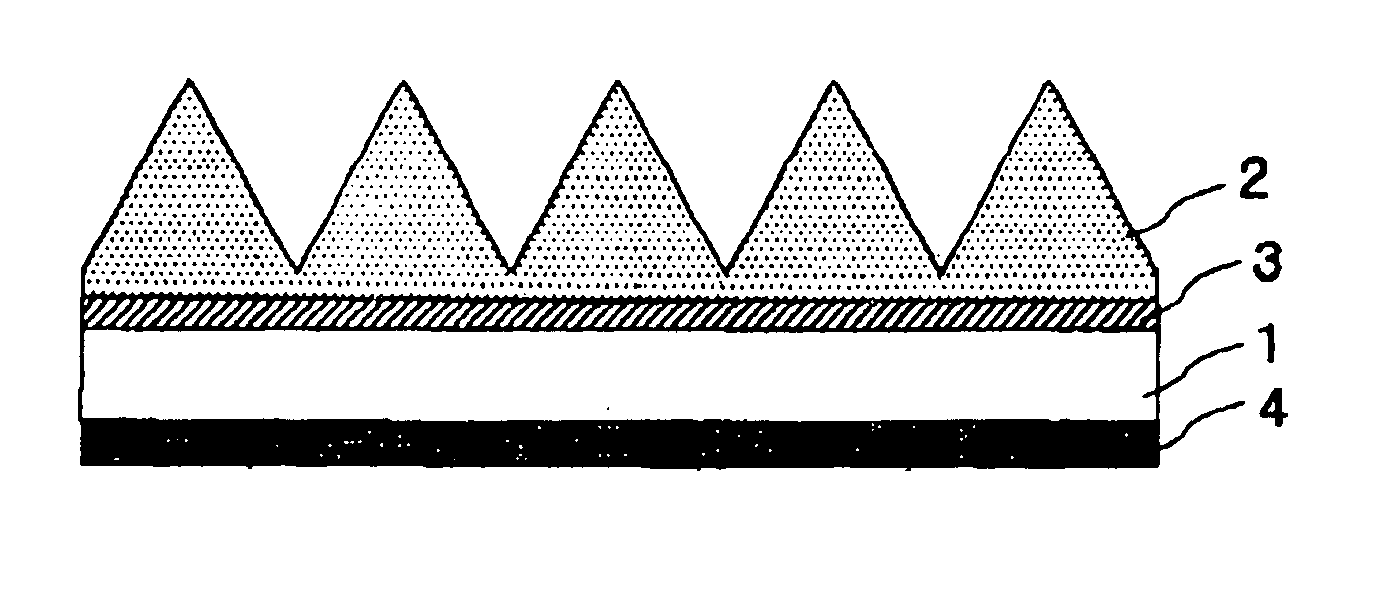

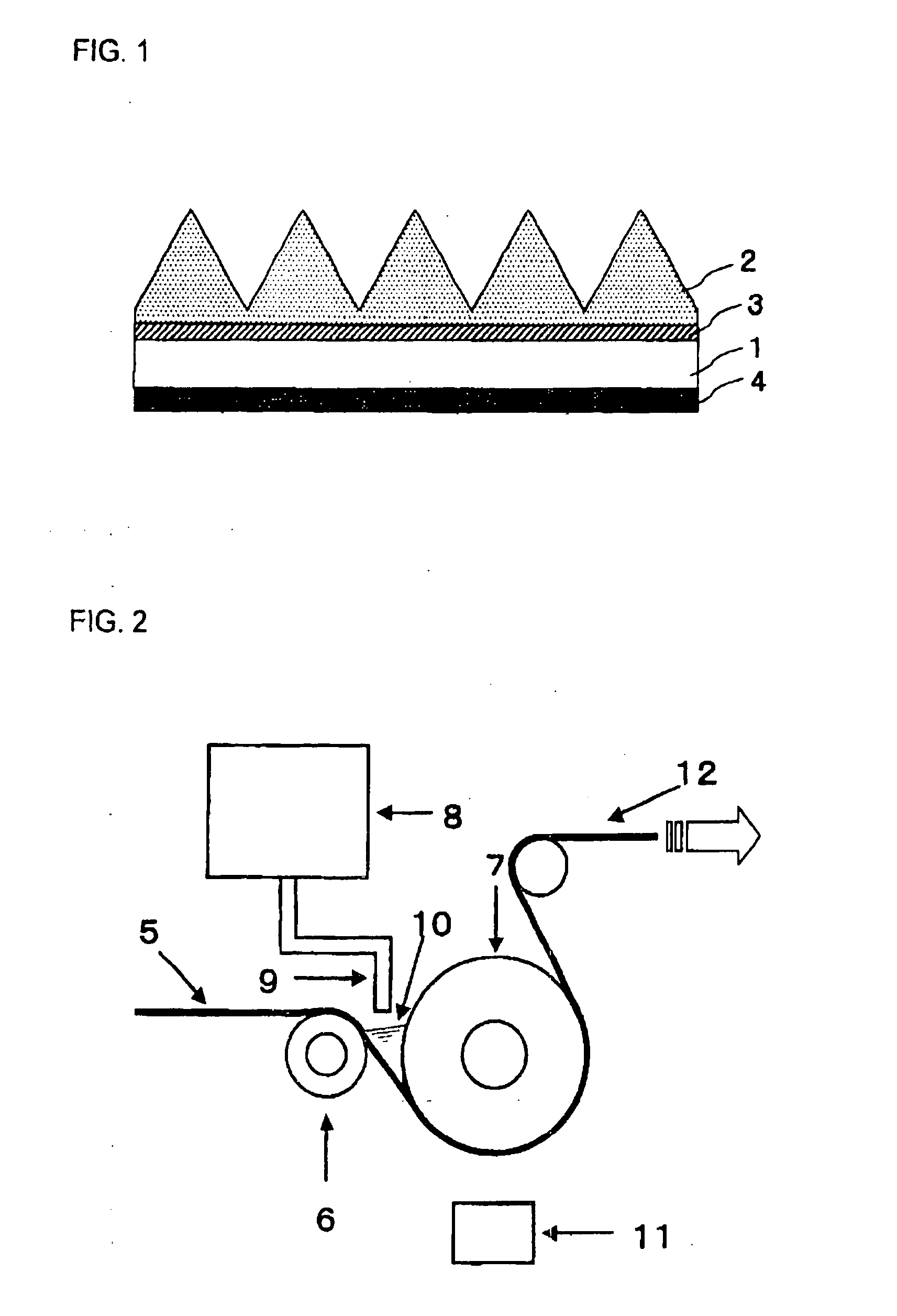

InactiveUS20090030104A1Reduce warpageImprove heat resistanceMixing methodsDiffusing elementsHeat resistancePrism

An active energy ray curable resin composition for a sheet-like optical article capable of providing a cured material having a dynamic elastic modulus at 25° C. of 950 MPa or less and a dynamic elastic modulus at 60° C. of 100 MPa or more and a sheet-like optical article prepared from the resin composition are disclosed. The sheet-like optical article (e.g., prism sheet) has good heat resistance and extremely small warpage.

Owner:MITSUBISHI CHEM CORP

Radiopaque cationically polymerizable compositions comprising a radiopacifying filler, and method for polymerizing same

InactiveUS20060052232A1Improve clarityLow transparencyPigmenting treatmentImpression capsCationic polymerizationReaction temperature

Polymerizable compositions that include: (a) a cationically active functional group; (b) an initiation system capable of initiating cationic polymerization of the cationically active functional group; and (c) a filler composition that includes various radiopacifying fillers in an amount sufficient to render the polymerizable composition radiopaque. Components (a), (b), and (c) are selected such that the polymerizable composition polymerizes to form a polymerized composition having a Barcol hardness, measured using a GYZJ-935 meter, of at least 10 within 30 minutes following initiation of the cationically active functional group at a reaction temperature of 25° C.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing hexamethylenediamine key intermediate 6-aminocapronitrile by two-step method

