Patents

Literature

353results about How to "High yield rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

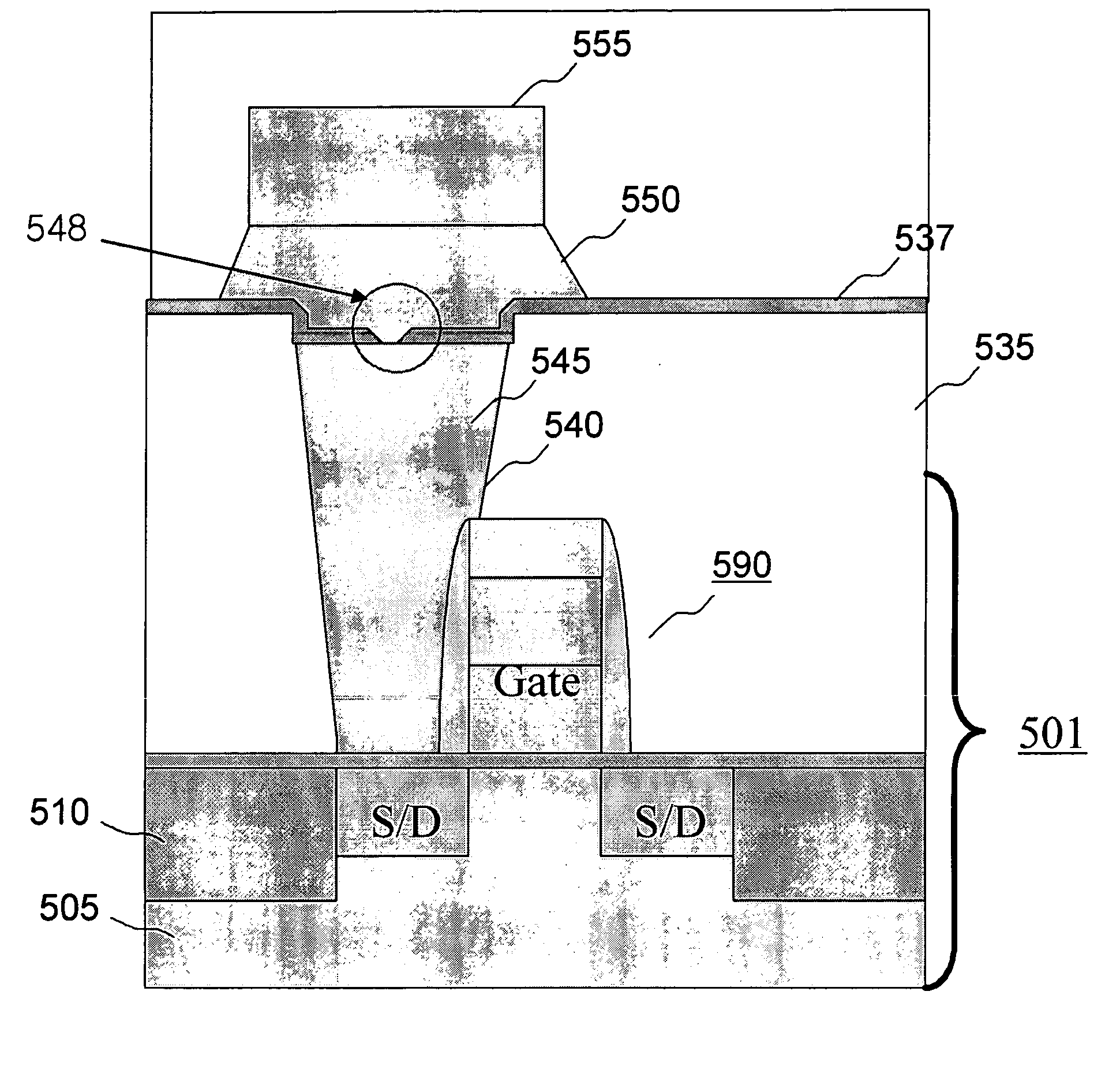

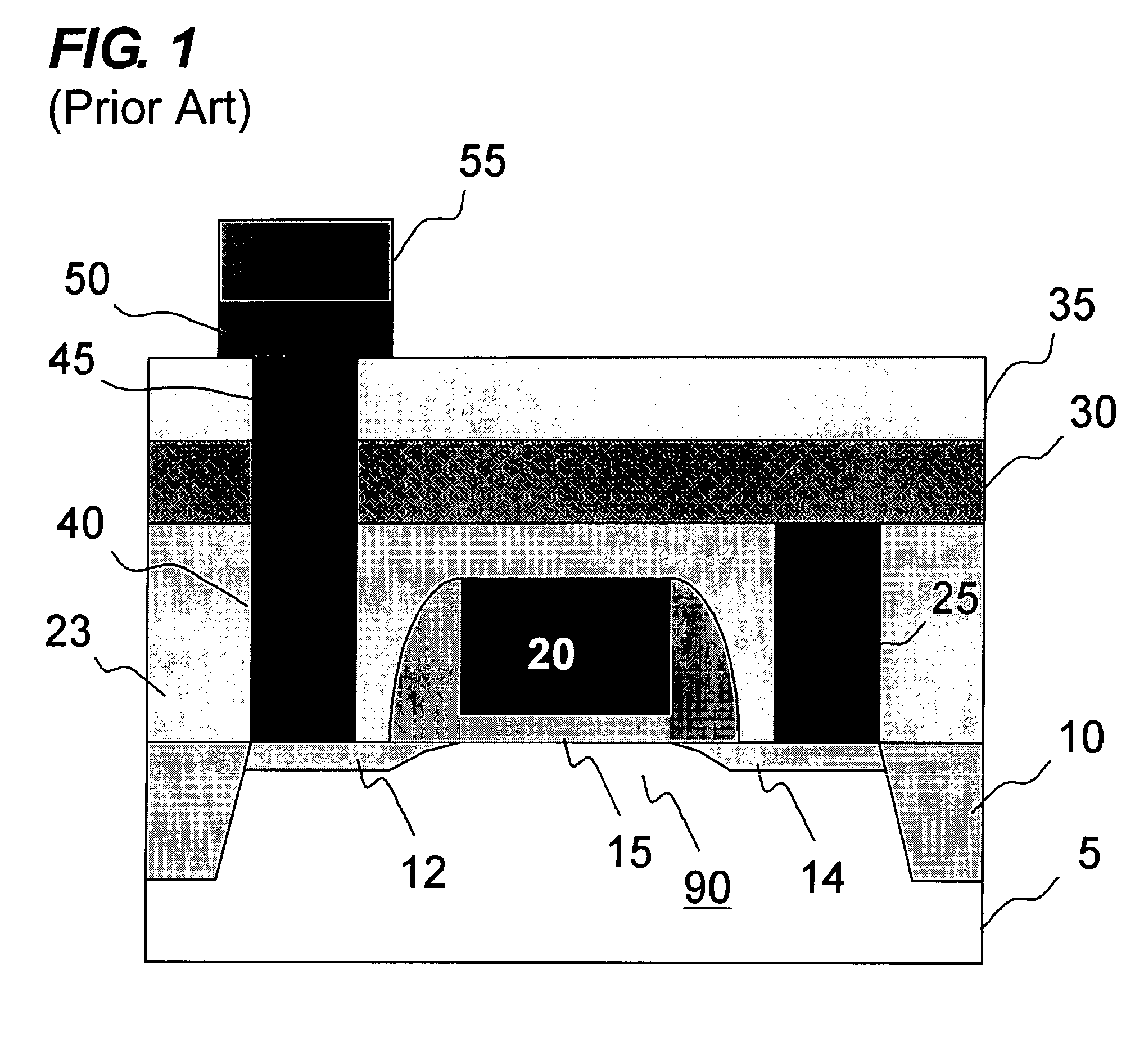

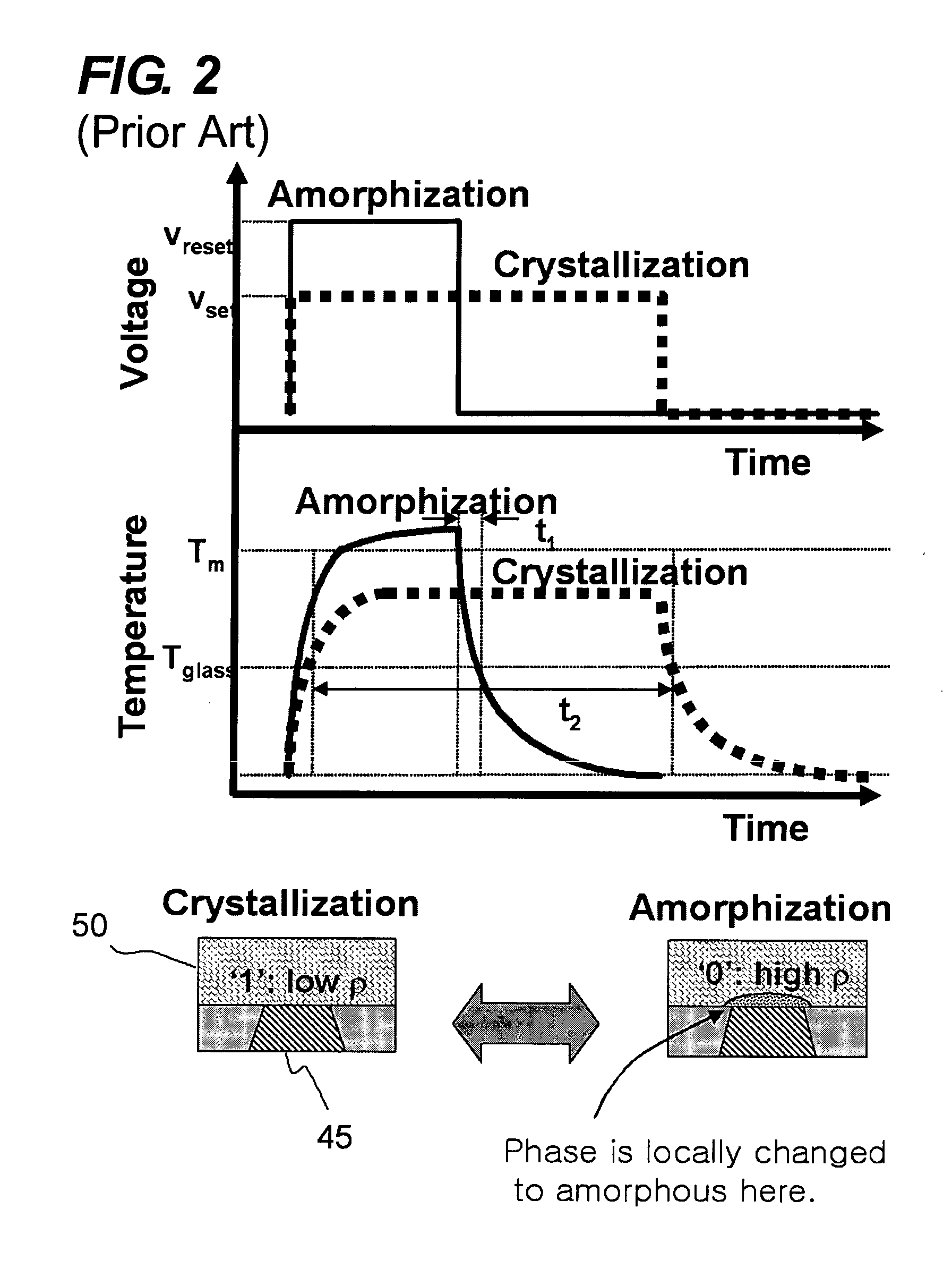

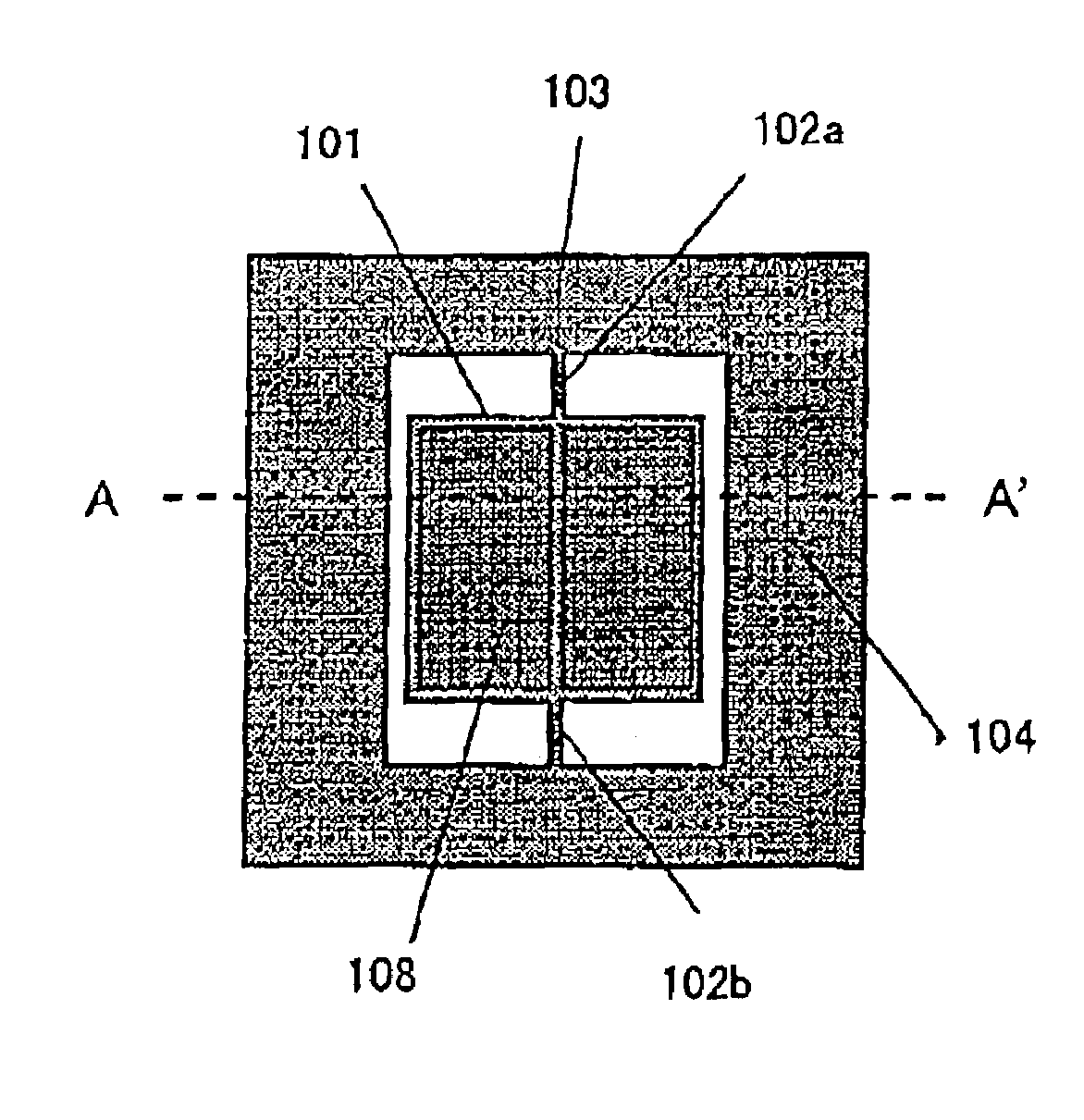

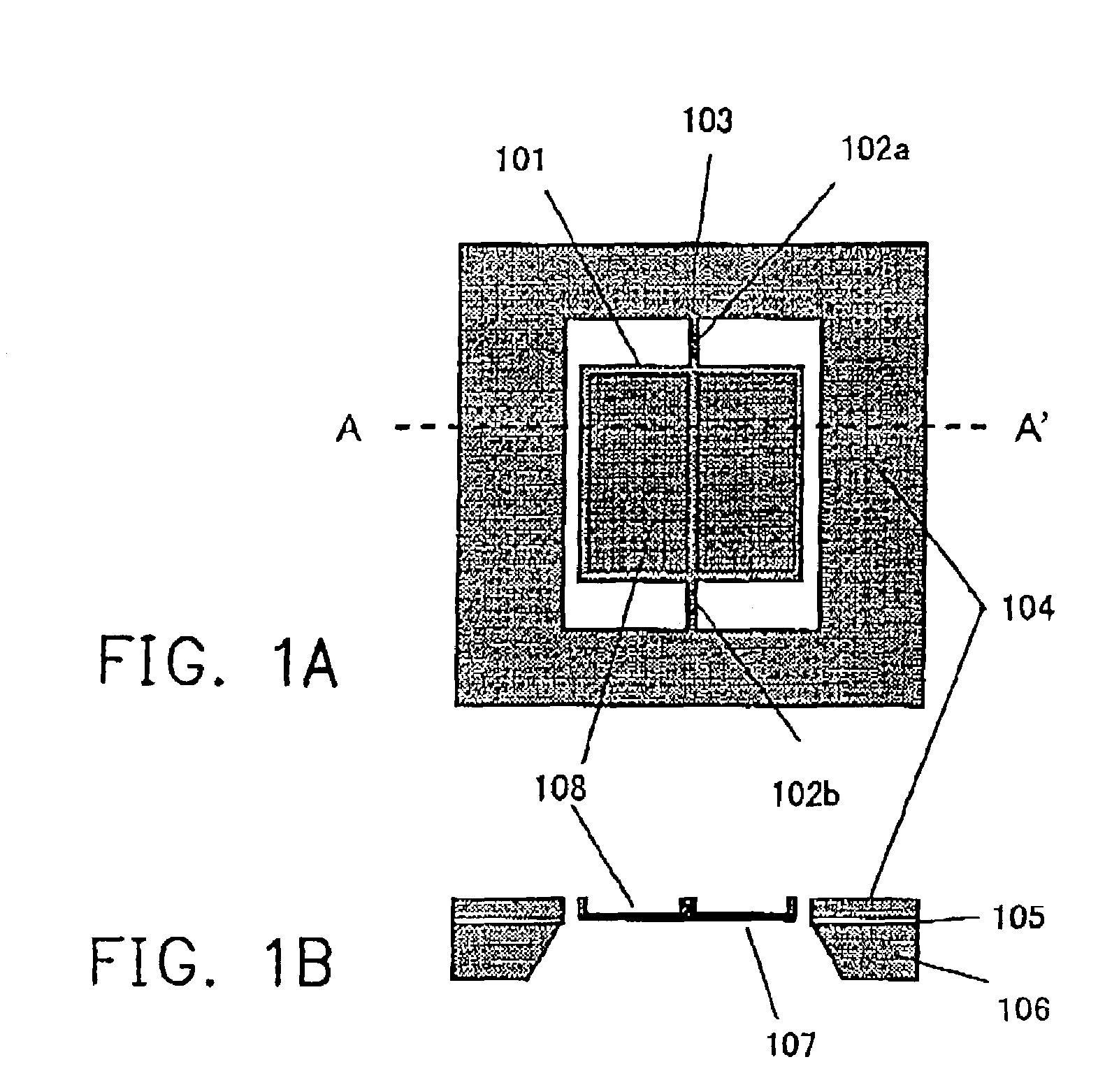

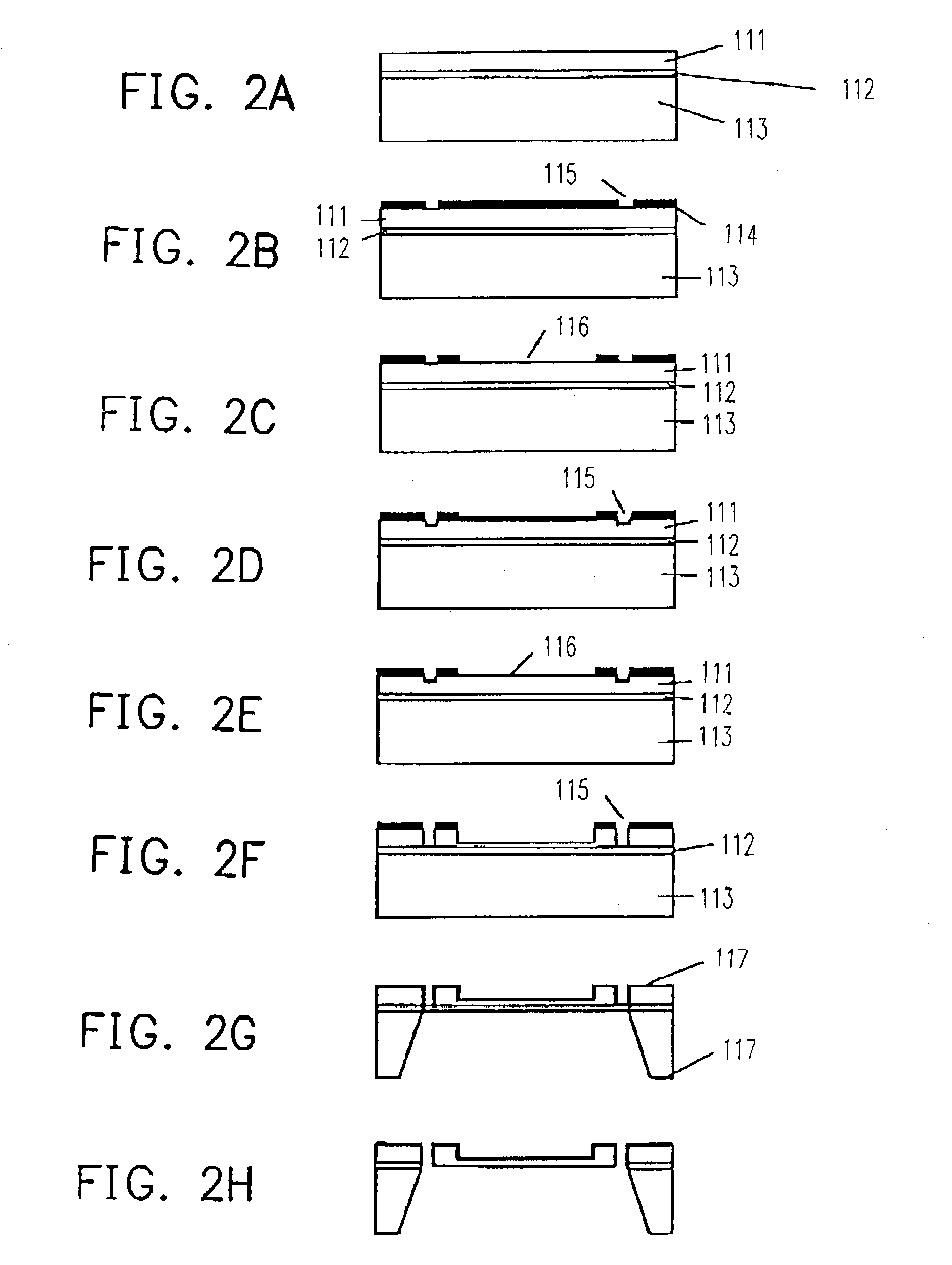

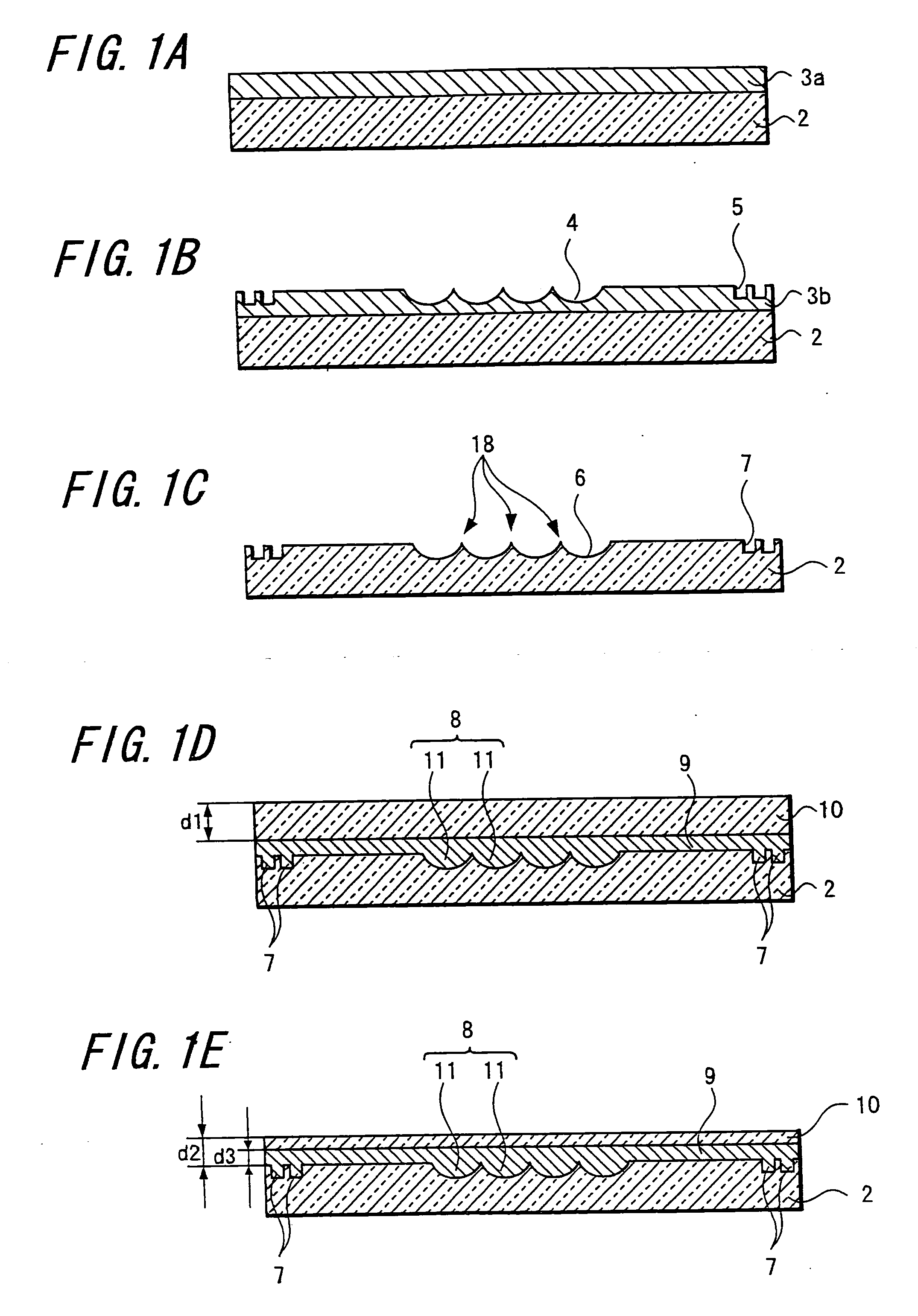

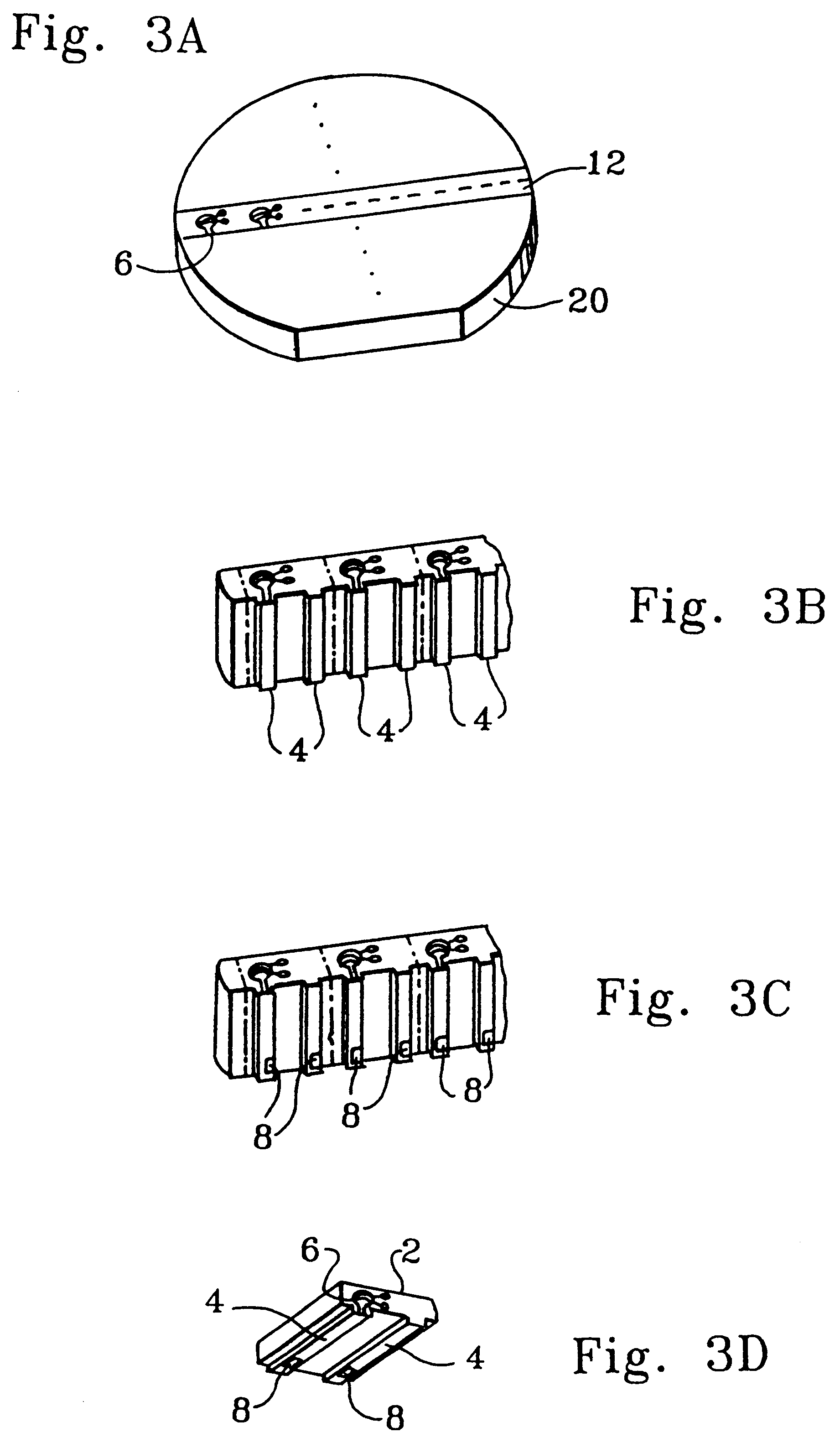

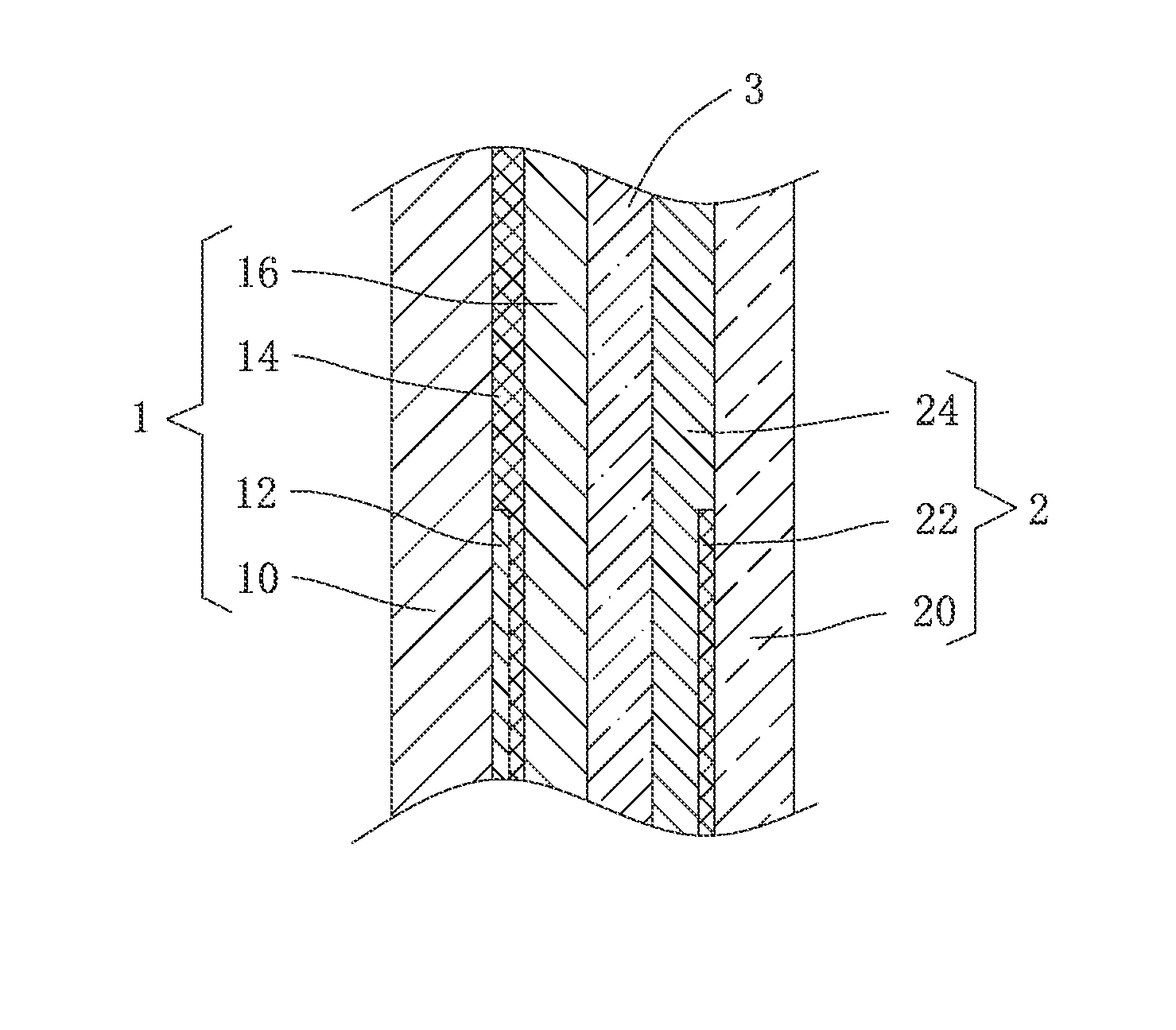

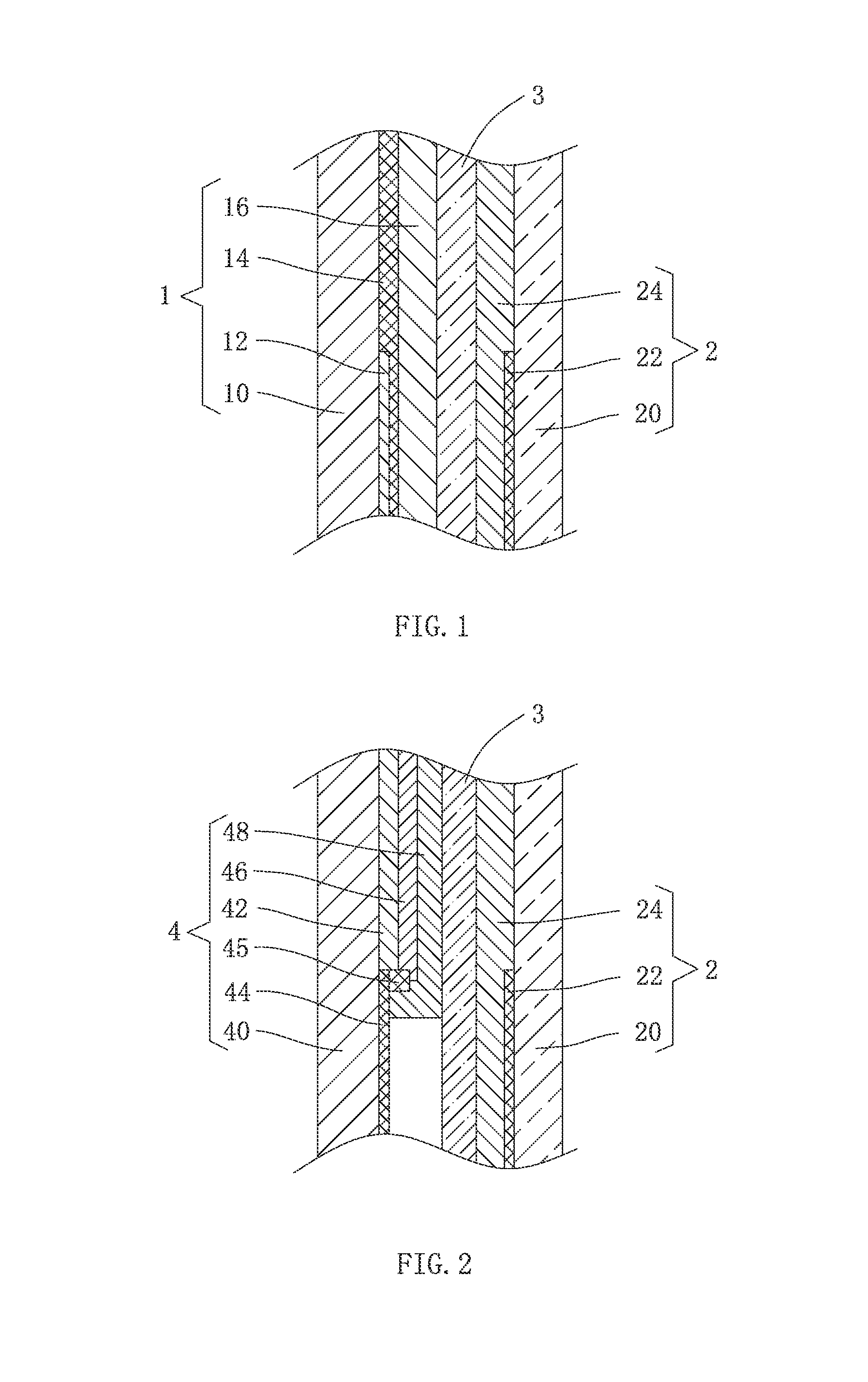

Phase-change memory device and manufacturing method thereof

InactiveUS20050018526A1Easy to manufactureHigh yield rateSolid-state devicesDigital storagePhase-change memoryDielectric layer

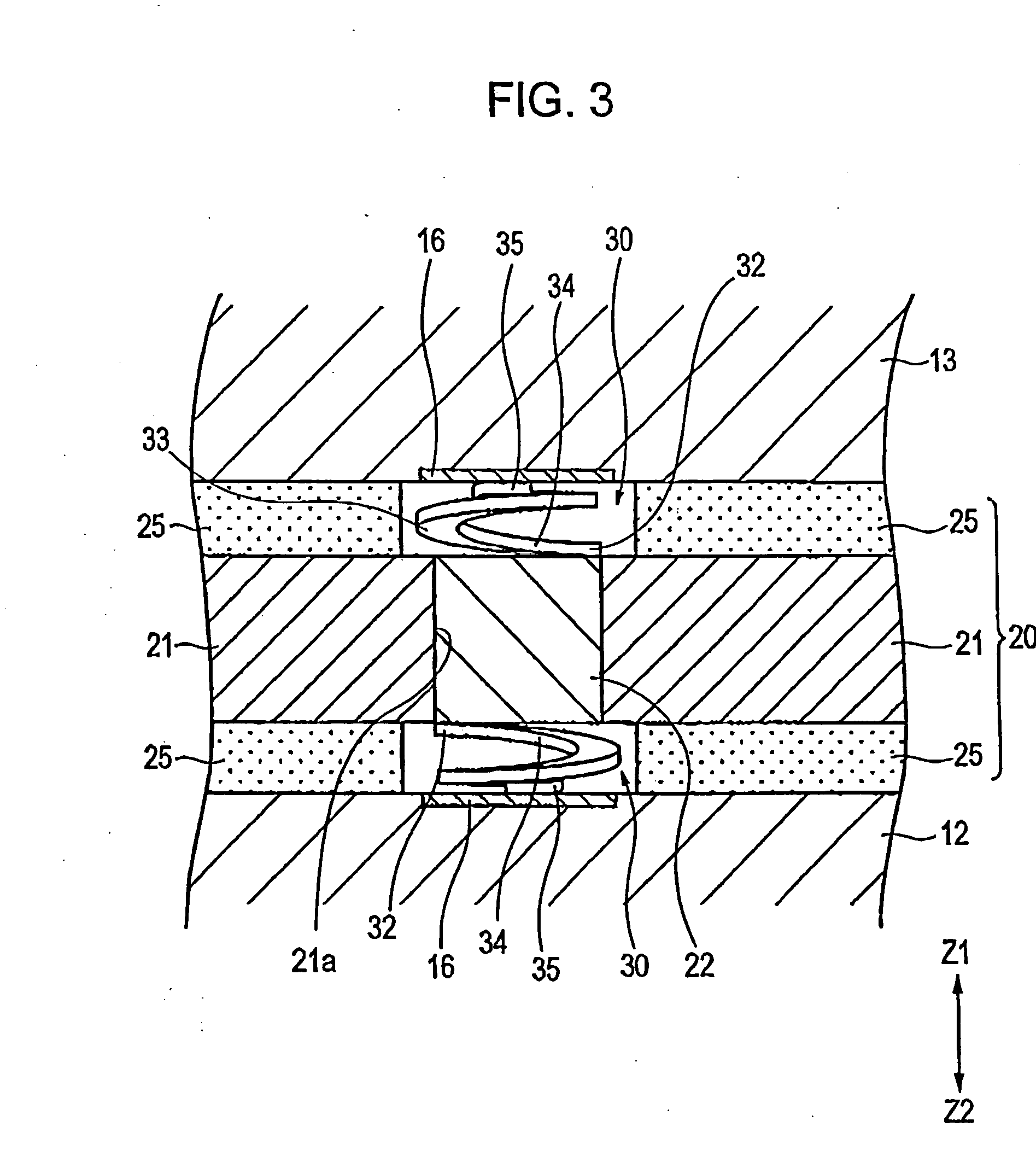

The present invention is to provide a phase change memory device having a new structure which can be easily manufactured by mass-production with a high yield rate, therefore, reducing the cost of process and providing reliable device characteristics, and a manufacturing method thereof. The present invention provides a phase-change memory device comprising: a lower dielectric layer; a lower electrode, at least a part of the lateral surface of the lower electrode being surrounded by the lower dielectric layer; a thin dielectric layer including a pore having smaller area than the top surface of the lower electrode, aligned to the top surface of the lower electrode and extending to the top surface of the lower electrode; and a phase-change resistor filling the pore and formed on the thin dielectric layer. In the proposed structure of the present invention, the pores or local damaged spots can provide a micro path of current and localize the phase-changing volume in the phase-change resistor. Thus, the phase-change memory device can be operated with very low power.

