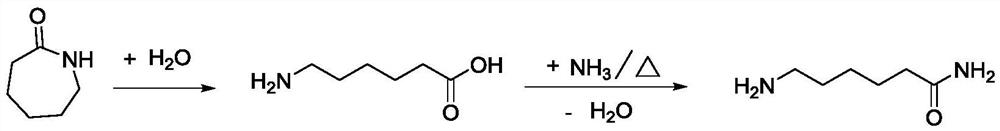

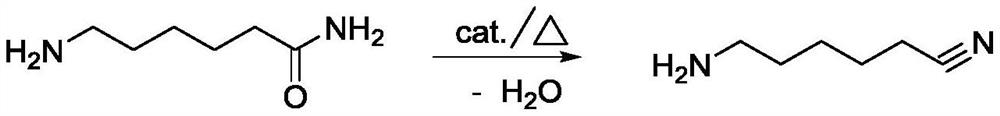

Method for preparing hexamethylenediamine key intermediate 6-aminocapronitrile by two-step method

A technology of aminocapronitrile and hexamethylenediamine, which is applied in the preparation of carboxylic acid amides, the preparation of cyanide reaction, chemical instruments and methods, etc., can solve the problems of easy coking of catalysts, and achieve the avoidance of coking of catalysts, lasting conversion rate, and prolonged use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix caprolactam and hydrogen chloride aqueous solution in a reaction kettle. The mass ratio of caprolactam: water: hydrogen chloride is 1:6:0.001. The mixture is reacted at 150°C and 0.5MPa for 48 hours. The obtained material is flashed to remove 80% of the water, and then the reaction Ammonia gas at 150° C. was passed into the kettle at a flow rate of 3 times the weight of caprolactam per hour for 5 hours to obtain crude aminocaproamide.

[0037] Aminocaproamide crude product was mass space velocity 8h -1 Pump into the reactor that alumina catalyst is housed from the top, pass into the ammonia gas of 300 ℃ with the flow rate of 7 times amino caproamide crude product weight, ammonia gas enters simultaneously from the reactor bottom and the middle part (bottom and middle part ammonia gas pumping ratio 2:1), the conversion rate of total caprolactam per pass is 99.5%, the highest selectivity of aminocapronitrile is 99.3%, and the single pass life of the catalyst is judged ...

Embodiment 2

[0039] Mix caprolactam and hydrogen chloride aqueous solution in a reaction kettle, the mass ratio of caprolactam:water:sodium hydroxide is 1:6:0.3, the mixture is reacted at 280°C and 7.5MPa for 12h, and the obtained material is flashed to remove 80% of the water, and then Ammonia gas at 200° C. was passed into the reactor at a flow rate of 1 times the weight of caprolactam per hour for 3 hours to obtain crude aminocaproamide.

[0040] Aminocaproamide crude product was mass space velocity 0.5h -1 Pump into the reactor that alumina catalyst is housed from the top, pass into the ammonia gas of 200 ℃ with the flow rate of 0.5 times amino caproamide crude product weight, ammonia gas enters simultaneously from the reactor bottom and middle part (bottom and middle part ammonia gas pumping ratio is 1:1), the conversion rate of total caprolactam per pass is 99.3%, the highest selectivity of aminocapronitrile is 98.7%, and the one-pass life of the catalyst is 1350h when the selectivit...

Embodiment 3

[0042] Mix caprolactam and hydrogen chloride aqueous solution in a reaction kettle. The mass ratio of caprolactam: water: hydrogen chloride is 1:3:0.01. The mixture is reacted at 200°C and 1.7MPa for 3 hours. Ammonia gas at 250° C. was passed into the kettle at a flow rate of 0.5 times the weight of caprolactam per hour for 2 hours to obtain crude aminocaproamide.

[0043] Aminocaproamide crude product was mass space velocity 1h -1 Pump into the reactor that alumina catalyst is housed from the top, pass into the ammonia gas of 230 ℃ with the flow rate of 4 times amino caproamide crude product weight, ammonia gas enters simultaneously from the reactor bottom and the middle part (bottom and middle part ammonia gas pumping ratio 1:1), the conversion rate of total caprolactam per pass is 99.8%, the highest selectivity of aminocapronitrile is 99.4%, and the single pass life of the catalyst is 1550h when the selectivity of aminocapronitrile is less than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com