ActiveCN111662210AAvoid cokingImprove conversion rateOrganic compound preparationCarboxylic acid amides preparationPtru catalystHexamethylenediamine

The invention provides a method for preparing a hexamethylenediamine key intermediate 6-aminocapronitrile by a two-step method. The method comprises the following steps: step S1, in a first reactor, after caprolactam is subjected to a hydrolysis reaction in an aqueous solution, introducing first hot ammonia gas into the first reactor to obtain an aminocaproamide crude product, the temperature of the first hot ammonia gas being 150-250 DEG C; S2, performing catalytic dehydration on the aminocaproamide crude product and second hot ammonia gas in a second reactor to obtain aminocapronitrile, wherein the temperature of the second hot ammonia gas ranges from 200 DEG C to 300 DEG C. According to the invention, the polymerization of the hydrolysate is effectively controlled in the step S1 so thatpolymerization of the polymer on the surface of the catalyst when the aminocaproamide crude product participates in the catalytic dehydration reaction in the step S2 is effectively relieved, coking of the catalyst is avoided, the service life of the catalyst is prolonged, and then lasting high-conversion-rate and high-selectivity preparation of 6-aminocapronitrile from caprolactam is guaranteed.

Owner:JIANGSU YANGNONG CHEM GROUP +2

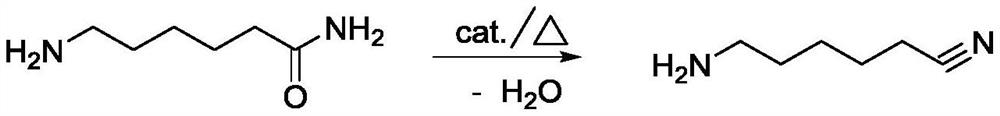

Catalyst composition for ethylene polymerization

ActiveUS7393910B2Low heat generationAlter productivity and polymer propertyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHeteroatom

A process for the polymerization of olefin monomers comprising contacting ethylene or a mixture of ethylene and one or more C4-8 α olefins with a catalyst composition comprising one or more Group 3-10 transition metal containing, Ziegler-Natta, procatalyst compounds; one or more alkylaluminum cocatalyts; and one or more polymerization control agents, said process being characterized in that at least one such polymerization control agent is an alkyl or aryl, ester of an aliphatic or aromatic (poly)carboxylic acid optionally containing one or more substituents comprising a Group 13, 14, 15, or 16 heteroatom.

Owner:DOW GLOBAL TECH LLC

Entrapping immobilization pellets and process for producing the same

InactiveUS20100209989A1Reduced activityHigh shape accuracyOn/in organic carrierBiological water/sewage treatmentCrystal structureUltimate tensile strength

Owner:HITACHI PLANT TECH LTD

Method for separating and cracking cyclopentadienyl from carbon 5 fraction

ActiveCN101450887AImprove product qualityReduce loss rateHydrocarbonsHydrocarbon preparationLoss rateTower

The invention discloses a method for separating and cracking cyclopentadiene in C5 distillate. The method belongs to the technical field of C5 separation. In order to solve the problems that the industry requires the dimerization reaction of cyclopentadiene as much as possible; and the industry also requires the higher quality of a dicyclopentadiene product and little loss of isoprene, the invention provides the method which comprises the following steps: setting a suspension type dimerization reactor on the body of a C5 mixture rectification tower, leading liquid phase material stream from a tower plate of the rectification tower and pumping the liquid phase material stream into the dimerization reactor, making the cyclopentadiene in the material stream to have a liquid phase dimerization reaction in the suspension type dimerization reactor, and then returning the material stream back to the rectification tower from the suspension type dimerization reactor. The method can be applied to the prior industrial C5 production device and the process of one-section extraction separation and cracking of C5 distillate. The method can reduce polyreaction besides the self-dimerization of cyclopentadiene, improve the quality of the dicyclopentadiene product, reduce the loss rate of isoprene, and reduce the cyclopentadiene content in the materials as much as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