Owner:LEE HEON

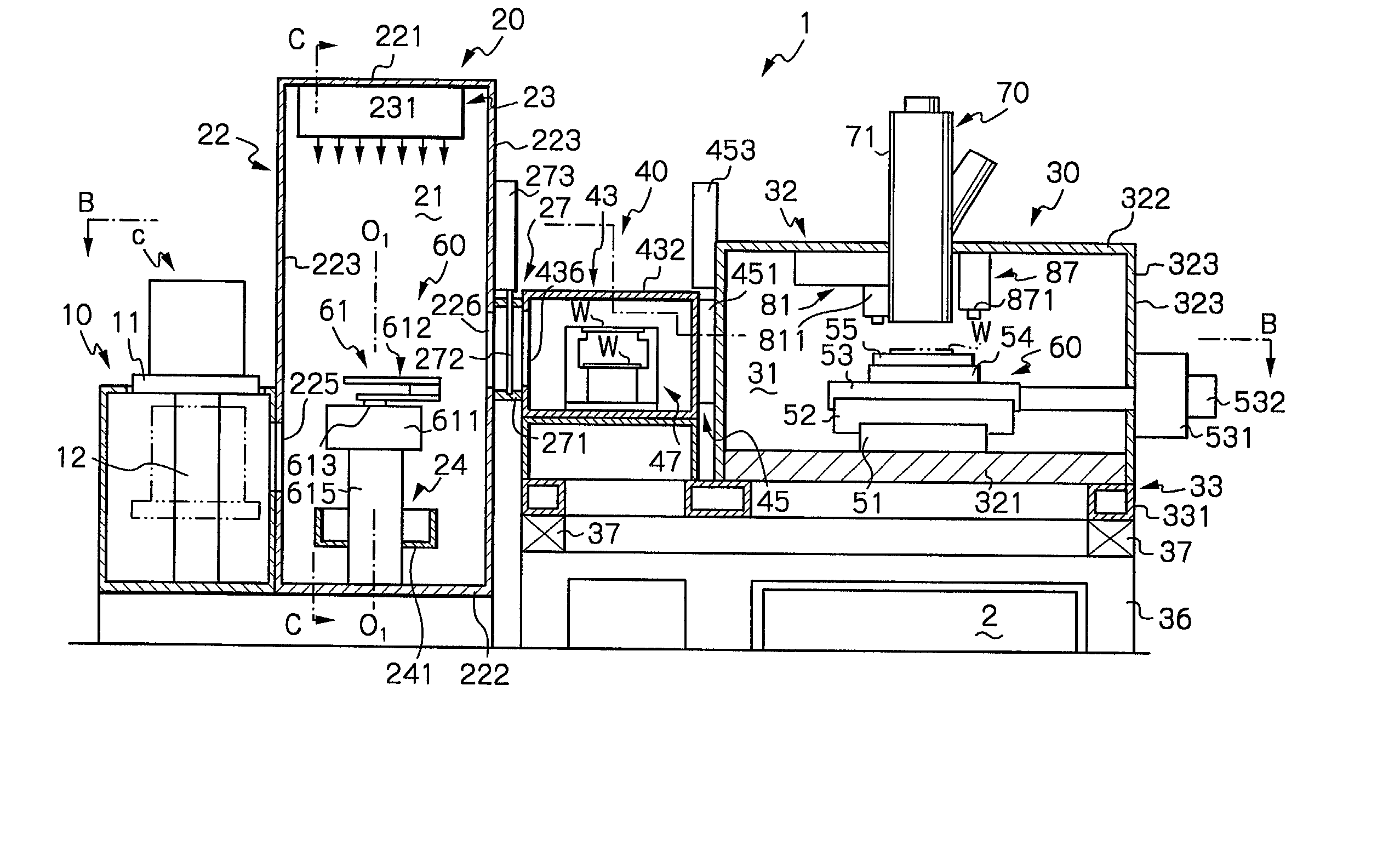

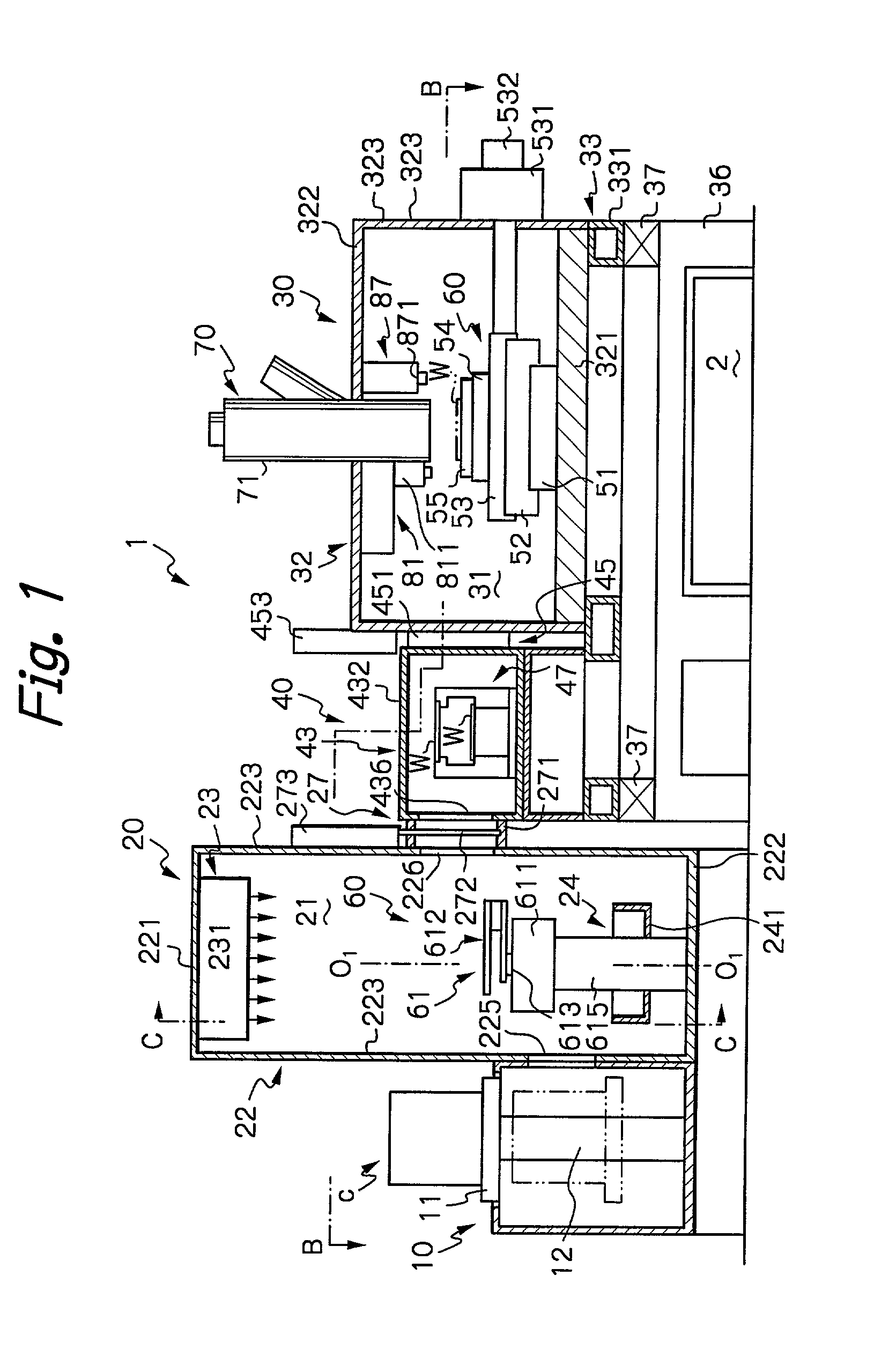

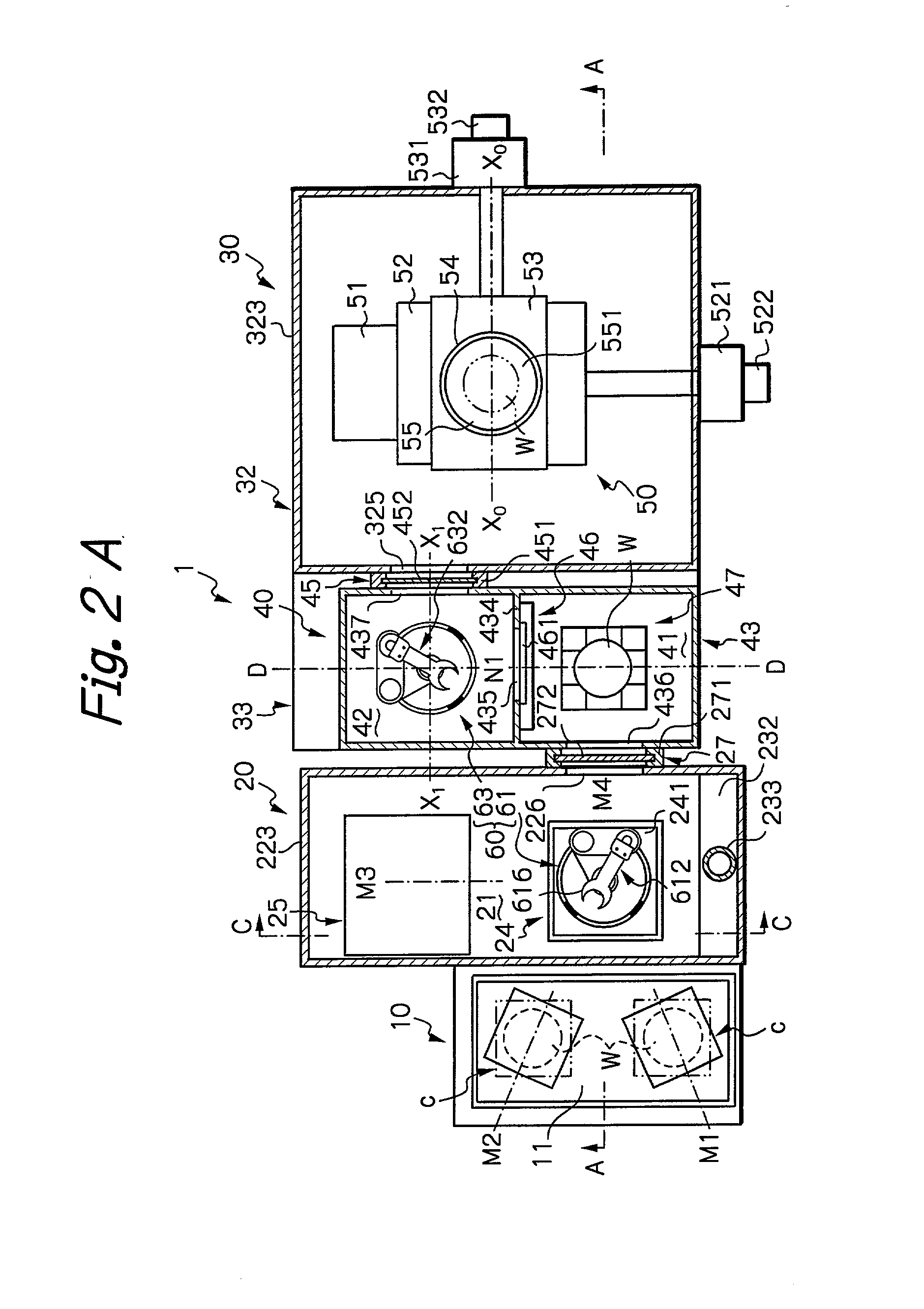

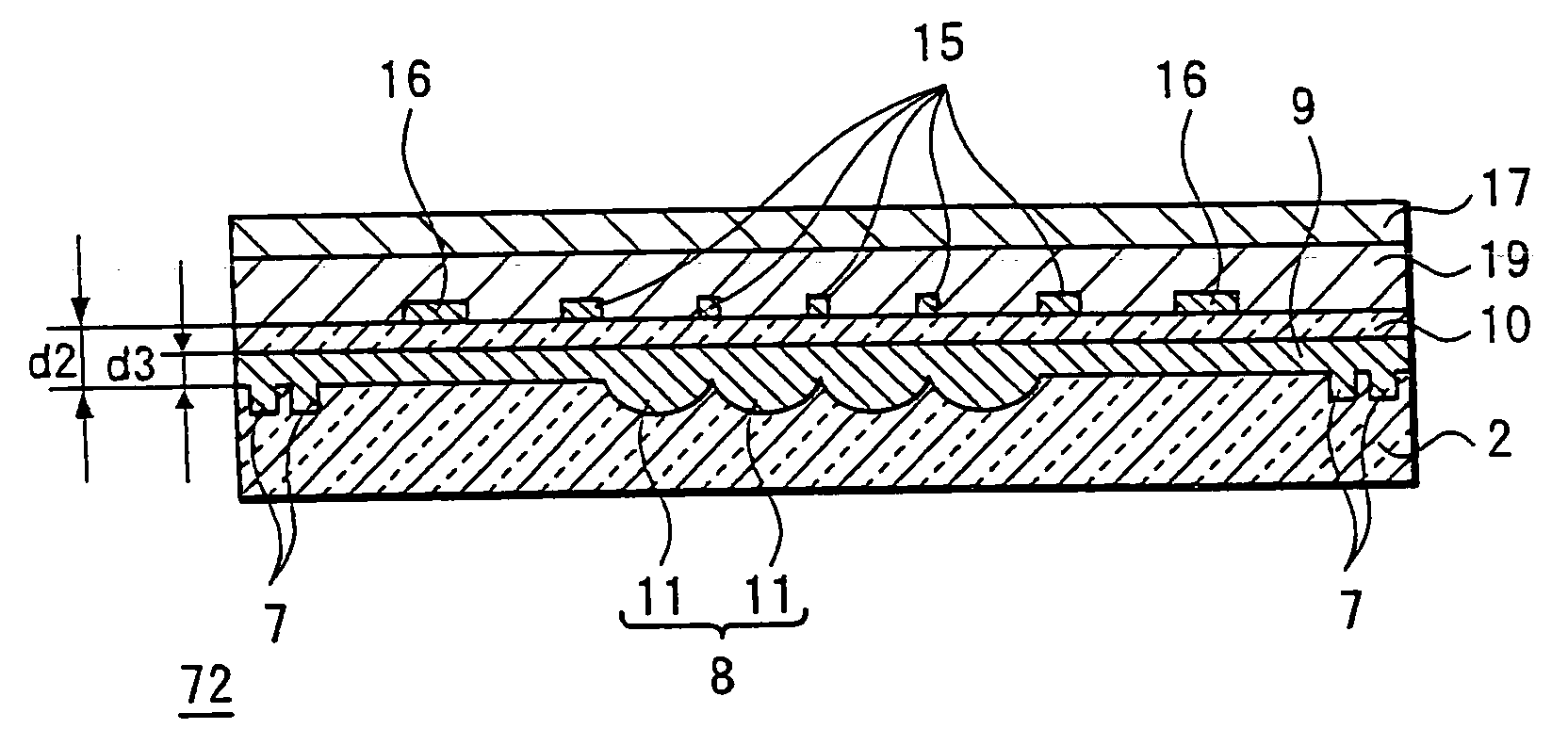

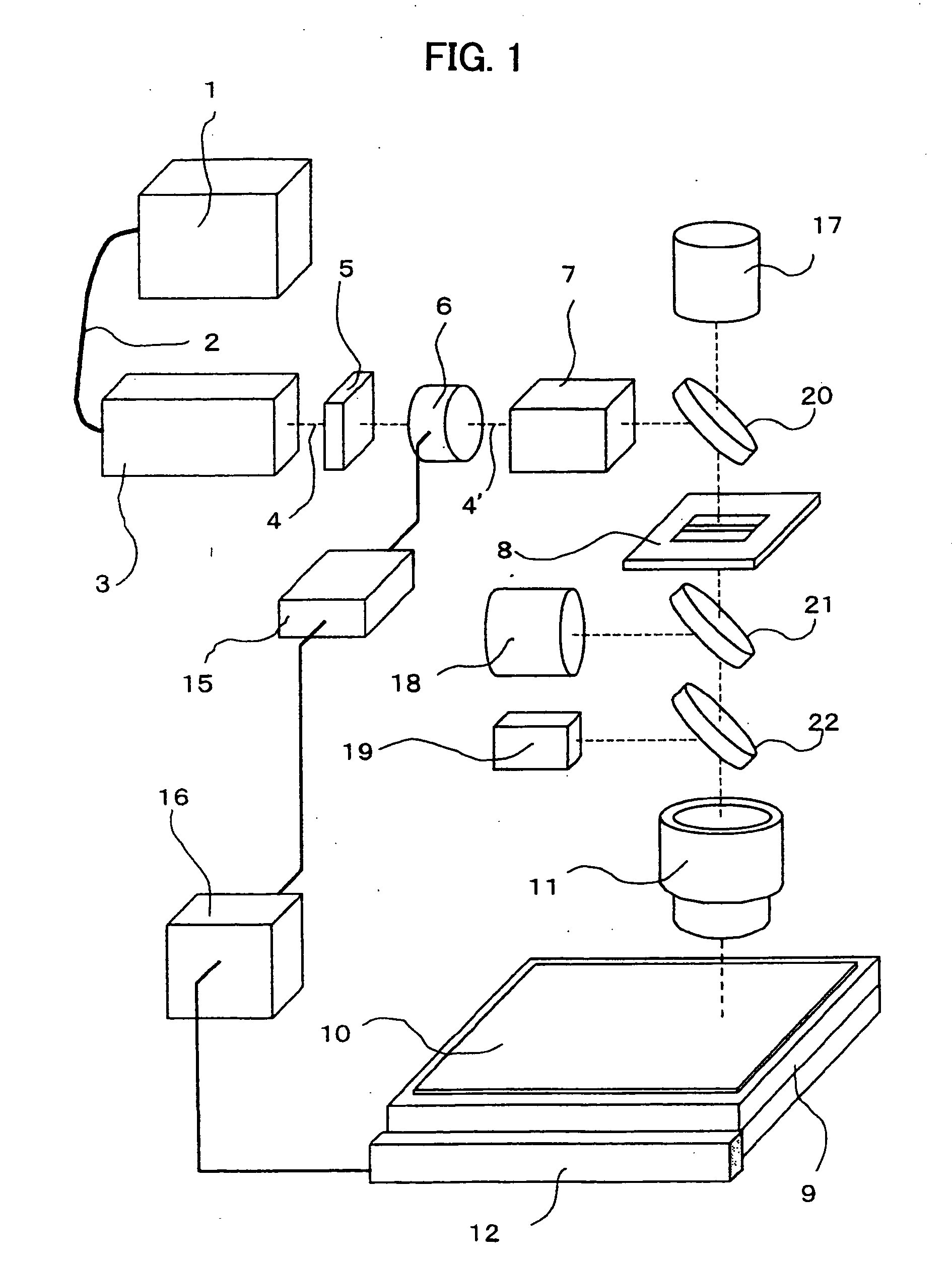

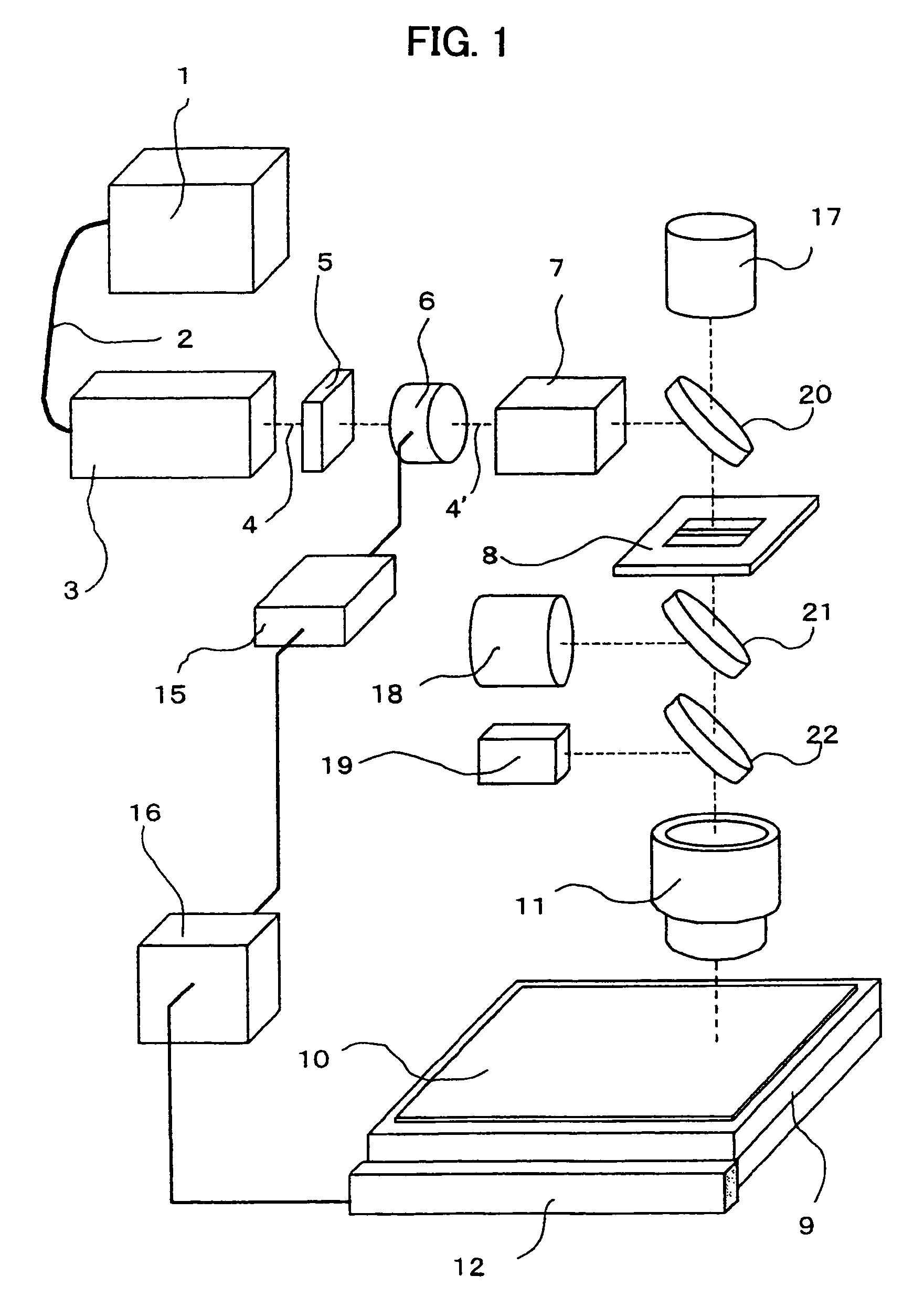

Inspection system by charged particle beam and method of manufacturing devices using the system

InactiveUS20020028399A1Efficiently and accurately inspecting objectAccurately inspect an objectMaterial analysis using wave/particle radiationElectrode and associated part arrangementsBeam sourceSecondary electrons

An inspection apparatus by an electron beam comprises: an electron-optical device 70 having an electron-optical system for irradiating the object with a primary electron beam from an electron beam source, and a detector for detecting the secondary electron image projected by the electron-optical system; a stage system 50 for holding and moving the object relative to the electron-optical system; a mini-environment chamber 20 for supplying a clean gas to the object to prevent dust from contacting to the object; a working chamber 31 for accommodating the stage device, the working chamber being controllable so as to have a vacuum atmosphere; at least two loading chambers 41, 42 disposed between the mini-environment chamber and the working chamber, adapted to be independently controllable so as to have a vacuum atmosphere; and a loader 60 for transferring the object to the stage system through the loading chambers.

Owner:EBARA CORP +1

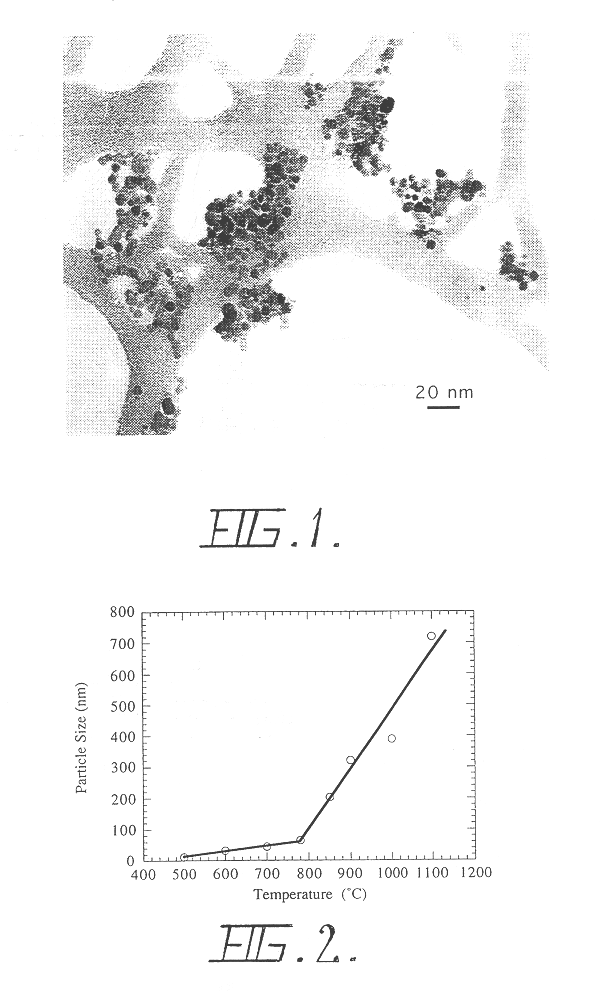

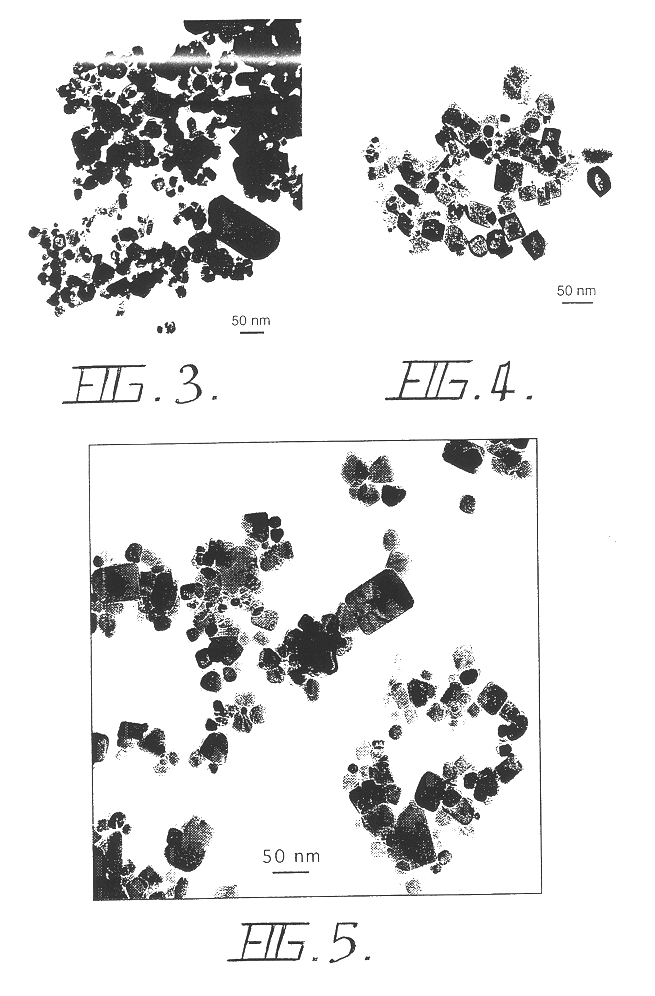

Process for the production of ultrafine powders of metal oxides

InactiveUS6503475B1Low costHigh yield rateAlkaline earth titanatesMaterial nanotechnologyDiluentBiological activation

A process for the production of ultrafine powders that includes subjecting a mixture of precursor metal compound and a non-reactant diluent phase to mechanical milling whereby the process of mechanical activation reduces the microstructure of the mixture to the form of nano-sized grains of the metal compound uniformly dispersed in the diluent phase. The process also includes heat treating the mixture of nano-sized grains of the metal compound uniformly dispersed in the diluent phase to convert the nano-sized grains of the metal compound into a metal oxide phase. The process further includes removing the diluent phase such that the nano-sized grains of the metal oxide phase are left behind in the form of an ultrafine powder.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD +1

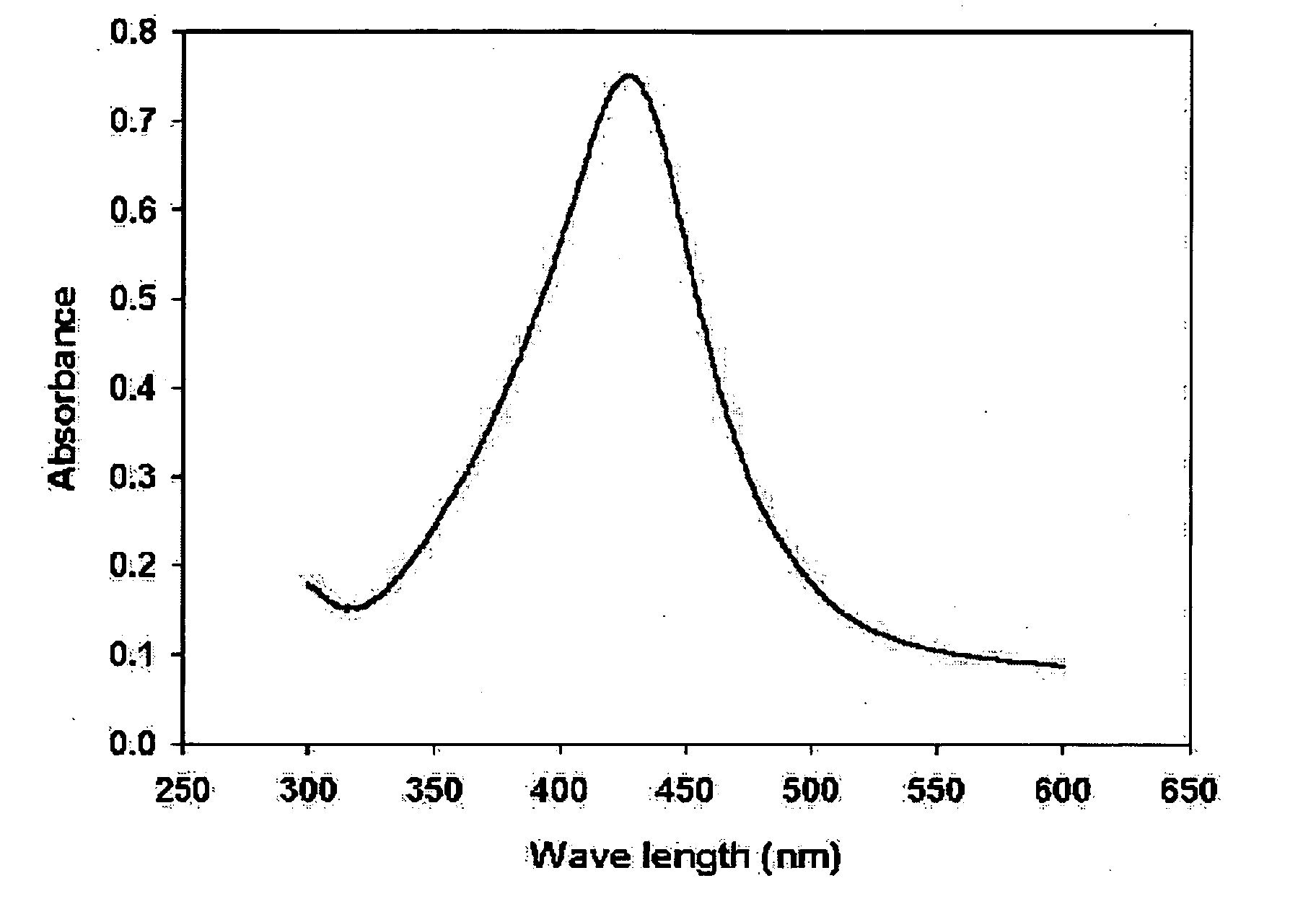

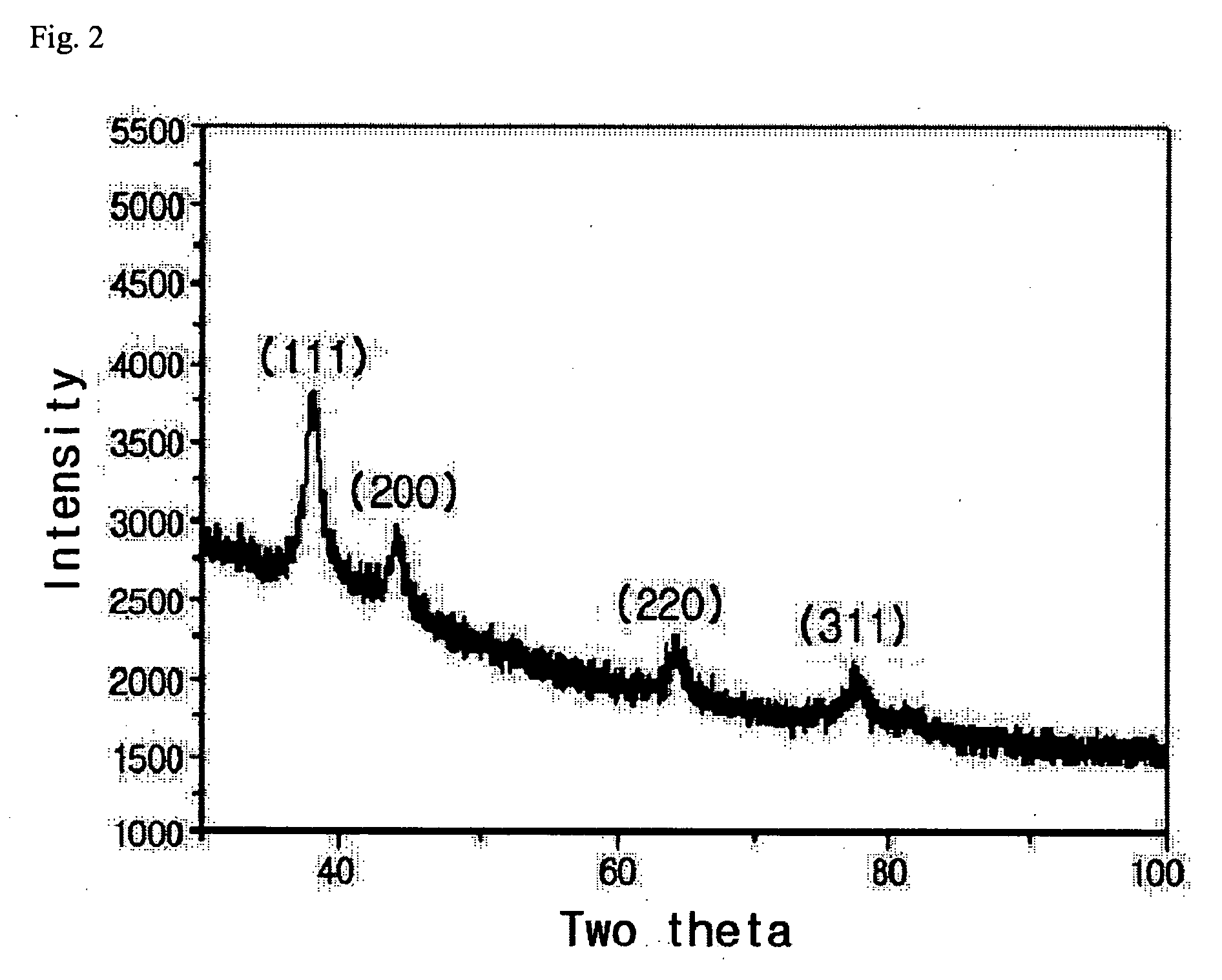

Metal nano particle and method for manufacturing them and conductive ink

InactiveUS20060254387A1Uniform particle size distributionHigh yield rateMaterial nanotechnologyBiocideSolventIon