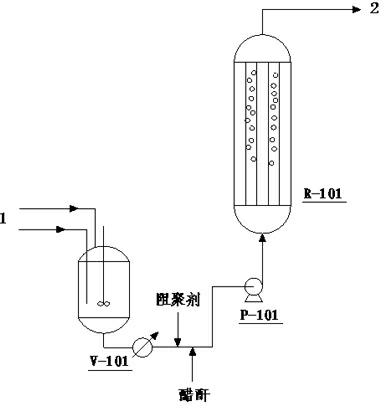

A kind of method for preparing isobornyl acetate by esterification of camphene

InactiveCN102276453AExtended service lifeImprove adsorption capacityOrganic compound preparationCarboxylic acid esters preparationAcetic acidIsobornyl acetate

The invention relates to a continuous preparation method for synthesizing isobornyl acetate by esterification of camphene and acetic acid. Using camphene and acetic acid as raw materials, using solid acid as a catalyst, and adding a certain amount of polymerization inhibitor and acetic anhydride, the esterification reaction is carried out under certain process conditions in a catalyst bed filled with suspension, and the target product acetic acid is obtained. Isobornyl. The invention has the advantages of mild reaction conditions, long service life of the catalyst, good product quality, high raw material conversion rate, continuous production and simple operation, and can be widely used in large-scale industrial production of isobornyl acetate.

Owner:FUZHOU UNIV

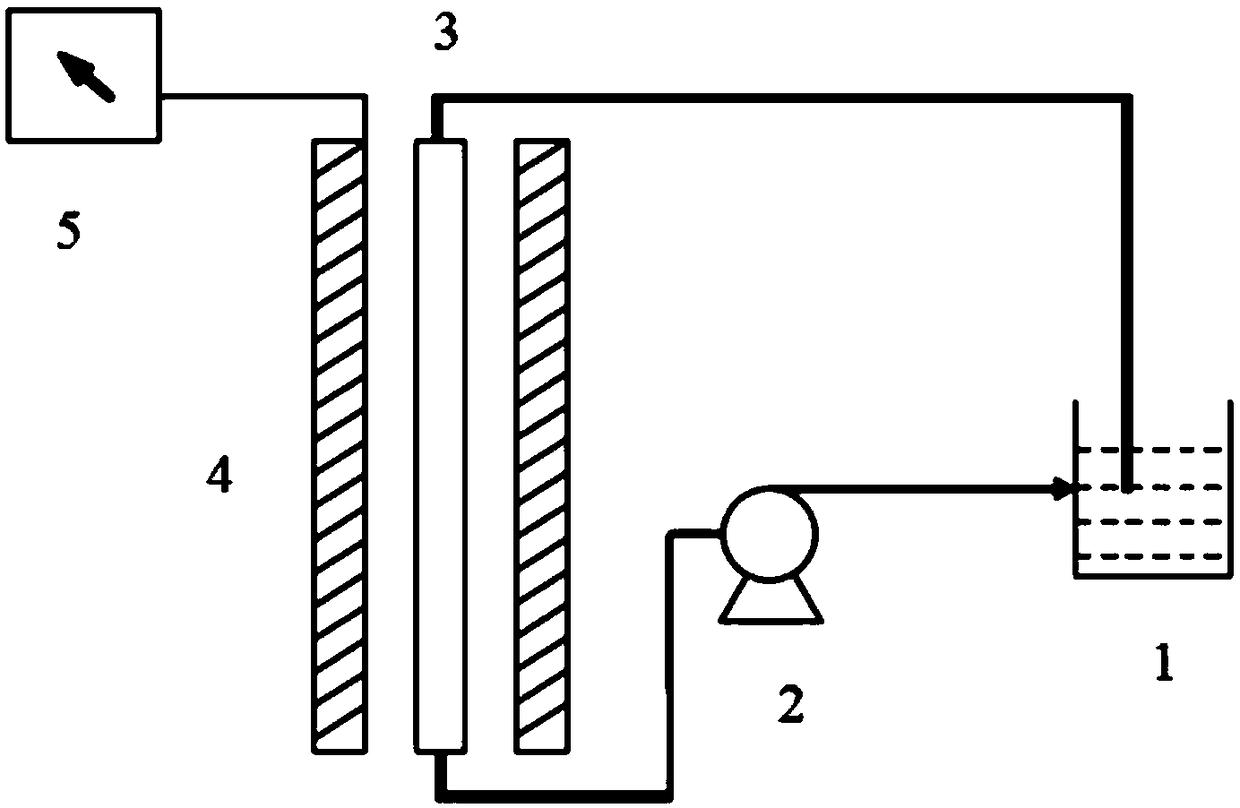

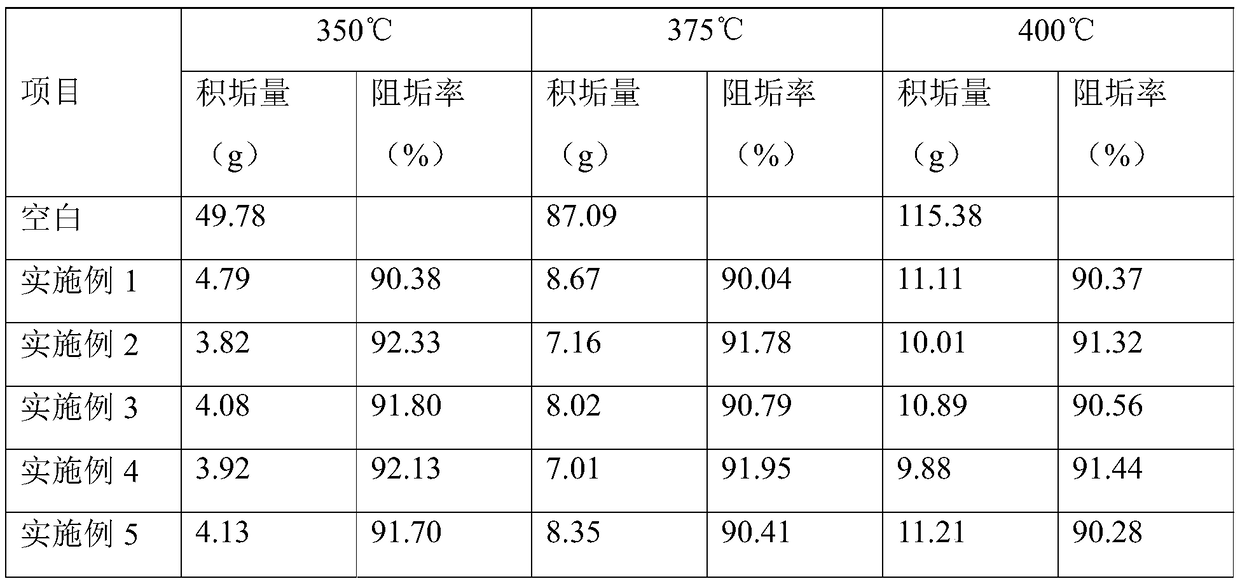

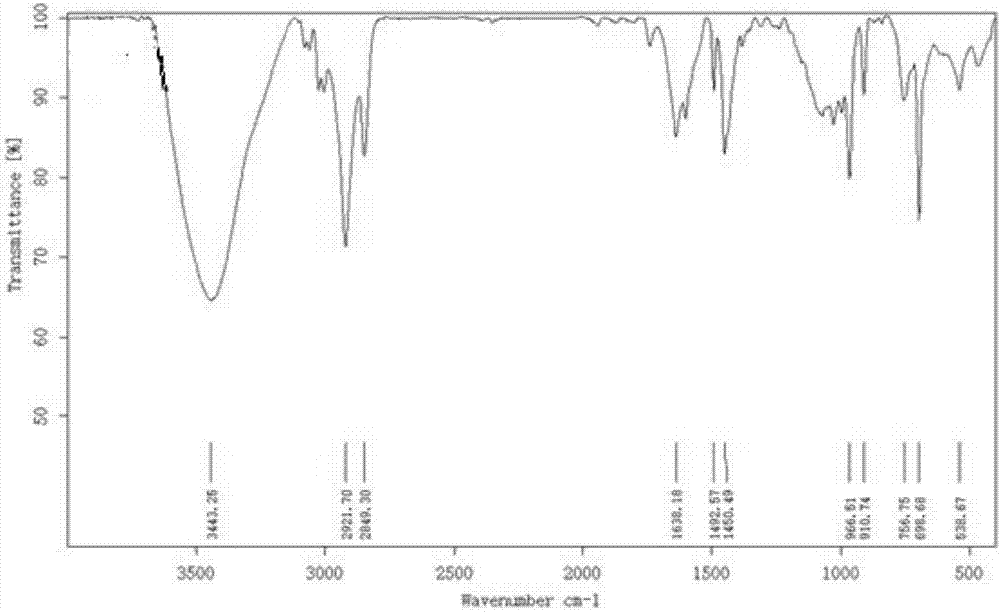

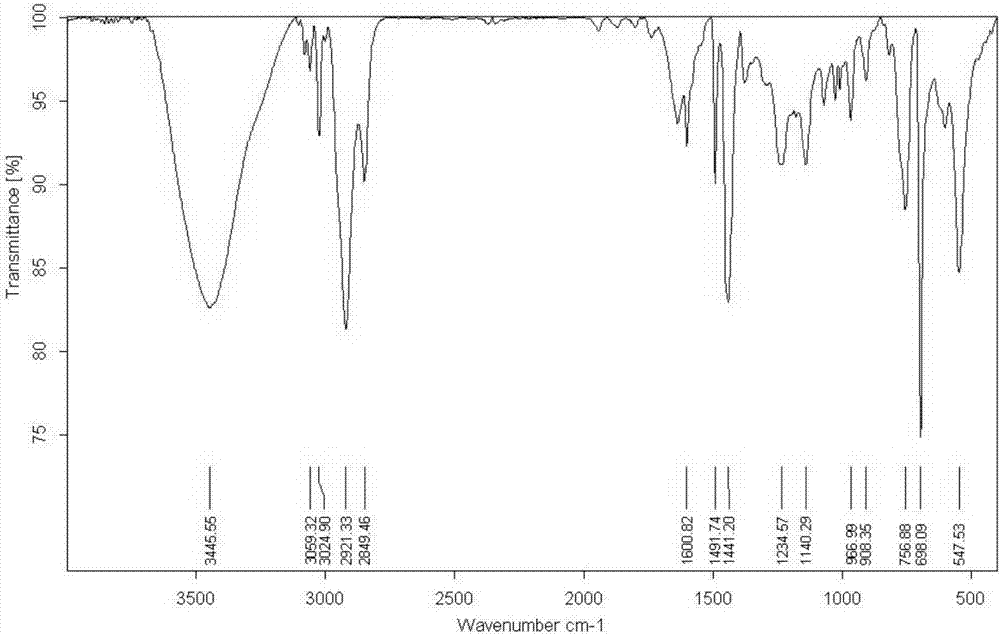

Oil slurry scale inhibitor

InactiveCN109504440ABarriers gather with each otherImprove lipophilicityTreatment apparatus corrosion/fouling inhibitionPhosphateOxidation resistant