A method of producing hydrophobic metal nanoparticles using a hydrophobic solvent, having uniform particle size distribution and high yield rate to allow mass production; the metal nanoparticles thus produced; and conductive ink including the metal nanoparticles are disclosed. According to one aspect of the invention, a method of producing metal nanoparticles is provided, comprising dissociating a metal compound with an amine-based compound, and adding a hydrocarbon-based compound and either one of an alkanoic acid or a thiol-based compound to the dissociated metal ion solution.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

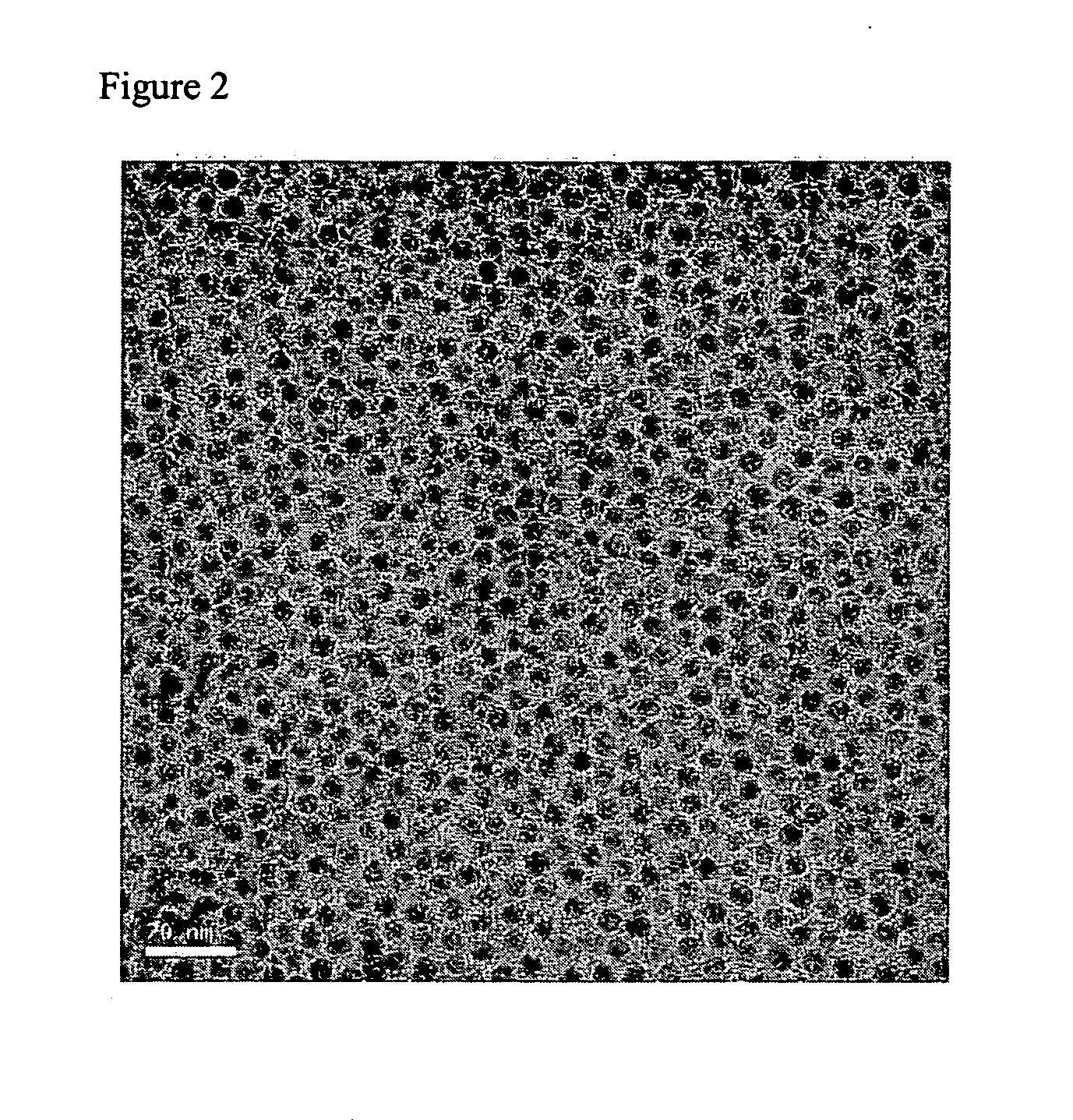

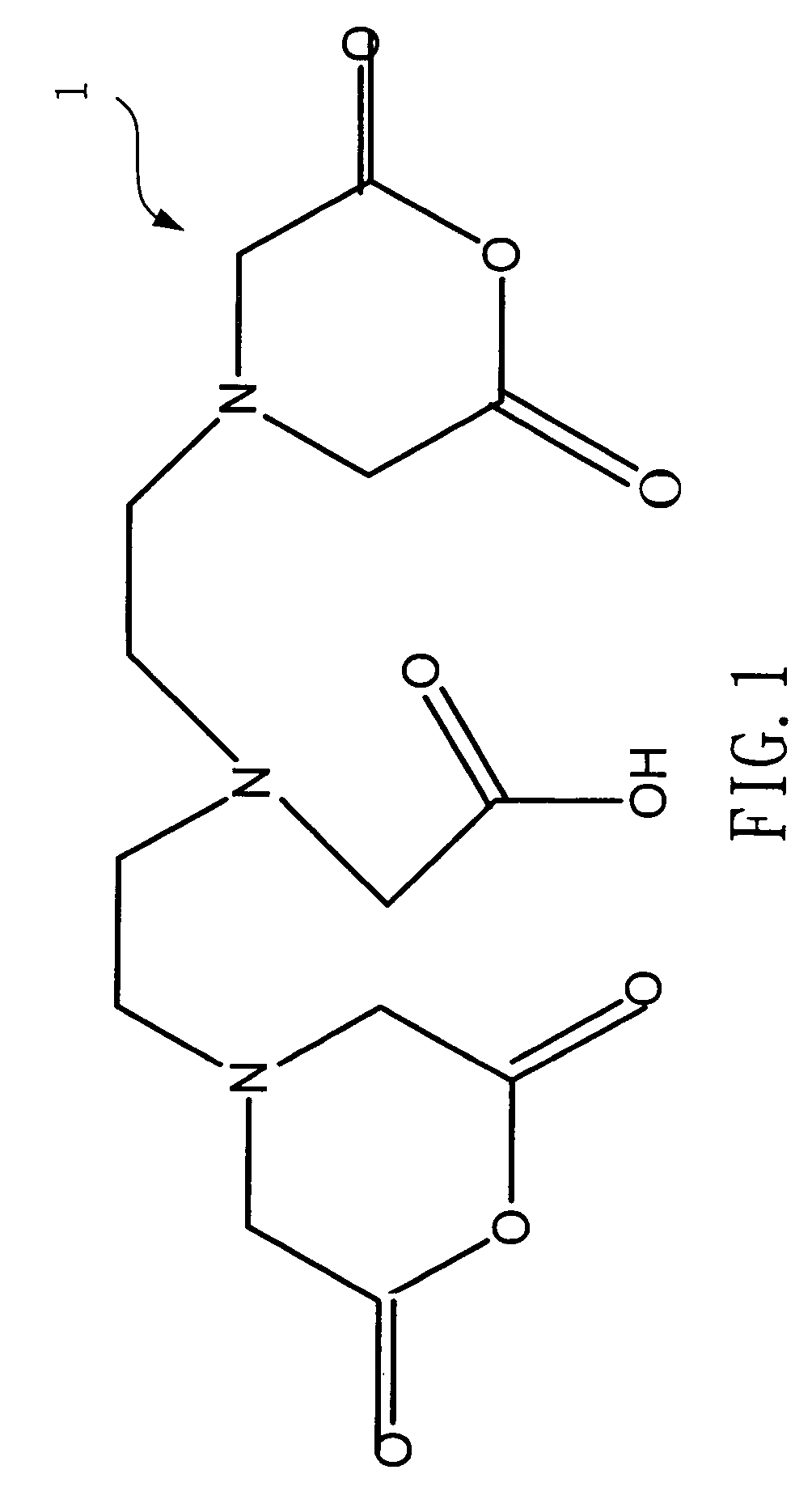

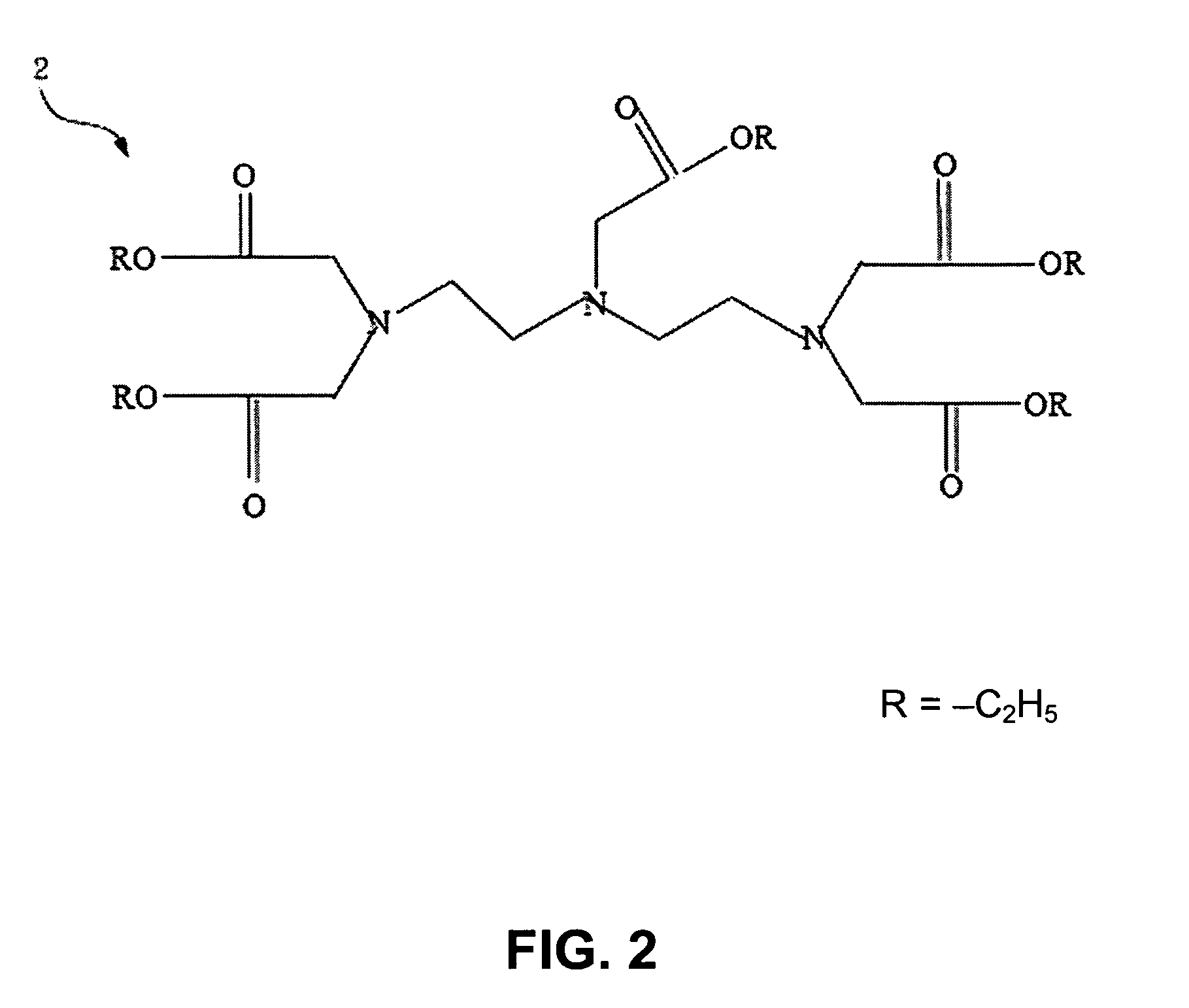

Method for manufacturing diethylene triamine pentaacetic acid derivative

InactiveUS7767844B2Simple production procedureHigh yield rateOrganic compound preparationAmino-carboxyl compound preparationMetalloleRegioselectivity

Owner:INST NUCLEAR ENERGY RES ROCAEC

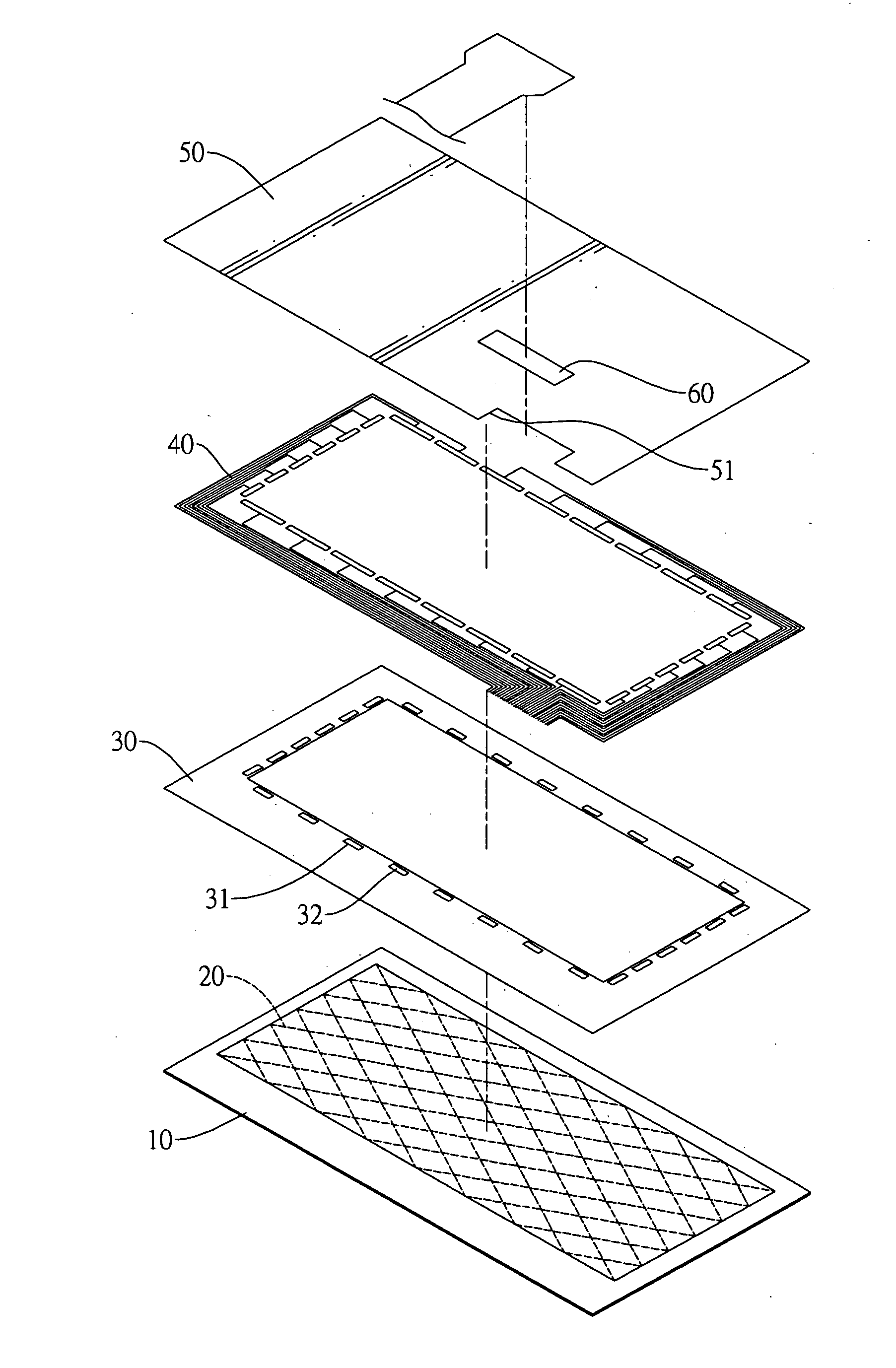

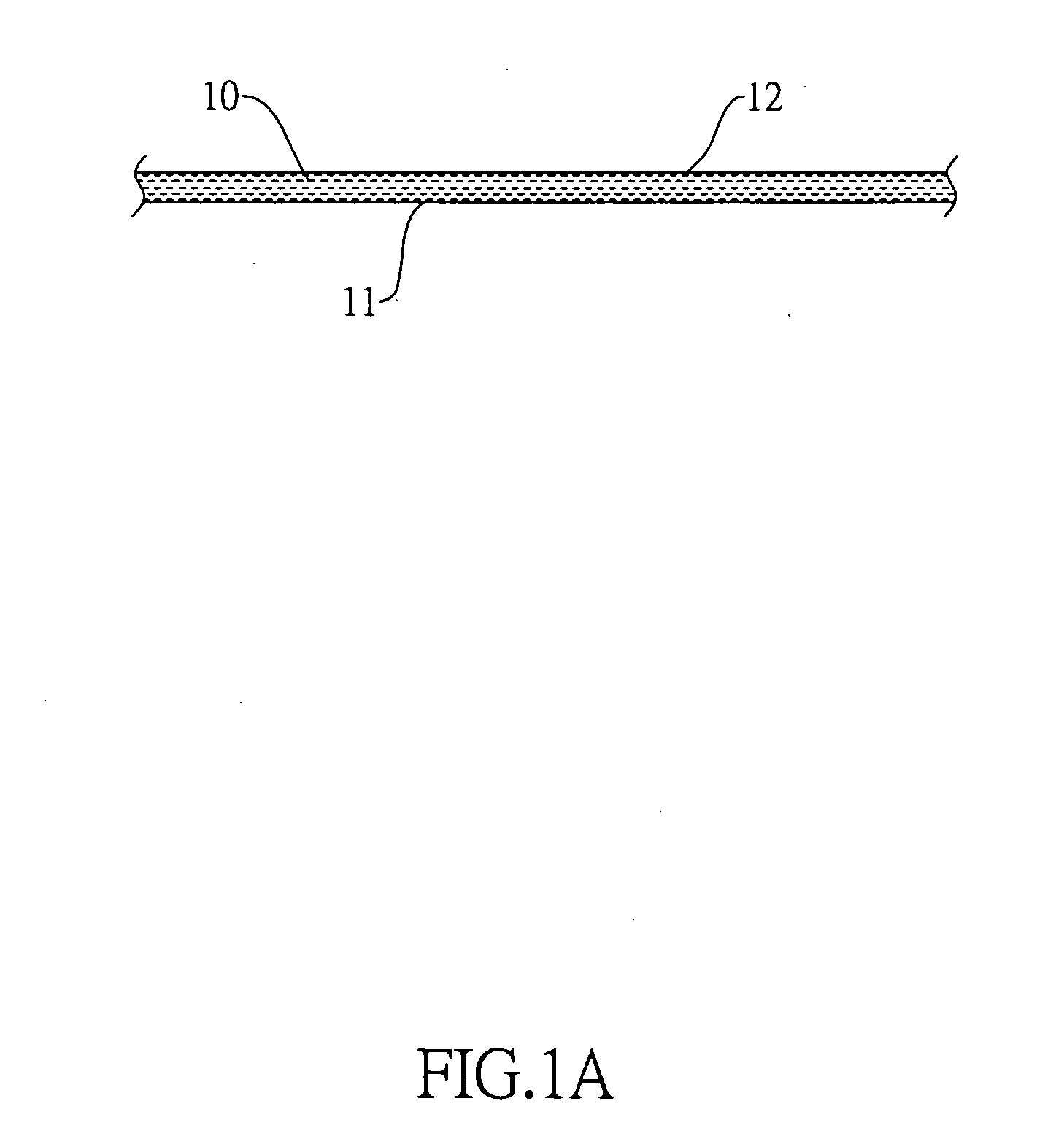

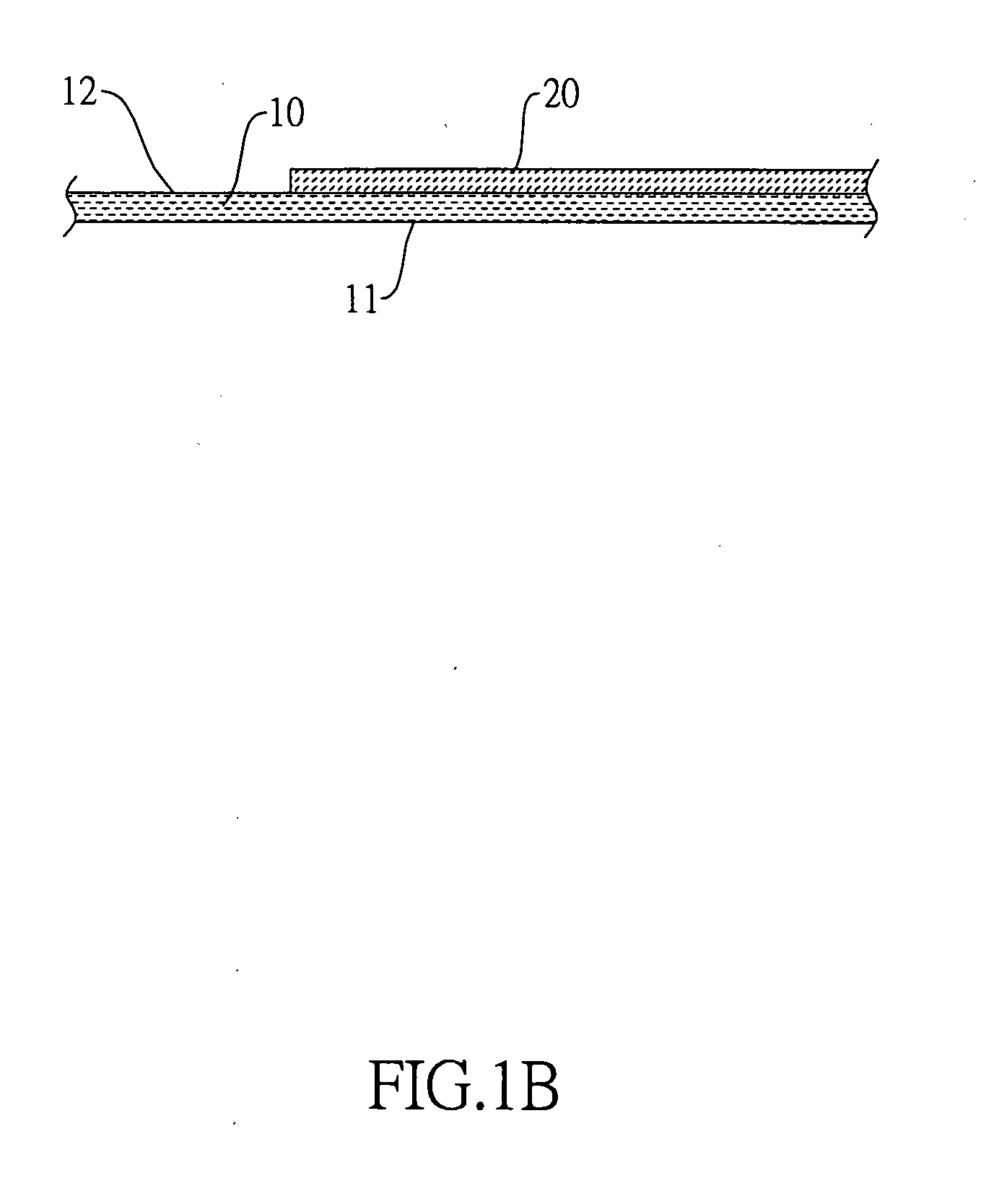

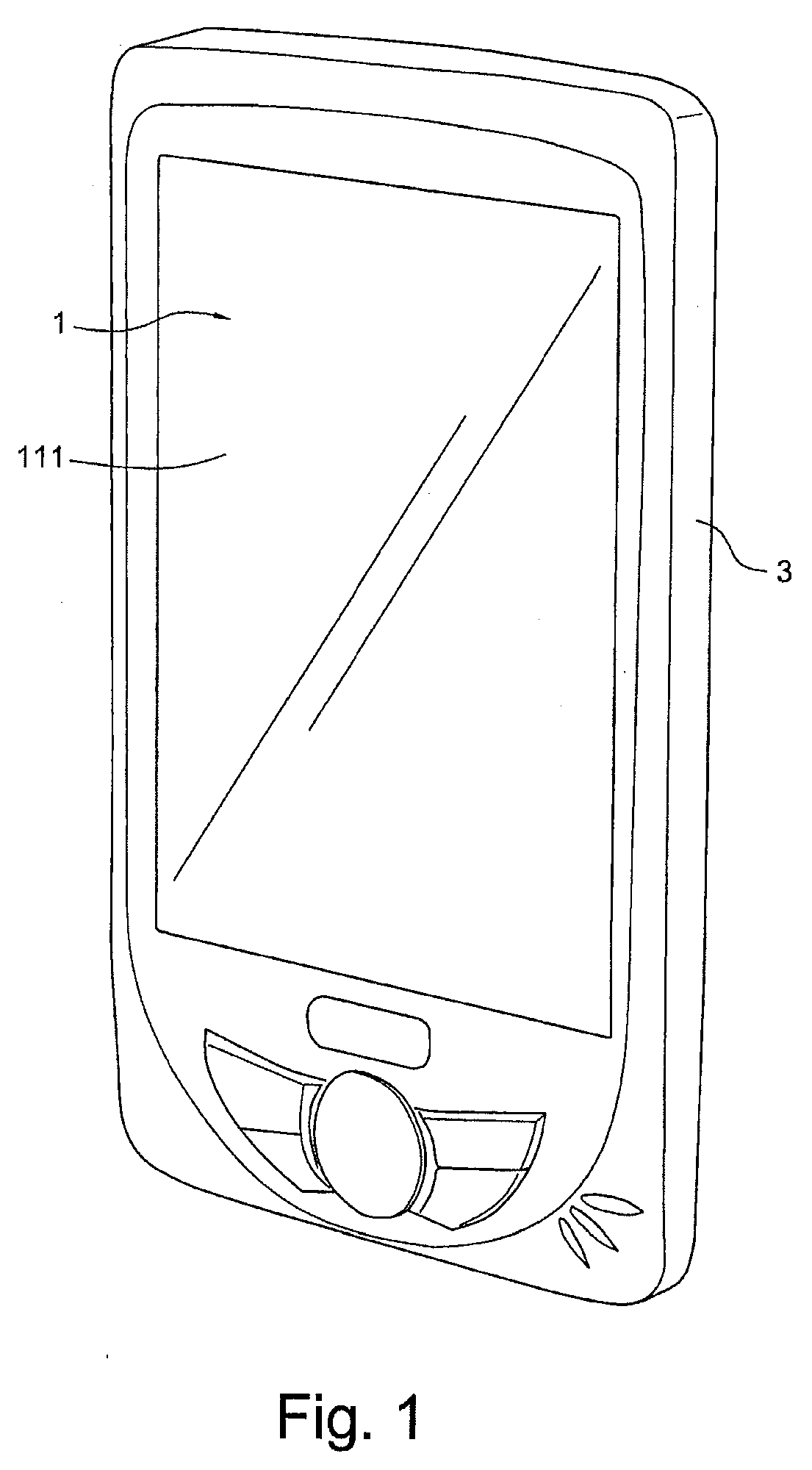

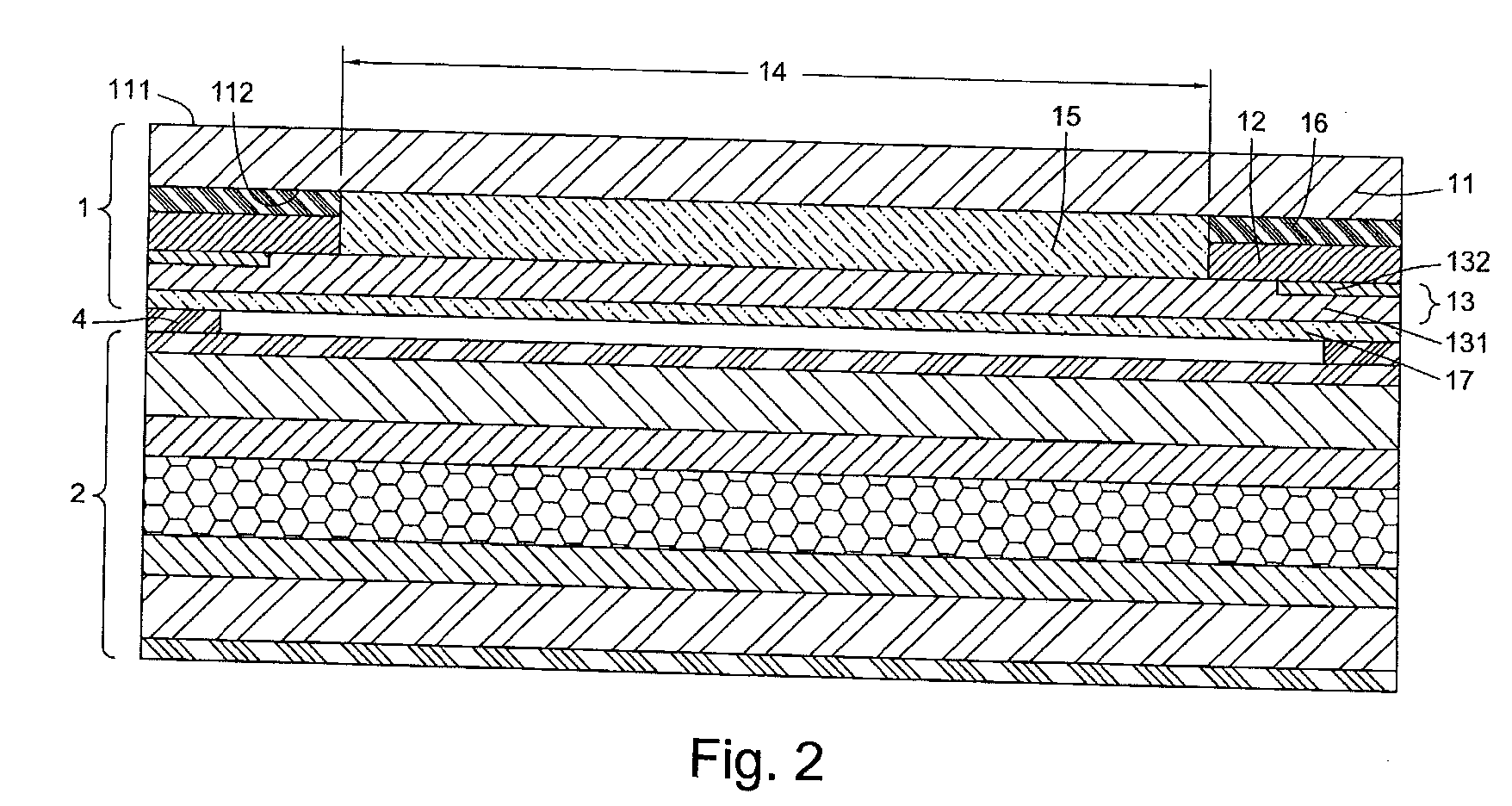

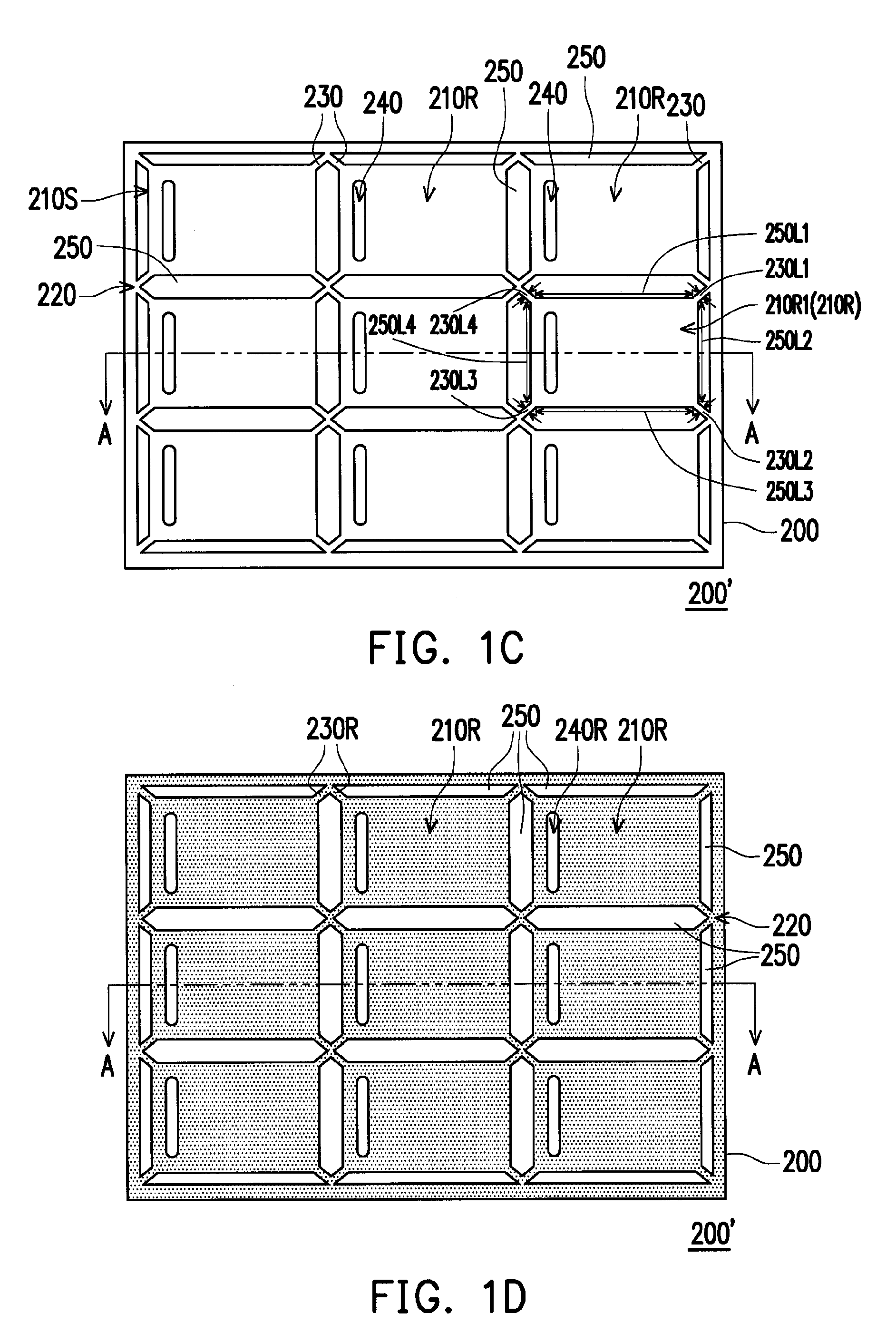

Single-layer projected capacitive touch panel and method of manufacturing the same

ActiveUS20110234526A1Improve permeabilityHigh yield ratePrinted circuit assemblingVessels or leading-in conductors manufactureGlass coverTouch Senses

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

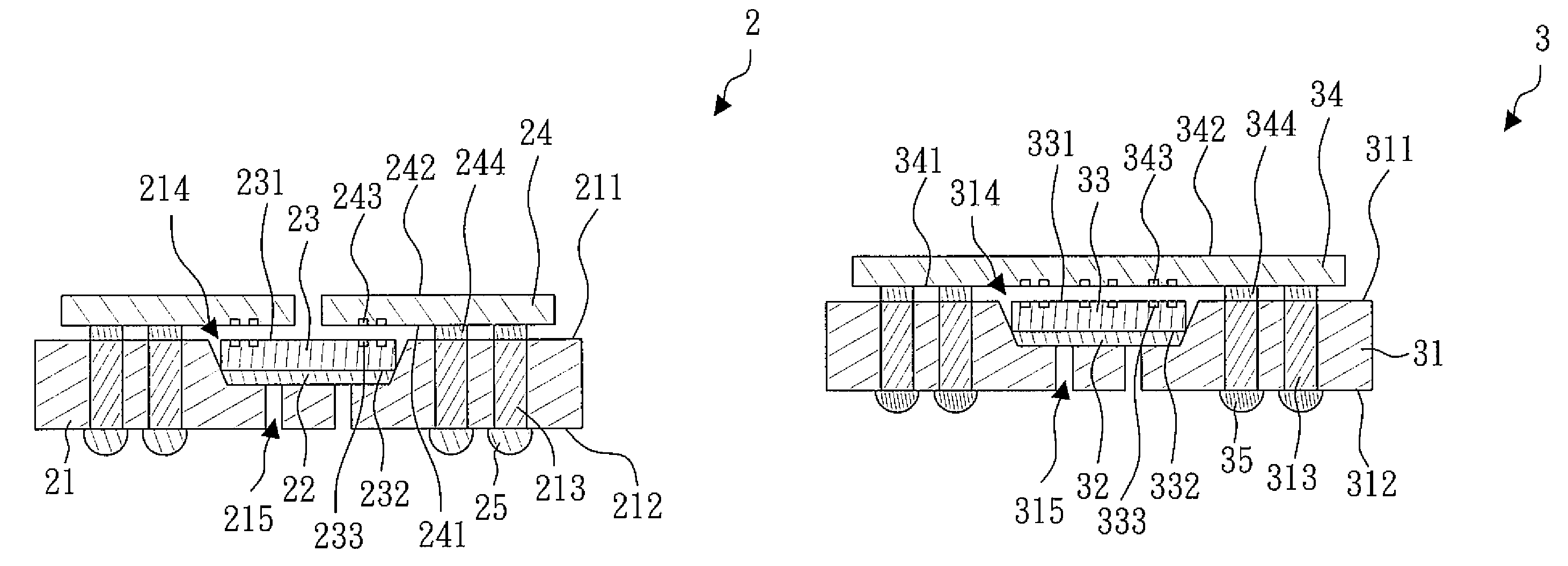

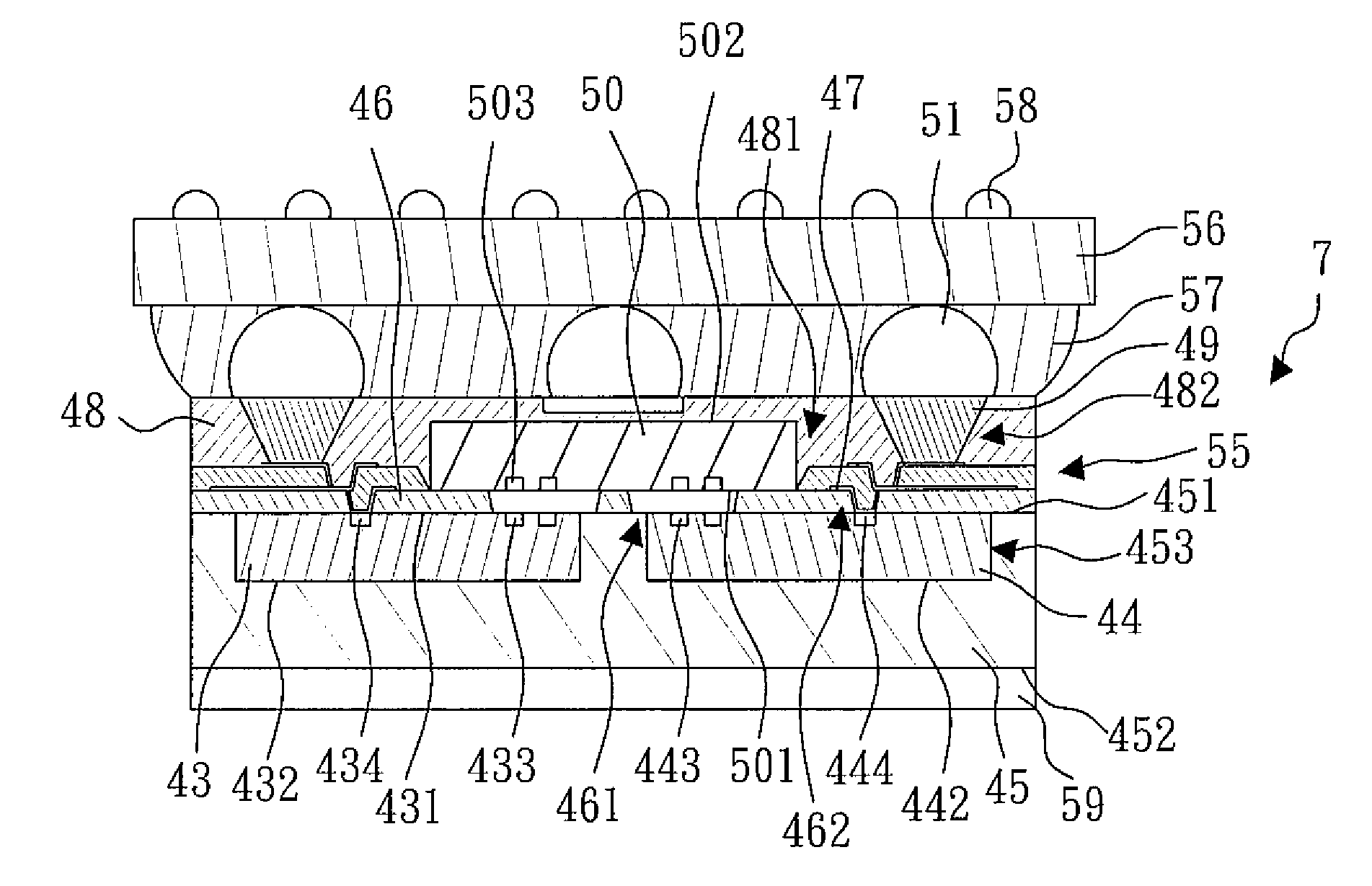

Semiconductor package and method for making the same

ActiveUS8288854B2Precise alignmentHigh yield rateSubstation/switching arrangement detailsDigital data processing detailsContact padSemiconductor package

The present invention relates to a semiconductor package and method for making the same. The semiconductor package includes a silicon substrate unit, a bridge chip and at least one active chip. The silicon substrate unit has a cavity and a plurality of vias. The bridge chip is attached to the cavity and has a plurality of non-contact pads. The active chip is disposed above the bridge chip and has a plurality of non-contact pads and a plurality of conducting elements. The conducting elements of the active chip contact the vias of the silicon substrate unit, the non-contact pads of the active chip face but are not in physical contact with the non-contact pads of the bridge chip, so as to provide proximity communication between the active chip and the bridge chip.

Owner:ADVANCED SEMICON ENG INC

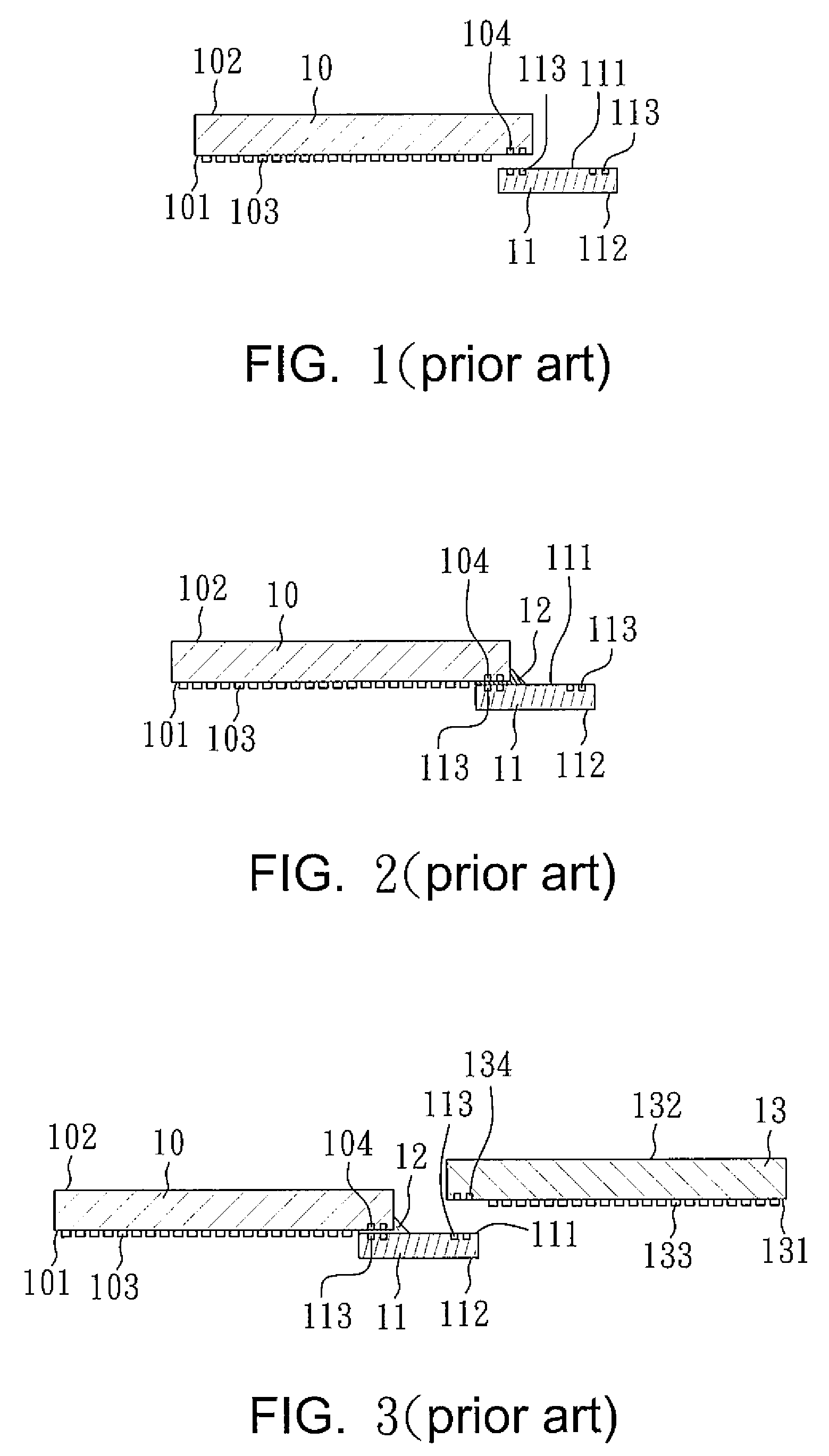

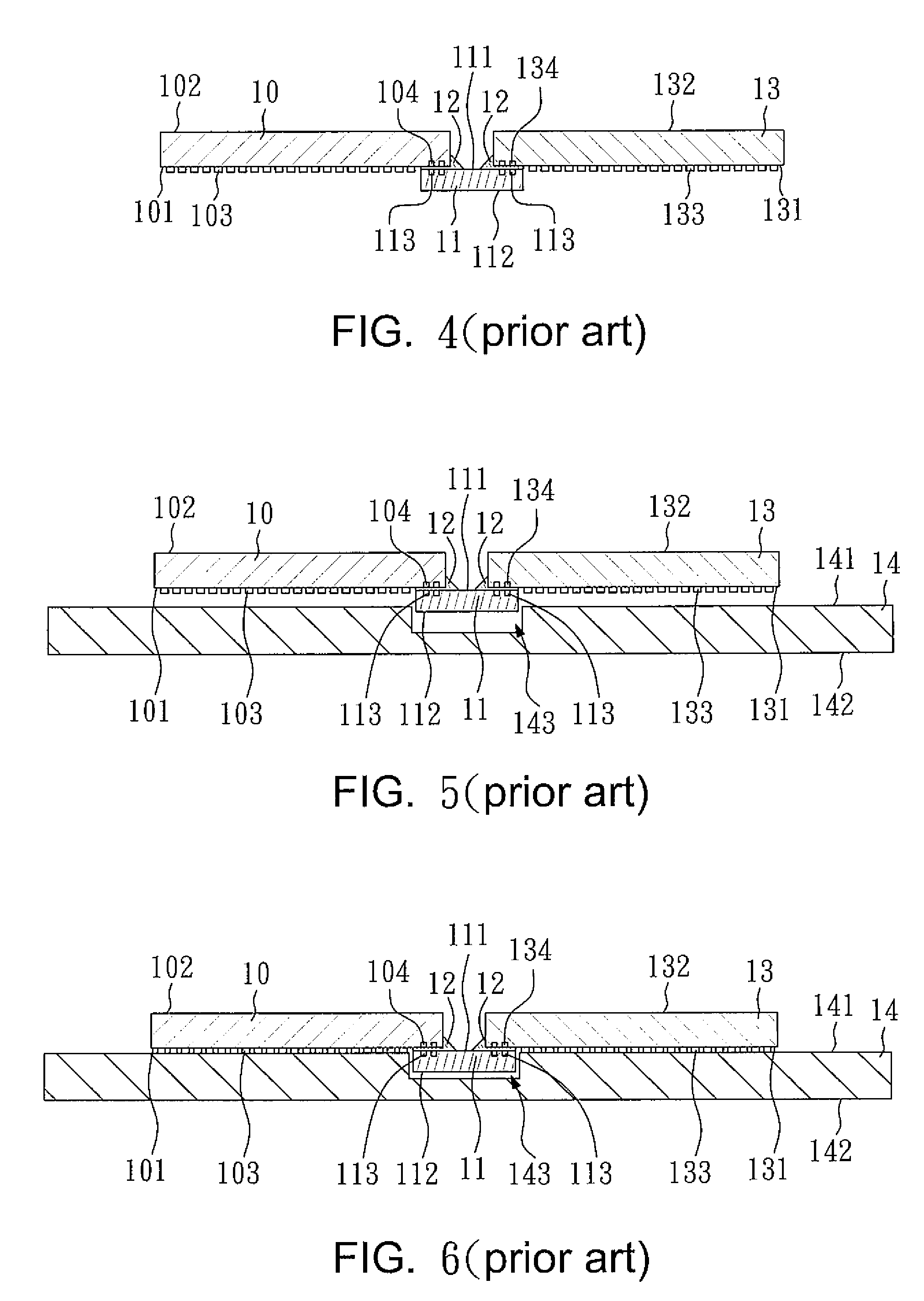

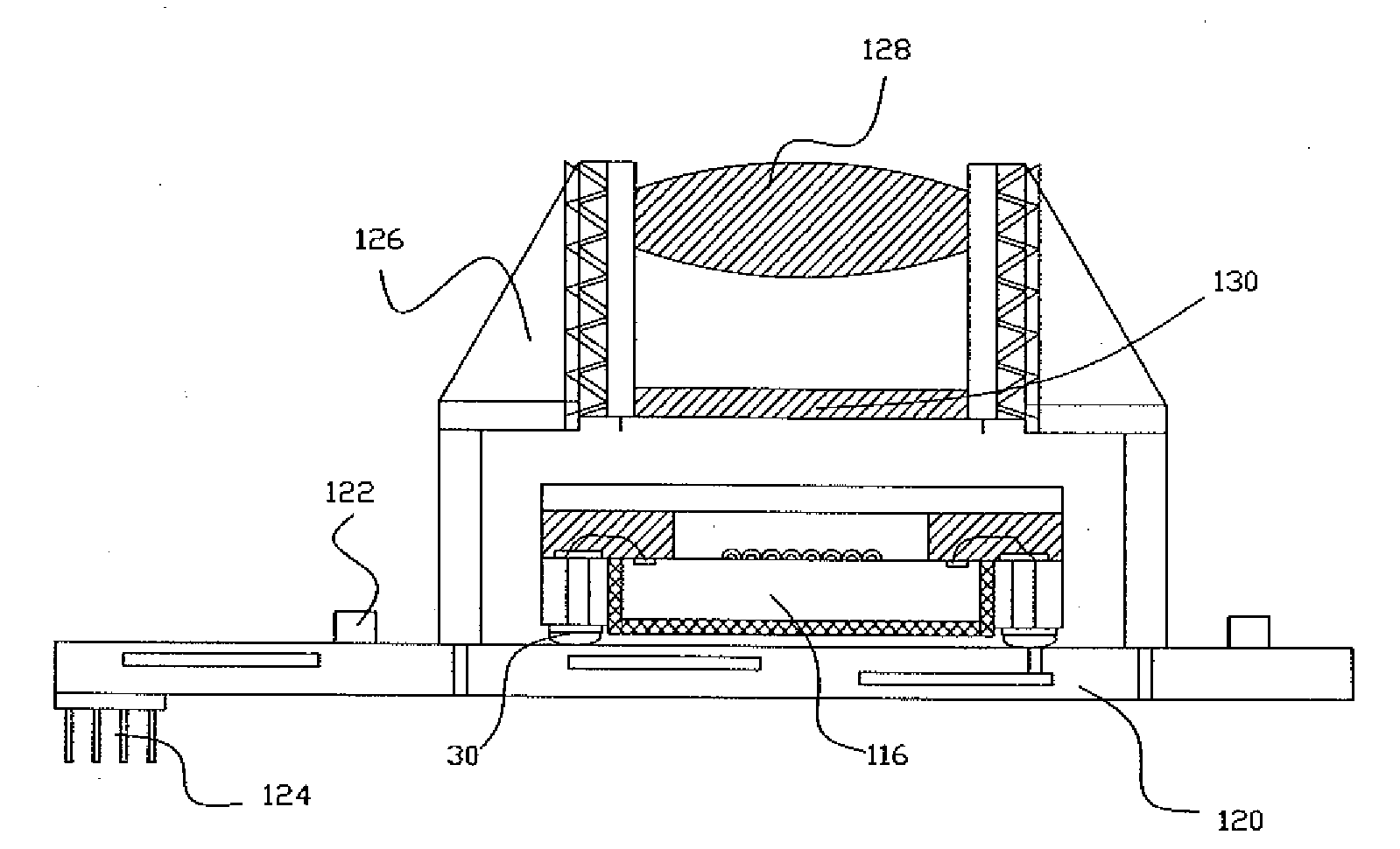

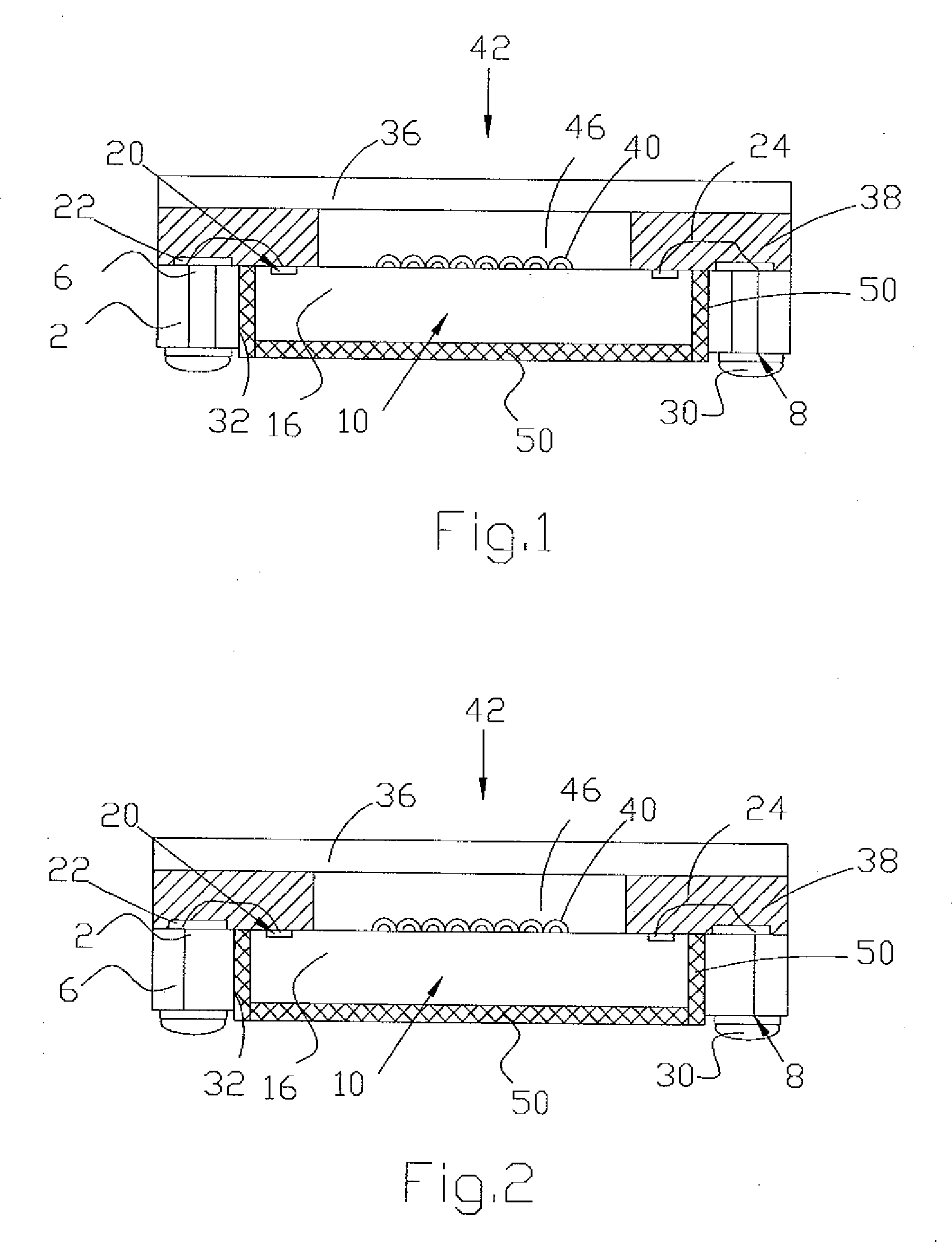

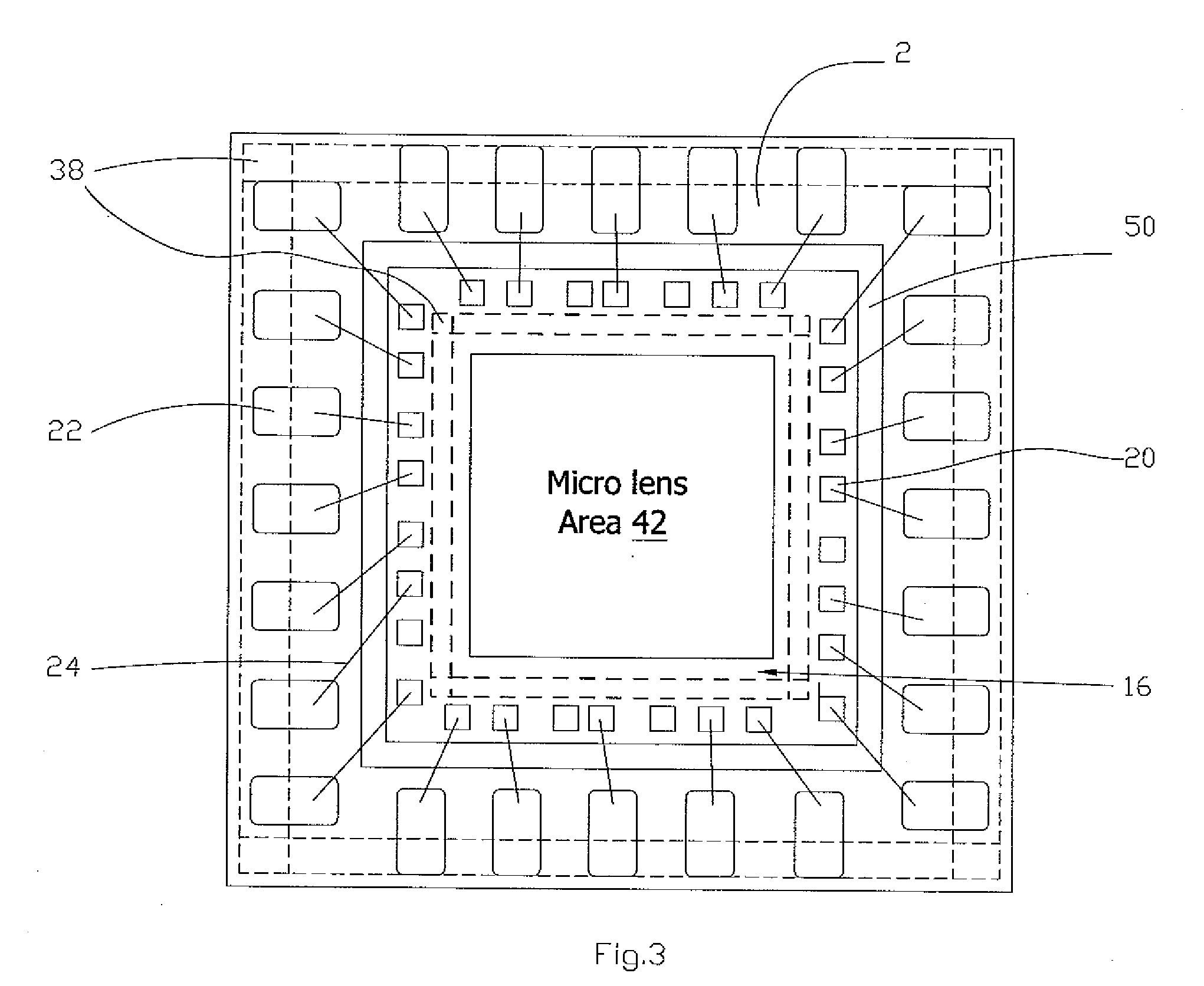

CMOS image sensor chip scale package with die receiving opening and method of the same

InactiveUS20080191335A1Improve throughputShorten cycle timeSemiconductor/solid-state device detailsSolid-state devicesMicrolensContact pad

The present invention provides a structure of package comprising a substrate with a die through hole and a contact through holes structure formed there through, wherein a terminal pad is formed under the contact through hole structure and a contact pad is formed on a upper surface of the substrate. A die having a micro lens area is disposed within the die through hole by adhesion. A thick dielectric layer is formed on the die and the substrate except the micro lens, bonding pads and contact pads. A wire bonding is formed on the die and the substrate, wherein the wire bonding is coupled to the die and the contact pad. And core paste is filled into the gap between the die edge and the sidewall of the die through hole of the substrate. A transparent cover is disposed on the die and the thick dielectric layer by adhesion to create a gap between the transparent cover.

Owner:ADVANCED CHIP ENG TECH

Semiconductor Package and Method for Making the Same

ActiveUS20110285006A1Precise alignmentHigh yield rateSubstation/switching arrangement detailsDigital data processing detailsContact padSemiconductor package

The present invention relates to a semiconductor package and method for making the same. The semiconductor package includes a silicon substrate unit, a bridge chip and at least one active chip. The silicon substrate unit has a cavity and a plurality of vias. The bridge chip is attached to the cavity and has a plurality of non-contact pads. The active chip is disposed above the bridge chip and has a plurality of non-contact pads and a plurality of conducting elements. The conducting elements of the active chip contact the vias of the silicon substrate unit, the non-contact pads of the active chip face but are not in physical contact with the non-contact pads of the bridge chip, so as to provide proximity communication between the active chip and the bridge chip.

Owner:ADVANCED SEMICON ENG INC

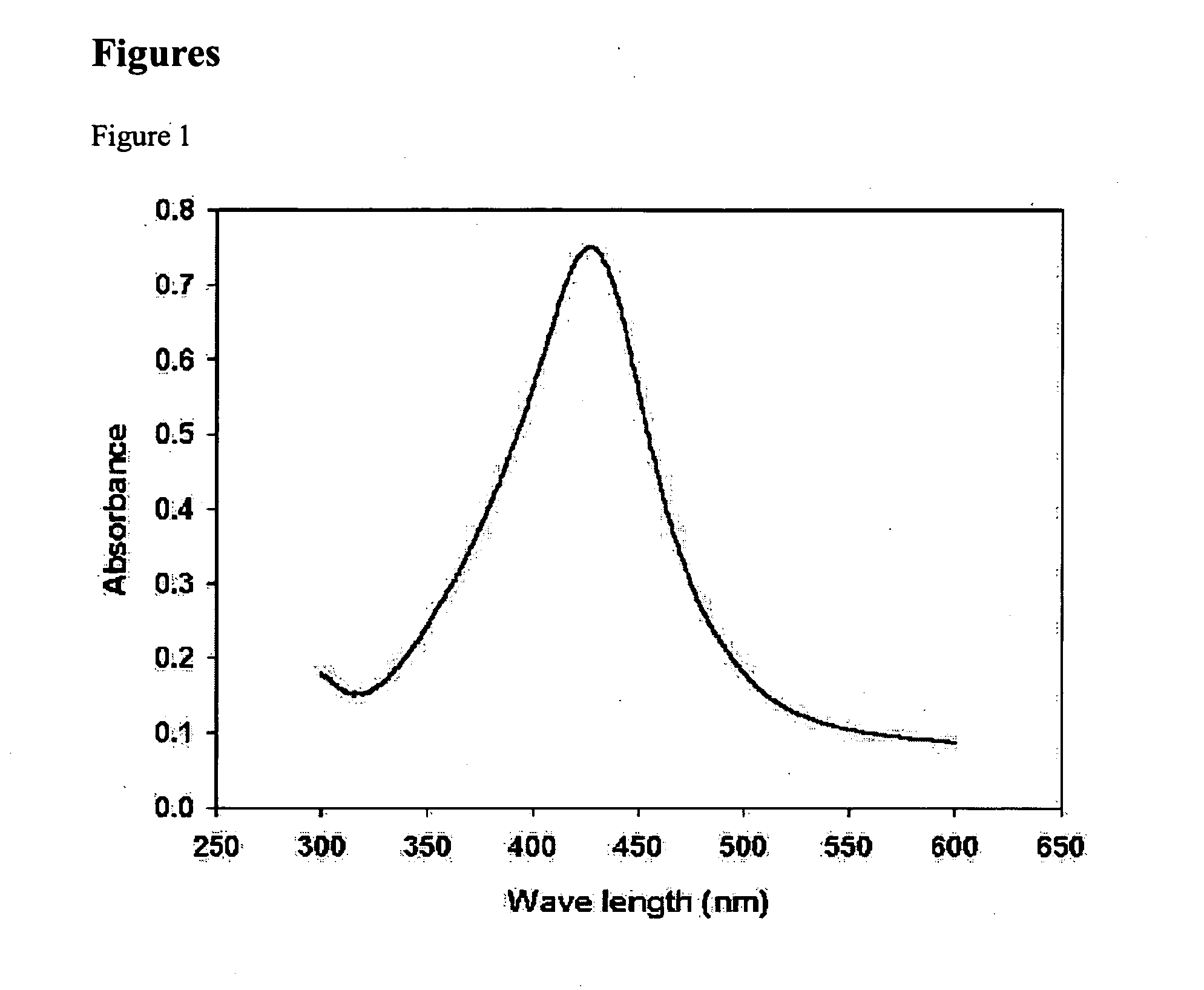

Metal nanoparticles and method for producing the same

InactiveUS20070018140A1High yield rateCheap methodMaterial nanotechnologyNanostructure manufactureAlkaline earth metalSolvent

A method of producing metal nanoparticles, having a high yield rate achieved by a simple heat-treatment of a metal alkanoate. The method of the invention is not only environment-friendly as it does not require additional solvents or supplements, but also economical as highly expensive equipment is not demanded. In addition, the invention provides metal nanoparticles having uniform shape and distribution, and provides conductive ink including the metal nanoparticles thus obtained. One aspect may provide a method of (a) producing a metal alkanoate by reacting a metal precursor with an alkanoate of alkali metals, alkaline earth metals or ammonium in an aqueous solution (b) filtrating and drying the metal alkanoate, and (c) heat-treating the metal alkanoate of (b).

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

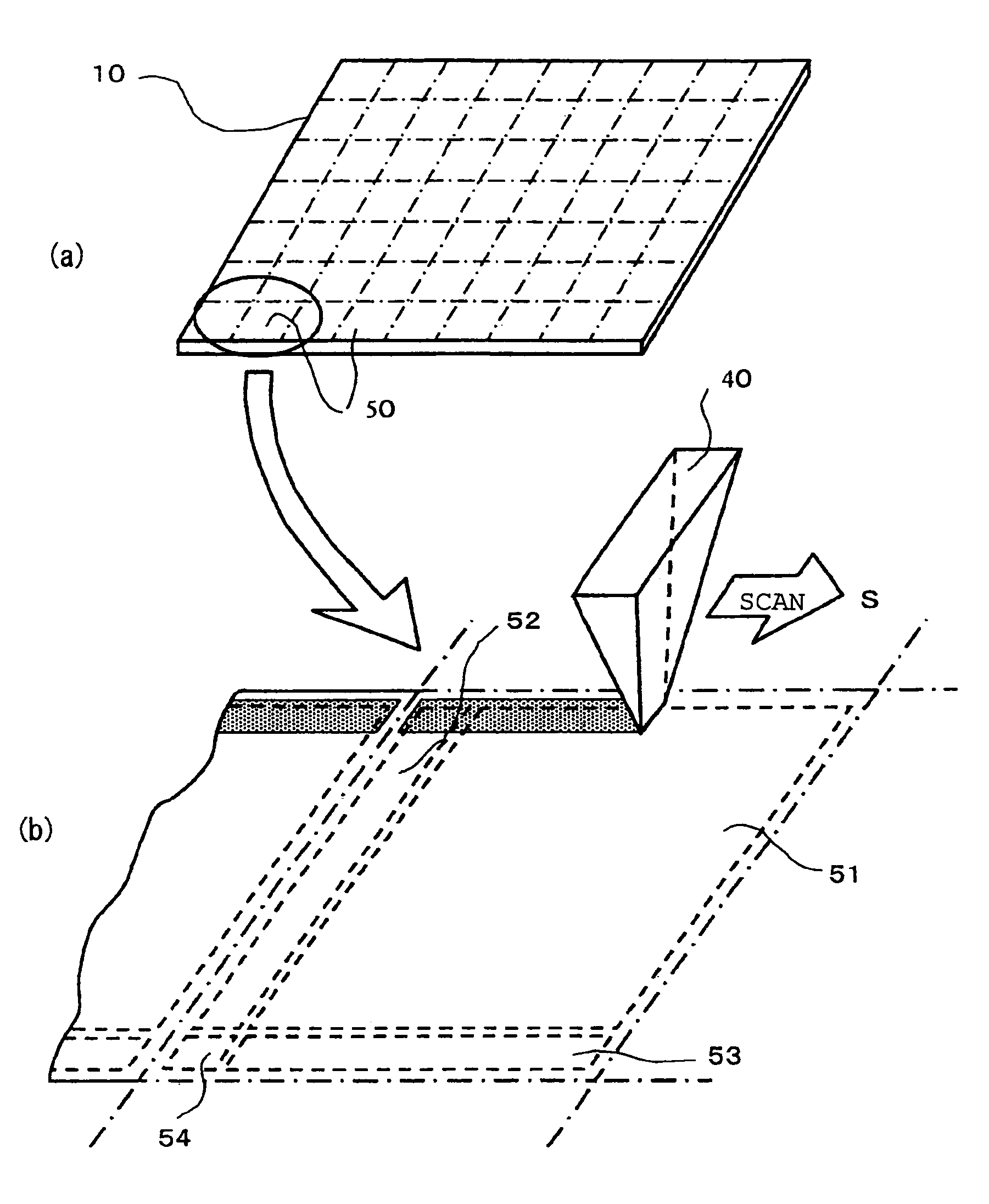

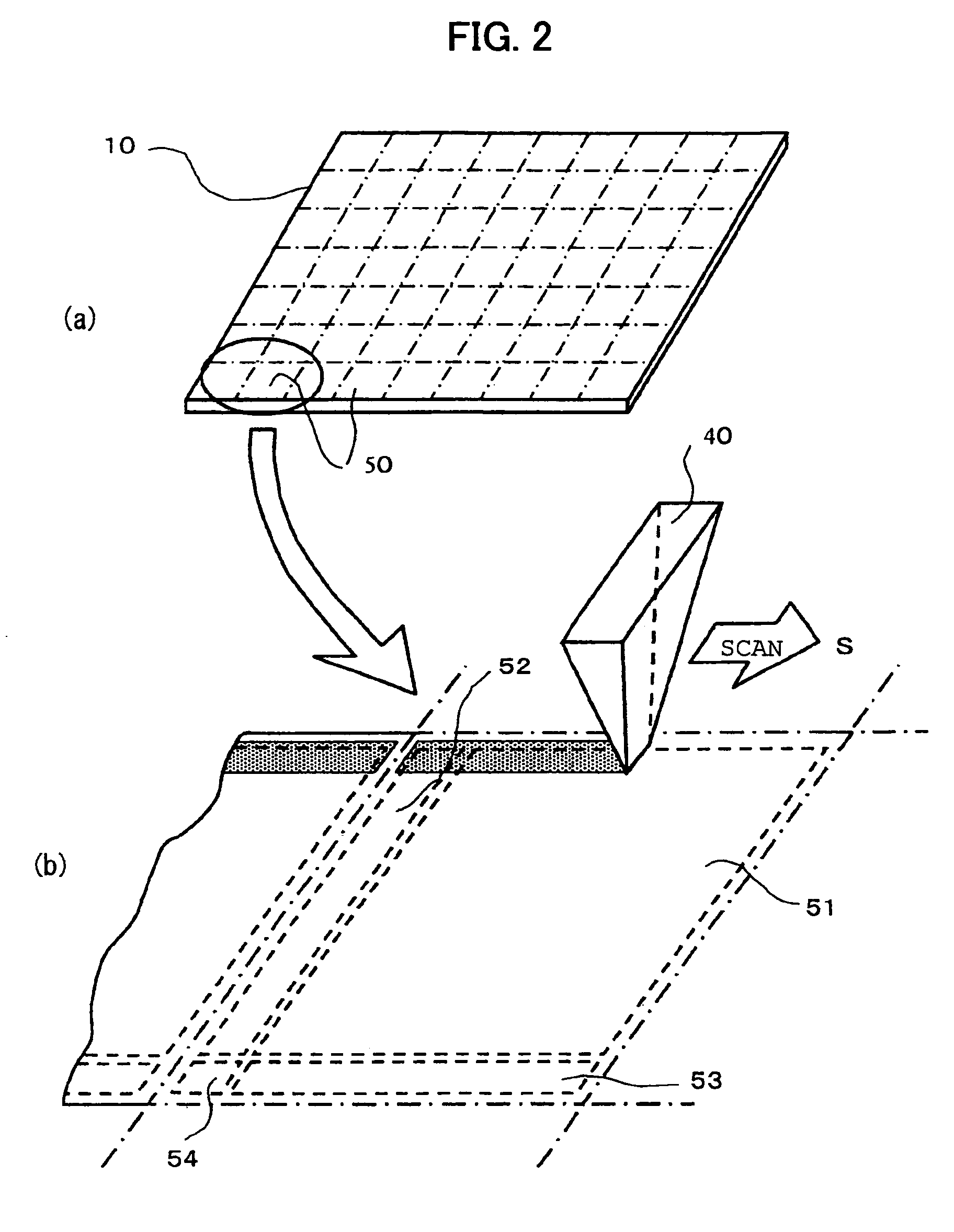

Vibration mirror, optical scanning device, and image forming using the same, method for making the same, and method for scanning image

InactiveUS6972883B2Simple processReduce weightInking apparatusElectrographic processes using charge patternElectricityImage formation

A vibration mirror is reciprocatively vibrated by an electrostatic force to reflect an incident light beam. The vibration mirror comprises a reflection means for reflecting the incident light beam; a reflection means holding substrate for holding the reflection means; a torsional rotation shaft comprising rod members rotatably supporting two ends of the reflection means holding substrate; movable electrodes formed on side faces of the reflection means holding substrate supported; a first substrate for supporting the reflection means supporting substrate via the torsional rotation shaft; first fixed electrodes formed on the first substrate so as to face the movable electrodes; a first electrically insulating and separating means formed on the first substrate to electrically insulate and separate the movable electrodes from the first fixed electrodes; and a second substrate overlaid on the first substrate with an insulating layer therebetween so as to be electrically insulated from and overlapped to adhere onto the first substrate.