The invention discloses an oil slurry scale inhibitor. The oil slurry scale inhibitor is prepared from the following components in percentage by mass: 25 to 40 percent of a detergent dispersant, 6 to12 percent of a phenol-amine type antioxidant, 5 to 10 percent of a corrosion inhibitor, 0.5 to 3 percent of a detergent, 0.4 to 0.5 percent of a metal passivating agent and the balance of a solvent,wherein the detergent dispersant is polyisobutylene succinimide and / or polybutadiene mercaptohexanediol phosphate. The oil slurry scale inhibitor disclosed by the invention has a low freezing point (less than or equal to -15 DEG C), small viscosity (the kinematic viscosity is less than or equal to 50 mm<2> / s at 20 DEG C), a strong anti-oxidization capability and good thermal stability; propertiesand utilization performance of the oil slurry scale inhibitor are not influenced at relatively high temperature of 350 to 400 DEG C and the oil slurry scale inhibitor is suitable for scale inhibitionand descaling in an oil slurry system in a catalytic cracking device; the adding amount of the oil slurry scale inhibitor in oil slurry is 30 to 100 ppm; the oil slurry scale inhibitor can be used foreffectively inhibiting equipment including the oil slurry system, a pipeline, a heat exchanger and the like from being coked; the scale inhibition rate can reach 90 percent and safe and stable operation of a device is ensured.

Owner:JIANGSU KECHUANG PETROCHEM

Brominated polymer flame retardant and preparation method thereof

The invention provides a brominated polymer flame retardant and a preparation method thereof and belongs to the field of chemical and constructing material flame retardants. The preparation method comprises the following steps: at 0 DEG C, dripping a certain ratio of diluted bromine into a styrene-butadiene copolymer solution; and reacting by adopting a specific temperature rising mechanism to finally prepare the target brominated polymer flame retardant. The brominated polymer flame retardant provided by the invention has good compatibility with a polystyrene material, a high oxygen index and a good flame retarding effect; the preparation method provided by the invention is simpler and bromine is directly used for carrying out bromine addition, so that introduction of other impurities and byproducts is effectively avoided; and the difficulty of post-treatment is reduced and the cost of a whole synthesizing process is reduced.