Owner:RICOH KK

Capacitive Touch Panel

ActiveUS20090207151A1Low costHigh yield rateDigital data processing detailsNon-linear opticsTouch panelMask layer

An integrally-formed capacitive touch panel is disclosed including: a singular lens substrate, a mask layer, and a sensing circuit integrally coupled with said singular lens substrate. Said singular lens substrate, said mask layer, and said sensing circuit are integrally formed.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

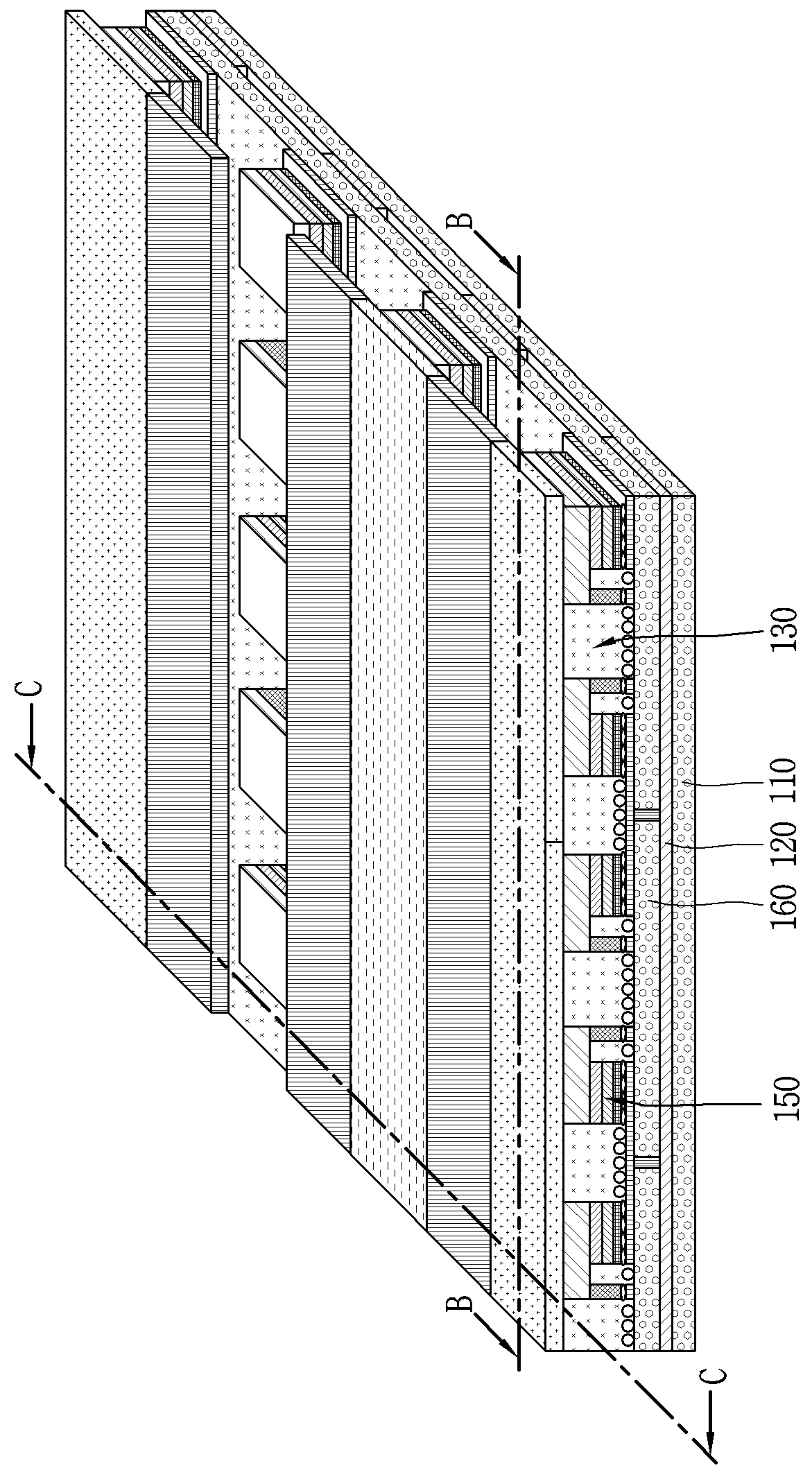

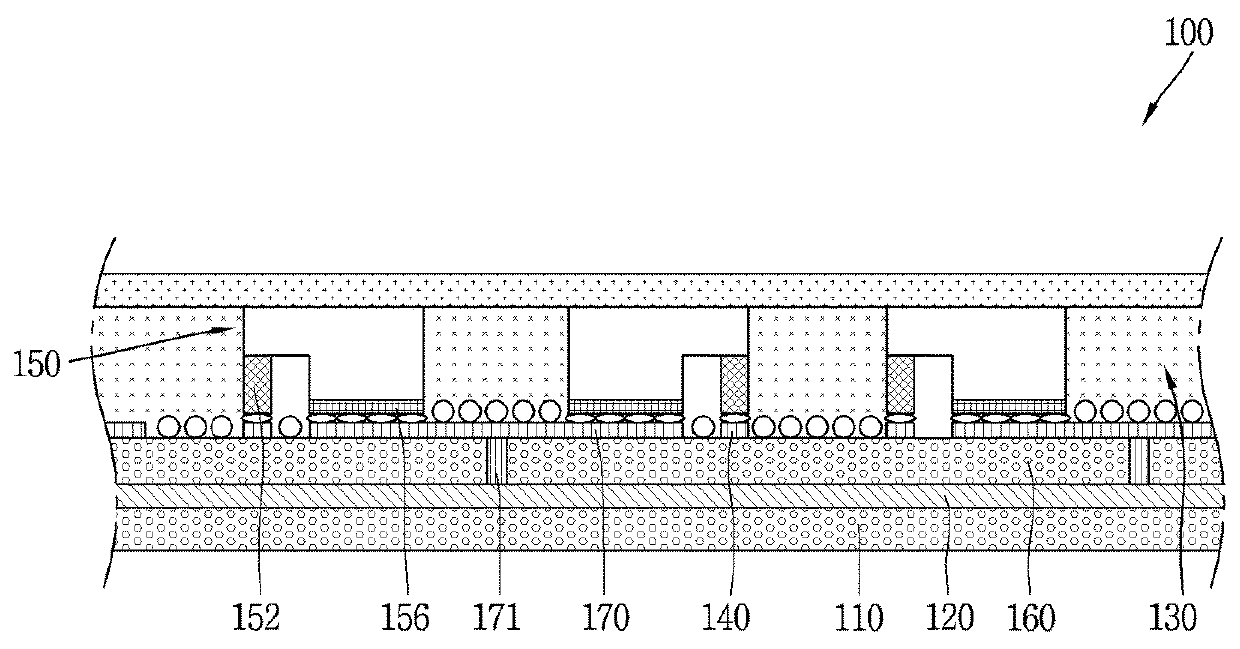

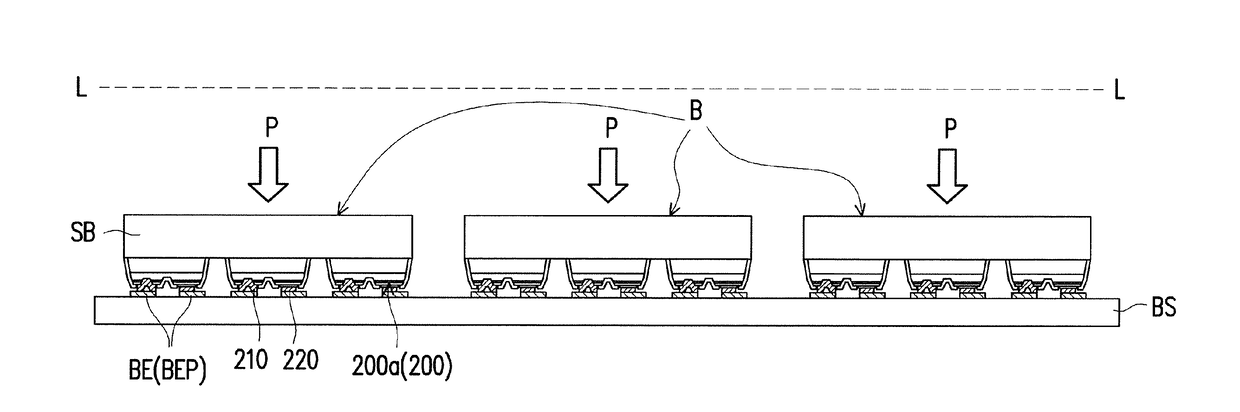

Transfer head and transfer system for semiconductor light-emitting device and method for transferring semiconductor light-emitting device

ActiveUS20180277524A1Increase clamping forcePrecise control for alignmentSolid-state devicesSemiconductor/solid-state device manufacturingTransfer systemDisplay device

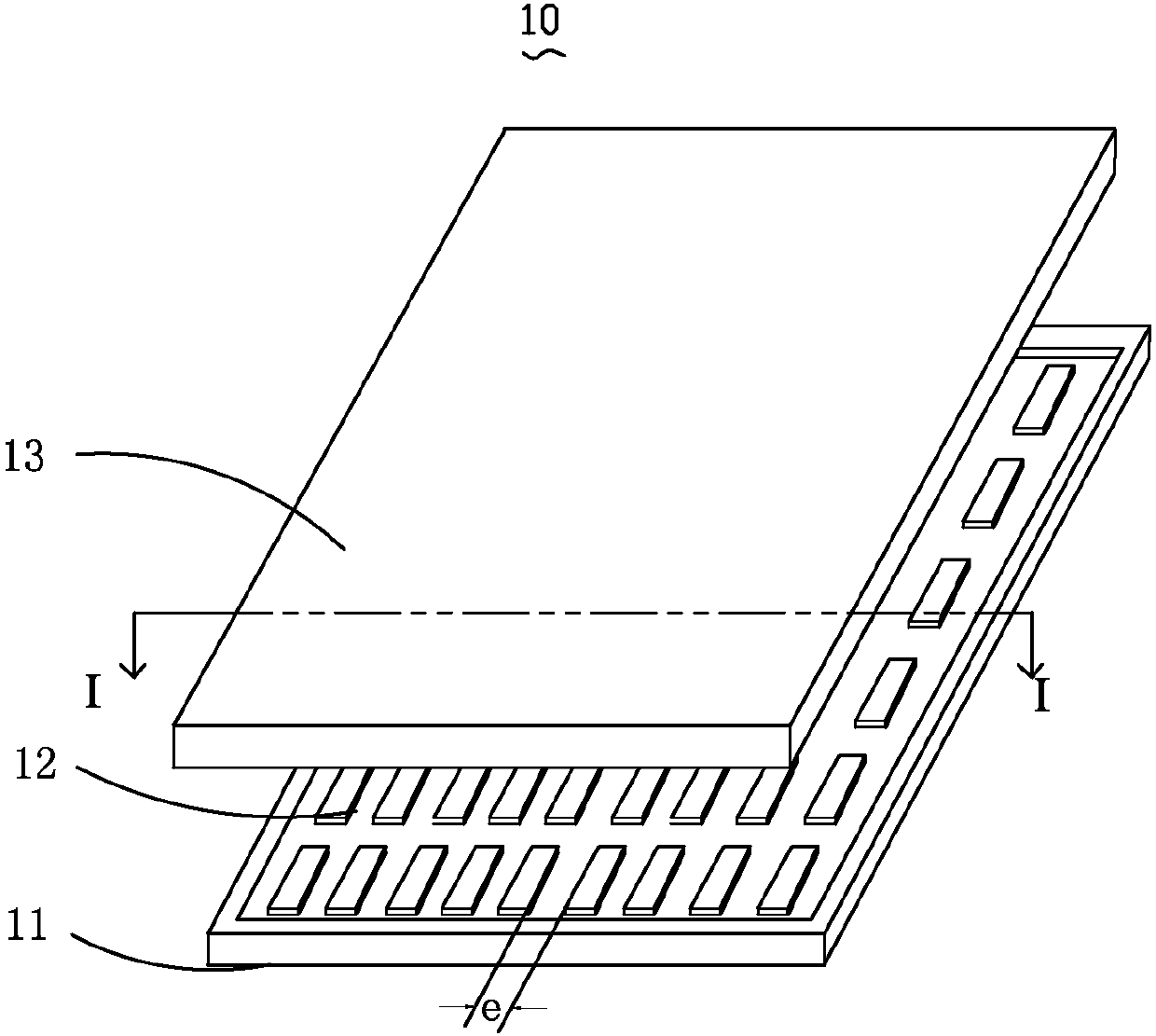

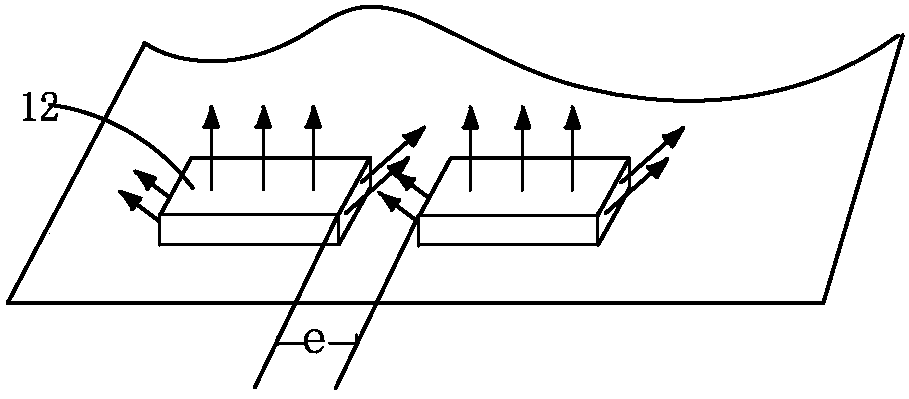

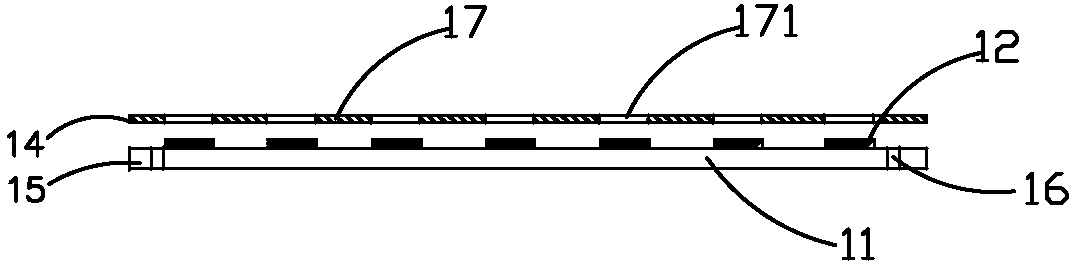

The present invention relates to a display device and, more particularly, to a transfer head for a semiconductor light-emitting device applied to the display device and a method for transferring a semiconductor light-emitting device. The transfer head for a semiconductor light-emitting device, according to the present invention, comprises: a base substrate; and an electrode unit disposed on the base substrate to generate an electrostatic force by charging an un-doped semiconductor layer of the semiconductor light-emitting device with electric charges, wherein the base substrate and the electrode unit are formed of light-transmitting materials so that at least a part of the semiconductor light-emitting device is viewable through the base substrate and the electrode unit in sequence.

Owner:LG ELECTRONICS INC

Reinforced glass cell and method for fabricating the same and cover glass having the reinforced glass cell

InactiveUS20130037308A1Increase production rateImprove yield ratePrinted circuit detailsCellulosic plastic layered productsEngineeringCover glass

A method of fabricating a reinforced glass cell including the following steps is provided. First, a mother glass having a plurality of glass cell predetermined regions is provided. A portion of the mother glass disposed on the outer edge of each glass cell predetermined region is removed, so as to form at least one through trench and at least one linking bridge. Herein, the through trench exposes the periphery section of each glass cell predetermined region, and the glass cell predetermined regions are formed as an entire patterned mother glass by the linking bridges. A reinforcing process is performed to the entire patterned mother glass, so that the exposed periphery sections of the glass cell predetermined regions are formed into reinforced sections. The linking bridges are removed so as to separate the glass cell predetermined regions having the reinforced sections to form a plurality of reinforced glass cells.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

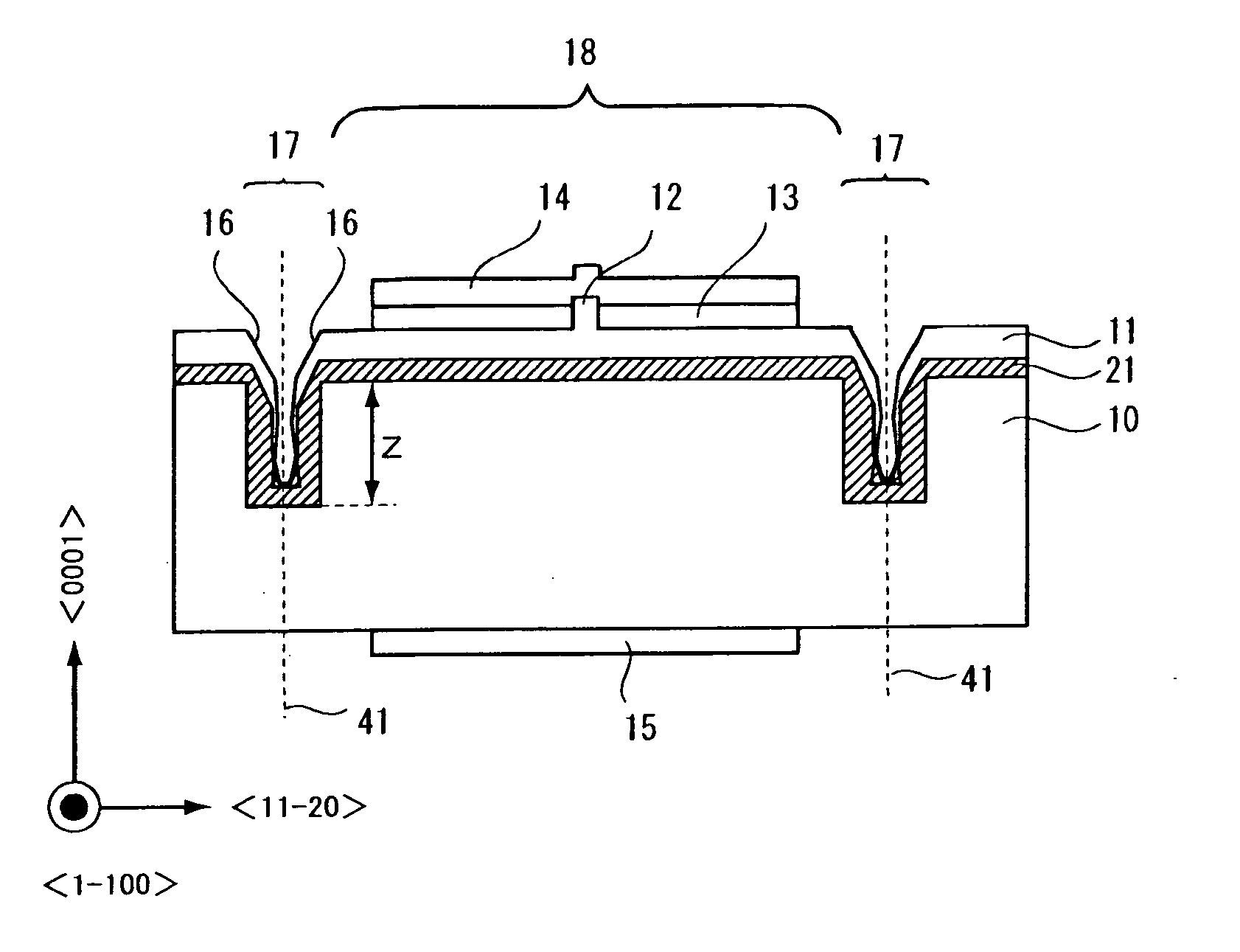

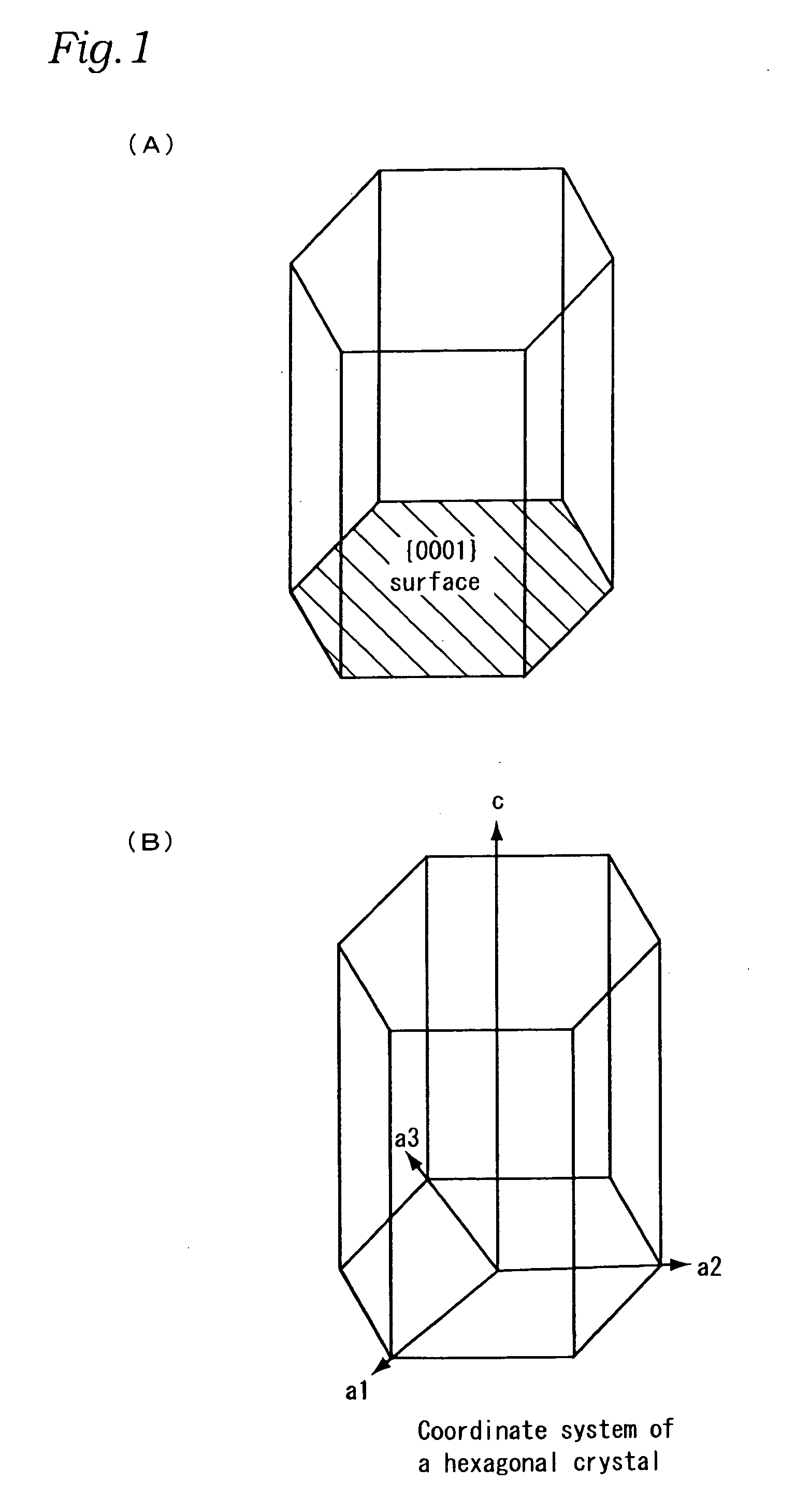

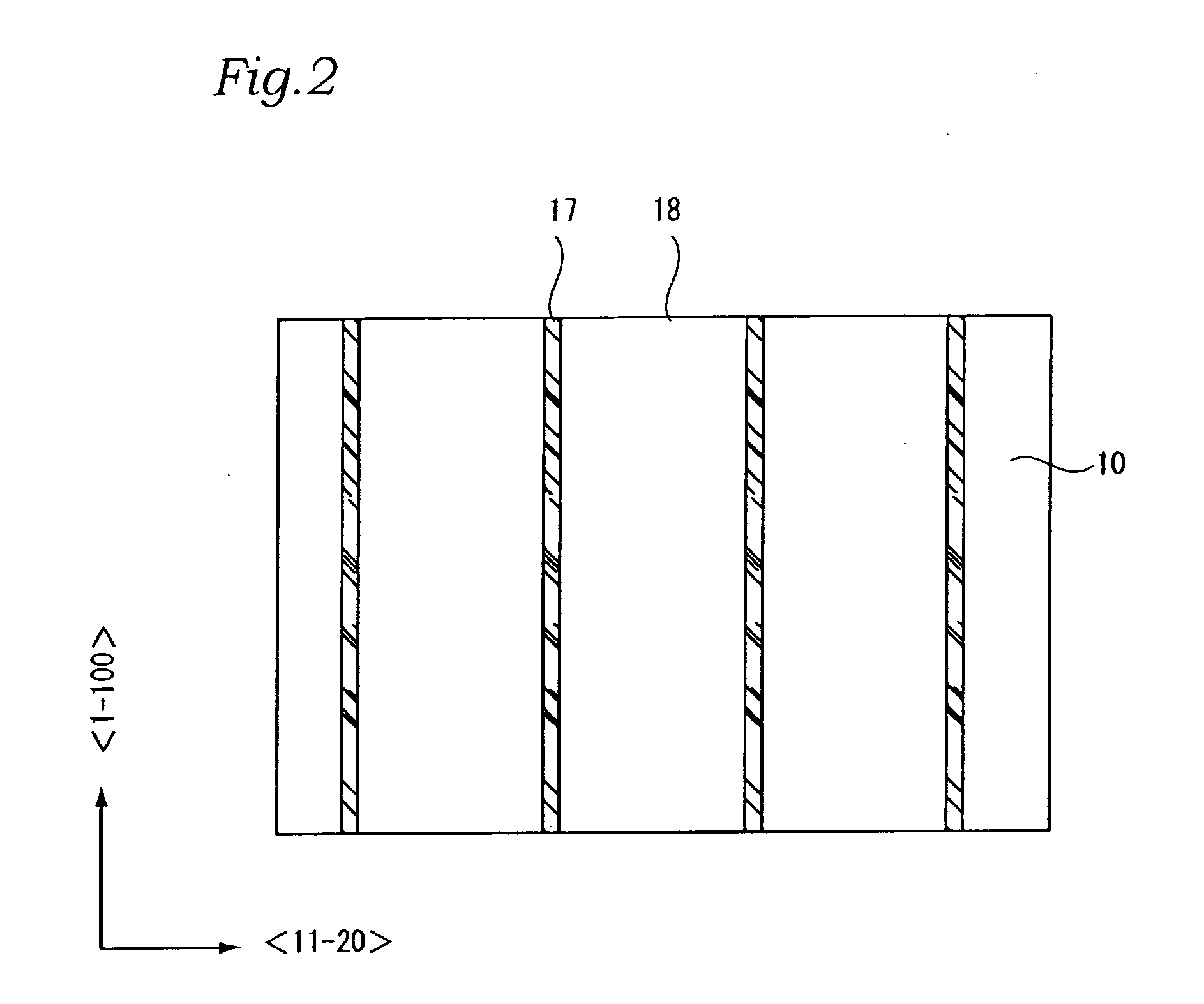

Nitride semiconductor light-emitting device and method for producing same

ActiveUS20060131590A1Good surface smoothnessAvoid crackingOptical wave guidanceLaser detailsActive layerLight emitting device

In a method for producing a nitride semiconductor light-emitting device according to the present invention, first, a nitride semiconductor substrate having groove portions formed is prepared. An underlying layer comprising nitride semiconductor is formed on the nitride semiconductor substrate including the side walls of the groove portions, in such a manner that the underlying layer has a crystal surface in each of the groove portions and the crystal surface is tilted at an angle of from 53.5° to 63.4° with respect to the surface of the substrate. Over the underlying layer, a light-emitting-device structure composed of a lower cladding layer containing Al, an active layer, and an upper cladding layer containing Al is formed. According to the present invention, thickness nonuniformity and lack of surface flatness, which occur when accumulating a layer with light-emitting-device structure of nitride semiconductor over the nitride semiconductor substrate, are alleviated while inhibiting occurrence of cracking.

Owner:SHARP FUKUYAMA LASER CO LTD

Method for manufacturing semiconductor device

InactiveUS20120064689A1Reduce leakage currentDecrease of interface stateSolid-state devicesSemiconductor/solid-state device manufacturingTitanium nitrideSemiconductor

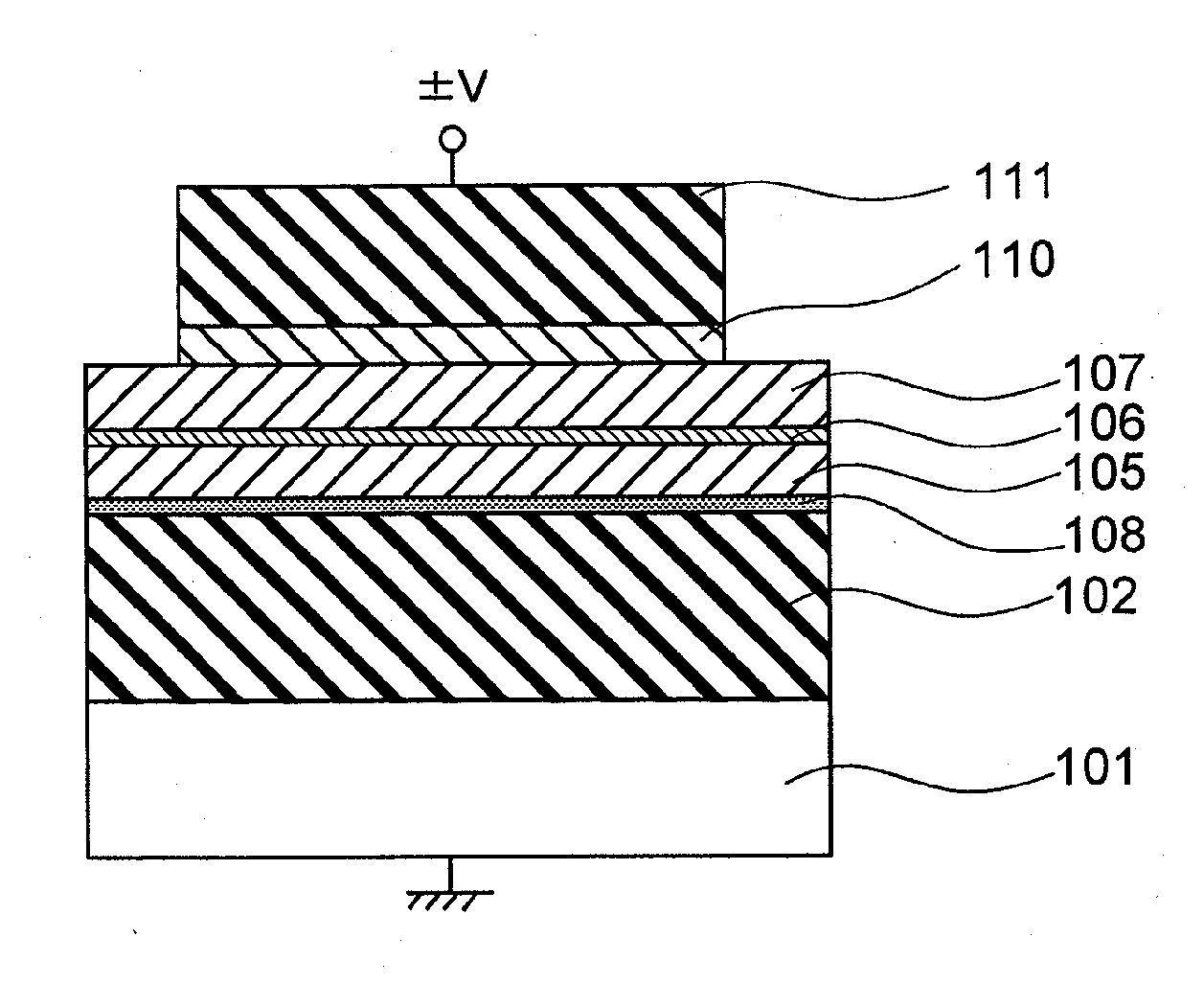

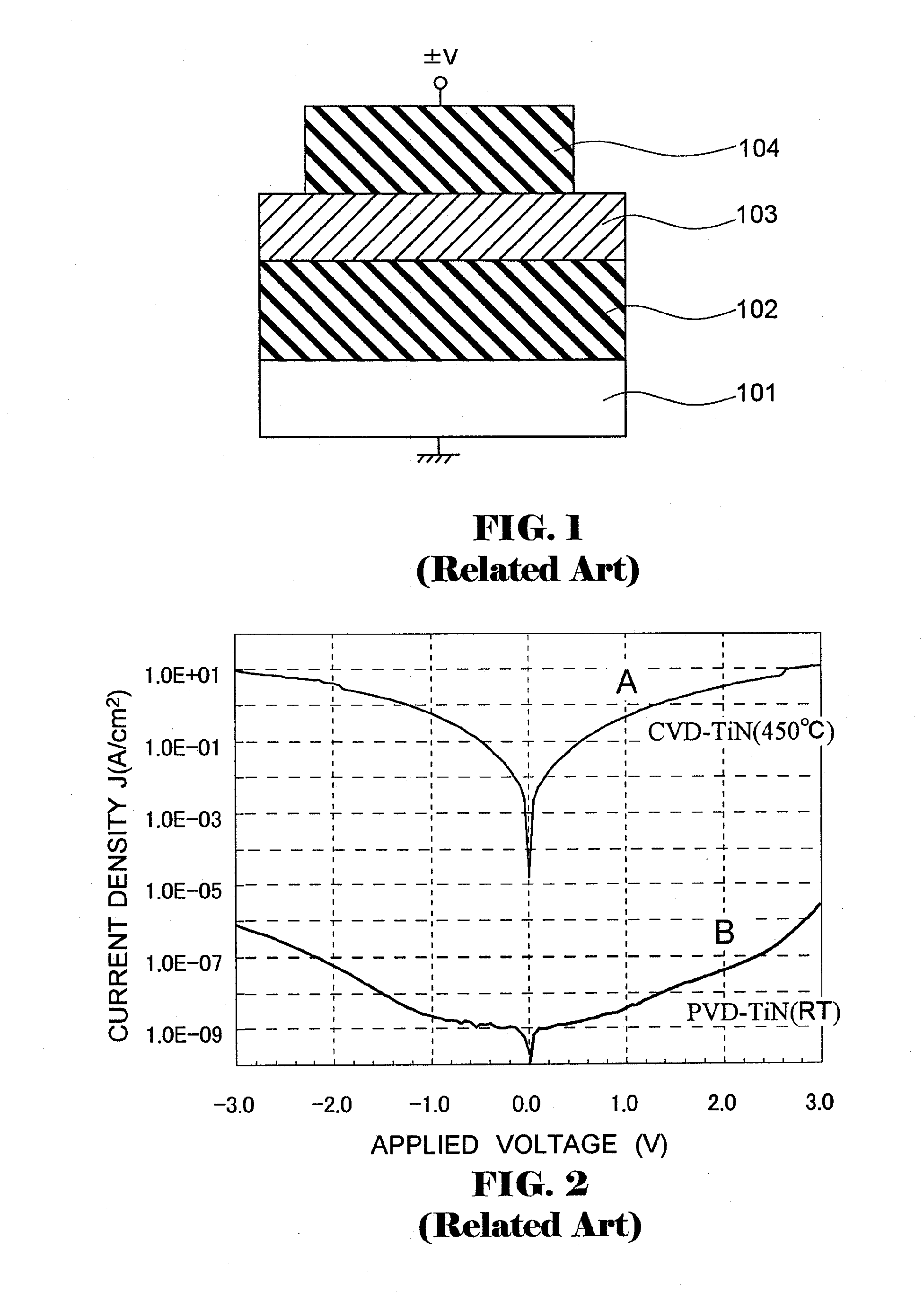

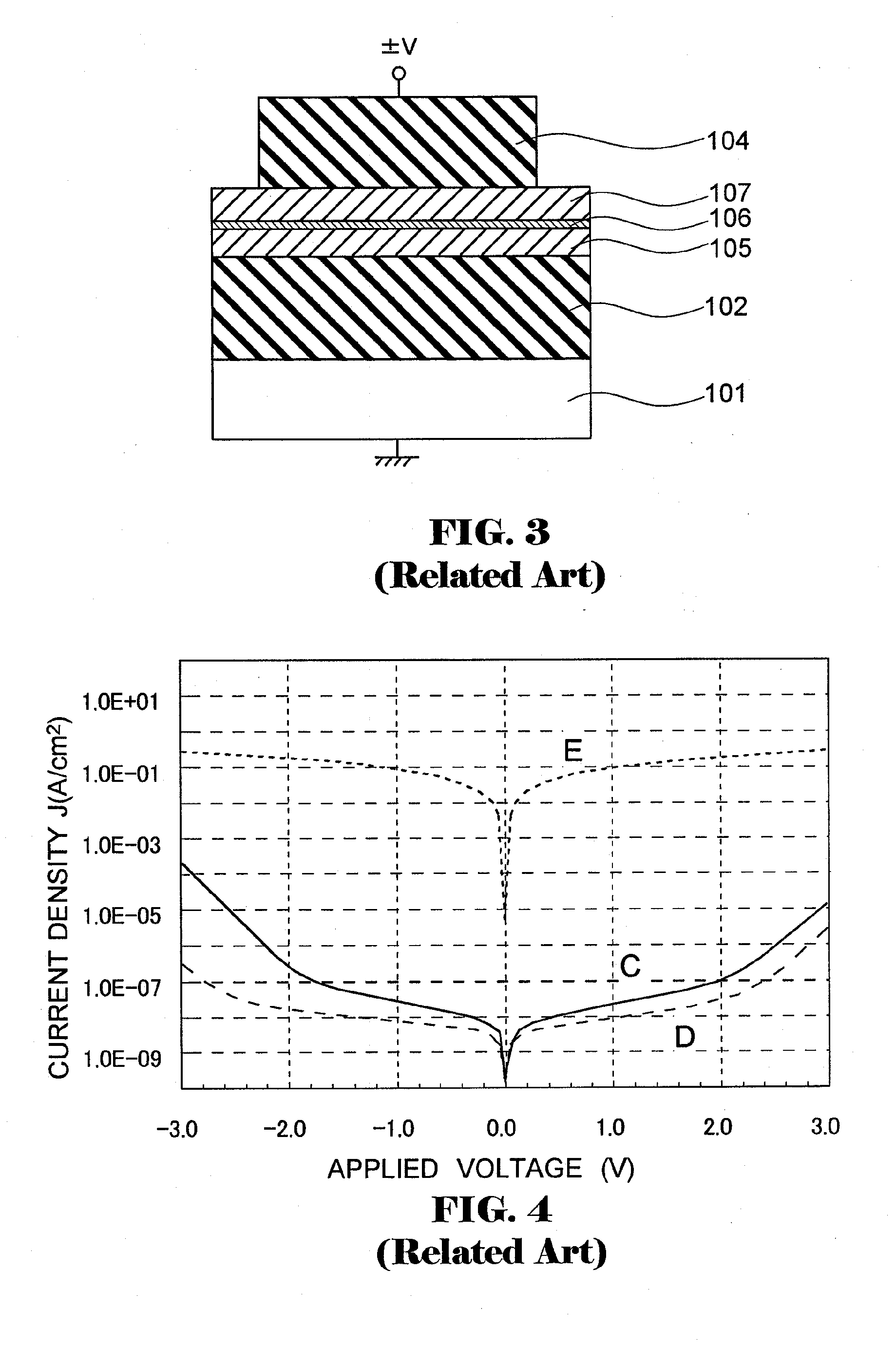

A method for manufacturing a semiconductor device includes at least forming a lower electrode comprising titanium nitride on a semiconductor substrate, forming a dielectric film comprising zirconium oxide as a primary constituent on the lower electrode, forming a first protective film comprising a titanium compound on the dielectric film, and forming an upper electrode comprising titanium nitride on the first protective film. The method can include a step of forming a second protective film on the lower electrode before the step of forming the dielectric film on the lower electrode.

Owner:PS4 LUXCO SARL

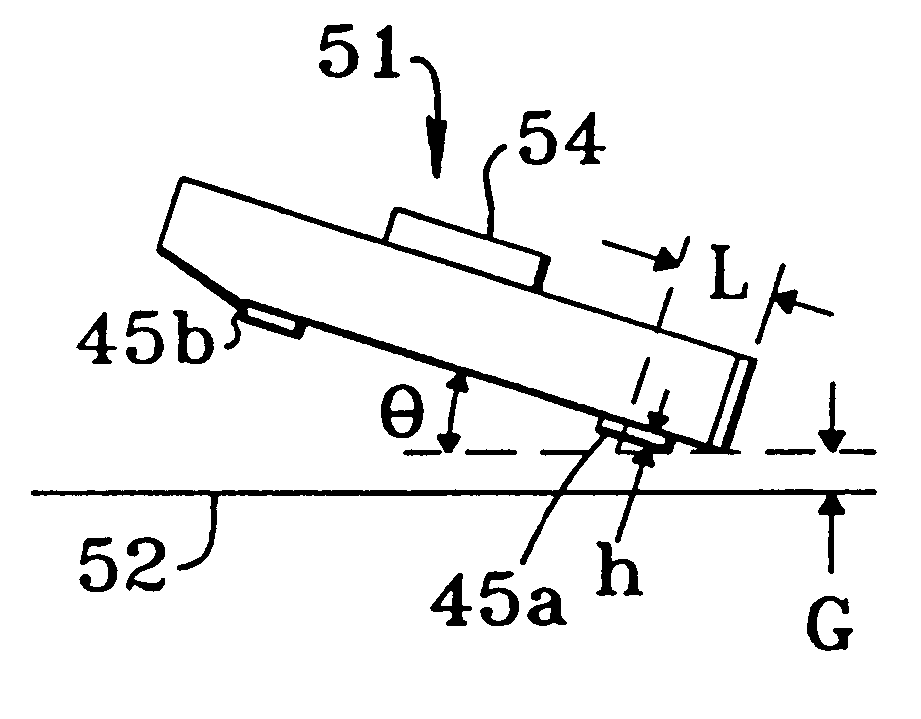

Microlens array substrate and production method therefor

InactiveUS20060215269A1Pattern size is accurateReduce materialNon-linear opticsLensResistImage resolution

A micro-lens substrate having a precise micro-lens array suitable for higher resolution, the micro-lens array substrate of high quality without having a distortion, and a method for manufacturing thereof are provided. In the micro-lens array substrate of the present invention, a micro-lens array formed of a plurality of consecutive concave lens-shaped micro-lenses is directly formed in a surface of a quartz substrate or glass substrate, and the micro-lens array is formed by a transfer method based on dry-etching. In the micro-lens array substrate of the present invention, a taper portion is formed toward the surface of the substrate in a peripheral portion of the micro-lens array in the quartz substrate or glass substrate. In a method for manufacturing the micro-lens array substrate of the present invention, a resist layer having a plurality of consecutive lens-shaped concave portions is formed in a surface of a quartz or glass substrate, the lens-shaped concave portion of the resist layer is transferred to the substrate by dry-etching, and a micro-lens array is formed by injecting a resin into the lens-shaped concave portion of this substrate. In addition, a taper portion is formed in a peripheral portion similarly to the formation of the lens-shaped concave portion, and a micro-lens array is formed by injecting a resin into the lens-shaped concave portion and taper portion.

Owner:SONY CORP

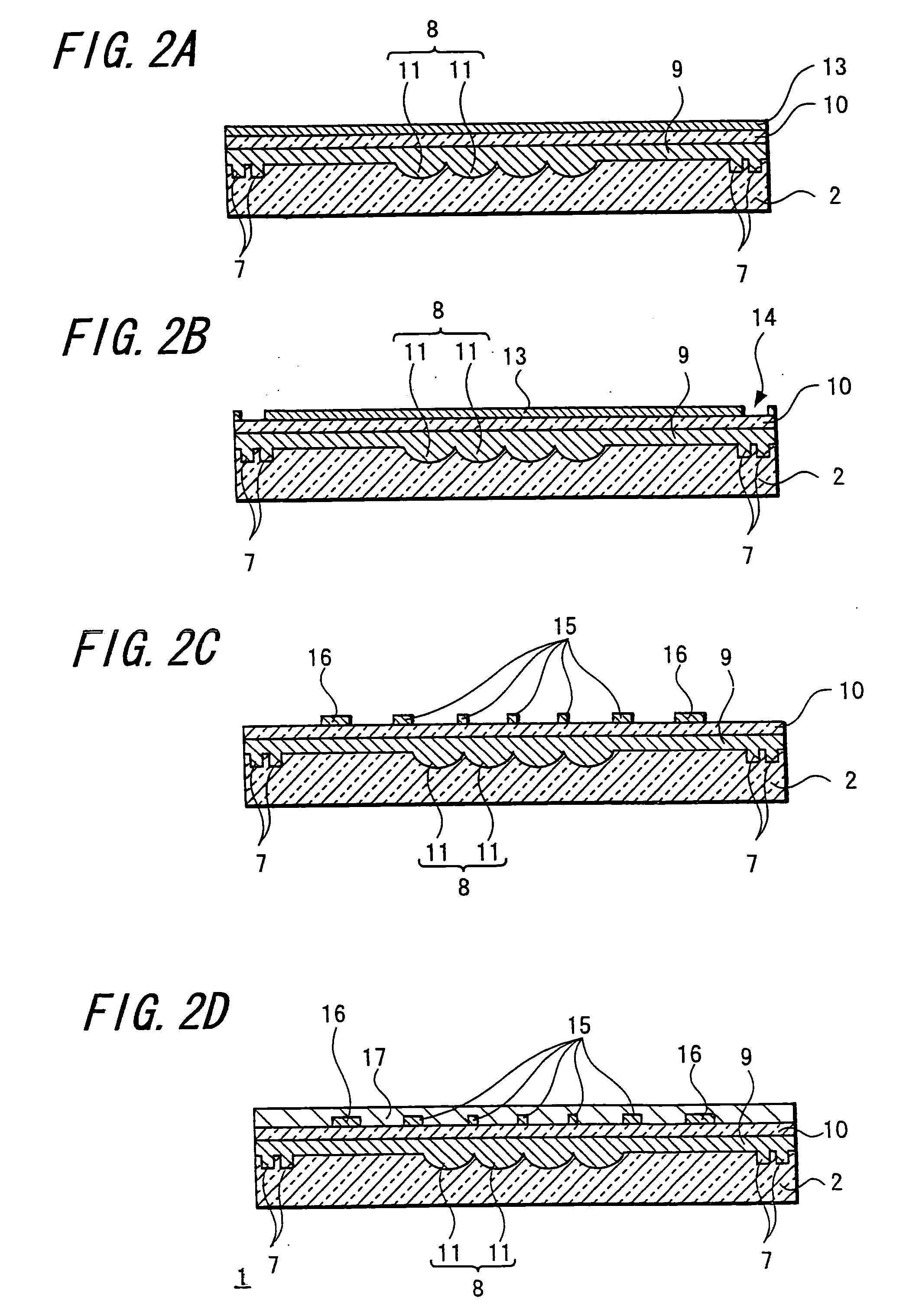

Magnetic disk drive with a floating head slider having projections arranged to float at a greater distance from magnetic disk than slider trailing end

InactiveUS6246538B1High yield rateGuaranteed uptimeManufacture head surfaceProtective coatings for layersMagnetic tapeTransducer

A head slider is composed of a substrate having a transducer on its outflow end, a rail plane formed on a surface near both sides of the substrate facing a magnetic disk. The head slider further includes a plurality of projection elements formed on the rail plane. When the slider is floating over the magnetic disk, the distance between the projection elements and the magnetic disk is greater than the distance between the outflow end of the slider and the magnetic disk.

Owner:TOSHIBA STORAGE DEVICE CORP

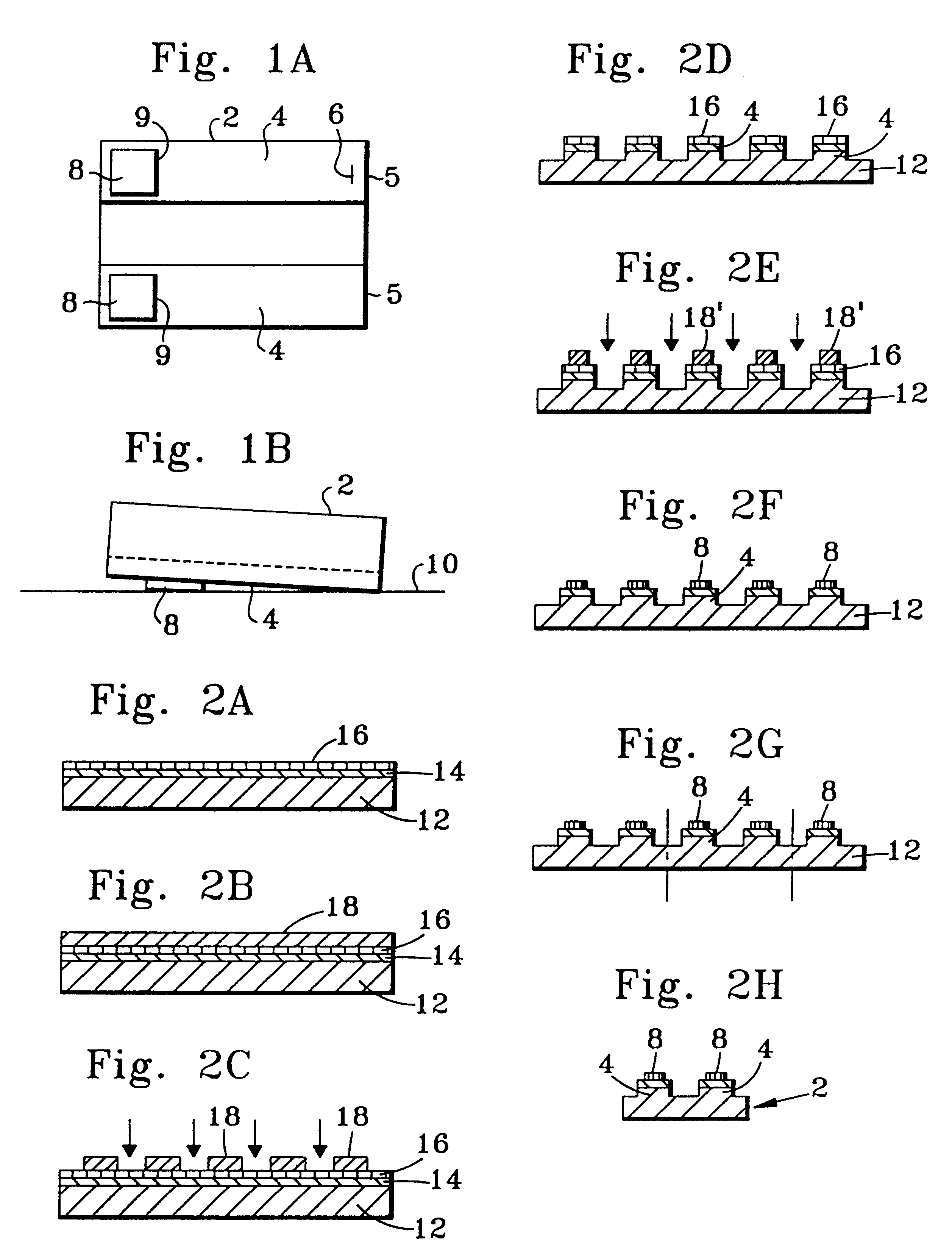

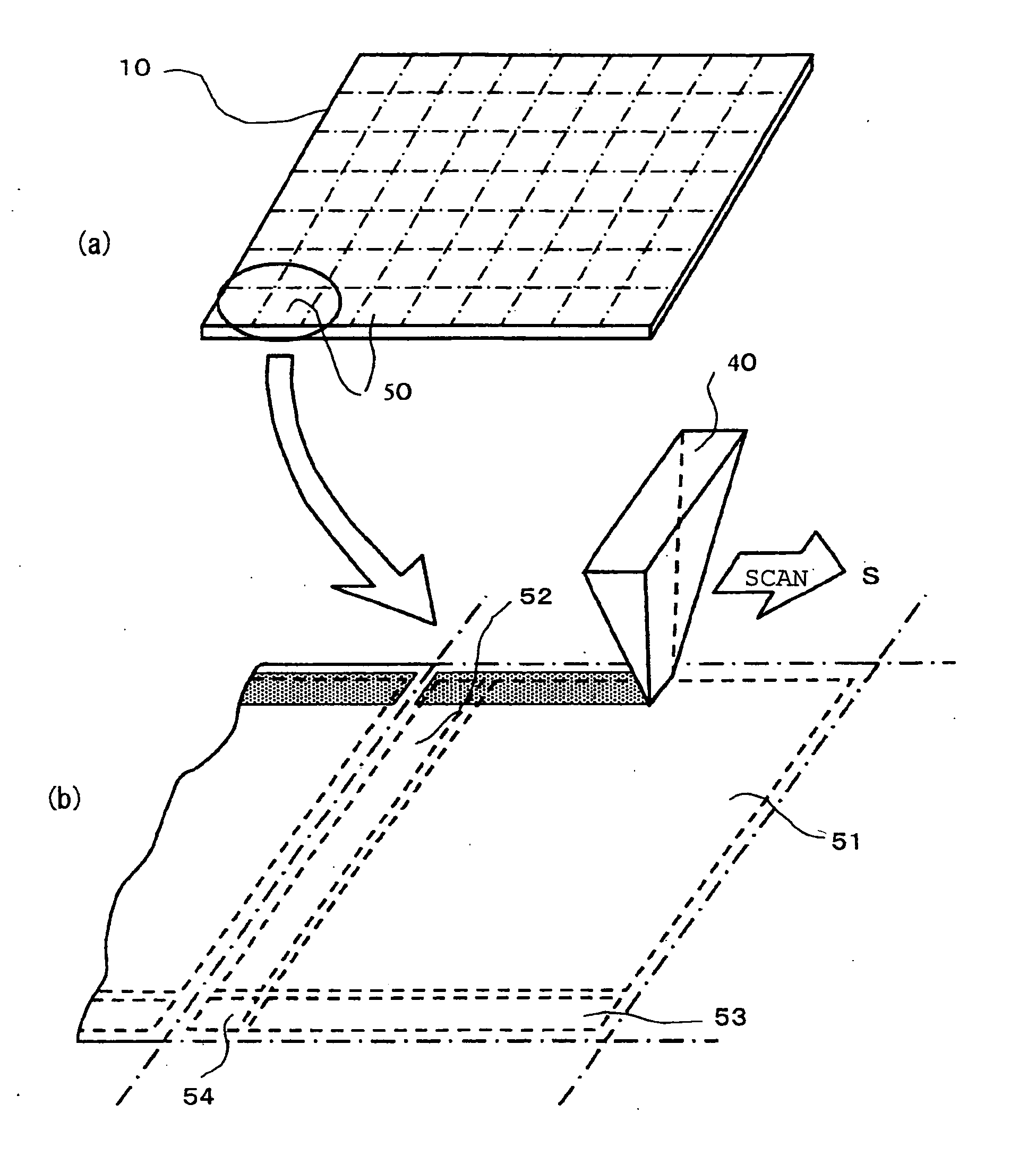

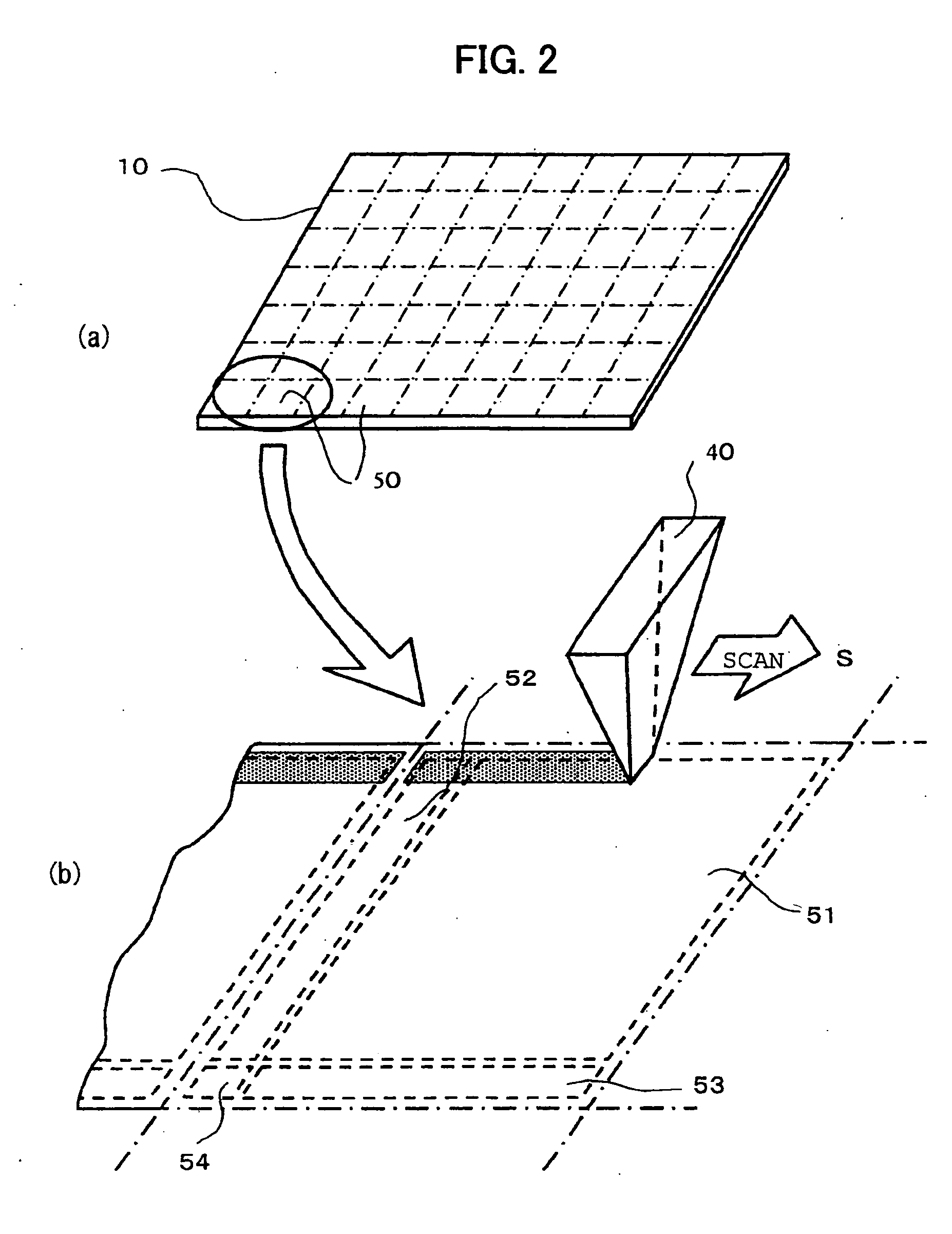

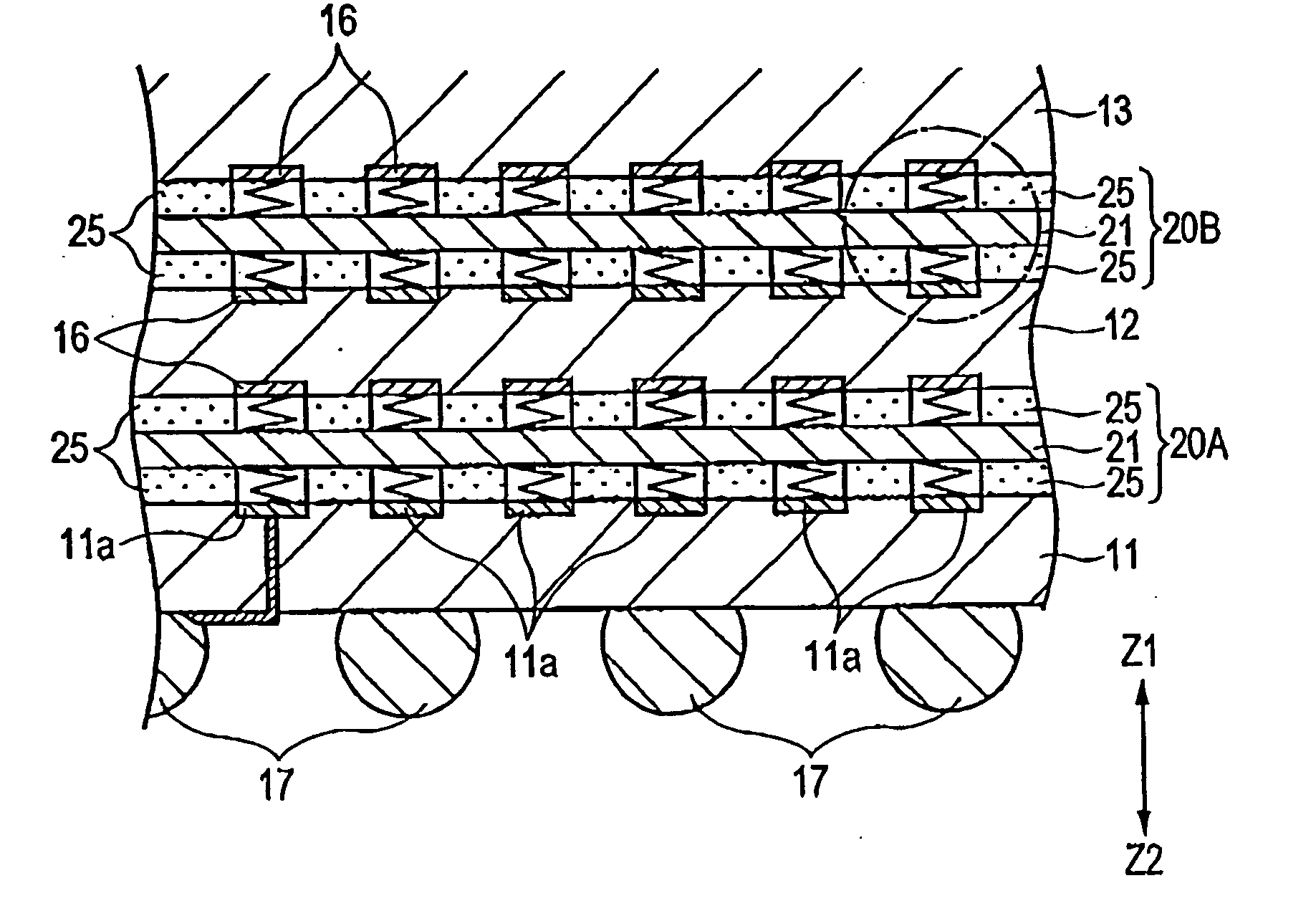

Display panel and method for manufacturing the same

ActiveUS20050070035A1High yield rateLow running costTransistorSolid-state devicesAmorphous siliconVolumetric Mass Density

An amorphous silicon film on an insulating substrate portion to be formed as an individual display panel in a large-sized insulating substrate is irradiated with a continuous-wave (CW) solid-state laser beam condensed linearly, while being scanned therewith at a fixed speed in the width direction of the condensed laser beam. A pixel portion and a peripheral circuit portion in the same insulating substrate portion are irradiated with the laser beam temporally modulated to have a power density high enough to provide predetermined crystallinity. The amorphous silicon film is transformed into a silicon film having crystallinity corresponding to performance required for thin film transistors to be built in each of the pixel portion and the peripheral circuit portion. In such a manner, a thin film transistor circuit having optimum crystallinity required in the pixel or peripheral circuit portion can be obtained while high throughput is kept. Thus, a product having good display features as a display panel can be provided inexpensively.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