Owner:天津天盈新型建材有限公司

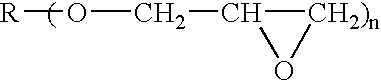

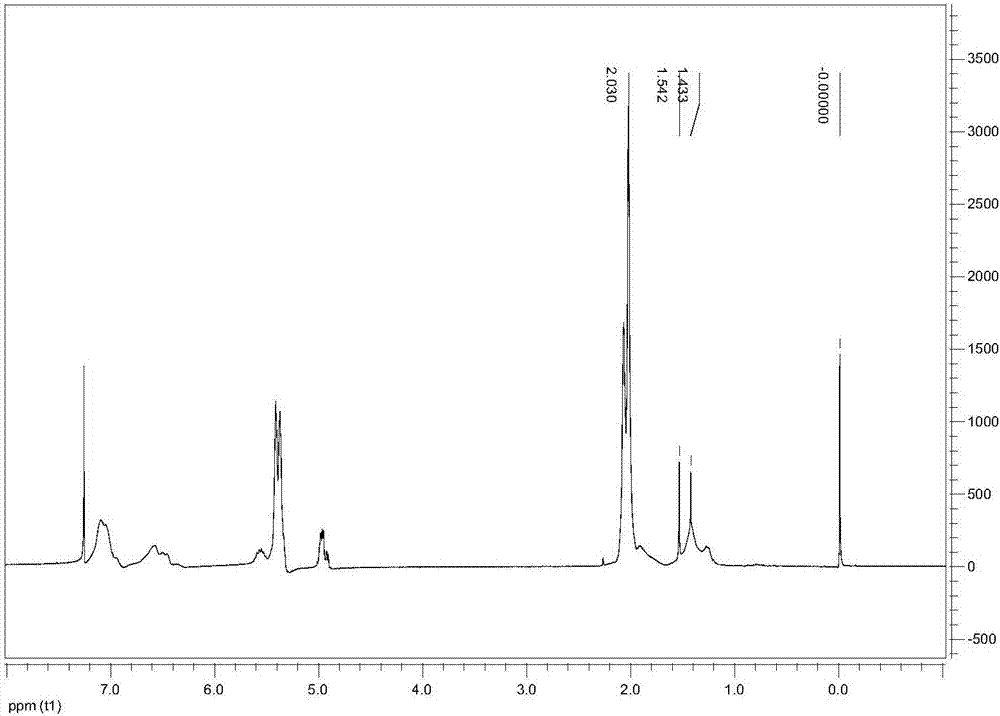

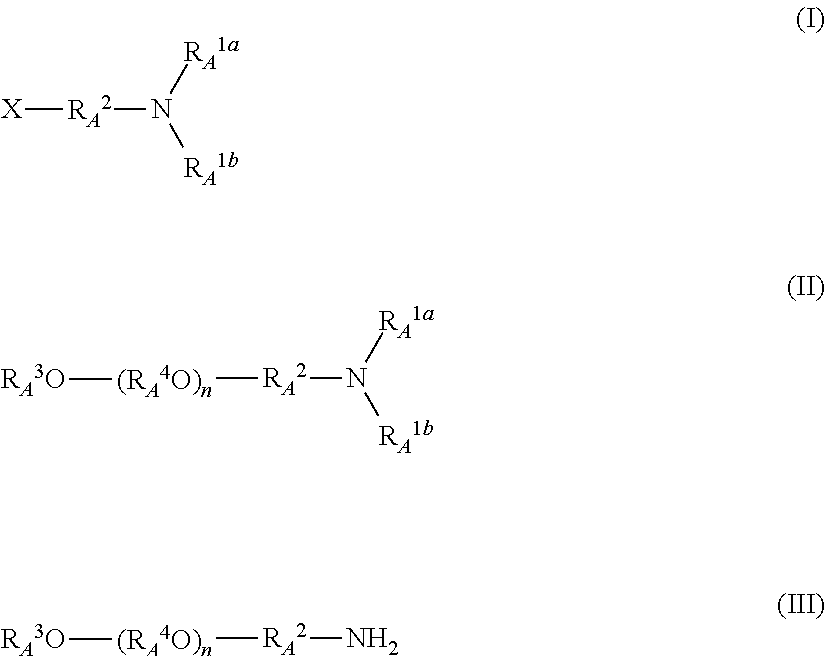

Method for producing polyalkylene glycol derivative having amino group at end

ActiveUS20160159831A1High yield rateAdverse effectSilicon organic compoundsOrganic compound preparationPtru catalystCombinatorial chemistry

A method simply produces a narrowly distributed and high-purity polyalkylene glycol derivative having an amino group at an end without using a heavy metal catalyst. A method for producing a polyalkylene glycol derivative having an amino group at the end by reacting a compound represented by the general formula (V) with an alkylene oxide, then reacting a reaction product with an electrophile represented by the general formula (I), and deprotecting the obtained product without using a heavy metal:RA3O(RA4O)k-1RA4O−M+ (V)wherein RA3 represents a linear; branched, or cyclic hydrocarbon group having 1 to 20 carbon atoms; RA4 represents an alkylene group having 2 to 8 carbon atoms; k represents an integer of 2 to 5; and M represents an alkali metal;wherein RA1a and RA1b each independently represent a protective group of the amino group, or one of RA1a and RA1b represents H and the other represents a protective group of the amino group, or RA1a and RA1b bind to each other to form a cyclic protective group, and the protective group is deprotectable without using a heavy metal; RA2 represents a linear, branched, or cyclic hydrocarbon group having 1 to 6 carbon atoms; and X represents a leaving group.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com