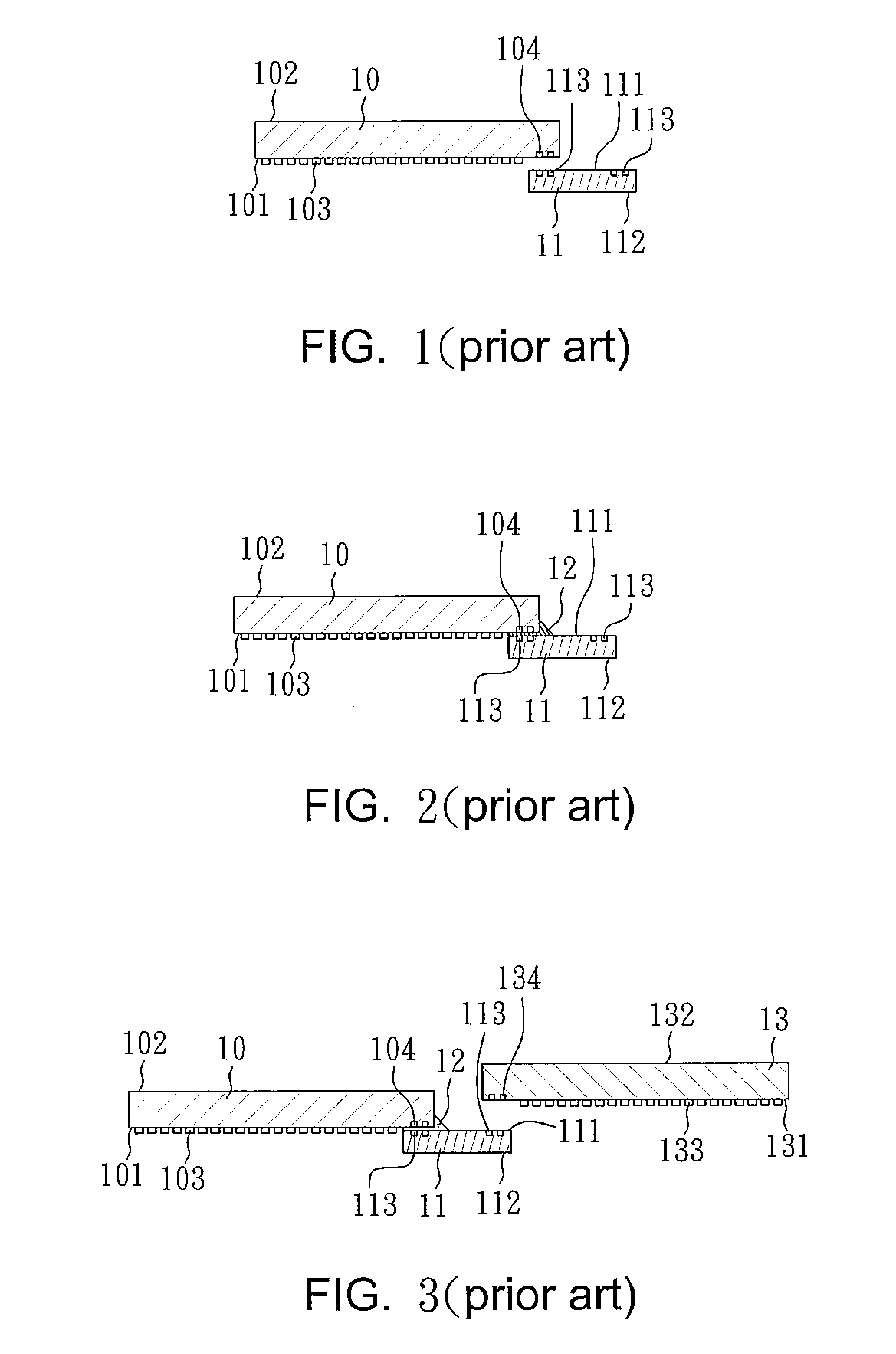

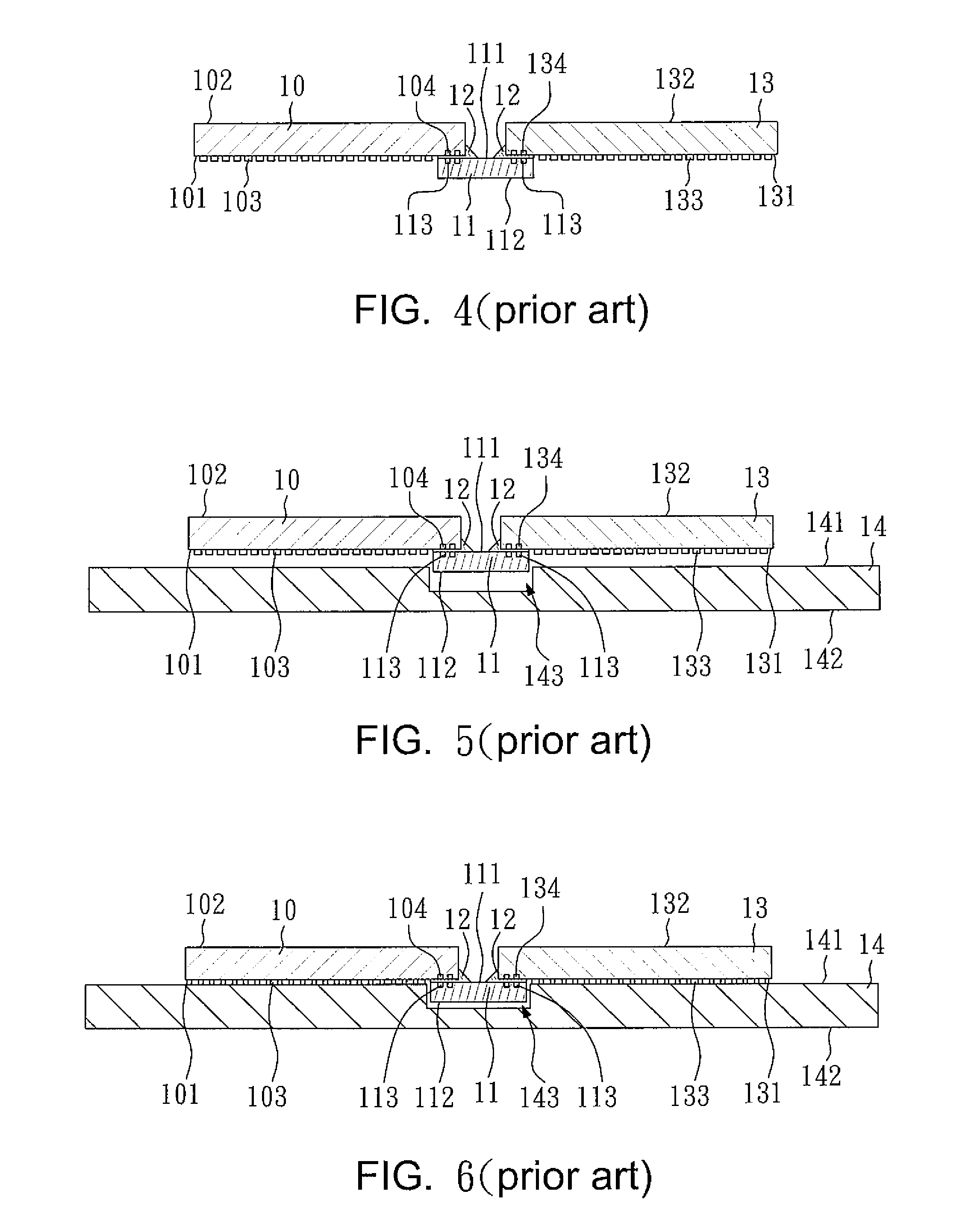

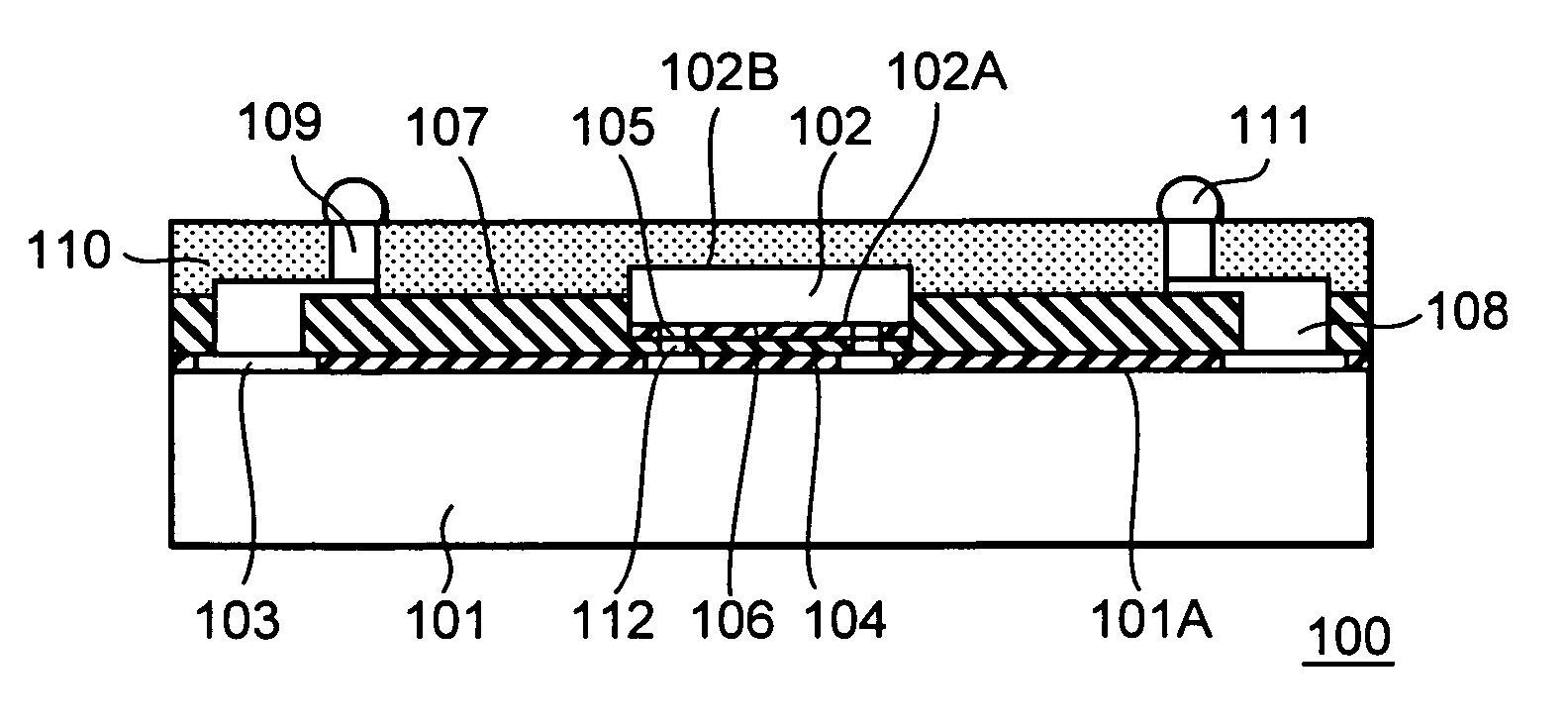

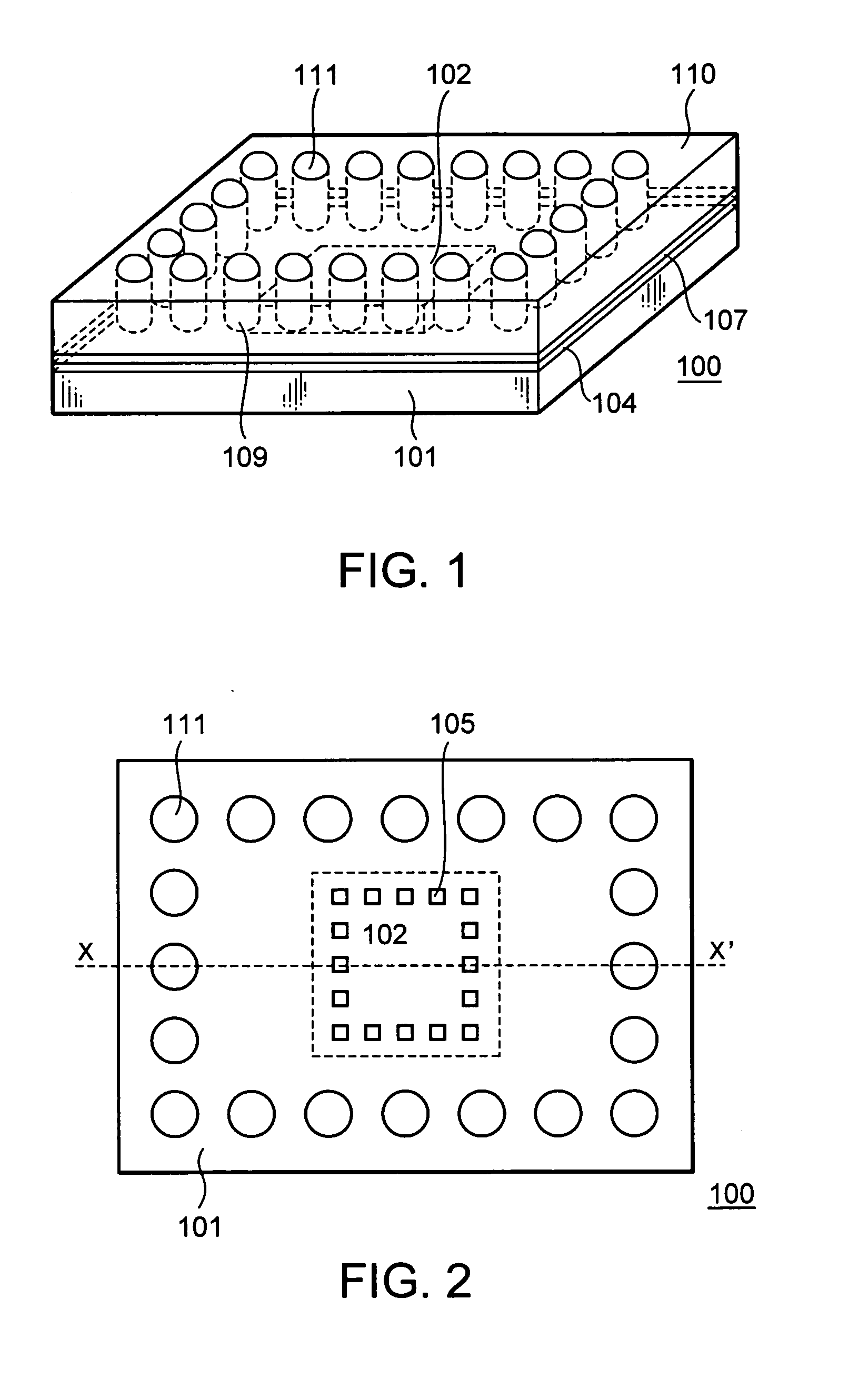

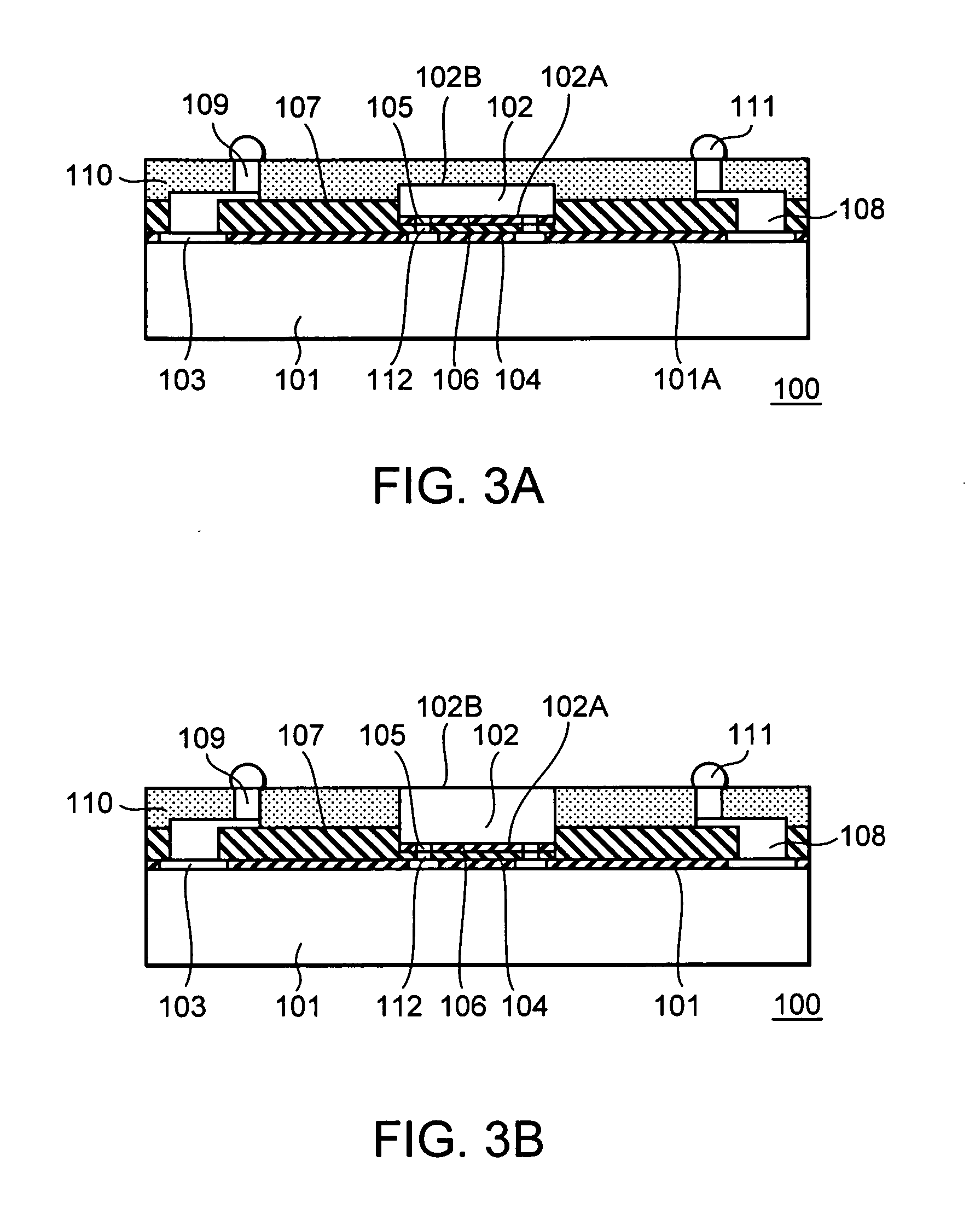

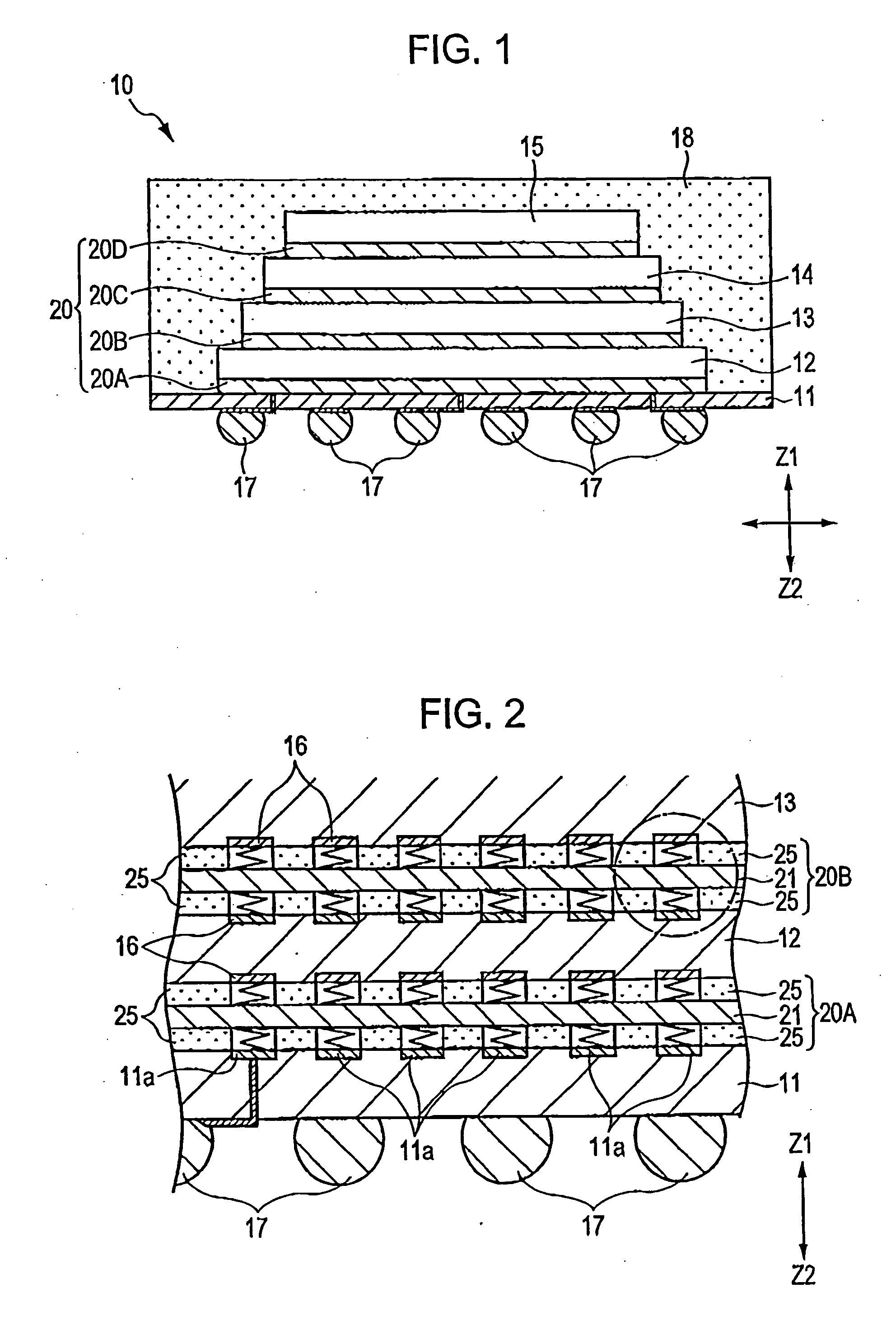

Semiconductor device including a plurality of circuit element chips and a manufacturing method thereof

ActiveUS20050258547A1Guaranteed uptimeHigh yield rateSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a first circuit element chip including a first surface on which a plurality of first electrodes are arranged, and a second circuit element chip including a first surface on which a plurality of second electrodes are arranged. The second circuit element chip is mounted on the first circuit element chip. The semiconductor device further includes an insulating film disposed on a side surface of the second circuit element chip and disposed between the first surfaces of the first and second circuit element chips. The semiconductor device still further includes a resin layer covering the second circuit element chip and the insulating film. Also, there is provided a manufacturing method of the semiconductor device which includes forming the insulating film after the second circuit element chip is mounted on the first circuit element chip.

Owner:LAPIS SEMICON CO LTD

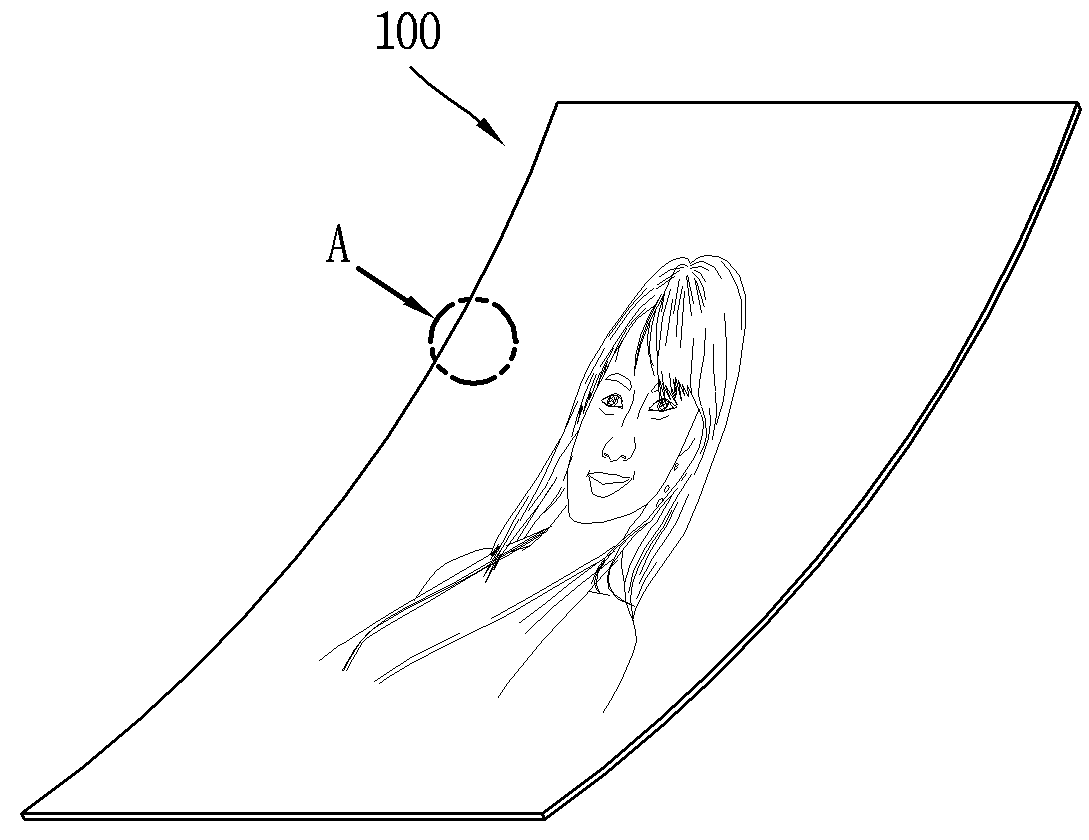

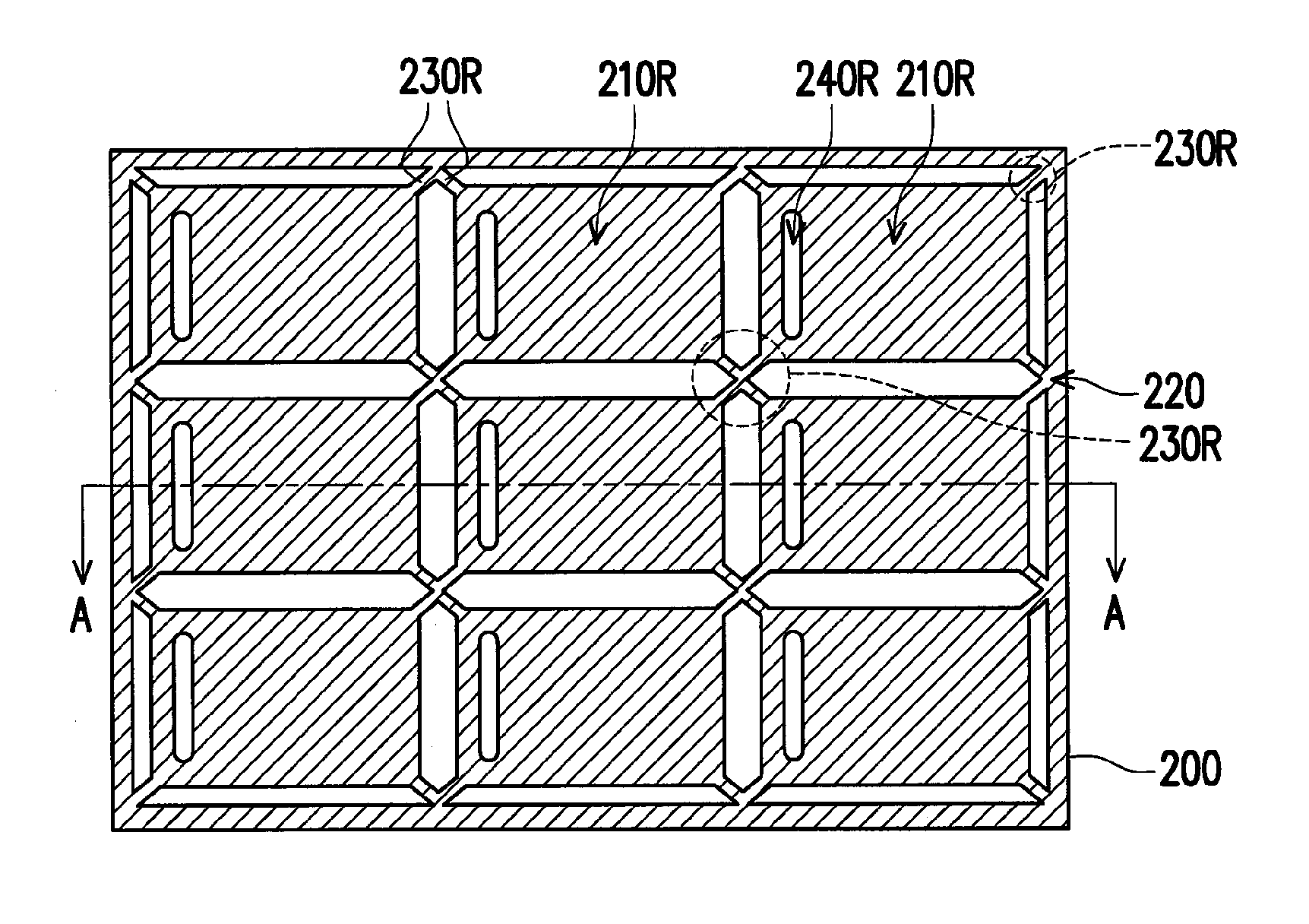

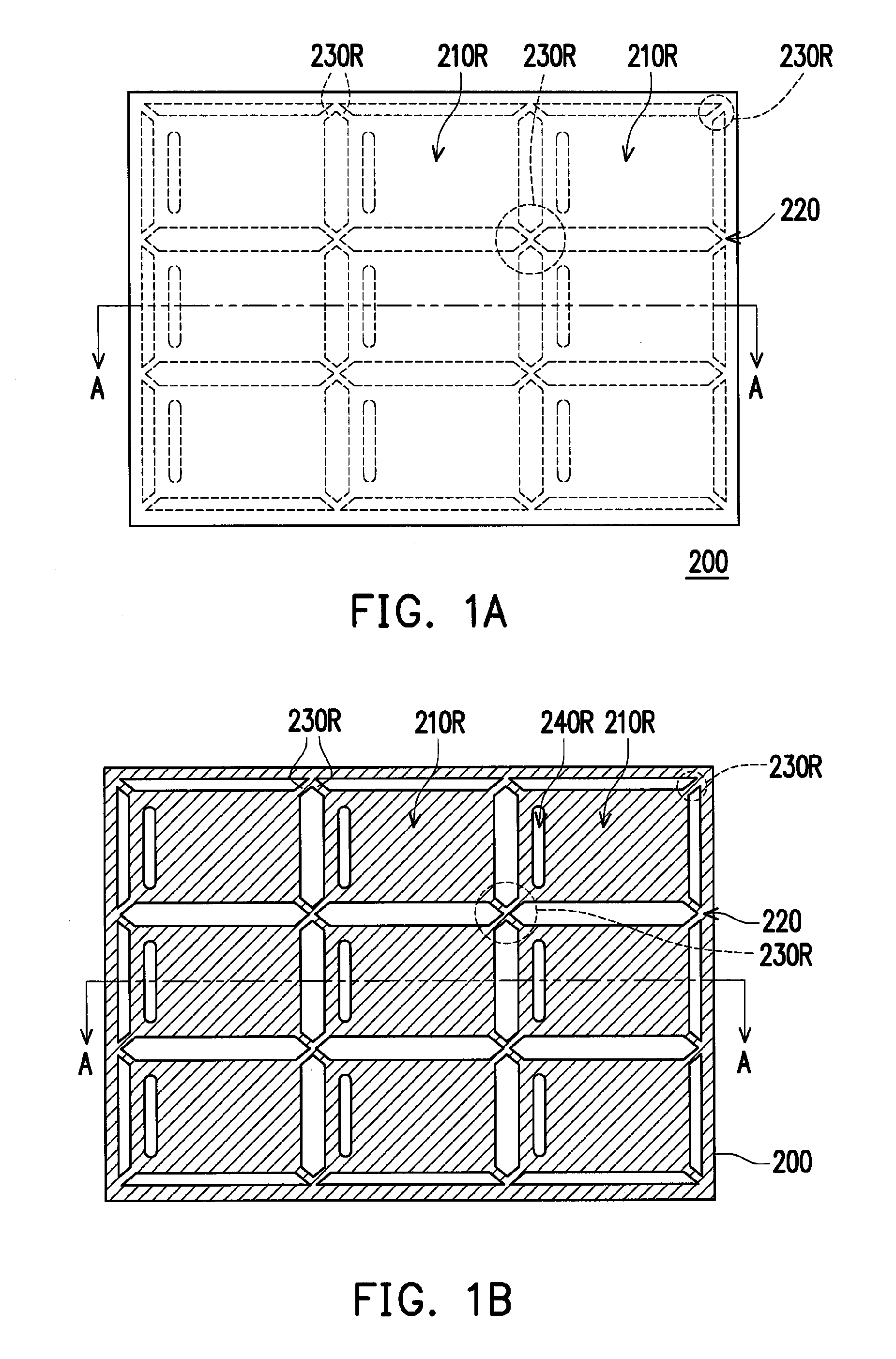

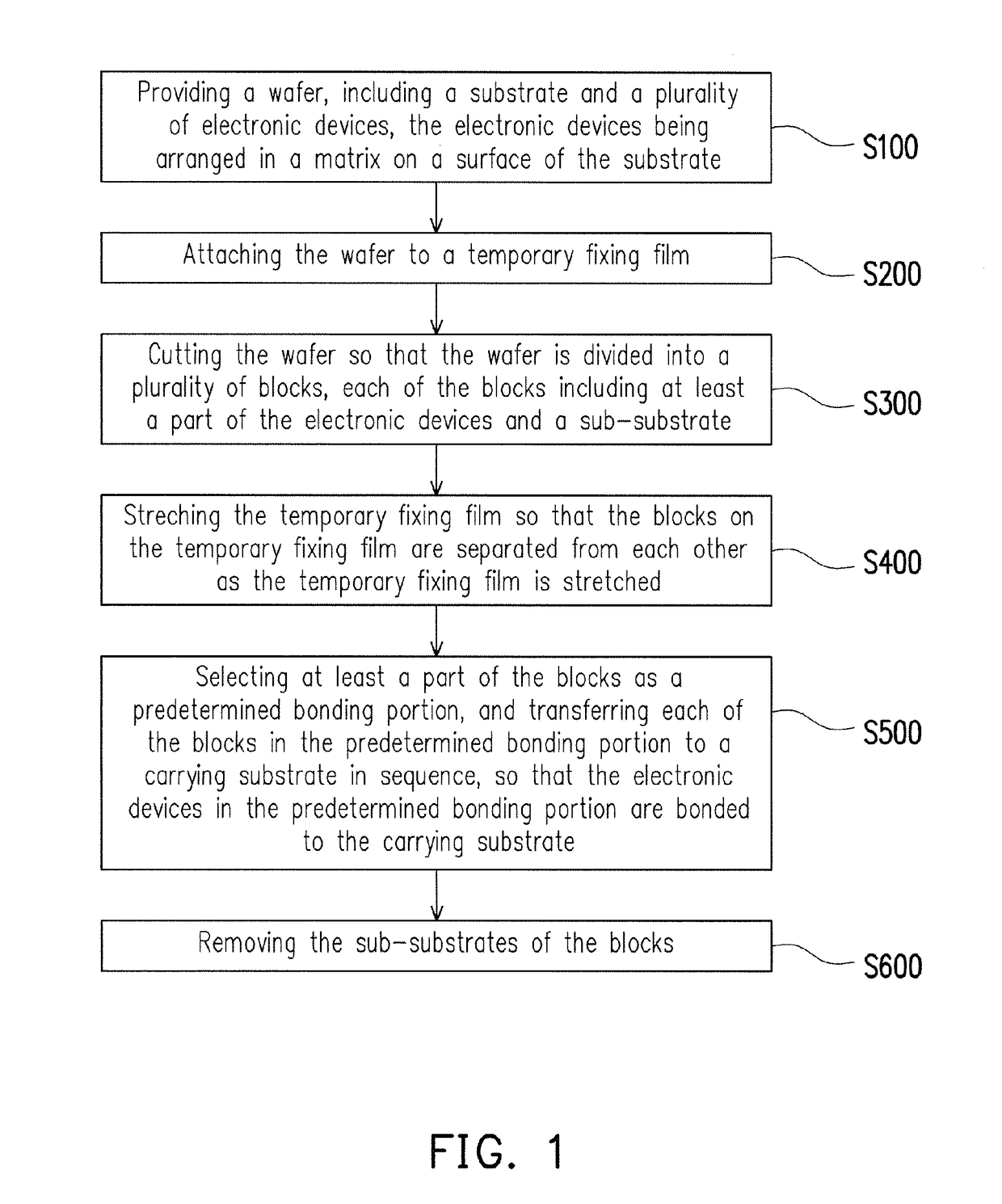

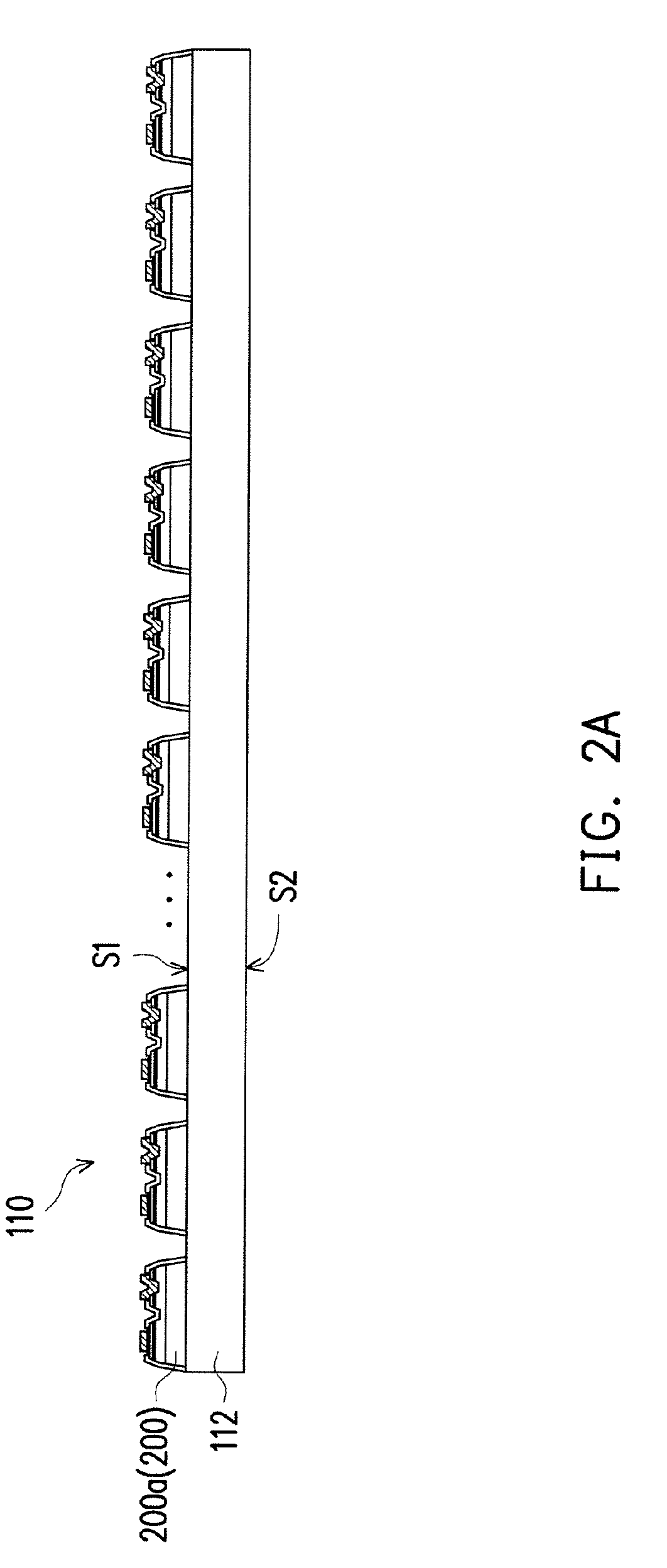

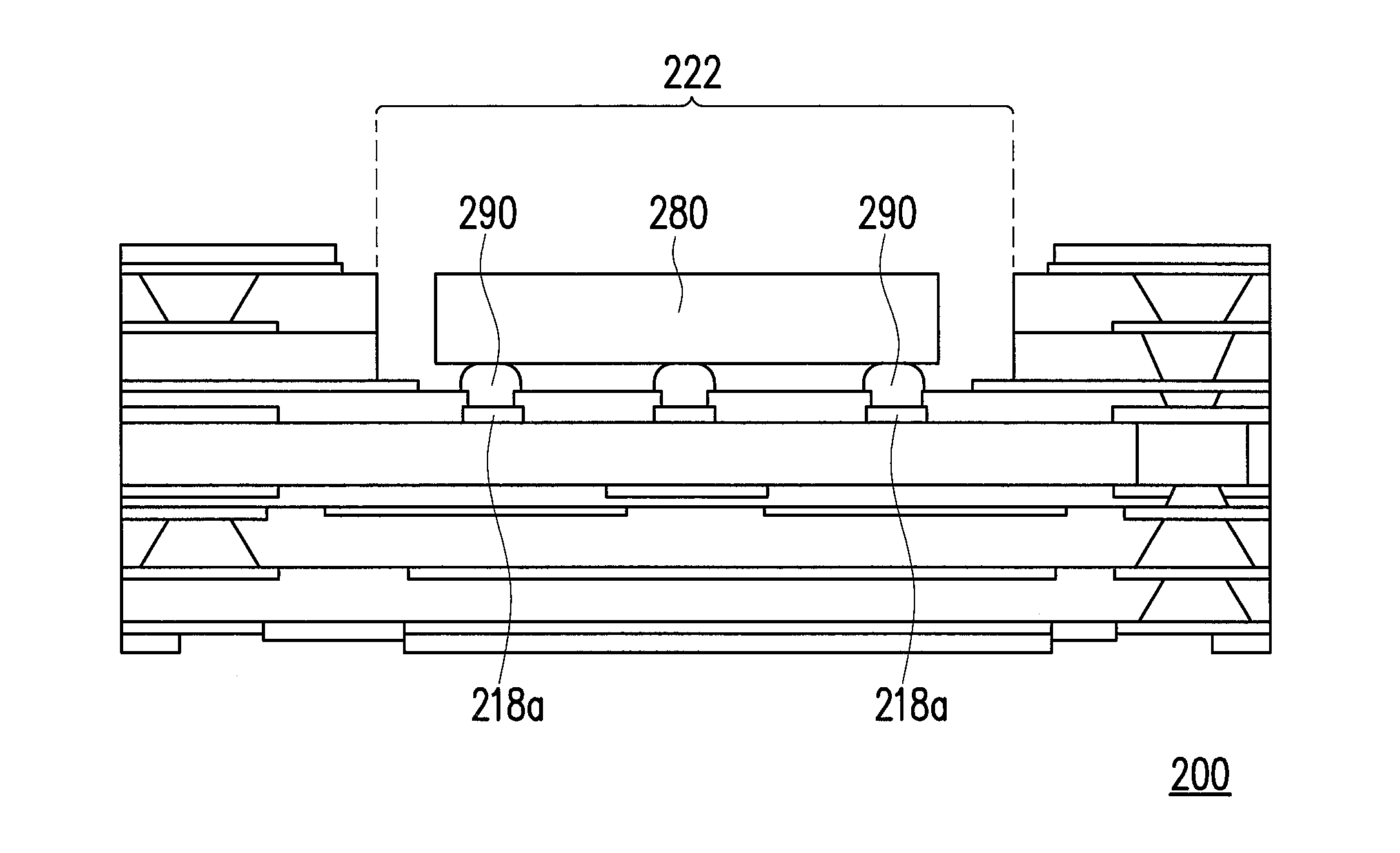

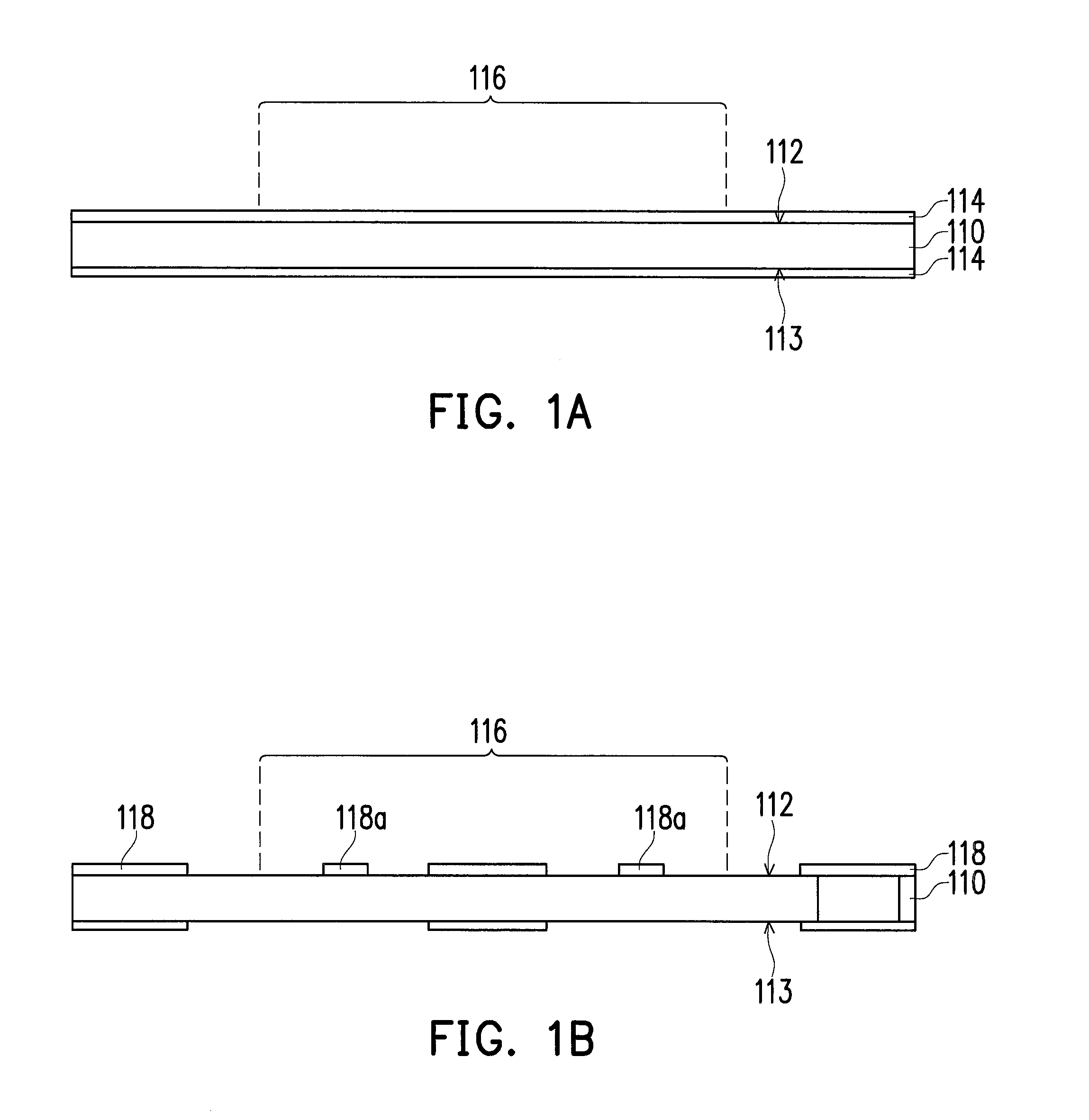

Method of mass transferring electronic device

ActiveUS20180053742A1Rapidly and accurately transferringRapidly and accurately transferSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A method of mass transferring electronic devices includes following steps. A wafer is provided. The wafer includes a substrate and a plurality of electronic devices. The electronic devices are arranged in a matrix on a surface of the substrate. The wafer is attached to a temporary fixing film. The wafer is cut so that the wafer is divided into a plurality of blocks. Each of the blocks includes at least a part of the electronic devices and a sub-substrate. The temporary fixing film is stretched so that the blocks on the temporary fixing film are separated from each other as the temporary fixing film is stretched. At least a part of the blocks is selected as a predetermined bonding portion, and each of the blocks in the predetermined bonding portion is transferred to a carrying substrate in sequence, so that the electronic devices in the predetermined bonding portion arc bonded to the carrying substrate. The sub-substrates of the blocks are removed. Another method of mass transferring electronic devices is also provided.

Owner:GENESIS PHOTONICS

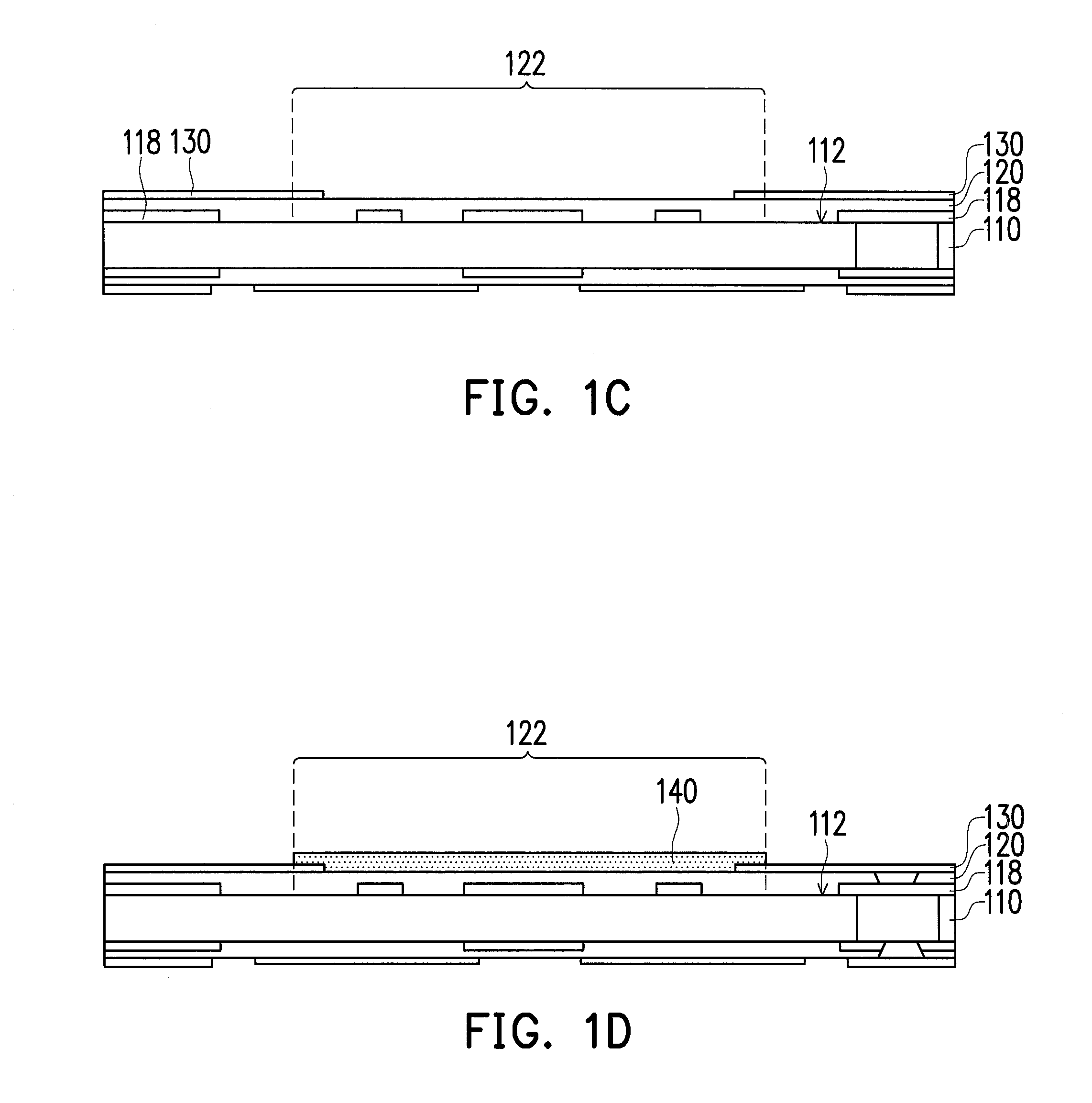

Substrate structure having component-disposing area and manufacturing process thereof

ActiveUS20140138130A1Simple processHigh yield ratePaper/cardboard articlesSemiconductor/solid-state device detailsDielectric layerLaser

A substrate structure having a component-disposing area and a process thereof are provided. The substrate structure having a component-disposing area includes a core layer, a first dielectric-layer, a laser-resistant metallic-pattern and a second dielectric-layer. The core layer includes a first surface, a component-disposing area and a patterned metallic-layer disposed on the first surface and including multiple pads, and the pads are located within the component-disposing area. The first dielectric-layer is disposed on the core layer and includes multiple openings to respectively expose the pads. The laser-resistant metallic-pattern is disposed on the first dielectric-layer and surrounds a projection area of the first dielectric-layer which the component-disposing area is orthogonally projected on. The second dielectric-layer is disposed on the first dielectric-layer and covers the laser-resistant metallic-pattern, the second dielectric-layer includes a component-disposing cavity corresponding to the projection area, penetrating through the second dielectric-layer and communicated with the openings to expose the pads.

Owner:UNIMICRON TECH CORP

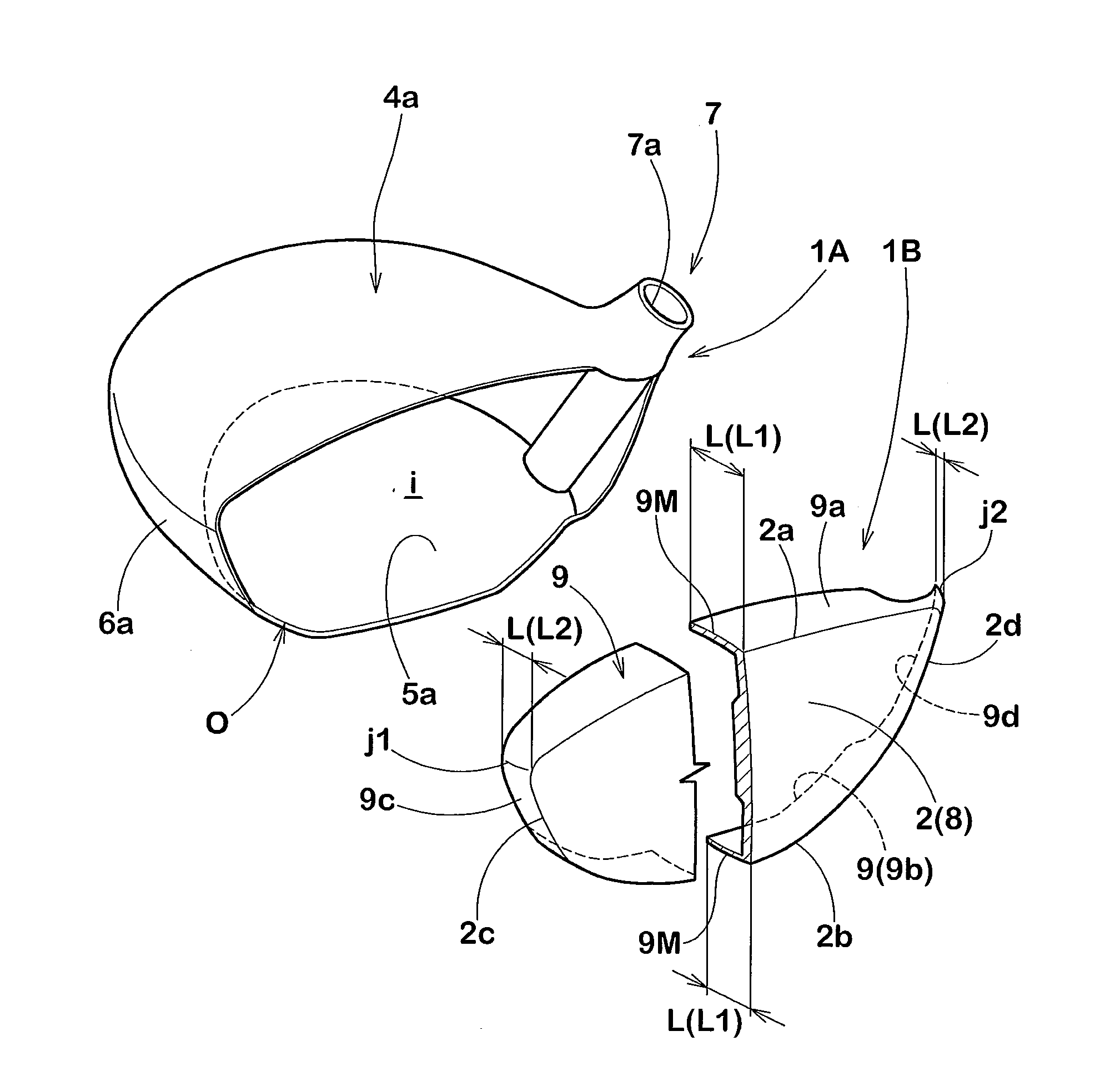

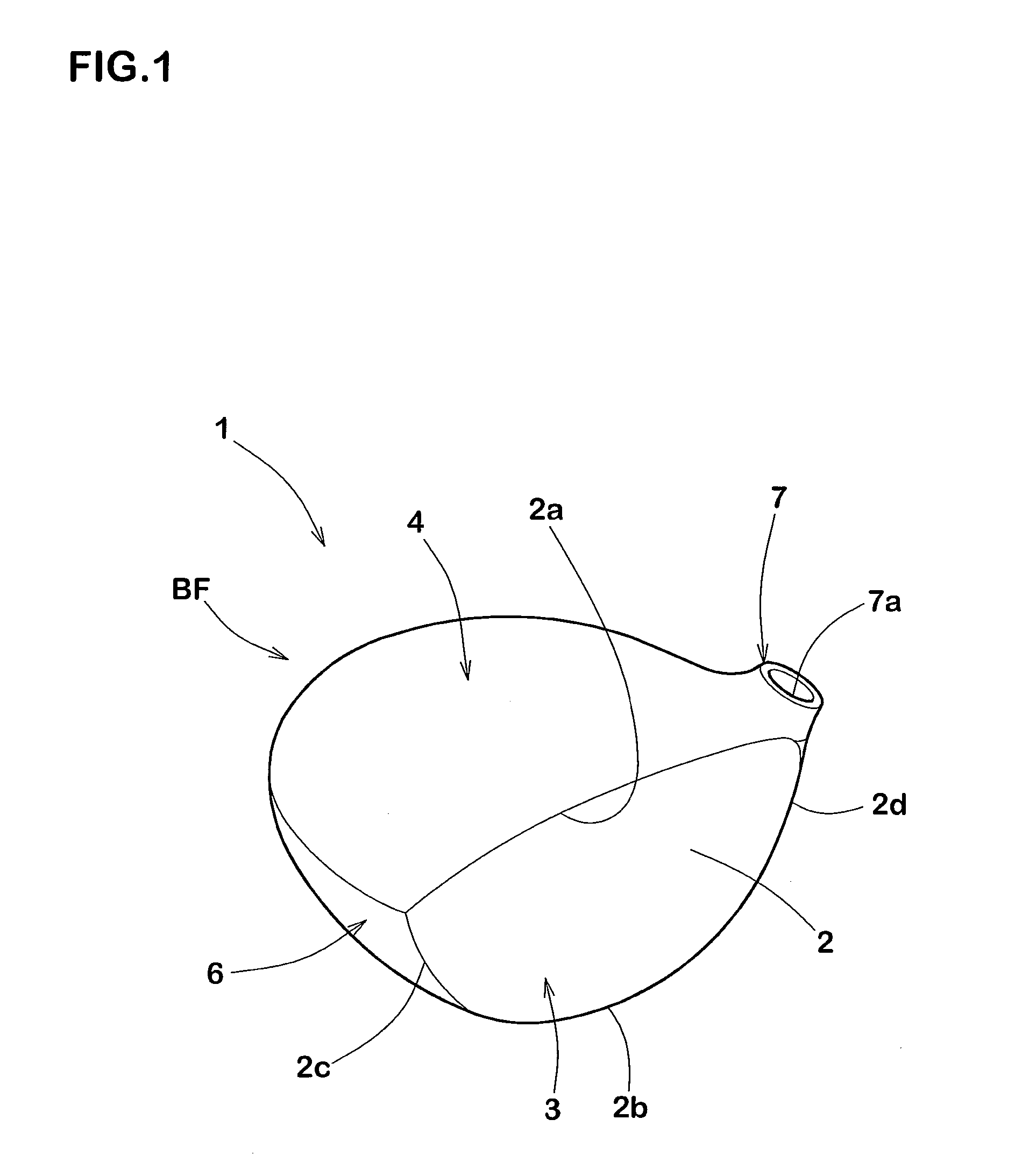

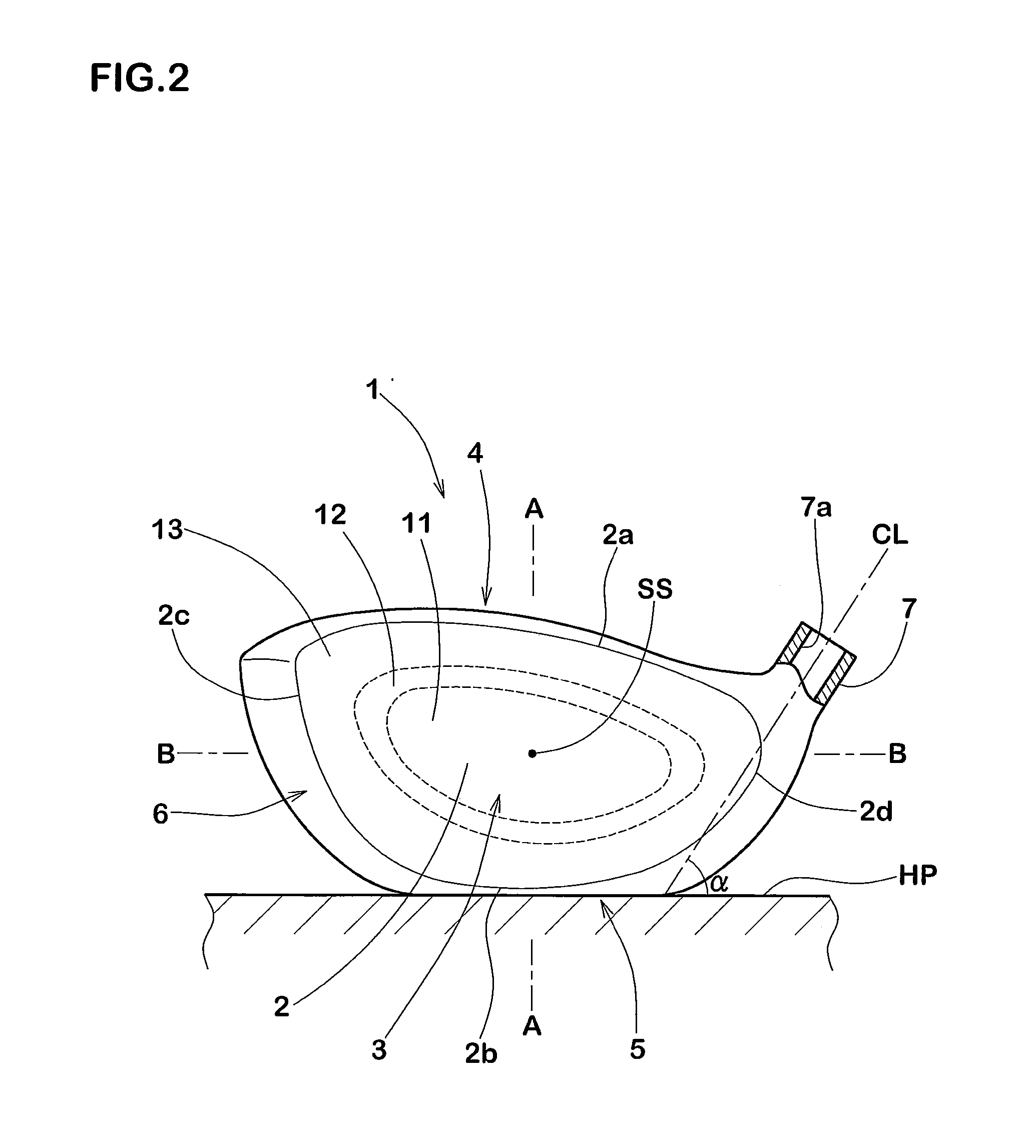

Method for manufacturing golf club head

ActiveUS20100154196A1High strengthSolve the lack of durabilityMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

Owner:SUMITOMO RUBBER IND LTD

Capacitive Touch Screen

InactiveUS20140176481A1Simple structureImprove production efficiencyInput/output processes for data processingOptical bondingProduction rate

This invention discloses a capacitive touch screen comprising an Indium Tin Oxide (ITO) tempered glass and an ITO film both of which are adhesively laminated integrally together via an optical adhesive. The ITO tempered glass comprises a glass substrate comprising a viewing window area and a non-viewing window area, a black ink layer disposed on a first lateral surface of the glass substrate and printed in a corresponding area thereof to the non-viewing window area, an ITO circuit plating layer covering the black ink layer and the viewing window area. The present invention utilizes the optical adhesive to directly adhesively laminate the ITO tempered glass and the ITO film, and as a result, its lamination structure is able to simplify. Furthermore, the present invention not only effectively reduces its integral thickness thereof, but also has simple production techniques, a low cost of manufacturing, and a high yield rate of production.

Owner:GAN ZHOU DPT TECH

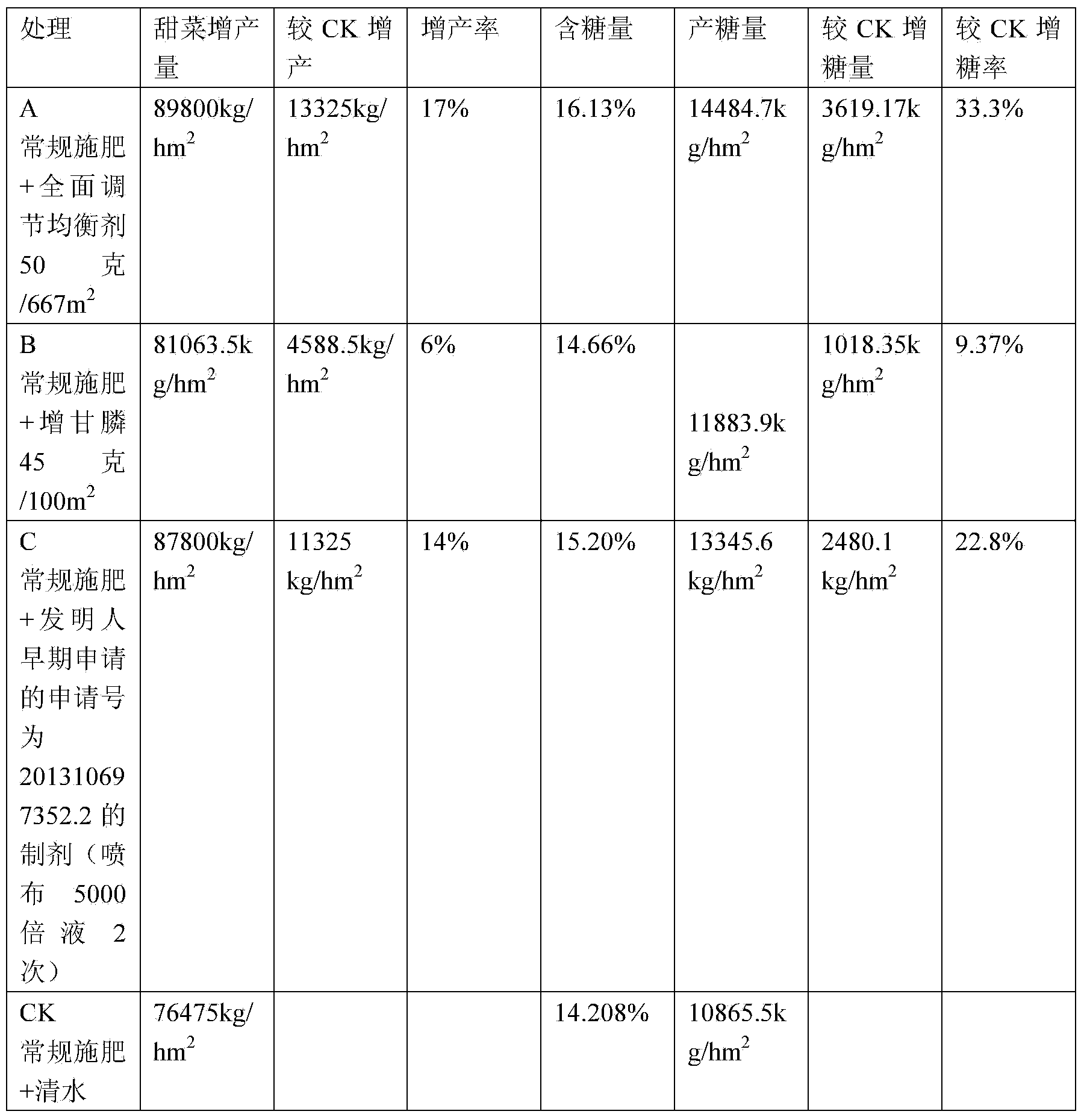

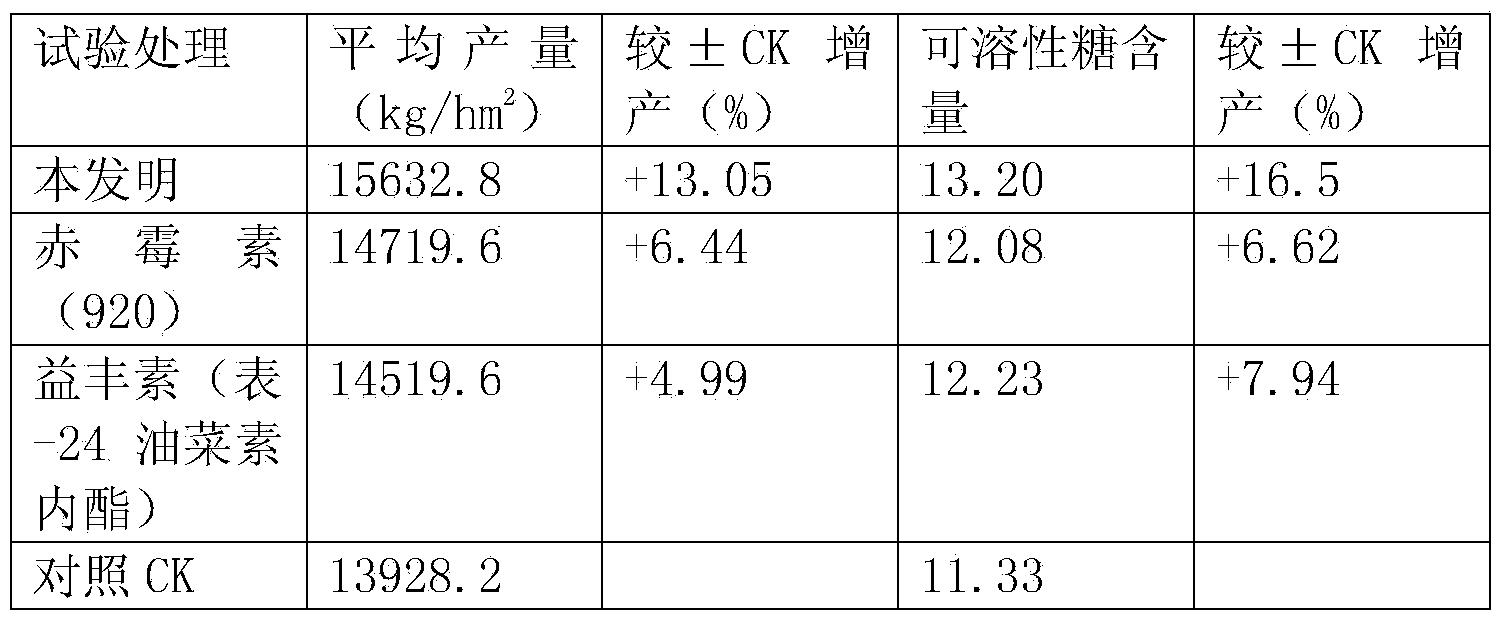

Balance growth regulator for plant and preparation method of balance growth regulator

InactiveCN103951523AEasy to prepareTenacious resilienceBiocidePlant growth regulatorsSalicylic acidPlant growth

The invention discloses a balance growth regulator for a plant. The balance growth regulator is characterized by comprising a filling agent and at least four crop growth regulators selected from brassinolide, methyl jasmonate, auxin (heteroauxin), salicylic acid, cytokinin, gibberellic acid, abscisic acid, ethylene and triacontanol. The product disclosed by the invention is a plant growth regulator prepared from at least more than four traditional endogenous plant growth regulators, the balance growth regulator not only can be used for greatly increasing the yield, but also can be used for additionally producing dry matters, shows favorable crop disease and disadvantage resistance and is green, safe and incapable of injuring eaters.

Owner:CHONGQING SUPER SCI & TECH DEV CO LTD

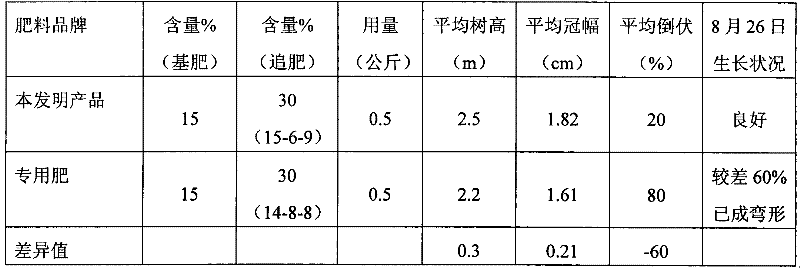

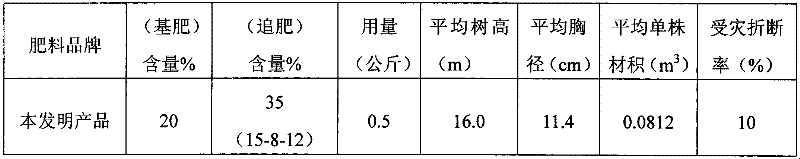

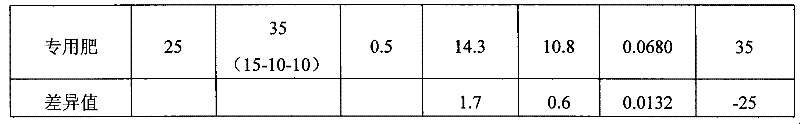

Eucalyptus ecological fertilizer containing Mn and Fe elements and fertilizing method

ActiveCN102503675AMeet nutrient needsImprove resistance to natural disasters (typhoonFertilising methodsFertilizer mixturesFrostAdditive ingredient

The invention discloses a eucalyptus ecological fertilizer containing Mn and Fe elements and a fertilizing method. The eucalyptus ecological fertilizer containing the Mn and Fe elements is prepared by mixing inorganic nutrients, organic fertilizers and a bonder, and includes following effective ingredients in mass percents of: 7-20 percent of the inorganic nutrients, 4-15 percent of P2O5, 4-20 percent of K2O4, 0.05-0.2 percent of B, 0.05-0.1 percent of Zn, 0.01-0.05 percent of Cu, 0.01-0.2 percent of Mn, 0.01-0.2 percent of Fe, 5-25 percent of organic matters and 0.15-5 percent of the bonder. According to the eucalyptus ecological fertilizer disclosed by the invention, major elements, secondary elements and trace elements are matched according to a reasonable proportion, and a property amount of the organic fertilizers are added, so that not only can the nutrient requirements of the eucalyptus growth be met, the use ratio of the fertilizer is improved, and the wastage rate of the fertilizer is decreased, but also the stress resistance and the lodging resistance of eucalyptus are enhanced, the capacity of resisting natural calamities (such as typhoon and frost), the loss is reduced and the economic benefit is improved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Display panel and method for manufacturing the same

ActiveUS7183148B2Improve manufacturing yieldReduce voltageTransistorSolid-state devicesAmorphous siliconCrystallinity

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Semiconductor device and method for manufacturing the same

InactiveUS20060261491A1Avoid separationAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesInterposerElectrical connection

The present invention relates to a semiconductor device and a method for manufacturing the same that prevent deformation or cracking caused by a difference in coefficient of thermal expansion. Elastic contacts provided on upper and lower surfaces of an interposer are elastically biased against the relatively displaced electrodes. The interposer thus compensates for displacement caused by different coefficients of thermal expansion so that an electrical connection between the electrodes of the first electronic component and the electrodes of the second electronic component is constantly maintained. Accordingly, this prevents separation or cracking in electrode connection areas.

Owner:ALPS ALPINE CO LTD

Light source assembly, display device and preparing method of light source assembly

InactiveCN107910322AReduce thicknessGuaranteed glow effectStatic indicating devicesElectric circuit arrangementsDisplay deviceOptoelectronics

The invention provides a light source assembly, a display device and a preparing method of a light source assembly. The light source assembly is characterized in that a carrier comprises two superposed film layers and a conductive layer between the two superposed film layers; the conductive layer comprises a plurality of pad patterns; the pad patterns are electrically connected through leads; onefilm layer is provided with a plurality of windows for exposing the pad patterns; LED chips are fixed on different pad patterns correspondingly through tin soldering; and the same fluorescent layer fills the clearances among the LED chips and covers all LED chips. Compared with a traditional backlight source, the light source assembly and the preparing method thereof according to the invention have advantages of ensuring high light emitting effect, realizing high flexibility and foldability of the light source assembly for matching preparation of a narrow-frame and even no-frame display device. Compared with an existing popular OLED screen, the display device according to the invention can realize a substitution plan with advantages of low cost, high yield and high popularization value forrealizing high screen-to-body ratio.

Owner:SHENZHEN LT OPTOELECTRONICS CO LTD

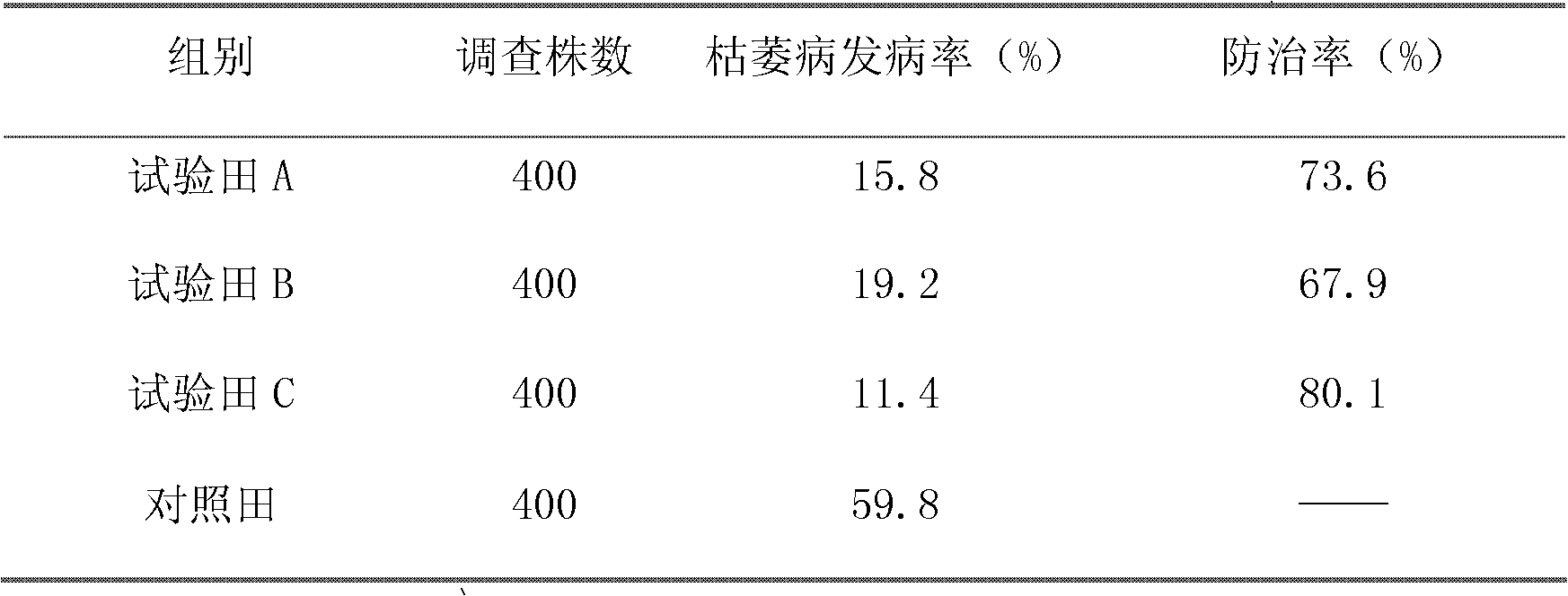

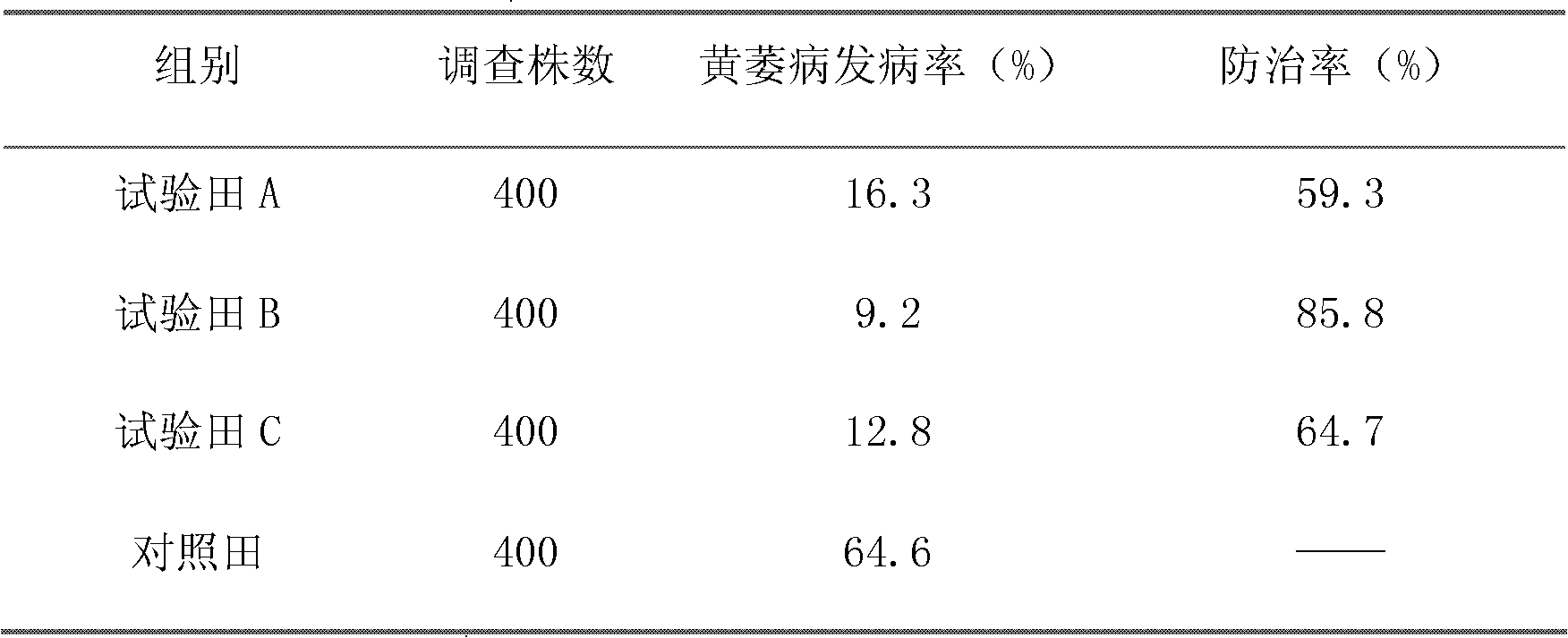

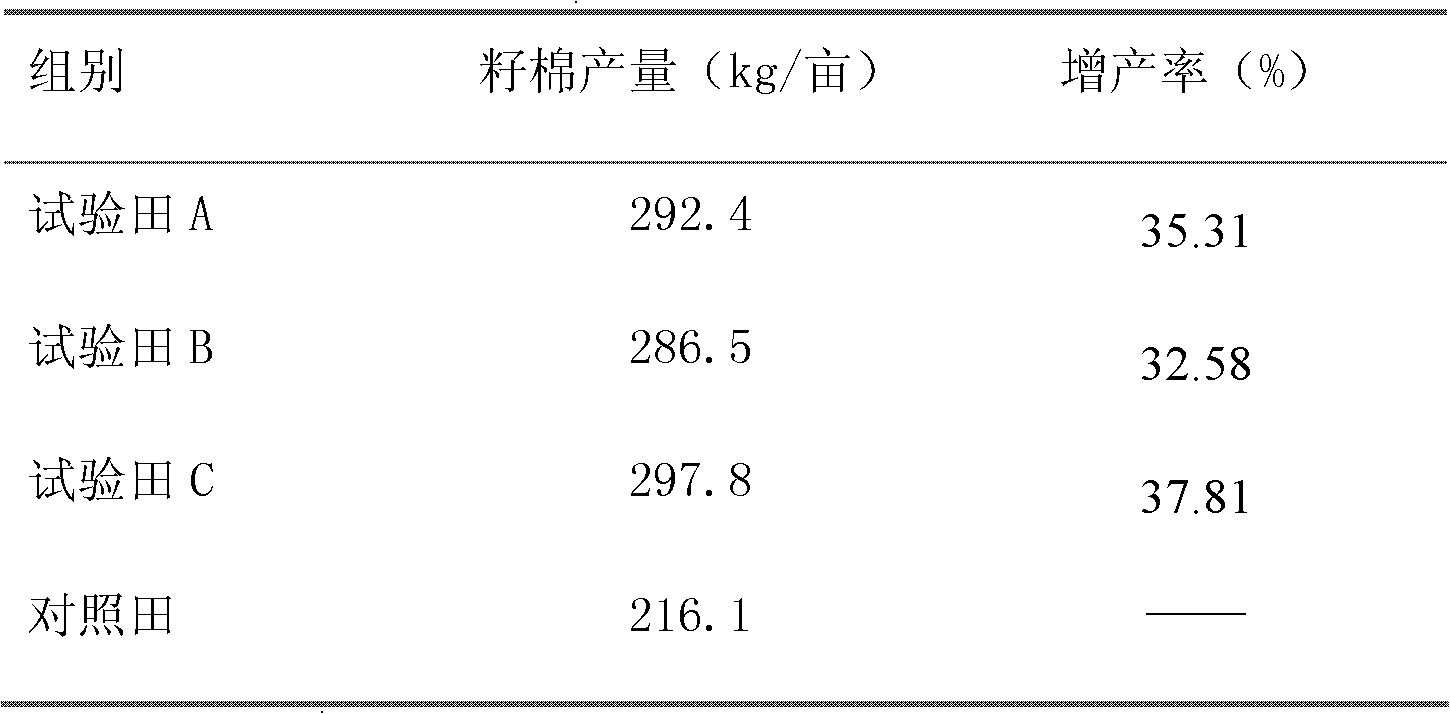

Composite biological antimicrobial for preventing wilt and greensickness of cotton

InactiveCN101990907AHigh control rateGood control effectBiocideFungicidesActive componentCandida tropicalis

The invention relates to a composite biological antimicrobial for preventing wilt and greensickness of cotton. The active components of the composite biological antimicrobial comprise Candida tropicalis, streptomyces microflavus, Trichoderma viride and Bacillus subtilis. The composite biological antimicrobial for preventing wilt and greensickness of cotton can reduce the seedling death rate effectively, has obvious preventing and treating effect on wild and greensickness of cotton and provides the cotton output.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com